Everything You Need to Know About South Et Sourcing in 2025

Introduction: Navigating the Global Market for south et

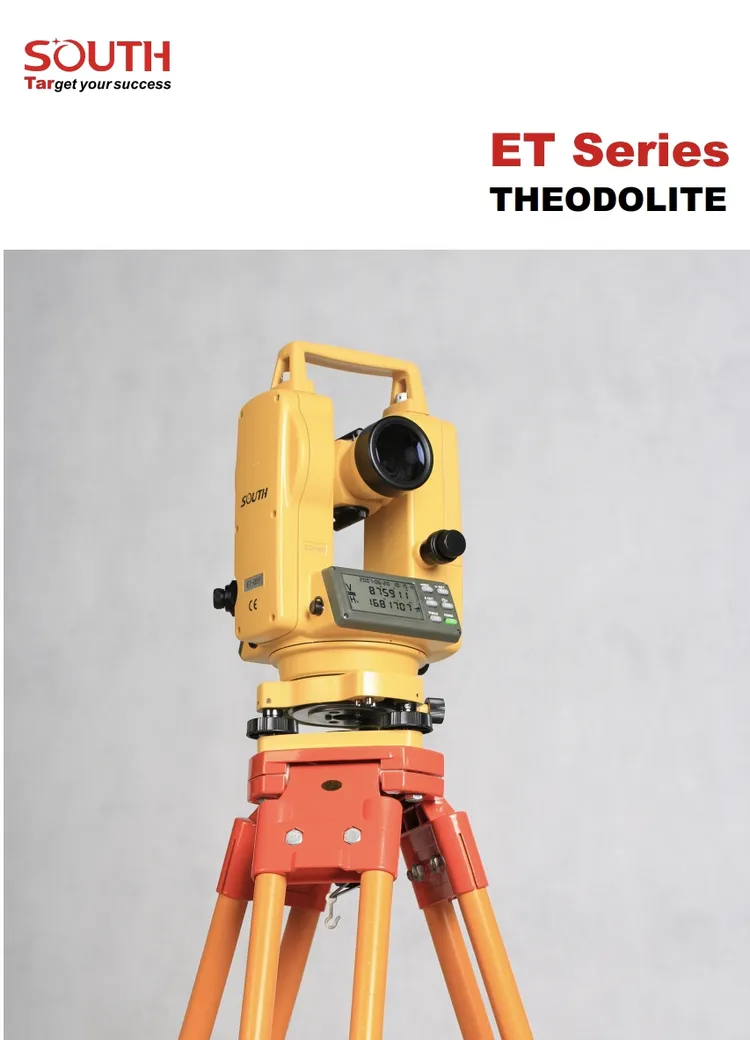

In the competitive landscape of surveying and construction, sourcing high-quality theodolites like the South ET Series can present significant challenges for international B2B buyers. With a myriad of options available, discerning the right equipment that meets specific project demands—be it for precision measurements, durability, or advanced technology—becomes crucial. This guide provides a comprehensive overview of the South ET Series, detailing its various types, applications in fields such as construction and engineering, and essential supplier vetting processes.

Moreover, we delve into cost considerations and the importance of warranty and support services, ensuring that buyers are equipped with the knowledge to make informed purchasing decisions. By focusing on the unique needs of B2B buyers from regions like Africa, South America, the Middle East, and Europe—including countries such as Nigeria and Germany—this guide empowers you to navigate the complexities of global sourcing effectively. Understanding the features and specifications of the South ET Series not only enhances your operational efficiency but also positions your business for success in an ever-evolving market.

With this resource, you will gain valuable insights to streamline your procurement process, mitigate risks, and ultimately achieve superior project outcomes.

Understanding south et Types and Variations

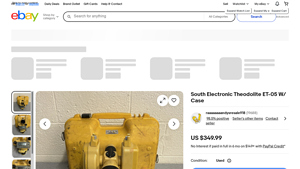

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| ET-02 | 30x magnification, 2″/5″ accuracy options, dual LCD display | Construction, Land Surveying | Pros: High accuracy, durable; Cons: Slightly heavier than competitors. |

| ET-02L | Laser plummet, laser pointer visible up to 100m | Precision Engineering, Topographic Surveys | Pros: Enhanced visibility, advanced technology; Cons: Higher cost due to added features. |

| ET-05 | Similar to ET-02 but with a 5″ accuracy option | General Surveying, Civil Engineering | Pros: Cost-effective for less critical tasks; Cons: Lower precision than ET-02. |

| ET-05L | Combines features of ET-05 with laser capabilities | Infrastructure Development, Mining | Pros: Versatile and reliable; Cons: Complexity may require additional training. |

| ET-02F/05F | Movable tribrach for versatility | Road Construction, Geodetic Surveys | Pros: Adaptable for various terrains; Cons: May need recalibration after adjustments. |

What Are the Key Characteristics of the ET-02 Theodolite?

The ET-02 is designed for professionals requiring precision in construction and land surveying. It features 30x magnification and offers options for 2″ or 5″ accuracy, making it suitable for high-stakes projects. Its dual LCD display allows for easy reading from multiple angles, enhancing usability in the field. Buyers should consider its durability and performance in various conditions, though its weight may be a factor for those prioritizing portability.

How Does the ET-02L Enhance Surveying Accuracy?

The ET-02L model stands out with its laser plummet and laser pointer, which are visible up to 100 meters. This feature significantly improves visibility and precision in measurement tasks. It is ideal for precision engineering and topographic surveys where accuracy is paramount. While the advanced technology provides exceptional value, buyers should weigh the higher investment cost against the benefits of enhanced performance.

Why Choose the ET-05 for General Surveying Needs?

