Everything You Need to Know About Silicone Tube Medical Use Sourcing in 2025

Introduction: Navigating the Global Market for silicone tube medical use

In the ever-evolving landscape of healthcare, sourcing high-quality silicone tubing for medical use poses a significant challenge for international B2B buyers. With the critical importance of biocompatibility and reliability in medical applications, understanding the nuances of silicone tubing becomes paramount. This guide serves as a comprehensive resource, addressing key considerations such as types of silicone tubing, their diverse applications, supplier vetting processes, and cost factors.

Navigating this complex market requires insight into the varying standards and certifications, including USP Class VI and FDA compliance, which are essential for ensuring safety and efficacy in medical environments. By equipping B2B buyers from regions such as Africa, South America, the Middle East, and Europe—countries like Nigeria and Germany—with actionable insights, this guide empowers informed purchasing decisions.

With a focus on high-performance materials and industry best practices, readers will gain a clearer understanding of how to select the right silicone tubing for their specific needs, ultimately enhancing patient care and operational efficiency. Whether you’re looking for custom solutions or standard products, this guide will help you make strategic choices that align with your organizational goals.

Understanding silicone tube medical use Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Medical Grade Silicone Tubing | High purity, biocompatible, and resistant to extreme temperatures | Catheters, drug delivery systems | Pros: Excellent biocompatibility; Cons: Higher cost than standard tubing. |

| Platinum Cured Silicone Tubing | Superior clarity, flexibility, and sterilization capability | Peristaltic pumps, surgical instruments | Pros: Highly durable and inert; Cons: Limited availability in some regions. |

| Braid Reinforced Silicone Tubing | Enhanced strength and pressure resistance | Dialysis machines, fluid transfer systems | Pros: Greater durability; Cons: Heavier and less flexible than non-reinforced options. |

| Anti-Microbial Silicone Tubing | Embedded anti-microbial properties to reduce infection risk | Hospital equipment, infusion systems | Pros: Reduces hospital-acquired infections; Cons: May require special handling. |

| Multi-Lumen Silicone Tubing | Multiple channels for simultaneous fluid transfer | Complex medical devices, diagnostic equipment | Pros: Versatile for various applications; Cons: Higher complexity may increase costs. |

What are the characteristics of Medical Grade Silicone Tubing?

Medical Grade Silicone Tubing is renowned for its high purity and biocompatibility, making it ideal for critical medical applications such as catheters and drug delivery systems. It is resistant to extreme temperatures, ensuring reliability in various environments. For B2B buyers, the key consideration is the tubing’s compliance with stringent health regulations, which may justify its higher price point compared to standard options. Buyers should assess their specific application requirements and regulatory standards to ensure optimal selection.

Why is Platinum Cured Silicone Tubing preferred in the medical field?

Platinum Cured Silicone Tubing is distinguished by its superior clarity, flexibility, and ability to withstand rigorous sterilization processes. This type of tubing is commonly used in peristaltic pumps and surgical instruments, where flexibility and purity are paramount. For B2B purchasers, the primary considerations include sourcing from reputable manufacturers that provide certifications of quality and compliance, as this tubing can be less readily available in certain markets, potentially impacting supply chain timelines.

How does Braid Reinforced Silicone Tubing enhance performance?

Braid Reinforced Silicone Tubing is designed to offer enhanced strength and pressure resistance, making it suitable for demanding applications such as dialysis machines and fluid transfer systems. Its construction allows it to handle higher pressures without compromising integrity. Buyers should weigh the benefits of increased durability against the potential drawbacks of added weight and reduced flexibility, especially in applications requiring intricate maneuverability.

What advantages does Anti-Microbial Silicone Tubing provide?

Anti-Microbial Silicone Tubing incorporates embedded properties that help reduce the risk of hospital-acquired infections, making it a critical component in hospital equipment and infusion systems. This feature is particularly appealing to healthcare providers focused on improving patient safety and reducing infection rates. However, B2B buyers must consider the special handling and storage requirements that may accompany these advanced materials, which can impact overall operational efficiency.

What are the benefits of Multi-Lumen Silicone Tubing for complex applications?

Multi-Lumen Silicone Tubing features multiple channels that enable simultaneous fluid transfer, making it invaluable in complex medical devices and diagnostic equipment. Its versatility allows for a range of applications, from multi-drug delivery systems to intricate diagnostic setups. Buyers should evaluate the complexity and cost implications of such tubing, as the specialized nature may lead to higher production costs and necessitate more detailed logistical planning.

Key Industrial Applications of silicone tube medical use

| Industry/Sector | Specific Application of silicone tube medical use | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical Devices | Catheters | Enhanced patient safety due to biocompatibility | Ensure USP Class VI certification and flexibility |

| Pharmaceutical | Drug delivery systems | Improved precision in dosing and reduced waste | Look for FDA compliance and resistance to chemicals |

| Diagnostics | Diagnostic equipment tubing | Reliable and accurate fluid transfer | Sourcing from certified manufacturers for quality |

| Biopharmaceuticals | Peristaltic pumps | Consistent performance under variable conditions | Assess temperature resistance and mechanical integrity |

| Hospital Equipment | Fluid management systems | Minimized risk of contamination and infection | Evaluate anti-microbial properties and sterilization compatibility |

How Are Silicone Tubes Used in Medical Devices like Catheters?

Silicone tubing is extensively used in catheters due to its biocompatibility, which significantly reduces the risk of adverse reactions in patients. These tubes are designed to maintain flexibility while providing strength and durability, which is crucial for patient comfort and safety. For B2B buyers, it is essential to source silicone tubes that meet USP Class VI standards to ensure they are safe for prolonged use within the body. International buyers should also consider the supplier’s ability to provide consistent quality and adhere to stringent regulatory requirements in their respective regions.

