Everything You Need to Know About Skull Helmet Sourcing in 2025

Introduction: Navigating the Global Market for skull helmet

In the rapidly evolving world of motorcycle safety gear, sourcing high-quality skull helmets presents a unique challenge for international B2B buyers. With a diverse range of styles and regulatory standards across regions—particularly in markets such as Africa, South America, the Middle East, and Europe—understanding the nuances of helmet specifications is crucial. This comprehensive guide delves into the various types of skull helmets, their applications, and essential considerations for selecting the right suppliers.

From DOT-approved models to graphic designs that cater to diverse consumer preferences, this guide aims to equip B2B buyers with the insights necessary to make informed purchasing decisions. We will explore critical factors such as compliance with safety regulations, pricing strategies, and the importance of supplier vetting processes to ensure product quality.

By addressing common pain points and offering actionable solutions, this resource empowers businesses in countries like Nigeria and Saudi Arabia to navigate the global market effectively. Whether you are looking to diversify your product offerings or streamline your supply chain, understanding the dynamics of the skull helmet market is essential for success. With this guide, you will be better positioned to meet customer demands while ensuring safety and compliance in your offerings.

Understanding skull helmet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| DOT Approved Skull Cap | Smallest D.O.T.-approved design, half-shell style | Motorcycle retailers, safety equipment suppliers | Pros: Compact, meets safety standards; Cons: Limited protection compared to full helmets. |

| Skull Cap with Inner Shield | Retractable inner shield, customizable graphics | Custom apparel stores, promotional merchandise | Pros: Enhanced visibility, stylish options; Cons: Slightly higher cost, more components to manage. |

| Carbon Fiber Skull Cap | Lightweight, durable carbon fiber construction | High-end motorcycle shops, performance accessory vendors | Pros: Superior strength-to-weight ratio; Cons: Higher price point may deter budget-conscious buyers. |

| Graphic Skull Cap | Variety of graphics and colors available | Retailers focusing on lifestyle and fashion | Pros: Appeals to diverse customer preferences; Cons: May compromise on safety for aesthetics. |

| Beanie Style Skull Cap | Minimalistic design, often without a visor | Urban motorcycle shops, scooter retailers | Pros: Trendy and lightweight; Cons: Limited face protection, may not meet all safety regulations. |

What Are the Key Characteristics of DOT Approved Skull Caps?

DOT Approved Skull Caps are designed to be the smallest D.O.T.-approved motorcycle helmets available. Their half-shell design provides a sleek look while ensuring compliance with safety standards. These helmets are ideal for motorcycle retailers and suppliers of safety equipment, as they cater to a market that prioritizes both style and safety. When purchasing, B2B buyers should consider the balance between aesthetics and safety compliance, as these helmets often offer limited protection compared to full-face options.

How Does a Skull Cap with Inner Shield Enhance Safety?

Skull Caps with Inner Shields feature a retractable visor that protects against sun glare and debris, enhancing the overall riding experience. They are particularly popular among custom apparel stores and those offering promotional merchandise due to their customizable graphics. B2B buyers should evaluate the additional cost of these helmets against the value of added safety features, as they may attract customers seeking both functionality and style.

Why Choose Carbon Fiber Skull Caps for High-End Markets?

Carbon Fiber Skull Caps are renowned for their lightweight and durable construction. This type of helmet appeals to high-end motorcycle shops and performance accessory vendors, where customers are often willing to invest more for superior quality. When sourcing these products, B2B buyers should consider the advanced materials and technology used in their production, which can justify the higher price point and enhance customer satisfaction.

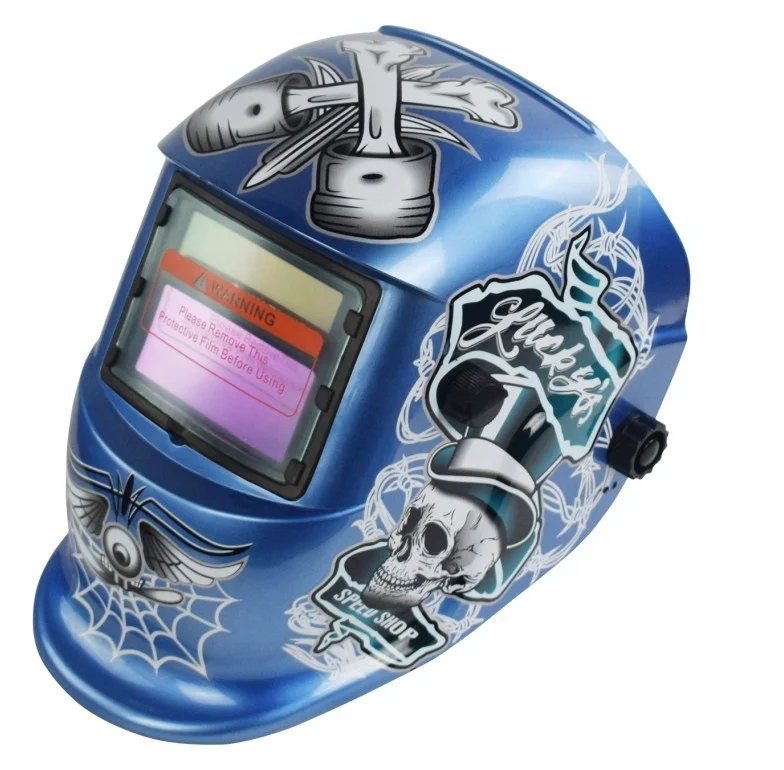

What Makes Graphic Skull Caps Popular Among Retailers?

