Everything You Need to Know About Russian Lathe Sourcing in 2025

Introduction: Navigating the Global Market for russian lathe

In the competitive landscape of industrial manufacturing, sourcing a reliable Russian lathe can be a daunting challenge for B2B buyers, especially those from diverse markets such as Africa, South America, the Middle East, and Europe. These powerful machines are integral to various sectors, from automotive to furniture production, yet their complexity and safety risks necessitate a thorough understanding before making a procurement decision. This guide aims to equip international buyers with the insights needed to navigate the global market for Russian lathes effectively.

Throughout this comprehensive resource, you will explore the different types of Russian lathes available, their specific applications, and the factors influencing cost. Additionally, we will delve into critical aspects such as supplier vetting, ensuring that you select manufacturers who uphold stringent safety protocols and quality standards. By highlighting essential features to consider and common pitfalls to avoid, this guide empowers you to make informed purchasing decisions that align with your operational needs and budget constraints.

As you embark on this journey to source a Russian lathe, this guide serves as your trusted partner, providing actionable insights and expert knowledge to facilitate a smooth procurement process. Whether you are based in Nigeria, Germany, or anywhere in between, understanding the intricacies of these machines will enhance your competitive edge and ensure safety in your manufacturing operations.

Understanding russian lathe Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Horizontal Lathe | Features a horizontal spindle; ideal for long workpieces | Metalworking, automotive parts | Pros: Versatile for various lengths; Cons: Requires more floor space. |

| Vertical Lathe | Utilizes a vertical spindle; excellent for large, heavy workpieces | Aerospace, shipbuilding | Pros: Efficient for heavy materials; Cons: Limited to specific applications. |

| CNC Lathe | Computer Numerical Control for precision and automation | High-volume production, prototyping | Pros: High precision and repeatability; Cons: Higher initial investment. |

| Turret Lathe | Equipped with multiple cutting tools for rapid operation | Mass production, complex parts | Pros: Increases productivity; Cons: Setup time can be lengthy. |

| Toolroom Lathe | Smaller, versatile lathe for precision work and repairs | Tool making, small batch production | Pros: Great for detailed work; Cons: Less suitable for large-scale production. |

What Are the Characteristics and Suitability of Horizontal Lathes for B2B Buyers?

Horizontal lathes are among the most commonly used types in various industries, particularly in metalworking and automotive applications. They feature a horizontal spindle that allows for the machining of long workpieces efficiently. This type of lathe is suitable for jobs requiring versatility in length and diameter, making it a preferred choice for manufacturers that produce a range of components. Buyers should consider the floor space available, as horizontal lathes typically require more room than other lathe types.

How Do Vertical Lathes Differ in Application and Functionality?

Vertical lathes are designed with a vertical spindle, making them ideal for heavy and large workpieces, such as those found in aerospace and shipbuilding industries. Their structure allows for better stability and control when handling bulky materials. This type of lathe is particularly suitable for tasks that require significant torque and strength. B2B buyers should assess the weight and dimensions of the materials they intend to machine, as vertical lathes excel in handling substantial loads but may not be as versatile for smaller parts.

What Advantages Do CNC Lathes Offer for Precision Production?

CNC lathes incorporate computer numerical control technology, allowing for high precision and automation in machining processes. They are ideal for high-volume production and prototyping, where consistency and repeatability are crucial. The investment in CNC lathes can be higher compared to traditional models, but the long-term savings in labor and material costs, along with increased production efficiency, often justify the initial expense. B2B buyers should evaluate their production scale and the complexity of parts when considering CNC lathes.

Why Choose Turret Lathes for Mass Production Needs?

Turret lathes are characterized by their ability to hold multiple cutting tools, which allows for rapid changes between operations. This feature makes them particularly useful in mass production settings where efficiency is essential. While turret lathes can significantly increase productivity, buyers should be aware that the setup time for different operations can be longer compared to other lathe types. Businesses focusing on high-volume production of complex parts will find turret lathes particularly beneficial.

What Makes Toolroom Lathes Ideal for Precision Work?

Toolroom lathes are smaller and more versatile, designed for precision work and repairs. They are commonly used in tool making and small batch production, where detailed work is required. These lathes offer a high degree of control and are suitable for intricate machining tasks. However, they may not be the best choice for large-scale production. B2B buyers should consider their specific needs for precision versus volume when evaluating toolroom lathes for their operations.

Key Industrial Applications of russian lathe

| Industry/Sector | Specific Application of Russian Lathe | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Precision component machining | High accuracy and consistency in parts | Ensure machine compatibility with specific materials |

| Aerospace | Custom aerospace component fabrication | Lightweight, durable components | Verify certification standards for safety and quality |

| Metalworking | Production of custom metal parts | Enhanced productivity and reduced waste | Assess machine capabilities for various metal types |

| Furniture Manufacturing | Shaping and finishing wooden products | Improved design flexibility and quality | Consider the lathe’s versatility with different woods |

| Heavy Machinery Production | Manufacturing of large, complex machinery parts | Increased operational efficiency | Evaluate maintenance support and availability of parts |

How is the Russian Lathe Used in Automotive Manufacturing?