What Role Does Silicone Tubing Play in Pharmaceutical Drug Delivery Systems?

In pharmaceutical applications, silicone tubing is integral to drug delivery systems, where precision and reliability are paramount. These tubes are engineered to withstand various chemicals and maintain integrity under pressure, ensuring accurate dosing and minimizing waste. For businesses in regions like South America and Africa, selecting suppliers that guarantee FDA compliance and offer a range of tubing options suitable for different drugs is critical. This helps in optimizing their production lines and improving overall efficiency.

Why Is Silicone Tubing Important in Diagnostic Equipment?

Silicone tubes in diagnostic equipment facilitate the safe and efficient transfer of fluids, which is essential for accurate test results. The inert nature of silicone ensures that it does not react with the fluids being transported, thus preserving the integrity of samples. B2B buyers in Europe should prioritize sourcing from manufacturers that have robust quality control processes in place, ensuring that the tubing can withstand the rigorous demands of diagnostic applications. Additionally, certifications such as ISO and GMP can further validate the reliability of the products.

How Is Silicone Tubing Used in Biopharmaceuticals with Peristaltic Pumps?

In biopharmaceuticals, silicone tubing is crucial for peristaltic pumps, where it must endure repeated compressions without compromising its mechanical properties. This capability ensures consistent fluid flow, which is vital for various bioprocessing applications. For international buyers, it is essential to consider the tubing’s temperature resistance and compatibility with different media used in bioprocessing. Partnering with suppliers that offer customizable options can also enhance operational efficiency and product performance.

What Benefits Do Silicone Tubes Provide in Hospital Fluid Management Systems?

Silicone tubing is vital for hospital fluid management systems, where it helps minimize the risk of contamination and infection. The material’s anti-microbial properties can significantly reduce hospital-acquired infections, enhancing patient safety. Buyers in the Middle East and Africa should focus on sourcing silicone tubes that are easy to sterilize and comply with local health regulations. Additionally, understanding the supply chain logistics and lead times is crucial for maintaining adequate inventory levels in healthcare facilities.

3 Common User Pain Points for ‘silicone tube medical use’ & Their Solutions

Scenario 1: Ensuring Compliance with Medical Standards

The Problem:

B2B buyers in the medical sector often face the daunting challenge of ensuring that silicone tubing meets stringent regulatory requirements, such as USP Class VI and FDA standards. This is particularly critical in regions like Africa and South America, where the medical infrastructure may not always provide clear guidance. Non-compliance can lead to costly recalls, legal repercussions, and, most importantly, compromised patient safety. Buyers might struggle to differentiate between low-quality and high-quality silicone products, leading to potential risks in their applications.

The Solution:

To navigate this compliance landscape, B2B buyers should prioritize sourcing silicone tubing from reputable manufacturers that provide comprehensive certification and documentation. Look for suppliers who can demonstrate compliance with both USP Class VI and FDA regulations. It’s advisable to request samples and conduct third-party testing to verify claims of biocompatibility and safety. Establishing a close relationship with your supplier can facilitate better communication regarding material specifications and compliance updates, ensuring that your products are always within regulatory standards. Additionally, consider attending industry trade shows or seminars that focus on medical device manufacturing to stay updated on the latest compliance requirements and innovations.

Scenario 2: Overcoming Material Performance Challenges

The Problem:

Buyers frequently encounter issues with silicone tubing not performing as expected under specific conditions, such as extreme temperatures or exposure to aggressive chemicals. This is especially pertinent in the medical field, where the tubing is often used in demanding applications like sterilization processes or drug delivery systems. Inadequate performance can lead to leaks, contamination, and equipment failure, which can significantly impact patient care and operational efficiency.

The Solution:

To address performance challenges, it’s essential to select the right type of silicone tubing that is specifically designed for your application. Buyers should consult with technical experts to determine the appropriate grade of silicone, such as platinum-cured or peroxide-cured options, which offer distinct advantages in terms of durability and chemical resistance. Additionally, ensure that the tubing is tested for the specific conditions it will face, such as temperature extremes or exposure to particular chemicals. Collaborating with suppliers who can provide detailed performance data and recommendations tailored to your needs will help mitigate these issues. Regularly reviewing and updating your material specifications based on evolving operational requirements will further enhance reliability.

Scenario 3: Managing Inventory and Cost Efficiency

The Problem:

B2B buyers often grapple with managing inventory levels of silicone tubing while trying to maintain cost efficiency. Excess inventory ties up capital and storage space, while insufficient stock can lead to production delays and lost business opportunities. This balancing act is particularly challenging in fluctuating markets across Europe and the Middle East, where demand can be unpredictable.

The Solution:

Implementing a just-in-time (JIT) inventory strategy can significantly enhance efficiency and reduce costs. Buyers should work closely with their suppliers to establish flexible ordering systems that allow for smaller, more frequent deliveries, minimizing the need for large stockpiles. Utilizing inventory management software can provide insights into usage trends, helping to forecast demand more accurately. Additionally, negotiating long-term contracts with suppliers can often yield better pricing and ensure availability during peak demand periods. By analyzing usage data and collaborating with suppliers, buyers can develop a responsive supply chain that optimally aligns with production needs while controlling costs effectively.

Strategic Material Selection Guide for silicone tube medical use

What are the Key Properties of Silicone Tubing Materials for Medical Use?

When selecting materials for silicone tubing in medical applications, it is crucial to consider their properties in relation to performance, safety, and regulatory compliance. Here, we analyze four common materials used in silicone tube medical applications: Platinum-Cured Silicone, Peroxide-Cured Silicone, Viton, and PVC. Each material has distinct characteristics that can significantly impact its suitability for various medical applications.

