Everything You Need to Know About Speed Bolt Sourcing in 2025

Introduction: Navigating the Global Market for speed bolt

In today’s fast-paced construction and manufacturing environments, sourcing the right speed bolt can significantly impact project efficiency and safety. Speed bolts, often referred to as “Quickie Bolts,” are designed for rapid assembly, providing a reliable solution for connecting structural beams and panels with minimal downtime. However, international B2B buyers face challenges in identifying suitable suppliers, navigating varying specifications, and ensuring compliance with local standards, particularly in regions such as Africa, South America, the Middle East, and Europe.

This comprehensive guide delves into the multifaceted world of speed bolts, covering various types, their applications across different industries, and critical factors for supplier vetting. Buyers will gain insights into the cost implications of sourcing speed bolts, enabling them to make informed purchasing decisions that align with their operational needs and budget constraints. Additionally, we will explore quality certifications and standards that are essential for ensuring product reliability and safety.

By equipping B2B buyers with actionable insights and best practices, this guide aims to empower businesses in diverse markets, such as Vietnam and Nigeria, to streamline their procurement processes. Ultimately, understanding the nuances of speed bolt sourcing will enhance operational efficiency and support successful project outcomes.

Understanding speed bolt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Quickie Bolt | Super coarse threads, welded nut on one end, loose nut on the other | Structural connections in steel framing | Pros: Quick assembly, strong connection. Cons: Not a replacement for standard bolts. |

| Fitting Up Bolt | Tapered nose for alignment, full-threaded options, heat-treated | Securing steel form panels for construction | Pros: Versatile lengths, easy assembly. Cons: May require specific tools for installation. |

| Standard Speed Bolt | Available in various sizes, designed for rapid tightening | General construction, scaffolding | Pros: Fast installation, reliable performance. Cons: Limited to specific applications. |

| Custom Length Bolt | Tailored lengths for specific projects, heat-treated for durability | Specialized construction projects | Pros: Optimized for unique needs. Cons: Longer lead times for custom orders. |

| Heavy-Duty Speed Bolt | Enhanced strength and threading, larger diameters | Heavy industrial applications | Pros: High load capacity, durable. Cons: Higher cost and weight. |

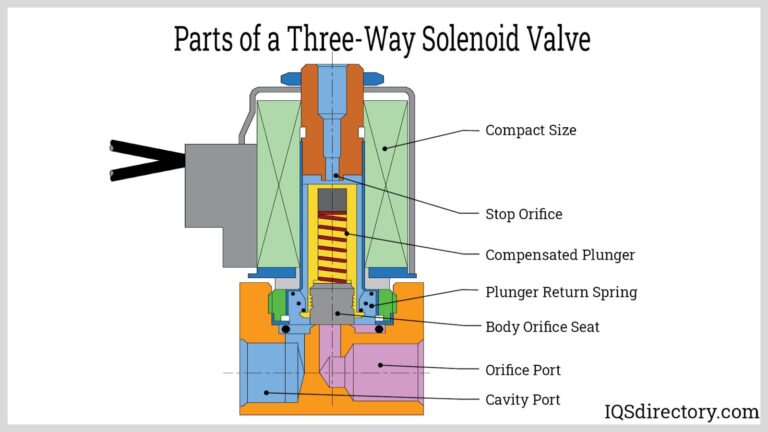

What are the Key Characteristics of Quickie Bolts?

Quickie bolts, also referred to as speed bolts, are characterized by their super coarse threads and a unique design that includes a welded nut on one end and a loose nut on the other. These bolts are primarily used in structural connections where quick assembly is essential, such as in steel framing. For B2B buyers, the main advantages include the speed of installation and the ability to create a strong connection rapidly. However, it is crucial to note that they are not intended to replace standard bolts, which may limit their application in some scenarios.

How Do Fitting Up Bolts Differ from Other Types?

Fitting up bolts feature a tapered nose that serves as a draft pin, aiding in the alignment of steel form panels. These bolts come in various lengths and are often heat-treated to enhance durability. They are predominantly used in construction projects that require the rapid assembly and dismantling of formwork. B2B buyers should consider the versatility offered by full-threaded options and the ease of use, although specific tools may be necessary for installation, which can be a drawback for some.

What are the Advantages of Standard Speed Bolts?

Standard speed bolts are designed for rapid tightening and are available in various sizes, making them suitable for a wide range of construction applications, including scaffolding and general assembly tasks. Their quick installation process is a significant advantage for contractors looking to save time on projects. However, their application might be limited to specific tasks, and buyers should assess whether they meet the requirements of their projects.

Why Consider Custom Length Bolts for Specialized Projects?

Custom length bolts are tailored to meet the specific needs of unique construction projects. These bolts are often heat-treated for added strength and durability, making them ideal for applications that require precision. While they offer the advantage of being optimized for particular uses, B2B buyers should be aware of the potential for longer lead times when ordering custom lengths, which could impact project timelines.

What Makes Heavy-Duty Speed Bolts Suitable for Industrial Applications?

Heavy-duty speed bolts are designed for high-load applications, featuring enhanced strength and larger diameters. These bolts are ideal for use in heavy industrial settings where reliability and durability are paramount. The primary benefit for B2B buyers is their ability to withstand significant stress and strain. However, the increased cost and weight of these bolts may be a consideration for projects with budget constraints.

