Everything You Need to Know About Spiral Staircase For Sale Sourcing in 2025

Introduction: Navigating the Global Market for spiral staircase for sale

Navigating the global market for spiral staircases can be a daunting task for international B2B buyers, particularly when seeking high-quality, cost-effective solutions that meet diverse project requirements. Sourcing spiral staircases for sale involves understanding the various types available, their applications in residential and commercial settings, and the nuances of supplier vetting in different regions. This comprehensive guide aims to demystify the process by offering detailed insights into design options, installation considerations, and supplier evaluation criteria tailored for markets in Africa, South America, the Middle East, and Europe, including specific countries like Vietnam and Brazil.

As a B2B buyer, you face unique challenges, from ensuring compliance with local building codes to balancing budget constraints with quality expectations. This guide empowers you to make informed purchasing decisions by providing actionable strategies for assessing suppliers, comparing costs, and identifying the best materials for your specific needs. With a focus on maximizing value while minimizing risk, you will gain the knowledge necessary to confidently navigate the complexities of the spiral staircase market. By leveraging this information, you can enhance your project outcomes and deliver superior results, ensuring that your investments yield the aesthetic and functional benefits desired in your architectural endeavors.

Understanding spiral staircase for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Indoor Spiral Staircases | Compact design, often made of wood or metal, aesthetic appeal | Residential buildings, commercial spaces | Pros: Space-saving, stylish; Cons: Limited load capacity, may require more maintenance. |

| Outdoor Spiral Staircases | Weather-resistant materials, robust construction | Patios, decks, outdoor facilities | Pros: Durable against elements, versatile; Cons: Higher upfront cost, installation complexity. |

| Custom Spiral Staircases | Tailored design, unique materials, specific dimensions | High-end residential, bespoke commercial | Pros: Perfect fit, unique aesthetics; Cons: Longer lead times, potentially higher costs. |

| Galvanized Spiral Staircases | Corrosion-resistant, ideal for exterior use | Industrial sites, outdoor installations | Pros: Longevity, low maintenance; Cons: Heavier, less aesthetic variety compared to wood. |

| Modular Spiral Staircases | Easy assembly, pre-fabricated sections | Retail environments, temporary structures | Pros: Quick installation, adjustable height; Cons: Limited customization, may lack sturdiness. |

What Are Indoor Spiral Staircases and Their Key Features?

Indoor spiral staircases are designed for aesthetic appeal and space efficiency, typically constructed from wood or metal. They are ideal for residential and commercial spaces where floor area is limited. B2B buyers should consider factors like design compatibility with existing interiors and load capacity, as some models may not support heavy traffic. While they enhance the visual appeal of a space, maintenance can be a concern depending on the material used.

How Do Outdoor Spiral Staircases Differ from Indoor Models?

Outdoor spiral staircases are built from robust, weather-resistant materials to withstand harsh environmental conditions. These staircases are commonly used in patios, decks, and other outdoor facilities. B2B buyers need to assess the durability and maintenance requirements of these structures, as they often face exposure to the elements. Although they may come with a higher upfront cost, their longevity and versatility make them a worthwhile investment for outdoor applications.

What Are the Advantages of Custom Spiral Staircases?

Custom spiral staircases offer tailored designs that cater to unique architectural needs, materials, and dimensions. They are particularly popular in high-end residential projects and bespoke commercial spaces. For B2B buyers, the ability to create a staircase that fits perfectly into a design scheme is a significant advantage. However, it’s essential to factor in longer lead times and potentially higher costs, which can impact project timelines and budgets.

Why Choose Galvanized Spiral Staircases for Industrial Use?

Galvanized spiral staircases are constructed from corrosion-resistant materials, making them ideal for industrial sites and outdoor installations. Their robust design ensures longevity and minimal maintenance, which is crucial for businesses operating in challenging environments. B2B buyers should weigh the benefits of durability against the typically heavier weight and limited aesthetic options compared to wooden alternatives.

What Makes Modular Spiral Staircases a Good Option for Retail?

Modular spiral staircases consist of pre-fabricated sections that allow for easy assembly and quick installation, making them suitable for retail environments and temporary structures. B2B buyers appreciate the flexibility in height adjustments and the speed of setup. However, the trade-off may include limited customization options and potential concerns regarding sturdiness, which should be carefully considered based on the intended use.

Key Industrial Applications of spiral staircase for sale

| Industry/Sector | Specific Application of spiral staircase for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Indoor and outdoor access in hotels and resorts | Enhances aesthetic appeal while maximizing space efficiency | Durability, compliance with safety standards, design flexibility |

| Retail | Showroom displays and multi-level stores | Optimizes floor space and improves customer flow | Customization options, ease of installation, material quality |

| Residential Construction | Space-saving solutions in urban apartments and homes | Adds functionality and style to small living areas | Building codes, aesthetic preferences, material selection |

| Industrial Facilities | Access to machinery and maintenance areas | Facilitates safe and efficient movement in tight spaces | Load capacity, weather resistance for outdoor use, safety features |

| Cultural Institutions | Exhibition spaces and auditoriums | Provides unique design elements while improving visitor access | Custom designs, integration with existing architecture, safety regulations |

How are Spiral Staircases Applied in the Hospitality Sector?

In the hospitality industry, spiral staircases are often used to connect different levels of hotels and resorts, providing both functionality and style. Their compact design allows for seamless integration into spaces where traditional staircases would be impractical. For international buyers, especially in regions like Africa and South America, sourcing durable materials that can withstand varying climates is crucial. Additionally, compliance with local safety regulations and aesthetic preferences can greatly influence purchasing decisions.