The ET-05 is a cost-effective alternative for general surveying and civil engineering tasks. It provides reliable functionality with a 5″ accuracy option, making it suitable for projects where extreme precision is not critical. Its affordability makes it appealing for businesses operating on tighter budgets. However, buyers should note that while it offers good performance, it may not meet the demands of high-precision applications.

What Advantages Does the ET-05L Offer for Infrastructure Development?

The ET-05L integrates the features of the ET-05 with additional laser capabilities, making it a versatile choice for infrastructure development and mining. This model combines reliability with advanced technology, providing professionals with the tools they need for effective measurements in complex environments. While its versatility is a significant advantage, the complexity of the device may necessitate additional training for optimal use.

How Does the Movable Tribrach Feature Benefit the ET-02F/05F Models?

The ET-02F and ET-05F models come equipped with a movable tribrach, adding versatility for various surveying applications. This feature is particularly beneficial in road construction and geodetic surveys, where adaptability to different terrains is essential. Buyers should appreciate the enhanced flexibility these models offer, but they must also be prepared for potential recalibration after adjustments, which may require additional time and resources.

Key Industrial Applications of south et

| Industry/Sector | Specific Application of south et | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Precision surveying for building layout and alignment | Enhanced accuracy reduces rework, saving time and costs. | Ensure compatibility with local regulations and standards. |

| Civil Engineering | Infrastructure project monitoring and inspections | Continuous monitoring aids in early problem detection. | Look for robust support and training for international buyers. |

| Agriculture | Land surveying for precision agriculture | Increases crop yield through accurate land management. | Consider local agricultural practices and terrain variations. |

| Mining and Resource | Geological surveying for resource extraction | Accurate mapping maximizes resource recovery and efficiency. | Evaluate the durability of equipment for harsh environments. |

| Environmental Monitoring | Land and water resource assessments | Supports compliance with environmental regulations. | Check for integration with local environmental monitoring systems. |

How is ‘south et’ Used in Construction Projects?

In the construction sector, the South ET Series theodolites are crucial for precision surveying, ensuring accurate building layout and alignment. By utilizing advanced absolute circle reading technology, these instruments enable professionals to achieve high precision in measurements, significantly reducing the likelihood of costly rework. International buyers, especially in regions like Nigeria or Germany, should ensure that the equipment meets local construction standards and can withstand varying environmental conditions.

What Role Does ‘south et’ Play in Civil Engineering?

For civil engineering projects, the South ET Series is instrumental in monitoring infrastructure development and conducting inspections. The ability to continuously assess structural integrity helps in the early detection of potential issues, thereby minimizing risks and enhancing safety. Buyers in the Middle East and Europe should prioritize sourcing equipment that offers reliable support and training, ensuring the effective use of technology in compliance with local engineering codes.

How Can ‘south et’ Enhance Agricultural Practices?

In agriculture, the South ET Series facilitates precise land surveying, which is essential for effective land management and crop planning. By providing accurate data on land topography, farmers can optimize planting strategies, leading to increased crop yields. Buyers from South America and Africa should consider the specific agricultural practices in their regions and ensure the equipment is adaptable to local terrain and conditions.

What Advantages Does ‘south et’ Offer in Mining and Resource Extraction?

In the mining sector, the South ET Series aids in geological surveying, allowing for accurate mapping of resource deposits. This precision is vital for maximizing resource recovery while minimizing environmental impact. International buyers should evaluate the durability and performance of the equipment in harsh mining environments, ensuring it meets the demands of rigorous fieldwork.

How is ‘south et’ Used for Environmental Monitoring?

Environmental monitoring applications benefit from the South ET Series through its ability to conduct comprehensive land and water resource assessments. This capability is essential for compliance with environmental regulations, providing data necessary for sustainable resource management. Buyers should ensure that the equipment can integrate seamlessly with existing environmental monitoring systems in their regions, facilitating effective data collection and analysis.

3 Common User Pain Points for ‘south et’ & Their Solutions

Scenario 1: Navigating Accuracy Concerns in Project Measurements

The Problem: Many B2B buyers in the construction and surveying industries face significant challenges when it comes to ensuring measurement accuracy. Users of the South ET series often express concerns about discrepancies in angle and distance measurements, which can lead to costly project delays and rework. These issues can stem from various factors, including improper setup, environmental conditions, or a lack of understanding of the equipment’s capabilities. For instance, a construction manager may find that their team consistently miscalculates elevations, resulting in misaligned structures and wasted resources.

The Solution: To mitigate accuracy concerns, buyers should focus on thorough training and understanding of the South ET series features. Implementing a comprehensive training program for staff on proper setup and calibration is essential. Buyers can leverage the dual LCD displays and laser pointer features of the ET series, ensuring that all team members can easily interpret readings from various angles. Additionally, investing in a regular maintenance schedule for the equipment can prevent performance issues. Understanding the optimal operating conditions, such as temperature ranges and focusing distances, will also help users achieve the best results. Finally, keeping a detailed log of measurements and any discrepancies can aid in identifying patterns and addressing potential issues proactively.

Scenario 2: Difficulty in Sourcing Spare Parts and Support

The Problem: B2B buyers often encounter challenges when sourcing spare parts and support for the South ET series, particularly in regions where local distributors may not carry the necessary inventory. This can lead to extended downtimes when equipment needs repairs, significantly impacting project timelines. A surveyor in Nigeria, for instance, may experience delays due to the unavailability of specific parts, leading to frustration and potential loss of contracts.