In the automotive sector, Russian lathes are utilized for precision machining of various components such as shafts, gears, and housings. These machines ensure high accuracy and repeatability, which are crucial for maintaining the performance and safety of vehicles. International buyers should look for lathes that can handle specific materials like aluminum and steel, as well as those with advanced CNC capabilities for complex designs. Additionally, understanding the local supply chain for parts and service support is essential to minimize downtime.

What Role Does the Russian Lathe Play in Aerospace Component Fabrication?

The aerospace industry relies heavily on Russian lathes for the fabrication of lightweight and durable components, such as turbine blades and landing gear parts. The precision required in this sector demands lathes that can meet stringent certification standards. Buyers from regions like Europe and the Middle East should prioritize sourcing lathes that comply with international aerospace quality regulations and provide detailed documentation of their manufacturing processes. This ensures that the components produced are both reliable and safe for flight.

In What Ways Does the Russian Lathe Benefit Metalworking?

In metalworking, Russian lathes are integral for producing custom metal parts, offering enhanced productivity and reduced waste through efficient machining processes. These machines can be adapted for various metal types, making them versatile for different projects. Buyers should consider the lathe’s ability to accommodate specific metalworking needs, such as the capacity for high-speed machining and the availability of tooling options. Additionally, understanding the machine’s maintenance requirements is critical to ensuring long-term performance.

How is the Russian Lathe Applied in Furniture Manufacturing?

Furniture manufacturers utilize Russian lathes for shaping and finishing wooden products, enabling intricate designs and high-quality finishes. The adaptability of these lathes allows for the production of various styles, from traditional to modern furniture. Buyers should assess the lathe’s versatility with different wood types and its capacity for fine detailing. Moreover, sourcing considerations should include the machine’s ability to integrate with other woodworking tools and the availability of local support for maintenance.

What Advantages Does the Russian Lathe Provide in Heavy Machinery Production?

In heavy machinery production, Russian lathes are used to manufacture large and complex parts, contributing to increased operational efficiency. These machines can handle substantial workloads and are essential for producing components that require precision and durability. Buyers should evaluate the lathe’s specifications to ensure it can accommodate the size and weight of the parts being produced. Additionally, understanding the machine’s maintenance support and parts availability is crucial for ensuring continuous operation in demanding environments.

3 Common User Pain Points for ‘russian lathe’ & Their Solutions

Scenario 1: Ensuring Operator Safety During Lathe Operations

The Problem: One of the most pressing challenges B2B buyers face when acquiring a Russian lathe is ensuring the safety of their operators. Incidents involving lathes can lead to severe injuries or even fatalities, as highlighted by past accidents. Operators may inadvertently become entangled in machinery due to loose clothing or improper handling, resulting in catastrophic outcomes. Buyers often struggle with implementing effective safety protocols that comply with regulations while also ensuring that their employees are well-trained to handle these powerful machines.

The Solution: To mitigate safety risks, it’s crucial to invest in comprehensive training programs tailored specifically for the Russian lathe operations. This training should encompass not only the technical aspects of machine operation but also the importance of personal safety measures, such as wearing appropriate clothing (e.g., fitted garments rather than loose clothing) and the use of personal protective equipment (PPE). Additionally, buyers should consider sourcing lathes equipped with advanced safety features, such as automatic shutoff mechanisms and protective guarding around moving parts. Implementing regular safety drills and hazard awareness training can help reinforce a culture of safety in the workplace, making operators more vigilant and prepared to handle potential risks.

Scenario 2: Navigating Maintenance and Equipment Longevity

The Problem: B2B buyers often encounter challenges related to the maintenance and longevity of Russian lathes. As these machines are subjected to heavy usage, wear and tear can significantly impact their performance and reliability. Inconsistent maintenance practices can lead to unanticipated breakdowns, resulting in costly downtime and delays in production schedules. Buyers may find it difficult to source the right parts and service support to keep their machinery running smoothly.

The Solution: To address maintenance challenges, companies should establish a proactive maintenance schedule that includes routine inspections and servicing of the lathe. This can involve partnering with suppliers who offer maintenance packages or support services specifically for Russian lathes. Buyers should also consider investing in a comprehensive inventory management system that tracks the usage of machine parts and identifies when replacements are due. Additionally, creating a relationship with reliable suppliers for genuine parts can help ensure that replacements are readily available, minimizing downtime. Training maintenance staff on the specific requirements of Russian lathes can further enhance equipment longevity and performance.

Scenario 3: Maximizing Operational Efficiency Through Proper Specifications

The Problem: Another common pain point for B2B buyers is ensuring that the specifications of the Russian lathe align with their production needs. Many buyers struggle with selecting the right model and configuration, which can lead to inefficiencies in production processes. Choosing a lathe that is either underpowered or overly complex for the intended tasks can result in wasted resources and increased operational costs.

The Solution: To optimize operational efficiency, buyers should conduct a thorough needs assessment before purchasing a Russian lathe. This involves evaluating the specific materials to be worked on, the precision required, and the volume of production. Engaging with manufacturers or experienced distributors can provide valuable insights into the most suitable specifications for the intended applications. Furthermore, buyers should consider investing in lathes that offer flexibility and adaptability, allowing for modifications as production demands change. Establishing a feedback loop with operators can also help in fine-tuning the setup, ensuring that the lathe is utilized to its full potential, thereby improving overall productivity and reducing costs.

