Everything You Need to Know About Spring Mechanism Sourcing in 2025

Introduction: Navigating the Global Market for spring mechanism

In an increasingly interconnected global marketplace, sourcing the right spring mechanism can be a daunting challenge for B2B buyers, especially when considering the diverse applications across industries. Whether you are in the automotive, aerospace, or consumer goods sector, understanding the nuances of different spring types—such as compression, extension, and torsion springs—can significantly impact product performance and reliability. This comprehensive guide delves into the critical aspects of spring mechanisms, offering insights into their various applications, design considerations, and the factors influencing cost.

Navigating the complexities of supplier vetting is crucial for international buyers from regions like Africa, South America, the Middle East, and Europe, including countries such as Vietnam and Nigeria. With an emphasis on quality assurance and compliance with international standards, this guide empowers you to make informed purchasing decisions. From evaluating material specifications to understanding the manufacturing processes, we provide you with the tools to assess potential suppliers effectively.

By equipping you with actionable insights and practical knowledge, this guide aims to streamline your sourcing strategy, reduce procurement risks, and enhance your product offerings in a competitive landscape. Join us on this journey to unlock the potential of spring mechanisms and elevate your business operations.

Understanding spring mechanism Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Compression Springs | Helical design; stores energy under compression; expands when force is released. | Automotive suspensions, industrial machinery, consumer products. | Pros: Excellent energy storage and shock absorption. Cons: Limited to compressive forces only. |

| Torsion Springs | Provides torque; exerts force when twisted; commonly features two ends. | Garage doors, control levers, mechanical clocks. | Pros: Efficient for rotational applications. Cons: Requires precise design to avoid failure. |

| Extension Springs | Designed to stretch; hooks or loops on ends; stores energy when extended. | Trampolines, screen doors, automotive applications. | Pros: Versatile for tension applications. Cons: Can wear out faster if overstretched. |

| Garter Springs | Continuous circular design; provides radial force; used in seals and belts. | Oil seals, rubber seals, slip-resistant belts. | Pros: Effective for maintaining pressure on seals. Cons: Limited to specific applications requiring radial force. |

| Oil Seal Springs | Specialized for sealing applications; often made from durable materials. | Automotive engines, machinery where fluid containment is critical. | Pros: Essential for preventing leaks. Cons: Material selection is crucial for performance. |

What are the Characteristics and Suitability of Compression Springs?

Compression springs are characterized by their helical structure, allowing them to store and release energy when subjected to compressive forces. They are widely utilized in automotive suspensions and industrial machinery, where shock absorption and vibration dampening are critical. When purchasing compression springs, buyers should consider factors such as load requirements, deflection limits, and material properties, as these will significantly influence performance and longevity.

How Do Torsion Springs Function and Where are They Used?

Torsion springs are designed to exert force when twisted, making them ideal for applications like garage doors and control levers. Their unique design allows for efficient torque generation, which is essential in mechanisms requiring rotational movement. When sourcing torsion springs, it’s vital for buyers to assess the required torque specifications and ensure the spring is correctly designed to prevent premature failure during operation.

What Makes Extension Springs Versatile for Tension Applications?

Extension springs are engineered to stretch and exert a pulling force, often featuring hooks or loops at their ends for easy attachment. Common applications include trampolines and automotive components, where a reliable tension mechanism is necessary. Buyers should focus on the spring’s load capacity, deflection characteristics, and potential wear factors, particularly in high-stress environments, to ensure optimal performance.

In What Applications are Garter Springs Most Effective?

Garter springs are continuous circular springs that provide radial force, making them particularly effective in applications like oil seals and slip-resistant belts. Their ability to maintain pressure on seals is crucial for preventing leaks in machinery and automotive components. When considering garter springs, buyers should evaluate the specific material requirements and design configurations to ensure compatibility with their sealing applications.

Why are Oil Seal Springs Critical for Fluid Containment?

Oil seal springs are specialized components designed to maintain a seal in applications where fluid containment is essential, such as in automotive engines. Their durability and resistance to various environmental factors are crucial for performance. Buyers must prioritize material selection, as the wrong choice can lead to premature failure and increased maintenance costs, highlighting the importance of understanding application-specific requirements when sourcing these springs.

Key Industrial Applications of spring mechanism

| Industry/Sector | Specific Application of spring mechanism | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Suspension systems | Enhances vehicle stability and comfort | Material durability, corrosion resistance, load capacity |

| Consumer Electronics | Mechanisms in devices like printers | Improves device reliability and performance | Precision in design, compatibility with existing parts |

| Industrial Machinery | Compression springs in manufacturing equipment | Increases operational efficiency and safety | Customization options, load specifications, lead times |

| Aerospace | Torsion springs in control systems | Ensures precision in flight control mechanisms | Weight considerations, material strength, compliance standards |

| Medical Devices | Springs in surgical instruments | Enhances functionality and patient safety | Biocompatibility, sterilization processes, precise tolerances |

How Are Springs Used in Automotive Suspension Systems?

In the automotive industry, spring mechanisms are integral to suspension systems, where compression and torsion springs absorb shocks from the road. This application enhances vehicle stability and passenger comfort by mitigating vibrations and impacts. Buyers in this sector must consider material durability and corrosion resistance, especially in regions with harsh environmental conditions, such as Africa and South America, where vehicles face challenging terrains.

What Role Do Springs Play in Consumer Electronics?

In consumer electronics, spring mechanisms are often found in devices like printers and keyboards, where they ensure reliable operation. Compression springs provide the necessary force for buttons and levers, improving user experience and device longevity. International buyers should focus on precision in design and compatibility with existing components to maintain performance standards across diverse markets, including Europe and the Middle East.

How Do Springs Enhance Industrial Machinery Efficiency?

Industrial machinery utilizes compression springs to maintain consistent pressure in various applications, from assembly lines to packaging equipment. This increases operational efficiency and safety by preventing equipment failures. When sourcing springs for industrial use, businesses should prioritize customization options to meet specific load specifications and lead times, particularly in fast-paced manufacturing environments in regions like Nigeria and Vietnam.

Why Are Torsion Springs Essential in Aerospace Applications?

In the aerospace sector, torsion springs are crucial for control systems in aircraft, providing the necessary force for precise maneuvers. Their lightweight design and high strength are essential for maintaining performance standards in flight. Buyers must consider weight limitations, material strength, and compliance with stringent aviation regulations, especially in Europe, where safety standards are rigorously enforced.

