Everything You Need to Know About Scooter Bike Gas Sourcing in 2025

Introduction: Navigating the Global Market for scooter bike gas

Navigating the global market for scooter bike gas can present significant challenges for B2B buyers, particularly when seeking reliable suppliers and understanding the diverse options available. With the rise in demand for efficient and eco-friendly transportation solutions, sourcing quality gas scooters has become a priority for businesses across regions, including Africa, South America, the Middle East, and Europe. This comprehensive guide will delve into various aspects of scooter bike gas, covering types of scooters, their applications in different markets, and essential supplier vetting processes.

As a B2B buyer, you must be equipped with insights into the costs associated with scooter bike gas, including wholesale pricing, shipping logistics, and potential tariffs that may affect your bottom line. Additionally, understanding the unique needs of your target market—whether it be urban commuters in Vietnam or leisure riders in Germany—will empower you to make informed purchasing decisions that align with consumer expectations.

This guide aims to equip international buyers with the knowledge to navigate the complexities of the scooter bike gas market confidently. By providing actionable insights and expert recommendations, we help you identify the best products and suppliers, ensuring your investments yield the highest returns and meet your business objectives effectively.

Understanding scooter bike gas Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 50cc Gas Scooters | Lightweight, low-speed (up to 30 mph), fuel-efficient | Urban commuting, rental services | Pros: Cost-effective, easy to maneuver. Cons: Limited power for long distances. |

| 150cc Gas Scooters | Mid-range speed (up to 60 mph), versatile | Delivery services, personal transport | Pros: Good balance of speed and fuel economy. Cons: Slightly higher maintenance costs. |

| 200cc Gas Mopeds | More powerful, suitable for varied terrains | Tourism, commercial transportation | Pros: Stronger engine, better for longer trips. Cons: Heavier, requires more skilled handling. |

| Electric Hybrid Scooters | Combines gas and electric power sources | Eco-friendly initiatives, urban mobility | Pros: Reduced emissions, versatile usage. Cons: Higher initial costs, complex maintenance. |

| High-Performance Scooters | Engine sizes over 300cc, designed for speed | Racing, performance-oriented applications | Pros: High speed and acceleration. Cons: Higher fuel consumption, more expensive. |

What are the characteristics of 50cc Gas Scooters and their suitability for B2B buyers?

50cc gas scooters are lightweight and designed for urban commuting. They typically reach speeds of up to 30 mph, making them ideal for short trips in congested areas. Their fuel efficiency allows for economical operation, often achieving 65-100 miles per gallon. B2B buyers in rental services or urban delivery can benefit from their low operational costs. However, their limited power may not suit businesses requiring longer-distance travel or higher speeds.

How do 150cc Gas Scooters cater to diverse B2B applications?

150cc gas scooters offer a balanced performance with speeds up to 60 mph, making them versatile for various applications, including delivery services and personal transport. They provide a good mix of power and fuel economy, appealing to businesses that need reliable and efficient transportation. While their slightly higher maintenance costs should be considered, their adaptability to different urban and suburban environments makes them a solid investment for B2B buyers.

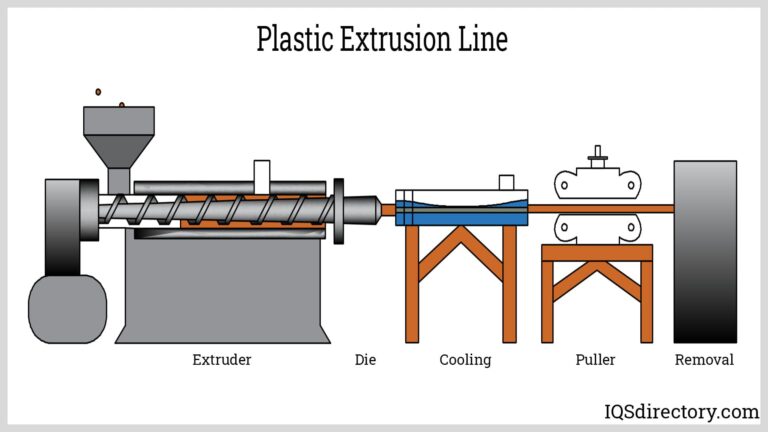

Illustrative image related to scooter bike gas

What advantages do 200cc Gas Mopeds offer for commercial use?

200cc gas mopeds are characterized by their robust engines, allowing for better performance on varied terrains. They are suitable for tourism and commercial transportation, providing a comfortable ride for longer trips. With greater power, these scooters can handle heavier loads and offer more stability. B2B buyers should weigh the advantages of their strength against the potential for higher fuel consumption and the need for skilled operators.

Why are Electric Hybrid Scooters becoming popular among B2B buyers?

