Everything You Need to Know About Rf Shielding Fabric Sourcing in 2025

Introduction: Navigating the Global Market for rf shielding fabric

In an increasingly interconnected world, the challenge of sourcing high-quality RF shielding fabric has never been more critical for businesses. As organizations across diverse sectors strive to protect sensitive electronic equipment and data from electromagnetic interference, understanding the nuances of RF shielding fabric becomes paramount. This guide offers an extensive overview of the types of RF shielding materials available, their various applications, and essential supplier vetting processes.

International B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe—such as Germany and Saudi Arabia—will find invaluable insights into the cost factors associated with RF shielding solutions. Whether you are looking to establish secure facilities, enhance data security, or mitigate the effects of electromagnetic pulses, this guide equips you with the knowledge to make informed purchasing decisions.

We delve into the technical specifications of different RF shielding fabrics, the certifications that ensure their effectiveness, and practical tips for implementation in real-world scenarios. By navigating the complexities of the global market for RF shielding fabric, buyers can confidently select solutions that meet their specific operational needs and regulatory requirements, ultimately safeguarding their investments and enhancing operational resilience.

Understanding rf shielding fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Nickel-Copper Composite Fabric | High conductivity, lightweight, corrosion-resistant | Military, aerospace, medical equipment shielding | Pros: Effective against a wide frequency range; Cons: Can be expensive due to material costs. |

| Silver-Infused Fabric | Excellent conductivity, antimicrobial properties | Hospitals, laboratories, sensitive electronics | Pros: Ideal for sensitive environments; Cons: Higher cost and limited durability. |

| Carbon-Based Fabric | Flexible, lightweight, and cost-effective | Consumer electronics, automotive applications | Pros: Economical and easy to work with; Cons: Lower shielding effectiveness compared to metal composites. |

| Woven Conductive Mesh | Durable and breathable, suitable for larger structures | Construction of RF shielding enclosures, tents | Pros: Versatile for various applications; Cons: Requires careful installation to maintain effectiveness. |

| Multi-Layered Shielding Fabric | Composed of multiple conductive layers for enhanced protection | Secure facilities, data centers, military operations | Pros: Superior shielding; Cons: More complex and costly installation process. |

What are the characteristics and suitability of Nickel-Copper Composite Fabric?

Nickel-Copper Composite Fabric is engineered for high conductivity, making it a preferred choice for applications requiring robust shielding against electromagnetic interference (EMI) and radio frequency interference (RFI). Its lightweight nature and corrosion resistance enhance its appeal in military and aerospace settings, where durability and reliability are paramount. B2B buyers should consider the initial investment, as the cost of materials can be higher, but the long-term benefits in terms of performance and longevity often justify the expense.

Why choose Silver-Infused Fabric for sensitive environments?

Silver-Infused Fabric is distinguished by its excellent conductivity and antimicrobial properties, making it ideal for environments where hygiene is critical, such as hospitals and laboratories. This fabric not only provides effective RF shielding but also helps in maintaining sanitary conditions. When purchasing, B2B buyers should weigh the benefits of enhanced performance against the higher cost and potential limitations in durability, particularly in high-wear applications.

What makes Carbon-Based Fabric a cost-effective option?

Carbon-Based Fabric is known for its flexibility and lightweight characteristics, making it a budget-friendly option for shielding applications in consumer electronics and automotive sectors. Its ease of handling allows for quick integration into various projects. However, buyers should be aware that while it offers economic advantages, its shielding effectiveness may not match that of metal composite fabrics, necessitating careful consideration of the specific shielding requirements.

