Everything You Need to Know About Seton Id Products Sourcing in 2025

Introduction: Navigating the Global Market for seton id products

In an increasingly interconnected world, sourcing high-quality seton ID products can be a daunting challenge for international B2B buyers. Whether you’re operating in Africa, South America, the Middle East, or Europe, the need for reliable workplace safety solutions is paramount. This comprehensive guide addresses key challenges faced by businesses, including the diverse types of seton ID products available, their varied applications, and essential supplier vetting processes. By exploring factors such as compliance with international safety standards, customization options, and cost considerations, this resource empowers buyers to make informed purchasing decisions.

Understanding the nuances of seton ID products—from safety signs and asset tags to custom labeling solutions—can significantly enhance workplace safety and efficiency. For businesses in regions like Vietnam and Brazil, where compliance with local regulations is critical, having access to expert insights on sourcing and implementing these products can be a game-changer. This guide is designed to equip B2B buyers with the knowledge necessary to navigate the global market confidently, ensuring that safety and compliance are never compromised. With actionable insights and a focus on practical solutions, you will be well-prepared to enhance your operational safety and productivity through informed procurement strategies.

Understanding seton id products Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Asset Tags | RFID, barcode, and metal options for durability | Equipment tracking, inventory management | Pros: Enhances asset tracking; Cons: Initial cost can be high. |

| Safety Signs | Compliant with OSHA and ANSI standards; various materials | Workplace safety, hazard communication | Pros: Improves safety compliance; Cons: May require regular updates. |

| Custom Labels | Tailored designs, various materials for specific needs | Branding, inventory control, safety labeling | Pros: Enhances brand visibility; Cons: Longer lead times for custom orders. |

| Pipe Markers | Self-adhesive, snap-around options for easy installation | Industrial safety, maintenance operations | Pros: Quick identification of hazards; Cons: Environmental factors may affect adhesion. |

| Lockout Tags | Durable materials with clear messaging | Equipment maintenance, safety protocols | Pros: Critical for safety during maintenance; Cons: Needs to be managed properly to avoid loss. |

What Are Asset Tags and How Are They Used in B2B Operations?

Asset tags are identification tools utilized to track and manage equipment and inventory efficiently. Available in various forms, including RFID and barcode labels, they help businesses monitor assets throughout their lifecycle. B2B buyers should consider the durability and technology of asset tags to ensure they meet specific operational needs, especially in industries with high-value equipment.

Why Are Safety Signs Essential for Workplace Compliance?

Safety signs are critical in communicating hazards and ensuring compliance with regulatory standards such as OSHA and ANSI. They come in multiple formats, including banners and wall signs, tailored to various environments. Businesses must prioritize quality and clarity in their signage to foster a safe workplace, and regular audits should be conducted to ensure compliance with evolving safety regulations.

How Do Custom Labels Enhance Business Branding and Operations?

Custom labels provide businesses with the flexibility to create unique identifiers for products or equipment, enhancing brand visibility and operational efficiency. They can be designed for specific applications, such as asset identification or safety compliance. When purchasing, businesses should consider the material and adhesive properties to ensure that the labels withstand their intended environments.

What Role Do Pipe Markers Play in Industrial Safety?

Pipe markers are essential for identifying the contents of pipes, thereby enhancing workplace safety and maintenance efficiency. They are available in self-adhesive and snap-around formats, making them easy to install. B2B buyers should evaluate the environmental conditions of their facilities, as factors such as temperature and humidity can affect the longevity and effectiveness of pipe markers.

How Do Lockout Tags Contribute to Workplace Safety Protocols?

Lockout tags are vital for ensuring that equipment is properly shut down and inoperable during maintenance. Made from durable materials, these tags provide clear instructions and warnings to prevent accidental machine startups. Businesses should implement a robust lockout/tagout program to maximize safety and compliance, ensuring that all employees understand the importance of these tags in their daily operations.

Key Industrial Applications of seton id products

| Industry/Sector | Specific Application of seton id products | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Pipe Marking & Valve Tags | Enhances safety compliance and reduces risk of accidents. | Ensure compliance with local regulations and standards. |

| Warehousing | Asset Tagging & Labeling | Improves inventory management and reduces loss of assets. | Consider durability and visibility of labels in the warehouse environment. |

| Construction | Custom Safety Signs | Communicates hazards and ensures compliance with safety protocols. | Evaluate the materials used for signs to withstand outdoor conditions. |

| Transportation & Logistics | Traffic & Parking Controls | Optimizes traffic flow and enhances safety in parking areas. | Assess the need for multilingual signs in diverse regions. |

| Healthcare | Safety Labels & Decals | Ensures clear communication of hazards and compliance with regulations. | Look for specific labels that comply with healthcare standards. |

How Are Seton ID Products Utilized in the Manufacturing Sector?

In the manufacturing sector, Seton ID products, particularly pipe marking and valve tags, are essential for ensuring safety and compliance. These products help workers quickly identify hazardous materials, thereby reducing the risk of accidents. International buyers should ensure that the products meet local regulatory standards, such as OSHA in the U.S. or similar regulations in their respective countries. The ability to customize labels can also address specific language needs, enhancing safety communication across diverse workforces.

What Role Do Seton ID Products Play in Warehousing?

In warehousing, asset tagging and labeling are critical for effective inventory management. Seton’s asset tags help businesses track equipment and supplies, minimizing losses and enhancing operational efficiency. For international buyers, it is important to consider the durability of these tags, especially in varying climates. Additionally, labels should be designed for high visibility to ensure they are easily readable in busy warehouse settings, thus promoting a safer working environment.