What Role Do Spiral Staircases Play in Retail Environments?

Retail spaces frequently utilize spiral staircases to create visually appealing showrooms and enhance customer experience. By maximizing vertical space, these staircases facilitate better customer flow between levels, improving accessibility to products. B2B buyers from Europe and the Middle East should consider customization options that align with brand identity and store layout. Moreover, ease of installation and material quality are key factors in ensuring longevity and maintaining a polished appearance.

Why Are Spiral Staircases Important in Residential Construction?

In urban residential construction, where space is often limited, spiral staircases serve as an effective solution for connecting multiple floors while saving valuable square footage. They can add a distinctive design element that enhances the overall aesthetic of a home. Buyers should pay close attention to local building codes and regulations when sourcing these staircases, as well as their preferences for materials and finishes, which can vary widely across different cultures and regions.

How Do Spiral Staircases Benefit Industrial Facilities?

Industrial facilities often require efficient access to machinery and maintenance areas, where space constraints are common. Spiral staircases provide a practical solution by enabling safe and effective movement in tight spaces. For buyers in sectors such as manufacturing or warehousing, considerations like load capacity and weather resistance for outdoor installations are vital. Ensuring that the chosen staircase meets safety standards is also a critical factor in the decision-making process.

What Are the Uses of Spiral Staircases in Cultural Institutions?

Cultural institutions, such as museums and galleries, often employ spiral staircases to enhance exhibition spaces while improving visitor access. These staircases can serve as striking architectural features that draw attention and elevate the overall experience. When sourcing for these applications, buyers should focus on custom designs that integrate well with existing structures and adhere to safety regulations. Given the importance of aesthetics in cultural settings, material selection and craftsmanship will also play significant roles in the purchasing decision.

3 Common User Pain Points for ‘spiral staircase for sale’ & Their Solutions

Scenario 1: Complicated Sizing and Customization Challenges

The Problem: B2B buyers often encounter difficulties with sizing and customization when ordering spiral staircases. Given the unique architectural requirements of various projects, specifying the correct dimensions and features can be a complex task. Buyers may struggle with fitting the staircase into an existing space while ensuring it meets safety standards and aesthetic expectations. This can lead to delays in project timelines and increased costs if the wrong specifications are made.

The Solution: To alleviate these challenges, buyers should start by conducting a thorough site assessment. Measure the height and diameter requirements of the staircase, and consider the intended use—whether it’s for residential or commercial purposes. It’s beneficial to consult with the manufacturer or supplier about customization options. Many suppliers offer bespoke solutions that can be tailored to specific project needs. Requesting detailed product specifications and installation guidelines can also help streamline the selection process. Utilizing 3D modeling tools, if available, can further assist in visualizing how the staircase will fit within the space.

Scenario 2: Difficulty in Comparing Quality and Pricing Across Suppliers

The Problem: With numerous suppliers offering a wide range of spiral staircases, B2B buyers often find it challenging to compare quality and pricing effectively. Some may encounter discrepancies in material quality, manufacturing standards, and warranty offerings, leading to confusion about the best value. This situation can result in buyers inadvertently choosing lower-quality products that may not meet their project needs, ultimately affecting safety and durability.

The Solution: To navigate this issue, buyers should prioritize conducting comprehensive market research. Begin by creating a checklist of essential criteria, including material specifications, design features, and compliance with local building codes. Request samples or detailed product descriptions from multiple suppliers to assess quality. Engaging in direct discussions with suppliers can provide deeper insights into their manufacturing processes and material sourcing. Additionally, reviewing customer testimonials and case studies can help gauge the reliability and performance of the staircases in real-world applications. By establishing clear evaluation criteria, buyers can make informed decisions that align with their project requirements.

Scenario 3: Installation and Maintenance Concerns

The Problem: Another significant pain point for B2B buyers is the installation and ongoing maintenance of spiral staircases. Many suppliers do not provide adequate installation instructions, which can lead to improper assembly and safety hazards. Additionally, buyers may worry about the long-term maintenance of the materials used in the staircase, particularly in harsh environmental conditions, affecting the overall lifespan and appearance.

The Solution: To address these concerns, buyers should seek suppliers that offer comprehensive installation support and maintenance guides. When purchasing, inquire whether the supplier provides professional installation services or detailed instructions for DIY assembly. It’s also wise to discuss maintenance requirements upfront, particularly regarding weather-resistant materials if the staircase is intended for outdoor use. Regular maintenance schedules should be established to ensure safety and longevity. Suppliers that offer warranties or service agreements can provide added assurance. Ultimately, investing time in understanding the installation process and maintenance needs can help mitigate future issues, ensuring the staircase remains a safe and attractive feature for years to come.

Strategic Material Selection Guide for spiral staircase for sale

What Are the Key Materials Used in Spiral Staircases?

When selecting a spiral staircase for sale, the choice of material is crucial for ensuring durability, aesthetic appeal, and compliance with local regulations. Here, we analyze four common materials used in the manufacturing of spiral staircases: steel, aluminum, wood, and fiberglass. Each material has unique properties, advantages, and disadvantages that can influence the decision-making process for B2B buyers, especially in diverse international markets.

How Does Steel Perform as a Material for Spiral Staircases?

Steel is one of the most popular materials for spiral staircases due to its strength and durability. It offers excellent temperature and pressure ratings, making it suitable for both indoor and outdoor applications. Steel is highly resistant to wear and tear, and when galvanized, it can also exhibit strong corrosion resistance.