Electric hybrid scooters combine gas and electric power, making them an attractive option for eco-conscious businesses. They support urban mobility initiatives while reducing emissions. Their versatility allows for use in various settings, from delivery services to city tours. However, the higher initial costs and complex maintenance requirements may deter some buyers. Companies focusing on sustainability and innovation will find these scooters align well with their values.

What makes High-Performance Scooters a specialized choice for businesses?

High-performance scooters, typically over 300cc, are designed for speed and agility, making them ideal for racing and performance-oriented applications. They offer rapid acceleration and superior handling, attracting businesses that prioritize performance. However, these scooters come with higher fuel consumption and costs, which may not suit every B2B operation. Companies in the racing industry or those looking to provide thrilling experiences will find these scooters highly beneficial.

Key Industrial Applications of scooter bike gas

| Industry/Sector | Specific Application of scooter bike gas | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Urban Mobility | Delivery services using gas scooters | Cost-effective transportation with low fuel consumption | Reliability of gas supply, maintenance support, regulatory compliance |

| Tourism and Recreation | Rental services for tourists in urban areas | Enhances tourist experience and convenience | Vehicle durability, local regulations, pricing competitiveness |

| Logistics and Distribution | Last-mile delivery operations | Quick and efficient deliveries, reducing traffic congestion | Fuel efficiency, vehicle capacity, supplier reliability |

| Emergency Services | Rapid response units utilizing gas scooters | Improved response times in urban settings | Vehicle performance, service availability, local support |

| Educational Institutions | Campus transportation for students and staff | Affordable mobility solutions, promoting eco-friendly transport | Compliance with safety standards, vehicle maintenance, cost-effectiveness |

How is scooter bike gas utilized in urban mobility?

In urban mobility, gas scooters are increasingly employed by delivery services to navigate congested city streets efficiently. The low fuel consumption of these scooters allows businesses to reduce operational costs significantly while providing timely deliveries. International B2B buyers, particularly from regions like Africa and South America, should prioritize sourcing suppliers who can ensure a consistent gas supply and offer maintenance support to enhance operational reliability.

What role do gas scooters play in tourism and recreation?

Gas scooters are popular in the tourism sector, where rental services provide an accessible way for tourists to explore urban environments. By offering gas scooters, businesses can enhance the tourist experience, allowing for convenient travel while reducing the environmental footprint compared to traditional vehicles. Buyers in this sector must consider local regulations regarding scooter rentals and ensure that the vehicles are durable enough to withstand frequent use.

Illustrative image related to scooter bike gas

How do logistics and distribution benefit from scooter bike gas?

In logistics and distribution, gas scooters are ideal for last-mile delivery operations. Their compact size and agility enable them to maneuver through traffic, ensuring quick deliveries and reducing the carbon footprint. For international buyers, factors such as fuel efficiency and the capacity of scooters are critical. Establishing partnerships with reliable suppliers can enhance service levels and ensure timely deliveries, making it essential for businesses to thoroughly vet potential sources.

Why are gas scooters important for emergency services?

Emergency services utilize gas scooters for rapid response units, particularly in urban areas where traffic congestion can delay traditional emergency vehicles. The ability to reach the scene quickly can be life-saving. Buyers in this sector must focus on vehicle performance and ensure that suppliers can provide timely service and support, as the reliability of the scooters is crucial for emergency operations.

How can educational institutions leverage scooter bike gas?

Educational institutions can implement gas scooters for campus transportation, offering an affordable and eco-friendly mobility solution for students and staff. This not only promotes sustainability but also eases parking congestion. When sourcing scooters, institutions must consider compliance with safety standards and the overall cost-effectiveness of the vehicles to ensure that they meet the needs of the campus community effectively.

3 Common User Pain Points for ‘scooter bike gas’ & Their Solutions

Scenario 1: Managing Fuel Supply Fluctuations in the Market

The Problem: B2B buyers in regions like Africa and South America often face significant challenges related to the availability and cost of gas for scooters. Fluctuating fuel prices can severely impact operational budgets, making it difficult to provide consistent service or maintain a competitive edge. Additionally, supply chain disruptions can lead to shortages, causing delays in scooter availability for end-users. Buyers may feel pressure to maintain a steady supply while contending with unpredictable market forces.

The Solution: To mitigate these risks, B2B buyers should establish relationships with multiple suppliers to ensure a steady fuel supply. Consider negotiating bulk purchase agreements that lock in prices for a set period, which can help stabilize costs. Additionally, conducting regular market analysis will allow buyers to anticipate price changes and adjust procurement strategies accordingly. Exploring partnerships with local fuel distributors can also provide insights into regional trends, enabling more informed purchasing decisions. Implementing inventory management systems to track fuel levels and usage can help buyers anticipate shortages before they become critical.

Illustrative image related to scooter bike gas

Scenario 2: Compliance with Regulatory Standards

The Problem: In many European and Middle Eastern countries, compliance with stringent environmental regulations regarding emissions and fuel quality presents a significant hurdle for B2B buyers of gas scooters. These regulations can vary dramatically from one region to another, and non-compliance can lead to hefty fines, reputational damage, and operational disruptions. Buyers often struggle to ensure that the fuel they source meets all local and international standards.