How Are Springs Used in Medical Devices?

In medical devices, spring mechanisms enhance the functionality of surgical instruments and diagnostic equipment. Springs provide necessary tension and release mechanisms, contributing to patient safety and operational efficiency. Buyers in the medical field must ensure that the materials used are biocompatible and can withstand sterilization processes, as well as adhere to precise tolerances to meet regulatory standards across different international markets.

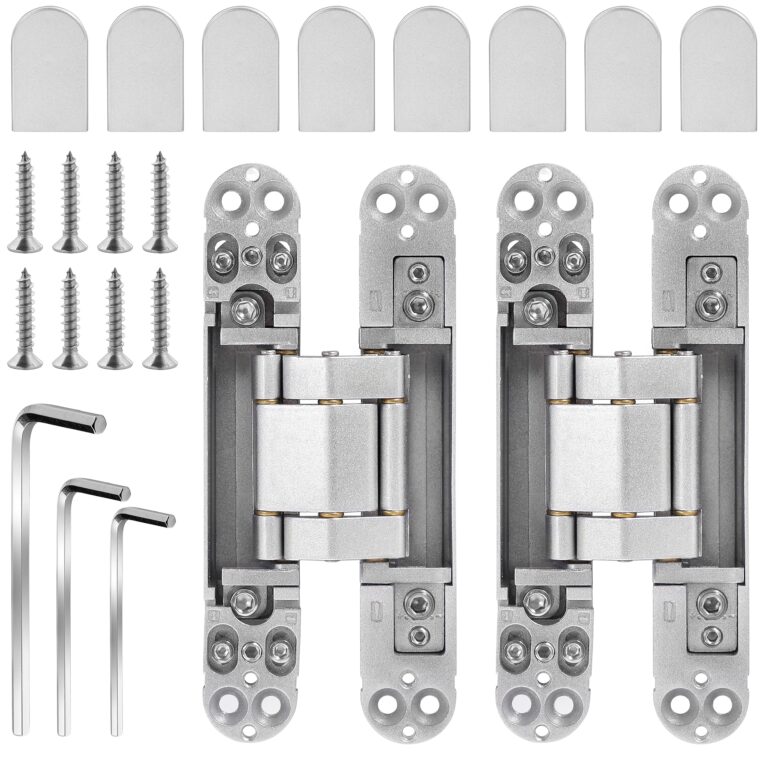

Illustrative image related to spring mechanism

3 Common User Pain Points for ‘spring mechanism’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Spring Material

The Problem: B2B buyers often struggle with selecting the appropriate material for springs in their applications. This challenge can stem from various factors, including environmental conditions, load requirements, and expected lifespan. For instance, a company manufacturing automotive parts may require springs that can withstand high stress and fluctuating temperatures. However, without proper material knowledge, they risk choosing a subpar option, leading to premature failure, increased maintenance costs, and potential safety hazards.

The Solution: To address this issue, it is crucial for buyers to engage in thorough material selection processes. They should consider factors such as tensile strength, corrosion resistance, fatigue limits, and operating temperatures when evaluating materials like carbon steel, stainless steel, or specialized alloys. Utilizing resources like spring calculators can help determine the appropriate spring constant and load capacity needed for their specific application. Collaborating with spring manufacturers or suppliers who offer expertise in material science can also provide valuable insights. By conducting comprehensive testing and simulations based on their operational parameters, buyers can ensure they select a spring material that will perform reliably and extend the lifespan of their products.

Scenario 2: Challenges with Spring Design Specifications

The Problem: Many B2B buyers face difficulties in designing springs that meet their specific operational needs. This challenge can arise from a lack of understanding of key design parameters, such as coil diameter, number of coils, and spring rate. For example, a manufacturer of consumer electronics may require a compact spring design that fits within tight space constraints while still providing adequate force. Miscalculations or oversight in design specifications can lead to components that do not function correctly, resulting in costly redesigns and production delays.

The Solution: To overcome design challenges, buyers should leverage advanced design tools and resources available from spring manufacturers. Engaging in a collaborative design process that includes engineers from both the buyer’s side and the supplier can lead to more accurate specifications. Utilizing spring calculators and CAD software can aid in visualizing and optimizing spring designs before production. Furthermore, buyers should request prototypes or samples to evaluate performance in real-world conditions, allowing for adjustments before full-scale manufacturing. Establishing clear communication with suppliers about application requirements and constraints is essential to achieving the desired spring performance.

Scenario 3: Managing Supply Chain Variability for Springs

The Problem: B2B buyers often encounter issues with supply chain variability, which can disrupt production schedules and increase costs. This is particularly true in industries where just-in-time manufacturing is prevalent, such as the automotive or electronics sectors. Unexpected delays in spring deliveries can lead to halted production lines and unmet customer demands, ultimately affecting the company’s reputation and bottom line.

The Solution: To mitigate supply chain risks, buyers should establish strong relationships with multiple spring suppliers to diversify their sourcing options. Implementing a vendor management system that tracks lead times, quality, and reliability can aid in identifying the best-performing suppliers. Additionally, engaging in forward planning and establishing safety stock levels for critical components can provide a buffer against unexpected supply disruptions. Communication with suppliers regarding their production capabilities and potential challenges is vital. Buyers can also explore long-term contracts to ensure priority access to materials during peak demand periods, fostering a more stable supply chain environment. By proactively managing supply chain relationships and expectations, companies can maintain operational continuity and enhance their competitive edge.

Strategic Material Selection Guide for spring mechanism

What Are the Key Properties of Carbon Steel for Spring Mechanisms?

Carbon steel is a widely used material in the manufacturing of springs due to its excellent mechanical properties. It offers high tensile strength and good elasticity, making it suitable for a variety of applications. Carbon steel springs can withstand high temperatures, typically up to 300°C, and exhibit decent corrosion resistance when properly treated. However, they are susceptible to rust if exposed to moisture without protective coatings.

Pros and Cons of Carbon Steel Springs

The primary advantage of carbon steel is its cost-effectiveness, as it is one of the most affordable materials available. Additionally, it is relatively easy to manufacture, allowing for quick turnaround times on custom orders. On the downside, its susceptibility to corrosion necessitates protective coatings, which can add to the overall cost and complexity of manufacturing. Furthermore, carbon steel springs may not be suitable for applications involving harsh chemical environments.