How Do Seton ID Products Contribute to Safety in Construction?

Custom safety signs are vital in the construction industry for communicating hazards and ensuring adherence to safety protocols. Seton’s signage solutions can be tailored to display specific warnings and instructions, which is crucial on dynamic job sites. Buyers in this sector should evaluate the materials used for these signs, ensuring they are weather-resistant and durable. Furthermore, multi-language options can be beneficial in regions with diverse workforces, ensuring that all workers understand safety messages.

Why Are Seton ID Products Important in Transportation & Logistics?

In the transportation and logistics sector, traffic and parking controls provided by Seton are instrumental in optimizing traffic flow and enhancing safety. Properly marked signs guide drivers and pedestrians, reducing the likelihood of accidents. For international buyers, it’s important to assess the need for multilingual signage, especially in regions with significant traffic from diverse linguistic backgrounds. Additionally, ensuring compliance with local traffic regulations is essential for maintaining operational integrity.

How Do Seton ID Products Enhance Safety in Healthcare?

In healthcare environments, safety labels and decals play a crucial role in communicating hazards and ensuring compliance with health regulations. Seton’s products help to clearly indicate the presence of biohazards and other risks, thereby safeguarding both staff and patients. Buyers in the healthcare sector should specifically look for labels that adhere to industry standards, ensuring they are suitable for clinical environments. The ability to customize these labels can also help in addressing specific needs within different departments.

3 Common User Pain Points for ‘seton id products’ & Their Solutions

Scenario 1: Navigating Compliance Challenges with Safety Products

The Problem: In many industries, compliance with safety regulations is not just a best practice—it’s a legal requirement. B2B buyers often struggle with understanding the specific compliance standards their products must meet, particularly when dealing with diverse regulations across different regions. For example, a company operating in both Europe and Africa may find that the safety signage requirements differ significantly. This inconsistency can lead to confusion, potential fines, and increased liability if the wrong products are used.

The Solution: To effectively navigate compliance challenges, B2B buyers should start by conducting a comprehensive audit of the relevant safety regulations in their operational regions, such as OSHA in the U.S. or EU directives in Europe. Once the requirements are clear, sourcing Seton ID products that are explicitly marked as compliant with these standards is crucial. Seton provides a range of products that adhere to various safety regulations. Buyers can consult with Seton’s OSHA-trained specialists for tailored advice on which products meet their specific compliance needs. Additionally, leveraging Seton’s resource center can provide invaluable guidance on regulatory compliance, ensuring that the selected products not only fulfill safety requirements but also enhance workplace safety culture.

Scenario 2: Customization Needs for Unique Business Applications

The Problem: Many B2B buyers face the challenge of needing customized safety and identification solutions that reflect their specific operational needs. For instance, a manufacturing facility may require unique asset tags that include company logos, barcodes, or specific safety messages tailored to their equipment. Standard products may not adequately communicate critical information, leading to operational inefficiencies and increased risk of errors.

The Solution: To address customization needs effectively, buyers should utilize Seton’s extensive range of customizable ID products. Seton allows businesses to design their own labels, signs, and tags that meet their exact specifications. When placing an order, it is beneficial to engage directly with Seton’s design team to ensure the final products align perfectly with operational requirements. Additionally, investing time in planning the design—including size, materials, and messaging—can significantly enhance the effectiveness of the communication. By implementing customized ID products, companies can improve operational efficiency, reduce miscommunication, and foster a safer work environment.

Scenario 3: Managing Inventory and Asset Tracking Challenges

The Problem: In industries with extensive inventories or numerous assets, tracking and managing items can quickly become overwhelming. B2B buyers often struggle with lost items, misidentification, or inefficient inventory management processes, leading to operational delays and financial losses. For example, a logistics company might find it challenging to keep track of multiple shipments, leading to confusion and increased costs.

The Solution: Implementing an effective asset tagging and inventory management system using Seton ID products can streamline operations significantly. Buyers should consider utilizing RFID tags or barcode labels available from Seton, as these products facilitate easy tracking and identification of assets. The first step is to conduct an inventory assessment to determine the types of tags needed for different assets. Following this, buyers can implement a systematic tagging process, where each item is labeled according to its unique identifier. Leveraging Seton’s buyer’s guide on asset tagging can provide deeper insights into the best products for specific needs. Additionally, integrating these tags with inventory management software can enhance visibility and tracking, ultimately leading to reduced losses and improved operational efficiency.

Strategic Material Selection Guide for seton id products

What Are the Key Properties of Common Materials Used in Seton ID Products?

When selecting materials for Seton ID products, understanding the properties and suitability of each material is crucial for ensuring optimal performance in various environments. Here, we analyze four common materials: vinyl, polyester, metal, and paper.

Vinyl: Versatile and Durable

Vinyl is a popular choice for labels and decals due to its excellent durability and flexibility. It can withstand a wide range of temperatures, typically from -40°F to 180°F, making it suitable for both indoor and outdoor applications. Vinyl is also resistant to moisture and UV light, which prevents fading and degradation over time.

Pros: Vinyl is highly durable and resistant to various environmental factors, making it ideal for long-term use. It is also relatively cost-effective, which is a significant advantage for bulk purchases.

Cons: While vinyl is robust, it may not be suitable for extreme temperatures or harsh chemical environments. Additionally, the manufacturing process can be complex, potentially leading to longer lead times.

Impact on Application: Vinyl labels are ideal for asset tagging, safety signs, and pipe markers, especially in environments where exposure to moisture is common.

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure that vinyl products meet local compliance standards, such as ASTM or DIN, to guarantee safety and performance.

