Everything You Need to Know About Shrinking Hose Sourcing in 2025

Introduction: Navigating the Global Market for shrinking hose

In today’s fast-paced global market, sourcing high-quality shrinking hoses can be a daunting task for B2B buyers. With an increasing demand for efficient and space-saving solutions in various industries—from agriculture to construction—the need for reliable suppliers has never been greater. This guide serves as a comprehensive resource for international buyers, particularly those in Africa, South America, the Middle East, and Europe, seeking to navigate the complexities of shrinking hose procurement.

Throughout this guide, we will delve into the diverse types of shrinking hoses available, their wide-ranging applications, and the critical aspects of supplier vetting. We will also provide insights into cost considerations, ensuring that you can make informed purchasing decisions that align with your business needs. Whether you are looking for hoses that are lightweight and expandable for gardening or durable options for industrial use, our extensive analysis will empower you to select the right product for your requirements.

By equipping B2B buyers with actionable insights and practical knowledge, this guide aims to streamline the purchasing process and enhance the overall experience. Understanding the intricacies of the shrinking hose market will not only save time and resources but also foster long-term partnerships with trusted suppliers, ultimately driving success in your ventures.

Understanding shrinking hose Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Expandable Hose | Lightweight, contracts significantly, easy storage | Agriculture, landscaping, gardening | Pros: Compact, flexible; Cons: Durability can vary, may require specific nozzles. |

| Coil Hose | Coils for easy storage, often made from durable materials | Industrial cleaning, automotive uses | Pros: Excellent recoil; Cons: Limited length options, can be heavy. |

| Heavy-Duty Shrink Hose | Thick walls, high burst pressure ratings | Construction, mining, heavy machinery | Pros: Highly durable, withstands high pressure; Cons: More expensive, less flexible. |

| Standard Garden Hose | Traditional design with shrinkage capabilities | Residential gardening, general watering | Pros: Widely available, cost-effective; Cons: Bulky when not contracted, prone to kinks. |

| Marine Hose | UV resistant, designed for marine environments | Boating, marine maintenance | Pros: Resistant to saltwater, durable; Cons: Heavier and more expensive than standard hoses. |

What are the characteristics of an expandable hose for B2B buyers?

Expandable hoses are designed to stretch when water flows through them and contract when empty. This feature makes them lightweight and easy to store, ideal for agricultural, landscaping, and gardening applications. For B2B buyers, considerations include the hose’s material quality, as this affects its durability and flexibility. Buyers should also assess the available length options and compatibility with nozzles, as some models may require specific fittings.

How does a coil hose meet the needs of industrial applications?

Coil hoses are constructed to recoil into a compact form, making them easy to manage and store. They are often made from robust materials that can withstand demanding industrial cleaning tasks and automotive applications. B2B buyers should consider the hose’s recoil performance, material durability, and weight. While coil hoses offer excellent performance, they may have limitations in length, which can affect usability in larger operations.

What advantages do heavy-duty shrink hoses offer for construction and mining?

Heavy-duty shrink hoses are engineered with thick walls and high burst pressure ratings, making them suitable for construction and mining environments where durability is essential. These hoses can withstand harsh conditions and high-pressure applications, providing reliable service. B2B buyers should weigh the cost against the longevity and performance benefits. While these hoses may be pricier, their resilience can lead to lower replacement costs over time.

Why choose a standard garden hose for residential applications?

Standard garden hoses are readily available and cost-effective, making them a popular choice for residential gardening and general watering tasks. They offer basic shrinkage capabilities but can become bulky when not contracted. B2B buyers focusing on residential markets should consider the balance between price and performance. While these hoses may not offer advanced features, their accessibility and affordability make them a practical option for many consumers.

What features make marine hoses essential for boating and marine maintenance?

Marine hoses are specifically designed to resist UV damage and withstand the corrosive effects of saltwater, making them essential for boating and marine maintenance applications. These hoses typically feature reinforced construction for enhanced durability. B2B buyers should evaluate the hose’s weight and cost, as marine hoses tend to be heavier and more expensive than standard options. However, their specialized design ensures longevity and reliability in marine environments.

Key Industrial Applications of shrinking hose

| Industry/Sector | Specific Application of Shrinking Hose | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Irrigation systems for crop watering | Efficient water usage and reduced storage space | Durability in harsh environments, UV resistance |

| Automotive | Fuel and coolant line systems | Enhanced safety and reduced risk of leaks | Temperature tolerance, compatibility with fluids |

| Construction | Temporary plumbing and drainage solutions | Flexibility in installation and ease of transport | Pressure ratings, size options for various projects |

| Manufacturing | Cable management and protection in machinery | Improved organization and reduced wear on cables | Material quality, resistance to abrasion and chemicals |

| Aerospace | Fuel lines and hydraulic systems | Lightweight, space-saving solutions for aircraft design | Compliance with aviation standards, heat resistance |

How is Shrinking Hose Used in Agriculture for Efficient Irrigation Systems?

In agriculture, shrinking hoses are utilized in irrigation systems to provide flexible and efficient watering solutions. These hoses expand when filled with water and contract when emptied, allowing for easy transport and storage. They help farmers optimize water usage, ensuring that crops receive adequate hydration while minimizing wastage. International buyers, particularly from regions like Africa and South America, should consider durability against environmental factors such as UV rays and extreme temperatures, ensuring longevity in various climates.