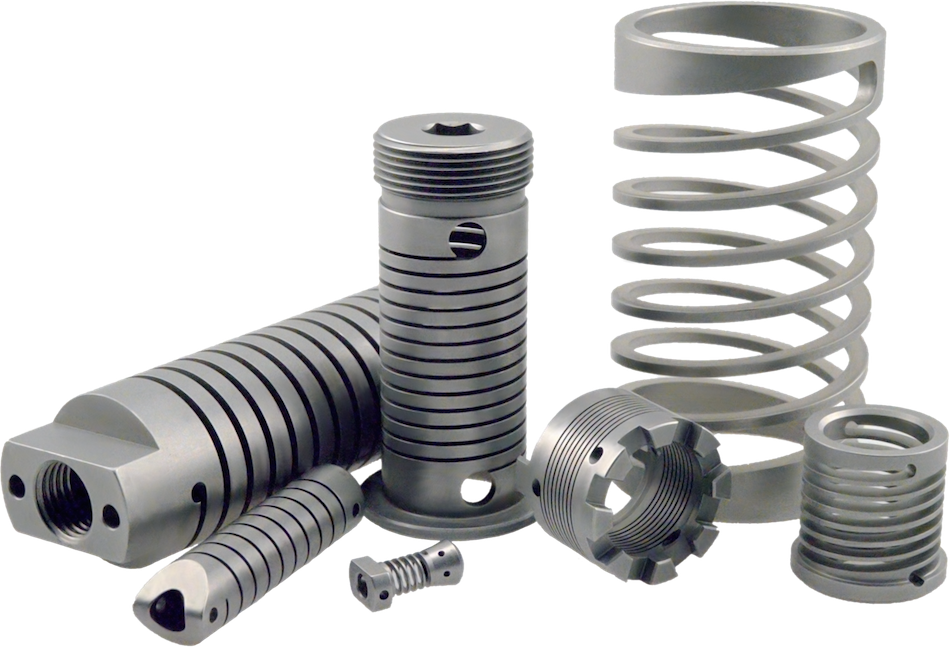

Illustrative image related to spring mechanism

Impact on Application

Carbon steel springs are commonly used in automotive and industrial applications, where strength and durability are paramount. However, buyers in regions with high humidity, such as parts of Africa and South America, should consider the potential for corrosion and may need to invest in additional protective measures.

How Does Stainless Steel Compare for Spring Mechanisms?

Stainless steel is another popular choice for spring manufacturing, particularly in environments where corrosion resistance is critical. This material can withstand temperatures up to 800°C and is highly resistant to rust and corrosion, making it ideal for applications in humid or chemically aggressive environments.

Pros and Cons of Stainless Steel Springs

The key advantage of stainless steel springs is their durability and longevity, which can reduce replacement costs over time. They are also versatile and can be used in a wide range of applications, from medical devices to automotive components. However, stainless steel is generally more expensive than carbon steel, which can be a consideration for budget-conscious buyers. Additionally, the manufacturing process can be more complex, potentially leading to longer lead times.

Impact on Application

Stainless steel springs are well-suited for applications requiring high hygiene standards, such as in the food and pharmaceutical industries. International buyers should ensure compliance with standards like ASTM and DIN, particularly in Europe and the Middle East, where regulations may be stricter.

What Are the Benefits of Using Chrome Silicon for Spring Mechanisms?

Chrome silicon is an alloy that combines silicon and chromium, providing excellent strength and fatigue resistance. This material can typically handle temperatures up to 400°C and is often used in high-performance applications where durability is essential.

Pros and Cons of Chrome Silicon Springs

The primary advantage of chrome silicon springs is their ability to maintain performance under high stress and fatigue conditions, making them ideal for heavy-duty applications. However, they can be more expensive than both carbon and stainless steel, which may deter some buyers. The manufacturing process can also be more challenging, requiring specialized equipment.

Impact on Application

Chrome silicon springs are often used in automotive suspension systems and heavy machinery. Buyers in regions with demanding operational conditions, such as the Middle East, should consider this material for its superior performance, despite the higher cost.

Why Consider Beryllium Copper for Specialized Spring Applications?

Beryllium copper is a unique material known for its excellent electrical conductivity and high strength. It can operate effectively at temperatures up to 300°C and is resistant to corrosion, making it suitable for specialized applications.

Pros and Cons of Beryllium Copper Springs

The key advantage of beryllium copper springs is their ability to conduct electricity while providing mechanical strength, making them ideal for electrical applications. However, the material is costly and can be more challenging to work with, requiring specialized manufacturing techniques. Additionally, beryllium is toxic in dust form, necessitating careful handling.

Impact on Application

Beryllium copper springs are commonly used in aerospace and electronic applications. International buyers should be aware of handling regulations, especially in Europe, where compliance with safety standards is essential.

Summary Table of Material Selection for Spring Mechanisms

| Material | Typical Use Case for spring mechanism | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Automotive, industrial machinery | Cost-effective, easy to manufacture | Susceptible to corrosion | Low |

| Stainless Steel | Food, pharmaceutical applications | High durability and corrosion resistance | Higher cost, complex manufacturing | Med |

| Chrome Silicon | Automotive suspension, heavy machinery | Excellent fatigue resistance | Higher cost, challenging to manufacture | High |

| Beryllium Copper | Aerospace, electronic applications | High strength and electrical conductivity | High cost, toxic handling requirements | High |

This strategic material selection guide provides insights into the properties, advantages, and limitations of various materials used in spring mechanisms. Buyers should consider their specific application needs, environmental conditions, and compliance with international standards when making material choices.

In-depth Look: Manufacturing Processes and Quality Assurance for spring mechanism

What Are the Key Stages in the Manufacturing Process of Spring Mechanisms?

The manufacturing process of spring mechanisms involves several critical stages, each contributing to the final product’s quality and performance. Understanding these stages will help B2B buyers ensure they are sourcing high-quality components that meet their specific requirements.

How Is Material Prepared for Spring Production?

The first stage in the manufacturing process is material preparation. Typically, high-carbon steel, stainless steel, or specialized alloys are selected based on the spring’s intended application. Material selection is crucial, as it affects the spring’s strength, elasticity, and resistance to corrosion.

Once the material is chosen, it undergoes several preparatory steps, including:

- Cutting: The raw material is cut into appropriate lengths using precision cutting tools.

- Heat Treatment: Depending on the desired properties, the material may undergo heat treatment to enhance its mechanical characteristics. This process can improve tensile strength and fatigue resistance.

- Surface Treatment: To prevent corrosion and enhance durability, surface treatments such as coating or galvanizing may be applied.

