Everything You Need to Know About Single Round Electrical Outlet Sourcing in 2025

Introduction: Navigating the Global Market for single round electrical outlet

In today’s global marketplace, sourcing the right single round electrical outlet can be a daunting task for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. The challenge lies in not only identifying the appropriate product type but also ensuring compliance with local regulations, understanding varying installation standards, and navigating a complex supply chain. This guide aims to demystify the process by providing a comprehensive overview of the different types of single round electrical outlets available, their applications across various industries, and best practices for supplier vetting.

Buyers will gain insights into the specifications and functionalities of these outlets, such as in-cabinet installations and recessed options, which are increasingly favored for their aesthetic appeal and space-saving designs. Additionally, we will explore the cost factors involved, helping you to budget effectively and make informed purchasing decisions. By equipping international B2B buyers with the necessary knowledge and resources, this guide empowers you to navigate the intricacies of sourcing single round electrical outlets confidently.

With a focus on practical solutions, this guide is designed to enhance your procurement strategy, ensuring that you choose products that not only meet your operational needs but also align with regional compliance and quality standards. Join us as we delve into the essential aspects of the single round electrical outlet market, tailored to your specific geographic and industry contexts.

Understanding single round electrical outlet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Sillites In-Cabinet Outlet | 2″ diameter, paintable cover, self-contained, easy installation | Residential and commercial cabinetry, kitchens | Pros: Space-saving, aesthetically pleasing; Cons: Limited to specific applications, lower power capacity. |

| Recessed Floor Outlet | Flush-mounted, available in various materials and finishes | Office spaces, conference rooms, retail environments | Pros: Discreet installation, customizable; Cons: Installation complexity, potential higher costs. |

| Standard Round Power Socket | Commonly used, typically 3″ or larger diameter | General-purpose applications, homes, offices | Pros: Versatile, widely available; Cons: Bulky, may require more space for installation. |

| In-Floor Electrical Outlet | Designed for flush mounting in floors, accommodates data options | Event spaces, auditoriums, commercial buildings | Pros: Efficient use of space, multi-functional; Cons: Installation can be disruptive, maintenance challenges. |

| Decorative Round Floor Box | Available in various finishes, often includes flip lids | High-end residential, hospitality design | Pros: Enhances aesthetics, durable; Cons: Higher price point, limited to premium markets. |

What are the Characteristics of Sillites In-Cabinet Outlets?

Sillites In-Cabinet Outlets are compact, measuring only 2 inches in diameter, making them ideal for installations where space is at a premium. Their paintable covers allow them to blend seamlessly into cabinetry, which is a significant advantage in kitchen and cabinet design. These outlets are particularly suitable for residential and commercial cabinetry applications, providing a neat solution for power access in tight spaces. B2B buyers should consider their limited power capacity and specific installation requirements, which may not suit all environments.

How Do Recessed Floor Outlets Differ from Other Types?

Recessed Floor Outlets are designed for flush mounting, providing a sleek and unobtrusive power solution. Available in various materials such as brass, aluminum, and nickel, they cater to aesthetic preferences and durability needs. These outlets are commonly used in office spaces and retail environments, allowing for clean lines and minimizing trip hazards. B2B buyers should be aware of the potential complexity in installation and the need for compatibility with existing flooring materials.

Why Choose Standard Round Power Sockets for General Use?

Standard Round Power Sockets are the most widely recognized and used outlets, typically featuring a diameter of 3 inches or more. They serve general-purpose applications in homes and offices, offering versatility and ease of availability. While they provide reliable power access, their bulkiness can be a drawback, requiring more space for installation. For B2B buyers, understanding the balance between versatility and installation space is crucial for effective procurement.

What Makes In-Floor Electrical Outlets Ideal for Commercial Spaces?

In-Floor Electrical Outlets are designed to be mounted within floors, providing a discreet and efficient power source. These outlets often accommodate both power and data connections, making them particularly useful in event spaces and commercial buildings. Their ability to maximize floor space while providing necessary electrical access is a key selling point. However, B2B buyers should consider the potential disruption during installation and the ongoing maintenance needs of such systems.

How Do Decorative Round Floor Boxes Enhance Aesthetics?

Decorative Round Floor Boxes are designed with aesthetics in mind, often featuring high-quality finishes and flip lids. These outlets are ideal for high-end residential and hospitality applications, where design plays a critical role. While they enhance the overall look of a space, they typically come at a higher price point, making them suitable for premium markets. B2B buyers should weigh the benefits of aesthetics against budget considerations when selecting these products.

Illustrative image related to single round electrical outlet

Key Industrial Applications of single round electrical outlet

| Industry/Sector | Specific Application of single round electrical outlet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Installation in hotel rooms and conference areas | Enhances guest experience with accessible power sources | Compliance with local electrical codes and safety standards |

| Retail | Point-of-sale systems and display units | Improves customer service by providing charging options | Aesthetic design options for branding and visibility |

| Commercial Offices | Workstations and meeting rooms | Supports modern work habits with convenient access to power | Durability and compatibility with existing furniture |

| Residential Construction | Kitchen islands and cabinetry | Maximizes space efficiency while maintaining aesthetics | Easy installation and color matching with cabinetry |

| Education | Classrooms and lecture halls | Facilitates technology integration in learning environments | Robustness and safety features to withstand heavy use |

How is the Single Round Electrical Outlet Used in Hospitality Settings?

In the hospitality industry, single round electrical outlets are strategically installed in hotel rooms and conference areas to provide guests with easy access to power for charging devices. This not only enhances the guest experience but also increases the hotel’s appeal in a competitive market. Buyers in this sector should ensure that the outlets comply with local electrical codes and safety standards to prevent electrical hazards and maintain a high level of service.

What Role Does the Single Round Electrical Outlet Play in Retail Environments?

In retail environments, single round electrical outlets are essential for powering point-of-sale systems and display units. They enable retailers to provide charging stations for customers, improving overall service and potentially increasing sales through enhanced customer engagement. When sourcing these outlets, businesses should consider aesthetic design options that blend seamlessly with their branding while ensuring reliability and ease of installation.