What Role Does Shrinking Hose Play in Automotive Fuel and Coolant Line Systems?

In the automotive sector, shrinking hoses are critical for fuel and coolant line systems. Their ability to withstand high temperatures and resist chemical degradation makes them suitable for various engine applications. By using shrinking hoses, manufacturers can enhance safety by reducing the risk of leaks, which can lead to hazardous situations. Buyers must evaluate compatibility with different fluids and the temperature tolerance of the hoses to ensure optimal performance in diverse vehicle models across international markets.

How is Shrinking Hose Applied in Construction for Temporary Plumbing Solutions?

Construction projects often require flexible plumbing solutions that can adapt to changing site conditions. Shrinking hoses serve as temporary plumbing and drainage solutions, allowing for quick adjustments during installation. Their lightweight nature facilitates easy transport, making them ideal for construction sites. Buyers in the construction industry should consider the pressure ratings and size options available to match specific project requirements, ensuring that the hoses can handle the demands of various applications.

In What Ways Does Shrinking Hose Benefit Manufacturing for Cable Management?

In manufacturing settings, shrinking hoses are widely used for cable management and protection. They help organize and shield cables from abrasion and environmental damage, leading to improved operational efficiency. This organization reduces downtime caused by cable wear and tear, thereby enhancing productivity. Buyers should focus on the material quality and resistance properties of the hoses to ensure they meet the rigorous demands of manufacturing environments, especially in regions with high industrial activity.

How Does Shrinking Hose Contribute to Aerospace Fuel Lines and Hydraulic Systems?

In the aerospace industry, shrinking hoses are crucial for fuel lines and hydraulic systems, where weight and space are critical factors. These hoses provide lightweight, space-saving solutions that do not compromise on performance. Their ability to withstand extreme temperatures and pressures is vital for aircraft safety and efficiency. Buyers in this sector must ensure compliance with stringent aviation standards and consider the heat resistance capabilities of the hoses to maintain safety and reliability in flight operations.

Illustrative image related to shrinking hose

3 Common User Pain Points for ‘shrinking hose’ & Their Solutions

Scenario 1: Dealing with Hose Durability Issues in Harsh Environments

The Problem: B2B buyers in industries such as agriculture or construction often face challenges with the durability of shrinking hoses when exposed to harsh environmental conditions. For instance, in regions with extreme temperatures or abrasive surfaces, these hoses can suffer premature wear and tear, leading to leaks or bursts. Buyers may find themselves frustrated with frequent replacements, impacting operational efficiency and increasing costs.

The Solution: To combat durability issues, it is crucial to source high-quality shrinking hoses specifically designed for resilience. Look for hoses made from advanced materials like reinforced thermoplastic or rubber blends that can withstand extreme temperatures and abrasive conditions. Additionally, consider hoses that feature UV protection and are rated for high burst pressure. Collaborate with suppliers who provide comprehensive product specifications and user reviews to ensure you are selecting hoses that meet your industry’s rigorous demands. Implementing a regular maintenance schedule, such as inspecting hoses for wear and cleaning them after use, can also prolong their lifespan.

Scenario 2: Navigating Limited Storage Space for Hoses

The Problem: Many B2B operations, especially in urban areas or smaller facilities, struggle with limited storage space for garden or industrial hoses. Traditional hoses can take up significant room, leading to disorganization and inefficiency. Buyers often grapple with the challenge of managing bulky equipment without compromising on functionality.

The Solution: Shrinking hoses are an excellent solution for space constraints. When sourcing these hoses, prioritize models that contract significantly when not in use, allowing for compact storage. For instance, hoses that shrink to less than a quarter of their original length can easily fit into small cabinets or storage bins. Additionally, consider utilizing hose reels or wall-mounted storage systems that can accommodate the compact size of shrinking hoses, further enhancing organization. Educating your team on proper storage techniques can also maximize space utilization, ensuring that hoses are easily accessible yet neatly stored.

Illustrative image related to shrinking hose

Scenario 3: Ensuring Compatibility with Existing Equipment

The Problem: B2B buyers frequently face compatibility issues between shrinking hoses and their existing equipment, such as nozzles, connectors, or irrigation systems. This can lead to inefficiencies and increased costs if the hoses do not fit standard fittings or require additional adapters that may not be readily available.

The Solution: To avoid compatibility issues, it’s essential to conduct thorough research before purchasing shrinking hoses. Focus on hoses with standardized fittings that match your existing equipment, and consider the hose diameter, length, and fitting type. Suppliers often provide detailed compatibility information; therefore, leveraging this resource can save time and prevent costly mistakes. If your operation uses a variety of equipment, investing in adjustable or universal connectors can also provide flexibility. Lastly, creating a centralized catalog of all hoses and their specifications within your operation can streamline future purchases and ensure that every team member is informed about what works best with your current systems.

Strategic Material Selection Guide for shrinking hose

What Are the Key Materials Used in Shrinking Hose Manufacturing?

When selecting materials for shrinking hoses, it is crucial to consider their performance characteristics, manufacturing complexities, and suitability for various applications. Below, we analyze four common materials used in the production of shrinking hoses, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Illustrative image related to shrinking hose

1. Polyethylene (PE)

Key Properties:

Polyethylene is known for its excellent chemical resistance, flexibility, and low-temperature performance. It can withstand moderate pressure ratings, typically up to 150 psi, making it suitable for various applications.