What Techniques Are Used in Forming Springs?

The next stage involves forming the springs into their desired shapes. This can be accomplished through various techniques, depending on the type of spring being produced:

- Coiling: For compression and extension springs, wire is coiled into helical shapes using CNC coiling machines. The precision of this process is vital for ensuring consistent spring rates and load capacities.

- Torsion Spring Formation: Torsion springs require a different approach, where the wire is twisted around a core to create the necessary torque. This process often involves specialized machinery that can handle the specific dimensions and tolerances required.

- Stamping: For flat springs, the material is stamped into shape using dies. This method allows for high-volume production and consistent quality.

How Is the Assembly Process Conducted for Spring Mechanisms?

Once formed, the components may require assembly, especially in complex spring mechanisms that incorporate multiple parts. Assembly techniques include:

- Welding: For certain types of springs, welding may be necessary to join components securely. This process must be performed with precision to maintain the integrity and functionality of the spring.

- Mechanical Fastening: In some cases, springs are assembled using screws or other mechanical fasteners, allowing for easy disassembly and maintenance.

- Quality Control Checks: Throughout the assembly process, quality control checkpoints are established to ensure that each component meets the required specifications.

What Finishing Techniques Are Commonly Used in Spring Manufacturing?

The final stage of the manufacturing process involves finishing, which enhances the spring’s performance and longevity. Common finishing techniques include:

- Surface Treatment: Additional coatings may be applied to improve corrosion resistance and reduce friction. Options include phosphate coating, powder coating, or chrome plating.

- Testing and Inspection: After finishing, springs undergo rigorous testing to ensure they meet performance criteria. This may include load testing, fatigue testing, and dimensional inspections.

How Is Quality Assurance Implemented in Spring Manufacturing?

Quality assurance is a critical aspect of the manufacturing process, ensuring that the springs produced meet both international standards and specific client requirements. B2B buyers must understand the quality assurance processes to select reliable suppliers.

What International Standards Should B2B Buyers Consider?

Several international standards govern spring manufacturing, with ISO 9001 being a cornerstone for quality management systems. Compliance with ISO standards indicates that the manufacturer has established a robust quality management framework. Additional certifications that may be relevant include:

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Specification: Particularly important for springs used in oil and gas applications, ensuring that products meet industry-specific requirements.

What Are the Key Quality Control Checkpoints in Spring Manufacturing?

Quality control is typically segmented into several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): At this stage, raw materials are inspected for compliance with specifications before they enter the production line. This ensures that only high-quality materials are used.

- In-Process Quality Control (IPQC): During production, periodic inspections are conducted to monitor manufacturing processes and detect any deviations from specifications early on.

- Final Quality Control (FQC): After production, finished springs undergo comprehensive testing to validate performance characteristics, dimensions, and overall quality.

What Common Testing Methods Are Employed for Spring Quality Assurance?

Testing methods are crucial for verifying that springs meet design specifications. Common techniques include:

- Load Testing: Evaluates how springs perform under specified loads to ensure they can handle operational demands.

- Fatigue Testing: Assesses the spring’s durability by subjecting it to repeated loading cycles to identify potential failure points.

- Dimensional Inspection: Utilizes precision measuring tools to confirm that springs meet specified dimensions and tolerances.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Ensuring that a supplier adheres to stringent quality control measures is essential for B2B buyers, especially in international markets. Here are some strategies to verify supplier quality control practices:

- Supplier Audits: Conducting regular audits of the supplier’s manufacturing facility can provide insights into their quality control processes and adherence to standards.

- Quality Control Reports: Requesting detailed quality control reports can help buyers understand the frequency and outcomes of inspections and tests performed on the springs.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality control measures, ensuring compliance with international standards.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality control when sourcing springs internationally. These include:

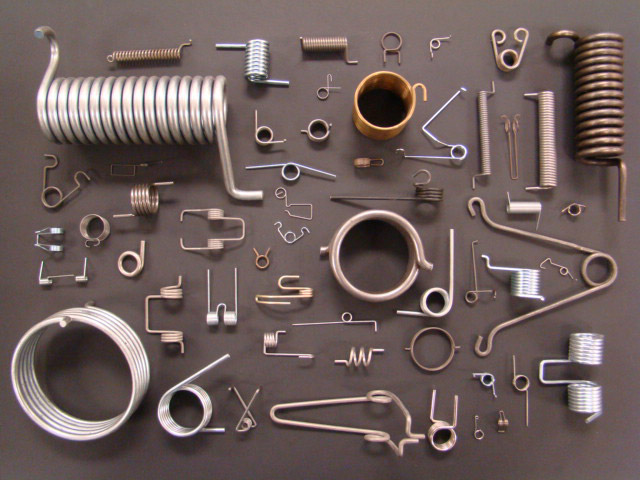

Illustrative image related to spring mechanism

- Cultural Differences: Understanding regional manufacturing practices and quality expectations is crucial. Local standards may vary, and communication barriers can impact quality assurance.

- Regulatory Compliance: Buyers must ensure that suppliers meet both local and international regulatory requirements, which may differ significantly across regions.

- Logistical Considerations: Quality control may be affected by logistics, including transportation methods and storage conditions, which can impact the integrity of spring mechanisms during transit.

By thoroughly understanding the manufacturing processes and quality assurance practices for spring mechanisms, B2B buyers can make informed decisions, ensuring they procure high-quality components that meet their specific application needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘spring mechanism’

Introduction

This practical sourcing guide is designed to assist B2B buyers in identifying and procuring effective spring mechanisms suitable for their specific applications. Whether you are in the automotive, industrial, or consumer goods sectors, understanding the nuances of spring mechanisms will help you make informed purchasing decisions that enhance product performance and reliability.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for the spring mechanism you need. Consider factors such as load capacity, dimensions, material type, and operational environment. A clear specification will facilitate better communication with suppliers and ensure that the springs meet your application needs.

- Load Capacity: Determine the maximum load the spring will need to support.

- Material Requirements: Identify if you need corrosion-resistant materials or springs that can withstand high temperatures.

Step 2: Research Potential Suppliers

Conduct thorough research to compile a list of potential suppliers. Look for manufacturers with a strong reputation in the market, especially those that specialize in the type of spring mechanisms relevant to your industry. Supplier reliability can significantly affect your production timelines and product quality.

- Industry Experience: Prefer suppliers with a proven track record in your specific sector.