The Solution: To overcome sourcing difficulties, buyers should establish a reliable relationship with authorized distributors and service centers for the South ET series. Engaging with suppliers that offer comprehensive warranties and support services can provide peace of mind. Additionally, buyers can inquire about extended warranties that include parts replacement. Maintaining a stock of commonly used spare parts, such as batteries and calibration tools, can also minimize downtime. For regions with limited access, exploring international shipping options or online marketplaces specializing in surveying equipment can help ensure that parts are readily available when needed.

Scenario 3: Integrating Technology for Enhanced Efficiency

The Problem: As the surveying industry evolves, many B2B buyers struggle to integrate new technologies into their existing workflows. Users of the South ET series may find it challenging to incorporate data collection software or integrate the equipment with modern surveying practices, leading to inefficiencies. For example, a civil engineering firm in South America may use the ET series but lack the capability to seamlessly transfer data to design software, resulting in data entry errors and wasted time.

The Solution: To enhance efficiency, buyers should explore compatible software solutions that work well with the South ET series. Investing in data collection software that allows for real-time data transfer can streamline workflows significantly. Buyers can also benefit from software training sessions to ensure their teams are adept at using these tools effectively. Furthermore, leveraging the advanced features of the South ET series, such as its internal memory for angle storage, can help teams manage data more efficiently. Collaboration with technology partners who specialize in surveying solutions can provide additional insights into optimizing equipment use and data integration, ultimately improving project outcomes.

Strategic Material Selection Guide for south et

What Are the Key Materials Used in the South ET Series Theodolites?

In the context of the South ET Series, the selection of materials significantly impacts performance, durability, and overall user satisfaction. Here, we analyze four common materials used in the construction of these precision instruments.

1. Aluminum Alloy

Key Properties: Aluminum alloys are lightweight yet strong, with excellent corrosion resistance. They typically have a temperature rating ranging from -50°C to 150°C, making them suitable for various environmental conditions.

Pros & Cons: The primary advantages of aluminum alloys include their low weight, which enhances portability, and their resistance to rust, ensuring longevity in outdoor applications. However, they can be more expensive than steel and may require specialized manufacturing processes, which can complicate production.

Impact on Application: Aluminum’s lightweight nature makes it ideal for portable surveying equipment, reducing user fatigue during extended use. Its corrosion resistance is particularly beneficial in humid or coastal regions, ensuring reliability in diverse climates.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the aluminum used meets local standards for durability. Compliance with international standards such as ASTM or DIN can also be crucial for quality assurance.

2. High-Strength Plastic

Key Properties: High-strength plastics, such as polycarbonate and ABS, offer excellent impact resistance and can withstand temperatures from -40°C to 80°C. They are also resistant to various chemicals.

Pros & Cons: These materials are cost-effective and lightweight, making them ideal for components that do not require heavy-duty metal. However, they may not provide the same level of structural integrity as metals and can degrade under UV exposure if not treated.

Impact on Application: High-strength plastics are often used in non-load-bearing parts of the theodolite, such as housing for electronics. This reduces overall weight while maintaining functionality.

Considerations for International Buyers: Buyers should verify that the plastics used are compliant with relevant safety and environmental regulations in their regions, particularly in Europe, where stringent standards apply.

3. Stainless Steel

Key Properties: Stainless steel is known for its high tensile strength and excellent corrosion resistance, withstanding temperatures up to 800°C. It is particularly resistant to rust and oxidation.

Pros & Cons: The durability of stainless steel makes it ideal for components that experience wear and tear. However, it is heavier than aluminum and can be more costly, impacting the overall weight and price of the product.

Impact on Application: Stainless steel components are often used in critical load-bearing parts, ensuring longevity and reliability even in harsh environments. This material is particularly beneficial in regions with high humidity or saline conditions.

Considerations for International Buyers: Buyers should ensure that the stainless steel used meets international standards for corrosion resistance, such as ASTM A240, especially in coastal areas where salt exposure is a concern.

4. Glass Optics

Key Properties: High-quality optical glass is essential for precision instruments, offering clarity, durability, and resistance to scratching. It generally performs well under a wide range of temperatures.

Pros & Cons: The primary advantage of glass optics is their superior clarity and ability to maintain focus over long distances. However, glass can be fragile and requires careful handling during manufacturing and use.

Impact on Application: Glass optics are crucial for the accuracy of theodolites, affecting measurement precision. The quality of the glass directly influences the performance in various lighting conditions.

Considerations for International Buyers: Buyers should look for products that use high-quality optical glass meeting international standards to ensure performance across diverse environments, particularly in regions with varying weather conditions.

Summary Table of Material Selection for South ET Series

| Material | Typical Use Case for south et | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloy | Housing and structural components | Lightweight and corrosion-resistant | Higher cost and manufacturing complexity | Medium |

| High-Strength Plastic | Non-load-bearing parts | Cost-effective and lightweight | Less structural integrity and UV sensitivity | Low |

| Stainless Steel | Load-bearing components | High durability and corrosion resistance | Heavier and more expensive | High |

| Glass Optics | Optical components | Superior clarity and focus | Fragile and requires careful handling | Medium |

This analysis provides B2B buyers with a comprehensive understanding of the material options available for the South ET Series, enabling informed decision-making based on performance requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for south et

What Are the Main Stages of Manufacturing for South ET Theodolites?

The manufacturing process for South ET theodolites is meticulously designed to ensure precision and reliability. The process can be broken down into four main stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves sourcing high-quality materials that meet strict industry standards. Components such as high-grade aluminum for the housing and advanced optical glass for lenses are carefully selected. This stage often includes rigorous testing of raw materials to ensure they meet the specifications required for durability and performance.