Pros & Cons:

The primary advantage of PE is its affordability and ease of manufacturing. It is lightweight, which reduces shipping costs. However, its durability can be a concern; it may become brittle over time, especially when exposed to UV light or extreme temperatures.

Impact on Application:

PE is compatible with a wide range of media, including water and some chemicals, but it is not suitable for high-temperature applications.

Considerations for International Buyers:

Buyers should ensure compliance with local standards, such as ASTM or DIN, particularly in regions like Europe and South America, where regulations may be stricter regarding chemical resistance and environmental impact.

Illustrative image related to shrinking hose

2. Polyvinyl Chloride (PVC)

Key Properties:

PVC offers good mechanical strength, chemical resistance, and a higher temperature rating compared to PE, generally up to 180 psi. It is also resistant to corrosion, making it ideal for various applications.

Pros & Cons:

The durability of PVC is a significant advantage, as it can withstand harsh environmental conditions. However, its rigidity can make it less flexible than other materials, which may hinder performance in certain applications.

Impact on Application:

PVC is well-suited for water and sewage applications but may not be compatible with certain solvents.

Considerations for International Buyers:

In regions like Africa and the Middle East, where heat and UV exposure are prevalent, buyers should look for UV-stabilized PVC options. Compliance with local standards is essential, as improper use can lead to regulatory issues.

3. Thermoplastic Elastomer (TPE)

Key Properties:

TPE combines the properties of rubber and plastic, offering excellent flexibility, elasticity, and a broad temperature range, typically up to 200 psi. It is also resistant to UV rays and ozone.

Pros & Cons:

The flexibility and durability of TPE make it an excellent choice for applications requiring frequent movement. However, it tends to be more expensive than PE and PVC, which may affect cost-sensitive projects.

Impact on Application:

TPE is compatible with a variety of media, including water and oils, making it versatile for different applications.

Considerations for International Buyers:

Buyers should ensure that TPE products meet relevant international standards, particularly in Europe, where environmental regulations may dictate material choices.

Illustrative image related to shrinking hose

4. Nylon

Key Properties:

Nylon is known for its high tensile strength and excellent abrasion resistance. It can handle high pressure, often exceeding 300 psi, and has good thermal stability.

Pros & Cons:

The primary advantage of nylon is its strength and durability, making it suitable for demanding applications. However, it is more expensive and can absorb moisture, which may affect its performance over time.

Impact on Application:

Nylon is suitable for high-pressure applications and is often used in industrial settings. However, its moisture absorption can limit its use in certain environments.

Illustrative image related to shrinking hose

Considerations for International Buyers:

In regions with high humidity, such as parts of South America and Southeast Asia, buyers should consider the moisture absorption properties of nylon and ensure compliance with relevant industrial standards.

Summary Table of Material Selection for Shrinking Hose

| Material | Typical Use Case for shrinking hose | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene (PE) | General water applications | Cost-effective and lightweight | Limited durability under UV exposure | Low |

| Polyvinyl Chloride (PVC) | Water and sewage systems | Good chemical and corrosion resistance | Less flexible than other materials | Medium |

| Thermoplastic Elastomer (TPE) | Versatile applications | Excellent flexibility and durability | Higher cost compared to PVC and PE | High |

| Nylon | High-pressure industrial applications | High strength and abrasion resistance | Moisture absorption can be an issue | High |

This guide provides a comprehensive overview of material options for shrinking hoses, enabling B2B buyers to make informed decisions based on performance, cost, and regional compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for shrinking hose

What Are the Key Stages in the Manufacturing Process of Shrinking Hose?

The manufacturing process of shrinking hose involves several critical stages, each ensuring that the final product meets the demands of durability, flexibility, and functionality. Understanding these stages can help B2B buyers assess the quality of the products they are considering.

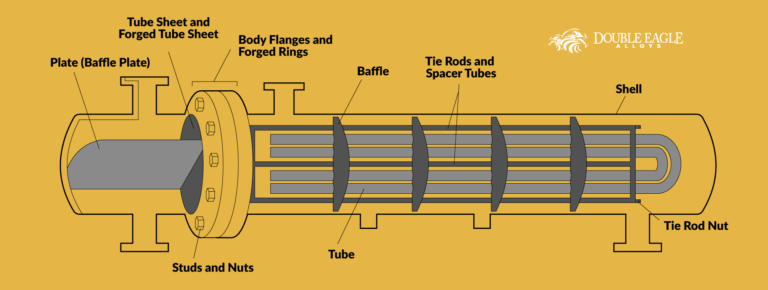

Material Preparation: What Raw Materials Are Used?

The manufacturing of shrinking hose typically begins with the selection of high-quality raw materials. Commonly used materials include thermoplastic elastomers (TPE), polyurethane (PU), and polyvinyl chloride (PVC). These materials are chosen for their flexibility, resistance to abrasion, and ability to contract and expand under varying pressures.

Before production, the raw materials undergo rigorous testing to ensure they meet specific performance characteristics. This includes assessing their tensile strength, elasticity, and resistance to environmental factors such as UV light and temperature fluctuations.

How Is the Forming Process Executed?