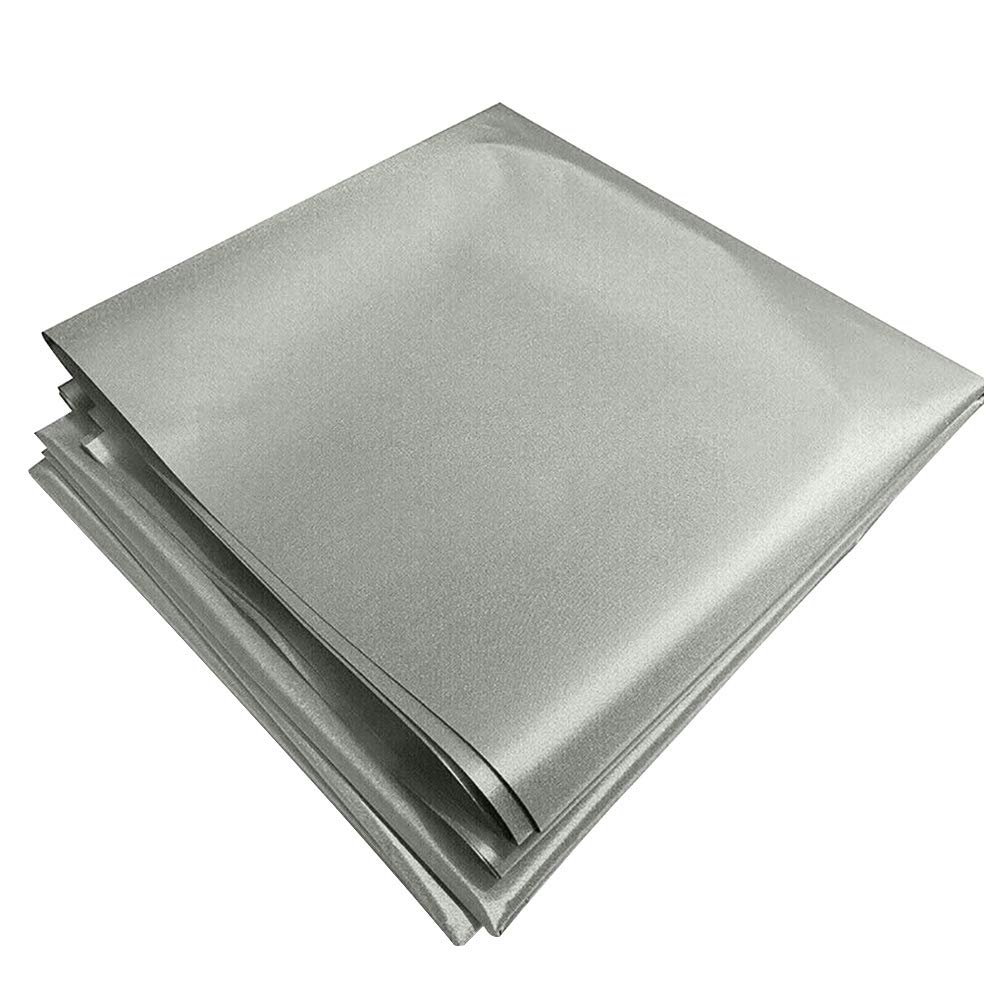

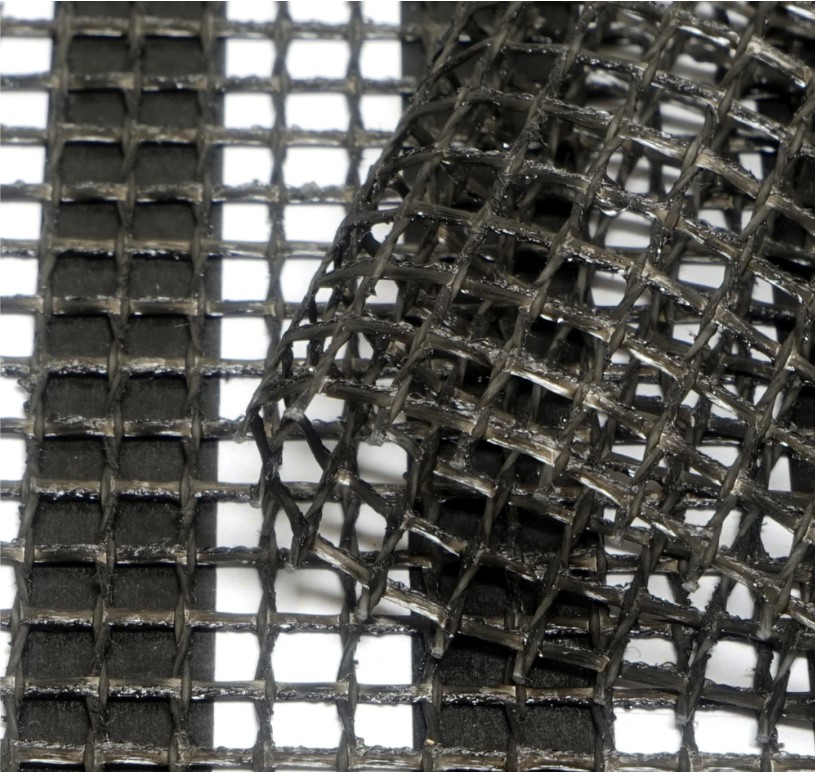

Illustrative image related to rf shielding fabric

How does Woven Conductive Mesh provide versatility?

Woven Conductive Mesh is a durable and breathable material suitable for larger RF shielding structures, such as tents or enclosures. Its versatility allows for a wide range of applications, from military operations to commercial uses. B2B buyers must ensure proper installation techniques are followed to maintain the fabric’s shielding effectiveness, as improper setup can lead to vulnerabilities in the shielding.

What are the advantages of Multi-Layered Shielding Fabric?

Multi-Layered Shielding Fabric consists of several conductive layers, providing enhanced protection against a broad spectrum of frequencies. This type is commonly used in secure facilities, data centers, and military operations where maximum shielding is essential. While it offers superior performance, buyers should be prepared for a more complex and potentially costly installation process, which may require specialized expertise to achieve optimal results.

