Everything You Need to Know About Rubber Mold Sourcing in 2025

Introduction: Navigating the Global Market for rubber mold

In today’s rapidly evolving manufacturing landscape, sourcing high-quality rubber molds presents a significant challenge for B2B buyers. The global market for rubber molds is vast, encompassing a range of materials, types, and applications that cater to diverse industries, from automotive to food production. This guide is designed to equip international buyers, particularly those in Africa, South America, the Middle East, and Europe, with the knowledge and insights necessary to make informed purchasing decisions.

Throughout this comprehensive resource, we will explore various types of rubber molds, including silicone and urethane options, and their specific applications in different sectors. Additionally, we will provide guidance on effective supplier vetting processes, ensuring that you partner with reputable manufacturers who can meet your quality and delivery standards. Cost considerations will also be addressed, highlighting strategies to optimize your investment while maintaining quality.

By the end of this guide, you will have a deeper understanding of the rubber mold market, empowering you to navigate it with confidence. This resource aims to mitigate risks associated with sourcing and enhance your ability to secure the best products for your business needs, ultimately driving efficiency and profitability in your operations.

Understanding rubber mold Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tin-Cure Silicone Rubber | Fast curing, excellent detail reproduction, low viscosity | Art and crafts, food-safe applications | Pros: Quick setup, durable; Cons: May not withstand high temperatures. |

| Urethane Rubber Molds | High tear strength, flexible, and durable | Industrial parts, automotive components | Pros: Strong and flexible; Cons: Generally more expensive. |

| Liquid Latex Molds | Versatile, easy to work with, good for intricate designs | Special effects, costume design | Pros: Excellent for fine details; Cons: Limited durability compared to silicone. |

| RTV Silicone Molds | Room temperature vulcanization, customizable hardness | Manufacturing, prototyping | Pros: Versatile and customizable; Cons: Longer curing time. |

| Foam Rubber Molds | Lightweight, easy to handle, suitable for large projects | Architectural features, props | Pros: Cost-effective; Cons: Less detail than silicone molds. |

What are the Characteristics of Tin-Cure Silicone Rubber Molds?

Tin-cure silicone rubber molds are known for their fast curing times and exceptional detail reproduction. This type of rubber is highly versatile, making it suitable for various applications, including art and crafts, and is compliant for food-safe uses. When purchasing, buyers should consider the mold’s ability to capture intricate details and its durability over time, especially in applications requiring repeated use.

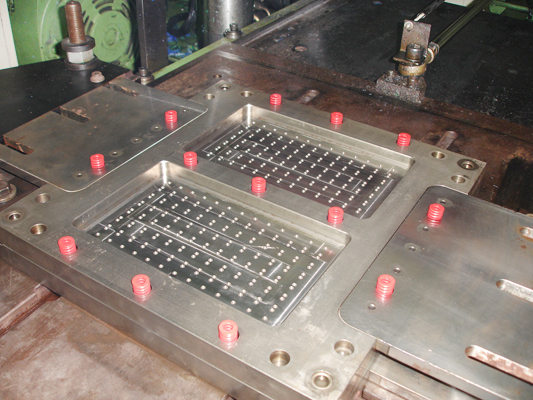

Illustrative image related to rubber mold

How Do Urethane Rubber Molds Stand Out?

Urethane rubber molds offer high tear strength and flexibility, making them ideal for industrial applications such as automotive components. These molds can withstand significant wear and tear, which is essential for manufacturers looking for longevity in their mold investments. Buyers should weigh the higher upfront costs against the durability and performance benefits, particularly for high-volume production.

In What Situations are Liquid Latex Molds Ideal?

Liquid latex molds are particularly effective for creating intricate designs and special effects. They are widely used in costume design and prop making due to their versatility and ease of use. However, while they excel in capturing fine details, their durability may not match that of silicone molds. Buyers should consider their specific project needs, including the longevity of the mold and the complexity of the design.

What Makes RTV Silicone Molds a Preferred Choice?

RTV (Room Temperature Vulcanization) silicone molds are customizable in terms of hardness and flexibility. They are widely used in manufacturing and prototyping due to their adaptability to various applications. Buyers should consider the curing time, which is longer compared to other types, and the specific requirements of their projects, such as the desired mold detail and production volume.

When Should Foam Rubber Molds Be Considered?

Foam rubber molds are lightweight and cost-effective, making them an excellent choice for larger projects, such as architectural features and props. While they may not capture details as finely as silicone molds, their affordability makes them attractive for businesses focused on budget constraints. Buyers should evaluate the trade-offs between detail and cost when considering foam rubber for their applications.

Key Industrial Applications of rubber mold

| Industry/Sector | Specific Application of rubber mold | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Architecture | Stone Veneer Production | High durability and detail in architectural designs | Need for custom molds; local sourcing options for reduced shipping costs |

| Automotive | Parts Manufacturing | Precision in component reproduction | Supplier certifications; compliance with industry standards |

| Food & Beverage | Culinary Molds for Chocolates & Cakes | FDA compliance; versatility in food applications | Food-safe materials; local regulations and certifications |

| Medical | Medical Device Prototyping | High accuracy and repeatability | Strict regulatory compliance; biocompatibility of materials |

| Arts & Crafts | Custom Crafting and Prototyping | Flexibility in design and rapid prototyping | Variety of mold options; support for small batch production |

How is rubber mold utilized in the construction and architecture sectors?

In the construction and architecture sectors, rubber molds are essential for producing stone veneers, which are used to create aesthetically pleasing exteriors. These molds allow for high detail and durability, ensuring that architectural designs can be replicated with precision. For international buyers, particularly in regions like Africa and South America, sourcing local suppliers can minimize shipping costs and lead times. Custom mold options are crucial for meeting specific design requirements, and buyers should consider the supplier’s ability to offer tailored solutions.

What role does rubber mold play in automotive parts manufacturing?

Rubber molds are pivotal in the automotive industry for manufacturing various components, such as gaskets and trim pieces. The precision offered by these molds ensures that parts fit seamlessly, improving the overall quality of the vehicle. International buyers, especially from Europe and the Middle East, must verify supplier certifications and compliance with industry standards to ensure that the molds meet stringent quality requirements. Additionally, understanding the supplier’s production capacity can help in planning for large-scale orders.