The Solution: Buyers should familiarize themselves with the specific regulatory requirements in their operating regions, including fuel quality standards and emissions limits. Partnering with reputable suppliers who can provide documentation and certifications of their fuel’s compliance is essential. It may also be beneficial to invest in training for staff on regulatory requirements and best practices for fuel management. Establishing a compliance checklist that includes fuel sourcing, usage, and disposal can help streamline processes and ensure that all practices adhere to local laws. Regular audits of fuel sources and usage can also help identify potential compliance risks before they escalate.

Scenario 3: Ensuring Fuel Efficiency and Performance

The Problem: B2B buyers often encounter issues with fuel efficiency and overall scooter performance, particularly when dealing with lower-quality gas. Poor fuel can lead to reduced engine performance, increased maintenance costs, and ultimately, customer dissatisfaction. Buyers may find it challenging to balance cost-saving measures with the need for high-quality fuel that ensures optimal performance.

The Solution: To address this issue, buyers should prioritize sourcing high-quality gas from reputable suppliers known for their consistent fuel standards. Investing in fuel testing technologies can help ensure that the gas being used meets the required performance criteria. Additionally, educating customers about the importance of using high-quality fuel can enhance brand loyalty and customer satisfaction. Implementing a regular maintenance schedule for scooters can also improve fuel efficiency and prolong engine life. Buyers might consider offering incentives for customers who consistently use recommended fuel types, creating a win-win situation that enhances performance and customer loyalty.

Strategic Material Selection Guide for scooter bike gas

What are the Common Materials Used in Scooter Bike Gas Components?

When selecting materials for scooter bike gas components, it is essential to consider the properties that influence performance, durability, and compliance with international standards. Here, we analyze four common materials used in the construction of gas scooters, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Aluminum Perform in Scooter Bike Gas Applications?

Aluminum is widely used in scooter bike gas components due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of up to 150°C and can withstand moderate pressure levels. The primary advantages of aluminum include its low weight, which enhances fuel efficiency, and its resistance to rust, making it ideal for outdoor applications. However, aluminum can be more expensive than steel and may require specialized manufacturing processes, such as extrusion or casting, which can increase production costs.

For international buyers, particularly in regions like Africa and South America, the availability of aluminum may vary. Compliance with standards such as ASTM or DIN is crucial, as these regions may have specific regulations regarding material specifications and safety.

What Role Does Steel Play in Scooter Bike Gas Manufacturing?

Steel is another common material used in scooter bike gas components, particularly for frames and structural elements. It boasts high strength and durability, with a temperature rating that can exceed 200°C. Steel is generally more affordable than aluminum and is easier to fabricate, making it a popular choice for manufacturers. However, steel is prone to corrosion if not properly treated, which can lead to longevity issues in humid or wet environments.

International buyers should be aware of the need for corrosion-resistant coatings or treatments, especially in regions like the Middle East, where high humidity can accelerate rusting. Compliance with local and international standards is also essential to ensure safety and performance.

Why is Plastic a Viable Option for Scooter Bike Gas Components?

Plastics, particularly high-density polyethylene (HDPE) and polypropylene, are increasingly used in gas scooter applications for components such as fuel tanks and body panels. Plastics offer excellent chemical resistance and can withstand temperatures up to 100°C. They are lightweight and can be produced at lower costs compared to metals. However, plastics may not provide the same structural integrity as metals and can be less durable under extreme conditions.

For B2B buyers in Europe, compliance with environmental regulations regarding plastic use is critical. Many countries have stringent laws governing the use of certain plastics, so manufacturers must ensure that their products meet these standards.

Illustrative image related to scooter bike gas

How Does Composite Material Enhance Scooter Bike Gas Performance?

Composite materials, such as fiberglass and carbon fiber, are becoming popular in high-performance scooter bike gas applications. These materials offer exceptional strength-to-weight ratios and can withstand high temperatures and pressures. Composites are resistant to corrosion and can be molded into complex shapes, providing design flexibility.

However, the cost of composites is significantly higher than traditional materials, and manufacturing processes can be complex, requiring specialized skills and equipment. For international buyers, understanding the cost-benefit ratio is crucial, especially in emerging markets where price sensitivity is higher. Compliance with international standards for composites is also essential, particularly in Europe, where regulations are stringent.

Summary Table of Material Selection for Scooter Bike Gas

| Material | Typical Use Case for scooter bike gas | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Frame and body panels | Lightweight and corrosion-resistant | Higher cost and complex manufacturing | Medium |

| Steel | Structural components | High strength and durability | Prone to corrosion without treatment | Low |

| Plastic | Fuel tanks and body panels | Chemical resistance and low cost | Less structural integrity | Low |

| Composite | High-performance parts | Exceptional strength-to-weight ratio | High cost and complex manufacturing | High |

This guide provides a comprehensive overview of material selection for scooter bike gas applications, enabling international B2B buyers to make informed decisions that align with their operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for scooter bike gas

What Are the Main Stages in the Manufacturing Process of Gas Scooters?