How Does the Single Round Electrical Outlet Enhance Commercial Office Spaces?

In commercial offices, single round electrical outlets are installed at workstations and in meeting rooms to support modern work habits that require frequent device charging. They provide convenient access to power, reducing clutter from extension cords and improving the overall workspace organization. Buyers should prioritize outlets that are durable and compatible with existing office furniture to ensure seamless integration.

Why Are Single Round Electrical Outlets Important in Residential Construction?

In residential construction, particularly in kitchens, single round electrical outlets are installed in cabinetry and kitchen islands to maximize space efficiency while maintaining a clean and aesthetic look. These outlets allow homeowners to charge appliances without sacrificing design. Buyers in this sector should look for easy installation options and color matching capabilities to ensure that the outlets complement the cabinetry seamlessly.

How Are Single Round Electrical Outlets Utilized in Educational Institutions?

In educational settings, single round electrical outlets are installed in classrooms and lecture halls to facilitate the integration of technology into learning environments. They provide students and teachers with easy access to power for laptops and other devices, enhancing the learning experience. When sourcing for educational institutions, it is crucial to consider the robustness and safety features of the outlets, as they will be subjected to heavy use.

3 Common User Pain Points for ‘single round electrical outlet’ & Their Solutions

Scenario 1: Complicated Installations in Tight Spaces

The Problem: B2B buyers often encounter challenges when trying to install electrical outlets in confined or uniquely designed spaces, such as kitchen islands, cabinets, or home office setups. Traditional outlets require extensive installation work, often necessitating the use of a junction box, which can be cumbersome and time-consuming. This complexity can lead to increased labor costs and project delays, frustrating both contractors and end-users.

The Solution: To overcome these installation challenges, sourcing single round electrical outlets, like the Sillites In-Cabinet Outlets, can be highly effective. These compact 2-inch diameter outlets are designed for easy installation in areas where conventional outlets cannot fit. They require only a 1.75-inch hole, eliminating the need for a junction box. B2B buyers should ensure that their suppliers offer outlets with a matching cover that can be painted to blend seamlessly into the surrounding cabinetry or walls. By utilizing these outlets, buyers can simplify the installation process, reduce labor costs, and enhance the overall aesthetic of the space without compromising functionality.

Scenario 2: Aesthetic Discrepancies in High-End Projects

The Problem: In high-end residential or commercial projects, maintaining a sleek and modern aesthetic is paramount. Traditional outlets can detract from the design, especially in open-concept spaces or luxury interiors. Buyers often struggle to find electrical solutions that provide both functionality and visual appeal, leading to compromises that can affect the project’s success and client satisfaction.

Illustrative image related to single round electrical outlet

The Solution: Opting for single round electrical outlets can address these aesthetic concerns effectively. These outlets are available in multiple finishes and can be painted to match the surrounding surfaces, making them an ideal choice for upscale projects. When specifying these outlets, B2B buyers should consider the color and material options available, such as black, white, or brown, and select those that align with the design vision. Furthermore, leveraging recessed or flush-mount configurations allows for a clean finish that complements modern interiors. By prioritizing these design-friendly options, buyers can elevate their projects while satisfying client expectations.

Scenario 3: Compliance with Local Electrical Codes

The Problem: Electrical regulations can vary significantly by region, and B2B buyers must navigate these complexities when sourcing electrical components like single round outlets. Non-compliance can lead to project delays, costly fines, and safety hazards. Buyers often face the challenge of ensuring that their chosen products meet the specific code requirements of the countries or regions where they are operating.

The Solution: To mitigate compliance risks, B2B buyers should engage with suppliers who provide comprehensive documentation and certification for their single round electrical outlets. Buyers should verify that the products meet local safety standards and electrical codes, which may include certifications such as UL, CE, or IEC. Additionally, maintaining close communication with local electrical authorities or hiring compliance consultants can provide clarity on the requirements that need to be met. By ensuring that sourced products are compliant, buyers can safeguard their projects against legal ramifications and ensure a safer installation process, ultimately leading to a smoother project execution and enhanced client trust.

Strategic Material Selection Guide for single round electrical outlet

When selecting materials for single round electrical outlets, several factors come into play, including performance characteristics, manufacturing complexity, and compliance with international standards. This guide analyzes four common materials used in the production of these outlets: thermoplastics, metals, ceramics, and composites. Each material presents distinct advantages and disadvantages that can significantly impact application suitability and buyer decision-making.

What Are the Key Properties of Thermoplastics in Electrical Outlets?

Thermoplastics, such as polycarbonate and nylon, are widely used in electrical outlet manufacturing due to their excellent electrical insulation properties and resistance to impact and chemicals. They typically operate effectively at temperatures up to 85°C and can withstand moderate pressure.

Pros: Thermoplastics are lightweight, cost-effective, and easy to mold, which simplifies the manufacturing process. They also offer good durability against environmental factors, making them suitable for various applications.

Cons: However, thermoplastics can be less durable than metals in high-stress environments and may degrade over time when exposed to UV light or extreme temperatures.

Impact on Application: Thermoplastics are ideal for indoor applications where exposure to harsh conditions is minimal. They are compatible with standard electrical media but may not be suitable for high-voltage applications.

Considerations for International Buyers: Compliance with standards such as IEC and UL is crucial. Buyers should ensure that the thermoplastic materials used meet local safety regulations, especially in regions like Europe and North America.

How Do Metals Enhance the Performance of Electrical Outlets?

Metals, particularly brass and aluminum, are often chosen for their exceptional conductivity and strength. Brass, for instance, has a high-temperature rating and excellent corrosion resistance, making it suitable for outdoor applications.

Pros: The durability and reliability of metal outlets make them ideal for high-load applications. They are also resistant to wear and can withstand harsh environmental conditions.

Cons: The main drawback is the higher cost and weight compared to thermoplastics. Additionally, metals can corrode if not properly treated, which may lead to performance issues over time.