Graphic Skull Caps offer a wide range of designs and colors, catering to diverse customer tastes and preferences. They are particularly effective for retailers focusing on lifestyle and fashion, as they can be marketed as both protective gear and a fashion statement. B2B buyers should be aware of the potential trade-off between aesthetics and safety, ensuring that the helmets still meet necessary safety standards while appealing to style-conscious consumers.

How Does the Beanie Style Skull Cap Fit into Urban Markets?

Beanie Style Skull Caps are characterized by their minimalistic design, often lacking a visor, making them a trendy choice for urban riders. They are commonly found in urban motorcycle shops and scooter retailers. B2B buyers need to consider the target market’s preference for lightweight, stylish options, while also being mindful of the limitations in face protection and safety compliance that come with this style.

Key Industrial Applications of skull helmet

| Industry/Sector | Specific Application of skull helmet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Motorcycle and Scooter Retail | Protective gear for motorcycle and scooter riders | Enhances customer safety and compliance with regulations | Ensure DOT approval, variety in styles and sizes, and competitive pricing |

| Construction and Heavy Industry | Safety gear for on-site workers operating machinery | Reduces workplace injuries and enhances worker safety | Look for helmets with additional safety certifications and durability features |

| Sports and Recreation | Safety equipment for sports such as BMX, skateboarding, and more | Protects athletes, reduces liability, and promotes brand trust | Focus on lightweight materials and customizable designs for branding |

| Logistics and Transportation | Protective gear for delivery personnel and couriers | Ensures safety during transport and enhances workforce morale | Prioritize comfort and breathability for extended wear in various climates |

| Emergency Services | Helmets for first responders and rescue teams | Provides essential head protection in hazardous environments | Seek helmets with advanced impact resistance and communication features |

How Are Skull Helmets Used in the Motorcycle and Scooter Retail Sector?

In the motorcycle and scooter retail sector, skull helmets serve as essential safety gear for riders. These helmets not only comply with local safety regulations but also enhance the overall riding experience by providing comfort and style. International buyers, particularly from regions like Africa and South America, should prioritize sourcing helmets that meet DOT standards, ensuring both safety and marketability. Offering a variety of designs and sizes can cater to diverse customer preferences, enhancing sales potential.

What Role Do Skull Helmets Play in Construction and Heavy Industry?

In the construction and heavy industry sectors, skull helmets are increasingly adopted as protective gear for workers operating heavy machinery. These helmets help mitigate the risk of head injuries, thereby promoting a safer work environment and potentially reducing liability costs for employers. Buyers in the Middle East and Europe should focus on sourcing helmets that meet rigorous safety standards and offer durability features, ensuring they can withstand harsh working conditions.

How Are Skull Helmets Relevant in Sports and Recreation?

Skull helmets have significant applications in sports and recreational activities, particularly in BMX, skateboarding, and similar sports. They provide essential protection for athletes while minimizing the risk of injury, which is crucial for maintaining brand trust and reducing liability for sports organizations. B2B buyers from Europe and South America should consider lightweight materials and customizable designs to attract a broader audience and enhance brand visibility.

Why Are Skull Helmets Important for Logistics and Transportation?

In logistics and transportation, skull helmets are vital for ensuring the safety of delivery personnel and couriers. As these workers navigate busy streets and potentially hazardous environments, wearing protective gear can significantly reduce the risk of head injuries. Buyers should prioritize comfort and breathability when sourcing helmets, particularly in hot climates like those found in Nigeria and Saudi Arabia, to ensure that employees can wear them comfortably during long hours of work.

What Benefits Do Skull Helmets Offer to Emergency Services?

For emergency services, skull helmets provide crucial head protection for first responders and rescue teams operating in hazardous environments. These helmets often come equipped with advanced features such as impact resistance and communication systems, enhancing operational efficiency and safety. B2B buyers in this sector should focus on sourcing helmets that meet stringent safety standards and offer additional functionalities, ensuring that their teams are well-protected while performing critical tasks.

Illustrative image related to skull helmet

3 Common User Pain Points for ‘skull helmet’ & Their Solutions

Scenario 1: Sourcing Quality Skull Helmets with Safety Certifications

The Problem: B2B buyers often struggle to find skull helmets that are not only stylish but also meet safety standards. With the proliferation of unregulated products in the market, there is a risk of purchasing helmets that do not comply with necessary safety certifications, like DOT (Department of Transportation) approval. This situation can lead to liability issues and compromised safety for end-users, particularly in regions where safety regulations are strictly enforced. Buyers need assurance that their helmets will protect their customers while also being compliant with local laws.