Strategic Material Selection Guide for russian lathe

When selecting materials for a Russian lathe, it is essential to consider the specific applications, performance requirements, and regional standards that may affect international procurement. Below, we analyze four common materials used in the manufacturing and operation of lathes, focusing on their properties, advantages, disadvantages, and considerations for B2B buyers from diverse regions.

What Are the Key Properties of Steel for Russian Lathes?

Steel is the most widely used material in lathe construction due to its excellent mechanical properties. It typically features high tensile strength, good wear resistance, and the ability to withstand high temperatures and pressures. Steel can be alloyed with other elements to enhance its properties further, such as chromium for corrosion resistance or carbon for increased hardness.

Pros & Cons: Steel is durable and cost-effective, making it suitable for a variety of applications. However, it can be prone to rust if not properly treated, and its manufacturing process can be complex, requiring precise machining to achieve desired tolerances.

Impact on Application: Steel is compatible with various media, including oils and coolants used in machining processes. However, its susceptibility to corrosion necessitates careful consideration in environments with high humidity or exposure to corrosive substances.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM A36 or DIN 17100, which govern the quality of structural steel. The choice of steel grade may also be influenced by local availability and cost.

How Does Aluminum Perform in Lathe Applications?

Aluminum is another popular material used in lathe components, particularly for parts requiring lightweight and high corrosion resistance. Its low density and excellent machinability make it a preferred choice for applications where weight savings are critical.

Pros & Cons: Aluminum is resistant to corrosion and has good thermal conductivity. However, it is less durable than steel and may not withstand high-stress applications as effectively. The cost of aluminum can be higher than that of steel, depending on market conditions.

Impact on Application: Aluminum is suitable for applications involving non-abrasive media and is often used in the aerospace and automotive industries. Its lightweight nature can enhance the performance of the final product, especially in mobile applications.

Considerations for International Buyers: Buyers should be aware of standards such as ASTM B221 for aluminum extrusions and ensure that the aluminum alloy selected meets the specific requirements of their application.

What Role Does Cast Iron Play in Lathe Construction?

Cast Iron is commonly used in lathe beds and frames due to its excellent damping properties and ability to absorb vibrations. This material provides stability during machining operations, which is crucial for achieving precision.

Pros & Cons: The primary advantage of cast iron is its rigidity and vibration-damping capacity. However, it is brittle and can fracture under excessive stress. Additionally, cast iron can be more expensive to machine compared to steel.

Impact on Application: Cast iron is compatible with various cutting fluids and is often used in heavy-duty machining applications where stability is paramount. Its weight can also contribute to a more stable machining environment.

Considerations for International Buyers: Buyers should consider compliance with standards such as ASTM A48 for gray cast iron and assess the availability of suitable grades in their region.

Why is Plastic Used in Some Lathe Applications?

Plastic, particularly engineering plastics like nylon or polycarbonate, can be used for non-structural components of lathes, such as guards or covers. These materials are lightweight and resistant to corrosion.

Pros & Cons: Plastics are generally low-cost and easy to manufacture, allowing for rapid prototyping and production. However, they lack the strength and heat resistance of metals, limiting their use in high-stress applications.

Impact on Application: Plastics are suitable for applications where weight reduction is essential, and they can provide effective insulation against electrical components. However, they may not be suitable for high-temperature environments.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM D638 for tensile properties of plastics and consider the specific environmental conditions in which the plastic components will operate.

Summary Table of Material Selection for Russian Lathes

| Material | Typical Use Case for Russian Lathe | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components and tools | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Lightweight parts and frames | Corrosion resistance and light weight | Less durable under stress | High |

| Cast Iron | Lathe beds and frames | Excellent vibration damping | Brittle and expensive to machine | Medium to High |

| Plastic | Guards and covers | Low-cost and easy to manufacture | Limited strength and heat resistance | Low |

This comprehensive analysis of materials for Russian lathes provides valuable insights for international B2B buyers, enabling them to make informed decisions that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for russian lathe

What Are the Main Stages in the Manufacturing Process of Russian Lathes?

The manufacturing process of Russian lathes is a complex sequence of operations designed to ensure precision and durability. The typical stages include material preparation, forming, assembly, and finishing. Each stage is critical in achieving the high standards expected in industrial applications.

Material Preparation: How Is the Right Material Chosen?

The first step in manufacturing a Russian lathe involves selecting high-quality raw materials. Common materials include high-carbon steel and alloyed steels, known for their strength and wear resistance. Before processing, materials undergo inspections to verify their chemical composition and mechanical properties, ensuring they meet industry specifications. This rigorous selection is crucial, as the material quality directly influences the lathe’s performance and longevity.

Forming: What Techniques Are Used to Shape Components?

Once the materials are prepared, the forming stage begins, which typically involves machining operations like turning, milling, and grinding. Advanced CNC (Computer Numerical Control) machines are often employed to achieve precise dimensions and surface finishes. For Russian lathes, particular attention is paid to the spindle and bed design, as these components must maintain alignment and stability during operation. Techniques such as heat treatment may also be applied to enhance the hardness and durability of critical components.

Assembly: How Are Components Integrated for Optimal Performance?

The assembly phase is where individual components come together to form the complete lathe. This stage requires skilled labor to ensure precise alignment and fitting of parts, which is essential for minimizing vibrations and ensuring smooth operation. During assembly, critical tolerances are checked, and adjustments are made to align the spindle and tool rest accurately. The assembly process may also involve integrating electronic components and control systems that enhance functionality and user experience.