The manufacturing of gas scooters involves several critical stages that ensure both the performance and safety of the final product. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial phase involves sourcing high-quality raw materials, such as steel, aluminum, and plastics. Suppliers should be vetted for compliance with international standards to ensure that materials meet the durability and safety requirements for scooter production. Pre-treatment processes like cutting and shaping are executed before moving on to forming.

-

Forming: In this stage, raw materials are transformed into specific components through various techniques such as stamping, welding, and machining. For example, the frame of the scooter is often stamped from sheets of metal, while engine components may be machined for precision. Advanced technologies, including Computer Numerical Control (CNC) machining, are commonly employed to enhance accuracy.

-

Assembly: The assembly process brings together all the components, including the engine, wheels, and electrical systems. Automated assembly lines may be utilized to increase efficiency, though skilled labor is essential for quality checks at this stage. Each scooter undergoes a preliminary inspection before final assembly to ensure all parts fit correctly and function as intended.

-

Finishing: This final stage involves applying coatings, paints, and decals to enhance aesthetics and protect against corrosion. Techniques such as powder coating or electroplating are frequently used. Quality assurance checks are vital here, as any defects in finishing could lead to performance issues or customer dissatisfaction.

What Quality Assurance Standards Are Relevant for Gas Scooter Manufacturing?

For B2B buyers, understanding the quality assurance standards applicable to gas scooter manufacturing is crucial. The following standards are commonly recognized:

-

ISO 9001: This international standard outlines the criteria for a quality management system. Manufacturers certified under ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

-

CE Marking: In Europe, CE marking indicates that a product complies with EU safety, health, and environmental protection standards. Gas scooters sold in European markets must have this certification to be legally marketed.

-

API Standards: For manufacturers that produce engine components, adherence to American Petroleum Institute (API) standards ensures that lubricants and other fluids meet specific performance criteria. This is particularly relevant for the engine’s operational efficiency and longevity.

How Are Quality Control Checkpoints Structured During Gas Scooter Production?

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process to mitigate risks and ensure compliance with standards. These checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint occurs upon the arrival of raw materials. Inspections at this stage verify that the materials meet specified standards and are free from defects.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC involves monitoring various stages to ensure that components are being produced within defined tolerances. This may include dimensional checks and functional tests on subassemblies.

-

Final Quality Control (FQC): Once the scooter is fully assembled, FQC assesses the entire unit for performance, safety, and compliance with specifications. This includes road tests, safety checks, and thorough inspections of all operational features.

What Common Testing Methods Are Used to Ensure Gas Scooter Quality?

B2B buyers should be aware of the testing methods employed to validate the quality of gas scooters:

-

Functional Testing: This testing evaluates the scooter’s overall performance, including acceleration, braking, and handling. It simulates real-world conditions to ensure reliability.

-

Durability Testing: Manufacturers often conduct stress tests to assess how components hold up under extreme conditions. This includes fatigue testing on frames and long-term engine operation tests.

-

Safety Testing: Compliance with safety regulations is paramount. Testing for electrical safety, emissions, and noise levels is standard to ensure that scooters meet regulatory requirements.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to ensure that their suppliers adhere to quality control standards. Here are several strategies:

-

Supplier Audits: Conducting regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. Audits should focus on compliance with international standards and the effectiveness of QC checkpoints.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers assess their production quality. These reports should include test results, defect rates, and any corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality practices. These inspections can be particularly beneficial for buyers from regions with stringent import regulations.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

-

Regulatory Compliance: Different regions have varying regulations regarding vehicle safety and emissions. Buyers should ensure that suppliers are compliant with local laws to avoid issues during customs clearance.

-

Cultural and Language Differences: Effective communication is essential in international transactions. Buyers should ensure that suppliers understand the quality requirements and standards expected in their market.

-

Logistical Considerations: The logistics of transporting scooters from the manufacturer to the buyer can introduce risks. Quality checks should extend to packaging and handling to prevent damage during transit.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions, ensuring that they partner with reliable suppliers who deliver high-quality gas scooters tailored to their specific market needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘scooter bike gas’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure scooter bike gas effectively. By following these steps, international buyers can ensure they make informed decisions while navigating the complexities of sourcing gas scooters from various suppliers, particularly in regions like Africa, South America, the Middle East, and Europe.

Step 1: Identify Your Market Needs

Understanding your target market is essential for successful procurement. Assess the specific requirements of your region, including demand for different scooter capacities (e.g., 50cc, 150cc) and preferred features like fuel efficiency and design. This insight will guide your sourcing strategy and help you select scooters that meet local preferences.