The Solution: To address this challenge, buyers should prioritize sourcing helmets from manufacturers who can provide verifiable safety certifications. Look for suppliers that explicitly state their compliance with DOT FMVSS 218 standards and offer detailed product specifications. Request samples and conduct thorough inspections to assess quality, fit, and comfort. Engaging in direct communication with manufacturers can provide insights into their production processes and quality control measures. Additionally, consider using third-party testing services to validate the safety claims of potential suppliers, ensuring that the helmets you choose are both fashionable and reliable.

Scenario 2: Addressing Diverse Market Preferences for Skull Helmet Designs

The Problem: In international markets, cultural preferences and regulations can significantly influence helmet design and style. Buyers may find it challenging to cater to a diverse customer base that demands unique aesthetics—such as graphics, colors, and materials—while still adhering to safety standards. This can lead to stock imbalances, where some designs are overstocked while others sell out quickly, impacting overall profitability.

The Solution: Conduct market research to identify the specific preferences of your target audience in different regions. This could involve surveys or focus groups to gather data on desired styles and features. With this information, you can collaborate with manufacturers to create a tailored product line that reflects these preferences. For instance, consider offering limited edition designs that resonate with local cultures or seasonal trends. Furthermore, implementing a just-in-time inventory system can help manage stock levels more effectively, reducing the risk of overproduction and ensuring that you can meet customer demand promptly.

Scenario 3: Ensuring Comfort and Fit for Skull Helmets in Varied Climates

The Problem: Buyers often face challenges in ensuring that the skull helmets they source provide comfort and fit across different climates, especially when dealing with regions that experience extreme heat or humidity. A helmet that is uncomfortable can lead to dissatisfaction among users, ultimately affecting brand loyalty and sales. Additionally, improper fit can compromise the helmet’s protective capabilities.

The Solution: To mitigate this issue, buyers should focus on sourcing helmets that come equipped with adjustable features and ventilation systems. Look for designs that include moisture-wicking liners and removable padding for easy cleaning and adaptability to various weather conditions. Additionally, developing partnerships with suppliers that specialize in ergonomic designs can enhance user comfort. Organizing feedback loops with customers can also provide valuable insights into fit and comfort, allowing you to adjust your offerings based on real-world user experiences. By prioritizing comfort alongside safety, you will improve customer satisfaction and reduce return rates, fostering long-term relationships with your clientele.

Strategic Material Selection Guide for skull helmet

What Are the Key Materials Used in Skull Helmets?

When selecting materials for skull helmets, it’s crucial to consider their properties, advantages, and limitations. The choice of material can significantly affect the helmet’s performance, safety, and marketability. Below, we analyze four common materials used in skull helmets: polycarbonate, fiberglass, carbon fiber, and thermoplastic.

How Does Polycarbonate Perform in Skull Helmet Manufacturing?

Polycarbonate is a thermoplastic polymer known for its high impact resistance and lightweight properties. It can withstand temperatures ranging from -40°C to 120°C, making it suitable for various climates. Polycarbonate helmets are often less expensive to manufacture, which can be a selling point in price-sensitive markets.

Pros:

– High impact resistance and durability.

– Lower manufacturing costs compared to other materials.

– Lightweight, enhancing comfort for the wearer.

Cons:

– Less heat resistance compared to fiberglass or carbon fiber.

– Can scratch more easily, affecting aesthetics over time.

For international buyers, particularly in regions like Africa and South America, polycarbonate helmets must comply with local safety standards, such as the DOT or ECE regulations. Buyers should also consider the climate, as polycarbonate can become brittle in extreme cold.

What Advantages Does Fiberglass Offer for Skull Helmets?

Fiberglass is a composite material that combines glass fibers with resin, resulting in a strong yet lightweight product. It has excellent temperature resistance and can endure high-pressure situations, making it suitable for high-performance applications.

Pros:

– Superior strength-to-weight ratio.

– Excellent temperature and pressure resistance.

– Aesthetic versatility due to the ability to mold into various shapes.

Cons:

– Higher manufacturing costs can limit market competitiveness.

– More complex manufacturing process, requiring skilled labor.

Illustrative image related to skull helmet

For B2B buyers in the Middle East and Europe, fiberglass helmets must meet stringent safety regulations, such as those set by ASTM or DIN. Additionally, the aesthetic appeal of fiberglass allows for customized designs, which can be a significant selling point in competitive markets.

Why Is Carbon Fiber Considered the Premium Choice for Skull Helmets?

Carbon fiber is renowned for its exceptional strength and lightweight properties, making it a premium choice for high-end skull helmets. It has a high-temperature tolerance and excellent resistance to corrosion, ensuring longevity.

Pros:

– Extremely lightweight and strong, enhancing safety.

– Excellent thermal stability and corrosion resistance.

– Can be molded into complex shapes, allowing for innovative designs.

Cons:

– Significantly higher costs, limiting accessibility for some markets.

– Requires specialized manufacturing techniques, increasing complexity.

International buyers, especially those in Europe, often seek carbon fiber helmets for their high-performance capabilities. Compliance with advanced safety standards is essential, and the premium nature of carbon fiber can justify higher price points in affluent markets.

What Role Does Thermoplastic Play in Skull Helmet Production?

Thermoplastic materials, such as ABS (Acrylonitrile Butadiene Styrene), are increasingly popular in helmet manufacturing due to their impact resistance and ease of molding. They can withstand a range of temperatures and are generally more affordable.