-

Forming: In this stage, the prepared materials undergo various forming techniques. CNC (Computer Numerical Control) machining is commonly employed for precision cutting and shaping of components. This technology allows for high accuracy in the fabrication of parts, such as the telescope body and internal mechanisms, which are crucial for the overall performance of the theodolite.

-

Assembly: The assembly phase is critical as it combines all individual components into a functioning unit. Skilled technicians utilize precise alignment techniques to ensure that optical components are correctly positioned, which directly impacts measurement accuracy. Advanced tools and jigs are often used to aid in this process, ensuring that every theodolite meets the stringent quality benchmarks set by the manufacturer.

-

Finishing: The final stage involves thorough inspections and finishing touches. This includes applying protective coatings to resist environmental factors and enhance durability. Each theodolite is calibrated and tested for functionality, ensuring that the readings are accurate before it is packaged and shipped.

How Is Quality Assurance Implemented in South ET Manufacturing?

Quality assurance (QA) is integrated throughout the manufacturing process to uphold the standards expected by international B2B buyers. The following practices highlight the QA measures taken:

-

International Standards Compliance: South ET theodolites are manufactured in accordance with international quality standards, such as ISO 9001. This certification ensures that the manufacturing processes are continuously monitored and improved to meet customer satisfaction and regulatory requirements.

-

Industry-Specific Certifications: Depending on the market, additional certifications may be required, such as CE marking for products sold in Europe, which signifies compliance with health, safety, and environmental protection standards. For buyers in specialized fields, such as oil and gas, certifications like API (American Petroleum Institute) may also be relevant.

-

Quality Control Checkpoints: Various checkpoints are established throughout the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are inspected upon receipt to verify that they meet required specifications.

– In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing process to identify and correct any defects in real time.

– Final Quality Control (FQC): Once assembly is complete, each unit undergoes a final inspection and testing phase to ensure it meets all performance criteria.

What Common Testing Methods Are Used for South ET Theodolites?

To ensure the highest standards of quality and performance, several testing methods are employed:

-

Optical Testing: This includes checking the alignment and accuracy of the optical components. Tests such as collimation and optical resolution assessments are conducted to ensure that the theodolites provide precise measurements.

-

Functional Testing: Each unit is subjected to functional tests that simulate real-world usage. This involves checking the dual LCD displays, laser plummet visibility, and angle measurement accuracy under various conditions.

-

Environmental Testing: Given the operational range of South ET theodolites, they are tested for performance in extreme conditions, including temperature variations from -20℃ to +50℃. This ensures reliability in diverse geographical locations.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some actionable insights:

-

Conduct Supplier Audits: Before finalizing a partnership, buyers should conduct thorough audits of the manufacturer’s facilities. This includes reviewing their quality management systems and processes to ensure compliance with international standards.

-

Request Quality Reports: Suppliers should provide detailed quality assurance reports, including data from IQC, IPQC, and FQC stages. These documents should outline the testing methods used and any corrective actions taken during production.

-

Engage Third-Party Inspectors: Utilizing independent third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control practices. These inspectors can evaluate the products and processes to ensure they meet the required standards.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, B2B buyers must be aware of certain nuances:

-

Understanding Local Regulations: Each region may have specific regulations that affect product quality and certification. Buyers should familiarize themselves with these regulations to ensure compliance.

-

Cultural Differences in Business Practices: The approach to quality control can vary significantly between cultures. Buyers should be prepared for different communication styles and practices when engaging with suppliers from diverse backgrounds.

-

Currency and Trade Considerations: Fluctuations in currency and trade policies can impact the cost and availability of quality materials. Buyers should consider these factors when negotiating contracts and assessing supplier reliability.

By understanding the manufacturing processes and quality assurance practices of South ET theodolites, international B2B buyers can make informed decisions, ensuring they partner with reliable suppliers that meet their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘south et’

To assist B2B buyers in procuring the South ET series, this guide outlines essential steps to ensure a successful sourcing experience. The South ET series theodolites are recognized for their precision and reliability, making them a valuable investment for construction and surveying professionals. By following this checklist, buyers can make informed decisions and secure high-quality products.

Step 1: Define Your Technical Specifications

Understanding your project requirements is crucial before sourcing the South ET series. Consider factors such as the accuracy needed (2” or 5”), the environment in which the equipment will be used, and any specific features that may be beneficial, like a laser pointer or dual LCD displays. Clearly defined specifications help streamline the search for suppliers that can meet your needs.

Step 2: Research Reputable Suppliers

Identifying suppliers with a strong reputation in the market is fundamental. Look for companies that specialize in surveying equipment and have a proven track record of customer satisfaction. Check for online reviews, case studies, and testimonials from other B2B buyers, particularly those from your target regions such as Africa, South America, the Middle East, and Europe.

Step 3: Evaluate Supplier Certifications

Before making any commitments, ensure that potential suppliers hold the necessary certifications and licenses. This could include ISO certifications or other quality assurance benchmarks relevant to surveying equipment. Certified suppliers are more likely to adhere to industry standards, ensuring the products you receive are of high quality and reliability.

Step 4: Request Detailed Product Information

Once you have shortlisted suppliers, request comprehensive product datasheets and manuals for the South ET series. Pay attention to specifications such as magnification, minimum focusing distance, and operating temperature range. This information is vital for assessing whether the product meets your technical requirements and performance expectations.

Step 5: Inquire About Warranty and Support

Ensure that the suppliers offer robust warranty options and customer support services. A good warranty protects your investment in case of defects or malfunctions. Additionally, responsive customer support can assist you with setup, troubleshooting, and maintenance, which is crucial for minimizing downtime on projects.