Finishing: What Processes Ensure the Lathe Meets Quality Standards?

The finishing stage is vital for both aesthetic and functional purposes. Processes such as polishing, painting, and applying protective coatings are carried out to enhance the lathe’s appearance and protect it from corrosion. Rigorous quality checks are conducted to ensure that all surfaces meet specified roughness levels. Additionally, testing for functionality, such as verifying the accuracy of the spindle speed and tool alignment, is performed before the lathe is deemed ready for delivery.

What Quality Assurance Standards Should B2B Buyers Expect?

Quality assurance is a cornerstone of the manufacturing process for Russian lathes, ensuring that products meet both international and industry-specific standards. Buyers should be aware of the following key standards and practices.

Which International Standards Are Relevant for Russian Lathes?

Many manufacturers adhere to international standards such as ISO 9001, which focuses on quality management systems. This certification demonstrates a commitment to consistent quality and customer satisfaction. Additionally, industry-specific standards such as CE marking for compliance with European safety regulations and API specifications for oil and gas equipment may apply, depending on the intended use of the lathe.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspections are performed on raw materials before they enter production to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring occurs during manufacturing to identify and rectify defects early in the process. This includes measuring dimensions and checking tolerances at critical stages.

- Final Quality Control (FQC): The final product undergoes comprehensive testing to verify that it meets all operational and safety requirements before shipment.

These checkpoints are essential in maintaining high standards of quality and reliability.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial for ensuring product reliability. Here are actionable steps to consider:

What Audits and Reports Should Be Requested?

Buyers should request access to the supplier’s quality management system documentation, including ISO certification and internal audit reports. These documents provide insight into the supplier’s commitment to quality and adherence to international standards. Additionally, buyers can ask for records of past inspections and quality control results to assess consistency in performance.

How Do Third-Party Inspections Enhance Trust?

Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control processes. These agencies perform audits and product inspections, verifying compliance with international standards. This additional layer of scrutiny can help mitigate risks associated with purchasing machinery from overseas suppliers.

What Are the Nuances of Quality Control for International Buyers?

International buyers must be aware of potential cultural and regulatory differences that may impact quality assurance practices. For example, certain regions may have different expectations regarding documentation and compliance. Engaging local representatives or consultants who understand these nuances can facilitate smoother transactions and ensure that quality standards are met.

Conclusion: Ensuring Quality in Russian Lathe Procurement

In summary, the manufacturing process of Russian lathes involves meticulous attention to detail at every stage, from material preparation to finishing. Buyers should prioritize suppliers who adhere to recognized international standards and maintain robust quality control practices. By understanding the manufacturing and quality assurance processes, B2B buyers can make informed decisions that ensure they receive reliable and high-quality lathe machinery tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘russian lathe’

In today’s competitive manufacturing landscape, sourcing a Russian lathe requires careful consideration and strategic planning. This guide provides a step-by-step checklist to help B2B buyers navigate the procurement process effectively, ensuring they make informed decisions that align with their operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful sourcing process. Determine the specific requirements of your operations, including the types of materials you will be working with, the lathe’s capacity, and the precision needed for your projects. Consider factors like spindle speed, tooling options, and the overall size of the machine to ensure it meets your production needs.

Step 2: Research Available Models and Features

Understanding the various models of Russian lathes and their features is crucial. Different models come with unique capabilities, such as CNC controls, manual operation, or hybrid options. Research the advantages and limitations of each model to identify which aligns best with your production requirements and budget constraints.

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet potential suppliers. Request company profiles, product catalogs, and case studies to assess their credibility and experience in the industry. Additionally, seek references from other buyers in similar regions or sectors to gauge the supplier’s reliability and customer service.

- Look for certifications: Ensure suppliers adhere to international quality standards, such as ISO certifications, which indicate a commitment to quality and safety.

- Check for after-sales support: Reliable suppliers should offer robust customer service, including training, maintenance, and parts availability.

Step 4: Verify Compliance with Safety Standards

Safety is paramount when operating heavy machinery like lathes. Verify that the lathe complies with local and international safety regulations. Look for features such as emergency stop buttons, guarding against moving parts, and operators’ manuals that outline safety protocols.

- Review incident records: Investigate the supplier’s history regarding safety incidents and how they address safety training for operators.

- Ensure proper documentation: Request safety compliance certifications and documentation related to the machine’s operation and maintenance.

Step 5: Request Demonstrations or Trials

Whenever possible, request a demonstration or trial period for the lathe. This allows you to assess the machine’s performance in real-world conditions and ensures it meets your operational expectations. Pay attention to aspects like ease of use, maintenance requirements, and overall functionality during the demonstration.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier and model, focus on negotiating favorable terms and conditions. Discuss pricing, payment options, delivery timelines, and warranty coverage. Ensure that all agreements are documented to avoid any misunderstandings down the line.

- Consider total cost of ownership: Evaluate not just the purchase price but also operational costs, maintenance, and potential downtime costs associated with the lathe.

- Clarify warranty and service agreements: Ensure you fully understand the warranty terms and what after-sales service is included.