- Customer Reviews: Look for testimonials or case studies that reflect the supplier’s performance and customer service.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers possess relevant certifications and compliance with international standards. Certifications such as ISO 9001 can indicate a commitment to quality management practices, which is crucial for ensuring the reliability of the spring mechanisms.

- Quality Assurance: Certifications demonstrate adherence to quality control processes.

- Regulatory Compliance: Ensure the supplier complies with local and international regulations applicable to your market.

Step 4: Request Samples for Testing

Before finalizing your order, request samples of the spring mechanisms for performance testing. This step is vital to assess if the springs meet your specifications and operational requirements under real-world conditions.

- Performance Evaluation: Test the samples under the expected load conditions to verify functionality.

- Durability Testing: Check for resistance to fatigue and wear over time.

Step 5: Analyze Pricing and Payment Terms

Discuss pricing models and payment terms with shortlisted suppliers. A comprehensive analysis of costs, including shipping and potential customs duties, will help you understand the total expenditure and budget accordingly.

- Bulk Discounts: Inquire about pricing structures for large orders or long-term contracts.

- Payment Flexibility: Evaluate payment terms that align with your cash flow requirements.

Step 6: Review Delivery Times and Logistics

Ensure that the supplier can meet your required delivery timelines. Delays in receiving spring mechanisms can disrupt production schedules and lead to increased costs.

- Lead Times: Confirm the expected lead times for production and delivery.

- Logistics Support: Assess the supplier’s capability in managing logistics, especially for international shipments.

Step 7: Establish a Long-term Partnership

Once you have identified a reliable supplier, consider establishing a long-term partnership. Building a strong relationship can lead to better pricing, priority service, and collaborative problem-solving for future projects.

- Communication Channels: Set up regular communication for updates on production and new product offerings.

- Feedback Loop: Create a system for providing feedback to continuously improve product quality and service.

By following this checklist, B2B buyers can ensure they are well-equipped to source spring mechanisms that meet their technical and operational needs, fostering successful partnerships that enhance their business operations.

Comprehensive Cost and Pricing Analysis for spring mechanism Sourcing

What Are the Key Cost Components in Spring Mechanism Sourcing?

When sourcing spring mechanisms, understanding the cost structure is crucial for B2B buyers to make informed purchasing decisions. The primary cost components include:

-

Materials: The choice of material significantly impacts the cost. Common materials for springs include carbon steel, stainless steel, and specialty alloys. Higher-grade materials often come with a premium but can offer enhanced durability and performance.

-

Labor: Labor costs vary by region and depend on the complexity of the spring design and manufacturing process. Skilled labor may be required for custom springs, which can drive up costs.

-

Manufacturing Overhead: This encompasses the indirect costs of production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can reduce overhead, leading to lower prices for buyers.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. These costs are typically amortized over larger production runs, making it essential to consider minimum order quantities (MOQs) when negotiating prices.

-

Quality Control (QC): Implementing stringent quality control measures is vital to ensure product reliability. The costs associated with QC processes can vary, and suppliers with robust QC protocols might charge more but provide better long-term value.

-

Logistics: Shipping and handling costs can fluctuate based on distance, shipping method, and the size of the order. Buyers must consider these costs as part of the total expenditure.

-

Margin: The supplier’s profit margin will also influence the final price. Understanding the market dynamics and competitor pricing can provide leverage during negotiations.

What Influences Pricing for Spring Mechanisms?

Several factors can significantly influence the pricing of spring mechanisms:

-

Volume/MOQ: Suppliers often provide better pricing for larger orders. Negotiating for bulk purchases can lead to considerable savings.

-

Specifications and Customization: Customized springs tailored to specific applications typically incur additional costs. Standardized designs may be more cost-effective, so determining the necessity of customization is essential.

-

Material Selection: As previously mentioned, the material chosen affects both the cost and the performance of the spring. Buyers should weigh the trade-off between cost and quality.

-

Quality Certifications: Springs that meet specific industry certifications or standards may come at a premium. However, these certifications can ensure reliability and reduce the risk of product failure.

-

Supplier Factors: The supplier’s reputation, production capabilities, and geographic location can influence pricing. Suppliers in regions with lower labor costs may offer more competitive rates.

-

Incoterms: Understanding the shipping terms (Incoterms) is crucial. They dictate who bears the shipping costs and risks, which can impact the total cost of ownership.

How Can Buyers Optimize Their Sourcing Strategy?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, optimizing sourcing strategies is key to achieving cost efficiency:

-

Negotiation Skills: Effective negotiation can lead to better pricing. Understand the cost structure and leverage volume discounts or long-term contracts to negotiate favorable terms.

-

Total Cost of Ownership (TCO): Consider the TCO, which includes purchase price, maintenance costs, and potential downtime. A lower upfront cost may not always equate to better value.

-

Understand Pricing Nuances: Be aware of regional pricing differences and economic conditions that may affect supplier costs. For instance, currency fluctuations can impact prices when sourcing internationally.

-

Build Relationships with Suppliers: Establishing strong relationships with suppliers can lead to better service, priority during production, and more favorable pricing.

-

Conduct Market Research: Continuous research on market trends, material costs, and supplier capabilities can empower buyers to make strategic decisions.

Conclusion

Understanding the comprehensive cost and pricing structure of spring mechanisms is essential for B2B buyers. By being informed about cost components and pricing influencers, and by adopting effective sourcing strategies, buyers can optimize their procurement processes, ensuring they achieve both quality and cost-efficiency in their spring mechanism purchases. Keep in mind that prices can vary widely based on the factors discussed, so always request indicative prices tailored to your specific requirements.

Alternatives Analysis: Comparing spring mechanism With Other Solutions

Understanding Alternative Solutions to Spring Mechanisms

In the realm of mechanical solutions, spring mechanisms are widely recognized for their efficiency in storing and releasing energy. However, various alternatives can also achieve similar objectives, each with its own set of advantages and disadvantages. This analysis aims to compare spring mechanisms with two viable alternatives: pneumatic systems and hydraulic systems. By examining key aspects such as performance, cost, ease of implementation, maintenance, and best use cases, B2B buyers can make informed decisions tailored to their specific needs.

| Comparison Aspect | Spring Mechanism | Pneumatic Systems | Hydraulic Systems |

|---|---|---|---|

| Performance | High energy storage and release | Quick response times; lower force | High force output; precise control |

| Cost | Generally low; material-dependent | Moderate; requires compressors | Higher; involves pumps and fluid systems |

| Ease of Implementation | Simple to install and integrate | Requires air supply and setup | Complex setup; requires skilled labor |

| Maintenance | Low; periodic checks needed | Moderate; air filter maintenance | High; regular fluid checks and replacements |

| Best Use Case | General applications like valves, suspensions | Lightweight applications, automation | Heavy machinery, precise movements |

Analyzing Pneumatic Systems as an Alternative

Pneumatic systems utilize compressed air to generate mechanical movement. They are particularly suited for applications requiring rapid actuation and flexibility. The primary advantage of pneumatic systems is their quick response time, making them ideal for automation tasks in manufacturing environments. However, they may not deliver the same force as spring mechanisms, making them less suitable for heavy-duty applications. Additionally, pneumatic systems require a constant air supply, which can lead to increased operational costs and downtime if leaks occur. Maintenance is moderate, focusing on air filters and compressor upkeep.