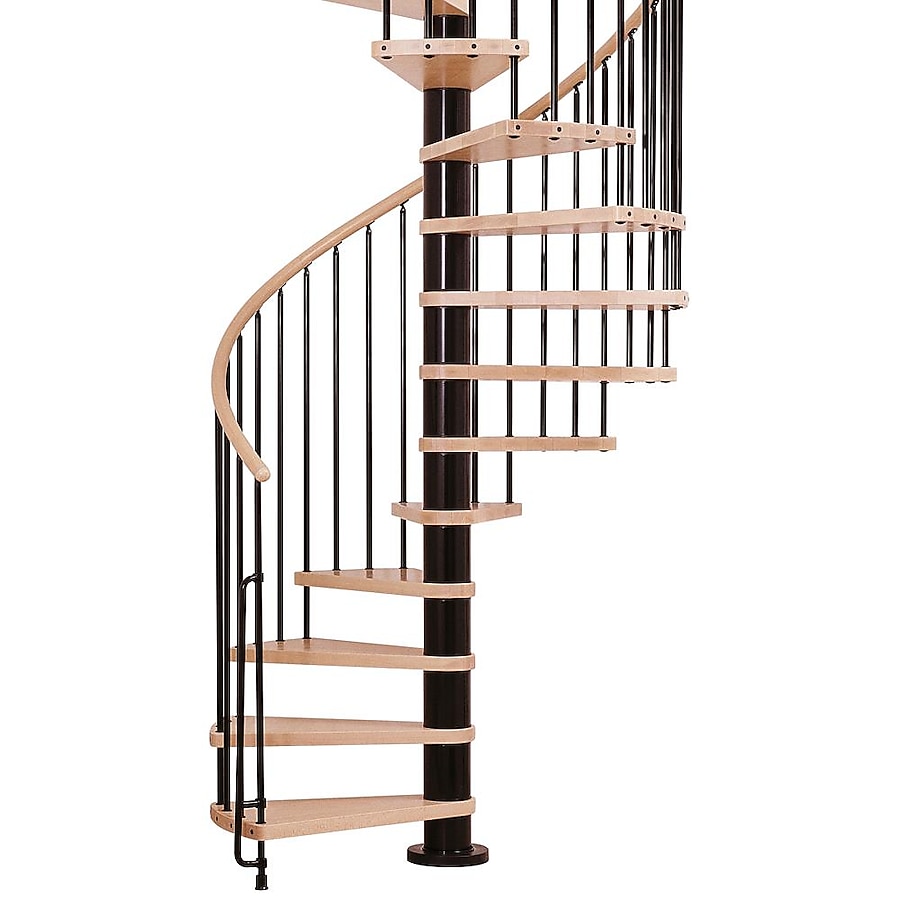

Illustrative image related to spiral staircase for sale

Pros: Steel staircases are robust and can support heavy loads, making them ideal for commercial and industrial settings. They are also relatively cost-effective compared to other materials, especially when mass-produced.

Cons: The primary drawback of steel is its susceptibility to rust if not properly treated. Additionally, steel staircases can be heavy, which may complicate installation and transportation.

Impact on Application: Steel is compatible with various coatings and finishes, allowing for customization in appearance. However, in regions with high humidity or coastal environments, additional protective measures may be necessary.

Considerations for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should ensure compliance with local building codes and standards, such as ASTM or DIN, particularly regarding load-bearing capacities and corrosion resistance.

What Are the Advantages of Aluminum in Spiral Staircases?

Aluminum is a lightweight alternative to steel, offering good strength-to-weight ratios. It is naturally resistant to corrosion, making it an excellent choice for outdoor applications or humid environments.

Pros: The lightweight nature of aluminum simplifies installation and reduces shipping costs. Additionally, aluminum can be anodized or painted for aesthetic purposes, providing versatility in design.

Cons: While aluminum is durable, it is not as strong as steel and may not support as heavy a load, which can limit its use in certain commercial applications. It is also typically more expensive than steel.

Illustrative image related to spiral staircase for sale

Impact on Application: Aluminum is suitable for residential and light commercial use, especially in environments where moisture is a concern. However, it may not be ideal for heavy-duty applications.

Considerations for International Buyers: Buyers should verify that aluminum products meet local standards for strength and corrosion resistance. In regions with extreme temperatures, thermal expansion could also be a concern.

How Does Wood Compare as a Material for Spiral Staircases?

Wood is often chosen for its aesthetic appeal and warmth, making it a popular choice for residential applications. Different types of wood can offer varying levels of durability and resistance to environmental factors.

Pros: Wood provides a classic look and can be customized with various finishes. It is generally easier to work with and can be produced in a range of styles.

Cons: Wood is susceptible to moisture damage, warping, and insect infestations, which can limit its lifespan. It may also require more maintenance than metal alternatives.

Impact on Application: Wood is suitable for indoor applications and can be used in low-traffic areas. However, in humid or wet environments, wood may not be the best choice.

Considerations for International Buyers: Buyers should ensure that the wood used complies with local regulations regarding sustainability and treatment against pests. Certifications like FSC can be beneficial.

What Role Does Fiberglass Play in Spiral Staircase Design?

Fiberglass is a composite material that has gained popularity due to its lightweight and corrosion-resistant properties. It is often used in environments where traditional materials may fail.

Pros: Fiberglass is highly resistant to weather conditions, making it ideal for outdoor applications. It is also low-maintenance and can be molded into various shapes and designs.

Cons: Fiberglass can be more expensive than traditional materials and may not support as heavy a load as steel or wood. Additionally, it can be less aesthetically pleasing for certain applications.