Polyester: High-Performance and Chemical Resistant

Polyester is known for its strength and chemical resistance, making it an excellent choice for labels that need to endure harsh conditions. It can handle temperatures ranging from -40°F to 300°F and is resistant to oils, solvents, and other chemicals.

Pros: The chemical resistance of polyester makes it suitable for industrial applications where exposure to hazardous materials is a concern. It also has a long lifespan, which can reduce replacement costs.

Cons: Polyester is generally more expensive than vinyl, which may be a consideration for budget-conscious buyers. Additionally, it may not adhere as well to surfaces that are not clean or smooth.

Impact on Application: Polyester labels are particularly effective in chemical manufacturing or laboratory settings, where durability and resistance to harsh substances are paramount.

Considerations for International Buyers: Compliance with international standards for chemical handling is essential, especially in regions like the Middle East, where regulations may vary significantly.

Metal: Robust and Long-Lasting

Metal tags, often made from aluminum or stainless steel, offer exceptional durability and resistance to extreme conditions. They can withstand high temperatures and are impervious to moisture, making them ideal for outdoor applications.

Pros: Metal tags are incredibly durable and can last for years without degradation. They are also resistant to corrosion, which is vital in humid or coastal environments.

Cons: The manufacturing process for metal tags can be more complex and costly compared to other materials. Additionally, they may not be suitable for applications requiring flexibility.

Impact on Application: Metal tags are ideal for asset tracking in outdoor environments, such as construction sites or warehouses, where exposure to the elements is a concern.

Considerations for International Buyers: Buyers should ensure that metal products comply with local regulations regarding materials used in industrial applications, particularly in Europe, where standards can be stringent.

Paper: Economical and Customizable

Paper is a cost-effective option for labels and tags, often used for temporary applications. While it is less durable than other materials, it can be treated with coatings to enhance its resistance to moisture and fading.

Pros: The low cost of paper makes it an attractive option for businesses looking to label items temporarily or in bulk. It is also highly customizable, allowing for easy printing of logos and information.

Cons: Paper labels may not withstand harsh environmental conditions, leading to quicker wear and tear. They are also less suitable for outdoor use unless treated.

Impact on Application: Paper labels are commonly used for inventory management, promotional materials, or short-term applications where cost is a primary concern.

Considerations for International Buyers: Compliance with local labeling standards is essential, especially in regions with strict regulations regarding product information and safety.

Summary Table of Material Selection for Seton ID Products

| Material | Typical Use Case for seton id products | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vinyl | Asset tagging, safety signs | Durable and flexible | Not suitable for extreme conditions | Medium |

| Polyester | Chemical labeling, industrial use | High chemical resistance | Higher cost than vinyl | High |

| Metal | Outdoor asset tracking | Exceptional durability | Complex and costly manufacturing | High |

| Paper | Temporary labels, inventory management | Cost-effective and customizable | Less durable, not for outdoor use | Low |

This strategic material selection guide provides essential insights for international B2B buyers, enabling informed decisions tailored to their specific operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for seton id products

What Are the Key Stages in the Manufacturing Process for Seton ID Products?

The manufacturing process for Seton ID products involves several critical stages designed to ensure high-quality output while meeting the specific needs of international B2B buyers.

Material Preparation

The first stage is material preparation, which involves sourcing high-quality raw materials that meet industry specifications. Materials used can vary widely, including durable plastics, metals, and specialty adhesives tailored for specific applications, such as extreme weather conditions or hazardous environments. Suppliers often conduct rigorous inspections to ensure that materials meet international quality standards before they enter the production line.

Forming

Once the materials are prepared, the forming stage begins. This involves cutting, stamping, or molding materials into the desired shapes. For example, plastic signs might be produced using injection molding, while metal tags may be created through stamping processes. Advanced techniques such as laser cutting can be employed for intricate designs, ensuring precision and consistency across products. This stage is crucial, as the quality of forming directly impacts the durability and functionality of the final product.

Assembly

After forming, the assembly stage takes place, where various components are brought together. For instance, when manufacturing asset tags, elements such as RFID chips and barcode labels are integrated. This process often requires skilled labor and sophisticated machinery to ensure that components fit together seamlessly. Automation may be employed in this stage to enhance efficiency and reduce human error, which is particularly beneficial for bulk orders from international clients.

Finishing

The final stage, finishing, involves applying protective coatings, printing information, and conducting any necessary quality checks. This can include lamination for durability or applying specialized inks for outdoor use. The finishing touches are essential for ensuring that products not only meet aesthetic standards but are also compliant with safety regulations, such as those set by OSHA or ANSI.

How Is Quality Assurance Implemented in Seton ID Products?

Quality assurance (QA) is a critical aspect of manufacturing Seton ID products, ensuring that each item meets stringent safety and performance standards.

What International Standards Are Followed for Quality Assurance?

Seton adheres to several international quality standards, with ISO 9001 being a cornerstone for their manufacturing processes. This standard emphasizes a customer-focused approach and continuous improvement, which resonates well with B2B buyers looking for reliable suppliers. Additionally, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may apply, depending on the product category. These certifications assure buyers that products are designed and manufactured to meet safety and performance criteria.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch any defects early. These checkpoints typically include:

- Incoming Quality Control (IQC): This step involves inspecting raw materials as they arrive to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During the forming and assembly stages, periodic checks are performed to monitor quality and adherence to specifications.

- Final Quality Control (FQC): Before products are packaged and shipped, a comprehensive inspection ensures that all items meet the established quality standards.