Step 2: Define Your Technical Specifications

Clearly outline the technical specifications for the scooters you intend to purchase. This includes engine size, fuel type, and safety features. Having detailed specifications will streamline communication with suppliers and ensure that the products you receive align with your expectations.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, it’s crucial to conduct a thorough evaluation. Request company profiles, product catalogs, and references from other buyers within your industry. Additionally, consider their experience in international shipping and compliance with local regulations, which can significantly impact your operations.

- Verify Certifications: Ensure that suppliers have the necessary certifications for the markets you serve, such as safety and environmental compliance.

- Assess Manufacturing Capabilities: Inquire about their production capacity and quality control processes to ensure they can meet your order volume and standards.

Step 4: Request Samples for Quality Assurance

Always request samples before placing a bulk order. This step allows you to assess the quality of the scooters firsthand, ensuring they meet your specifications and standards. Pay attention to details such as build quality, performance, and any unique selling points that may appeal to your customers.

Step 5: Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, it’s time to negotiate the terms of your agreement. Discuss pricing, payment terms, delivery schedules, and warranty provisions. Clear agreements can prevent misunderstandings and ensure a smoother transaction process.

Illustrative image related to scooter bike gas

- Consider Volume Discounts: If you plan to order in bulk, inquire about potential discounts which can significantly reduce your overall costs.

- Clarify Return Policies: Understanding the return policy for defective products is crucial for managing risk in your procurement strategy.

Step 6: Establish a Logistics Plan

Develop a logistics plan that outlines how the scooters will be delivered to your location. Consider factors such as shipping methods, customs clearance, and local distribution channels. A well-structured logistics plan will help you avoid delays and ensure timely delivery to your customers.

Step 7: Continuously Monitor Supplier Performance

After procurement, maintain ongoing communication with your supplier to monitor performance. Regularly assess the quality of the products received and the supplier’s responsiveness to any issues. This proactive approach can lead to long-term partnerships and improved supply chain efficiency.

By adhering to this step-by-step checklist, B2B buyers can navigate the complexities of sourcing scooter bike gas, ensuring a successful procurement process that meets market demands.

Comprehensive Cost and Pricing Analysis for scooter bike gas Sourcing

What Are the Key Cost Components in Scooter Bike Gas Sourcing?

When sourcing gas scooters, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The type of materials used in the construction of scooters significantly impacts pricing. Common materials include high-strength steel and aluminum, which provide durability while keeping weight low. The choice of engine components and fuel systems also plays a crucial role.

-

Labor: Labor costs can vary significantly based on geographical location. In regions with higher labor costs, such as Europe, expect a larger portion of the budget to be allocated to skilled labor. Conversely, manufacturers in Asia may offer lower labor costs, influencing the overall pricing strategy.

-

Manufacturing Overhead: This encompasses costs associated with factory maintenance, utilities, and other operational expenses. Efficient production lines can help reduce overhead, which in turn can be reflected in the pricing of the scooters.

-

Tooling: Specialized tooling for manufacturing different scooter models can be a significant initial investment. This cost is often amortized over the production volume, making it essential to consider the minimum order quantities (MOQ) when negotiating prices.

-

Quality Control (QC): Quality assurance processes are vital in maintaining product integrity and safety standards. The investment in QC can influence pricing, especially if certifications (like ISO) are required for international markets.

-

Logistics: Transportation costs, including shipping and customs duties, can heavily influence the final cost, particularly for international buyers. Understanding Incoterms can help clarify responsibilities and costs between buyers and suppliers.

-

Margin: Suppliers will typically include a profit margin in their pricing. This margin can vary based on competition, market demand, and the perceived value of the product.

What Influences Pricing for Gas Scooters?

Several factors can influence the pricing of gas scooters beyond the basic cost structure:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases can lead to significant discounts. Buyers looking to source larger quantities should negotiate favorable terms that reflect economies of scale.

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers should carefully evaluate whether these customizations align with their target market’s needs to avoid unnecessary expenses.

-

Materials and Quality Certifications: Higher quality materials and adherence to safety certifications can increase the price but often result in a better product lifespan and customer satisfaction.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a history of quality and timely delivery may command higher prices but could offer better assurance.

-

Incoterms: Understanding the implications of Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help buyers manage shipping costs and responsibilities effectively.

How Can Buyers Negotiate for Cost-Efficiency?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, negotiation strategies are crucial for cost-efficiency:

Illustrative image related to scooter bike gas

-

Research and Prepare: Understanding market prices and competitor offerings can provide leverage in negotiations. Gathering data on cost structures can help in discussions with suppliers.

-

Focus on Total Cost of Ownership (TCO): Rather than just the purchase price, consider the TCO, including maintenance, fuel efficiency, and potential resale value. This broader perspective can justify higher upfront costs if they lead to lower long-term expenses.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms over time. Frequent communication and trust can foster collaboration and flexibility in negotiations.