Key Industrial Applications of speed bolt

| Industry/Sector | Specific Application of speed bolt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Connecting steel beams in structural frameworks | Accelerates assembly time, enhancing project efficiency | Ensure compliance with local building codes and standards |

| Manufacturing | Securing form panels in precast concrete production | Reduces labor costs and improves safety during assembly | Look for heat-treated options for durability in harsh environments |

| Oil and Gas | Fastening equipment and pipelines | Minimizes downtime and enhances operational reliability | Verify corrosion resistance for offshore applications |

| Heavy Machinery | Attaching components in heavy equipment assembly | Facilitates quicker repairs and maintenance | Assess thread design for compatibility with existing machinery |

| Renewable Energy | Assembling wind turbine structures | Supports rapid installation, crucial for project timelines | Evaluate sourcing for sustainability certifications |

In the construction industry, speed bolts are essential for quickly connecting steel beams in structural frameworks. Their design allows for rapid tightening, which significantly reduces assembly time and enhances overall project efficiency. Buyers should ensure that the speed bolts comply with local building codes and standards, particularly in regions like Africa and South America where regulations may vary.

In manufacturing, these bolts are commonly used to secure form panels during precast concrete production. Their quick assembly and dismantling capabilities not only reduce labor costs but also improve safety for workers on-site. International buyers should consider heat-treated options that provide extended durability, especially in harsh environmental conditions, which is crucial for projects in the Middle East and Africa.

The oil and gas sector utilizes speed bolts for fastening equipment and pipelines. Their ability to minimize downtime during installation and maintenance is vital for maintaining operational reliability in this high-stakes industry. Buyers should verify the corrosion resistance of these bolts, particularly for offshore applications where exposure to harsh elements is a concern.

In the heavy machinery sector, speed bolts facilitate the attachment of components during assembly. Their design allows for quicker repairs and maintenance, which is essential for minimizing equipment downtime. Buyers need to assess the thread design of speed bolts to ensure compatibility with existing machinery, especially in diverse markets across Europe and South America.

Lastly, in the renewable energy sector, speed bolts are instrumental in assembling wind turbine structures. The ability to install components rapidly is crucial for meeting project timelines and ensuring operational efficiency. Buyers should evaluate sourcing options for sustainability certifications, reflecting a growing demand for environmentally responsible practices in energy projects globally.

3 Common User Pain Points for ‘speed bolt’ & Their Solutions

Scenario 1: Delays in Project Timelines Due to Inadequate Fastening Solutions

The Problem: Many B2B buyers in construction and manufacturing face significant delays when their fastening solutions do not meet the speed and efficiency required for tight connections between structural beams. Traditional bolts can be cumbersome to install, leading to increased labor time and, ultimately, project overruns. This is particularly concerning in regions where timely project completion is critical for maintaining contractual obligations and competitive advantage.

The Solution: To mitigate these delays, businesses should consider sourcing speed bolts specifically designed for quick assembly. Speed bolts, such as the Rudedog USA Quickie Bolt, offer super coarse threads that enable rapid tightening and pulling together of structural components. When specifying these bolts, it’s essential to assess the load requirements and ensure they are compatible with the materials being joined. B2B buyers should also establish relationships with reliable suppliers who can provide consistent availability and support, ensuring that they always have the necessary inventory on hand to avoid project interruptions.

Scenario 2: Complications in Inventory Management and Sourcing

The Problem: B2B buyers often struggle with managing their inventory of fasteners, particularly when dealing with multiple projects that require various bolt sizes and types. This can lead to stockouts or overstocking of less needed items, resulting in unnecessary costs. For buyers in regions like Africa and South America, where logistics can be challenging, sourcing the right speed bolts in a timely manner becomes even more critical.

The Solution: Implementing a just-in-time (JIT) inventory system can help streamline the management of speed bolts. By analyzing historical usage data, businesses can better predict their needs and align orders with project schedules. Additionally, establishing partnerships with local suppliers or distributors can enhance accessibility and reduce lead times. Buyers should also consider investing in a centralized inventory management software that tracks usage patterns and alerts them when stock levels drop below a predefined threshold, enabling proactive ordering and minimizing the risk of project delays.

Scenario 3: Quality Assurance and Performance Reliability

The Problem: The integrity of structural connections is paramount, and B2B buyers often face concerns about the quality and reliability of fasteners, including speed bolts. Substandard products can lead to structural failures, resulting in safety hazards and costly reworks. This challenge is exacerbated in regions where quality standards may vary, making it difficult to ensure that all purchased bolts meet necessary specifications.

The Solution: To ensure quality assurance, B2B buyers should prioritize sourcing speed bolts from reputable manufacturers who provide certifications and testing results for their products. It’s essential to evaluate suppliers based on their compliance with international standards, such as ASTM or ISO certifications. Additionally, establishing a quality control protocol for incoming shipments can help in identifying defective products before they are used on-site. This might include random sampling and testing of bolts for tensile strength and thread integrity. By focusing on quality sourcing and implementing rigorous inspection processes, businesses can significantly reduce the risks associated with fastener failures, ensuring the safety and reliability of their projects.

Strategic Material Selection Guide for speed bolt

What Are the Key Materials for Speed Bolts and Their Properties?

When selecting materials for speed bolts, it’s crucial to consider the specific performance characteristics required for the intended application. Here, we analyze four common materials used in speed bolt manufacturing: carbon steel, stainless steel, alloy steel, and aluminum. Each material has its unique properties that cater to different industrial needs.

How Does Carbon Steel Perform in Speed Bolt Applications?