These checkpoints help minimize defects and ensure that only products that meet quality standards reach the buyer.

What Testing Methods Are Commonly Used in Quality Assurance?

To ensure the reliability and safety of Seton ID products, various testing methods are employed, including:

- Durability Testing: Products are subjected to stress tests, including exposure to extreme temperatures, humidity, and UV light, to evaluate their longevity.

- Adhesive Testing: For labels and tags, adhesive performance is tested under various conditions to ensure they will adhere properly in the field.

- Compliance Testing: Products are tested to ensure they meet specific regulatory requirements, such as flammability standards or chemical resistance.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to ensure the quality of Seton ID products can take several steps to verify the supplier’s QC processes:

- Audits: Conducting regular audits of the supplier’s manufacturing facilities can provide insights into their processes and adherence to quality standards.

- Quality Reports: Requesting detailed quality reports that outline the results of various testing methods and inspections can help buyers assess product reliability.

- Third-Party Inspections: Engaging third-party organizations to conduct independent inspections can further validate the supplier’s quality assurance claims.

What Are the Quality Control Considerations for International B2B Buyers?

When purchasing from suppliers in different regions, international B2B buyers must consider various quality control nuances:

- Regulatory Compliance: Different countries may have varying regulations regarding safety and quality. Buyers should ensure that products comply with local regulations in their respective markets.

- Cultural Differences in Quality Standards: Understanding cultural perceptions of quality can help buyers set realistic expectations when negotiating with suppliers in regions like Africa, South America, the Middle East, and Europe.

- Logistics and Delivery: Quality assurance also extends to logistics. Buyers should ensure that suppliers have robust logistics processes to minimize product damage during transit.

By understanding the manufacturing processes and quality assurance measures in place for Seton ID products, B2B buyers can make informed purchasing decisions that align with their safety and compliance needs. This comprehensive approach not only helps in selecting reliable suppliers but also contributes to building a safer working environment across industries.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘seton id products’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure Seton ID products. Whether you need safety signs, asset tags, or custom labels, following these steps will help ensure that you make informed decisions and secure the best solutions for your workplace safety needs.

Step 1: Identify Your Specific Needs

Before initiating the sourcing process, clearly define what types of Seton ID products you require. Consider factors such as the nature of your business, the specific hazards present, and compliance with local safety regulations.

– Product Categories: Determine whether you need workplace safety signs, pipe markers, asset tags, or custom solutions.

– Volume Requirements: Assess how many products you need to ensure you can leverage bulk purchasing options for cost savings.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that offer Seton ID products. Look for suppliers that specialize in workplace safety and have a strong reputation in the industry.

– Supplier Background: Investigate the company’s history, mission, and values to ensure alignment with your business.

– Customer Reviews: Check testimonials and case studies to gain insights into other customers’ experiences and satisfaction levels.