-

Explore Alternative Suppliers: Diversifying your supplier base can lead to competitive pricing. Engaging with multiple suppliers can provide options and help avoid dependency on a single source.

Conclusion

In the competitive landscape of gas scooter sourcing, understanding cost components and pricing influencers is essential for B2B buyers. By leveraging negotiation tactics and focusing on long-term value, international buyers can navigate the complexities of procurement effectively. Always consider that the prices listed are indicative and can fluctuate based on market conditions and supplier negotiations.

Alternatives Analysis: Comparing scooter bike gas With Other Solutions

Exploring Alternatives to Gas-Powered Scooters

In the evolving landscape of personal and commercial transportation, the need for efficient, cost-effective, and environmentally friendly solutions is paramount. Gas-powered scooters, while popular, face competition from various alternatives. This section compares gas scooters with electric scooters and bicycles, focusing on their performance, cost, implementation ease, maintenance requirements, and ideal use cases.

| Comparison Aspect | Scooter Bike Gas | Electric Scooter | Bicycle |

|---|---|---|---|

| Performance | Speeds up to 60 mph; good range | Speeds typically up to 28 mph; limited range (20-50 miles) | Moderate speeds (15-30 mph); range depends on rider effort |

| Cost | Initial cost: $600-$2,000; fuel costs | Initial cost: $300-$1,500; charging costs | Initial cost: $200-$1,500; no fuel costs |

| Ease of Implementation | Requires fuel stations; more regulations | Charging infrastructure needed; fewer regulations | No special infrastructure needed; easily accessible |

| Maintenance | Regular oil changes, fuel system upkeep | Minimal; battery replacement needed | Low; mostly tire maintenance and occasional repairs |

| Best Use Case | Urban commuting and delivery services | Urban commuting, short-distance travel | Recreational use, fitness, short distances |

What Are the Advantages and Disadvantages of Electric Scooters Compared to Gas-Powered Scooters?

Electric scooters present a compelling alternative to gas scooters. They are quieter, produce no emissions during operation, and have lower operational costs since electricity is generally cheaper than gasoline. Additionally, many cities are increasingly investing in electric charging infrastructure, enhancing their practicality. However, electric scooters often have a limited range and slower speeds compared to gas scooters, which may deter users needing longer travel distances or higher speeds.

How Do Bicycles Stand Against Gas Scooters in Terms of Cost and Usability?

Bicycles are the most environmentally friendly option among the three alternatives. They require minimal investment and maintenance, making them accessible for a broad audience. Bicycles also promote health benefits and are suitable for short-distance travel without the need for fuel or charging. However, they depend heavily on physical effort, which may not be feasible for all users or in all geographical areas, particularly those with hilly terrains or long commutes.

Making the Right Choice for Your Business: Which Solution Fits Best?

When choosing between gas scooters, electric scooters, and bicycles, B2B buyers should consider their specific operational needs and target market. For delivery services in urban environments, gas scooters may offer the necessary speed and range. In contrast, companies focused on sustainability or operating in areas with established charging infrastructure may benefit from electric scooters. Bicycles serve well for businesses promoting fitness or leisure activities. Ultimately, evaluating the operational environment, cost constraints, and performance requirements will guide buyers in selecting the most suitable transportation solution for their needs.

Illustrative image related to scooter bike gas

Essential Technical Properties and Trade Terminology for scooter bike gas

What Are the Key Technical Properties of Gas-Powered Scooters?

When engaging in the B2B market for gas-powered scooters, understanding the essential technical properties can significantly influence purchasing decisions. Here are several critical specifications to consider:

-

Engine Displacement (CC)

This metric refers to the size of the engine, measured in cubic centimeters (CC). Common sizes for gas scooters range from 50cc to 300cc. Larger engine displacements generally provide more power and speed, making them suitable for longer commutes or hilly terrains. For B2B buyers, selecting the right engine size is crucial for meeting specific market demands and consumer preferences. -

Fuel Efficiency (Miles Per Gallon)

Gas scooters are known for their fuel efficiency, often ranging from 65 to 100 miles per gallon. High fuel efficiency translates to lower operational costs, a critical consideration for businesses looking to offer economical transportation options. B2B buyers should prioritize models with excellent fuel efficiency to appeal to cost-conscious consumers. -

Weight Capacity (lbs)

The weight capacity indicates how much load a scooter can carry, including the rider and any additional cargo. This specification is vital for ensuring that scooters can accommodate diverse users and their needs, particularly in commercial applications. Understanding weight limits helps B2B buyers select products that align with their target market’s requirements. -

Top Speed (MPH)

The top speed of a gas scooter is an important performance metric, typically ranging from 30 to 60 MPH, depending on the engine size and design. Knowing the top speed helps B2B buyers assess whether a scooter meets the needs of urban commuters or recreational users, allowing for better alignment with market demand. -

Build Material

The materials used in the scooter’s frame and body significantly impact durability and maintenance. Common materials include steel, aluminum, and plastic composites. For B2B buyers, selecting scooters made from high-quality materials can lead to lower maintenance costs and longer product lifespans, enhancing customer satisfaction. -

Transmission Type

Scooters may feature automatic or manual transmission systems. Automatic transmissions are easier for novice riders and are preferred in urban environments, while manual transmissions can offer better control for experienced riders. Understanding transmission types helps B2B buyers cater to different skill levels within their customer base.