Step 6: Compare Pricing and Shipping Options

Gather quotes from multiple suppliers to compare pricing structures. Be sure to consider shipping costs and delivery times, especially if you are sourcing from international suppliers. Understanding the total cost of ownership, including import duties and taxes, can help you make a more informed purchasing decision.

Step 7: Finalize Purchase and Confirm Delivery Details

Once you have selected a supplier, finalize your purchase and ensure that all details are confirmed, including payment terms and delivery timelines. It’s advisable to keep communication open with the supplier throughout this process to clarify any last-minute questions or concerns. Confirming these details helps mitigate potential issues that may arise during the procurement process.

By following these steps, B2B buyers can efficiently navigate the sourcing process for the South ET series, ensuring they acquire high-quality surveying equipment that meets their specific needs.

Comprehensive Cost and Pricing Analysis for south et Sourcing

What Are the Key Cost Components in the South ET Sourcing Process?

When considering the sourcing of South ET products, understanding the cost structure is paramount. The total cost comprises several components:

-

Materials: High-quality materials are essential for the production of the South ET series theodolites. The choice of optics, electronic components, and durable housing materials directly influences the cost. The use of premium materials ensures longevity and performance, which is critical for surveying equipment.

-

Labor: Skilled labor is required for assembly and quality control of these sophisticated instruments. Labor costs can vary significantly based on the manufacturing location, with regions known for higher wages impacting overall pricing.

-

Manufacturing Overhead: This includes utilities, equipment depreciation, and facility costs. Efficient manufacturing processes can help in minimizing overhead, thereby reducing the final price.

-

Tooling: Initial tooling costs can be substantial, particularly for custom or specialized equipment. Investing in high-quality tooling can lead to better precision and lower defect rates, ultimately enhancing product value.

-

Quality Control (QC): Rigorous QC processes are essential to ensure the accuracy and reliability of the theodolites. These processes add to the cost but are necessary to maintain brand reputation and customer satisfaction.

-

Logistics: The cost of transporting the products from the manufacturing facility to the end user can vary widely. Factors such as distance, shipping method, and any tariffs or import duties imposed by the destination country will affect logistics costs.

-

Margin: Manufacturers and suppliers will typically add a margin to cover their costs and ensure profitability. This margin can vary based on market demand, competition, and the perceived value of the product.

How Do Price Influencers Affect the Sourcing of South ET Products?

Several factors can influence the pricing of South ET products:

-

Volume/MOQ: Purchasing in larger quantities can lead to discounts. Buyers should negotiate minimum order quantities (MOQs) to benefit from reduced prices.

-

Specifications/Customization: Custom features or specifications can increase costs. Buyers should assess whether standard products meet their needs before opting for customization.

-

Materials: The choice of materials affects both the cost and quality of the product. High-grade materials might raise the price but will likely offer better performance and longevity.

-

Quality/Certifications: Products with industry certifications or higher quality standards may come at a premium. Buyers should consider the long-term benefits of investing in certified equipment.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may offer better warranty terms and support, justifying a higher price point.

-

Incoterms: Understanding the Incoterms used in the transaction can help buyers anticipate additional costs related to shipping, insurance, and customs clearance.

What Are the Best Negotiation Tips for B2B Buyers in International Markets?

To ensure cost-efficiency in sourcing South ET products, consider the following negotiation tips:

-

Research Market Prices: Familiarize yourself with the market rates for similar products. This knowledge will empower you during negotiations.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, operational costs, and potential resale value. A lower initial price may not always equate to better value.

-

Leverage Volume Discounts: If your organization has the capability to order in bulk, use this to negotiate better pricing terms with suppliers.

-

Consider Payment Terms: Flexible payment terms can ease cash flow issues. Discuss options that might include deferred payment or installment plans.

-

Assess Supplier Reliability: Ensure that the supplier has a good track record for quality and delivery. A slightly higher price might be worth it if it guarantees better service and reliability.

What Should International Buyers Keep in Mind Regarding Pricing Nuances?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of specific pricing nuances:

-

Currency Fluctuations: Exchange rates can significantly impact the final cost. Consider the timing of purchases and potential hedging strategies.

-

Import Duties and Taxes: Research applicable tariffs and import duties that could affect the overall pricing. Factor these into the TCO.

-

Local Regulations: Compliance with local standards and regulations can influence product specifications and pricing. Ensure that the sourced products meet local requirements to avoid additional costs.

-

Shipping and Handling: Understand the logistics involved in importing goods, including potential delays and additional fees that may arise during customs clearance.

Disclaimer on Indicative Prices

Prices mentioned in various sources may fluctuate based on market conditions, supplier negotiations, and changes in material costs. It is advisable to obtain quotes directly from suppliers to get the most accurate and current pricing information.

Alternatives Analysis: Comparing south et With Other Solutions

Exploring Alternatives to South ET Theodolites

In the competitive landscape of surveying and construction, selecting the right equipment is crucial for achieving accurate and efficient results. While the South ET Series offers advanced capabilities for angle and distance measurements, several alternative solutions also cater to the same needs. This analysis will compare the South ET Series with two notable alternatives: the Leica LINO L2P5 and the Topcon GPT-3300.