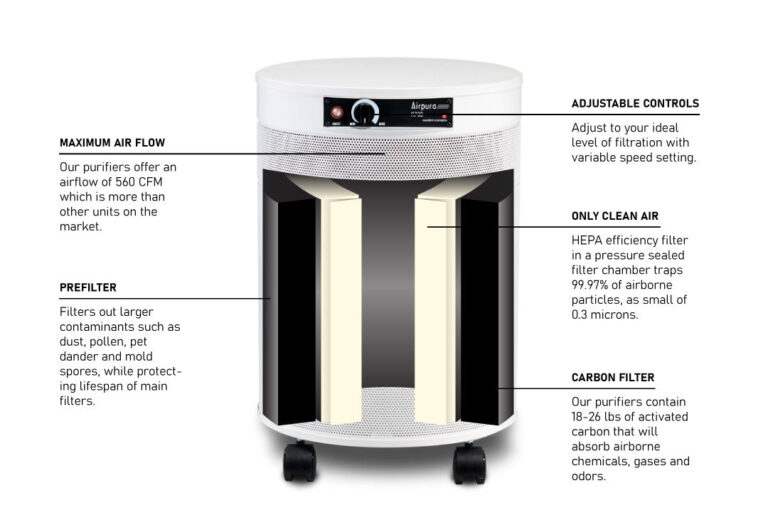

How Does Platinum-Cured Silicone Perform in Medical Applications?

Key Properties: Platinum-cured silicone exhibits exceptional biocompatibility, high-temperature resistance (up to 200°C), and excellent mechanical properties. Its inertness ensures that it does not leach harmful substances into fluids, making it ideal for drug delivery and patient contact applications.

Illustrative image related to silicone tube medical use

Pros & Cons: The primary advantage of platinum-cured silicone is its superior purity and durability, which can withstand repeated sterilization cycles. However, it is more expensive than other silicone types, which may deter cost-sensitive buyers. Manufacturing complexity is also higher, requiring specialized equipment.

Impact on Application: This material is particularly well-suited for applications involving sensitive biological fluids, such as peristaltic pumps and catheters, where contamination must be minimized.

Considerations for International Buyers: Compliance with standards such as USP Class VI and FDA regulations is essential. Buyers in regions like Europe and the Middle East should also consider local regulations that may apply to medical devices.

What Advantages Does Peroxide-Cured Silicone Offer?

Key Properties: Peroxide-cured silicone is known for its excellent mechanical strength and resistance to aging and UV exposure. It can typically handle temperature ranges from -60°C to 200°C.

Pros & Cons: While peroxide-cured silicone is generally less expensive than platinum-cured options, it may not offer the same level of biocompatibility. This can limit its use in applications requiring direct patient contact. The manufacturing process is simpler, which can lower production costs.

Impact on Application: This material is suitable for less critical applications, such as tubing for laboratory equipment or non-invasive medical devices.

Considerations for International Buyers: Buyers should ensure that peroxide-cured silicone meets relevant international standards, such as ISO 10993 for biocompatibility, particularly in regions with stringent medical regulations.

How Does Viton Compare for Medical Tubing?

Key Properties: Viton, a fluoropolymer, offers excellent chemical resistance and can withstand high temperatures (up to 230°C). It is particularly effective in applications involving aggressive chemicals.

Pros & Cons: The key advantage of Viton is its robust chemical resistance, making it suitable for applications where silicone may not perform well. However, it is less flexible than silicone and can be more expensive, which may limit its use in certain medical applications.

Impact on Application: Viton is often used in medical devices that require exposure to harsh cleaning agents or chemicals, such as in sterilization processes.

Considerations for International Buyers: Compliance with ASTM and FDA standards is crucial, especially for applications involving direct contact with patients or pharmaceuticals.

What Role Does PVC Play in Medical Applications?

Key Properties: Polyvinyl chloride (PVC) is a widely used thermoplastic that offers good chemical resistance and flexibility. It can operate effectively in temperatures up to 60°C.

Illustrative image related to silicone tube medical use

Pros & Cons: PVC is cost-effective and easy to manufacture, making it a popular choice for disposable medical devices. However, it lacks the biocompatibility of silicone and may leach harmful substances, which can be a significant drawback for applications involving patient contact.

Impact on Application: PVC is commonly used in applications such as IV bags and tubing where cost is a primary concern, but it is less suitable for critical applications requiring high biocompatibility.

Considerations for International Buyers: Buyers must ensure that PVC products comply with regional regulations, such as the European Union’s REACH regulations, which govern the use of hazardous substances.

Summary Table of Material Selection for Silicone Tube Medical Use

| Material | Typical Use Case for silicone tube medical use | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Platinum-Cured Silicone | Catheters, drug delivery systems | Superior biocompatibility and durability | Higher cost and manufacturing complexity | High |

| Peroxide-Cured Silicone | Laboratory equipment, non-invasive devices | Cost-effective and good mechanical strength | Limited biocompatibility | Medium |

| Viton | Sterilization processes, chemical exposure | Excellent chemical resistance | Less flexible and higher cost | High |

| PVC | IV bags, disposable medical devices | Cost-effective and easy to manufacture | Lacks biocompatibility | Low |

This strategic material selection guide provides a comprehensive overview of the options available for silicone tubing in medical applications, helping international B2B buyers make informed decisions based on their specific needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for silicone tube medical use

The manufacturing processes and quality assurance mechanisms for silicone tubes used in medical applications are pivotal in ensuring safety, efficacy, and compliance with international standards. This section explores the critical stages of manufacturing, key techniques employed, and the quality control measures necessary for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe.

What Are the Main Stages in the Manufacturing Process of Silicone Tubes for Medical Use?