Step 7: Plan for Installation and Training

Finally, prepare for the installation and training process. Coordinate with your supplier to schedule installation and ensure that your operators receive comprehensive training on the lathe’s operation and safety protocols. Proper training is essential for maximizing the lathe’s capabilities and minimizing the risk of accidents.

By following this checklist, B2B buyers can navigate the complexities of sourcing a Russian lathe with confidence, ensuring they select the right equipment that enhances their production capabilities while prioritizing safety and efficiency.

Comprehensive Cost and Pricing Analysis for russian lathe Sourcing

What Are the Key Cost Components in Russian Lathe Sourcing?

When sourcing Russian lathes, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The raw materials for lathes, such as high-grade steel and specialized alloys, significantly influence the overall cost. The quality of these materials directly affects the durability and performance of the machine.

-

Labor: Labor costs vary based on the region and skill level required for manufacturing. In Russia, labor rates may be lower than in Western Europe, but the expertise needed for precision machining can demand higher wages.

-

Manufacturing Overhead: This includes costs related to factory operations such as utilities, rent, and equipment maintenance. Efficient manufacturing practices can help minimize these overheads, which can be a significant portion of the total cost.

-

Tooling: Specific tools and fixtures required for the production of lathes can add to the initial investment. Tooling costs can fluctuate based on the complexity of the lathe design and the production volume.

-

Quality Control (QC): Implementing stringent QC measures is essential to ensure the reliability of lathes. These costs can include testing equipment and personnel, impacting the final price but ultimately ensuring product longevity.

-

Logistics: Shipping costs are a critical factor, especially when importing lathes internationally. Factors such as distance, mode of transport, and customs duties can significantly affect total logistics expenses.

-

Margin: Suppliers will include a profit margin, which varies based on market demand, competition, and the supplier’s business strategy. Understanding typical margins in the industry can aid buyers in negotiations.

How Do Price Influencers Affect the Cost of Russian Lathes?

Several factors can influence the pricing of Russian lathes, including:

-

Volume/MOQ: Purchasing in bulk often results in lower per-unit costs. Suppliers may offer discounts for larger orders, making it beneficial for companies that have significant machining needs.

-

Specifications/Customization: Customized lathes designed for specific applications typically incur higher costs. Buyers should assess their exact requirements to avoid unnecessary expenditures on features that may not be needed.

-

Materials: The choice of materials can significantly impact price. High-performance materials may offer better longevity and efficiency, justifying a higher upfront cost.

-

Quality/Certifications: Lathes that meet international quality standards or come with certifications can command higher prices. Buyers should consider the long-term benefits of investing in quality machinery.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but often provide better support and warranty options.

-

Incoterms: Understanding the terms of shipping and delivery (Incoterms) is essential for calculating total costs. These terms define the responsibilities of buyers and sellers regarding transport costs and risks.

What Are Effective Buyer Tips for Negotiating Russian Lathe Prices?

To navigate the complexities of pricing when sourcing Russian lathes, international buyers can employ several strategies:

-

Negotiate Wisely: Always approach negotiations with a clear understanding of market prices and the specific needs of your business. Leverage multiple quotes to create competitive pressure among suppliers.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, maintenance, operational costs, and potential downtime. A lower initial price may not always yield the best long-term value.

-

Understand Pricing Nuances for International Markets: Be aware of regional pricing differences and the impact of currency fluctuations. This is particularly relevant for buyers from Africa, South America, the Middle East, and Europe.

-

Consider Local Regulations and Standards: Ensure that the lathes comply with local safety and operational standards, which may affect pricing. Non-compliance can lead to additional costs down the line.

-

Request Detailed Quotations: Always ask for itemized quotes that break down the costs associated with materials, labor, and logistics. This transparency can help in understanding where savings can be achieved.

Disclaimer on Indicative Prices

Prices for Russian lathes can vary widely based on the factors discussed above. It is advisable for buyers to conduct thorough research and obtain multiple quotations to ensure they are getting competitive pricing tailored to their specific requirements.

Alternatives Analysis: Comparing russian lathe With Other Solutions

Understanding Alternative Solutions to Russian Lathes

When considering industrial machinery for shaping and crafting materials, the Russian lathe is a notable option due to its robust performance and versatility. However, there are alternative technologies and methods available that can meet similar needs, each with unique advantages and disadvantages. This section explores viable alternatives to the Russian lathe, enabling B2B buyers to make informed decisions based on their specific requirements.

Comparison Table

| Comparison Aspect | ‘Russian Lathe’ | CNC Lathe | Vertical Machining Center |

|---|---|---|---|

| Performance | High precision for various materials | Exceptional precision, automation | Versatile with complex shapes |

| Cost | Moderate initial investment | Higher initial investment | High initial investment |

| Ease of Implementation | Requires skilled operators | Requires programming knowledge | Requires skilled operators |

| Maintenance | Regular maintenance needed | Lower frequency, but complex | Higher maintenance due to complexity |

| Best Use Case | General machining tasks | Mass production, intricate designs | Complex 3D machining |

What Are the Pros and Cons of CNC Lathes as an Alternative?

CNC (Computer Numerical Control) lathes are increasingly popular due to their automation capabilities. They offer exceptional precision and repeatability, making them ideal for mass production and intricate designs. The downside is that they require a higher initial investment compared to traditional lathes, which may be a barrier for smaller businesses. Additionally, operators need programming skills to effectively utilize CNC technology, which can necessitate further training.