Comparison Table

| Comparison Aspect | South ET | Leica LINO L2P5 | Topcon GPT-3300 |

|---|---|---|---|

| Performance | 2″/5″ accuracy, advanced absolute circle reading technology | 2mm accuracy, versatile laser capabilities | 1″/2″ accuracy, integrated GNSS options |

| Cost | Mid-range pricing | Higher-end pricing | Mid-range pricing |

| Ease of Implementation | User-friendly setup, dual LCD displays | Simple setup with intuitive interface | Requires calibration, user training recommended |

| Maintenance | Low maintenance, durable design | Moderate maintenance, requires periodic checks | Moderate to high, especially for GNSS integration |

| Best Use Case | Construction and surveying | Indoor and outdoor applications needing precision laser lines | High-precision surveying and mapping tasks |

In-Depth Analysis of Alternatives

Leica LINO L2P5

The Leica LINO L2P5 is designed for professionals who require precise laser measurements for both indoor and outdoor applications. Its performance is commendable, providing accuracy within 2mm and versatile laser features that support a wide range of tasks. However, the higher price point may deter some buyers, particularly in budget-conscious markets. Additionally, while it is user-friendly, the device may require more frequent maintenance compared to South ET due to its advanced laser systems.

Topcon GPT-3300

Topcon’s GPT-3300 is a robust theodolite that incorporates integrated GNSS capabilities, allowing for exceptional accuracy of 1″/2″. This makes it an ideal choice for high-precision surveying and mapping tasks. However, the need for calibration and potential complexity in use may pose challenges for less experienced operators. Maintenance can also be moderate to high, particularly with GNSS components, which may not be suitable for all users, especially in regions with limited technical support.

Making the Right Choice for Your Surveying Needs

When evaluating surveying solutions, B2B buyers must consider their specific project requirements, budget constraints, and the skill level of the operators. The South ET Series is an excellent choice for those seeking a balance between performance and cost, offering reliable accuracy and ease of use. In contrast, if the project demands high precision and advanced laser functionality, the Leica LINO L2P5 may be more suitable, albeit at a higher cost. For projects that require exceptional accuracy in challenging environments, the Topcon GPT-3300 presents a powerful option, although it may necessitate additional training and maintenance efforts.

Ultimately, the right solution will depend on the unique needs of the buyer and the specific applications they intend to pursue. By carefully weighing these alternatives, organizations can ensure they invest in the most appropriate surveying technology to achieve their operational goals.

Essential Technical Properties and Trade Terminology for south et

What Are the Key Technical Properties of South ET Theodolites?

When considering the South ET Series theodolites for your surveying and construction projects, understanding their technical specifications is essential for making informed purchasing decisions. Here are several critical specifications to consider:

-

Accuracy Options (2″/5″)

The South ET Series offers selectable accuracy of either 2 inches or 5 inches. This is crucial for B2B buyers as it allows for flexibility depending on the precision required for specific projects. Higher accuracy is typically demanded for detailed surveying tasks, while less precision may suffice for general construction. -

Magnification (30x)

With a 30x magnification capability, these theodolites provide detailed observations, essential for accurate angle measurements. This feature is particularly beneficial for surveying professionals who need to analyze fine details over long distances, ensuring quality results in their projects. -

Dual LCD Display

The presence of dual LCD displays allows for readings from various angles, enhancing usability in diverse working conditions. This is important for teams that require collaboration, as multiple users can view measurements simultaneously, reducing the chances of errors during data collection. -

Internal Memory Capacity (256 Pairs)

The South ET Series can store up to 256 pairs of horizontal and vertical angles in its internal memory. This specification is vital for B2B buyers who work on large projects, as it minimizes the need for constant data recording and facilitates efficient project management. -

Operating Temperature Range (−20℃ to +50℃)

The robust operating temperature range ensures that the equipment performs reliably in various environmental conditions. For international buyers, especially in regions with extreme climates, this durability is a significant selling point, ensuring that the equipment can withstand local conditions without compromising performance.

Which Trade Terminology Should Buyers Know When Purchasing South ET Products?

Navigating the procurement process for technical equipment like the South ET Series involves familiarizing oneself with key trade terms. Here are several important terms to understand:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of South ET products, understanding OEM relationships can help buyers identify trusted brands and ensure compatibility with existing equipment. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers to assess whether the purchase aligns with their budget and project needs, especially in bulk procurement scenarios. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and other terms for specific products or services. For B2B buyers, issuing an RFQ for South ET products can streamline the purchasing process and ensure competitive pricing from multiple suppliers. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping responsibilities, risks, and costs associated with importing South ET products, particularly when sourcing from overseas manufacturers. -

Warranty and Support

Understanding the warranty terms and support options available for South ET products is crucial for making a secure investment. Buyers should inquire about the duration and coverage of warranties, as well as the availability of technical support, to ensure they receive assistance when needed. -

Trade Compliance

This term refers to the adherence to international laws and regulations governing trade, including import/export duties and standards. Buyers must ensure that their procurement processes comply with relevant trade regulations to avoid delays and additional costs.

By comprehensively understanding these technical properties and trade terminologies, international B2B buyers can make informed decisions when considering South ET products for their surveying and construction needs.

Navigating Market Dynamics and Sourcing Trends in the south et Sector

What Are the Key Market Dynamics and Trends in the South ET Sector?

The South ET sector is experiencing a significant transformation, driven by advances in technology and a growing demand for precision in construction and surveying applications. Global drivers such as urbanization, infrastructure development, and environmental sustainability are shaping purchasing decisions among international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. In countries such as Nigeria and Germany, the emphasis on high-quality equipment that integrates advanced features is paramount. Buyers are increasingly seeking tools that offer not only accuracy but also user-friendly interfaces and durability in varying environmental conditions.

Emerging trends indicate a shift towards integrating IoT capabilities and AI analytics within surveying equipment. This evolution allows for real-time data collection and analysis, enhancing decision-making processes in construction projects. Additionally, there’s a notable preference for equipment that supports remote sensing and GIS functionalities, as these technologies enable comprehensive site assessments and monitoring. The global market for surveying instruments, including the South ET series, is projected to expand as businesses prioritize investments in advanced technology to enhance efficiency and accuracy.