Material Preparation: Selecting the Right Silicone

The manufacturing journey begins with the careful selection of silicone materials. Medical-grade silicone, often platinum-cured, is preferred due to its exceptional biocompatibility, durability, and resistance to extreme temperatures and chemicals. Suppliers must ensure that the silicone meets the stringent requirements set forth by regulatory bodies such as the U.S. Pharmacopeia (USP) and the Food and Drug Administration (FDA). The preparation phase involves thorough testing for purity and consistency to avoid contamination, which could compromise the final product’s safety.

Forming: Extrusion Techniques for Precision

Once the materials are prepared, the next step is forming the silicone into tubes through extrusion. This process involves pushing the silicone through a die to achieve the desired diameter and wall thickness. Advanced techniques such as multi-lumen extrusion may be employed for applications requiring multiple channels within a single tube. The extruded silicone is then subjected to precise temperature controls to ensure uniform curing, which is crucial for maintaining the mechanical properties of the tubing.

Assembly: Integrating Components for Functionality

Depending on the application, silicone tubes may require additional assembly, such as attaching fittings or connectors. This stage demands high precision to ensure that all components function seamlessly together. Automated assembly lines are often utilized to enhance efficiency while maintaining the accuracy necessary for medical applications. Manufacturers may also employ clean-room environments during this phase to minimize the risk of contamination.

Finishing: Quality Surface Treatment

The finishing stage involves several processes, including cutting the tubes to specified lengths, applying surface treatments, and conducting final inspections. Surface treatments may include cleaning, sterilization, and sometimes coating, depending on the intended use of the tubing. Each of these processes must be performed under strict protocols to ensure that the final product meets all regulatory and safety requirements.

What Quality Control Measures Are Essential for Medical-Grade Silicone Tubes?

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should familiarize themselves with several international standards that govern the quality of medical devices, including silicone tubes. ISO 9001 is a foundational quality management standard that applies to all manufacturers, ensuring consistency in quality and customer satisfaction. Additionally, specific certifications like ISO 13485 are crucial for manufacturers of medical devices, as they focus on the regulatory requirements for quality management systems within the industry.

In Europe, CE marking is required for medical devices to ensure compliance with health, safety, and environmental protection standards. In the U.S., compliance with FDA regulations, particularly CFR 21 177.2600, is essential for materials intended for medical applications. Buyers should verify that their suppliers have these certifications readily available.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that every aspect of production meets the required standards. Common checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials for compliance with specifications before they enter the production line. Suppliers should provide certificates of analysis (CoA) to validate material quality.

-

In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted to monitor parameters such as temperature, pressure, and dimensions. This stage ensures that any deviations from specifications are addressed immediately.

-

Final Quality Control (FQC): Once the silicone tubes are complete, they undergo a final inspection where they are tested for defects, functionality, and compliance with the required standards. Common tests include burst pressure tests, tensile strength evaluations, and biocompatibility assessments.

How Can B2B Buyers Verify Supplier Quality Control?

What Audit and Inspection Methods Are Available?

B2B buyers must take proactive steps to verify the quality control processes of their suppliers. One effective method is conducting audits, either remotely or on-site, to assess the supplier’s quality management systems and production capabilities. During these audits, buyers should examine documentation related to production processes, quality control measures, and compliance with relevant standards.

Additionally, buyers can request third-party inspections, where independent organizations evaluate the supplier’s manufacturing processes and quality assurance protocols. These inspections provide an unbiased assessment and can help mitigate risks associated with sourcing from suppliers in different geographical regions.

What Are the Specific QC and Certification Nuances for International B2B Buyers?

For international buyers, understanding the nuances of quality control and certification is crucial. Different regions may have varying regulations and standards, and it is essential to ensure that suppliers are compliant with both local and international requirements. For example, while a supplier may hold ISO certifications, they may also need to comply with specific regional standards applicable in markets like Nigeria or Germany.

Furthermore, B2B buyers should consider the implications of lead times and logistics in their sourcing strategy. Suppliers that maintain a robust quality control system can often provide faster turnaround times and more reliable delivery schedules, which is a critical factor in the medical field where timely supply can be a matter of life and death.

Conclusion: Ensuring Quality in Silicone Tube Manufacturing

In summary, the manufacturing processes and quality assurance measures for silicone tubes intended for medical use are integral to ensuring safety and efficacy. By understanding the key stages of manufacturing and the relevant quality control measures, B2B buyers can make informed decisions when selecting suppliers. Awareness of international standards and the ability to verify supplier quality through audits and third-party inspections will further enhance the reliability of the supply chain, ultimately leading to better outcomes in medical applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘silicone tube medical use’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure silicone tubing specifically for medical use. Given the critical nature of medical applications, it is essential to ensure that the selected silicone tubing meets stringent quality and safety standards. This step-by-step approach will help you make informed decisions that align with regulatory requirements and operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Consider factors such as tube diameter, wall thickness, length, and the intended application (e.g., peristaltic pumps, catheters). It’s also essential to specify whether you require features such as multi-lumen configurations or reinforcement for durability.

- Application Requirements: Identify the specific medical applications for which the tubing will be used.

- Performance Criteria: Determine the necessary temperature range, pressure rating, and chemical compatibility.

Step 2: Research Regulatory Compliance

Confirm that the silicone tubing complies with relevant industry standards and regulations. For medical applications, look for certifications such as USP Class VI and FDA approval, which indicate biocompatibility and safety.

- Certification Documentation: Request copies of compliance certificates from suppliers.

- Quality Assurance Processes: Inquire about the supplier’s quality control measures to ensure ongoing compliance.

Step 3: Evaluate Supplier Experience and Reputation

Before making a commitment, thoroughly vet potential suppliers. Their experience in the medical industry can significantly impact the quality and reliability of the silicone tubing.

- Track Record: Look for suppliers with a proven history of providing medical-grade materials.