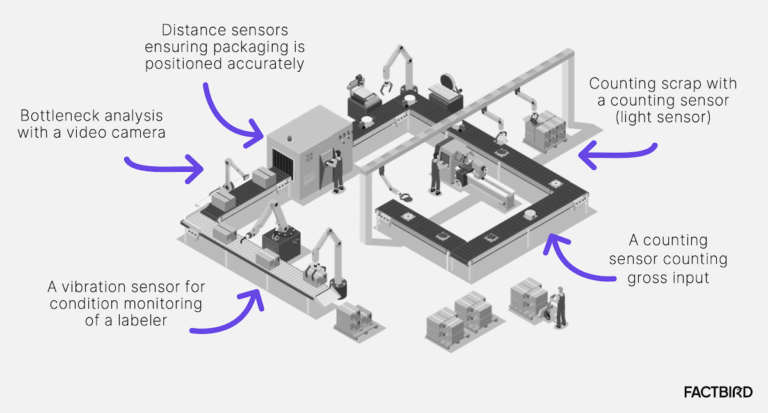

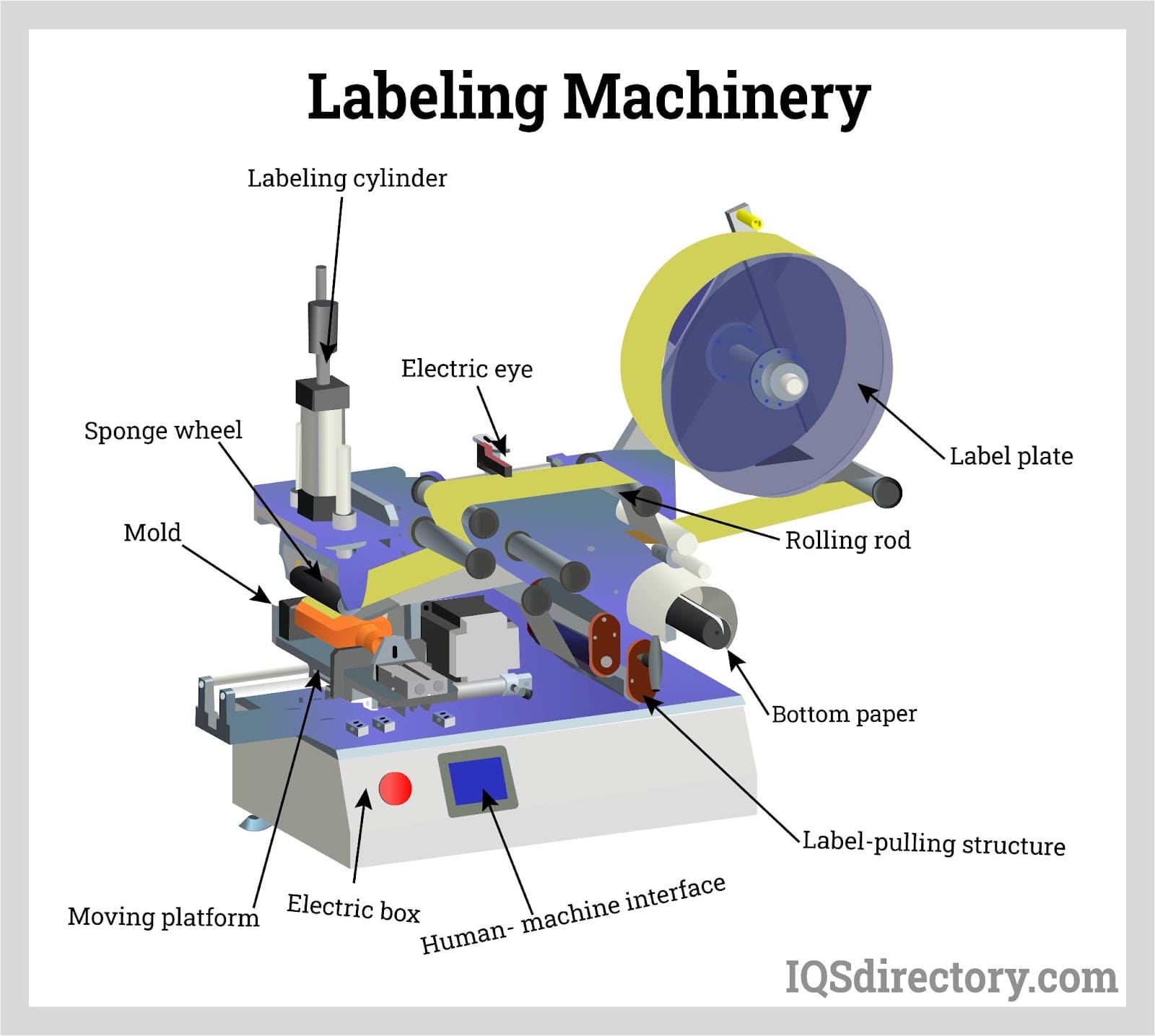

Illustrative image related to seton id products

Step 3: Evaluate Product Quality and Compliance

Quality and compliance are paramount when sourcing safety products. Ensure that the products meet relevant safety standards and regulations applicable in your region.

– Certifications: Look for certifications such as OSHA compliance and MUTCD standards.

– Material Durability: Assess the materials used in the products to ensure they can withstand the specific conditions of your workplace.

Step 4: Request Samples and Customization Options

Once you’ve shortlisted potential suppliers, request samples of the products you are interested in. This will allow you to evaluate the quality firsthand.

– Customization: Inquire about options for customizing products to better suit your specific needs, such as branded labels or tailored safety signs.

– Testing: Use the samples in your workplace to test their effectiveness and durability before making a bulk purchase.

Step 5: Compare Pricing and Terms

Pricing is a critical factor in the sourcing process. Collect quotes from multiple suppliers and compare them not only on price but also on terms of service.

– Bulk Discounts: Check for any available discounts for bulk purchases or loyalty programs.

– Shipping and Delivery: Review shipping costs and delivery timelines to ensure they align with your project deadlines.

Step 6: Verify Supplier Support and Resources

A reliable supplier should offer excellent customer support and additional resources. This can be crucial for ongoing maintenance and compliance.

– Customer Service: Assess the availability of customer service representatives who can assist with inquiries and troubleshooting.

– Educational Resources: Look for suppliers that provide guides or resources on workplace safety best practices, as this can enhance your overall safety program.

Step 7: Finalize Your Order and Establish a Relationship

Once you’ve completed your evaluation and selected a supplier, finalize your order while ensuring that all specifications are met. Establishing a good relationship with your supplier can lead to better support in the future.

– Order Confirmation: Double-check that all product specifications, quantities, and pricing are accurately reflected in your order confirmation.

– Long-term Partnership: Consider discussing future needs and potential partnerships for ongoing safety product requirements. This can lead to more favorable terms and better service in subsequent orders.

Illustrative image related to seton id products

Comprehensive Cost and Pricing Analysis for seton id products Sourcing

What Are the Key Cost Components for Sourcing Seton ID Products?

When analyzing the cost structure of Seton ID products, several key components must be considered. First, materials are crucial; the choice of raw materials significantly impacts the final cost. For instance, high-quality, durable materials used in safety signs and labels can drive up expenses but are necessary for compliance and longevity.

Next, labor costs include not only the wages of those involved in production but also the expenses related to skilled labor for custom designs. Manufacturing overhead, such as facility costs and utilities, also plays a role. Additionally, tooling costs for custom products can vary depending on the complexity of the design and the technology used.

Quality Control (QC) measures are essential in ensuring that products meet safety standards, which can add to costs but ultimately save money by reducing returns and compliance issues. Lastly, logistics expenses, including shipping and handling, are particularly relevant for international buyers who may face additional tariffs and duties.

How Do Price Influencers Affect the Cost of Seton ID Products?

Several factors can influence the pricing of Seton ID products. Volume and Minimum Order Quantity (MOQ) are significant; larger orders often qualify for discounts, making them more cost-effective. Customization specifications also play a crucial role—more complex designs and specific material requirements typically result in higher prices.

The quality and certifications of materials can affect pricing as well. Products that meet international safety standards, such as OSHA or ANSI, may have a premium due to their compliance costs. Supplier factors, including reputation and reliability, can influence pricing, with established suppliers potentially charging more for their brand trust and assurance of quality.