Impact on Application: Metal outlets are suitable for both indoor and outdoor use, particularly in industrial settings where high electrical loads are common.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is essential, especially in regions like Germany and Brazil, where specific material certifications may be required.

Illustrative image related to single round electrical outlet

What Role Do Ceramics Play in Electrical Outlet Manufacturing?

Ceramics are known for their high-temperature resistance and excellent dielectric properties. They can withstand temperatures exceeding 1000°C, making them suitable for specialized applications.

Pros: Ceramics are highly durable and resistant to thermal shock and chemical corrosion, which makes them ideal for high-performance environments.

Cons: The main limitations include their brittleness, which can lead to breakage under mechanical stress, and their higher manufacturing costs.

Impact on Application: Ceramics are often used in high-temperature environments, such as industrial settings where electrical outlets are exposed to extreme conditions.

Considerations for International Buyers: Buyers should ensure that ceramic materials comply with international standards for electrical safety and performance, particularly in regions with stringent regulations.

How Do Composites Improve Versatility in Electrical Outlets?

Composite materials, which combine properties of plastics and metals, offer a balance of durability, insulation, and weight. They can be engineered to meet specific performance criteria, making them versatile for various applications.

Pros: Composites are lightweight, resistant to corrosion, and can be tailored for specific electrical and mechanical properties, enhancing their suitability for diverse environments.

Cons: The complexity of manufacturing composites can lead to higher costs and longer production times compared to traditional materials.

Impact on Application: Composites are suitable for applications requiring a combination of strength and insulation, such as in residential and commercial settings.

Illustrative image related to single round electrical outlet

Considerations for International Buyers: Compliance with international standards and certifications is critical, particularly in regions like Africa and the Middle East, where safety regulations may vary.

Summary Table of Material Selection for Single Round Electrical Outlets

| Material | Typical Use Case for single round electrical outlet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastics | Indoor residential applications | Lightweight and cost-effective | Less durable under extreme conditions | Low |

| Metals | Industrial and outdoor applications | High durability and conductivity | Higher cost and potential for corrosion | High |

| Ceramics | High-temperature industrial environments | Excellent thermal and chemical resistance | Brittle and higher manufacturing costs | Medium |

| Composites | Versatile applications in residential/commercial | Tailored properties and lightweight | Higher complexity and cost of production | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various materials used in single round electrical outlets, facilitating informed purchasing decisions tailored to specific application needs.

In-depth Look: Manufacturing Processes and Quality Assurance for single round electrical outlet

What Are the Key Stages in the Manufacturing Process of Single Round Electrical Outlets?

The manufacturing of single round electrical outlets involves several critical stages, each essential for ensuring that the final product meets quality and safety standards.

Material Preparation: What Raw Materials Are Used?

The process begins with the careful selection of materials. Most single round electrical outlets are made from durable thermoplastics for the outer casing and copper or brass for the electrical components. These materials are chosen for their excellent insulating properties and conductivity, respectively. Suppliers must ensure that the raw materials comply with relevant international standards, such as RoHS (Restriction of Hazardous Substances), which limits the use of specific hazardous materials in electrical and electronic equipment.

How Are Electrical Outlets Formed?

Once the materials are prepared, the next stage involves forming the components of the outlet. This typically includes injection molding for the plastic casing, where molten plastic is injected into a mold to create the desired shape. For metal components, stamping and machining processes are employed to achieve precise dimensions and electrical connectivity. Advanced techniques such as CNC machining may be used for higher precision in more complex designs, ensuring the outlets fit seamlessly into various applications.

What Is Involved in the Assembly of Single Round Electrical Outlets?

The assembly stage combines all the formed components. This process typically involves automated assembly lines where the plastic casing, electrical contacts, and internal wiring are integrated. Quality control personnel closely monitor this stage to ensure that each component is correctly positioned and securely fastened. Soldering techniques, such as wave soldering or reflow soldering, may be used for attaching electronic components, ensuring a robust connection that can withstand repeated use.

How Is the Finishing Process Conducted for Electrical Outlets?

After assembly, the finishing stage involves several steps aimed at enhancing the product’s aesthetics and functionality. This may include surface treatments like painting or coating, which can improve resistance to wear and tear. For outlets designed for specific environments, such as those used in kitchens or outdoor settings, additional treatments may be applied to enhance water and dust resistance. Finally, each outlet is inspected for cosmetic defects before packaging.

What Quality Assurance Standards Are Relevant for Electrical Outlets?

Quality assurance (QA) is critical throughout the manufacturing process. For international B2B buyers, understanding the certifications and standards that apply to single round electrical outlets is vital. ISO 9001 is one of the most recognized quality management standards and ensures that manufacturers maintain consistent quality in their processes.

In addition to ISO standards, electrical outlets must often meet regional safety certifications, such as CE marking in Europe, which indicates compliance with health, safety, and environmental protection standards. In regions like Africa and South America, local standards may apply, and it’s crucial for buyers to ensure that their suppliers are compliant with these regulations.

Illustrative image related to single round electrical outlet

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are implemented at various stages of production to ensure adherence to quality standards. These checkpoints typically include:

-

Incoming Quality Control (IQC): This initial stage verifies the quality of incoming raw materials. Inspectors check for compliance with specifications and standards, ensuring that only materials that meet quality requirements proceed to production.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring takes place to identify any deviations from quality standards. This includes checking dimensions, electrical connections, and overall assembly integrity at various stages of the process.

-

Final Quality Control (FQC): The final inspection is crucial before the products are packaged for shipment. This stage involves comprehensive testing of the finished outlets to ensure they meet all functional specifications and safety standards. Common tests include electrical continuity tests, insulation resistance tests, and mechanical strength tests.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control measures of their suppliers. Here are several actionable strategies:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing practices and quality control systems. Buyers should look for evidence of compliance with international standards like ISO 9001.