The forming stage is where the selected materials are transformed into the desired hose shape. This is often achieved through extrusion, where the raw materials are heated and forced through a die to create a continuous length of hose.

For expandable hoses, the extrusion process may include multiple layers to enhance strength and flexibility. Some manufacturers employ a co-extrusion technique to create a multi-layer hose that combines different materials, optimizing performance.

Illustrative image related to shrinking hose

What Does the Assembly Process Involve?

After forming, the hoses may require assembly, particularly if they come with attachments such as nozzles or connectors. This step often includes the addition of features like pressure regulators or anti-kink designs.

Quality control at this stage is crucial; ensuring that all components are securely attached and meet the design specifications is essential to prevent future failures.

What Finishing Techniques Are Applied?

The final stage in the manufacturing process is finishing, which may involve additional treatments to enhance the product’s durability and aesthetics. This can include surface treatments that improve grip or coatings that provide extra protection against environmental factors.

Additionally, hoses may undergo a quality inspection to check for visual defects, ensuring that the product meets the expected standards before it is packaged for distribution.

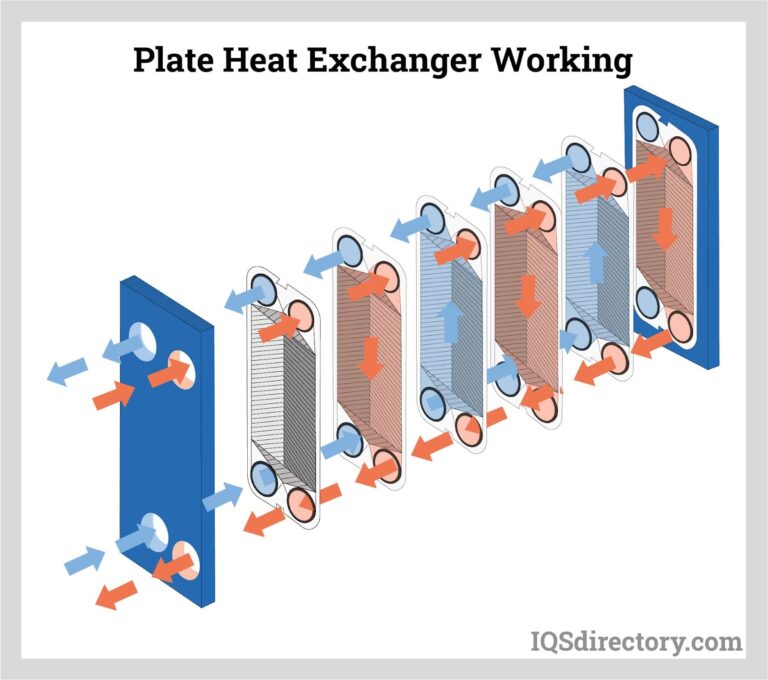

How Is Quality Assurance Implemented in Shrinking Hose Production?

Quality assurance (QA) is a critical component in the production of shrinking hoses, ensuring that products meet both international and industry-specific standards. This is particularly relevant for B2B buyers who require reliable performance from their suppliers.

Which International Standards Are Relevant for Quality Control?

Adherence to international standards is essential in the manufacturing of shrinking hoses. One of the most recognized standards is ISO 9001, which focuses on quality management systems and continuous improvement. Compliance with ISO 9001 indicates that the manufacturer has established a robust quality management framework, which can enhance buyer confidence.

In addition to ISO standards, industry-specific certifications such as CE marking (indicating conformity with health, safety, and environmental protection standards) and API standards (for hoses used in the oil and gas industry) may also apply, depending on the intended use of the product.

Illustrative image related to shrinking hose

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are integral to maintaining product integrity throughout the manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): This initial phase involves inspecting raw materials upon arrival to ensure they meet predefined specifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, random samples are tested to monitor production quality. This can include checking dimensions, pressure resistance, and flexibility.

-

Final Quality Control (FQC): Once the hoses are completed, a final inspection is conducted to verify that the products are free from defects and conform to the specified standards.

What Common Testing Methods Are Employed?

Testing methods vary but typically include:

-

Burst Pressure Testing: Evaluates the maximum pressure the hose can withstand before failure.

-

Flexibility Testing: Assesses the hose’s ability to bend without kinking or breaking.

-

Temperature Resistance Testing: Ensures the hose can function effectively within specified temperature ranges.

-

Abrasion Resistance Testing: Determines how well the hose can withstand wear and tear during use.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is vital. Here are some actionable steps buyers can take:

What Should Be Included in Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess quality control practices. Buyers should look for:

-

Documentation of Quality Management Systems: Ensure that the supplier has a documented process that complies with ISO 9001 or other relevant standards.

-

Records of Quality Control Checks: Review the records of IQC, IPQC, and FQC to ensure they are thorough and consistent.

-

Testing Reports: Request access to testing reports for various batches of products to verify compliance with performance specifications.

How Can Buyers Utilize Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control practices. These services can conduct:

-

Factory Inspections: Assess the manufacturing environment and operational practices.

-

Product Inspections: Evaluate the quality of finished products before shipment.

This approach not only enhances trust but also mitigates risks associated with product failures.

What Are the Unique QC and Certification Nuances for International Buyers?

B2B buyers must be aware of the nuances in quality control and certification that can vary significantly by region. For instance, compliance with CE marking may be essential for sales in Europe, while specific certifications may be required in African and South American markets.