Moreover, Incoterms—the international commercial terms that define the responsibilities of buyers and sellers—impact logistics costs. Buyers should consider whether they are responsible for shipping, insurance, and duties, as these can significantly alter the total cost of ownership.

What Are the Best Buyer Tips for Negotiating Seton ID Product Prices?

For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, negotiating prices for Seton ID products requires a strategic approach. One effective strategy is to emphasize total cost of ownership (TCO) rather than just the purchase price. This includes considering quality, durability, and maintenance costs over the product’s lifespan.

Buyers should also be prepared to negotiate based on volume discounts. If a buyer can commit to larger orders or ongoing purchases, they may secure better pricing or additional perks, such as free shipping or expedited production timelines.

Another important aspect is understanding local market conditions. Buyers should be aware of regional pricing trends and the cost of competing products, which can provide leverage in negotiations. Additionally, maintaining good relationships with suppliers and being transparent about needs and expectations can foster better terms.

Finally, buyers should be cautious of pricing nuances related to international transactions. Factors such as currency fluctuations, exchange rates, and local regulations can all affect final costs, so it’s wise to conduct thorough market research and seek advice from local experts when necessary.

Disclaimer on Pricing Information

Prices for Seton ID products can vary widely based on the aforementioned factors. It is advisable to request quotes from multiple suppliers and to be aware that indicative prices may fluctuate due to market conditions, material availability, and changes in production costs. Always confirm current pricing directly with the supplier to ensure accuracy in budgeting.

Alternatives Analysis: Comparing seton id products With Other Solutions

Introduction: Understanding Alternative Solutions for Seton ID Products

When selecting identification and safety solutions for workplace environments, businesses often face a multitude of options. Seton ID products are recognized for their high quality and compliance with safety regulations. However, it’s essential to evaluate alternatives that might suit specific needs, budgets, or operational frameworks. This analysis will compare Seton ID products with alternative solutions to provide B2B buyers with a clearer understanding of their options.

Comparison Table

| Comparison Aspect | Seton ID Products | Alternative 1: RFID Asset Management Systems | Alternative 2: Traditional Manual Labeling |

|---|---|---|---|

| Performance | High durability and compliance | Real-time tracking and inventory management | Basic identification, prone to human error |

| Cost | Moderate to high, depending on customizations | High initial investment but cost-effective in long-term | Low initial cost but high labor costs |

| Ease of Implementation | Easy online ordering and support | Requires setup and training for staff | Simple to implement, no tech required |

| Maintenance | Low; durable materials and designs | Moderate; software updates and maintenance needed | Low; minimal upkeep required |

| Best Use Case | Safety compliance and clear identification | Large facilities needing real-time tracking | Small operations with limited identification needs |

Detailed Breakdown of Alternatives

Alternative 1: RFID Asset Management Systems

RFID (Radio-Frequency Identification) technology provides a sophisticated approach to asset management. This system allows for real-time tracking of equipment and inventory, significantly reducing the risk of loss or misplacement. The initial investment for RFID systems can be substantial due to the necessary hardware and software, as well as staff training. However, the long-term savings from improved inventory management and reduced labor costs can justify this expense. The complexity of implementation may deter some businesses, but those with large inventories or assets may find it invaluable.

Alternative 2: Traditional Manual Labeling

Traditional manual labeling involves using simple labels and decals to identify equipment and assets. This method is cost-effective, particularly for small businesses with limited budgets. The ease of implementation makes it attractive, as it requires no special training or technology. However, this approach is prone to human error, especially in environments with high turnover or where staff may not consistently follow labeling protocols. While it may suffice for smaller operations, it lacks the scalability and efficiency of more advanced systems like Seton ID products or RFID technology.

Conclusion: Choosing the Right Solution for Your Business Needs

Selecting the appropriate identification and safety solution hinges on your specific operational needs, budget constraints, and compliance requirements. Seton ID products offer robust performance, especially for businesses focused on safety and regulatory compliance. In contrast, RFID systems may be ideal for larger operations requiring real-time inventory management, while traditional manual labeling could serve small businesses with simpler needs. By carefully evaluating these alternatives, B2B buyers can make informed decisions that align with their strategic objectives and enhance workplace safety and efficiency.

Essential Technical Properties and Trade Terminology for seton id products

What Are the Key Technical Properties of Seton ID Products?

Understanding the technical properties of Seton ID products is crucial for B2B buyers who prioritize quality and compliance in workplace safety solutions. Here are some essential specifications to consider:

-

Material Grade

The material grade refers to the quality and composition of the materials used in manufacturing ID products, such as labels, tags, and signs. Common materials include vinyl, polyester, and aluminum. High-grade materials enhance durability, ensuring that products withstand various environmental conditions, which is particularly important for outdoor signage and labeling in diverse climates. -

Adhesive Strength

Adhesive strength is a critical property that determines how well labels and decals adhere to surfaces. This is especially important for safety labels that must remain intact under various conditions, such as extreme temperatures or exposure to chemicals. Strong adhesive properties reduce the risk of labels peeling off, which could lead to compliance issues and safety hazards. -

Print Quality and Resolution

The print quality of Seton ID products affects the legibility and clarity of information conveyed. High-resolution printing ensures that text and graphics are sharp and easily readable from a distance, which is vital for safety signs and labels. This property can significantly impact the effectiveness of communication in a workplace environment. -

Compliance Standards

Many Seton products are designed to meet specific industry compliance standards such as OSHA and ANSI. Understanding these compliance standards is essential for B2B buyers to ensure that their workplace meets legal requirements. Products that adhere to these standards not only enhance safety but also protect companies from potential liabilities. -

Customizability

Customizability refers to the ability to tailor products to meet specific business needs, such as unique branding requirements or specific safety messages. This property allows organizations to create solutions that align with their operational needs and communicate effectively with employees and visitors. -

Temperature Resistance

This specification indicates the range of temperatures that a product can withstand without degrading or losing functionality. For labels and tags used in industrial environments, high-temperature resistance is crucial to maintain visibility and adherence in extreme conditions.