-

Quality Reports: Requesting detailed quality reports can give buyers a clearer picture of a supplier’s commitment to quality. This should include data on defect rates, returns, and corrective actions taken to address quality issues.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct audits and tests to validate that the products meet specified quality and safety standards.

What Are the Nuances of QC and Certification for International B2B Buyers?

For international buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is paramount. Buyers should be aware of the specific standards that apply in their region and ensure that their suppliers can provide the necessary documentation to prove compliance.

Additionally, cultural differences in business practices may affect how quality assurance is perceived. It is essential to establish clear communication channels with suppliers and set expectations regarding quality standards from the outset.

By understanding the manufacturing processes and quality assurance measures associated with single round electrical outlets, B2B buyers can make informed purchasing decisions, ensuring that they source high-quality, compliant products that meet their specific needs.

Illustrative image related to single round electrical outlet

Practical Sourcing Guide: A Step-by-Step Checklist for ‘single round electrical outlet’

To assist B2B buyers in sourcing single round electrical outlets, this guide provides a comprehensive checklist designed to streamline the procurement process. Whether you’re operating in Africa, South America, the Middle East, or Europe, following these steps will help ensure you select the right product for your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful sourcing process. Determine the required voltage, amperage, and compliance with local electrical codes. It’s also essential to specify the materials and finishes that will suit your application, such as whether you need a weather-resistant option for outdoor use or a more aesthetic finish for interior installations.

Step 2: Research Market Trends and Innovations

Staying informed about the latest trends in electrical outlets can provide a competitive edge. Investigate innovations such as energy-efficient models or smart outlets that integrate with home automation systems. Understanding market trends will enable you to select products that not only meet current needs but also future-proof your installations.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to thoroughly vet potential suppliers. Request detailed company profiles, product catalogs, and case studies that showcase their experience in your industry. Look for suppliers who have positive reviews from other international buyers, particularly those in your region, to ensure reliability and quality.

- Sub-bullets:

- Check for industry certifications that validate the supplier’s credibility.

- Request references to gauge their customer service and support.

Step 4: Assess Product Quality and Standards

Quality assurance is paramount when procuring electrical outlets. Verify that the products meet international safety standards such as IEC or UL certifications. This not only ensures safety but also compliance with local regulations, minimizing the risk of legal issues down the line.

Step 5: Compare Pricing and Payment Terms

Gather quotes from multiple suppliers to compare pricing effectively. Be mindful of payment terms, including any available discounts for bulk orders or long-term contracts. Understanding the total cost of ownership, including shipping and potential tariffs, will help you make a more informed financial decision.

- Sub-bullets:

- Consider the supplier’s shipping options and timelines.

- Evaluate the cost-effectiveness of purchasing in bulk versus smaller orders.

Step 6: Negotiate Terms and Contracts

Once you’ve selected a supplier, engage in negotiation to finalize pricing, delivery schedules, and after-sales support. Clear contracts outlining all terms can prevent misunderstandings and ensure accountability. Be sure to include clauses related to warranty and return policies for additional protection.

Step 7: Plan for Logistics and Installation

Finally, coordinate logistics for delivery and installation. Ensure that your team is prepared for the integration of the new outlets into existing systems. Consider scheduling training sessions if necessary, especially when dealing with new technologies or products that require specialized installation techniques.

By following this checklist, B2B buyers can enhance their procurement process for single round electrical outlets, ensuring quality products while maintaining cost-effectiveness and compliance with industry standards.

Comprehensive Cost and Pricing Analysis for single round electrical outlet Sourcing

When sourcing single round electrical outlets, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis focuses on the various cost components involved in the manufacturing and distribution of these products, as well as key price influencers that can impact overall purchasing decisions.

What Are the Key Cost Components in Sourcing Single Round Electrical Outlets?

-

Materials: The primary materials for single round electrical outlets include high-quality plastics and metals, such as copper for wiring and aluminum or brass for the housing. The cost of these raw materials can fluctuate based on market demand and availability, affecting the overall price.

-

Labor: Labor costs encompass the wages paid to workers involved in the manufacturing process. This varies significantly by region, with labor-intensive processes in countries with higher wage standards (e.g., Germany) potentially leading to higher costs compared to regions with lower labor costs (e.g., some parts of Africa or South America).

-

Manufacturing Overhead: This includes costs associated with utilities, equipment maintenance, and facility management. Efficient manufacturing processes can help minimize these overheads, impacting the pricing structure favorably.

-

Tooling: The initial investment in molds and tools required to produce single round electrical outlets can be substantial. These costs are typically amortized over the production volume, meaning larger orders can lead to a lower per-unit tooling cost.

-

Quality Control (QC): Ensuring compliance with safety and quality standards is vital. This includes testing and certification processes that can add to the overall cost but are essential for market acceptance, especially in regions with stringent regulations.

-

Logistics: Shipping costs, including freight and handling, play a significant role in the total cost. Factors such as distance from the supplier, shipping method, and the choice of Incoterms (e.g., FOB, CIF) can greatly influence these logistics costs.

-

Margin: The profit margin set by manufacturers and distributors also affects the final price. This can vary based on the competitive landscape and market positioning of the supplier.

How Do Price Influencers Affect the Cost of Electrical Outlets?

-

Volume/MOQ: Purchasing in larger quantities often results in price breaks. Suppliers may offer more favorable pricing for minimum order quantities (MOQs), which can significantly reduce the unit cost.

-

Specifications and Customization: Custom features, such as specific colors or added functionalities (like USB ports), can increase costs. Buyers should assess whether these enhancements justify the additional expense.

-

Material Quality and Certifications: Higher quality materials and compliance with international safety certifications (e.g., CE, UL) can elevate costs. Buyers should consider the long-term benefits of investing in certified products that reduce liability and enhance safety.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may command higher prices due to perceived reliability and quality assurance, while emerging suppliers might offer competitive pricing to gain market share.

-

Incoterms: Understanding the implications of different Incoterms is crucial for cost management. Terms like CIF include shipping costs in the quoted price, while FOB places the responsibility of shipping costs on the buyer, potentially leading to unforeseen expenses.