Furthermore, understanding the regulatory landscape, including any tariffs or trade agreements that may affect supply chains, is crucial. Buyers should also consider the implications of local regulations on product safety and environmental impact.

Illustrative image related to shrinking hose

By having a comprehensive understanding of the manufacturing processes and quality assurance standards, B2B buyers can make informed decisions when sourcing shrinking hoses, ensuring they select suppliers that meet their quality requirements and operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘shrinking hose’

When sourcing shrinking hoses, particularly for international markets, it’s essential to follow a structured approach to ensure you meet your specific needs while minimizing risks. This guide provides a step-by-step checklist to assist B2B buyers in navigating the complexities of procurement.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for the shrinking hose you need. Consider factors such as diameter, length, burst pressure, and material composition. These specifications are vital as they will influence the performance and durability of the hoses in your intended applications.

- Material Considerations: Look for materials that offer flexibility and resistance to wear and tear, especially if the hoses will be used in harsh environments.

- Performance Metrics: Specify the required burst pressure and temperature tolerance to ensure the hose can withstand your operational conditions.

Step 2: Identify Your Target Market

Understanding the market you plan to serve is crucial. Different regions may have unique requirements based on climate, soil conditions, or specific industry practices.

- Regional Preferences: For instance, buyers in Africa may prioritize durability due to harsher conditions, while European markets might focus on sustainability and eco-friendliness.

- Regulatory Compliance: Ensure that the hoses comply with local regulations and standards, which can vary significantly across regions.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure they meet your standards. Request detailed company profiles, product catalogs, and case studies from similar industries.

- References and Reviews: Seek testimonials or references from other businesses that have used their products. This can provide insights into the supplier’s reliability and product performance.

- Certifications: Verify any relevant certifications, such as ISO or industry-specific quality standards, which can indicate a commitment to quality.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the hoses for testing. This step is crucial to ensure the products meet your specifications and quality standards.

- Testing Criteria: Evaluate the samples based on flexibility, ease of use, and durability under simulated operational conditions.

- Performance Evaluation: Assess how well the hoses expand and contract, and check for any signs of wear or failure during testing.

Step 5: Negotiate Pricing and Terms

Pricing can vary widely based on order volume, supplier location, and material costs. Engage in negotiations to achieve favorable terms.

- Bulk Discounts: Inquire about discounts for larger orders or long-term contracts to optimize your procurement budget.

- Payment Terms: Clarify payment terms and conditions, including any upfront deposits or credit options, to ensure financial flexibility.

Step 6: Confirm Logistics and Delivery Timelines

Logistics can significantly impact your supply chain. Ensure you understand the shipping options and delivery timelines offered by your supplier.

- Shipping Methods: Discuss the best shipping methods to balance cost and delivery speed, particularly for international orders.

- Tracking and Communication: Establish a communication plan for tracking shipments and addressing any potential delays.

Step 7: Establish a Quality Assurance Process

Finally, implement a quality assurance process to monitor the performance of the hoses once received.

- Inspection Protocols: Develop inspection criteria to evaluate the hoses upon arrival, ensuring they meet your quality expectations.

- Feedback Mechanism: Create a feedback loop with your supplier to address any issues that arise during the usage phase, fostering a collaborative relationship.

By following this checklist, B2B buyers can ensure a more effective and efficient sourcing process for shrinking hoses, tailored to their specific operational needs.

Comprehensive Cost and Pricing Analysis for shrinking hose Sourcing

What Are the Key Cost Components in Sourcing Shrinking Hoses?

When sourcing shrinking hoses, understanding the cost structure is vital for B2B buyers to make informed purchasing decisions. The primary cost components include:

Illustrative image related to shrinking hose

-

Materials: The choice of materials significantly impacts the cost. High-quality thermoplastics or rubber compounds are common, but the cost can vary based on the source and specifications. Buyers should seek suppliers that offer a balance between quality and price.

-

Labor: Labor costs include wages for skilled workers involved in the manufacturing process. Regions with lower labor costs can offer competitive pricing, but it’s essential to consider the skill level of the workforce to ensure product quality.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and maintenance of equipment. Efficient manufacturing processes can help reduce overhead and, consequently, the final price of the hoses.

-

Tooling: Custom molds and tools are necessary for producing specific hose designs or sizes. The initial investment in tooling can be substantial, but it is often amortized over high-volume production runs.

-

Quality Control (QC): Implementing robust QC processes ensures that products meet industry standards and customer specifications. While this adds to costs, it reduces the risk of returns and enhances brand reputation.

-

Logistics: Shipping and handling costs are influenced by the distance between the manufacturer and the buyer, as well as the mode of transport. Understanding the logistics involved can help buyers negotiate better terms.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. This margin can vary widely based on market conditions and competition.

How Do Price Influencers Affect Shrinking Hose Costs?

Several factors can influence the pricing of shrinking hoses:

-

Volume/MOQ: Minimum order quantities (MOQ) often affect pricing. Higher volumes usually lead to lower per-unit costs, so negotiating for bulk orders can yield significant savings.

-

Specifications and Customization: Custom features or specific performance metrics can increase costs. Buyers should clearly communicate their requirements to avoid unexpected price surges.