Carbon steel is one of the most widely used materials for speed bolts due to its excellent strength-to-weight ratio. It typically exhibits good tensile strength and hardness, making it suitable for high-load applications. However, carbon steel is prone to corrosion, especially in humid or saline environments, which can limit its use without proper coatings or treatments.

Pros: High strength, cost-effective, readily available.

Cons: Susceptible to rust, requires protective coatings for outdoor use.

Impact on Application: Carbon steel speed bolts are ideal for structural applications in dry environments but may not perform well in coastal or wet conditions without additional protection.

Considerations for International Buyers: Compliance with ASTM standards (like ASTM A325) is essential. Buyers in regions with high humidity, such as parts of Africa and South America, should consider corrosion-resistant coatings.

What Advantages Does Stainless Steel Offer for Speed Bolts?

Stainless steel is known for its exceptional corrosion resistance and durability, making it a preferred choice for applications exposed to harsh environments. It maintains its strength at elevated temperatures and is less likely to deform under stress. However, stainless steel bolts can be more expensive than their carbon steel counterparts.

Pros: Excellent corrosion resistance, high strength, retains appearance over time.

Cons: Higher cost, potential for galling during installation.

Impact on Application: Stainless steel speed bolts are suitable for marine, chemical, and food processing applications where corrosion is a significant concern.

Considerations for International Buyers: Compliance with international standards such as DIN and JIS is important. Buyers from the Middle East, where saline conditions are common, will benefit from stainless steel’s properties.

What Role Does Alloy Steel Play in Speed Bolt Manufacturing?

Alloy steel, which includes elements such as chromium, nickel, and molybdenum, offers enhanced mechanical properties compared to standard carbon steel. It provides improved toughness, wear resistance, and strength, making it suitable for high-stress applications. However, alloy steel can be more complex to manufacture and may require specialized heat treatment processes.

Pros: Superior strength and toughness, enhanced wear resistance.

Cons: Higher manufacturing complexity and cost.

Impact on Application: Alloy steel speed bolts are ideal for heavy-duty applications, such as in construction and mining, where high strength is critical.

Considerations for International Buyers: Buyers should ensure compliance with ASTM standards, particularly in heavy industrial sectors prevalent in regions like Africa and South America.

How Does Aluminum Compare as a Material for Speed Bolts?

Aluminum is lightweight and resistant to corrosion, making it an attractive option for applications where weight savings are crucial. However, aluminum speed bolts may not provide the same tensile strength as steel options, which can limit their use in high-load applications. They are often used in aerospace and automotive industries.

Pros: Lightweight, excellent corrosion resistance, good thermal conductivity.

Cons: Lower tensile strength compared to steel, can be more expensive.

Impact on Application: Aluminum speed bolts are suitable for applications where weight is a concern, such as in aircraft or lightweight structures.

Considerations for International Buyers: Compliance with international standards is essential, especially in aerospace applications. Buyers from Europe and regions with stringent weight regulations should consider aluminum options.

Summary Table of Material Properties for Speed Bolts

| Material | Typical Use Case for speed bolt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Structural applications in dry environments | High strength, cost-effective | Susceptible to corrosion | Low |

| Stainless Steel | Marine and chemical applications | Excellent corrosion resistance | Higher cost, galling potential | High |

| Alloy Steel | Heavy-duty construction and mining applications | Superior strength and toughness | Higher manufacturing complexity | Medium |

| Aluminum | Aerospace and lightweight structures | Lightweight, good corrosion resistance | Lower tensile strength | Medium |

This guide provides a comprehensive overview of material selection for speed bolts, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for speed bolt

What Are the Key Stages in the Manufacturing Process of Speed Bolts?

Manufacturing speed bolts involves several critical stages to ensure the final product meets the necessary specifications and performance standards. Here’s a detailed look at the main stages of the manufacturing process:

-

Material Preparation

The primary materials for speed bolts typically include high-grade steel or alloy steel, which are chosen for their strength and durability. The first step involves sourcing raw materials that comply with international standards, such as ASTM (American Society for Testing and Materials) or ISO certifications. Once procured, the materials undergo chemical and mechanical testing to verify their properties, ensuring they can withstand the stresses they will encounter in use. -

Forming

After preparation, the raw materials are subjected to various forming processes. Common techniques include forging, cold heading, and machining. Forging is often preferred for speed bolts as it aligns the grain structure of the metal, enhancing strength. Cold heading is utilized to create the bolt’s head and threads without losing material integrity. Precision machining is then applied to refine dimensions and ensure proper threading, especially for the coarse threads that characterize speed bolts. -

Assembly

The assembly stage involves attaching nuts to the speed bolts. Typically, a welded nut is fixed on one end of the bolt while a loose nut is provided on the other. This dual-nut configuration facilitates quick adjustments and tight connections between beams or plates. Automated assembly lines may be used to enhance efficiency, but manual assembly is also common for quality control purposes. -

Finishing

The finishing stage includes surface treatments such as galvanizing, coating, or plating to enhance corrosion resistance and aesthetic appeal. This is particularly important for speed bolts used in outdoor or marine environments. Quality checks are performed during this stage to ensure that the finishing meets specified standards and does not compromise the bolt’s structural integrity.

How Is Quality Assurance Integrated into Speed Bolt Manufacturing?