What Are Common Trade Terms Related to Seton ID Products?

Familiarity with industry jargon can streamline communication and enhance purchasing decisions. Here are several key terms to know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of Seton ID products, understanding OEM relationships can help buyers identify trusted suppliers and ensure product compatibility with existing equipment. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers to manage inventory costs effectively and ensure that they meet their operational needs without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products or services. This process is critical for obtaining competitive pricing and ensuring that all specifications are met before making a purchase. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce. They are used in international contracts to clarify the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs. Familiarity with Incoterms can help B2B buyers navigate international purchases more effectively. -

Lead Time

Lead time refers to the amount of time between placing an order and receiving the goods. Understanding lead times is vital for planning inventory and ensuring that safety measures are in place without unnecessary delays. -

SKU (Stock Keeping Unit)

SKU is a unique identifier for each distinct product and service that can be purchased. Knowing the SKU helps in inventory management and simplifies the ordering process, ensuring that buyers receive the correct products.

By understanding these properties and terms, B2B buyers can make informed decisions that enhance workplace safety and compliance while optimizing their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the seton id products Sector

What Are the Current Market Dynamics and Key Trends in the Seton ID Products Sector?

The Seton ID products sector is experiencing significant growth driven by heightened safety regulations and a global push for workplace safety. As businesses across Africa, South America, the Middle East, and Europe strive to comply with stringent health and safety standards, the demand for innovative identification products, including safety signs, labels, and asset tagging solutions, continues to rise. B2B buyers are increasingly looking for suppliers that offer comprehensive safety solutions tailored to their specific industry needs, which is shaping sourcing strategies.

Emerging technologies are also influencing the market. The integration of digital solutions such as RFID and barcode tracking into asset management and safety compliance has transformed how companies approach workplace safety. Buyers are now seeking products that not only meet regulatory requirements but also enhance operational efficiency. Additionally, the trend toward custom products is gaining momentum, as businesses prefer tailored solutions that address their unique challenges. The ability to quickly adapt to changing market dynamics, such as fluctuations in raw material costs and supply chain disruptions, is becoming a critical factor for suppliers aiming to maintain competitive pricing and reliability.

How Can Sustainability and Ethical Sourcing Impact B2B Buying Decisions in the Seton ID Products Sector?

Sustainability is increasingly becoming a focal point for B2B buyers in the Seton ID products sector. Companies are now more aware of the environmental impact of their sourcing decisions, which has led to a demand for products made from sustainable materials. Eco-friendly labels, biodegradable signage, and recyclable packaging are just a few examples of how suppliers can meet the growing expectations for sustainability.

Ethical sourcing practices are equally important. Buyers are scrutinizing their suppliers’ supply chains to ensure they adhere to fair labor practices and environmental standards. Certifications such as FSC (Forest Stewardship Council) for paper products or ISO 14001 for environmental management systems are becoming key indicators of a supplier’s commitment to sustainability. By prioritizing suppliers who demonstrate ethical sourcing and sustainability, businesses not only enhance their corporate social responsibility (CSR) profile but also appeal to a growing base of environmentally conscious customers.

What Is the Brief Evolution and History of the Seton ID Products Sector?

The Seton ID products sector has evolved significantly since its inception in the mid-20th century. Initially focused on basic safety signage, the sector has expanded to include a wide range of products, from asset tagging solutions to custom labels and decals. As workplace safety regulations became more stringent, particularly in the United States with the establishment of OSHA in 1970, the demand for compliant safety products surged.

Over the years, advancements in materials and printing technologies have allowed for greater customization and durability of products. The introduction of digital solutions, such as RFID technology, further revolutionized asset tracking and safety compliance, positioning the sector as a crucial component of modern workplace safety strategies. Today, the Seton ID products sector is recognized not just for compliance but also for enhancing overall operational efficiency and employee safety.

Frequently Asked Questions (FAQs) for B2B Buyers of seton id products

-

How do I ensure compliance with safety regulations when sourcing Seton ID products?

To ensure compliance with safety regulations, familiarize yourself with local and international safety standards, such as OSHA and MUTCD, which govern workplace safety signage and labeling. Review the product specifications provided by Seton to confirm that their offerings meet these standards. Additionally, consider consulting with Seton’s OSHA-trained specialists for expert advice tailored to your industry and region. Proper documentation and certification can also aid in demonstrating compliance during audits. -

What types of Seton ID products are customizable for my business needs?

Seton offers a wide range of customizable products, including safety signs, labels, asset tags, and valve tags. Businesses can tailor these products to reflect specific safety messages, branding, or operational requirements. Custom options also extend to materials, sizes, and colors, ensuring that the products align with your safety protocols and workplace aesthetics. To explore customization, engage with Seton’s customer support for assistance in designing products that meet your unique specifications. -

What are the minimum order quantities (MOQs) for Seton ID products?

Minimum order quantities can vary depending on the specific product category and customization requirements. Generally, standard products may have lower MOQs, while custom items could require larger quantities to justify production costs. It is advisable to inquire directly with Seton’s sales team to determine the MOQs for your desired products, especially when planning for large-scale orders or specific safety initiatives. -

How can I evaluate the reliability of Seton as a supplier for my international business?