Pros:

– Cost-effective and easy to manufacture.

– Good impact resistance and lightweight.

– Versatile for various designs and colors.

Illustrative image related to skull helmet

Cons:

– Lower durability compared to fiberglass and carbon fiber.

– May not meet higher safety standards in some regions.

For buyers in regions like Nigeria and Saudi Arabia, thermoplastic helmets can be a practical choice due to their affordability. However, it’s essential to ensure that they meet local safety standards, as lower-cost options may not always provide adequate protection.

Summary Table of Material Selection for Skull Helmets

| Material | Typical Use Case for skull helmet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Entry-level helmets | Lightweight and cost-effective | Scratches easily | Low |

| Fiberglass | Mid-range helmets | High strength-to-weight ratio | Higher manufacturing cost | Medium |

| Carbon Fiber | Premium helmets | Exceptional strength and lightweight | Very high cost | High |

| Thermoplastic | Budget-friendly helmets | Affordable and easy to mold | Lower durability | Low |

This strategic material selection guide provides a comprehensive overview for B2B buyers in diverse international markets, enabling informed decisions based on material properties, costs, and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for skull helmet

What Are the Key Stages in the Manufacturing Process of Skull Helmets?

The manufacturing process for skull helmets encompasses several critical stages, each designed to ensure that the final product meets safety and aesthetic standards. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used and How Are They Processed?

Skull helmets are typically constructed using advanced materials such as polycarbonate, fiberglass, and carbon fiber. These materials are selected for their lightweight properties and high-impact resistance. The preparation phase involves sourcing raw materials from verified suppliers, conducting material inspections, and ensuring compliance with relevant standards. Manufacturers often use computer-aided design (CAD) software to create precise specifications for the helmet components, ensuring uniformity in production.

How Are Skull Helmets Formed and Shaped?

The forming stage is where raw materials are shaped into the helmet structure. This typically involves molding processes, such as injection molding for polycarbonate shells or hand lay-up techniques for fiberglass and carbon fiber helmets. The use of molds ensures that each helmet meets the specified dimensions and safety standards. Advanced techniques such as vacuum forming can also be employed to enhance the structural integrity of the helmet.

What Assembly Techniques Are Utilized in Skull Helmet Production?

Assembly is a crucial stage in the manufacturing process, where various components of the helmet are put together. This includes attaching the inner padding, straps, and visors, if applicable. Skilled workers or automated systems conduct this assembly to ensure that all parts fit securely and function as intended. Quality assurance checkpoints are integrated throughout the assembly process, allowing for immediate identification and rectification of any issues.

What Finishing Processes Enhance the Quality of Skull Helmets?

The finishing stage involves applying surface treatments, painting, and decals to enhance both the aesthetic appeal and durability of the helmet. This may include UV-resistant coatings to protect against sun damage and chemical treatments to prevent scratches. Each helmet undergoes a final inspection to ensure that it meets quality and design specifications before packaging.

How Is Quality Assurance Implemented in Skull Helmet Manufacturing?

Quality assurance (QA) is integral to the helmet manufacturing process, ensuring that each product adheres to both international standards and customer expectations. Manufacturers typically implement a multi-tiered QA system that includes several checkpoints throughout production.

What International Standards Govern Skull Helmet Production?

International standards such as ISO 9001 play a pivotal role in establishing a framework for quality management systems. Compliance with these standards ensures that manufacturers consistently produce products that meet customer and regulatory requirements. Additionally, specific certifications such as DOT (Department of Transportation) in the USA and ECE (Economic Commission for Europe) provide guidelines for safety and performance that skull helmets must meet to be marketed in various regions.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are established at various stages of production, including:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet the required specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help detect and address defects in real-time.

- Final Quality Control (FQC): A thorough examination of the finished product ensures that it meets all safety and quality standards before distribution.

What Testing Methods Are Commonly Used in Skull Helmet Quality Assurance?

Manufacturers employ various testing methods to verify the safety and performance of skull helmets. These may include:

- Impact Testing: Evaluates how well the helmet withstands force during an accident.

- Penetration Testing: Assesses the helmet’s ability to resist sharp objects.

- Retention System Testing: Ensures that straps and buckles can hold the helmet in place during an impact.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Buyers can take several steps to ensure compliance and quality:

Illustrative image related to skull helmet

- Conduct Supplier Audits: Regular audits of manufacturing facilities can provide insights into the supplier’s adherence to quality standards.

- Request Quality Assurance Documentation: Suppliers should provide detailed QA reports, including test results and compliance certifications.

- Engage Third-party Inspection Services: Utilizing independent inspection agencies can offer an unbiased assessment of product quality and manufacturing practices.

What Are the Nuances of Quality Control for International Buyers?

When sourcing skull helmets from manufacturers in different regions, buyers should be aware of specific nuances related to quality control. For example, variations in regulatory requirements across countries may affect product specifications and certifications. It is essential for buyers to understand local regulations, particularly in regions like Nigeria or Saudi Arabia, where compliance with national safety standards may differ from those in Europe or the Americas.