How Do Vertical Machining Centers Compare to Russian Lathes?

Vertical machining centers (VMCs) are another alternative that excels in handling complex shapes and three-dimensional machining tasks. They provide versatility and can process a wider range of materials and designs compared to traditional lathes. However, the initial cost and maintenance requirements are generally higher, making them less accessible for companies with tighter budgets. VMCs also require skilled operators, similar to lathes, which can be a consideration in workforce training and availability.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting between a Russian lathe and alternative solutions like CNC lathes or vertical machining centers, B2B buyers must assess their specific needs, including budget constraints, the complexity of machining tasks, and available operator skills. For businesses focused on high-volume production with intricate designs, CNC lathes may be the best fit, despite their higher costs. Conversely, for general machining tasks that require reliability and moderate investment, the Russian lathe remains a strong contender. Vertical machining centers are ideal for organizations looking to handle complex shapes but should be considered only if the budget allows for the associated costs. Ultimately, understanding the unique strengths and limitations of each option will empower buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for russian lathe

What Are the Key Technical Properties of Russian Lathes?

When considering the acquisition of a Russian lathe, understanding its technical specifications is crucial for ensuring it meets the operational needs of your business. Below are some of the essential properties to evaluate:

1. Material Grade

The material grade of a lathe refers to the quality and type of metals used in its construction. Common materials include cast iron and high-grade steel, which provide durability and stability during operation. For B2B buyers, opting for high-grade materials ensures longevity and reduces the frequency of maintenance, ultimately lowering operational costs.

2. Spindle Speed

Spindle speed, measured in revolutions per minute (RPM), indicates how fast the lathe can rotate the workpiece. Higher spindle speeds allow for faster machining processes, which can significantly enhance productivity. Understanding the spindle speed is vital for buyers in industries where time efficiency is critical, such as automotive or aerospace manufacturing.

3. Tolerance

Tolerance refers to the allowable deviation from a specified dimension in the machining process. High precision lathes may offer tolerances as tight as ±0.01 mm. For B2B buyers, selecting a lathe with suitable tolerance levels is essential for ensuring product quality and meeting customer specifications, especially in sectors like electronics and precision engineering.

4. Bed Length and Width

The bed length and width of a lathe determine the size of workpieces it can handle. A longer bed allows for larger components to be machined, while the width affects stability and rigidity. Businesses that plan to work with larger materials should prioritize lathes with appropriate bed dimensions to optimize their operational capabilities.

5. Tooling Compatibility

Tooling compatibility refers to the types of cutting tools that can be used with a lathe. Different lathes may accommodate various tool holders and cutting inserts. For international buyers, ensuring that the lathe can use widely available tooling can streamline operations and reduce costs associated with sourcing specialized tools.

What Are Common Trade Terminology and Their Significance in B2B Transactions?

Understanding trade terminology is crucial for effective communication and negotiation in the B2B landscape. Here are some key terms related to the procurement of Russian lathes:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of lathes, buyers should consider whether they are purchasing from an OEM or a reseller, as this can impact product authenticity and warranty terms.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. It is an important factor for businesses, especially startups or smaller manufacturers, as it can determine the feasibility of a purchase. Understanding MOQ helps buyers plan their budgets and inventory levels effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and availability for specific products. For international buyers, submitting an RFQ for Russian lathes can help in comparing costs and understanding the market rates, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers, as it clarifies the logistics involved in importing machinery like lathes from Russia, ensuring smooth delivery and compliance with regulations.

5. Lead Time

Lead time is the duration between the placement of an order and its delivery. For businesses relying on timely project completion, understanding the lead time for lathes can help in planning production schedules and meeting customer demands efficiently.

By grasping these technical properties and trade terms, international buyers can make more informed decisions when sourcing Russian lathes, ultimately enhancing their operational effectiveness and market competitiveness.

Navigating Market Dynamics and Sourcing Trends in the russian lathe Sector

What Are the Current Market Dynamics and Key Trends in the Russian Lathe Sector?

The global lathe market, particularly concerning Russian lathes, is experiencing transformative dynamics driven by advancements in technology and shifting sourcing practices. One significant driver is the increasing demand for precision engineering across various industries, including aerospace, automotive, and manufacturing. As businesses in Africa, South America, the Middle East, and Europe (e.g., Nigeria and Germany) seek to enhance production capabilities, the versatility and reliability of Russian lathes have made them an appealing choice.

Emerging trends in the B2B sector include the integration of smart technology and automation. Companies are increasingly adopting CNC (Computer Numerical Control) lathes, which offer enhanced precision and efficiency. This shift not only reduces labor costs but also minimizes the risk of human error, making it an attractive option for international buyers looking to optimize their operations. Additionally, there is a growing trend towards sourcing equipment that can be easily integrated with existing systems, emphasizing compatibility and ease of use.

Market dynamics are also influenced by geopolitical factors, which may impact supply chains and procurement strategies. Buyers must navigate these complexities by establishing strong relationships with reliable suppliers who can provide not only machinery but also ongoing support and maintenance services. Furthermore, as the global economy becomes more interconnected, the importance of understanding local regulations and compliance standards in different regions cannot be overstated.

How Is Sustainability and Ethical Sourcing Addressed in the Russian Lathe Sector?