How are rubber molds used in the food and beverage industry?

In the food and beverage sector, rubber molds are utilized for creating intricate chocolate designs and cake decorations, providing versatility in culinary applications. The FDA compliance of these molds guarantees safety for food contact, which is a significant concern for businesses. For international buyers, particularly in regions like Nigeria and Saudi Arabia, it is essential to ensure that the molds meet local food safety regulations. Furthermore, suppliers should offer a range of mold designs to cater to diverse culinary needs.

In what ways does rubber mold support medical device prototyping?

Rubber molds are crucial for the prototyping of medical devices, where precision and accuracy are paramount. These molds allow for the rapid production of prototypes, which can be tested and iterated quickly. For international buyers in the medical field, compliance with strict regulatory standards is non-negotiable. It is important to source from suppliers who can guarantee the biocompatibility of their materials, ensuring that the prototypes are safe for use in medical applications.

Illustrative image related to rubber mold

How do rubber molds facilitate arts and crafts applications?

In the arts and crafts industry, rubber molds provide artists and creators with the flexibility to produce custom designs and prototypes efficiently. These molds enable rapid prototyping, allowing for experimentation with various materials and shapes. International buyers, particularly those involved in small batch production, should seek suppliers that offer a wide variety of mold options and support for custom requests. This ensures that they can achieve unique designs that stand out in the competitive market.

3 Common User Pain Points for ‘rubber mold’ & Their Solutions

Scenario 1: Difficulty Achieving Precision in Mold Reproduction

The Problem: Many B2B buyers, especially in manufacturing and prototyping sectors, struggle with achieving high precision and detail in their rubber molds. The challenge lies in the inability of standard molds to capture intricate designs or textures, which can result in wasted materials, increased production time, and ultimately unsatisfied customers. Buyers may find that their existing molds fail to reproduce critical details, particularly when working with complex shapes or fine textures, leading to costly rework and project delays.

The Solution: To overcome this issue, buyers should invest in high-quality, tin-cure silicone rubber molds that are specifically designed for detailed reproduction. Selecting a silicone with low viscosity can significantly enhance detail capture, as it flows easily into intricate designs. For maximum effectiveness, consider using brands known for their fast-curing properties and excellent tear resistance, such as Amazing Mold Rubber. Additionally, ensuring that the mixing and pouring processes are conducted in a controlled environment—maintaining low humidity and stable temperatures—will further enhance the mold’s ability to capture fine details. By using a mold release agent, you can also facilitate smoother demolding, preserving the integrity of the mold and the finished product.

Scenario 2: High Costs Due to Mold Durability Issues

The Problem: Another common pain point for B2B buyers is the high cost associated with frequent mold replacements due to wear and tear. Industries such as construction and manufacturing often require molds that can withstand repeated use without deteriorating quickly. Buyers may face substantial expenses related to sourcing new molds, not to mention the downtime incurred while waiting for replacements, which can disrupt production schedules and affect overall profitability.

The Solution: To address mold durability issues, it is essential to choose rubber molds made from high-quality materials that are engineered for longevity. Look for molds with proven tear resistance and flexibility, which can endure the stresses of repeated use. Brands like Rubber Mold Company offer products specifically designed for high-performance applications in the stone veneer industry, ensuring that molds maintain their shape and functionality over time. Furthermore, implementing proper care and maintenance routines, such as cleaning molds after each use and storing them in a cool, dry environment, can extend their lifespan significantly. This proactive approach not only reduces replacement costs but also ensures continuous production efficiency.

Scenario 3: Challenges with Compatibility for Diverse Materials

The Problem: B2B buyers often encounter compatibility issues when trying to use rubber molds with different casting materials, such as resin, wax, or concrete. These challenges can lead to adverse reactions, such as sticking or warping, which compromise the quality of the final product. As businesses expand their product lines or experiment with new materials, the need for versatile molds becomes increasingly critical, yet finding a suitable solution can be daunting.

Illustrative image related to rubber mold

The Solution: To navigate material compatibility issues, buyers should prioritize sourcing molds that are versatile and specifically formulated for multi-material use. Products that are FDA compliant and suitable for food-safe applications can also indicate a level of quality that supports a range of materials. For instance, choosing silicone molds designed to handle a wide temperature range and various casting materials can mitigate these problems. Additionally, conducting small-scale tests with new materials before full-scale production can help identify potential issues early on, ensuring that the molds perform as expected without compromising the final product’s quality. Utilizing mold release agents tailored for specific materials can also enhance compatibility, ensuring smoother casting and easier demolding, ultimately leading to improved production outcomes.

Strategic Material Selection Guide for rubber mold

What Are the Key Materials for Rubber Molds in B2B Applications?

When selecting materials for rubber molds, it is essential to consider their properties, advantages, and limitations. This analysis focuses on four common materials: silicone rubber, polyurethane rubber, natural rubber, and EPDM rubber. Each material has distinct characteristics that can impact performance, cost, and suitability for specific applications.

How Does Silicone Rubber Perform in Mold Making?

Silicone rubber is widely used in the mold-making industry due to its excellent flexibility and durability. It can withstand a broad temperature range, typically from -60°F to 400°F (-51°C to 204°C), making it suitable for various casting applications. Its resistance to UV light and moisture also ensures longevity.

Pros: Silicone rubber molds are known for their high detail reproduction and tear resistance. They are ideal for intricate designs and can be used multiple times without significant wear.

Cons: The cost of silicone rubber is generally higher than other materials, which may be a consideration for budget-conscious buyers. Additionally, the manufacturing process can be more complex due to the need for precise mixing and curing.

Impact on Application: Silicone rubber is compatible with a variety of casting materials, including resins, waxes, and concrete. This versatility makes it a preferred choice for industries ranging from crafting to construction.

What Are the Advantages of Polyurethane Rubber for Molds?

Polyurethane rubber is another popular choice for mold making, known for its exceptional hardness and abrasion resistance. It typically operates well in temperatures ranging from -40°F to 200°F (-40°C to 93°C).

Pros: Polyurethane molds offer excellent durability and can withstand heavy use, making them ideal for industrial applications. They are also relatively easy to manufacture and can be produced in various hardness levels.

Cons: While polyurethane is more affordable than silicone, it may not provide the same level of detail reproduction. Additionally, it can be sensitive to moisture during the curing process, which may complicate production in humid environments.