Conclusion: Prioritizing Quality in Skull Helmet Manufacturing

In the competitive landscape of skull helmet manufacturing, understanding the intricacies of production processes and quality assurance is vital for B2B buyers. By focusing on verified manufacturing practices, compliance with international standards, and robust quality control measures, buyers can ensure they partner with reliable suppliers who provide safe, high-quality products that meet the demands of their markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘skull helmet’

When sourcing skull helmets for your business, it is essential to approach the process methodically. This guide provides a step-by-step checklist to help you navigate the complexities of procurement, ensuring you select high-quality products that meet your operational needs.

Step 1: Define Your Technical Specifications

Before you begin sourcing, clarify the specific features and standards your helmets must meet. This includes understanding the required certifications, such as DOT approval, which ensures compliance with safety regulations. Identify the design preferences, such as half-shell versus full-face styles, and any additional features like inner shields or ventilation systems.

- Consider regional preferences: Different markets may have unique style or safety requirements, so tailor your specifications accordingly.

Step 2: Research Market Trends

Stay informed about the latest trends in helmet design and technology. This knowledge will not only help you understand customer preferences but also guide you in selecting suppliers who are innovative and forward-thinking.

Illustrative image related to skull helmet

- Analyze competitors: Look at what successful companies in your region are offering. This can provide insight into popular designs and features that resonate with buyers.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your specifications and standards. Request detailed company profiles, including their production capabilities, quality assurance processes, and any relevant certifications.

- Check references: Ask for case studies or testimonials from other B2B clients in similar industries or regions to gauge their reliability.

Step 4: Request Samples

Always request samples before placing a bulk order. This step is crucial for assessing the product quality firsthand. Examine the craftsmanship, materials, and comfort of the helmets to ensure they align with your specifications.

- Conduct safety tests: If possible, perform impact tests or other safety evaluations to ensure compliance with safety standards.

Step 5: Negotiate Pricing and Terms

Engage in negotiations to secure the best pricing and terms for your procurement. Understanding the market price for skull helmets can provide leverage during negotiations.

- Consider bulk discounts: Many suppliers offer better rates for larger orders, so outline your expected purchase volume upfront.

Step 6: Confirm Shipping and Delivery Details

Establish clear shipping and delivery expectations with your supplier. Confirm lead times and shipping methods to ensure timely delivery, especially if you are working with tight deadlines.

Illustrative image related to skull helmet

- Discuss logistics: Clarify who bears the responsibility for shipping costs and customs duties, particularly for international transactions.

Step 7: Monitor Compliance and Quality Post-Purchase

After procurement, continuously monitor product quality and compliance with safety standards. Establish a feedback loop with your customers to identify any issues and address them promptly.

- Implement quality checks: Regularly assess the helmets you receive against your initial specifications to ensure ongoing quality and safety compliance.

By following this checklist, B2B buyers can streamline their sourcing process for skull helmets, ensuring they make informed decisions that lead to successful procurement outcomes.

Comprehensive Cost and Pricing Analysis for skull helmet Sourcing

What Are the Key Cost Components in Skull Helmet Sourcing?

When sourcing skull helmets, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. Common materials for skull helmets include polycarbonate, fiberglass, and carbon fiber. While carbon fiber offers enhanced durability and weight savings, it is considerably more expensive than traditional options.

-

Labor: Labor costs vary depending on the manufacturing location. Countries with lower labor costs may offer competitive pricing, but this can sometimes compromise quality. It’s essential to assess the skill level of the workforce and the labor conditions in the supplier’s country.

-

Manufacturing Overhead: This encompasses costs related to factory operations, including utilities, equipment maintenance, and rent. Efficient manufacturing practices can help reduce overhead costs, which can be reflected in the final pricing.

-

Tooling: Custom tooling for unique designs or specifications can add significant upfront costs. Buyers should consider whether the tooling cost can be amortized over large production runs to make it more cost-effective.

-

Quality Control (QC): Implementing stringent QC measures ensures that helmets meet safety standards, such as DOT approval. While this may add to the initial cost, it protects against future liabilities and enhances brand reputation.

-

Logistics: Shipping costs can vary dramatically based on the origin of the helmets and the chosen Incoterms. Understanding the logistics involved, including tariffs and shipping times, is vital for calculating the total landed cost.

-

Margin: Suppliers typically have a markup that reflects their business model, market positioning, and competitiveness. It’s advisable to understand the margin expectations of different suppliers to negotiate effectively.

How Do Price Influencers Affect Skull Helmet Sourcing?

Several factors influence the pricing of skull helmets in the international market:

-

Volume/MOQ (Minimum Order Quantity): Ordering in larger quantities often results in discounted prices. Buyers should assess their demand forecasts to negotiate favorable terms.

-

Specifications and Customization: Custom designs or additional features, such as built-in visors or unique graphics, can increase costs. Buyers should weigh the benefits of customization against the potential price increase.

-

Materials Quality and Certifications: Helmets that meet stringent safety certifications often come at a premium. Buyers should prioritize quality certifications that align with their market requirements to ensure compliance and safety.

-

Supplier Factors: The reputation and reliability of suppliers can significantly impact pricing. Established suppliers may charge more due to their brand reputation but may also provide better service and quality assurance.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) affects the cost structure by determining who is responsible for shipping and insurance. Understanding these terms can help buyers manage their overall costs effectively.