Impact on Application: Fiberglass is suitable for both residential and commercial applications, especially in coastal or high-humidity areas.

Considerations for International Buyers: Buyers should check for compliance with local safety standards and ensure that the fiberglass used is of high quality to prevent degradation over time.

Summary Table of Material Selection for Spiral Staircases

| Material | Typical Use Case for Spiral Staircase for Sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Commercial and industrial applications | High strength and durability | Susceptible to rust without treatment | Medium |

| Aluminum | Residential and light commercial applications | Lightweight and corrosion-resistant | Not as strong as steel | High |

| Wood | Indoor residential applications | Aesthetic appeal and customization | Susceptible to moisture and pests | Medium |

| Fiberglass | Outdoor and high-humidity environments | Weather-resistant and low-maintenance | Higher cost and lower load capacity | High |

This guide provides a comprehensive overview of material selection for spiral staircases, helping international B2B buyers make informed decisions tailored to their specific needs and local conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for spiral staircase for sale

What Are the Key Manufacturing Processes for Spiral Staircases?

The manufacturing of spiral staircases involves several critical stages designed to ensure both aesthetic appeal and structural integrity. Below are the main phases of production, along with key techniques utilized throughout the process.

How Is Material Prepared for Spiral Staircases?

The first step in the manufacturing process is material preparation. High-quality materials, typically steel or aluminum, are sourced and inspected for compliance with industry standards. This involves assessing the chemical composition and mechanical properties of the materials. For wooden spiral staircases, premium hardwoods or engineered wood are selected based on their durability and aesthetic qualities.

What Techniques Are Used in Forming Spiral Staircase Components?

Once materials are prepared, they undergo various forming techniques. For metal components, processes like laser cutting, CNC machining, and bending are employed to create precise shapes and dimensions. This ensures that each component fits together seamlessly during assembly. For wooden parts, techniques such as routing and shaping are used to achieve intricate designs and to ensure a perfect fit.

How Are Spiral Staircase Components Assembled?

The assembly phase is critical for the overall stability and functionality of the spiral staircase. Components such as treads, risers, and handrails are meticulously assembled, often using advanced jigs and fixtures to maintain alignment. This phase may also include welding or bolting metal parts together, while wooden components may be joined using dowels or adhesive to enhance strength.

What Finishing Processes Enhance the Appearance and Durability of Spiral Staircases?

Finishing processes play a vital role in enhancing both the aesthetic and functional qualities of spiral staircases. Metal components typically receive treatments such as galvanization or powder coating to prevent rust and corrosion, ensuring longevity, especially for outdoor applications. Wooden components are often sanded and treated with stains or sealants to enhance their natural beauty while providing protection against wear and moisture.

What Quality Assurance Measures Are In Place for Spiral Staircase Manufacturing?

Quality assurance (QA) is a crucial aspect of the manufacturing process, ensuring that products meet international standards and customer expectations. Here’s how manufacturers implement QA protocols throughout the production cycle.

Which International Standards Are Relevant for Spiral Staircase Quality Assurance?

Manufacturers often adhere to international quality management standards like ISO 9001, which provides a framework for consistent quality across all processes. For products sold in Europe, compliance with CE marking is essential, indicating that the product meets EU safety, health, and environmental protection requirements. Additionally, specific certifications like API (American Petroleum Institute) may be relevant for products used in industrial applications.

What Are the Key Quality Control Checkpoints in Spiral Staircase Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet specified standards. Any subpar materials are rejected to maintain quality.

-

In-Process Quality Control (IPQC): During manufacturing, random sampling and inspections are conducted to ensure that components are being produced according to specifications. This includes measuring dimensions and assessing weld quality.

-

Final Quality Control (FQC): Once assembly is complete, a comprehensive inspection is performed on the finished product. This includes checking for structural integrity, finish quality, and compliance with design specifications.

What Testing Methods Are Commonly Used to Ensure Product Quality?

Manufacturers employ various testing methods to validate the quality of spiral staircases, including:

- Load Testing: Assessing the staircase’s ability to withstand specified loads without deformation or failure.

- Corrosion Resistance Testing: For metal components, this test checks the effectiveness of protective coatings against environmental factors.

- Dimensional Inspection: Ensuring that all components adhere to specified measurements to guarantee proper fit and function.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential. Here are some actionable insights:

What Steps Can Buyers Take to Audit Suppliers?

Buyers can conduct audits of potential suppliers to assess their manufacturing processes and quality assurance protocols. This involves visiting manufacturing facilities, reviewing documentation related to quality management systems, and observing production practices firsthand.

Illustrative image related to spiral staircase for sale

How Important Are Quality Control Reports?

Requesting quality control reports from suppliers can provide insight into their adherence to standards. These reports should detail inspection results, testing methodologies, and any corrective actions taken for non-conformities.

Should Buyers Consider Third-Party Inspections?

Engaging third-party inspection services can add an additional layer of assurance. These independent entities can verify that the manufacturing processes and final products meet industry standards and buyer specifications, providing peace of mind, especially for large-scale projects.

What Are the Nuances of Quality Control and Certification for International Buyers?

International buyers should be aware of specific nuances related to certification and quality control when sourcing spiral staircases. Different regions may have varying standards and regulations that affect product compliance. Understanding these regional differences can help buyers ensure that the products they purchase are suitable for their specific markets.