Sustainability has emerged as a crucial consideration for international B2B buyers in the lathe sector. The environmental impact of manufacturing processes, particularly in heavy industries, is a growing concern. Companies are now prioritizing suppliers who demonstrate a commitment to sustainable practices, such as reducing waste, energy consumption, and emissions during production.

Ethical sourcing is equally important, with buyers increasingly demanding transparency in supply chains. This includes ensuring that materials used in the production of lathes are sourced responsibly and that labor practices comply with international standards. Suppliers who can provide certifications for sustainable materials, such as recycled metals or environmentally friendly lubricants, are more likely to attract discerning buyers.

Additionally, as regulatory frameworks around sustainability tighten globally, companies that invest in ‘green’ certifications will find themselves at a competitive advantage. Buyers should look for suppliers who are certified by recognized organizations, as this not only demonstrates a commitment to sustainability but also aligns with the growing consumer demand for ethical products.

What Is the Brief Evolution and History of the Russian Lathe Sector?

The evolution of the Russian lathe sector is deeply rooted in the country’s industrial heritage, dating back to the early 20th century when lathes became essential tools in manufacturing. Initially, Russian lathes were designed to meet the needs of a burgeoning industrial base, focusing on functionality and durability. Over the decades, advancements in technology led to significant improvements in precision and efficiency, paving the way for modern CNC lathes.

During the Soviet era, the emphasis was on mass production, which resulted in robust lathe designs that could withstand the rigors of heavy use. Post-Soviet reforms opened the market to international influences, facilitating the adoption of advanced technologies and practices. Today, Russian manufacturers are recognized for their ability to produce high-quality lathes that meet international standards, making them competitive players in the global market.

As the sector continues to evolve, the focus on innovation, automation, and sustainability will likely shape its future, providing ample opportunities for international buyers seeking reliable and cutting-edge lathe solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of russian lathe

-

How do I ensure the safety of workers when using a Russian lathe?

To ensure worker safety while operating a Russian lathe, implement comprehensive training programs that cover machine operation, safety protocols, and hazard recognition. Regularly inspect and maintain machinery to prevent malfunctions. Establish strict guidelines against wearing loose clothing, and provide personal protective equipment (PPE) such as safety goggles and gloves. Additionally, create a culture of safety where workers feel comfortable reporting unsafe conditions or suggesting improvements. -

What are the key features to look for in a high-quality Russian lathe?

When sourcing a Russian lathe, prioritize features such as precision, durability, and versatility. Look for lathes equipped with advanced safety mechanisms, such as automatic shutoffs and protective guards. Consider the machine’s power capacity, speed options, and the range of materials it can handle. Additionally, assess the availability of customization options to fit specific production needs and the manufacturer’s reputation for reliability and support. -

How can I vet suppliers of Russian lathes effectively?

To vet suppliers, conduct thorough research on their reputation in the industry. Check for customer reviews, testimonials, and case studies showcasing their product performance. Request references from previous clients and ensure they have a track record of timely deliveries and responsive customer service. Additionally, assess their compliance with international standards and certifications, which can indicate reliability and commitment to quality. -

What are typical payment terms when purchasing a Russian lathe?

Payment terms can vary significantly among suppliers. Typically, you may encounter options such as a deposit upfront (usually 30-50% of the total cost) with the remainder due upon delivery or installation. Some suppliers may offer flexible financing options or letters of credit. It’s crucial to clarify payment conditions, including any penalties for late payments, to avoid misunderstandings and ensure a smooth transaction. -

What is the minimum order quantity (MOQ) for Russian lathes?

Minimum order quantities can differ by supplier and the specific model of the lathe. Some manufacturers may have no MOQ for standard models, while others might require orders of several units, especially for customized machines. Discuss your needs with potential suppliers to negotiate terms that work for your business. Be prepared to justify your order size to secure favorable pricing and terms. -

How do I assess the quality assurance (QA) processes of a supplier?

To assess a supplier’s QA processes, inquire about their quality control standards and testing procedures. Request documentation that demonstrates their compliance with international quality standards, such as ISO certifications. Additionally, ask about the frequency of inspections and the criteria they use to evaluate machine performance. A reputable supplier should be transparent about their QA processes and willing to share results of past audits. -

What logistics considerations should I keep in mind when importing a Russian lathe?

When importing a Russian lathe, consider shipping methods, customs duties, and import regulations in your country. Evaluate the supplier’s experience with international shipping and their ability to handle logistics efficiently. Ensure that all documentation, including commercial invoices and certificates of origin, is in order to avoid delays. Additionally, factor in the cost of insurance and potential tariffs to calculate the total landed cost of the lathe. -

What customization options are available for Russian lathes?