What Are the Best Buyer Tips for Cost-Efficiency in Skull Helmet Sourcing?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies for cost-effective sourcing:

-

Negotiation: Engaging in open negotiations can yield better pricing and terms. Establishing long-term relationships with suppliers can also lead to better deals over time.

-

Total Cost of Ownership (TCO): Beyond the initial purchase price, buyers should calculate the TCO, which includes shipping, customs duties, storage, and potential warranty costs. This comprehensive view helps in making more informed decisions.

-

Pricing Nuances: Buyers should be aware that prices can fluctuate based on market conditions, currency exchange rates, and geopolitical factors. Staying informed about these variables can aid in timing purchases strategically.

-

Market Research: Conducting thorough market research on suppliers, materials, and pricing trends can provide leverage during negotiations and help identify the best sourcing options.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on market fluctuations, supplier negotiations, and regional factors. Always conduct due diligence and seek quotes from multiple suppliers to obtain the most accurate pricing.

Alternatives Analysis: Comparing skull helmet With Other Solutions

Understanding Alternatives to Skull Helmets

When considering protective headgear for motorcyclists and riders of various vehicles, evaluating alternatives to skull helmets is essential for making informed purchasing decisions. While skull helmets offer unique benefits, there are other solutions that may better meet the needs of specific user groups based on performance, cost, and other factors. This analysis compares the skull helmet against two viable alternatives: full-face helmets and modular helmets.

| Comparison Aspect | Skull Helmet | Full-Face Helmet | Modular Helmet |

|---|---|---|---|

| Performance | Lightweight; minimal protection | Maximum coverage; excellent impact protection | Versatile; offers both full and open-face options |

| Cost | Generally lower ($50 – $100) | Mid-range ($100 – $300) | Higher ($150 – $400) |

| Ease of Implementation | Simple design; easy to wear | Slightly heavier; requires adjustment | Adjustable; may require more time to fit |

| Maintenance | Low maintenance; easy to clean | Moderate maintenance; requires regular inspection | Moderate maintenance; moving parts may need attention |

| Best Use Case | Cruising, leisurely rides | Racing, long-distance travel | Commuting, variable riding conditions |

What Are the Advantages and Disadvantages of Full-Face Helmets?

Full-face helmets provide the highest level of protection due to their design, covering the entire head, face, and chin. They are ideal for high-speed riding and long-distance travel where impact protection is paramount. However, they can be bulkier and heavier, which may not appeal to all riders. The cost of full-face helmets can also be significantly higher compared to skull helmets, which might be a consideration for budget-conscious buyers.

How Do Modular Helmets Compare to Skull Helmets?

Modular helmets offer flexibility, allowing riders to switch between a full-face and an open-face configuration. This adaptability is particularly useful for those who commute in varying conditions or prefer the option of increased ventilation. However, modular helmets are typically more expensive and may require more maintenance due to their moving parts. Additionally, the weight can be an issue for some riders, particularly during long rides.

Conclusion: Which Headgear Solution Should B2B Buyers Choose?

Selecting the right headgear ultimately depends on the specific needs and preferences of the rider or the end-user. For businesses catering to a diverse customer base, offering a range of helmets, including skull helmets, full-face, and modular options, can meet varying demands. Skull helmets are perfect for casual riders who prioritize style and comfort, while full-face helmets cater to those needing maximum safety. Modular helmets serve as a middle ground, appealing to those looking for versatility. Understanding these options allows B2B buyers to align their offerings with customer expectations, ensuring satisfaction and safety across their product range.

Illustrative image related to skull helmet

Essential Technical Properties and Trade Terminology for skull helmet

What Are the Key Technical Properties of Skull Helmets?

When considering the procurement of skull helmets, understanding their technical properties is crucial for ensuring product safety, compliance, and customer satisfaction. Here are the essential specifications to evaluate:

1. Material Composition

The materials used in skull helmets often include high-density polycarbonate, fiberglass, and carbon fiber. Each material offers varying levels of impact resistance, weight, and comfort. For instance, carbon fiber is lighter and stronger but may come at a higher price point. B2B buyers should assess material properties to balance cost with performance requirements, especially in regions where safety regulations are stringent.

2. Safety Certification Standards

Skull helmets must meet specific safety standards, such as the Department of Transportation (DOT) certification in the U.S. or the Economic Commission for Europe (ECE) standards in Europe. Compliance with these standards ensures that the helmets provide adequate protection during accidents. B2B buyers should prioritize products that carry these certifications to reduce liability risks and enhance brand reputation.

3. Size and Fit Tolerances

Proper sizing and fit are critical for the effectiveness of a helmet. Manufacturers often provide detailed sizing charts, and helmets should accommodate a range of head sizes. Tolerances in manufacturing processes should be minimal to ensure that each helmet fits snugly without being uncomfortable. This aspect is particularly important for retailers aiming to minimize returns due to sizing issues.

4. Weight

The weight of a skull helmet can significantly affect rider comfort and usability. Lighter helmets, typically made from advanced materials like carbon fiber, are preferable for long rides. However, buyers must ensure that weight savings do not compromise safety. Understanding weight specifications can help buyers select products that enhance user experience without sacrificing protection.