Illustrative image related to spiral staircase for sale

For instance, buyers from Europe must ensure that products have the CE mark, while those in North America might focus on ANSI (American National Standards Institute) standards. Being knowledgeable about these requirements will facilitate smoother transactions and reduce the risk of non-compliance.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for spiral staircases is vital for B2B buyers. By focusing on material preparation, forming techniques, assembly, and finishing processes, alongside robust quality control practices, buyers can make informed purchasing decisions that align with their project needs and regional compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘spiral staircase for sale’

This guide provides a comprehensive checklist for B2B buyers looking to procure spiral staircases. By following these steps, you will ensure that your purchasing process is efficient, cost-effective, and meets your specific requirements.

Step 1: Define Your Technical Specifications

Begin by outlining the specific technical requirements for your spiral staircase. Consider factors such as dimensions, weight capacity, material (steel, wood, or composite), and design aesthetics. This clarity will help you communicate effectively with suppliers and ensure that the final product meets your needs.

- Dimensions: Measure the height and diameter required for your installation.

- Weight Capacity: Determine the expected load to ensure safety and compliance with local building codes.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in spiral staircases. Look for companies with a strong reputation and a proven track record in your region. Online reviews, industry ratings, and referrals from other businesses can provide valuable insights.

- Experience: Choose suppliers with extensive experience in manufacturing and selling spiral staircases.

- Portfolio: Review their previous projects to assess the quality and variety of their offerings.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers possess the necessary certifications and comply with international standards. This step is crucial to ensure product safety, quality, and legal compliance.

- Quality Assurance: Look for ISO certifications or other relevant quality standards.

- Building Codes: Ensure that the supplier adheres to local building regulations and safety standards.

Step 4: Request Detailed Quotes

Obtain detailed quotes from multiple suppliers, ensuring they include all relevant costs such as shipping, installation, and any additional features. This will enable you to make a well-informed comparison and avoid unexpected expenses.

- Itemized Costs: Ensure the quote breaks down all costs, including materials and labor.

- Lead Times: Ask about the expected delivery times to align with your project schedule.

Step 5: Assess Customer Support and Warranty

Evaluate the level of customer support and warranty offered by the supplier. A responsive customer service team can be invaluable during the procurement process and after installation.

- Warranty Terms: Look for warranties that cover defects and structural integrity over a reasonable period.

- Support Availability: Ensure that the supplier provides accessible support channels for any post-purchase inquiries.

Step 6: Check Shipping and Delivery Options

Understand the shipping and delivery options available, especially if you are sourcing internationally. This step is vital to ensure timely delivery and to avoid potential customs issues.

- Shipping Methods: Inquire about shipping methods and timelines.

- Customs Handling: Ensure the supplier can assist with customs clearance if importing from another country.

Step 7: Finalize the Order and Payment Terms

Once you have selected a supplier, finalize the order by agreeing on payment terms that suit both parties. Clear communication at this stage can prevent misunderstandings later in the process.

Illustrative image related to spiral staircase for sale

- Payment Options: Discuss various payment methods, such as credit terms or deposits.

- Contractual Agreement: Ensure all terms are documented in a contractual agreement to protect both parties.

By following this checklist, B2B buyers can navigate the procurement process of spiral staircases with confidence, ensuring that they select the best products and suppliers for their needs.

Comprehensive Cost and Pricing Analysis for spiral staircase for sale Sourcing

When considering the sourcing of spiral staircases for sale, it’s crucial to understand the intricate cost structure and pricing factors that affect your purchasing decisions. This analysis will guide international B2B buyers in making informed choices, particularly in regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components for Spiral Staircases?

The total cost of spiral staircases can be broken down into several key components:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials include steel, aluminum, wood, and composite options. High-quality materials typically come with a higher price tag but offer better durability and aesthetic appeal.

-

Labor: Labor costs encompass the assembly and installation of the spiral staircases. These costs can vary based on local labor rates and the complexity of the installation. Custom designs may require specialized labor, further increasing costs.

-

Manufacturing Overhead: This includes costs related to the production process, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help lower these costs, which may be passed on to buyers.

-

Tooling: For custom spiral staircases, specific tooling may be necessary to achieve desired designs. This can include molds or machinery tailored to produce unique elements, adding to the initial investment.

-

Quality Control (QC): Quality assurance measures are essential to ensure that the staircases meet safety and design standards. This process incurs additional costs but is vital for maintaining product integrity.

-

Logistics: Shipping costs can vary based on distance, weight, and dimensions of the staircase kits. International shipping may also involve customs duties, tariffs, and insurance, which should be factored into the total cost.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. This margin can vary significantly between manufacturers and is influenced by market demand and competition.

How Do Price Influencers Affect Spiral Staircase Costs?

Several factors can influence the pricing of spiral staircases:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to discounts. Buyers should negotiate terms that reflect their purchasing power, especially if they anticipate repeat orders.

-

Specifications and Customization: Unique designs or specific requirements (e.g., size, material) can raise costs. Buyers should be clear about their specifications to receive accurate quotes and avoid unexpected expenses.

-

Material Quality and Certifications: Higher quality materials and certifications (like ISO) can lead to increased costs. However, they often ensure better performance and longevity, contributing to lower Total Cost of Ownership (TCO) in the long run.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while newer suppliers might offer competitive pricing to enter the market.

-

Incoterms: Understanding shipping terms is essential for budgeting. Incoterms dictate who is responsible for shipping costs, insurance, and risk during transit, which can significantly impact the final price.

What Are the Best Buyer Tips for Negotiating Spiral Staircase Prices?

-

Negotiate Terms: Don’t hesitate to negotiate prices, especially for larger orders. Request quotes from multiple suppliers to leverage better pricing.