To evaluate Seton’s reliability as a supplier, consider their track record and reputation in the industry. Review customer testimonials and case studies to gauge satisfaction levels. Additionally, assess their compliance with international quality standards, such as ISO certifications, and inquire about their customer support structure. Engaging in direct communication with Seton can also provide insights into their responsiveness and willingness to address your concerns. -

What payment terms are typically offered for international orders of Seton ID products?

Payment terms for international orders may vary based on factors such as order size, customer history, and country of origin. Seton generally offers flexible payment options, including wire transfers, credit terms, and credit card payments. It’s essential to discuss payment terms with their sales team upfront to ensure alignment with your financial policies and to confirm any requirements for deposits or letters of credit, particularly for larger orders. -

How does Seton handle quality assurance for their ID products?

Seton implements stringent quality assurance measures throughout the manufacturing process to ensure that all products meet established safety and durability standards. This includes regular testing of materials, adherence to industry regulations, and inspections before shipment. Customers can request detailed quality documentation, including compliance certificates, to verify that the products meet necessary safety requirements for their specific applications. -

What logistics support does Seton provide for international shipping of ID products?

Seton is equipped to handle international shipping logistics, offering various shipping options to ensure timely delivery. They collaborate with reliable logistics partners to manage customs documentation and duties, making the process seamless for B2B buyers. When placing an order, inquire about estimated shipping times, tracking options, and any potential delays to better plan your inventory and operations. -

How can I effectively communicate my specific needs when ordering Seton ID products?

To effectively communicate your needs, prepare detailed specifications regarding the products you require, including dimensions, materials, and any customizations. Clear communication can be facilitated through an initial consultation with Seton’s customer support team, where you can discuss your safety goals and challenges. Providing examples or referencing previous orders can also help convey your expectations, ensuring that the products delivered align with your operational requirements.

Top 6 Seton Id Products Manufacturers & Suppliers List

1. Seton Identification Products – Identification Markers

Domain: arcat.com

Registered: 1995 (30 years)

Introduction: Seton Identification Products offers a range of identification markers including Pipe Markers, Valve Tags, and Outdoor Pipe Markers. Key products include: 1. Snap-Around Identification Markers – ANSI-standardized, designed for indoor/outdoor use, suitable for dirty surfaces. 2. Opti-Code™ Self-Adhesive Identification Markers – Vinyl markers for clean, dry surfaces, temperature resistant from -40°F…

2. Seton – Industrial Name Plates

Domain: nameplate-manufacturers.com

Registered: 2007 (18 years)

Introduction: Seton Identification Products is a leading provider of high-quality industrial identification and safety products, established in 1956. Their core product line includes Name Plates available in various materials such as aluminum, brass, stainless steel, and plastic. These Name Plates can be customized with text, graphics, and logos. Types of Name Plates offered include:

1. Equipment Nameplates – f…

3. Ferguson – Safety & Security Solutions

Domain: ferguson.com

Registered: 1999 (26 years)

Introduction: This company, Ferguson – Safety & Security Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. SETON IDENTIFICATION PRODUCTS – GHS Chemical Labels – Ethanol

Domain: fishersci.com

Registered: 1995 (30 years)

Introduction: {“product_name”: “GHS Chemical Labels – Ethanol”, “dimensions”: “2-1/4″ H x 3-3/4″ W”, “supplier”: “SETON IDENTIFICATION PRODUCTS”, “catalog_number”: “NC1789738”, “price”: “$29.10 / Pack of 1”, “features”: “Durable self-adhesive labels that stick to any surface, ensures GHS compliance.”}

5. Seton – Safety and Labeling Solutions

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Seton Identification Products offers over 57,000 products focused on safety, labeling, and signage solutions. Their products are designed to enhance workplace safety and facility marking applications. They emphasize top-quality products and services that are Guaranteed Fast & Flawless.

6. Seton Identification Products – Essential Supplies

Domain: fermag.com

Registered: 1997 (28 years)

Introduction: Seton Identification Products specializes in various categories including Building Components & Cleaners, Components & Miscellaneous, Furnishings & Décor, Tabletop & Servingware, and Warewashing & Janitorial Supplies. Their subcategories include Ashtrays & Stands, Bulletin Boards, Mats/Anti-Fatigue, Menu & Message Boards, Neon Signs, Signs & Signage, Smoking Stands & Sand Urns, Stickers & Marking …

Strategic Sourcing Conclusion and Outlook for seton id products

As the global market increasingly prioritizes workplace safety and efficiency, strategic sourcing of Seton ID products presents a compelling opportunity for B2B buyers in diverse regions such as Africa, South America, the Middle East, and Europe. By investing in high-quality safety signs, labels, and asset identification solutions, companies can not only enhance compliance with local regulations but also foster a safer working environment that boosts employee morale and productivity.

Key takeaways include the importance of tailored solutions to meet specific operational needs and the economic benefits of bulk purchasing from a trusted supplier like Seton. Leveraging a comprehensive range of customizable products ensures that businesses can effectively address unique safety challenges while maintaining budgetary constraints.

Looking ahead, international buyers are encouraged to explore the extensive offerings of Seton ID products to transform their workplace safety strategies. By prioritizing effective sourcing and investing in innovative safety solutions, businesses can position themselves as leaders in their industries, ultimately driving growth and success in an increasingly competitive global market. Embrace the opportunity to enhance your operations today—safety is not just a requirement; it is a strategic advantage.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.