Impact on Application: Polyurethane is often used for casting concrete and other heavy materials, making it suitable for construction and architectural applications.

How Does Natural Rubber Compare in Terms of Mold Making?

Natural rubber is a traditional material used in mold making, valued for its elasticity and resilience. It can typically handle temperatures from -20°F to 160°F (-29°C to 71°C).

Pros: Natural rubber molds are cost-effective and provide good flexibility, making them suitable for a range of applications, including food-grade molds.

Cons: However, they have a shorter lifespan compared to silicone or polyurethane molds and can degrade when exposed to UV light or extreme temperatures.

Impact on Application: Natural rubber is often used in food applications due to its compliance with health regulations. However, it may not be suitable for high-temperature applications.

What Role Does EPDM Rubber Play in Mold Applications?

EPDM (Ethylene Propylene Diene Monomer) rubber is known for its excellent weather resistance and durability. It can withstand temperatures from -60°F to 300°F (-51°C to 149°C).

Pros: EPDM is highly resistant to ozone, UV light, and extreme temperatures, making it an excellent choice for outdoor applications. It is also relatively inexpensive compared to silicone and polyurethane.

Cons: The detail reproduction of EPDM molds may not be as high as that of silicone molds. Additionally, it may not be suitable for applications requiring high flexibility.

Illustrative image related to rubber mold

Impact on Application: EPDM is often used in applications exposed to the elements, such as construction molds for outdoor use.

Summary of Material Selection for Rubber Molds

| Material | Typical Use Case for rubber mold | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicone Rubber | Intricate designs, various casting | High detail reproduction | Higher cost, complex manufacturing | High |

| Polyurethane Rubber | Industrial applications, concrete | Excellent durability | Less detail reproduction | Medium |

| Natural Rubber | Food-grade molds, general use | Cost-effective, good flexibility | Shorter lifespan, UV sensitivity | Low |

| EPDM Rubber | Outdoor applications, construction | Excellent weather resistance | Lower detail reproduction | Medium |

In conclusion, the choice of material for rubber molds significantly impacts the performance and suitability of the final product. B2B buyers should consider their specific application needs, budget constraints, and compliance with local standards when making material selections.

In-depth Look: Manufacturing Processes and Quality Assurance for rubber mold

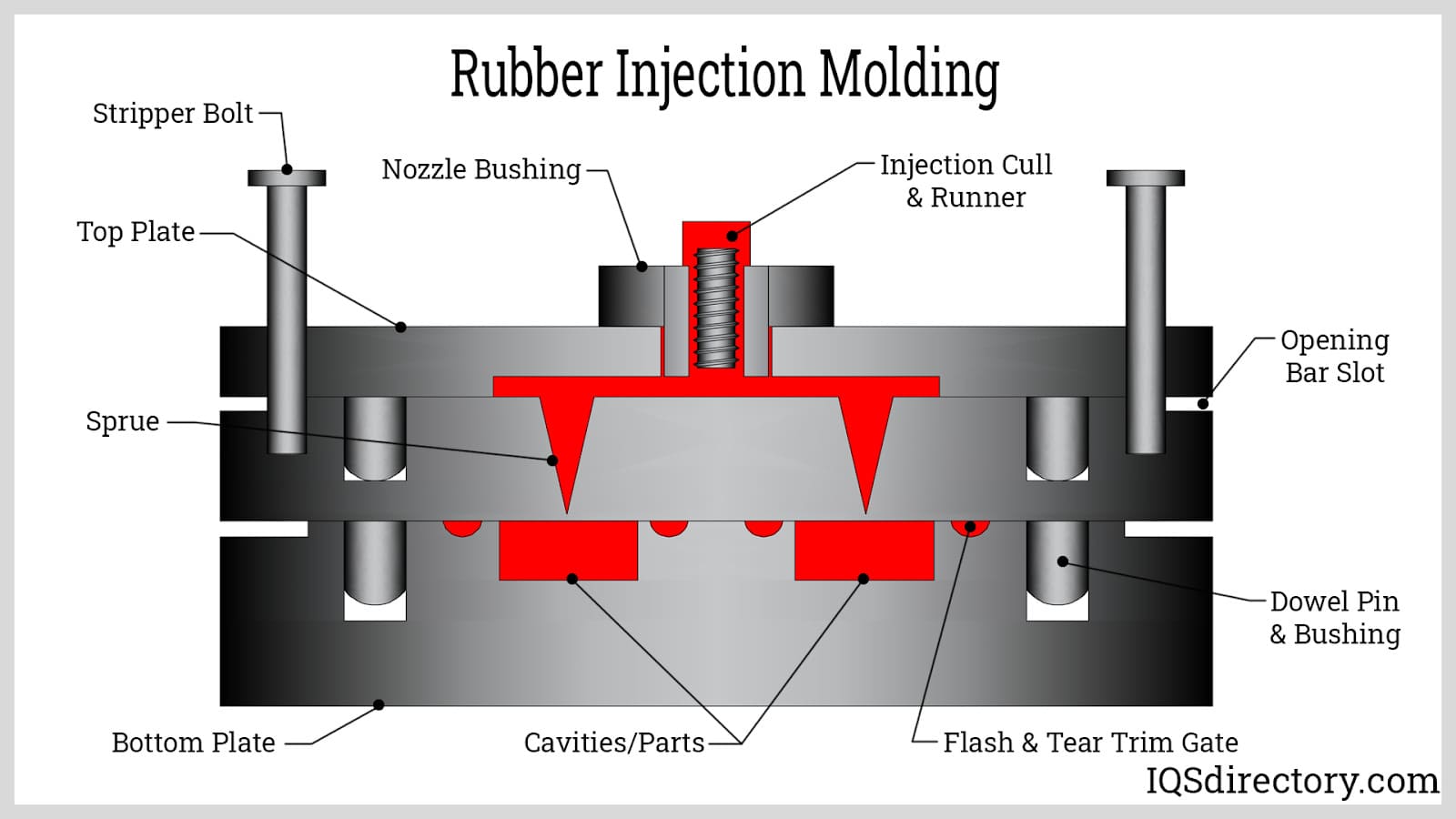

What Are the Main Stages in the Manufacturing Process of Rubber Molds?