Quality assurance (QA) is a critical component in the manufacturing of speed bolts, ensuring that products meet both international standards and customer expectations. Here’s an overview of the QA process:

-

International Standards Compliance

Compliance with standards such as ISO 9001 (Quality Management Systems) is essential for manufacturers targeting international markets. Additionally, certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant depending on the application of the speed bolts. These certifications demonstrate a commitment to quality and safety in manufacturing processes. -

Quality Control Checkpoints

The quality control process is typically divided into several checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During the manufacturing process, various parameters such as dimensions, thread integrity, and material properties are continuously monitored.

– Final Quality Control (FQC): Once the speed bolts are assembled and finished, a final inspection is conducted. This includes testing for load-bearing capacity and checking for defects in threading and surface finishes. -

Common Testing Methods

Various testing methods are employed to verify the quality of speed bolts:

– Tensile Testing: Measures the strength and ductility of the bolts.

– Hardness Testing: Ensures that the material hardness meets required specifications.

– Dimensional Inspection: Uses tools like calipers and gauges to ensure that all dimensions conform to the design specifications.

– Non-Destructive Testing (NDT): Techniques such as ultrasonic or magnetic particle testing can be used to identify internal defects without damaging the bolts.

What Are the Best Practices for B2B Buyers to Verify Supplier Quality Control?

For B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is vital for ensuring product reliability and performance. Here are some best practices:

-

Supplier Audits

Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices. During an audit, buyers can assess the supplier’s compliance with international standards, observe the production line, and evaluate the effectiveness of their quality control systems. -

Requesting Quality Reports

Buyers should request detailed quality assurance reports from suppliers, including documentation of testing results and compliance certifications. These reports should outline the results from IQC, IPQC, and FQC stages, providing transparency into the manufacturing process. -

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased evaluation of the manufacturer’s quality assurance processes. These inspectors can assess compliance with relevant standards and provide certification that can enhance buyer confidence. -

Understanding Regional Compliance Nuances

It’s important for international buyers to understand the specific compliance requirements in their regions. For instance, speed bolts used in construction may need to adhere to local building codes or safety regulations. Buyers should verify that suppliers are familiar with these regional requirements and have the necessary certifications to operate in those markets. -

Establishing Long-term Relationships

Building long-term relationships with trusted suppliers can lead to improved quality assurance practices. Regular communication and collaboration can help ensure that quality standards are maintained and that any issues are promptly addressed.

In conclusion, the manufacturing processes and quality assurance practices for speed bolts are intricate and vital for ensuring product reliability. By understanding these processes and implementing best practices for supplier verification, B2B buyers can significantly mitigate risks and enhance their procurement strategies.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘speed bolt’

In this guide, we provide a practical checklist to help B2B buyers effectively source speed bolts for their construction or manufacturing needs. This step-by-step approach will ensure that you make informed decisions, ensuring quality and efficiency in your procurement process.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it is crucial to have a clear understanding of your technical requirements. Speed bolts come in various sizes, thread types, and materials, which can affect their performance in specific applications.

– Key considerations:

– Determine the diameter (e.g., 3/4″ or 7/8″) and length needed for your project.

– Specify the thread type (e.g., super coarse threads) to ensure compatibility with existing structures.

Illustrative image related to speed bolt

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in speed bolts. Look for manufacturers with a solid reputation in the industry and positive customer feedback.

– What to do:

– Utilize online platforms, trade shows, and industry directories to compile a list of potential suppliers.

– Check reviews and ratings to gauge their reliability and product quality.

Step 3: Evaluate Supplier Certifications

Verifying supplier certifications is essential to ensure compliance with industry standards and safety regulations. This step protects your business from liability and ensures the quality of the bolts you procure.

– What to look for:

– Ask for ISO certifications or other relevant industry standards (e.g., ASTM).

– Ensure that the supplier can provide documentation verifying the material specifications and quality assurance processes.

Step 4: Request Samples

Before placing a bulk order, request samples of the speed bolts. This allows you to assess the quality and suitability of the products for your specific applications.

– Why it matters:

– Testing samples can help identify any potential issues with fit or performance.

– It provides an opportunity to evaluate the supplier’s responsiveness and customer service.

Step 5: Compare Pricing and Terms

Once you have selected a few potential suppliers, compare their pricing and payment terms. This step will help you identify the best value for your investment without compromising quality.

– What to consider:

– Look for bulk order discounts or loyalty programs.

– Review shipping costs, lead times, and return policies to ensure they align with your operational needs.

Step 6: Negotiate Contracts

After selecting a supplier, engage in contract negotiations to secure favorable terms. This step is vital for protecting your interests and ensuring clarity in the transaction.

– Key points to discuss:

– Payment terms, delivery schedules, and warranty provisions should be clearly outlined.

– Include clauses for quality assurance and penalties for non-compliance to safeguard your business.

Step 7: Establish Ongoing Communication

Finally, maintain open communication with your supplier throughout the sourcing and delivery process. This fosters a strong relationship and can lead to improved service and collaboration in the future.

– Best practices:

– Schedule regular check-ins to discuss order progress and address any concerns.

– Provide feedback on product performance, which can help the supplier improve their offerings.

By following this checklist, B2B buyers can navigate the complexities of sourcing speed bolts effectively, ensuring they acquire high-quality products that meet their project requirements.

Comprehensive Cost and Pricing Analysis for speed bolt Sourcing

What Are the Key Cost Components in Speed Bolt Manufacturing?