What Are Common Trade Terms in the Gas Scooter Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are several important terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the scooter industry, OEMs supply components such as engines, frames, and other essential parts. B2B buyers should establish relationships with reputable OEMs to ensure quality and reliability in their products. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ helps B2B buyers negotiate orders that align with their inventory needs and cash flow. It’s crucial for managing stock levels and ensuring a steady supply of scooters. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and other details for specific products. This process helps B2B buyers compare costs and make informed purchasing decisions. Crafting a clear RFQ can facilitate better responses from suppliers, ensuring that all relevant details are addressed. -

Incoterms (International Commercial Terms)

These are standardized trade terms used in international transactions to define the responsibilities of buyers and sellers. Understanding Incoterms is essential for B2B buyers involved in cross-border sales, as they dictate who is responsible for shipping, insurance, and tariffs. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. For B2B buyers, understanding lead times is critical for planning inventory and meeting customer demands. Shorter lead times can enhance competitiveness in the market. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the product and the commitment to repair or replace defective items. B2B buyers should carefully evaluate warranty terms to ensure they are receiving adequate protection against potential defects, thereby enhancing customer trust.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions in the gas scooter market, ultimately leading to better product offerings and enhanced customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the scooter bike gas Sector

What Are the Key Market Drivers and Trends in the Gas Scooter Sector?

The global scooter bike gas market is experiencing significant growth, driven by urbanization, increasing fuel prices, and a rising demand for affordable transportation solutions. In emerging markets such as Africa and South America, scooters are becoming the preferred mode of transport due to their cost-effectiveness and ability to navigate congested urban areas. In Europe and the Middle East, environmental concerns are pushing consumers towards more fuel-efficient vehicles, further driving demand for gas scooters.

Current B2B sourcing trends reflect a shift towards online marketplaces where international buyers can compare products and prices easily. E-commerce platforms are increasingly becoming a vital channel for sourcing, allowing buyers from various regions to access a wider array of products. Additionally, advancements in technology have enabled the development of smarter scooters equipped with features such as GPS tracking, anti-theft systems, and better fuel efficiency. This technological integration is appealing to B2B buyers looking to offer enhanced products to their customers.

Illustrative image related to scooter bike gas

How Does Sustainability Impact B2B Sourcing in the Gas Scooter Market?

Sustainability is becoming a crucial factor in B2B sourcing strategies within the scooter bike gas sector. As environmental regulations tighten globally, companies are under increasing pressure to adopt ethical sourcing practices that minimize their ecological footprint. This includes sourcing materials from suppliers who adhere to sustainable practices and obtaining certifications such as ISO 14001 for environmental management.

Furthermore, the use of ‘green’ materials in the manufacturing of gas scooters can enhance a company’s marketability. Buyers are increasingly looking for products that not only meet performance standards but also align with their sustainability goals. By prioritizing suppliers who demonstrate a commitment to environmental stewardship, B2B buyers can improve their brand reputation and attract eco-conscious consumers.

What Is the Historical Context of the Gas Scooter Market?

The gas scooter market has evolved significantly since its inception in the mid-20th century, when scooters were primarily viewed as recreational vehicles. The oil crises of the 1970s sparked interest in fuel-efficient transportation, leading to the rise of gas scooters as practical commuting alternatives. Over the decades, advancements in technology and manufacturing processes have resulted in more reliable, efficient, and affordable models. Today, gas scooters are not only popular in developed nations but are also gaining traction in developing markets, where they serve as essential transportation solutions for millions.

In summary, understanding the dynamics of the gas scooter market, focusing on sustainability, and recognizing its historical evolution provide invaluable insights for B2B buyers looking to navigate this sector effectively.

Illustrative image related to scooter bike gas

Frequently Asked Questions (FAQs) for B2B Buyers of scooter bike gas

-

How do I choose the right supplier for scooter bike gas?

Selecting the right supplier involves thorough research and due diligence. Start by verifying the supplier’s credentials, including licenses and certifications relevant to your region. Look for reviews or testimonials from other B2B clients to gauge reliability. It’s also prudent to request samples of the gas to assess quality before making larger commitments. Engage in discussions regarding their production capabilities, lead times, and after-sales support to ensure they align with your business needs. -

What are the key specifications to consider when sourcing scooter bike gas?