Illustrative image related to skull helmet

5. Ventilation Systems

Effective ventilation is vital for rider comfort, especially in warmer climates. Helmets equipped with ventilation systems help regulate temperature and reduce moisture build-up. B2B buyers should inquire about the design and effectiveness of ventilation features to meet consumer needs, particularly in regions with high temperatures.

6. Visor Options

Some skull helmets come with integrated visors or the option for aftermarket visors. These can include tinted, anti-fog, or retractable visors. The presence of a visor can enhance functionality and safety by protecting the eyes from debris and UV rays. Buyers should assess the visor options available and their compatibility with the helmets to offer comprehensive solutions to end-users.

What Are Common Trade Terms in the Skull Helmet Industry?

Navigating the skull helmet market also involves understanding key trade terminology. Here are some essential terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the skull helmet industry, buyers may source helmets from OEMs to offer branded products without the need for in-house manufacturing. Understanding OEM relationships can enhance supply chain efficiency.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum quantity that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory management and cash flow. Buyers should negotiate MOQs that align with their sales forecasts to optimize their purchasing strategy.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers. In the skull helmet market, submitting an RFQ can help buyers compare prices, specifications, and delivery terms from multiple suppliers, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers involved in cross-border purchases of skull helmets, as they determine who is responsible for shipping, insurance, and tariffs.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. In the skull helmet industry, understanding lead times is vital for planning inventory levels and meeting customer demand. Buyers should discuss lead times with suppliers to ensure timely delivery.

6. Certification Mark

A certification mark indicates that a product meets specific safety standards. In the context of skull helmets, certification marks (like DOT or ECE) provide assurance to B2B buyers about the safety and reliability of the helmets being sourced.

Illustrative image related to skull helmet

Navigating Market Dynamics and Sourcing Trends in the skull helmet Sector

What Are the Key Market Dynamics and Trends in the Skull Helmet Sector?

The skull helmet market is experiencing significant growth driven by several global factors. Increasing motorcycle usage across regions such as Africa, South America, and the Middle East, coupled with a rising interest in motorcycle culture, fuels demand. Regulatory frameworks worldwide are tightening, requiring helmets to meet stringent safety standards, such as DOT and ECE certifications. This compliance not only bolsters consumer confidence but also emphasizes the importance of sourcing high-quality products that adhere to these regulations.

Emerging technologies in manufacturing, such as 3D printing and smart helmet innovations, are reshaping the sourcing landscape. B2B buyers are increasingly looking for suppliers who can provide customizable options and advanced safety features, such as integrated communication systems and impact sensors. Additionally, the rise of e-commerce platforms enables international buyers to access a broader range of products and suppliers, facilitating more competitive pricing and varied inventory.

Market dynamics are also influenced by shifting consumer preferences. Today’s buyers are inclined towards stylish designs and lightweight materials, such as carbon fiber, which enhance comfort without compromising safety. Understanding these trends is crucial for international B2B buyers who aim to remain competitive in the evolving marketplace.

How Is Sustainability and Ethical Sourcing Reshaping the Skull Helmet Industry?

Sustainability is becoming a cornerstone of the skull helmet sector, as both consumers and businesses increasingly prioritize environmentally friendly practices. The environmental impact of manufacturing processes, particularly in terms of material sourcing and waste generation, is under scrutiny. B2B buyers are now seeking suppliers that incorporate sustainable materials, such as recycled plastics and bio-based composites, into their products.

Illustrative image related to skull helmet

The importance of ethical supply chains cannot be overstated. Buyers are urged to partner with manufacturers who demonstrate transparency in their sourcing practices, ensuring fair labor conditions and responsible resource management. Certifications such as ISO 14001 (Environmental Management) and Fair Trade are becoming valuable indicators of a supplier’s commitment to sustainability and ethical practices.

Furthermore, the demand for ‘green’ certifications and environmentally friendly materials is influencing product design and marketing strategies. Suppliers who can showcase their sustainable practices are likely to gain a competitive edge, as consumers increasingly favor brands that align with their values. B2B buyers must therefore consider not only the product specifications but also the ethical implications of their sourcing decisions.

What Is the Brief Evolution and History of Skull Helmets in the B2B Context?

The skull helmet, originally designed for minimalistic protection, has evolved significantly since its inception. Initially favored by motorcycle enthusiasts for its lightweight design and aesthetic appeal, the helmet has undergone substantial advancements in safety technology and materials. The introduction of rigorous safety standards, such as DOT and ECE regulations, has transformed it into a necessary safety gear rather than just a style statement.

As motorcycle culture expanded globally, particularly in regions like Africa and South America, the demand for compliant and stylish helmets surged. Manufacturers responded by innovating with new materials and designs, leading to the diverse range of skull helmets available today. This evolution is not only relevant for consumer safety but also presents B2B opportunities for suppliers to differentiate themselves through quality and compliance, catering to a market that increasingly values both style and protection.