The cost structure of speed bolts comprises several critical components that influence the final pricing for buyers. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The primary material for speed bolts is high-strength steel, which can vary in price based on global market conditions. Specialty coatings or finishes, such as galvanization for corrosion resistance, can further increase costs.

-

Labor: Labor costs vary significantly depending on the region of production. In countries with lower labor costs, like some in Africa and South America, manufacturers may offer more competitive pricing, but this can also affect quality control and consistency.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, maintenance, and administrative costs. Efficient production processes can help minimize overhead and ultimately lower prices.

-

Tooling: The initial investment in tooling for production can be substantial, especially for custom speed bolts. Suppliers often pass these costs onto buyers, particularly in low-volume orders.

-

Quality Control: Ensuring that speed bolts meet specific standards (e.g., ASTM certifications) requires rigorous testing, which adds to the overall cost. Buyers should prioritize suppliers who adhere to recognized quality standards to avoid issues in the field.

-

Logistics: Shipping costs can vary widely based on the distance from the manufacturer to the buyer, the mode of transport, and current fuel prices. International buyers should account for customs duties and tariffs, which can significantly affect total costs.

-

Margin: Finally, suppliers will include a profit margin that varies based on market competition and their business model. Understanding these factors can help buyers identify reasonable pricing.

How Do Price Influencers Affect Speed Bolt Costs?

Several key influencers can impact the pricing of speed bolts, especially for international B2B buyers:

-

Volume/MOQ: Manufacturers often have minimum order quantities (MOQs). Higher volumes typically lead to lower per-unit prices due to economies of scale. Buyers should negotiate MOQs that align with their project needs to optimize costs.

-

Specifications and Customization: Custom specifications, such as unique sizes or thread patterns, will incur additional costs. Buyers should assess whether standard products meet their needs to avoid unnecessary expenses.

-

Materials and Quality Certifications: The choice of materials affects both cost and quality. Buyers should consider not only the upfront cost but also the long-term durability and performance of the bolts, especially in demanding environments.

-

Supplier Factors: The reputation and reliability of suppliers play a significant role in pricing. Established suppliers with a track record of quality may charge more but can offer better warranties and support.

-

Incoterms: Understanding Incoterms is crucial for international transactions, as they dictate shipping responsibilities and costs. Familiarity with these terms can help buyers avoid unexpected charges and streamline the procurement process.

What Are the Best Buyer Tips for Cost-Efficiency in Speed Bolt Sourcing?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, here are actionable tips to enhance cost-efficiency:

-

Negotiation: Always negotiate with suppliers. Discuss pricing based on volume, payment terms, and delivery timelines. Building a good relationship can lead to better deals over time.

-

Total Cost of Ownership (TCO): Consider the TCO, which includes not just the purchase price but also logistics, installation, and maintenance costs. A lower upfront price may lead to higher overall expenses if quality is compromised.

-

Research and Compare: Investigate multiple suppliers and compare their offerings. Look for reviews, certifications, and case studies that highlight their performance in similar projects.

-

Consider Local Suppliers: Where feasible, sourcing from local manufacturers can reduce logistics costs and lead times. It can also enhance communication and responsiveness.

-

Stay Informed: Keep abreast of market trends and material costs. Being informed can empower buyers to make timely purchases before price hikes occur.

By understanding these components and influences, B2B buyers can make more informed sourcing decisions, ultimately leading to cost savings and enhanced project success. Please note that the prices mentioned in this analysis are indicative and subject to change based on market conditions and supplier negotiations.

Alternatives Analysis: Comparing speed bolt With Other Solutions

When considering the best fastening solutions for construction and industrial applications, it’s essential to evaluate various alternatives to speed bolts. Speed bolts, known for their quick connection capabilities, can be compared to other fastening technologies that serve similar purposes. This analysis will help B2B buyers make informed decisions based on their specific needs, especially in international markets like Africa, South America, the Middle East, and Europe.

| Comparison Aspect | Speed Bolt | Alternative 1: Hex Bolt | Alternative 2: Structural Bolt |

|---|---|---|---|

| Performance | Fast tightening due to coarse threads; ideal for quick assembly. | Reliable in high-stress applications; slower to install. | Excellent for heavy loads; requires precise installation. |

| Cost | Generally affordable ($19.15 – $31.00). | Moderate pricing; varies by size and material. | Higher cost due to strength and certification. |

| Ease of Implementation | Simple installation; designed for quick use. | Requires tools and more time for installation. | Complex installation; often needs specialized equipment. |

| Maintenance | Low maintenance; durable for repeated use. | Moderate; may require periodic checking. | High maintenance; needs inspection for structural integrity. |

| Best Use Case | Ideal for temporary structures or fast assembly tasks. | Suitable for general construction where time is not critical. | Best for permanent installations in heavy-load scenarios. |

What are the Advantages and Disadvantages of Using Hex Bolts?

Hex bolts are a common alternative to speed bolts, primarily used in various construction applications. Their hexagonal head allows for easy gripping with standard tools, providing reliable fastening. While hex bolts are robust and suitable for high-stress applications, they require more time for installation compared to speed bolts. Additionally, they may not provide the same rapid assembly features, making them less ideal for projects that prioritize speed.

How Do Structural Bolts Compare to Speed Bolts?

Structural bolts are designed for heavy-duty applications and are often used in steel structures where significant load-bearing is required. These bolts offer exceptional strength and are typically used in permanent installations. However, their installation can be complex and often requires specialized tools, which can slow down the process. While structural bolts excel in strength and stability, they may not be the best choice for projects needing quick assembly or temporary connections.