The manufacturing process for rubber molds typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is essential in ensuring that the final product meets the desired specifications and quality standards.

Material Preparation

The first step in the manufacturing process is material preparation. This involves selecting high-quality raw materials, such as silicone or urethane rubbers, that are specifically formulated for mold-making. The materials are often pre-weighed and mixed according to precise ratios to ensure consistency and reliability in the final product. This stage may also involve the addition of colorants or other additives to enhance the physical properties of the rubber, such as flexibility, durability, and resistance to temperature extremes.

Illustrative image related to rubber mold

Forming Techniques for Rubber Molds

Once the materials are prepared, the next stage is forming. This can be accomplished using various techniques, including:

-

Pouring: In this method, the mixed rubber is poured into a pre-made mold that shapes the rubber into the desired form. This technique is particularly effective for creating complex shapes with fine details.

-

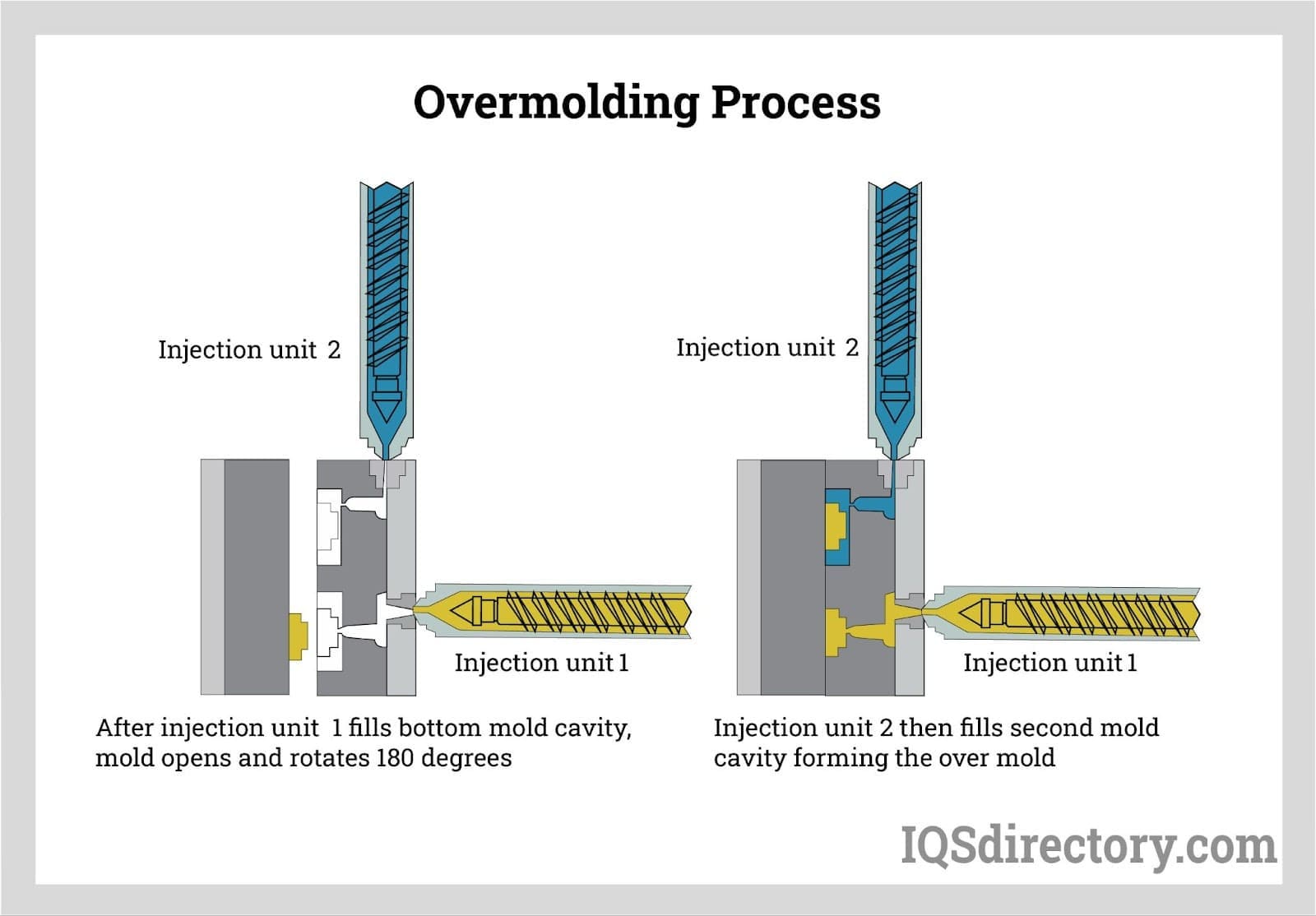

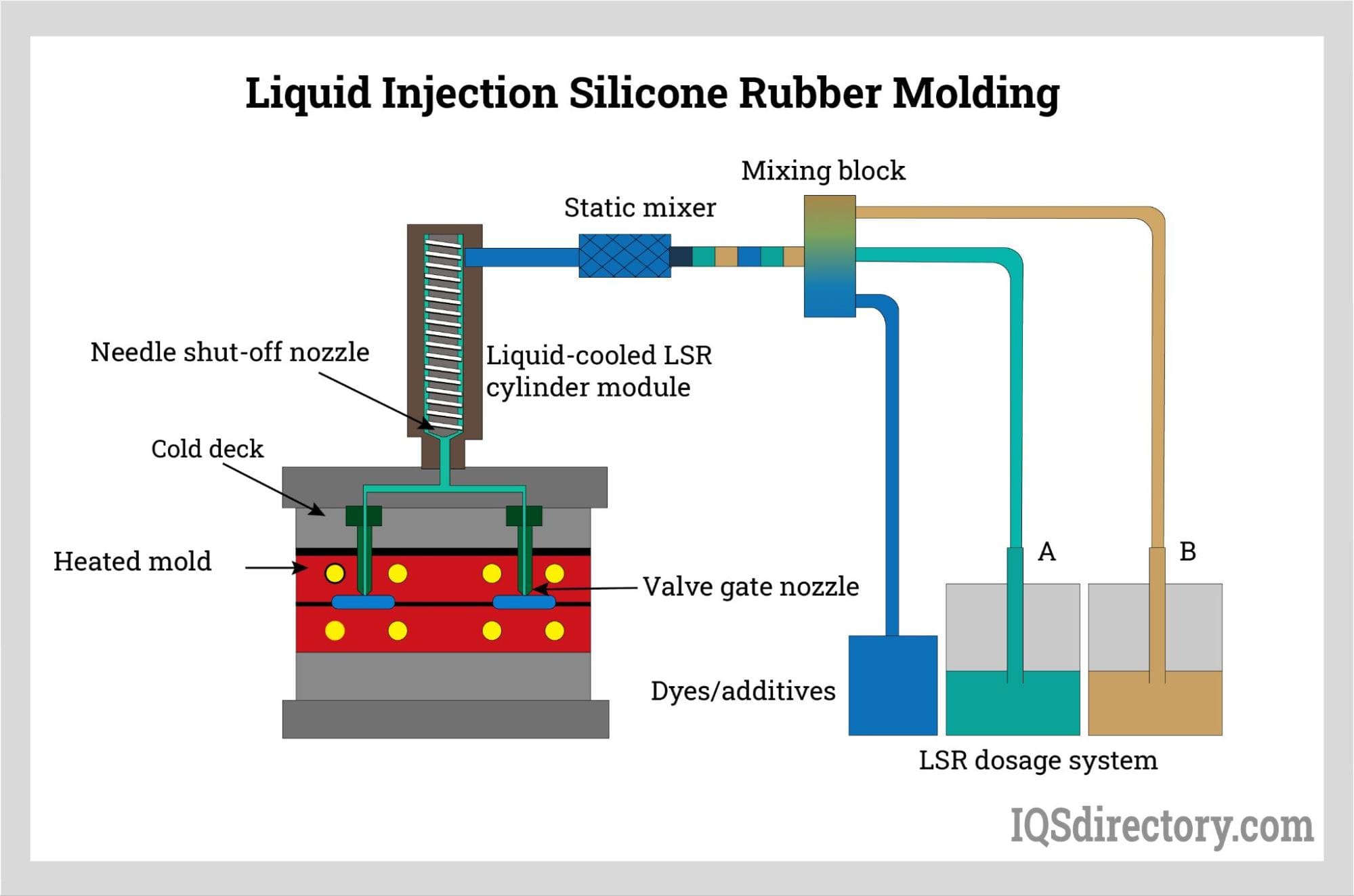

Injection Molding: This process involves injecting the rubber into a mold under high pressure. It is suitable for high-volume production and can produce intricate details and smooth finishes.

-

Compression Molding: This method involves placing rubber material into an open mold, which is then closed and heated. This technique is widely used for larger, simpler shapes and is cost-effective for mass production.

Assembly and Finishing of Rubber Molds

After forming, the molds are often assembled if they consist of multiple parts. This may include the integration of support structures or additional features that enhance the mold’s functionality.

Finishing is the final stage in the manufacturing process, which may involve trimming excess material, surface treatments, or applying release agents to ensure easy demolding. This step is crucial as it impacts the mold’s performance and the quality of the final products produced using the molds.

How Is Quality Assurance Ensured in Rubber Mold Manufacturing?

Quality assurance is critical in the rubber mold manufacturing process to ensure that the products meet international standards and customer expectations. Here, we explore the relevant standards, quality control checkpoints, common testing methods, and how B2B buyers can verify supplier quality.

What Are the Relevant International Standards for Rubber Mold Quality?

International standards such as ISO 9001 are essential benchmarks for quality management systems in manufacturing. Compliance with ISO 9001 indicates that a manufacturer has implemented effective quality control processes and is committed to continuous improvement.

In addition to ISO standards, industry-specific certifications such as CE marking (indicating conformity with health, safety, and environmental protection standards) and API (American Petroleum Institute) standards for oil and gas applications may also be relevant. These certifications provide additional assurance of the quality and reliability of rubber molds used in specialized applications.

What Quality Control Checkpoints Are Commonly Implemented?