-

Focus on Cost-Efficiency: Consider the Total Cost of Ownership rather than just the initial purchase price. Higher upfront costs for quality materials may yield savings in maintenance and replacement.

-

Be Aware of Pricing Nuances for International Purchases: International buyers must consider additional costs such as tariffs, taxes, and shipping fees. It’s beneficial to have a clear understanding of these costs upfront to avoid budget overruns.

-

Request Detailed Quotes: Always ask for comprehensive quotes that break down costs, including materials, labor, and logistics. This transparency helps in comparing suppliers effectively.

-

Stay Informed on Market Trends: Market conditions can impact pricing. Regularly review industry trends and pricing changes to make timely purchasing decisions.

Disclaimer

The prices mentioned for spiral staircases are indicative and can vary widely based on specific requirements, supplier negotiations, and market conditions. Always consult with suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing spiral staircase for sale With Other Solutions

When exploring the market for spiral staircases, it’s essential to consider various alternatives that may better suit specific needs or preferences. This analysis will compare spiral staircases available for sale against two viable alternatives: straight staircases and modular stair systems. Each option offers unique benefits and challenges that can impact a buyer’s decision.

| Comparison Aspect | Spiral Staircase For Sale | Straight Staircase | Modular Stair System |

|---|---|---|---|

| Performance | Space-saving design, aesthetically pleasing, suitable for smaller areas | Excellent for heavy foot traffic, typically more stable | Highly customizable, can adapt to various spaces |

| Cost | Ranges from $1,200 to $7,000 depending on materials and design | Generally lower initial cost, but can vary widely with custom designs | Mid-range, costs vary based on customization and materials |

| Ease of Implementation | Requires precise installation and may need professional help | Generally easier to install; can be a DIY project | Installation complexity varies; some kits are designed for easy assembly |

| Maintenance | Low maintenance, durable materials available | Requires regular upkeep, especially in high-traffic areas | Varies based on materials; some modular systems are designed for easy maintenance |

| Best Use Case | Ideal for residential spaces with limited square footage | Best for commercial spaces or homes with ample room | Suitable for both residential and commercial applications, especially in adaptive reuse projects |

What are the Pros and Cons of Straight Staircases Compared to Spiral Staircases?

Straight staircases are often favored for their straightforward design and ease of use. They provide a stable and secure option, making them suitable for high-traffic areas such as commercial buildings. Their initial cost is generally lower than that of spiral staircases, especially when constructed from standard materials. However, straight staircases require more space, which can be a limiting factor in smaller environments. They also demand more maintenance over time, particularly if constructed from wood, as wear and tear can lead to increased upkeep costs.

How Do Modular Stair Systems Compare to Spiral Staircases?

Modular stair systems present a flexible alternative to traditional spiral staircases. These systems can be customized to fit various design specifications, making them highly adaptable for unique spaces. They can be a cost-effective solution, striking a balance between functionality and aesthetics. The ease of installation is a significant advantage, as many systems are designed for DIY assembly. However, the complexity can vary, and some modular options may not offer the same aesthetic appeal as a well-designed spiral staircase. Maintenance levels can also differ based on the materials chosen, making it essential for buyers to consider their long-term needs.

How Can B2B Buyers Choose the Right Stair Solution for Their Needs?

When selecting a staircase solution, B2B buyers should first assess the specific requirements of their project, including space constraints, budget, and intended use. Spiral staircases excel in environments where space is limited, offering a unique aesthetic appeal. In contrast, straight staircases are ideal for locations that can accommodate larger structures and require durability. Modular stair systems can serve as a middle ground, providing flexibility and customization. Ultimately, the choice should align with both immediate project goals and long-term operational needs, ensuring that the selected staircase meets functional and aesthetic standards.

Essential Technical Properties and Trade Terminology for spiral staircase for sale

When considering the procurement of spiral staircases, it is crucial for B2B buyers to understand essential technical specifications and industry terminology. This knowledge not only aids in making informed purchasing decisions but also ensures that the selected products meet specific project requirements.

Illustrative image related to spiral staircase for sale

What Are the Key Technical Properties of Spiral Staircases?

-

Material Grade

Spiral staircases are typically constructed from various materials, including steel, aluminum, and wood. The material grade indicates the strength, durability, and suitability for specific environments. For instance, galvanized steel is often preferred for outdoor use due to its corrosion resistance, while wood may be used for interior designs. Understanding material grades helps buyers assess the longevity and maintenance needs of the staircase. -

Tread Count

The tread count refers to the number of steps or treads in the staircase. A higher tread count generally indicates a more gradual ascent, which can enhance safety and comfort. For B2B buyers, specifying the appropriate tread count is vital, especially for commercial applications where foot traffic is high and safety standards are paramount. -

Diameter

The diameter of a spiral staircase is a critical dimension that affects both aesthetics and space utilization. Common diameters range from 42 inches to 60 inches, with some custom options available. Buyers need to consider the available space and the intended use to select an appropriate diameter, ensuring that the staircase fits well within the architectural design. -

Weight Capacity

Each staircase comes with a specified weight capacity that must be adhered to for safety and structural integrity. This specification is particularly important in commercial settings where heavier loads may be expected. Buyers should ensure that the chosen staircase meets the required load-bearing standards for its intended application. -

Height Range

The height range indicates the adjustable limits for installation, typically expressed in inches. This specification allows for versatility in different building designs, making it easier for buyers to find a suitable solution for varying floor-to-floor heights.

What Are Common Trade Terms Relevant to Spiral Staircase Purchases?