Illustrative image related to speed bolt

Conclusion: How Can B2B Buyers Choose the Right Fastening Solution?

In selecting the appropriate fastening solution, B2B buyers should consider their specific project requirements, including load-bearing needs, assembly speed, and budget constraints. Speed bolts are ideal for fast-paced environments where quick assembly is critical, while hex bolts provide reliability for general applications. For heavy-duty requirements, structural bolts offer unparalleled strength but come with increased complexity and cost. By assessing these factors, buyers can make an informed decision that aligns with their operational goals, ensuring efficiency and effectiveness in their projects.

Essential Technical Properties and Trade Terminology for speed bolt

What Are the Key Technical Properties of Speed Bolts?

Understanding the technical specifications of speed bolts is crucial for B2B buyers, as these properties directly impact the performance and suitability of the bolts for various applications. Here are some essential technical properties to consider:

-

Material Grade

Speed bolts are typically made from high-strength steel, often classified under ASTM A325 or A490 standards. These grades indicate the tensile strength and yield strength of the material, which are critical for ensuring that the bolts can withstand the loads and stresses they will encounter in structural applications. Selecting the right material grade is vital for safety and durability. -

Thread Design

Speed bolts feature a super coarse thread design, which allows for rapid tightening and loosening. This design is essential for applications where time efficiency is a priority, such as in construction or assembly processes. The coarse threads enable faster engagement with the nuts, significantly reducing installation time compared to standard bolts. -

Nut Configuration

Speed bolts typically come with a welded nut on one end and a loose nut on the other. The welded nut provides a stable anchor point, while the loose nut allows for quick adjustments. This configuration is particularly advantageous in scenarios where frequent adjustments or temporary connections are necessary. -

Length and Diameter Options

Speed bolts are available in various lengths and diameters, which allows for versatility in application. For example, common diameters include 3/4″ and 7/8″, while lengths can vary to accommodate different structural needs. Understanding these options helps buyers select the appropriate bolt for their specific projects. -

Heat Treatment

Many speed bolts undergo heat treatment to enhance their durability and resistance to wear and tear. Heat-treated bolts can perform better under extreme conditions, making them a reliable choice for critical structural applications. This added durability translates to lower maintenance costs and longer service life. -

Tolerance Levels

Tolerance refers to the permissible limit of variation in a physical dimension. For speed bolts, maintaining tight tolerances is essential to ensure a proper fit and function within connection points. This precision is crucial for structural integrity and safety, particularly in high-load applications.

What Are Common Trade Terms in the Speed Bolt Industry?

Familiarity with industry jargon can facilitate smoother transactions and better communication between buyers and suppliers. Here are some common terms related to speed bolts:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or components that are used in another company’s products. In the context of speed bolts, OEMs are vital for ensuring that the bolts meet the specific requirements and standards of original equipment designs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it can impact inventory management and cost-effectiveness. Buyers must assess whether they can meet the MOQ without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing and terms for specific products. For speed bolts, submitting an RFQ allows buyers to compare prices and terms across multiple suppliers, aiding in informed decision-making. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers, as they clarify shipping responsibilities, insurance, and risk management, ensuring smoother international trade. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. For speed bolts, understanding lead time is critical for project planning and scheduling. Longer lead times can affect project timelines, making it important for buyers to clarify expected delivery dates. -

Certification

Certification indicates that a product meets specific industry standards or regulations. For speed bolts, certifications such as ISO or ASTM are important as they assure buyers of the quality and reliability of the product, which is particularly crucial in safety-sensitive applications.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when procuring speed bolts, ultimately leading to better project outcomes and stronger supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the speed bolt Sector

What Are the Current Market Dynamics and Key Trends Affecting the Speed Bolt Sector?

The speed bolt sector is experiencing significant growth driven by the increasing demand for efficient and reliable fastening solutions in construction and industrial applications. Global drivers such as urbanization, infrastructure development, and the expansion of manufacturing sectors in emerging markets like Africa, South America, and the Middle East are propelling the demand for high-quality speed bolts. The construction industry is particularly focused on rapid assembly and disassembly processes, leading to a preference for products that allow for quick tightening and secure connections, such as speed bolts with extra course threads.

Emerging B2B technology trends are also shaping the landscape. Digital platforms for sourcing and procurement are becoming crucial for international buyers, enabling them to compare prices, track orders, and manage supply chains more effectively. Additionally, advancements in materials science are leading to the development of stronger, lighter, and more corrosion-resistant speed bolts, enhancing their performance in various environments. Buyers are increasingly looking for suppliers who can offer customization options to meet specific project requirements, reflecting a shift towards tailored solutions rather than one-size-fits-all products.

International buyers from regions such as Europe and Africa are particularly attuned to sourcing trends that emphasize local manufacturing capabilities and shorter lead times. The pandemic has highlighted the vulnerabilities in global supply chains, prompting businesses to seek suppliers closer to their operational bases or those who can provide more reliable logistics solutions. Overall, the speed bolt market is adapting to these dynamics, with suppliers focusing on innovation, efficiency, and responsiveness to buyer needs.

How Can Sustainability and Ethical Sourcing Impact the Speed Bolt Supply Chain?

Sustainability is becoming a cornerstone of business operations across industries, and the speed bolt sector is no exception. The environmental impact of manufacturing processes, particularly regarding resource extraction and waste generation, is under scrutiny. Buyers are increasingly prioritizing suppliers who employ sustainable practices, such as using recycled materials or minimizing energy consumption in production. This shift is not only beneficial for the environment but also aligns with the growing consumer demand for responsible business practices.