What Tips Can Help Buyers Optimize Their Purchasing Decisions?

-

Negotiate Effectively: Engaging suppliers in discussions about pricing can yield better deals, especially when presenting a commitment to larger orders or long-term partnerships.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on upfront costs, consider the TCO, which includes maintenance, energy efficiency, and replacement costs over the product’s lifespan.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations, import tariffs, and local taxes can significantly alter the final cost of imported goods. Buyers from Africa, South America, and the Middle East should factor these elements into their budgeting.

-

Conduct Market Research: Familiarizing oneself with local market prices and competitor offerings can provide leverage during negotiations and help identify the best sourcing options.

Conclusion

Understanding the comprehensive cost structure and pricing influences is essential for international B2B buyers of single round electrical outlets. By considering the outlined components and utilizing the provided tips, buyers can make informed sourcing decisions that align with their operational needs and budget constraints. Always remember to consult multiple suppliers and gather indicative prices to ensure competitive purchasing.

Alternatives Analysis: Comparing single round electrical outlet With Other Solutions

Introduction to Alternative Solutions for Electrical Outlets

In the quest for efficient power solutions, the single round electrical outlet presents a practical option for a variety of applications. However, several alternatives exist that can cater to different needs, environments, and use cases. This analysis will compare the single round electrical outlet with two viable alternatives: in-cabinet outlets and recessed in-floor outlets. Understanding the strengths and weaknesses of each option will help B2B buyers make informed decisions based on their specific requirements.

Comparison Table

| Comparison Aspect | Single Round Electrical Outlet | In-Cabinet Outlets | Recessed In-Floor Outlets |

|---|---|---|---|

| Performance | Standard power delivery | Limited to low-traffic areas | High versatility for both power and data |

| Cost | Moderate initial investment | Low-cost option, around $21.29 | Higher cost, starting at $72 |

| Ease of Implementation | Requires standard installation | Easy installation with minimal tools | Requires more complex installation |

| Maintenance | Low maintenance required | Low maintenance required | Moderate maintenance due to accessibility |

| Best Use Case | General use in homes or offices | Ideal for kitchen cabinets and islands | Suitable for commercial spaces and high-traffic areas |

Detailed Breakdown of Alternatives

In-Cabinet Outlets

In-cabinet outlets, such as the Sillites model, are designed for specific, often confined spaces. They are compact, measuring only 2 inches in diameter, and are particularly advantageous for installations where traditional outlets may not fit. The low cost, typically around $21.29, and straightforward installation process make these outlets a cost-effective choice. However, their performance is limited to low-traffic areas, making them less suitable for environments that require frequent access to power.

Recessed In-Floor Outlets

Recessed in-floor outlets are an innovative solution for providing power access in commercial settings. These outlets can be installed flush with the floor, allowing for a clean aesthetic and minimizing tripping hazards. They support both power and data connections, making them versatile for modern office environments. However, the installation process can be complex and may require professional help, resulting in a higher initial investment, typically starting at $72. The maintenance level is moderate, as access can be limited based on floor layout, but their adaptability in high-traffic areas is a significant advantage.

Conclusion: How to Choose the Right Electrical Outlet Solution

Selecting the right electrical outlet solution depends on the specific needs of your environment. For general use in residential or office settings, the single round electrical outlet remains a reliable choice. If space is a concern and aesthetic integration is key, in-cabinet outlets provide a seamless solution at a lower cost. Conversely, for commercial applications where accessibility and versatility are paramount, recessed in-floor outlets may be the best option despite their higher installation complexity and cost. Evaluating these factors will enable B2B buyers to make informed decisions that align with their operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for single round electrical outlet

What are the Key Technical Properties of a Single Round Electrical Outlet?

When sourcing single round electrical outlets, understanding their technical specifications is essential for ensuring compatibility and performance in various applications. Here are some critical properties to consider:

1. Material Grade

The material grade of an electrical outlet typically refers to the type of plastic or metal used in its construction. Common materials include thermoplastics for insulation and copper or brass for contacts. High-grade materials enhance durability and conductivity, which is crucial for high-demand environments. For B2B buyers, selecting outlets with superior material grades minimizes the risk of failure and ensures longevity, reducing replacement costs.

2. Voltage and Current Ratings

Voltage and current ratings determine how much electrical load an outlet can safely handle. Standard ratings for outlets may range from 120V to 240V, and current ratings often vary from 10A to 20A. Understanding these ratings is vital for compliance with local electrical codes and for ensuring the outlet’s performance in specific applications. Buyers must match the outlet’s ratings with their electrical systems to avoid hazards and inefficiencies.

3. Installation Depth

Installation depth is the required space behind the outlet for proper mounting and operation. This is particularly important for flush-mounted outlets, as insufficient depth can lead to improper installation and functionality. For B2B buyers, knowing the installation depth helps in planning and executing electrical layouts, especially in tight spaces or custom installations.

4. Temperature Rating

Temperature ratings indicate the maximum and minimum operational temperatures an outlet can withstand. Outlets typically have ratings ranging from -10°C to 60°C. This property is critical for environments with extreme temperatures, as exceeding these limits can lead to malfunction or safety hazards. Buyers should consider the operational environment when selecting outlets to ensure they perform reliably under expected conditions.

5. Compliance and Certification

Electrical outlets must meet various safety standards and certifications, such as UL (Underwriters Laboratories) or CE (Conformité Européenne). These certifications ensure that the products have undergone rigorous testing for safety and performance. For international B2B buyers, compliance with local regulations is non-negotiable, as it affects liability and marketability.

What Are Common Trade Terms Associated with Single Round Electrical Outlets?