Evaluating Hydraulic Systems as a Viable Option

Hydraulic systems operate by using pressurized fluid to transmit force. They are known for their ability to generate significant power and provide precise control over movement. This makes hydraulic systems particularly advantageous in heavy machinery and industrial applications where high force and accuracy are essential. However, the complexity of hydraulic systems is a notable drawback; they require skilled labor for installation and maintenance. Additionally, the initial investment and ongoing costs can be higher than those of spring mechanisms, due to the need for pumps, valves, and regular fluid maintenance. While they excel in power and precision, they may not be the best choice for simpler applications.

Conclusion: Choosing the Right Solution for Your Needs

When evaluating alternatives to spring mechanisms, B2B buyers must consider the specific requirements of their applications. While spring mechanisms offer a balance of performance, cost, and ease of use, pneumatic and hydraulic systems provide unique advantages in speed and power, respectively. Understanding the trade-offs between these technologies—such as performance capabilities, installation complexity, and maintenance needs—will empower buyers to select the most suitable solution. Ultimately, the right choice hinges on the particular demands of the application, whether it be light automation or heavy-duty machinery.

Essential Technical Properties and Trade Terminology for spring mechanism

What Are the Key Technical Properties of Spring Mechanisms?

When selecting spring mechanisms for B2B applications, understanding their technical properties is crucial for ensuring optimal performance and reliability. Here are some essential specifications to consider:

1. Material Grade

The material grade of a spring significantly influences its strength, durability, and resistance to environmental factors. Common materials include carbon steel, stainless steel, and alloys such as chrome silicon. For instance, stainless steel offers excellent corrosion resistance, making it ideal for applications in humid or chemically aggressive environments. B2B buyers must assess material grades to ensure the selected spring meets specific operational demands.

2. Tolerance

Tolerance refers to the permissible limit of variation in a spring’s dimensions, including wire diameter and coil spacing. High precision is often required in critical applications such as automotive or aerospace components, where even minor deviations can lead to functional failures. Understanding tolerance specifications helps buyers ensure compatibility with other components in their assembly, reducing the risk of costly reworks or product failures.

3. Load Capacity

Load capacity is the maximum load a spring can handle before deformation occurs. It is essential to select springs with a load capacity that matches the application requirements to prevent premature failure. This specification is particularly vital in industrial machinery, where excessive load can lead to operational downtime and increased maintenance costs.

4. Spring Constant

The spring constant (k) measures the stiffness of a spring and is defined as the ratio of the force affecting the spring to the displacement produced. A higher spring constant indicates a stiffer spring, which is crucial for applications requiring significant resistance to deformation. Understanding the spring constant allows B2B buyers to select springs that can achieve desired performance characteristics under varying loads.

5. Fatigue Limit

The fatigue limit is the maximum stress a spring can endure for an extended period without failing. This property is critical in dynamic applications, where springs undergo repeated loading and unloading cycles. Selecting a spring with an adequate fatigue limit is essential for ensuring longevity and reliability, which is particularly important for manufacturers aiming to minimize warranty claims and enhance customer satisfaction.

What Are Common Trade Terms in the Spring Mechanism Industry?

Navigating the spring mechanism market requires familiarity with specific trade jargon. Here are some common terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are marketed under another company’s brand. In the spring industry, understanding OEM relationships can help buyers identify reliable suppliers who can provide components that meet their quality standards and specifications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is vital for B2B buyers as it impacts inventory management and purchasing strategies. Understanding MOQ can help companies plan their budgets and ensure they do not overstock or run short on critical components.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for price quotes on specific products or services. This process allows buyers to compare costs and negotiate terms effectively. By issuing RFQs, businesses can ensure they receive competitive pricing and favorable conditions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping goods. Understanding these terms helps B2B buyers determine who is responsible for shipping costs, insurance, and risk during transit, which is crucial for managing logistics and ensuring timely delivery.

5. Lead Time

Lead time refers to the duration from placing an order to receiving the products. In the spring mechanism industry, lead times can vary significantly based on manufacturing processes and inventory levels. Buyers should consider lead times when planning production schedules to avoid delays in their operations.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing spring mechanisms, ultimately enhancing their product performance and market competitiveness.

Navigating Market Dynamics and Sourcing Trends in the spring mechanism Sector

What Are the Key Market Dynamics and Trends Impacting the Spring Mechanism Sector?

The global market for spring mechanisms is experiencing significant growth, driven by increasing demand across various industries such as automotive, aerospace, consumer electronics, and industrial machinery. Key trends include the shift towards automation and smart manufacturing, which are enhancing the precision and customization capabilities of spring designs. Moreover, the rise of electric vehicles is creating opportunities for specialized spring applications in suspension systems and energy storage solutions.

International B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe, are increasingly seeking suppliers that can provide innovative spring solutions tailored to specific applications. This has led to a surge in the adoption of advanced manufacturing technologies, including 3D printing and computer-aided design (CAD), which allow for rapid prototyping and more efficient production processes. Additionally, there is a growing emphasis on reducing lead times and increasing supply chain transparency, which are critical factors for buyers looking to maintain competitiveness in their respective markets.

Another notable trend is the move towards digital procurement platforms, which facilitate easier access to a wider range of suppliers and products. These platforms enable buyers to compare pricing, quality, and delivery options, thus streamlining the sourcing process. The integration of data analytics into procurement strategies is also becoming prevalent, allowing businesses to make more informed decisions based on market trends and supplier performance.

How Does Sustainability Influence Sourcing Decisions in the Spring Mechanism Industry?