Ethical sourcing is critical in ensuring that materials used in speed bolt production are obtained without exploitation or harm to communities. Buyers should consider suppliers who adhere to ethical labor practices and provide transparency in their supply chains. Certifications such as ISO 14001 for environmental management or Fair Trade certifications can serve as indicators of a supplier’s commitment to sustainability and ethical sourcing.

Illustrative image related to speed bolt

Moreover, many companies are adopting “green” certifications or utilizing eco-friendly materials in their products, which can enhance their marketability and appeal to a broader customer base. As sustainability becomes a competitive differentiator, B2B buyers must evaluate the environmental credentials of their suppliers, ensuring that their procurement choices contribute positively to both the planet and their brand reputation.

What Is the Historical Context of Speed Bolt Development for B2B Buyers?

The evolution of speed bolts traces back to the growing needs of the construction and manufacturing sectors for efficient fastening solutions. Originally, traditional bolts were the standard, but the demand for quicker assembly processes led to innovations in bolt design. Speed bolts, often referred to as “quickie bolts,” were developed to facilitate rapid connections between structural elements without compromising security.

Over the decades, advancements in material science and engineering have resulted in the production of stronger and more durable speed bolts. Manufacturers began to incorporate features such as super coarse threading and specialized nut designs to enhance performance, allowing for faster installation and greater reliability under stress. This historical progression has not only improved the functionality of speed bolts but has also positioned them as essential components in modern construction practices, catering to the evolving demands of international B2B buyers seeking efficiency and quality in their projects.

Frequently Asked Questions (FAQs) for B2B Buyers of speed bolt

-

How do I choose the right speed bolt for my construction project?

Selecting the right speed bolt involves considering several factors, including the size, thread type, and specific application requirements. Ensure that the bolt’s diameter and length match the specifications of the beams or plates you intend to connect. Additionally, assess the thread design; super coarse threads provide faster tightening but may not be suitable for all applications. Consult with your suppliers about the materials used in manufacturing to ensure they meet the necessary strength and durability standards for your projects. -

What is the best type of speed bolt for steel construction?

For steel construction, the 3/4″ or 7/8″ speed bolts, often referred to as Quickie Bolts, are preferred due to their robust design and quick assembly capabilities. These bolts feature super coarse threads that allow for rapid tightening, making them ideal for connecting beams and plates in structural applications. Ensure that the bolts are made from high-quality materials, such as heat-treated steel, to withstand the stresses of heavy-duty construction and provide long-lasting performance. -

What are the standard payment terms when sourcing speed bolts internationally?

Payment terms can vary significantly by supplier and region. Typically, B2B transactions may involve upfront payments, letters of credit, or payment upon delivery. It’s crucial to establish clear payment terms before finalizing any contracts to avoid potential disputes. Many suppliers may require a deposit, usually around 30%, with the balance due upon shipment or delivery. Always discuss payment options with your supplier to find a mutually agreeable solution that aligns with your cash flow and risk management strategies. -

What minimum order quantities (MOQs) should I expect when purchasing speed bolts?

Minimum order quantities for speed bolts often depend on the supplier and the specific product. Generally, MOQs can range from 100 to 500 units. Suppliers may set these limits to ensure cost-effectiveness in production and shipping. If your project requires fewer units, consider negotiating with the supplier or looking for manufacturers that specialize in smaller orders. Understanding the MOQ can help you better plan your inventory and project timelines. -

How can I ensure the quality of speed bolts from international suppliers?

To ensure quality, start by vetting suppliers through reviews, certifications, and industry references. Request product samples to assess their durability and performance. Additionally, inquire about quality assurance processes and certifications, such as ISO standards, which demonstrate a commitment to quality control. Regular audits and inspections during production can further safeguard against defects. Establishing a strong communication channel with your supplier can also help in addressing any quality concerns promptly. -

What logistics considerations should I keep in mind when importing speed bolts?

When importing speed bolts, consider shipping methods, costs, and potential customs regulations in your country. Evaluate whether air freight or sea freight is more economical based on your timeline and budget. Ensure that your supplier provides necessary documentation, such as invoices and certificates of origin, to facilitate smooth customs clearance. Additionally, factor in lead times for production and shipping, as delays can impact your project schedules. Collaborating with a reliable freight forwarder can simplify the logistics process. -

Are customization options available for speed bolts?

Many manufacturers offer customization options for speed bolts, including variations in size, thread type, and coatings. Customization can be essential for specific project requirements or to comply with local regulations. When discussing options with suppliers, clearly outline your specifications, including any special materials or finishes needed for corrosion resistance or enhanced strength. Keep in mind that custom orders may have longer lead times and higher costs, so plan accordingly. -

What are the common applications of speed bolts in construction?

Speed bolts are primarily used in steel construction for quickly connecting beams and plates, particularly in temporary structures or formwork. Their design facilitates rapid assembly and disassembly, making them ideal for projects that require frequent modifications or relocations. Additionally, they can be used in various applications, including scaffolding, bridge construction, and industrial frameworks. Understanding the specific applications will help you select the right type of speed bolt for your construction needs.