-

OEM (Original Equipment Manufacturer)

In the context of spiral staircases, OEM refers to manufacturers that produce components that other companies may rebrand or incorporate into their products. Understanding OEM relationships can help buyers ensure quality and compatibility when sourcing parts or complete staircases. -

MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity of a product that a supplier is willing to sell. This term is essential for B2B buyers as it can impact inventory management and overall project costs. Knowing the MOQ allows for better planning and budgeting when procuring spiral staircases. -

RFQ (Request for Quotation)

An RFQ is a formal process through which buyers request pricing information from suppliers for specified products. For B2B buyers, submitting an RFQ can help them receive competitive pricing and detailed specifications, facilitating better decision-making. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is crucial for B2B buyers, particularly those engaged in cross-border purchases of spiral staircases, as they affect shipping costs, risk, and responsibility. -

Lead Time

This term refers to the time it takes from placing an order to receiving the product. Understanding lead times is essential for project planning, as it can influence construction schedules and timelines. -

Customization Options

Many manufacturers offer customization options for spiral staircases, such as size, material, and finish. Knowing what customization is available helps buyers tailor products to meet specific design and functional requirements.

By grasping these technical properties and trade terms, B2B buyers can navigate the complex landscape of spiral staircase procurement more effectively, ensuring they select products that not only meet aesthetic and functional needs but also align with their operational goals.

Navigating Market Dynamics and Sourcing Trends in the spiral staircase for sale Sector

What Are the Key Market Dynamics and Trends Influencing the Spiral Staircase Sector?

The global spiral staircase market is witnessing significant growth, driven by urbanization, increasing investments in real estate, and the rising demand for aesthetically appealing yet space-saving architectural solutions. In regions such as Africa and South America, rapid urban development is a primary catalyst, as cities expand and modernize. Meanwhile, in Europe and the Middle East, there is a growing trend toward customization and premium materials, reflecting consumer preferences for unique designs and high-quality craftsmanship.

Emerging technologies are reshaping the sourcing landscape. The integration of digital tools in procurement processes allows international buyers to streamline sourcing, enhance supplier communication, and access real-time inventory data. Additionally, 3D modeling and virtual reality are becoming increasingly prevalent, enabling buyers to visualize and customize their staircase solutions before purchase.

Sourcing trends are also evolving towards a preference for suppliers who offer quick turnaround times and efficient logistics. Fast shipping options, as seen with companies that can deliver within 24 hours, are becoming a critical factor for B2B buyers aiming to keep projects on schedule. This need for speed, combined with a demand for high-quality products, is creating a competitive market landscape.

How Is Sustainability Reshaping Sourcing Practices in the Spiral Staircase Industry?

Sustainability has emerged as a paramount concern for B2B buyers in the spiral staircase sector. Companies are increasingly prioritizing environmentally friendly materials and ethical sourcing practices, recognizing the importance of reducing their carbon footprint. This shift is essential not only for meeting regulatory standards but also for catering to a growing base of environmentally conscious consumers.

The use of sustainably sourced wood, recycled metals, and non-toxic finishes is becoming commonplace, with buyers actively seeking suppliers that can provide certifications such as FSC (Forest Stewardship Council) for wood products and ISO certifications for manufacturing processes. Additionally, the demand for ‘green’ certifications is influencing supplier selection, as businesses aim to enhance their brand reputation and align with corporate social responsibility goals.

Moreover, manufacturers are investing in eco-friendly production techniques that minimize waste and energy consumption, further contributing to a sustainable supply chain. This focus on sustainability not only addresses environmental concerns but also offers a competitive edge in the marketplace, appealing to buyers who prioritize ethical considerations in their purchasing decisions.

What Is the Historical Context of Spiral Staircases in B2B Markets?

The evolution of spiral staircases dates back centuries, with their origins rooted in medieval architecture, where they served both functional and aesthetic purposes. Historically, spiral staircases were common in castles and towers, allowing for efficient use of space in vertical construction. Over time, advancements in materials and manufacturing processes have transformed these structures into modern design elements, adaptable to both residential and commercial applications.

In recent years, the spiral staircase market has shifted from traditional designs to a focus on contemporary aesthetics and customization. This evolution has been fueled by changing consumer preferences, with buyers increasingly seeking unique, stylish solutions that complement modern architectural trends. As a result, the spiral staircase has transitioned from a purely functional element to a statement piece, reflecting broader shifts in design philosophy and consumer expectations within the B2B sector.

Illustrative image related to spiral staircase for sale

Frequently Asked Questions (FAQs) for B2B Buyers of spiral staircase for sale

-

How do I ensure the quality of spiral staircases when sourcing internationally?

To ensure the quality of spiral staircases when sourcing from international suppliers, it is crucial to conduct thorough due diligence. Request samples or product certifications that demonstrate compliance with relevant standards, such as ISO or ASTM. Consider visiting the manufacturing facility if possible, or use third-party inspection services to assess quality before shipment. Establishing clear communication with suppliers about your quality expectations and specifications can also help mitigate risks. -

What are the common materials used in spiral staircases, and which is best for my project?

Spiral staircases are typically constructed from materials such as steel, aluminum, and wood. Steel is preferred for its durability and strength, making it ideal for outdoor applications, while aluminum is lightweight and rust-resistant, suitable for environments with high humidity. Wood offers aesthetic appeal and is often used for indoor staircases. The best material depends on your project requirements, including location, design preferences, and budget. -

What customization options are available for spiral staircases?