Familiarity with industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are some common terms related to single round electrical outlets:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of electrical outlets, knowing whether a product is an OEM item can influence purchasing decisions, especially regarding quality assurance and brand reliability.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budget planning and inventory management. For B2B buyers, negotiating MOQs can lead to cost savings and better inventory turnover.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This process is crucial for B2B buyers to compare options and ensure they receive competitive pricing for single round electrical outlets.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms used to clarify the responsibilities of buyers and sellers. Understanding these terms helps B2B buyers navigate shipping and delivery obligations, ensuring smooth transactions across borders.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. Knowing the lead time is critical for inventory management and project planning. Buyers should consider lead times in their procurement strategies to avoid delays in project execution.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing single round electrical outlets, ensuring they meet both operational needs and regulatory requirements.

Illustrative image related to single round electrical outlet

Navigating Market Dynamics and Sourcing Trends in the single round electrical outlet Sector

What are the Key Market Trends Influencing the Single Round Electrical Outlet Sector?

The global market for single round electrical outlets is witnessing a significant transformation driven by several key factors. Firstly, the rise of smart home technology is propelling demand for versatile and innovative electrical solutions. International B2B buyers are increasingly looking for outlets that can integrate with smart systems, enhancing convenience and energy efficiency. Additionally, the growth of urbanization in regions like Africa and South America is leading to an increased focus on compact and aesthetically pleasing electrical solutions that fit modern living spaces.

Emerging trends also include the adoption of modular designs, which allow for easy installation in various applications, from residential kitchens to commercial office spaces. For instance, products like in-cabinet outlets are gaining traction for their ability to blend seamlessly into cabinetry, making them ideal for both functionality and design. Furthermore, the rising focus on customization, where buyers can select colors and finishes to match their interior designs, is reshaping sourcing strategies.

Market dynamics are influenced by regional variations in electrical standards and regulations. For instance, European markets may prioritize compliance with stringent safety standards, while buyers in the Middle East may seek outlets designed for high-temperature environments. Understanding these regional requirements is essential for international buyers to ensure compliance and quality.

How Can Sustainability and Ethical Sourcing Impact the Single Round Electrical Outlet Sector?

Sustainability is becoming a cornerstone of procurement strategies in the electrical outlet sector. B2B buyers are increasingly aware of the environmental impact of their sourcing decisions, pushing manufacturers to adopt greener practices. This includes using recyclable materials and minimizing waste during production. For instance, outlets made from sustainable plastics or metals can appeal to eco-conscious buyers looking to enhance their corporate social responsibility (CSR) profiles.

Ethical sourcing is equally important, as buyers are keen to ensure that their supply chains adhere to fair labor practices and environmental standards. Certifications such as Energy Star or RoHS (Restriction of Hazardous Substances) can serve as benchmarks for quality and sustainability. Buyers should prioritize suppliers who can demonstrate compliance with these standards, as this not only enhances their brand reputation but also reduces the risk of regulatory challenges.

Moreover, the push for energy efficiency aligns with global efforts to combat climate change. Outlets that are designed to minimize energy consumption and integrate with renewable energy systems are becoming increasingly sought after. As the demand for sustainable products grows, buyers should consider the long-term benefits of investing in outlets that contribute positively to both the environment and their operational costs.

What is the Historical Context of Single Round Electrical Outlets?

The evolution of single round electrical outlets can be traced back to the early 20th century, when the need for standardized electrical components emerged alongside the widespread adoption of electricity in homes and businesses. Initially, outlets were designed primarily for functionality, with little consideration for aesthetics or safety standards. Over time, advancements in technology and changes in consumer preferences led to the development of more compact and versatile designs.

By the late 20th century, the rise of modular electrical systems allowed for greater flexibility in installation and usage, paving the way for innovations such as the in-cabinet and recessed outlets we see today. These developments not only improved safety and efficiency but also catered to the growing demand for stylish and integrated electrical solutions in modern architecture. As the market continues to evolve, the focus on smart technology and sustainability promises to further shape the future of single round electrical outlets.

Illustrative image related to single round electrical outlet

Frequently Asked Questions (FAQs) for B2B Buyers of single round electrical outlet

1. How do I choose the right round electrical outlet for my needs?

Selecting the appropriate round electrical outlet depends on the specific application and environment. Consider factors such as the outlet’s size, voltage rating, and installation requirements. For example, the Sillites 2″ round power outlet is compact and designed for installation in tight spaces like kitchen cabinets. Additionally, think about color options and whether a paintable cover is necessary to match your décor. Always ensure the outlet complies with local electrical standards to guarantee safety and reliability.

2. What are the advantages of using a single round electrical outlet over traditional options?

Single round electrical outlets offer several benefits, particularly in space-constrained areas. Their compact design allows for installation in unique locations, such as kitchen islands or cabinetry, where traditional outlets may not fit. These outlets are also self-contained, eliminating the need for a junction box, which simplifies installation. Furthermore, many round outlets feature paintable covers, enabling them to blend seamlessly with their surroundings, enhancing the aesthetic appeal.

3. What is the typical minimum order quantity (MOQ) for round electrical outlets when sourcing internationally?

The MOQ for round electrical outlets can vary significantly based on the supplier and the specific product. Generally, MOQs range from 50 to 500 units. It’s essential to negotiate with suppliers to find a quantity that suits your needs while also considering potential bulk discounts. When sourcing internationally, ensure that the MOQ aligns with your inventory management strategies and market demand to avoid excess stock.

4. How can I ensure the quality of round electrical outlets from international suppliers?

To guarantee the quality of round electrical outlets, conduct thorough supplier vetting. Request samples before placing large orders to assess product quality firsthand. Check for certifications that comply with international electrical safety standards, such as IEC or UL certifications. Additionally, consider visiting the supplier’s manufacturing facility or utilizing third-party quality assurance services to inspect the production process and final products.

5. What payment terms should I expect when sourcing round electrical outlets from overseas?

Payment terms for international purchases can vary widely, but common practices include partial upfront payments (typically 30-50%) and the balance before shipment. Ensure that you discuss and agree upon payment methods that provide security, such as letters of credit or escrow services. Understanding the currency exchange rates and potential transaction fees is also crucial, especially when dealing with suppliers in different regions.