Frequently Asked Questions (FAQs) for B2B Buyers of skull helmet

-

1. How do I choose the right skull helmet supplier for my business?

When selecting a skull helmet supplier, prioritize those with a proven track record in quality and compliance with safety standards, such as DOT certification. Research their reputation through reviews, industry associations, and previous client testimonials. Engage in direct communication to assess their responsiveness and willingness to accommodate your specific needs. Additionally, request product samples to evaluate quality firsthand before committing to larger orders. -

2. What is the best skull helmet design for motorcycle safety?

The best skull helmet design for motorcycle safety combines a lightweight structure with a low profile for comfort and aerodynamics. Look for helmets that are DOT-approved and feature a robust outer shell material, such as fiberglass or carbon fiber, for maximum protection. Additionally, models with inner padding for comfort and ventilation will enhance the rider’s experience. Consider styles that also include visors or shields to protect against debris and UV exposure. -

3. What are the typical minimum order quantities (MOQs) for skull helmets?

Minimum order quantities (MOQs) for skull helmets can vary significantly based on the manufacturer and the complexity of the design. Generally, MOQs range from 100 to 500 units for standard designs, while custom designs may require higher quantities. It’s crucial to discuss MOQs with potential suppliers to understand their production capabilities and to align them with your business needs, especially if you are targeting specific markets. -

4. How can I customize skull helmets for my brand?

Customizing skull helmets typically involves selecting specific colors, graphics, and branding elements such as logos and labels. Many manufacturers offer customization options; thus, it’s important to discuss your vision with them early in the negotiation process. Ensure that the supplier can meet your design specifications while maintaining safety standards. Request prototypes before finalizing the order to ensure the quality and appearance meet your expectations. -

5. What payment terms should I expect when sourcing skull helmets internationally?

Payment terms for international orders can vary widely, but common practices include a deposit (typically 30-50%) upfront with the balance due upon shipment or delivery. Some suppliers may offer letters of credit or escrow services for larger transactions to protect both parties. It’s essential to clarify payment terms before placing orders and to consider the implications of currency fluctuations in international trade. -

6. How do I ensure quality assurance for skull helmets?

To ensure quality assurance for skull helmets, partner with suppliers who adhere to recognized safety standards, such as DOT or ECE certifications. Conduct regular audits and inspections during the manufacturing process and request detailed reports of quality checks. Additionally, consider implementing a third-party quality assurance service to verify product specifications and compliance before shipment, ensuring that the helmets meet your standards. -

7. What logistics considerations should I keep in mind when importing skull helmets?

When importing skull helmets, consider logistics factors such as shipping costs, customs regulations, and lead times. It’s advisable to work with a freight forwarder who understands the specific requirements of transporting helmets across borders. Ensure that all necessary documentation, such as bills of lading and customs declarations, is prepared to avoid delays. Additionally, factor in the time required for customs clearance in your delivery schedule. -

8. What are the trends in skull helmet designs for international markets?

Current trends in skull helmet designs for international markets include lightweight materials, eco-friendly production processes, and customizable graphics that cater to local tastes. Popular styles often feature retro and minimalist aesthetics, appealing to a broad range of riders. Additionally, helmets with advanced safety features, such as integrated communication systems or enhanced ventilation, are gaining traction. Understanding local preferences can help tailor your offerings to specific markets effectively.

Top 1 Skull Helmet Manufacturers & Suppliers List

1. Skull Helmets – Key Product Details

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Key product details for Skull Helmets on eBay include:

– Size Types: XS, S, M, L, XL, XXL, 3XL, 4XL, XXS

– Types: Full Face, Half Helmet, Modular, Open Face, Off-Road, Dual Sport, Vintage, Convertible

– Colors: Black, White, Red, Multicolor, Blue, Yellow, Green, Pink, Orange, Silver

– Brands: Harley-Davidson, SHOEI, Bell, HJC, LS2, Arai, AGV, Icon, Scorpion, Fly Racing, Shark, Fox Racing, Nolan, D…

Strategic Sourcing Conclusion and Outlook for skull helmet

What Are the Key Takeaways for B2B Buyers in the Skull Helmet Market?

In the evolving landscape of skull helmets, strategic sourcing remains paramount for international buyers seeking to maximize value and ensure compliance with safety standards. Emphasizing the importance of sourcing D.O.T.-approved helmets, companies must prioritize suppliers who not only meet regulatory requirements but also offer diverse product options, such as various styles and materials, to cater to different market segments. By leveraging strategic sourcing, businesses can enhance their product offerings while ensuring customer safety and satisfaction.

How Can B2B Buyers Prepare for Future Trends in Skull Helmets?

As global markets expand, particularly in regions like Africa, South America, the Middle East, and Europe, there is an increasing demand for innovative designs and sustainable materials in motorcycle safety gear. Buyers should stay ahead of trends by investing in suppliers who prioritize eco-friendly practices and cutting-edge technology. This proactive approach not only positions businesses favorably in competitive markets but also meets the growing consumer demand for environmentally conscious products.

Why Is It Time to Act on Strategic Sourcing for Skull Helmets?

The skull helmet market presents lucrative opportunities for those ready to adapt and innovate. International B2B buyers, especially from emerging markets, should take actionable steps towards establishing strong supplier relationships that align with their strategic goals. By doing so, they can secure a competitive edge, ensuring they meet the needs of an increasingly safety-conscious consumer base. Engage with suppliers today to explore options that not only fulfill current demands but also anticipate future market shifts.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.