Quality control in rubber mold manufacturing typically includes several checkpoints:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon receipt to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor production parameters and identify any deviations from quality standards.

-

Final Quality Control (FQC): Once the molds are completed, a thorough inspection is conducted to ensure they meet the required specifications. This may include dimensional checks, visual inspections, and functional testing.

Which Common Testing Methods Are Used in Rubber Mold Quality Control?

Several testing methods are employed to assess the quality and performance of rubber molds, including:

-

Tensile Testing: This test measures the strength and elasticity of the rubber, ensuring it can withstand the stresses of production and use.

-

Hardness Testing: The Shore durometer test is commonly used to measure the hardness of the rubber, which affects its flexibility and durability.

-

Thermal Stability Testing: This test assesses the mold’s ability to withstand high temperatures without deforming or losing performance.

How Can B2B Buyers Verify Supplier Quality Assurance?

B2B buyers seeking to ensure quality in their rubber mold suppliers can take several steps:

-

Conduct Supplier Audits: Regular audits of potential suppliers can provide insights into their quality control processes and overall manufacturing capabilities.

-

Request Quality Assurance Reports: Suppliers should be able to provide documentation detailing their quality control procedures, test results, and compliance with international standards.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s quality assurance practices and the performance of their products.

-

Check for Certifications: Verify that the supplier holds relevant certifications and standards that demonstrate their commitment to quality.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is vital. Different regions may have varying standards and expectations, so it’s crucial to align with suppliers who understand local regulations and market requirements.

Illustrative image related to rubber mold

Additionally, logistical considerations such as shipping times, customs regulations, and potential delays can impact the overall quality assurance process. Establishing clear communication channels and expectations with suppliers can help mitigate these challenges and ensure a consistent quality of rubber molds, regardless of geographical boundaries.

By understanding the manufacturing processes and quality assurance standards for rubber molds, B2B buyers can make informed decisions that enhance their procurement strategies and ensure the reliability of their supply chain.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rubber mold’

In the competitive landscape of rubber mold procurement, it’s vital for B2B buyers to follow a structured approach. This guide provides a step-by-step checklist to help you source high-quality rubber molds efficiently and effectively, ensuring that your business remains competitive and meets your production needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements. This includes the type of rubber mold needed, dimensions, and specific applications (e.g., food-safe molds, molds for industrial use). Documenting these specifications will streamline communication and ensure that potential suppliers can meet your needs accurately.