-

Materials: The selection of materials, particularly if they require certification for safety or environmental standards, can significantly influence pricing. Ensure that the chosen materials align with regulatory requirements in your market.

-

Quality and Certifications: Products that meet specific quality standards or certifications (such as ISO or ASTM) may have higher costs but can offer better reliability and market acceptance.

-

Supplier Factors: Different suppliers may have varying pricing strategies based on their operational efficiencies, market positioning, and reputation. Building relationships with suppliers can lead to better pricing and terms.

-

Incoterms: Understanding international shipping terms is critical. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost of the hoses.

What Are the Best Buyer Tips for Cost-Efficient Sourcing of Shrinking Hoses?

-

Negotiation: Always negotiate terms and pricing with suppliers. Highlighting your potential for long-term business can lead to better deals.

-

Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), which includes not just the purchase price but also shipping, handling, storage, and potential wastage or returns. This broader perspective can lead to more informed decisions.

-

Pricing Nuances for International Buyers: For buyers in regions like Africa, South America, the Middle East, and Europe, consider currency fluctuations and import tariffs, which can significantly impact costs. Working with local suppliers or establishing regional partnerships can mitigate these risks.

-

Quality vs. Price: While lower prices are attractive, ensure that quality is not compromised. Investing in high-quality hoses can reduce maintenance costs and improve customer satisfaction in the long run.

-

Market Research: Stay updated on market trends and competitors’ pricing. This knowledge can empower you during negotiations and help you identify the best sourcing strategies.

Disclaimer on Indicative Prices

Prices for shrinking hoses can vary widely based on the factors discussed. It is essential for buyers to conduct thorough market research and request quotes from multiple suppliers to obtain the most accurate pricing for their specific needs.

Alternatives Analysis: Comparing shrinking hose With Other Solutions

When evaluating options for flexible and space-saving hose solutions, it’s essential to consider a variety of alternatives to shrinking hoses. These alternatives can offer different advantages depending on specific needs such as performance, cost, and ease of use. Below is a comparative analysis of shrinking hoses against two viable alternatives: expandable hoses and coil hoses.

| Comparison Aspect | Shrinking Hose | Expandable Hose | Coil Hose |

|---|---|---|---|

| Performance | Excellent flexibility and lightweight; can handle high water pressure. | Good flexibility and lightweight; may kink under pressure. | Good recoil and low profile; limited reach. |

| Cost | Moderate; typically ranges from $20 to $50. | Budget-friendly; typically ranges from $15 to $60. | Moderate; typically ranges from $30 to $80. |

| Ease of Implementation | Simple to connect and disconnect; requires minimal setup. | Easy to use; expands automatically with water pressure. | Requires more effort to coil and uncoil; can be cumbersome. |

| Maintenance | Low maintenance; occasional checking for leaks. | Low maintenance; requires drying after use to prevent mold. | Moderate; needs regular cleaning to prevent debris buildup. |

| Best Use Case | Ideal for tight storage spaces and frequent moving. | Best for general garden use with varying lengths. | Suitable for small gardens or where minimal storage is needed. |

What Are the Advantages and Disadvantages of Expandable Hoses Compared to Shrinking Hoses?

Expandable hoses, such as the popular Pocket Hose, are designed to expand when water flows through them, offering a lightweight and flexible option. They generally have a lower price point, making them an attractive choice for budget-conscious buyers. However, they can kink under high water pressure and may not be as durable as shrinking hoses. They also require drying after use to prevent mold growth, which could be a drawback for users in humid environments.

How Do Coil Hoses Stack Up Against Shrinking Hoses?

Coil hoses provide a compact storage solution and are designed to recoil back to a coiled shape after use. This makes them easy to store and less likely to tangle. While they are effective for smaller gardens or tasks that require quick access to water, they typically have a more limited reach compared to shrinking hoses and can be cumbersome to uncoil. Furthermore, they may require more maintenance to keep the coil clean and free of debris.

Illustrative image related to shrinking hose

How Can B2B Buyers Choose the Right Hose Solution for Their Needs?

When selecting the most suitable hose solution, B2B buyers should consider their specific use cases and operational requirements. For businesses needing frequent mobility and flexibility in tight spaces, shrinking hoses may be the best fit due to their compact nature and high performance. On the other hand, for buyers focused on cost-effectiveness and general gardening tasks, expandable hoses could be the ideal choice. Lastly, if storage space is minimal and tasks are limited in scope, coil hoses may serve well, albeit with some trade-offs in terms of reach and ease of use. Evaluating these factors carefully will ensure that the chosen solution aligns with the operational goals and budget constraints of the organization.

Essential Technical Properties and Trade Terminology for shrinking hose

What Are the Essential Technical Properties of Shrinking Hose?

When evaluating shrinking hoses for B2B applications, understanding key technical properties is crucial. Here are some critical specifications that decision-makers should consider:

1. Material Composition

Shrinking hoses are typically made from materials like PVC (polyvinyl chloride), silicone, or polyethylene. Each material offers different characteristics in terms of flexibility, durability, and resistance to environmental factors such as UV rays and temperature variations. Selecting the right material can significantly impact the hose’s lifespan and performance in specific applications.