- Customer Testimonials: Seek out reviews or case studies from other businesses in similar sectors to gauge supplier performance.

Step 4: Assess Material Quality

Material quality is paramount in medical applications, where any imperfection can have serious consequences. Ensure that the silicone used is high-purity, platinum-cured, and free from fillers that could compromise safety.

Illustrative image related to silicone tube medical use

- Material Specifications: Request detailed material data sheets that outline the properties of the silicone used.

- Testing Procedures: Inquire about the testing protocols employed to assess the material’s biocompatibility and durability.

Step 5: Request Samples for Testing

Obtaining samples is a crucial step before placing a bulk order. This allows you to perform necessary tests to verify that the tubing meets your specifications and application requirements.

- Testing Procedures: Conduct tests for physical properties, biocompatibility, and performance under expected operational conditions.

- Feedback Loop: Involve key stakeholders, such as engineers and quality assurance personnel, in the evaluation of the samples.

Step 6: Negotiate Pricing and Terms

Once you’ve identified a suitable supplier, it’s time to negotiate pricing and contract terms. Understand the total cost of ownership, including shipping, handling, and any potential duties or tariffs.

- Volume Discounts: Inquire about bulk purchasing discounts to optimize your procurement budget.

- Payment Terms: Discuss payment options and terms to ensure they align with your financial policies.

Step 7: Establish a Long-term Partnership

Consider building a long-term relationship with your chosen supplier. Ongoing collaboration can lead to better service, improved pricing, and access to new products that meet evolving medical standards.

- Performance Reviews: Schedule regular assessments of supplier performance to ensure consistent quality and service.

- Feedback Mechanism: Implement a system for providing feedback to your supplier to foster continuous improvement.

By following these steps, you can effectively navigate the procurement process for silicone tubing used in medical applications, ensuring that your choices enhance both operational efficiency and patient safety.

Comprehensive Cost and Pricing Analysis for silicone tube medical use Sourcing

What Are the Key Cost Components in Sourcing Silicone Tubes for Medical Use?

When sourcing silicone tubes for medical applications, understanding the cost structure is crucial. The primary cost components include:

-

Materials: The type of silicone used significantly impacts cost. Medical-grade silicone, particularly platinum-cured variants, is more expensive due to its superior biocompatibility and performance in demanding applications. The selection between peroxide-cured and platinum-cured silicone can also affect pricing, with the latter typically commanding a premium.

-

Labor: Labor costs can vary based on the manufacturing location and the complexity of the production process. Skilled labor is essential for ensuring the high standards required in the medical industry, particularly in clean-room environments.

-

Manufacturing Overhead: This includes costs associated with maintaining the manufacturing facility, equipment depreciation, utilities, and compliance with Good Manufacturing Practices (GMP). Facilities that adhere to stringent standards, such as USP Class VI, typically incur higher overhead costs.

-

Tooling: The cost of molds and machinery used for production can be significant, especially for custom or specialized tubing. Initial tooling costs may be high, but they can be amortized over larger production runs.

-

Quality Control (QC): Ensuring that silicone tubes meet regulatory and safety standards requires robust quality control processes, which can add to the overall cost. This includes testing for biocompatibility, leaching, and mechanical properties.

-

Logistics: Shipping costs, particularly for international buyers, can be substantial. Factors such as distance, shipping method, and import duties must be considered when evaluating total costs.

-

Margin: Suppliers will factor in their profit margins, which can vary widely depending on market competition and perceived value.

What Factors Influence the Pricing of Silicone Tubes in the Medical Sector?

Several factors can influence the pricing of silicone tubes, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically reduce the per-unit cost due to economies of scale. Buyers should negotiate for favorable terms, particularly if they anticipate high-volume needs.

-

Specifications and Customization: Custom-designed tubes that meet specific application requirements will generally incur higher costs. Standard products are usually less expensive, but may not meet all operational needs.

-

Materials and Quality Certifications: Tubing that meets FDA and USP standards will cost more due to the rigorous testing and quality assurance processes involved. Buyers should weigh the importance of these certifications against their budget.

-

Supplier Factors: The reputation and reliability of the supplier can also influence pricing. Established suppliers may charge a premium for their products due to their track record of quality and reliability.

-

Incoterms: The terms of shipping and delivery can affect overall costs. Understanding Incoterms helps buyers manage shipping responsibilities, costs, and risks effectively.

What Strategies Can Buyers Employ to Ensure Cost-Efficiency in Sourcing Silicone Tubes?

To achieve cost efficiency in sourcing silicone tubes, consider the following strategies:

-

Negotiate Terms: Engage suppliers in discussions about pricing, especially for bulk purchases. Leverage your position as a potential long-term customer to secure better deals.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the TCO, which includes maintenance, longevity, and compliance costs. Higher-quality silicone tubes may have a higher upfront cost but could result in savings over time due to reduced replacements and lower risk of failure.

-

Research Local Suppliers: For buyers in regions like Africa or South America, sourcing from local manufacturers can reduce shipping costs and lead times. Additionally, local suppliers may offer better support and customization options.

-

Stay Informed About Market Trends: Understanding market dynamics, including material availability and pricing fluctuations, can help buyers make informed decisions and time their purchases strategically.

What Should Buyers Keep in Mind Regarding Pricing Nuances in Different Regions?

International B2B buyers should be aware of the following pricing nuances:

-

Regional Regulations: Compliance with local regulations may necessitate additional certifications or modifications, impacting costs.

-

Currency Fluctuations: Exchange rates can significantly influence pricing, particularly for international transactions. Buyers should consider hedging strategies to mitigate risks associated with currency volatility.

-

Cultural Factors: Building relationships with suppliers in different regions can lead to better pricing and terms. Understanding cultural differences can aid negotiations and foster long-term partnerships.