Step 2: Conduct Market Research

Perform thorough market research to identify potential suppliers of rubber molds. Look for companies that specialize in the type of mold you require, such as silicone, urethane, or latex molds. Utilize online directories, industry forums, and trade shows to gather information on suppliers’ capabilities and reputation.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their experience in producing the specific type of rubber mold you need, as well as their ability to deliver on time and maintain quality standards.

- Key Considerations:

- Review their portfolio for similar projects.

- Inquire about their production capacity and lead times.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers have the necessary certifications that comply with international standards. For instance, ISO certifications or FDA compliance for food-related molds are essential. This step helps mitigate risks associated with product quality and safety.

Step 5: Request Samples

Before placing a bulk order, request samples of the rubber molds you intend to purchase. Testing samples allows you to evaluate the material quality, flexibility, and durability. This firsthand experience can prevent costly mistakes later on and ensures that the molds meet your expectations.

Step 6: Assess Pricing and Terms

Once you have shortlisted suppliers, compare pricing structures and payment terms. Look for transparency in pricing, including shipping costs and any potential hidden fees. Consider negotiating terms that could benefit your cash flow, such as bulk purchase discounts or extended payment periods.

Step 7: Establish a Communication Plan

Clear communication is essential for successful procurement. Establish a plan for regular updates and feedback with your suppliers. This can include setting milestones for production timelines and quality checks to ensure that any issues are addressed promptly.

By following this comprehensive checklist, B2B buyers can navigate the complexities of rubber mold procurement with confidence, ensuring they select the best suppliers to meet their specific needs.

Comprehensive Cost and Pricing Analysis for rubber mold Sourcing

What Are the Key Cost Components in Rubber Mold Manufacturing?

When sourcing rubber molds, understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include:

-

Materials: The choice of silicone or urethane rubber significantly impacts costs. High-quality materials that ensure durability and flexibility may command higher prices but can lead to lower replacement frequencies and better performance.

-

Labor: Skilled labor is required for both mold creation and quality assurance. Labor costs can vary based on geographic location and the complexity of the molds being produced.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and equipment depreciation. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Initial investment in molds and machinery is substantial. Tooling costs vary depending on the complexity of the mold and the technology used in its production.

-

Quality Control (QC): Ensuring that molds meet specifications through rigorous testing is crucial. QC processes can add to the overall cost but are necessary to ensure product reliability.

-

Logistics: Shipping and handling costs can fluctuate based on the distance from the manufacturer to the buyer and the shipping method. International logistics may involve additional customs duties and tariffs.

-

Margin: Suppliers typically mark up their prices to achieve a profit margin, which can vary based on competition and market demand.

How Do Price Influencers Affect Rubber Mold Costs?

Several factors influence the pricing of rubber molds, including:

-

Volume/MOQ: Larger orders often lead to reduced per-unit costs. Establishing minimum order quantities (MOQs) can help buyers negotiate better pricing.

-

Specifications and Customization: Custom molds tailored to specific applications generally cost more due to additional design and production efforts.

-

Material Selection: The type of rubber chosen (e.g., tin-cure silicone vs. urethane) can significantly impact price. Higher-grade materials may come at a premium but offer better performance.

-

Quality Certifications: Molds that meet international quality standards may attract higher prices. Buyers should verify certifications relevant to their industries.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a proven track record may charge more due to their expertise.

-

Incoterms: Understanding shipping terms can help buyers anticipate additional costs. Different Incoterms (e.g., FOB, CIF) can affect the total landed cost.

What Negotiation Strategies Can Enhance Cost-Efficiency for Buyers?

-

Volume Commitments: Committing to larger orders can provide leverage for negotiating lower prices. Consider consolidating orders across different projects to meet MOQ requirements.

-

Long-Term Relationships: Building a long-term partnership with suppliers can lead to better pricing and terms over time. Suppliers are more likely to offer discounts to repeat customers.

-

Total Cost of Ownership (TCO): Evaluate the TCO, which includes not only the initial purchase price but also maintenance, longevity, and replacement costs. Investing in higher-quality molds can reduce overall expenses.

-

Market Research: Understanding market trends and competitor pricing can provide insights into reasonable price ranges, helping in negotiation discussions.

-

Flexibility in Specifications: If possible, being flexible with mold specifications can allow buyers to take advantage of existing molds or materials, reducing costs.

What Pricing Nuances Should International Buyers Consider?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific pricing nuances:

Illustrative image related to rubber mold

-

Currency Fluctuations: Be mindful of currency exchange rates, which can impact the overall cost when sourcing from international suppliers.

-

Import Duties and Taxes: Research applicable import duties and taxes that may apply to rubber molds, as these can significantly affect total costs.

-

Cultural Considerations: Understanding cultural differences in negotiation styles can enhance communication and lead to more favorable terms.

-

Lead Times: Longer shipping times can affect project timelines. Ensure that lead times are factored into project planning to avoid costly delays.

Disclaimer on Indicative Prices

Prices for rubber molds can vary widely based on specifications, supplier, and market conditions. The information presented here serves as a general guide and may not reflect current market prices. Buyers are encouraged to conduct thorough research and obtain quotes tailored to their specific needs.

Alternatives Analysis: Comparing rubber mold With Other Solutions

Exploring Alternatives to Rubber Molds: A Comprehensive Comparison

In the ever-evolving landscape of manufacturing and production, businesses often seek alternatives to traditional solutions to enhance efficiency, reduce costs, and improve product quality. Rubber molds are widely recognized for their versatility in various applications, but understanding how they stack up against alternative solutions is crucial for informed decision-making. Below is a detailed comparison of rubber molds against two viable alternatives: silicone molds and 3D printing technologies.

| Comparison Aspect | Rubber Mold | Silicone Mold | 3D Printing |

|---|---|---|---|

| Performance | High durability; excellent detail reproduction | Good flexibility; captures fine details | Versatile; can create complex geometries |

| Cost | Moderate initial investment; long-term savings | Generally lower cost for small runs; higher for large volumes | High initial costs; variable material costs |

| Ease of Implementation | Requires expertise to create molds; longer lead times | Easier to set up; faster production | Requires design software; technical expertise needed |

| Maintenance | Low maintenance; can withstand repeated use | Moderate; needs care to avoid tearing | Maintenance dependent on printer and materials used |

| Best Use Case | Ideal for high-volume production of consistent parts | Best for low to medium volume; prototyping | Excellent for custom, one-off designs or prototypes |

Analyzing Silicone Molds as an Alternative

Silicone molds present a compelling alternative to rubber molds, particularly for businesses that prioritize flexibility and lower initial costs. These molds are relatively easy to produce and can capture intricate details, making them suitable for various applications, from crafts to food production. However, silicone molds may not withstand high-volume production as effectively as rubber molds. While they are cheaper for small runs, the cost can escalate with larger quantities due to the materials and production processes involved.