Many manufacturers offer a range of customization options for spiral staircases, including different materials, finishes, dimensions, and tread designs. You can also choose the railing style and color to match your project’s aesthetic. It’s advisable to discuss your specific requirements with suppliers to explore all available customization options, ensuring the staircase fits perfectly within your intended space and design. -

What is the minimum order quantity (MOQ) for spiral staircases?

The minimum order quantity (MOQ) for spiral staircases can vary significantly between suppliers. Some may offer single units, especially for standard models, while others might require bulk orders for custom designs. It’s important to clarify the MOQ during your initial discussions with potential suppliers to ensure it aligns with your purchasing needs and budget constraints. -

What payment terms should I expect when sourcing spiral staircases internationally?

Payment terms for international orders can vary widely among suppliers. Common arrangements include a deposit upfront (typically 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer credit terms based on your relationship and order history. Always ensure to negotiate favorable terms that protect your interests and consider using secure payment methods, such as letters of credit or escrow services, for larger transactions. -

How can I verify the reliability of a spiral staircase supplier?

To verify the reliability of a spiral staircase supplier, conduct background research including checking their business credentials, industry experience, and customer reviews. Request references from previous clients and inquire about their production capabilities and quality assurance processes. Engaging in direct communication can also provide insights into their customer service and responsiveness, which are critical for a successful long-term partnership. -

What logistics considerations should I keep in mind when importing spiral staircases?

When importing spiral staircases, consider logistics aspects such as shipping methods, delivery timelines, and customs regulations in your country. Discuss with your supplier about packaging to prevent damage during transit. Additionally, factor in import duties, taxes, and insurance costs. Partnering with a reliable freight forwarder can streamline the shipping process and ensure compliance with all regulations. -

What are the typical lead times for ordering spiral staircases?

Lead times for ordering spiral staircases can vary based on factors such as the complexity of the design, customization options, and supplier production schedules. Typically, standard models can be delivered within 4-6 weeks, while custom orders may take longer, often ranging from 8-12 weeks or more. It’s advisable to confirm lead times upfront and plan your project schedule accordingly to avoid delays.

Top 5 Spiral Staircase For Sale Manufacturers & Suppliers List

1. Arke – Nice Stairway Balcony Rail Kit

Domain: stairwayshop.com

Registered: 2007 (18 years)

Introduction: Clearance Spiral Stairways for Sale | Discount Stairs

Key Products:

1. Arke Nice Stairway Balcony Rail Kits – 3′ 10″L Section – As low as $256.60

2. Arke Enduro Spiral Stairway Balcony Rail Kit – 3′ 10″L Section – $256.60

3. Arke Eureka Modular Stairway Balcony Rail Kit – As low as $199.37

4. Arke Civik Spiral Stairway Balcony Rail Kits – 3′ 10″L Section – As low as $192.45

5. Arke Sky Galvanized…

2. Spiral Stair Warehouse – Spiral Staircase Kits

Domain: spiralstairwarehouse.com

Registered: 2007 (18 years)

Introduction: Spiral Stair Warehouse offers high-quality spiral staircase kits for both indoor and outdoor use. The company has been in operation since 1975 and manufactures all products in the United States. Their staircases are crafted from premium, weather-resistant materials designed to withstand harsh environments while maintaining aesthetic appeal. The purchasing process is streamlined with expert guidanc…

3. Facebook – Spiral Staircase for Sale

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Spiral Staircase for Sale, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Staircase and Railing Store – Modular Staircase Kits

Domain: staircaseandrailingstore.com

Registered: 2012 (13 years)

Introduction: {“products”:[{“name”:”ROME Modular Staircase Kit”,”price”:”Sold Out”},{“name”:”GRAZ Modular Staircase Kit”,”price”:”$1,429.00″},{“name”:”LYON Modular Staircase Kit – Black”,”price”:”$1,829.00″},{“name”:”LUGANO Modular Staircase Kit – White”,”price”:”$1,499.00″},{“name”:”TORONTO Gardenspin Spiral Staircase Kit”,”price”:”from $2,699.00″},{“name”:”CALGARY 47\” Diameter Standard Spiral Staircase Kit”,…

5. Paragon Stairs – Spiral Staircases

Domain: paragonstairs.com

Registered: 2005 (20 years)

Introduction: Spiral staircases for any space and budget since 1947. Indoor spiral stairs designed to maximize space with function and style. Outdoor spiral stairs are weather-resistant and low-maintenance. Available materials include metal (galvanized, aluminum, forged iron, steel), wood, and custom options. Various styles include functional, modern, coastal, and industrial. Products include The Finley, The Ex…

Strategic Sourcing Conclusion and Outlook for spiral staircase for sale

In conclusion, the strategic sourcing of spiral staircases presents a unique opportunity for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Understanding the diverse offerings—from clearance sales to customizable options—enables buyers to make informed decisions that align with their project needs and budget constraints. By leveraging competitive pricing, quality assurance, and innovative designs, businesses can enhance their aesthetic appeal while maximizing functionality.

Strategic sourcing not only streamlines procurement processes but also fosters long-term partnerships with suppliers who understand regional market dynamics and compliance requirements. As the demand for stylish and space-efficient architectural solutions grows, staying ahead of trends and supplier capabilities will be crucial.

Looking ahead, B2B buyers are encouraged to explore the vast array of spiral staircase options available and engage with suppliers who can deliver tailored solutions. Embrace the potential of spiral staircases to elevate your projects and stand out in the marketplace. Take the next step—reach out to trusted manufacturers today to discuss your specific requirements and secure the best deals for your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to spiral staircase for sale

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.