Customization options for Russian lathes can vary by manufacturer but often include features such as specialized tooling, enhanced safety guards, and specific size configurations to meet unique production requirements. Some suppliers may also offer software upgrades for improved operational efficiency or integration with existing production lines. Discuss your specific needs with potential suppliers to explore available customization options that can enhance productivity and safety in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Russian Lathe Manufacturers & Suppliers List

1. HowStuffWorks – Lathe Machines

Domain: science.howstuffworks.com

Registered: 1998 (27 years)

Introduction: Lathe machines are industrial machines used to shape materials like metal, wood, and plastic by rotating them against a cutting tool. They are crucial in various industries, including automotive manufacturing and furniture production. Key risks associated with lathe machines include entanglement, flying debris, and improper use. Safety measures include comprehensive training programs, updated safe…

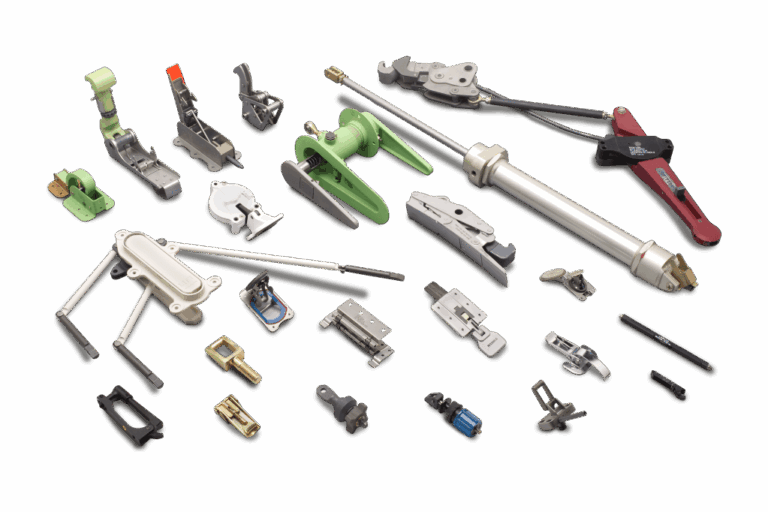

2. Safety and Health Magazine – Machine Safety Solutions

Domain: safetyandhealthmagazine.com

Registered: 2013 (12 years)

Introduction: Manual lathe, aftermarket clamping device, guarding for machines, hazard awareness training, job hazard analysis procedure.

3. Gata Industrial – Russian Lathe

Domain: gataindustrial.com

Registered: 2008 (17 years)

Introduction: {“product_name”: “Russian Lathe”, “price”: “14,000.00 CDN”, “dimensions”: “24\”x84\” lg.”, “color”: “Green”, “product_code”: “206080”, “description”: “Call us today for more specs on this machine.”}

4. Facebook – Engaging Educational Content

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Engaging Educational Content, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Estanko – Used Russian Lathe

Domain: machinio.com

Registered: 2013 (12 years)

Introduction: Used Russian Lathe for sale. Key details include: 1. Manufacturer: Estanko, DMTG, miUmac, JT, Wadjay, YASHU, Stanko. 2. Specifications: Max. length of workpiece: 3000 mm; Range of spindle speed: 26 – 2000 r.p.m; Diameter: 600 mm; Length: 2000 mm; Chuck: 2800 mm; Swing: 3200 mm; Height: 1650 mm. 3. Price examples: $10,500 USD for a DMTG Iron Machine. 4. Locations: Guadalajara, Mexico; Zhejiang, Chi…

6. OAO Michurinskiy Zavod Progress – Russian Miniature Round-bed Lathe

Domain: lathes.co.uk

Registered: 1998 (27 years)

Introduction: Product Name: Russian Miniature Round-bed Lathe (Universal 3-inch, Delphin, ExeCut)\nManufacturer: OAO Michurinskiy Zavod Progress\nSwing Over Bed: 150 mm (3-inch center height)\nSwing Over Carriage: 90 mm\nCapacity Between Centres: 250 mm (10 inches)\nHeadstock Spindle: No. 2 Morse taper, bore of 15.2 mm (0.5\”)\nMotor: Original 0.5 kW, recent models 0.75 kW\nSpindle Speeds: 9 speeds ranging from…

7. CNC Lathe – Made In Russia Vertical Lathes

Domain: makinecim.com

Registered: 2006 (19 years)

Introduction: {“category”:”CNC Lathe”,”total_records”:3,”ads”:[{“title”:”Made In Russia Cnc Vertical Lathe 1525″,”type”:”Used”,”date”:”29 May 2025″,”location”:”İstanbul”,”price”:”Ask For Price”},{“title”:”Made In Russia Cnc Vertical Lathe 1516″,”type”:”Used”,”date”:”29 May 2025″,”location”:”İstanbul”,”price”:”Ask For Price”},{“title”:”Made In Russia Cnc Vertical Lathe 1512″,”type”:”Used”,”date”:”29 May 2025″,”l…

Strategic Sourcing Conclusion and Outlook for russian lathe

In summary, the strategic sourcing of Russian lathes presents a unique opportunity for international B2B buyers seeking high-quality machinery for diverse applications. Key takeaways emphasize the importance of not only evaluating the machine’s specifications and capabilities but also understanding the critical need for robust safety protocols and training programs. The tragic incidents associated with lathe operations underscore the necessity for comprehensive hazard awareness and regular equipment inspections.

As industries across Africa, South America, the Middle East, and Europe continue to evolve, the demand for reliable and precise machining tools like Russian lathes is set to grow. Buyers should prioritize sourcing from reputable suppliers who not only provide quality equipment but also emphasize safety and operational training.

Looking ahead, international buyers are encouraged to engage with manufacturers and suppliers who can offer not just machines, but also ongoing support and training. By doing so, businesses can enhance their operational efficiency while ensuring the safety of their workforce. Take the proactive step today to secure the right Russian lathe for your needs, ensuring your operations are both productive and safe.