2. Burst Pressure Rating

The burst pressure rating is an essential specification that indicates the maximum pressure the hose can withstand before failing. Measured in pounds per square inch (psi), this property is vital for ensuring the hose can handle the operational pressures encountered in various industrial settings. A higher burst pressure rating provides greater safety and reliability, particularly in high-pressure environments.

Illustrative image related to shrinking hose

3. Temperature Tolerance

Understanding the temperature tolerance of a shrinking hose is critical for applications involving hot or cold liquids. This specification defines the range of temperatures the hose can safely operate within without degrading or losing its structural integrity. A hose with a wide temperature tolerance is suitable for diverse applications, making it a more versatile choice for B2B buyers.

4. Shrink Ratio

The shrink ratio indicates how much the hose can contract relative to its expanded size. A high shrink ratio allows for easier storage and handling, making the hose more user-friendly. For businesses with limited storage space, this property can lead to significant logistical efficiencies.

5. Length and Diameter Options

Hoses come in various lengths and diameters, which can influence their suitability for specific tasks. Offering multiple options allows buyers to select the most appropriate size for their applications, reducing waste and improving operational efficiency. In B2B transactions, being able to customize lengths can also meet specific customer needs more effectively.

What Are the Common Trade Terms Associated with Shrinking Hose?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B sector. Here are several common terms relevant to shrinking hoses:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of shrinking hoses, understanding OEM relationships can help buyers identify reliable suppliers that adhere to industry standards and quality control.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is crucial for B2B buyers as it can impact inventory management and purchasing strategies. Understanding MOQ helps businesses plan their orders efficiently, ensuring they meet production demands without overstocking.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products. In the shrinking hose industry, issuing an RFQ allows buyers to compare prices and terms from multiple vendors, facilitating informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers, especially when sourcing products globally, as they dictate shipping responsibilities, risk transfer, and cost allocation.

5. Lead Time

Lead time is the duration between placing an order and receiving the product. Understanding lead times is vital for effective supply chain management, as delays can impact production schedules and customer satisfaction. Buyers should always inquire about lead times when negotiating contracts for shrinking hoses.

By grasping these technical properties and trade terms, B2B buyers can make informed purchasing decisions, ensuring they acquire the right shrinking hoses for their specific applications while optimizing costs and logistics.

Navigating Market Dynamics and Sourcing Trends in the shrinking hose Sector

What Are the Key Trends Shaping the Shrinking Hose Market?

The global market for shrinking hoses is evolving rapidly, driven by various factors that significantly impact B2B sourcing strategies. Increasing demand for lightweight, portable, and space-saving solutions in gardening and industrial applications is propelling the adoption of shrinking hoses. Internationally, buyers from regions such as Africa, South America, the Middle East, and Europe are particularly interested in products that combine functionality with convenience. The expansion of urban gardening and landscaping projects, coupled with the growth of DIY home improvement trends, is further fueling market growth.

Illustrative image related to shrinking hose

Emerging technologies are also influencing the shrinking hose sector. Innovations in materials, such as advanced polymers, enhance durability and flexibility, while the integration of smart technology—like pressure sensors and automated watering systems—offers added convenience for end-users. Moreover, e-commerce platforms are becoming essential channels for B2B buyers, enabling easy access to a wide range of products, competitive pricing, and real-time inventory updates. Companies that leverage these digital platforms effectively can streamline their sourcing processes and enhance supply chain efficiency.

How Is Sustainability Influencing the Shrinking Hose Supply Chain?

Sustainability is increasingly becoming a priority in the shrinking hose sector, with buyers showing a keen interest in environmentally friendly products. The impact of plastic waste on the environment has prompted manufacturers to seek alternatives, such as biodegradable materials and recyclable options. This shift not only appeals to eco-conscious consumers but also aligns with global sustainability goals.

Ethical sourcing is crucial for B2B buyers, as it reflects a company’s commitment to social responsibility. Suppliers that adhere to ethical practices—such as fair labor standards and transparent supply chains—are more likely to attract business partnerships. Certifications like ISO 14001 for environmental management and OEKO-TEX for textile safety can enhance a company’s credibility and appeal to buyers looking for responsible sourcing.

Incorporating ‘green’ materials into product offerings not only helps mitigate environmental impacts but can also differentiate a brand in a competitive marketplace. As sustainability becomes a key decision-making factor, international buyers must prioritize partnerships with suppliers committed to eco-friendly practices and innovative materials.

What Is the Historical Context Behind Shrinking Hoses in B2B Markets?

The concept of shrinking hoses has its roots in the quest for convenience and efficiency in water management systems. Initially developed for residential gardening, these hoses gained traction due to their lightweight and space-saving features. Over time, advancements in materials and manufacturing processes have led to improved durability and functionality.

As urbanization increased in various regions, the demand for practical gardening solutions grew. This shift prompted manufacturers to innovate continuously, resulting in the modern shrinking hoses we see today. The evolution from traditional rubber hoses to advanced expandable designs has opened new markets and applications, including industrial and commercial uses, making them appealing to a diverse range of B2B buyers.

In summary, the shrinking hose sector is characterized by dynamic market trends, a strong focus on sustainability, and a rich history that continues to shape its future. B2B buyers must navigate these evolving dynamics to make informed sourcing decisions that align with their operational goals and sustainability commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of shrinking hose

-

How do I solve issues with my shrinking hose not retracting properly?