Disclaimer

Prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific requirements. Always conduct thorough research and consult multiple suppliers to obtain accurate pricing information tailored to your needs.

Alternatives Analysis: Comparing silicone tube medical use With Other Solutions

Exploring Alternatives to Silicone Tube Medical Use: A Comprehensive Comparison

In the medical industry, selecting the appropriate tubing for applications such as drug delivery, fluid transfer, and patient monitoring is crucial. While silicone tubing is a popular choice due to its biocompatibility and mechanical properties, several alternatives may also meet specific needs. This analysis compares silicone tube medical use with two viable alternatives: PVC (Polyvinyl Chloride) tubing and TPE (Thermoplastic Elastomer) tubing.

| Comparison Aspect | Silicone Tube Medical Use | PVC Tubing | TPE Tubing |

|---|---|---|---|

| Performance | High biocompatibility, withstands high temperatures | Good flexibility, but less biocompatible | Excellent elasticity, good chemical resistance |

| Cost | Higher initial investment, longer lifespan | Lower initial cost, shorter lifespan | Moderate cost, competitive performance |

| Ease of Implementation | Requires proper handling and sterilization | Easy to handle and install | User-friendly, compatible with automated processes |

| Maintenance | Low maintenance, durable under sterilization | Prone to degradation over time | Requires regular inspection but generally durable |

| Best Use Case | Critical medical applications, peristaltic pumps | Non-critical applications, general fluid transfer | Medical devices needing flexibility and durability |

Detailed Breakdown of Alternatives

1. PVC Tubing

PVC tubing is widely used in various medical applications due to its affordability and versatility. It is relatively easy to handle and install, making it suitable for non-critical applications such as general fluid transfer. However, PVC lacks the biocompatibility that silicone offers, which can be a concern in applications involving direct contact with bodily fluids. Its tendency to degrade over time and potential for leaching harmful chemicals into fluids are significant drawbacks, particularly in sensitive medical environments.

2. TPE Tubing

Thermoplastic elastomer (TPE) tubing presents a middle ground between silicone and PVC. It offers excellent elasticity and good chemical resistance, making it a flexible option for various applications. TPE is also easier to process and can be compatible with automated manufacturing systems. While it provides a good balance of performance and cost, TPE may not achieve the same level of biocompatibility as silicone, which limits its use in certain critical applications. Regular inspections are recommended to ensure performance longevity.

Conclusion: How to Choose the Right Tubing Solution for Your Medical Needs

When selecting the appropriate tubing for medical applications, B2B buyers should consider multiple factors, including performance requirements, budget constraints, and specific application needs. Silicone tubing stands out for critical applications requiring high biocompatibility and durability, while PVC and TPE offer viable alternatives for less demanding scenarios. By carefully evaluating each option against the unique requirements of their applications, buyers can make informed decisions that enhance patient safety and operational efficiency.

Essential Technical Properties and Trade Terminology for silicone tube medical use

What Are the Key Technical Properties of Silicone Tubes for Medical Use?

When sourcing silicone tubes for medical applications, understanding critical technical properties is essential for ensuring compliance with industry standards and operational efficiency. Below are some key specifications that B2B buyers should consider:

-

Material Grade

Silicone tubing is classified into various grades, with medical-grade silicone being the most important for healthcare applications. Medical-grade silicone is biocompatible, which means it does not provoke an immune response when in contact with bodily fluids. This property is crucial for applications such as catheters, drug delivery systems, and peristaltic pumps. Choosing the right material grade ensures safety and regulatory compliance, reducing the risk of product recalls or legal issues. -

Tensile Strength

This property refers to the maximum amount of tensile (pulling) stress that silicone tubing can withstand before failing. High tensile strength is vital in applications where the tubing will undergo repeated flexing or stretching. For medical devices, ensuring that the tubing can handle these stresses without rupturing is critical for maintaining the integrity of fluid transfer systems. -

Durometer Hardness

Measured on the Shore A scale, durometer hardness indicates the material’s resistance to indentation. Medical-grade silicone typically has a durometer rating between 30A and 80A. The hardness affects the tubing’s flexibility and the ease of installation. Selecting the appropriate durometer is essential for applications requiring precise fluid control and ease of manipulation. -

Temperature Resistance

Silicone tubing must withstand a wide range of temperatures, from sterilization processes (up to 135°C) to cold storage environments. Understanding the temperature resistance of the tubing helps ensure its reliability in various applications, including those that require autoclaving or exposure to harsh chemicals. This property is particularly important for products that will be used in critical care settings. -

USP Class VI Certification

The United States Pharmacopeia (USP) Class VI certification indicates that the silicone has passed rigorous biocompatibility tests. This certification is vital for medical applications where the tubing will come into contact with patients. Selecting USP Class VI certified products helps buyers ensure compliance with regulatory standards, enhancing product credibility and safety. -

Chemical Resistance

Silicone exhibits excellent resistance to a variety of chemicals, including many cleaning agents and bodily fluids. This property is crucial for maintaining the integrity and performance of the tubing in medical settings, where exposure to disinfectants or pharmaceuticals is common. Buyers should verify that the tubing is compatible with the specific substances it will encounter in its intended application.

What Are Common Trade Terms Related to Silicone Tubes in the Medical Industry?