How Is Sustainability Influencing Sourcing Decisions in the South ET Sector?

Sustainability is becoming a critical factor in the sourcing strategies of B2B buyers in the South ET sector. Companies are increasingly aware of their environmental impact, prompting a shift towards more sustainable practices. This includes sourcing equipment that adheres to ethical supply chain standards and utilizes eco-friendly materials. Buyers from regions like Europe are particularly motivated by compliance with stringent environmental regulations, pushing manufacturers to integrate sustainability into their production processes.

Moreover, the demand for ‘green’ certifications is on the rise. Buyers are looking for products that not only fulfill their operational needs but also contribute positively to environmental conservation. This trend is evident in the preferences for products designed with energy-efficient technologies and recyclable materials. As businesses strive to enhance their corporate social responsibility (CSR) profiles, the emphasis on sustainable sourcing will likely continue to grow, influencing supplier selection and partnerships in the South ET sector.

What Historical Developments Have Shaped the South ET Sector?

The South ET sector has evolved significantly over the past few decades, transitioning from traditional surveying methods to modern, technology-driven solutions. Initially, surveying relied heavily on manual tools and techniques, which often resulted in limitations regarding accuracy and efficiency. With the introduction of electronic theodolites and total stations, the industry began to witness a paradigm shift towards automation and precision.

This evolution accelerated in the late 20th century with the advent of GPS technology and digital data collection methods, which have become integral to modern surveying practices. Today, the South ET series exemplifies this evolution, incorporating advanced features such as dual LCD displays, laser pointers, and high-quality optics that cater to the demanding needs of construction and surveying professionals. As international B2B buyers seek reliable and precise instruments, the historical progression of technology in the South ET sector continues to inform current sourcing decisions and market dynamics.

Frequently Asked Questions (FAQs) for B2B Buyers of south et

-

How do I ensure the quality of South ET products before purchasing?

To ensure quality, verify that the supplier provides detailed specifications and quality assurance (QA) certifications for South ET products. Request samples if possible, and inquire about the manufacturing processes used. Additionally, check for reviews or testimonials from other clients, and consider sourcing from established dealers with a proven track record. Engaging in direct communication with the supplier can also help clarify any concerns regarding product reliability and performance. -

What is the best South ET model for construction and surveying applications?

The South ET Series, particularly models ET-02 and ET-05, are ideal for construction and surveying due to their advanced absolute circle reading technology and high accuracy options (2” and 5”). These models offer features like dual LCD displays and a laser pointer visible up to 100 meters, making them versatile for various tasks. Assess your specific needs, such as range and precision, to choose the model that best fits your application. -

What are the payment terms typically offered by suppliers for South ET products?

Payment terms can vary widely among suppliers, but common practices include upfront payment, partial payment upon order confirmation, and the remainder upon shipment. For international transactions, consider using secure payment methods like letters of credit or escrow services to protect your investment. It’s essential to negotiate terms that align with your cash flow requirements while ensuring the supplier’s confidence in the transaction. -

What are the minimum order quantities (MOQ) for South ET products?

Minimum order quantities for South ET products depend on the supplier and the specific model. Generally, MOQs can range from a single unit for smaller suppliers to larger quantities for bulk orders from major distributors. Always clarify MOQs with your supplier, as negotiating lower MOQs may be possible, especially for first-time orders or long-term partnerships. -

How can I verify the legitimacy of a supplier for South ET products?

To verify a supplier’s legitimacy, conduct thorough research by checking their business registration, customer reviews, and industry reputation. Utilize platforms like Alibaba or Global Sources to read feedback from previous buyers. Additionally, request references from the supplier and assess their responsiveness and transparency during initial communications. Engaging in a trial order can also help gauge their reliability and service quality. -

What logistics considerations should I keep in mind when sourcing South ET products?

When sourcing South ET products, consider shipping methods, customs regulations, and potential tariffs in your region. Evaluate the supplier’s shipping capabilities and delivery timelines to ensure they align with your project schedules. Additionally, inquire about shipping insurance options to protect against damage or loss during transit. Collaborating with a logistics provider familiar with international trade can streamline the process and mitigate risks. -

Can I customize South ET products for specific project requirements?

Customization options for South ET products may be available, depending on the supplier and the model. Inquire about specific features or configurations that can be tailored to meet your project needs, such as software integration or additional accessories. Be prepared to discuss your requirements in detail, as customization may involve additional costs and longer lead times. -

What support is available for troubleshooting South ET products after purchase?

Most suppliers offer post-purchase support, including technical assistance and warranty services. Check if the supplier provides detailed manuals and online resources for troubleshooting. Establishing a relationship with the supplier’s customer service team can facilitate quicker resolutions to any issues. Additionally, consider joining user forums or groups where professionals share their experiences and solutions related to South ET products.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 South Et Manufacturers & Suppliers List

1. South Instrument – Electronic Laser Theodolite

Domain: southinstrument.com

Registered: 2008 (17 years)

Introduction: {“Model”:”ET-02/ET-02L, ET-05/ET-05L”,”Type”:”Electronic/Laser Theodolite”,”Accuracy”:”2\”/5\””,”Telescope Image”:”Erect”,”Magnification”:”30x”,”Effective Aperture”:”45mm”,”Resolving Power”:”3\””,”Field of View”:”1°30′”,”Minimum Focusing Distance”:”1.4m”,”Stadia Ratio”:”100″,”Stadia Constant”:”0″,”Tube Length”:”157mm”,”Angle Measurement Reading System”:”Absolute Encoding”,”Diameter of Circle (VHz)…

2. Global GPS Systems – South ET Series Theodolite

Domain: globalgpssystems.com

Registered: 2019 (6 years)

Introduction: The South ET Series theodolite combines advanced absolute circle reading technology with high-quality optics, offering unmatched accuracy for construction and surveying professionals. Key features include:

– Laser pointer visible up to 100 meters

– Dual LCD displays

– Accuracy options of 2″/5″

– Durable, efficient, and versatile design

– Ideal for precise measurements in various projects.