Illustrative image related to rubber mold

Evaluating 3D Printing Technologies

3D printing has emerged as a transformative technology in manufacturing, allowing for the rapid prototyping and production of complex designs. This method offers unparalleled versatility, enabling businesses to create unique, customized parts without the need for traditional molds. However, the initial investment in 3D printers and materials can be substantial. Additionally, the need for technical expertise in design software can pose a barrier for some companies. While 3D printing excels in creating one-off designs, it may not be as cost-effective for high-volume production compared to rubber molds.

Making the Right Choice for Your Business Needs

When selecting the appropriate solution for your production needs, consider the specific requirements of your projects, including volume, complexity, and budget. Rubber molds remain a strong choice for businesses focused on high-volume production with consistent quality, while silicone molds may be better suited for smaller runs or prototyping. Conversely, if your projects demand customization and you have the capacity for initial investment and technical expertise, 3D printing could offer significant advantages.

Ultimately, a careful assessment of each alternative’s strengths and weaknesses, aligned with your operational goals, will guide you toward the most suitable solution for your manufacturing processes. This strategic approach ensures that you optimize production efficiency while meeting quality standards and cost constraints.

Essential Technical Properties and Trade Terminology for rubber mold

What Are the Key Technical Properties of Rubber Molds in B2B Manufacturing?

Understanding the technical properties of rubber molds is crucial for international B2B buyers who seek reliable and efficient manufacturing solutions. Here are several essential specifications to consider:

1. Material Grade

The material grade of rubber used in molds, such as silicone or urethane, significantly impacts the mold’s performance. High-quality grades offer improved durability, flexibility, and resistance to various chemicals and temperatures. For instance, silicone molds are generally favored for their ability to withstand high temperatures, making them ideal for applications in food production and industrial casting.

2. Shore Hardness

Shore hardness measures the rubber’s firmness, with values typically ranging from 10A (very soft) to 80D (very hard). A mold’s hardness affects its flexibility and tear resistance, crucial for maintaining precision in casting processes. For B2B buyers, selecting the appropriate Shore hardness ensures that the molds can handle the specific requirements of their applications, such as intricate designs or high-volume production.

3. Tear Strength

Tear strength is a critical property that indicates how well a rubber mold can withstand mechanical stress without breaking. This property is essential for molds used in high-demand environments, where repeated use is expected. A higher tear strength translates to longer mold life and reduced downtime, which is a key consideration for manufacturers looking to optimize production efficiency.

4. Temperature Resistance

Temperature resistance defines the range of temperatures a mold can endure without deforming or degrading. Molds that can handle both high and low temperatures are particularly valuable in diverse industries, including automotive, aerospace, and food processing. Understanding the temperature limits helps buyers select the right mold for their specific applications, ensuring safety and reliability.

5. Curing Time

The curing time refers to the duration required for the rubber to set and achieve its final properties after mixing. Fast-curing molds allow for quicker turnaround times in production, which is crucial for businesses aiming to meet tight deadlines. B2B buyers should consider curing time when planning their production schedules to avoid delays.

What Are Common Trade Terms Associated with Rubber Molds?

Familiarity with industry jargon can facilitate smoother transactions and better communication between buyers and suppliers. Here are several common terms relevant to rubber molds:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is essential for buyers looking for custom rubber mold solutions that meet specific design requirements.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly relevant for B2B buyers who need to assess cost-effectiveness. Understanding MOQs can help buyers negotiate better terms and manage inventory more efficiently.

Illustrative image related to rubber mold

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price bids from suppliers for specific products or services. For B2B buyers, issuing an RFQ can streamline the procurement process and ensure competitive pricing for rubber molds.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping responsibilities, risk management, and cost allocation in cross-border trade.

5. Lead Time

Lead time refers to the period from the initiation of an order to the completion of production. In the context of rubber molds, understanding lead times is vital for planning and ensuring that manufacturing timelines align with project deadlines.

Illustrative image related to rubber mold

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing rubber molds, ultimately enhancing their operational efficiency and competitive edge in the marketplace.

Navigating Market Dynamics and Sourcing Trends in the rubber mold Sector

What Are the Current Market Dynamics and Key Trends in the Rubber Mold Sector?

The rubber mold sector is experiencing significant growth driven by various global factors. The increasing demand for customized products across industries—ranging from automotive to consumer goods—has led to a surge in the use of rubber molds. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly looking for suppliers who can provide high-quality, durable molds that meet specific needs. Emerging technologies such as 3D printing and advanced silicone formulations are transforming the way rubber molds are produced, enabling faster prototyping and more intricate designs.

Sourcing trends indicate a shift toward digital procurement platforms that streamline the supply chain process. B2B buyers are now leveraging online marketplaces to compare products, prices, and supplier ratings, making informed decisions quicker than ever. Additionally, the adoption of automation in manufacturing processes is enhancing efficiency and reducing lead times. This is particularly beneficial for international buyers who often deal with longer supply chains.

The market dynamics are also influenced by economic factors, such as fluctuating raw material costs and geopolitical tensions. These elements can impact pricing and availability, making it crucial for buyers to establish strong relationships with reliable suppliers to mitigate risks.

How Is Sustainability Shaping the Rubber Mold Supply Chain?

Sustainability has become a pivotal concern in the rubber mold sector. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to environmentally friendly practices. This includes sourcing materials that are recyclable or biodegradable and minimizing waste during the manufacturing process. The environmental impact of rubber production, including carbon emissions and chemical runoff, is prompting buyers to seek out suppliers with sustainable certifications.