Understanding industry jargon can facilitate smoother transactions and enhance communication between buyers and suppliers. Here are some common terms used in the silicone tube market:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are sold under another company’s brand. In the medical industry, OEMs often require silicone tubing that meets specific standards for use in their medical devices. Buyers should engage with reputable OEMs to ensure the quality and compliance of the components used in their products. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for buyers to plan their inventory and budget effectively. Suppliers often set MOQs to ensure production efficiency, so negotiating favorable terms can lead to cost savings. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to potential suppliers to request pricing and other information for a specific quantity of products. An effective RFQ will outline the desired specifications, certifications, and delivery timelines, enabling suppliers to provide accurate quotes. -

Incoterms

Incoterms, or International Commercial Terms, are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand their obligations concerning shipping, insurance, and customs clearance, which is vital for importing medical-grade silicone tubing. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. In the medical industry, shorter lead times can be critical, especially in emergencies. Buyers should discuss lead times with suppliers to ensure timely delivery and maintain operational continuity. -

Batch Testing

This term refers to the process of testing a specific batch of silicone tubing for quality assurance and compliance with relevant standards. Batch testing is crucial for ensuring that each production run meets the required specifications, especially in regulated industries like healthcare.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when sourcing silicone tubing for medical use, ultimately enhancing the safety and efficacy of medical devices and applications.

Navigating Market Dynamics and Sourcing Trends in the silicone tube medical use Sector

What Are the Current Market Dynamics and Key Trends in the Silicone Tube Medical Use Sector?

The global silicone tube medical use market is experiencing substantial growth, driven by an increasing demand for high-quality medical devices and equipment, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Key drivers include a rising aging population, advancements in healthcare technology, and a growing emphasis on patient safety and comfort. As healthcare systems modernize and expand, the need for reliable, biocompatible materials like silicone tubing is becoming more pronounced.

Emerging B2B technology trends are reshaping the sourcing landscape. The adoption of Industry 4.0 technologies, such as IoT and AI, is enabling manufacturers to optimize production processes and enhance quality control. Additionally, digital procurement platforms are streamlining the sourcing process, allowing international buyers to connect with suppliers more efficiently. For instance, platforms that facilitate direct sourcing from manufacturers can reduce costs and lead times, which is particularly beneficial for buyers in regions with logistical challenges.

Moreover, sustainability is increasingly influencing market dynamics. Buyers are now more conscientious about sourcing materials that meet stringent environmental standards. The focus on certifications, such as USP Class VI for biocompatibility and FDA compliance, is crucial for ensuring product safety and quality. This trend is particularly relevant in regions like Germany, where regulatory standards are stringent, and in Africa and South America, where there is a growing push for quality healthcare solutions.

How Does Sustainability and Ethical Sourcing Impact the Silicone Tube Medical Use Sector?

Sustainability and ethical sourcing have become essential considerations for B2B buyers in the silicone tube medical use sector. The environmental impact of manufacturing processes and materials is under scrutiny as companies strive to minimize their carbon footprints. Buyers are increasingly looking for suppliers who prioritize eco-friendly practices, such as using renewable energy sources and reducing waste during production.

Ethical supply chains are gaining importance as consumers demand transparency regarding product origins and manufacturing processes. Buyers are encouraged to partner with manufacturers that adhere to sustainable practices, ensuring that their products do not contribute to environmental degradation or exploitative labor practices. Certifications such as ISO 14001 for environmental management and ethical sourcing certifications can significantly enhance a supplier’s credibility.

Furthermore, the demand for ‘green’ materials is rising. Biodegradable silicone options or those produced through sustainable methods are becoming attractive to buyers who wish to align their procurement practices with broader sustainability goals. This shift not only satisfies regulatory requirements but also caters to the growing consumer base that prioritizes environmentally responsible products.

What Is the Brief Evolution and History of Silicone Tubes in Medical Applications?

The use of silicone in medical applications dates back to the mid-20th century when its unique properties, such as biocompatibility and thermal stability, were first recognized. Early silicone tubes were utilized in various medical devices, including catheters and surgical instruments, primarily due to their inertness and resistance to sterilization processes.

Illustrative image related to silicone tube medical use

Over the decades, advancements in silicone manufacturing technology, particularly the introduction of platinum curing processes, have significantly enhanced the performance characteristics of silicone tubing. These developments have led to the creation of high-purity, flexible tubing that meets stringent medical standards, such as USP Class VI certification. Today, silicone tubes are integral to a wide range of medical applications, from drug delivery systems to advanced surgical tools, reflecting the material’s evolution into a cornerstone of modern healthcare technology.

This historical context highlights the importance of continuous innovation in the silicone tube sector, which is essential for meeting the evolving demands of the global medical market. As healthcare continues to advance, the role of silicone tubing will likely expand, further reinforcing its significance in medical applications worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of silicone tube medical use

-

How do I choose the right silicone tubing for medical applications?

Selecting the appropriate silicone tubing involves considering several factors including biocompatibility, temperature resistance, and the specific application requirements. Look for tubing that meets USP Class VI certification, indicating it has passed stringent biocompatibility tests. Additionally, evaluate the tubing’s resistance to sterilization methods, such as steam or ethylene oxide, and ensure it can handle the specific fluids or medications it will be exposed to. Consulting with manufacturers or suppliers who specialize in medical-grade silicone products can provide valuable insights tailored to your needs. -

What are the key benefits of using platinum-cured silicone tubing in medical devices?

Platinum-cured silicone tubing offers numerous advantages for medical applications, including superior biocompatibility, resistance to extreme temperatures, and exceptional durability. Unlike peroxide-cured silicone, which can degrade over time, platinum-cured silicone maintains its integrity and performance, making it ideal for long-term use. It is also less likely to leach chemicals, which is crucial for patient safety. This type of tubing is commonly used in critical applications such as catheters and drug delivery systems, ensuring both safety and efficacy in medical treatments. -

What certifications should I look for when sourcing silicone tubing for medical use?