Av…

3. South – Electronic Theodolite ET-05

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“title”:”South Electronic Theodolite ET-05 W/ Case”,”condition”:”Used”,”price”:”$349.99″,”shipping”:”Free shipping”,”estimated_delivery”:”Mon, Sep 8 – Fri, Sep 12″,”brand”:”South”,”model”:”ET-05″,”item_number”:”135477546254″,”description”:”An item that has been used previously. The item may have some signs of cosmetic wear, but is fully operational and functions as intended. This item may be a fl…

4. South ET-05 – Electronic Theodolite

Domain: eps.com.ua

Introduction: {“name”:”South ET-05″,”type”:”Electronic Theodolite”,”price”:”37,410.00 UAH”,”features”:{“vertical_compensator”:”Yes”,”built_in_memory”:”Yes”,”moisture_proof”:”Yes”,”automatic_compensator”:”Yes”,”interface_ports”:”2 (for rangefinder and PDA)”,”display”:”Large and clear numbers”,”internal_memory”:”256 pairs of H. & V. angle”},”telescope”:{“image”:”Erect”,”magnification”:”30x”,”lens_diameter”:”45 mm…

5. South – ET-02 Electronic/Laser Theodolite

Domain: skycraftsurplus.com

Registered: 1999 (26 years)

Introduction: {“name”: “South ET-02 Electronic/Laser Theodolite”, “sku”: “020335”, “price”: “$249.95”, “condition”: “Used, Sold As-Is. Battery Not Included. Powers Up, Appears To Function, Unable To Fully Test.”, “accuracy_options”: [“2\””, “5\””], “features”: {“EDM Design”: “Advanced”, “laser_functions”: [“laser plummet”, “laser pointer”], “movable_tribrach”: “for ET-02F/05F”, “telescope”: {“image”: “Erect”, “…

6. GNSS – ET Series Total Stations

Domain: gnss.ae

Introduction: {“model”:”ET-02/ET-02L | ET-05/ET-05L”,”accuracy”:”2\”/5\””,”features”:[“Advanced EDM design”,”Laser plummet and laser pointer function for ET-02L/05L”,”Movable tribrach for ET-02F/05F”,”Digit LCD Screen with simple keys for easier operation”,”Powerful laser pointer and laser plummet for simplified measurement”],”specifications”:{“telescope”:{“image”:”Erect”,”magnification”:”30x”,”effective_apertu…

7. South Electronic – ET-02 Digital Theodolite

Domain: cn-surveying.com

Registered: 2023 (2 years)

Introduction: {“Product Name”: “South Electronic ET-02”, “Type”: “Digital Theodolite”, “Accuracy”: “2””, “Telescope Magnification”: “30x”, “Minimum Focusing Distance”: “1.4m”, “Display”: “Dual side LCD”, “Measuring Method”: “Absolute Code”, “Horizontal Angle Measurement”: “Dual”, “Vertical Angle Measurement”: “Dual”, “Field of View”: “1°30′”, “Resolving Power”: “3””, “Auto Compensator System”: “Liquid-Electric …

8. South Et-02 – Electronic Theodolites and Total Stations

Domain: spicsoft.com

Registered: 2005 (20 years)

Introduction: Electronic Theodolites and Total Stations from South Et-02 are designed for precise geographic measurements. They feature advanced technology for accurate angle and distance measurement, making them ideal for surveying and construction applications. The devices are equipped with user-friendly interfaces, robust construction for durability, and are suitable for various environmental conditions.

9. South Electronic – Theodolite ET-02

Domain: vpcivil.co.in

Registered: 2010 (15 years)

Introduction: Product Name: South Electronic Theodolite ET-02

Accuracy: 2″

Telescope Magnification: 30x

Minimum Focusing Distance: 1.4m

Display: Dual side display

Measuring Method: Absolute encoding

Angle Measurement: Horizontal & Vertical

Hold Key: Yes

Dimensions: L145 x H318 x W179 mm

Weight: 5.2 kg

Power Supply: Rechargeable Ni-H Battery/AA Battery, DC 6V

Continuous Operation Time: 10 hours

Field of View: 1°…

Strategic Sourcing Conclusion and Outlook for south et

What Are the Key Takeaways for B2B Buyers in the South ET Market?

The South ET Series offers unparalleled accuracy and reliability, making it a crucial investment for construction and surveying professionals across diverse markets. With advanced features like dual LCD displays, high-quality optics, and a robust design capable of withstanding extreme conditions, these theodolites meet the demanding needs of today’s projects. Strategic sourcing of the South ET Series not only ensures access to cutting-edge technology but also positions businesses to enhance operational efficiency and project outcomes.

How Can Strategic Sourcing Impact Your Business Growth?

By engaging in strategic sourcing, international buyers can optimize their procurement processes, reducing costs while ensuring quality. This is particularly vital for regions in Africa, South America, the Middle East, and Europe, where infrastructure development is rapidly evolving. The South ET Series stands out as a tool that not only delivers precision but also fosters innovation in surveying practices.

What Should You Do Next?

As the global demand for advanced surveying solutions continues to rise, now is the time to consider the South ET Series for your operational needs. Explore partnerships with reputable suppliers and leverage the technological advancements these tools offer to stay ahead in your industry. Embrace the future of surveying and construction by integrating reliable equipment that supports your business objectives.