6. What shipping options are available for round electrical outlets when importing?

When importing round electrical outlets, several shipping options are available, including air freight, sea freight, and express courier services. Sea freight is often the most cost-effective for bulk shipments but may take longer. Air freight is faster but generally more expensive. Discuss shipping terms with your supplier, including delivery times, costs, and insurance options, to choose the best method for your needs and budget.

7. Are there customization options for round electrical outlets?

Many suppliers offer customization options for round electrical outlets, including variations in color, size, and even branding. If you require specific features or designs, communicate your needs to the supplier early in the negotiation process. Customization may involve additional costs and longer lead times, so factor these into your planning. Always request samples of customized products to ensure they meet your expectations before finalizing the order.

8. How do I handle potential customs duties and taxes when importing round electrical outlets?

Customs duties and taxes are important considerations when importing electrical outlets. Research the import regulations in your country to understand applicable tariffs and taxes for electrical goods. Engage a customs broker to help navigate the complexities of international shipping, ensuring compliance with local laws. Preparing accurate documentation, including invoices and certificates of origin, can facilitate smoother customs clearance and avoid unexpected fees.

Top 4 Single Round Electrical Outlet Manufacturers & Suppliers List

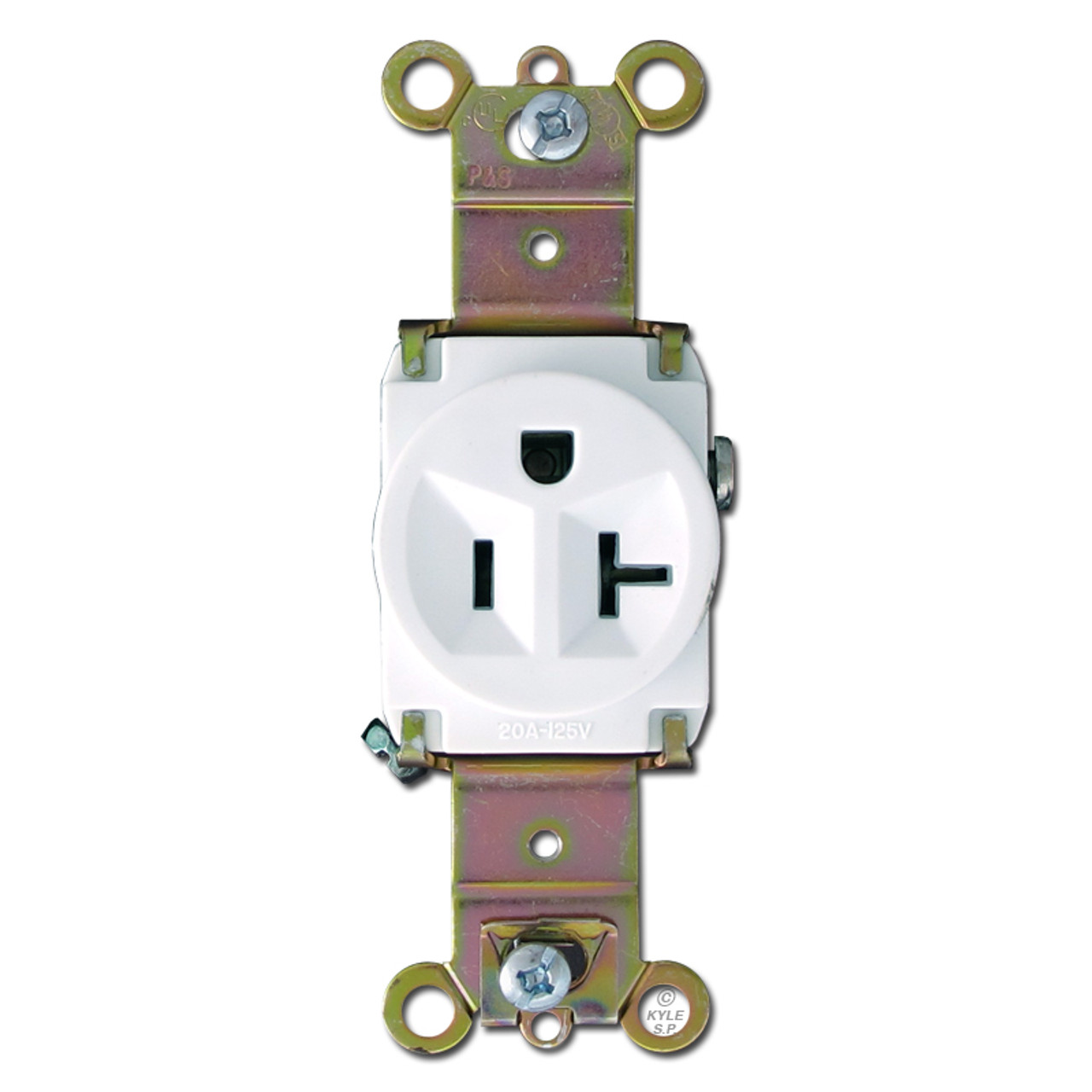

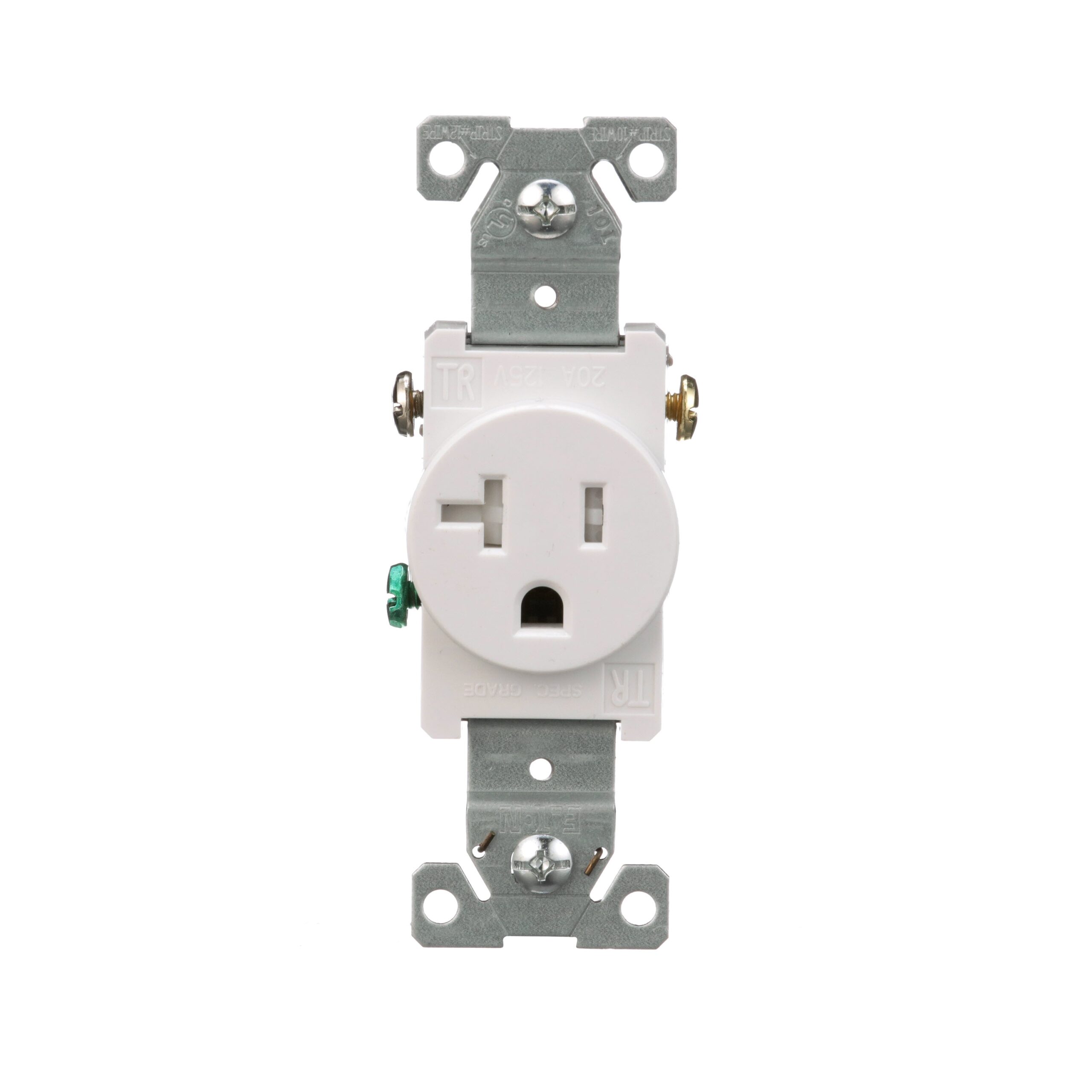

1. Pass & Seymour – Round Outlet Receptacles

Domain: kyleswitchplates.com

Registered: 2012 (13 years)

Introduction: Round outlets and single receptacles available in 15A and 20A sockets. Options include: 15A Single Round Outlet Receptacles (Pass & Seymour 5261) priced at $20.95, Round 20 Amp Single Receptacle Outlets (Pass & Seymour 5361) priced between $9.50 – $10.50, Tamper Resistant 15A Single Round Outlets (TR5251) priced at $7.95, Tamper Resistant Round 20A Single Outlet Receptacle (TR5351) priced at $13.9…

2. Kitchen Power Popups – Sillites In-Cabinet Outlets

Domain: kitchenpowerpopups.com

Registered: 2017 (8 years)

Introduction: {“product_name”: “Sillites In-Cabinet Outlets”, “type”: “Round Power Socket”, “size”: “2 inches in diameter”, “colors_available”: [“brown”, “white”, “black”], “features”: [“smallest socket on the market”, “paintable cover to blend into surfaces”, “easy installation with a 1.75 inch hole”, “no junction box required”, “self-contained”], “ideal_for”: [“kitchen islands”, “cabinets”, “window sills”], “…