Sustainability is becoming a cornerstone of sourcing strategies in the spring mechanism sector. The environmental impact of production processes and materials used in spring manufacturing is under increasing scrutiny, prompting buyers to prioritize suppliers that demonstrate a commitment to sustainable practices. This includes minimizing waste, reducing carbon footprints, and utilizing eco-friendly materials.

Ethical sourcing is also gaining traction, with buyers placing greater importance on transparency in supply chains. They are increasingly looking for suppliers who adhere to ethical labor practices and environmental regulations. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management are becoming essential indicators of a supplier’s commitment to sustainability.

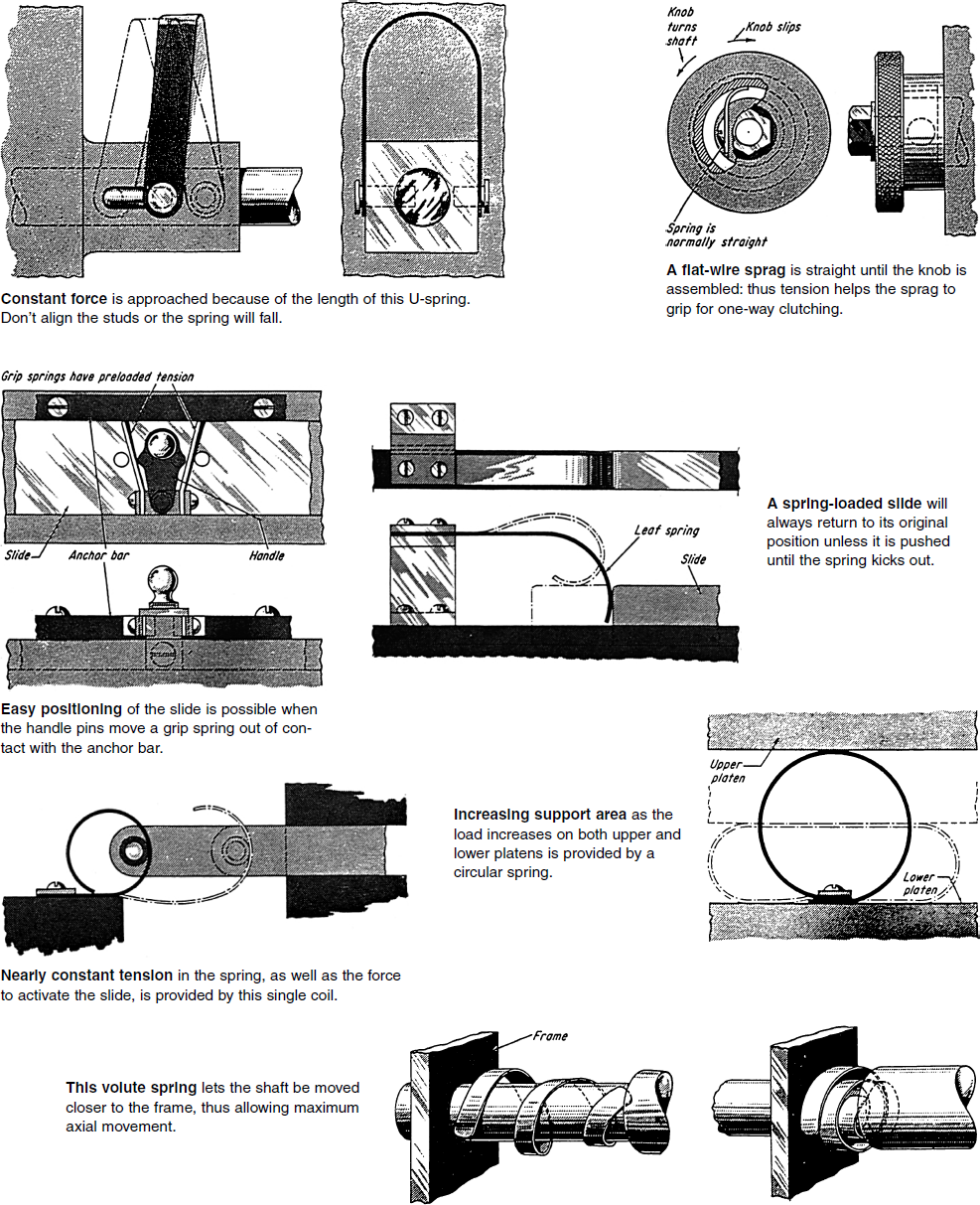

Illustrative image related to spring mechanism

Moreover, the use of ‘green’ materials, such as recyclable metals and biodegradable polymers, is on the rise. Buyers are encouraged to explore partnerships with suppliers who can provide products that align with their sustainability goals. This not only enhances a company’s reputation but also meets the growing consumer demand for environmentally friendly products.

What Is the Historical Context of the Spring Mechanism Industry and Its Evolution?

The spring mechanism sector has a rich history that dates back to ancient civilizations, where simple spring designs were used in various applications. Over time, advancements in metallurgy and manufacturing processes have transformed the industry, enabling the production of more complex and high-performance springs.

The Industrial Revolution marked a significant turning point, as mass production techniques allowed for the widespread use of springs in machinery and consumer goods. The introduction of new materials, such as stainless steel and alloys, further enhanced the performance and durability of springs.

In recent decades, the focus has shifted towards customization and precision engineering, driven by the demands of modern industries. The integration of technology into the design and manufacturing processes has led to innovations such as computer-aided design (CAD) and automated production lines, ensuring that springs can meet the increasingly specific requirements of diverse applications. This evolution has positioned the spring mechanism sector as a vital component in the machinery and manufacturing landscape, catering to a global market that continues to expand.

Frequently Asked Questions (FAQs) for B2B Buyers of spring mechanism

-

How do I choose the right spring mechanism for my application?

Choosing the right spring mechanism involves understanding the specific requirements of your application, such as load capacity, deflection, and space constraints. Assess whether you need compression, extension, or torsion springs based on the direction of the force. Consider factors like material properties, environmental conditions, and the expected lifespan of the spring. Collaborating with a manufacturer who can offer customization options and technical support can also ensure that you select the most effective spring for your needs. -

What are the key factors to consider when sourcing spring mechanisms internationally?

When sourcing spring mechanisms internationally, consider factors such as supplier reliability, product quality, and compliance with international standards. Evaluate the supplier’s experience in your industry and their ability to meet your specific requirements. Additionally, understand the logistics involved, including shipping times, customs regulations, and potential tariffs. It’s also wise to check for certifications and references from other international clients to ensure a trustworthy partnership. -

What customization options are available for spring mechanisms?