When sourcing silicone tubing for medical applications, prioritize suppliers that offer products certified to USP Class VI standards, which confirm biocompatibility and safety. Additionally, FDA approval under CFR 21 177.2600 is essential for rubber articles used in food and drug applications. Other relevant certifications may include ISO 13485 for quality management systems in medical devices. Thoroughly verifying these certifications helps ensure that the silicone tubing meets the necessary regulatory requirements for your market. -

What is the typical minimum order quantity (MOQ) for silicone tubing in the medical sector?

The minimum order quantity for silicone tubing can vary significantly depending on the supplier and the specific product specifications. Generally, MOQs can range from 100 meters for standard products to several kilometers for custom or specialized tubing. It is advisable to discuss your needs with potential suppliers to find a balance between your order size and the supplier’s production capabilities. Some suppliers may offer flexible MOQs for first-time buyers or ongoing partnerships. -

How can I ensure quality assurance when purchasing silicone tubing?

To ensure quality assurance when purchasing silicone tubing, request detailed product specifications and certifications from suppliers. Ask for samples to evaluate the tubing’s physical properties, biocompatibility, and performance under sterilization conditions. Additionally, inquire about the supplier’s quality control processes and whether they conduct regular audits and testing of their products. Establishing a clear communication channel with your supplier can also help address any concerns regarding quality and compliance. -

What payment terms are commonly offered for silicone tubing purchases in international trade?

Payment terms for silicone tubing purchases in international trade can vary widely among suppliers. Common arrangements include payment in advance, letter of credit, or net 30/60/90 days after delivery. When negotiating payment terms, consider factors such as order size, supplier reputation, and your own financial capabilities. Be sure to clarify any associated fees, such as currency conversion or bank charges, and consider using escrow services for larger transactions to mitigate risks. -

What logistics considerations should I be aware of when importing silicone tubing?

When importing silicone tubing, consider the shipping method that best balances cost and speed, such as air freight for urgent needs versus ocean freight for larger, less time-sensitive orders. Be aware of customs regulations in your country, including any import duties or taxes that may apply. It’s also crucial to confirm that the supplier can provide the necessary documentation, such as a Certificate of Origin or Bill of Lading, to facilitate smooth customs clearance. -

How can I vet suppliers for silicone tubing in the medical industry?

Vetting suppliers for silicone tubing involves researching their industry reputation, certifications, and customer feedback. Start by checking if they have relevant certifications like ISO 13485 and USP Class VI. Request references from other businesses in the medical sector to gauge their reliability and product quality. Additionally, consider visiting the supplier’s manufacturing facility if possible, or conducting virtual audits to assess their production processes and quality control measures. Engaging in thorough due diligence will help ensure you partner with a reputable supplier.

Top 5 Silicone Tube Medical Use Manufacturers & Suppliers List

1. ElastoStar – Silicone Tubing

Domain: elastostar.com

Registered: 2013 (12 years)

Introduction: Silicone tubing is a flexible and durable tube made from silicone rubber, widely used for transferring liquids, gases, or other substances. It is known for its heat resistance, chemical stability, and flexibility, making it suitable for industries such as medical, food processing, and industrial applications. Types of silicone tubing include: 1. Medical Silicone Tubing – Non-toxic and biocompatibl…

2. Medical Silicone – Surgical Tubes

Domain: medicalsiliconetube.com

Registered: 2023 (2 years)

Introduction: Silicone surgical tubes are ideal for medical devices due to their excellent biocompatibility, high temperature resistance, softness, and antibacterial properties. They are used in various applications including airway management (tracheal intubation, ventilator connection, bronchoscopic guide tubes), urinary tubes (long-term and short-term catheterization), stomach and bowel tubes (gastric and in…

3. NewAge Industries – SILCON MEDICAL Tubing

Domain: newageindustries.com

Registered: 1998 (27 years)

Introduction: This company, NewAge Industries – SILCON MEDICAL Tubing, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. ScienceDirect – Silicone Tubes

Domain: sciencedirect.com

Registered: 1997 (28 years)

Introduction: A silicone tube is a flexible conduit made from silicone, known for its hemocompatibility and gas penetration properties. It is commonly used in renal equipment, plasma oxygenators, and cardiac surgical equipment. Silicone tubes are utilized in medical applications such as nerve repair, where their stable and inert properties, smooth inner surface, and flexibility support regeneration. They can be…

5. US Plastic – Silcon® Medical Grade Silicone Tubing

Domain: usplastic.com

Registered: 1996 (29 years)

Introduction: Silcon® Medical Grade Silicone Tubing is made under proper manufacturing procedures and conforms to the biocompatibility requirements of USP Class VI. It features soft and pliable properties, contains no plasticizers, and has surface properties that resist sticking and encrustation while not supporting bacteria growth. The tubing is nonreactive to body tissues and fluids, supplied in individual, h…

Strategic Sourcing Conclusion and Outlook for silicone tube medical use

In navigating the complexities of sourcing silicone tubing for medical applications, international B2B buyers must prioritize quality and compliance with stringent standards such as USP Class VI and FDA regulations. The unique biocompatibility and mechanical properties of silicone make it a preferred choice for critical applications, including peristaltic pumps, catheters, and drug delivery systems. By strategically sourcing high-grade silicone tubing, companies can enhance the reliability of their medical devices while mitigating risks associated with inferior materials.

Investing in premium silicone products not only ensures compliance with safety regulations but also supports the longevity and performance of medical equipment. As healthcare systems globally continue to evolve, the demand for high-quality silicone tubing will only increase, particularly in emerging markets across Africa, South America, the Middle East, and Europe.

Looking ahead, B2B buyers are encouraged to foster partnerships with reputable suppliers who adhere to rigorous manufacturing practices. By doing so, organizations can secure a competitive advantage in the medical device landscape. Make informed sourcing decisions today to ensure the success of your medical applications and contribute to better patient outcomes tomorrow.

Illustrative image related to silicone tube medical use

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.