To address a shrinking hose that fails to retract, first ensure that it is fully drained of water. Check for kinks or blockages in the hose that may be restricting its movement. If the hose is still not retracting, inspect for any leaks or damage, as these can affect performance. Regular maintenance, such as cleaning and proper storage, can prevent these issues. If problems persist, consider consulting the manufacturer or supplier for troubleshooting advice or warranty claims. -

What is the best shrinking hose for commercial landscaping applications?

For commercial landscaping, the best shrinking hose should be durable, lightweight, and capable of withstanding high water pressures. Look for hoses with reinforced materials and a higher burst pressure rating (ideally over 650 psi) to ensure longevity and performance. Models like the Pocket Hose Silver Bullet are often recommended for their flexibility and ease of storage, but evaluate based on specific needs, such as hose length and nozzle compatibility for your projects. -

How can I evaluate the quality of a shrinking hose supplier?

To assess the quality of a shrinking hose supplier, begin by reviewing their product specifications and certifications. Request samples to evaluate the hose’s durability, flexibility, and performance under pressure. Investigate customer reviews and testimonials to gauge reliability and service. Additionally, verify their compliance with international quality standards and inquire about their production processes, warranty policies, and after-sales support to ensure they meet your business requirements. -

What are the typical minimum order quantities (MOQs) for shrinking hoses?

Minimum order quantities for shrinking hoses can vary significantly by supplier and product type. Generally, MOQs range from 100 to 1,000 units, depending on the manufacturer’s production capabilities and the materials used. When negotiating with suppliers, clarify MOQs upfront, as lower quantities may be available at higher prices. Consider consolidating orders with other buyers to meet MOQ requirements and reduce overall costs. -

What payment terms should I expect when sourcing shrinking hoses internationally?

International payment terms can vary widely based on the supplier’s policies and your negotiation. Common terms include advance payment, letter of credit, or payment upon delivery. Many suppliers offer a 30% deposit with the balance due before shipment. It’s advisable to establish clear payment terms in your purchase agreement to mitigate risks. Always ensure that payment methods are secure and traceable to protect your investment. -

How do I ensure quality assurance (QA) for my shrinking hose orders?

To ensure quality assurance for shrinking hose orders, implement a multi-step QA process. First, establish clear product specifications and quality standards with your supplier before production begins. Request regular updates and photos during the manufacturing process. Consider conducting third-party inspections prior to shipment to verify compliance with your standards. Additionally, maintain open communication with your supplier regarding any quality concerns that arise during the order fulfillment process. -

What are the logistics considerations for importing shrinking hoses?

When importing shrinking hoses, key logistics considerations include choosing the right shipping method (air vs. sea), understanding customs regulations, and preparing accurate documentation. Assess shipping costs and transit times to determine the most efficient delivery method. Collaborate with a freight forwarder who understands the regulations of your target market, especially for African, South American, Middle Eastern, or European countries. Ensure that you have the necessary import licenses and that all customs duties are accounted for to avoid delays. -

Can I customize my order of shrinking hoses?

Yes, many suppliers offer customization options for shrinking hoses, including length, color, and branding. When placing an order, communicate your specific requirements clearly to the supplier. Be aware that custom orders may have higher MOQs and longer lead times. Discuss any additional costs associated with customization upfront. Request samples of custom designs if possible to ensure they meet your expectations before finalizing the bulk order.

Top 2 Shrinking Hose Manufacturers & Suppliers List

1. Tech Gear Lab – Pocket Hose Silver Bullet

Domain: techgearlab.com

Registered: 2013 (12 years)

Introduction: {“best_expandable_hoses”: [{“name”: “Pocket Hose Silver Bullet”, “overall_score”: 67, “price”: “$30”, “pros”: [“Shrinks back to original size well”, “Flexible”, “Easy to use”, “Budget-friendly”], “cons”: [“Poor quality nozzle”, “Limited length options”], “available_lengths”: [25, 50, 100], “expansion_type”: “Expandable”}, {“name”: “Flexi Hose”, “overall_score”: 67, “price”: “$55”, “pros”: [“Shrink…

2. Reddit – Durable Expandable Garden Hose

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Expandable garden hose that is durable and does not fail within 3 years.

Strategic Sourcing Conclusion and Outlook for shrinking hose

What Key Takeaways Should International Buyers Consider for Shrinking Hose?

In summary, the strategic sourcing of shrinking hoses presents significant opportunities for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. These hoses, known for their flexibility and space-saving capabilities, align well with the growing demand for efficient and user-friendly gardening and irrigation solutions. By prioritizing quality, durability, and supplier reliability, businesses can ensure they meet customer expectations while optimizing their supply chain.

How Can Strategic Sourcing Enhance Your Business Operations?

Investing in strategic sourcing not only mitigates risks but also enhances cost-effectiveness and fosters long-term partnerships with suppliers. As the market for shrinking hoses continues to evolve, staying informed about product innovations and trends will be crucial for maintaining a competitive edge.

What’s Next for B2B Buyers in the Shrinking Hose Market?

Looking ahead, we encourage international buyers to explore diverse sourcing options and leverage market intelligence to make informed purchasing decisions. Engage with suppliers that demonstrate a commitment to quality and sustainability. The future of the shrinking hose market is promising, and by taking proactive steps now, businesses can capitalize on this growth opportunity and strengthen their position in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.