Top 8 Speed Bolt Manufacturers & Suppliers List

1. Rudedog – USA Speed Bolt Quickie Bolt

Domain: ironworkergear.com

Registered: 2000 (25 years)

Introduction: Product Name: Rudedog USA Speed Bolt “Quickie Bolt”

SKU: 5010

Price: 3/4″ – $28.59 USD, 7/8″ – $29.66 USD

Size Options: 3/4″, 7/8″

Description: A 7/8″ super course thread bolt with a 1 7/16″ nut welded on one end and a 1 7/16″ loose nut on the other. Designed to pull 2 beams (connecting plates) together quickly for a tight connection, allowing a standard bolt to be inserted into the connection poi…

2. Rudedog USA – 5010 Speed Bolt

Domain: ironworkertools.com

Registered: 2002 (23 years)

Introduction: Rudedog USA 5010 – 3/4″ Speed Bolt

3. OCM – Fitting Up (Speed) Bolts

Domain: ocm-inc.com

Registered: 2002 (23 years)

Introduction: {‘product_name’: ‘Fitting Up (Speed) Bolts’, ‘description’: ‘OCM Fitting Up (Speed) Bolts are used for securing steel form panels together. The tapered nose of the bolt acts as a draft pin and helps align the forms. The thread design and clearances between the nut and bolt permits quick assembly and dismantling of the forms. The open thread design permits concrete to be easily knocked out of the t…

4. Doka – Speed Bolt

Domain: shop.doka.com

Registered: 1996 (29 years)

Introduction: Speed Bolt for securing formwork components, designed for quick assembly and disassembly. Compatible with various Doka formwork systems. Made from high-quality materials for durability and reliability. Available in different sizes to meet project requirements.

5. Rudedog – Ironworker Speed Bolt 3/4

Domain: harryepstein.com

Registered: 2001 (24 years)

Introduction: {“product_name”: “Rudedog Ironworker Speed Bolt/Quickie Bolt 3/4”, “sku”: “5010RD”, “price”: “19.15 USD”, “length”: “9 in”, “diameter”: “3/4 in”, “nut”: “7/8 hard nut welded”, “made_in”: “United States”, “availability”: “22 In stock”, “condition”: “New”}

6. Rudedog USA – Speed Bolt ‘Quickie Bolt’

Domain: hardhatgear.com

Registered: 2003 (22 years)

Introduction: {“name”: “Rudedog USA Speed Bolt ‘Quickie Bolt'”, “SKU”: “5010”, “sizes”: [“3/4”, “7/8”], “price”: {“3/4”: “$28.59”, “7/8”: “$29.66”}, “description”: “This Speed Bolt, or ‘Quickie Bolt’, is a 7/8′ super course thread bolt with a 1 7/16′ Nut welded on one end and a 1 7/16′ loose nut on the other. These are designed to pull 2 beams (connecting plates) together quickly to make a tight connection. All…

7. Rudedog – 5010 Speed Bolt

Domain: toolfactoryoutlet.com

Registered: 1998 (27 years)

Introduction: {“name”: “Rudedog 5010 3/4″ Speed Bolt”, “price”: “$23.99”, “vendor”: “Rudedog USA”, “barcode”: “”, “availability”: “In stock”, “product_type”: “Work Gear”, “description”: “This Speed Bolt, some call them ‘Quickie Bolts’, is a 3/4″ super course thread bolt with a 1 7/16″ Nut welded on one end and a 1 1/4” loose nut on the other. These are designed to pull 2 beams (connecting plates) together quick…

8. Rudedog USA – Rudedog 7/8” Speed Bolt Ironworkers Quickie Bolt

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”:”Rudedog 7/8” Speed Bolt Ironworkers Quickie Bolt”,”Brand”:”Rudedog USA”,”Model Number”:”#5009″,”Condition”:”New”,”Thread Size”:”7/8 inch”,”Color”:”Silver”,”Product Dimensions”:”9 x 2 x 2 inches”,”Weight”:”2 Pounds”,”Material”:”Steel”,”Country of Origin”:”USA”,”Head Style”:”Flat”,”Department”:”Ironworker Tools”,”Returns Accepted”:”30 days, buyer pays for return shipping”,”Shipping”…

Strategic Sourcing Conclusion and Outlook for speed bolt

What Are the Key Takeaways for B2B Buyers in Sourcing Speed Bolts?

In the rapidly evolving landscape of construction and manufacturing, speed bolts, or quickie bolts, have emerged as a crucial component for enhancing operational efficiency. Their design—featuring super coarse threads and dual nuts—facilitates rapid assembly and disassembly, making them invaluable for projects requiring swift turnaround times. By strategically sourcing these bolts, businesses can significantly reduce labor costs and improve project timelines, which is especially important in competitive markets across Africa, South America, the Middle East, and Europe.

How Can Strategic Sourcing Enhance Supply Chain Resilience?

Investing in reliable suppliers of speed bolts not only ensures quality and durability but also enhances supply chain resilience. By fostering strong relationships with manufacturers, B2B buyers can secure favorable terms and timely delivery, mitigating risks associated with delays and supply disruptions. As global markets continue to fluctuate, proactive sourcing strategies will be vital for maintaining competitive advantages.

What’s Next for International B2B Buyers?

As you consider the future of your procurement strategies, prioritize partnerships with manufacturers that emphasize quality and innovation. The demand for speed bolts is expected to grow, driven by increasing infrastructure projects worldwide. Embrace this opportunity to enhance your operational capabilities and position your business for success. Reach out to suppliers today to explore the potential of speed bolts in your projects and secure your place in the evolving global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to speed bolt

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.