Customization options for spring mechanisms can include variations in size, shape, material, and load specifications. Many manufacturers offer tailored solutions to meet specific performance requirements, such as different coil configurations for compression springs or varied hook designs for extension springs. Discussing your application needs with the supplier can help identify the best customization options available, ensuring that the springs perform optimally in your equipment or product. -

What is the minimum order quantity (MOQ) for spring mechanisms?

Minimum order quantities (MOQs) for spring mechanisms can vary widely based on the supplier and the complexity of the springs being ordered. Some manufacturers may have low MOQs for standard products, while custom springs might require higher quantities to be cost-effective. It’s essential to clarify MOQ with your supplier during negotiations, as this can significantly impact your purchasing strategy and overall project budget. -

What payment terms should I expect when sourcing spring mechanisms?

Payment terms can differ among suppliers, but common practices include upfront deposits, payment upon delivery, or net terms (e.g., 30 or 60 days). It’s crucial to discuss and agree upon payment terms before finalizing your order to avoid any misunderstandings. Additionally, consider using secure payment methods and verify the supplier’s payment policies to protect your investment and ensure a smooth transaction process. -

How can I ensure quality assurance for my spring mechanism orders?

To ensure quality assurance, request detailed product specifications and certifications from your supplier. Implement a quality control process that includes inspections at various stages of production and prior to shipment. Many suppliers offer sample testing, which allows you to evaluate the springs before placing a larger order. Establishing a clear communication line with your supplier regarding quality standards and expectations will help mitigate risks related to product quality. -

What are the best practices for shipping spring mechanisms internationally?

Best practices for shipping spring mechanisms internationally include selecting reliable logistics partners and understanding the shipping regulations of both the exporting and importing countries. Ensure that the springs are properly packaged to prevent damage during transit and comply with any customs documentation requirements. Consider choosing shipping methods that balance speed and cost, and track shipments to stay informed about their status throughout the delivery process. -

How do I vet potential suppliers for spring mechanisms?

Vetting potential suppliers for spring mechanisms involves several steps: reviewing their certifications, manufacturing capabilities, and industry experience. Request references from previous clients, especially those in your industry, to gauge their reliability and product quality. It’s also beneficial to conduct site visits if feasible, or use third-party inspection services to assess the supplier’s facilities. Additionally, engage in open discussions about their production processes and quality control measures to ensure they align with your standards.

Top 7 Spring Mechanism Manufacturers & Suppliers List

1. Acxesspring – Mechanical Springs

Domain: acxesspring.com

Registered: 1996 (29 years)

Introduction: Mechanical Springs are metal wire springs that function in various mechanisms to compress, extend, rotate, slide, pull, and exert force when an equal or greater force is applied. They can exert pressure, rotational force, or pulling strength in diverse applications. Types of mechanical springs include: 1. Compression Springs: Used in valves, suspensions, ballpoint pens, and anywhere a compressing …

2. IDC Spring – Quality Springs

Domain: idcspring.com

Registered: 2018 (7 years)

Introduction: IDC Spring offers a variety of springs including garage door springs, torsion springs, extension springs, and Holmes® one-piece springs. The springs are made from different materials such as galvanized wire, oil tempered wire, square wire, hard drawn wire, music wire, and chrome silicon wire. The main types of mechanical springs available are compression springs, torsion springs, and extension spr…

3. Lesjofors – Compression Springs

Domain: lesjoforssprings.com

Registered: 2021 (4 years)

Introduction: Compression springs store and release energy when subjected to a compressive force. They are typically designed as helical wire coil springs and come in various shapes and sizes, including conical and cylindrical. Key concepts include elastic deformation, Hooke’s Law (F = k * x), stress and strain measurements, and the significance of the spring constant. Material selection is crucial for performa…

4. Weber Knapp – Mechanical Spring Designs

Domain: blog.weberknapp.com

Registered: 1995 (30 years)

Introduction: Mechanical Spring Designs: 1. Compression Springs: Store energy when compressed, used in switches, vehicle suspensions, and lid counterbalancing. 2. Extension Springs: Increase force when stretched, used in screen door hinges, trampolines, and garage doors. 3. Torsion Springs: Generate torque from twisting motions, used in saloon doors, horse trailer ramps, and keyboard mechanisms. 4. Constant For…

5. Reddit – Spring Release Mechanism

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Design a spring mechanism that mechanically releases after being depressed beyond a certain depth. The mechanism includes a platform on top of a spring inside a metal cup, with a top cup that compresses the spring. After a certain distance, the platform decouples from the top cup, allowing the spring to push the platform upwards. Seeking mechanisms for releasing the platform from the top cup.

6. Carr Lane – Spring-Loaded Mechanisms

Domain: carrlane.com

Registered: 1996 (29 years)

Introduction: This company, Carr Lane – Spring-Loaded Mechanisms, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Spring Store – Spring Finder Tools

Domain: thespringstore.com

Registered: 2012 (13 years)

Introduction: Spring Loaded Applications include tools for finding and buying stock compression, extension, and torsion springs. The Spring Finder allows users to search for springs based on specific dimensions and tolerances in both English and metric units. For compression springs, users can enter outer diameter, free length, and spring rate in a basic search, with advanced options including load, deflection,…

Strategic Sourcing Conclusion and Outlook for spring mechanism

How Can Strategic Sourcing Enhance Your Supply Chain for Spring Mechanisms?

In today’s competitive landscape, effective strategic sourcing is pivotal for optimizing your supply chain, particularly when it comes to spring mechanisms. By focusing on quality materials, precise engineering, and reliable suppliers, businesses can enhance product performance and reduce costs. Understanding the various types of springs—compression, extension, and torsion—enables buyers to select the right solutions tailored to their specific applications, from automotive to industrial machinery.

Moreover, leveraging technological advancements, such as spring calculators and design software, can significantly streamline the sourcing process. This not only ensures adherence to industry standards but also fosters innovation in product development. As international markets continue to evolve, B2B buyers from Africa, South America, the Middle East, and Europe should prioritize partnerships with manufacturers who offer customization and sustainability in their offerings.

Looking ahead, the demand for high-quality spring mechanisms will only increase as industries seek more efficient, durable solutions. Now is the time to evaluate your sourcing strategies and align them with future market trends. Embrace this opportunity to enhance your supply chain and ensure your business remains competitive in a rapidly changing environment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.