Ethical sourcing is also gaining traction, with businesses looking to ensure that their supply chains are free from exploitation and adhere to fair labor practices. Buyers are encouraged to inquire about suppliers’ ethical certifications and sustainability practices to ensure compliance with international standards. This is particularly relevant for buyers from regions with stringent environmental regulations, as aligning with sustainable practices can enhance their market reputation and customer loyalty.

Furthermore, the development of ‘green’ rubber materials—such as bio-based silicones and recycled rubber—offers promising alternatives that meet both performance and sustainability criteria. International buyers should actively seek suppliers who are innovating in this space, as this can provide a competitive advantage in increasingly eco-conscious markets.

How Has the Rubber Mold Sector Evolved Over Time?

The evolution of the rubber mold sector can be traced back several decades, with significant advancements driven by technological innovations and changing market demands. Initially, rubber molds were primarily used in the automotive and manufacturing sectors for producing parts with high durability. Over time, the applications have expanded to include a wide range of industries, including food and beverage, medical, and consumer goods.

The introduction of advanced silicone materials and digital technologies has revolutionized mold-making processes, allowing for greater precision and customization. Today, suppliers can create molds that capture intricate details and withstand varying environmental conditions, providing a competitive edge in product development.

As market dynamics continue to shift, the rubber mold sector remains poised for further growth, driven by innovation and the increasing importance of sustainability in sourcing strategies. B2B buyers must stay informed about these trends to make strategic sourcing decisions that align with their business goals.

Frequently Asked Questions (FAQs) for B2B Buyers of rubber mold

-

How do I choose the right rubber mold for my project needs?

Selecting the appropriate rubber mold involves assessing your specific application requirements, including the type of material you will be using for casting, the complexity of the design, and the desired durability of the mold. Consider whether you need a mold that can withstand high temperatures or one that allows for intricate detailing. Additionally, consult with suppliers to understand the properties of different rubber types, such as silicone versus urethane, to ensure compatibility with your production process. -

What is the best rubber mold for producing stone veneer?

For producing stone veneer, molds made from high-quality silicone rubber are recommended due to their exceptional durability and flexibility. These molds are designed to capture fine details and withstand repeated use without degradation. Look for suppliers that specialize in stone veneer molds, as they often have proprietary technologies that enhance mold longevity and performance. Always request samples or detailed specifications to ensure the mold meets your production standards. -

How can I ensure the quality of rubber molds from international suppliers?

To ensure quality, start by thoroughly vetting potential suppliers through online reviews, certifications, and past project examples. Request references from previous clients and consider visiting manufacturing facilities if feasible. It’s also beneficial to ask for samples before committing to a bulk order. Implementing quality assurance protocols, such as third-party inspections or testing, can further mitigate risks associated with international sourcing. -

What are the typical minimum order quantities (MOQs) for rubber molds?

Minimum order quantities can vary significantly by supplier and mold type. Generally, MOQs for custom rubber molds may range from a few pieces to several hundred. Larger suppliers may offer lower MOQs for standard molds, while custom designs often require higher quantities to justify production costs. Always discuss your needs with suppliers to find flexibility in MOQs, especially if you are a smaller business. -

What payment terms should I expect when sourcing rubber molds internationally?

Payment terms can vary widely among suppliers but typically include options like upfront payment, partial deposits, or payment upon delivery. Be sure to clarify terms before placing an order and consider using secure payment methods, such as letters of credit or escrow services, for larger transactions. Understanding the currency exchange rates and potential fees associated with international payments is also crucial to avoid unexpected costs. -

How do I handle shipping and logistics for rubber molds sourced from abroad?

When sourcing rubber molds internationally, it’s essential to work with a reliable logistics provider experienced in handling such shipments. Discuss shipping options, estimated delivery times, and customs clearance procedures with your supplier. Ensure that you understand the incoterms (International Commercial Terms) that define the responsibilities of buyers and sellers in the shipping process. Proper documentation and labeling are critical to prevent delays at customs. -

Can rubber molds be customized for specific design requirements?

Yes, many suppliers offer customization options for rubber molds to meet specific design needs. This could include adjusting the size, shape, or material properties of the mold. When discussing customization, provide detailed specifications and, if possible, 3D models or drawings to ensure accurate production. Be mindful that custom molds may require longer lead times and higher costs, so plan your project timelines accordingly. -

What are the common applications of rubber molds in various industries?

Rubber molds are utilized across diverse industries including construction, automotive, culinary, and arts and crafts. In construction, they are often used for producing decorative concrete elements, while in the culinary sector, they serve for making chocolates or cakes. Additionally, rubber molds find applications in prototyping and model making within the arts. Understanding the applications relevant to your industry can help in selecting the right type of mold and material for your projects.

Top 1 Rubber Mold Manufacturers & Suppliers List

1. Contenti – Spin Casting Mold Rubber

Domain: contenti.com

Registered: 1997 (28 years)

Introduction: Spin Casting Mold Rubber from Contenti includes various types of mold rubber suitable for vulcanizing and casting. The product range features silicone and organic black mold rubber available in several diameters. Key items include: 1. Lower Silicone Mold Making Putty, 1.2 lbs. – $32.50 2. RTV (Room Temperature Vulcanizing) Silicone Rubber – Starting at $34.70 3. Nicem® White Lower Cost Silicone Mo…

Strategic Sourcing Conclusion and Outlook for rubber mold

In today’s competitive landscape, strategic sourcing of rubber molds is essential for businesses looking to enhance product quality and operational efficiency. By leveraging high-quality materials and innovative mold designs, companies can achieve superior detail reproduction and durability, which are crucial for meeting customer demands. The versatility of rubber molds extends across various industries, from construction to culinary applications, making them a valuable asset for diverse markets.

Investing in reliable suppliers who prioritize quality and innovation can significantly reduce production costs and lead times, providing a competitive edge. For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, establishing strong partnerships with reputable manufacturers can facilitate access to advanced mold technologies and customized solutions tailored to specific needs.

Illustrative image related to rubber mold

Looking ahead, the rubber mold industry is poised for growth, driven by advancements in material science and increasing demand across multiple sectors. As you evaluate potential suppliers, prioritize those who demonstrate a commitment to sustainability and innovation. Take action now by exploring partnerships that align with your strategic goals, ensuring your business remains at the forefront of the market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.