When sourcing scooter bike gas, consider specifications such as octane rating, volatility, and emissions standards. Ensure that the gas meets local regulatory requirements for environmental impact. Additionally, inquire about the gas’s compatibility with various scooter models, as different engines may require specific formulations. Understanding these specifications helps prevent operational issues and ensures customer satisfaction with the product. -

What are common payment terms for international orders of scooter bike gas?

Payment terms can vary significantly by supplier and region, but common practices include letters of credit, advance payments, or payment upon delivery. For larger orders, suppliers may offer net 30 or net 60 terms, allowing you time to sell the product before payment is due. Always clarify payment methods, currency, and any associated fees upfront to avoid surprises during transactions. -

What is the Minimum Order Quantity (MOQ) for scooter bike gas?

Minimum Order Quantities (MOQ) for scooter bike gas can vary based on the supplier and your specific requirements. Typically, suppliers may set MOQs to optimize production and shipping costs. It’s advisable to discuss your needs directly with the supplier to negotiate terms that suit your business model, especially if you are a new buyer or require a trial order to assess quality. -

How can I ensure quality assurance for scooter bike gas?

To ensure quality assurance, work with suppliers who have established quality control processes. Request documentation such as certificates of analysis or quality inspection reports. Consider implementing third-party testing, especially for larger shipments, to verify that the gas meets specified standards. Establishing a clear quality agreement in the contract can also protect your interests and ensure compliance with your quality expectations. -

What logistics considerations should I keep in mind when importing scooter bike gas?

Logistics for importing scooter bike gas include selecting reliable freight forwarders experienced in hazardous materials transport, as gas falls under strict regulations. Assess shipping times, costs, and customs clearance processes for your target market. Additionally, ensure that packaging meets international safety standards to prevent leaks or spills during transport. Understanding these logistics helps streamline the import process and reduce delays. -

Are there customization options available for scooter bike gas?

Many suppliers offer customization options to meet specific market needs, such as varying octane levels or specialized blends for different climates. If you have unique requirements based on local regulations or customer preferences, communicate these to potential suppliers. Custom formulations can enhance performance and customer satisfaction, making it an important factor when selecting a supplier. -

How can I evaluate the market demand for scooter bike gas in my region?

To evaluate market demand, conduct thorough market research, including competitor analysis and consumer surveys. Analyze sales data from local scooter retailers and assess trends in scooter usage within your target demographic. Engaging with industry associations or trade shows can provide insights into market dynamics and help identify opportunities for growth in your region.

Top 3 Scooter Bike Gas Manufacturers & Suppliers List

1. Scooter Stop – Gas Scooters

Domain: scooter-stop.com

Registered: 2012 (13 years)

Introduction: Gas scooters available for sale, delivered 100% assembled and road tested. Key brands include Niu, Kymco, Sym, Genuine Scooter Co., Lance Powersports, Chicago Scooter Co., and Wolf Brand Scooters. Engine sizes range from 50cc to 550cc. Prices for gas scooters range from $1,900 to $3,400. Notable models include G0 50 Chicago Scooter, Chicago Pug 50, Nitro 50 Sport, Wolf RX 50, and various models fr…

2. Upzy – Gas Scooters

Domain: upzy.com

Registered: 2015 (10 years)

Introduction: This company, Upzy – Gas Scooters, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Gokarts USA – Tank 200 Street Scooter

Domain: gokartsusa.biz

Registered: 2020 (5 years)

Introduction: {“products”:[{“name”:”Tank 200 Street Scooter”,”features”:”Automatic Shifting, Full Disc Brakes, 13-inch Wheels, LED Lights”,”price”:”$1,710.45″,”colors”:[“yellow”,”red”,”green”,”black”,”grey”]},{“name”:”TrailMaster Turino 150cc Street Scooter”,”features”:”12″ Wheels, Ships Fully Assembled”,”price”:”$2,047.14″,”colors”:[“black”,”cream”,”white”,”pink”]},{“name”:”TrailMaster Turino 50cc Street Scoot…

Strategic Sourcing Conclusion and Outlook for scooter bike gas

In conclusion, strategic sourcing of gas scooters presents a significant opportunity for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. As the demand for cost-effective and efficient urban transportation solutions continues to rise, sourcing high-quality gas scooters can enhance your product portfolio while meeting consumer needs for affordability and sustainability.

Leveraging strategic partnerships with reputable suppliers not only ensures competitive pricing but also guarantees access to the latest innovations in scooter technology. This approach allows businesses to stay ahead in a rapidly evolving marketplace, where customer preferences are shifting towards versatile and eco-friendly transportation options.

Looking forward, we encourage buyers to explore diverse sourcing channels and consider factors such as quality, regulatory compliance, and after-sales support when selecting suppliers. By prioritizing these elements, you can position your business for success in the dynamic gas scooter market. Engage with suppliers today to unlock new opportunities and drive your business growth in this thriving sector.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.