3. Floor Box Outlet – Recessed In-Floor Outlet Boxes

Domain: floorboxoutlet.com

Registered: 2017 (8 years)

Introduction: Recessed and Flush Receptacle Boxes for In-Floor Outlets, available in round design. Suitable for wood floors and can be installed in new or retrofit commercial or residential applications. Compatible with unfinished and finished floors including carpet, tile, linoleum, or wood. Available in various colors: brass, aluminum, dark bronze, nickel, brown, black, and bronze. Key products include: 1) Fl…

4. Reddit – 20A Outlet Specifications

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The outlet is a single 20A, 120V outlet, NEMA 5-20, used for a dedicated circuit for appliances like an AC unit or furnace. It is fed by a 15A breaker, and the wiring appears to be 14AWG, which is appropriate for a 15A breaker. It is suggested to replace it with a 15A outlet if the wiring is indeed 14AWG. There are code requirements for using a singleton outlet for certain applications, such as a …

Strategic Sourcing Conclusion and Outlook for single round electrical outlet

In conclusion, strategic sourcing for single round electrical outlets presents significant opportunities for international B2B buyers. By prioritizing quality, compatibility, and innovative designs, businesses can enhance their operational efficiencies while catering to diverse market needs. The compact nature of round outlets, such as the Sillites in-cabinet options, makes them ideal for unique installations in various settings, from residential kitchens to commercial spaces.

Moreover, sourcing from reputable manufacturers ensures compliance with safety standards and reliability, essential for maintaining customer trust in regions like Africa, South America, the Middle East, and Europe. Engaging with suppliers who offer customizable solutions and a range of aesthetic options can also provide a competitive edge.

Looking ahead, the demand for versatile and space-saving electrical solutions is set to grow. B2B buyers are encouraged to leverage this trend by establishing strong partnerships with manufacturers that align with their vision and operational requirements. By adopting a forward-thinking sourcing strategy, companies can position themselves at the forefront of the electrical supply industry, ready to meet evolving market demands and drive sustainable growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.