Key Industrial Applications of rf shielding fabric

| Industry/Sector | Specific Application of rf shielding fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Shielding for cell towers and base stations | Enhances signal integrity and reduces interference | Certification compliance, material durability, and ease of installation |

| Healthcare | Protection for medical devices and sensitive equipment | Ensures operational reliability and patient safety | Compliance with health regulations, fabric flexibility, and EMF shielding effectiveness |

| Defense and Security | Construction of secure communication rooms | Protects against eavesdropping and unauthorized signal interception | Military-grade certifications, customization options, and proven performance in high-risk environments |

| Electronics Manufacturing | RF shielding for electronic components and devices | Prevents signal interference during production and testing | Material compatibility with manufacturing processes and cost-effectiveness |

| Renewable Energy | Shielding for solar inverters and generators | Increases efficiency and reliability of energy systems | Resistance to environmental factors and compatibility with existing installations |

How is RF Shielding Fabric Used in Telecommunications?

In the telecommunications sector, rf shielding fabric is critical for protecting cell towers and base stations from external interference. By effectively blocking unwanted signals, this fabric enhances the integrity of communication networks, ensuring clearer voice and data transmission. For international B2B buyers, especially in regions with varying electromagnetic environments, sourcing materials that meet local regulations and offer high durability is essential. Consideration for ease of installation is also crucial, as many telecommunications projects require rapid deployment.

Why is RF Shielding Fabric Important in Healthcare?

In healthcare, rf shielding fabric is utilized to protect sensitive medical devices, such as MRI machines and patient monitoring systems, from electromagnetic interference (EMI). This shielding is vital for maintaining operational reliability and ensuring patient safety, as any interference can lead to inaccurate readings or device malfunctions. Buyers in this sector should prioritize sourcing fabrics that comply with stringent health regulations, have a proven track record in medical applications, and offer flexibility for various device shapes and sizes.

How Does RF Shielding Fabric Enhance Defense and Security?

The defense and security industry employs rf shielding fabric to construct secure communication rooms that protect against eavesdropping and unauthorized signal interception. This application is crucial for maintaining confidentiality in sensitive operations. B2B buyers in this sector must focus on materials that have military-grade certifications and can withstand high-risk environments. Customization options to fit unique facility layouts and proven performance metrics are also important factors when sourcing these materials.

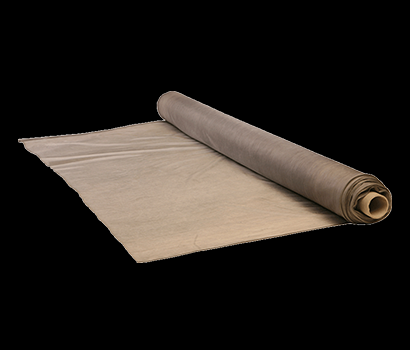

Illustrative image related to rf shielding fabric

What Role Does RF Shielding Fabric Play in Electronics Manufacturing?

In electronics manufacturing, rf shielding fabric is essential for shielding electronic components and devices during production and testing phases. This fabric helps prevent signal interference, which can lead to defects and quality issues. For manufacturers, sourcing materials that are compatible with existing production processes and offer cost-effectiveness is key. Additionally, the fabric’s ability to maintain performance under various manufacturing conditions should be a priority for international buyers looking to ensure product reliability.

How is RF Shielding Fabric Used in Renewable Energy Applications?

In the renewable energy sector, rf shielding fabric is used to protect solar inverters and generators from electromagnetic interference, which can affect their efficiency and reliability. By blocking unwanted signals, this fabric ensures that energy systems operate optimally. Buyers in this field should consider fabrics that are resistant to environmental factors such as moisture and UV exposure, as well as those that can easily integrate with existing energy solutions. Ensuring that the materials meet industry standards for performance and longevity is crucial for successful sourcing.

3 Common User Pain Points for ‘rf shielding fabric’ & Their Solutions

Scenario 1: Difficulty in Achieving Effective RF Shielding

The Problem: B2B buyers often struggle to achieve the desired level of RF shielding in their applications. This challenge can arise from a lack of understanding about the specific shielding requirements for their environment. For instance, a company in South America may need to protect sensitive medical devices from RF interference but may not realize that a single layer of shielding fabric is insufficient for complete protection. This can lead to costly errors, including operational disruptions or compromised data integrity.

The Solution: To effectively shield against RF interference, buyers should first conduct a thorough assessment of their specific shielding needs, including the frequency range of the signals they need to block. Sourcing high-quality RF shielding fabric, such as those certified to military standards like MIL STD 188-125, can provide assurance of performance. Additionally, using multiple layers of fabric can enhance shielding effectiveness significantly. For optimal results, it’s advisable to consult with manufacturers or suppliers for tailored advice on the thickness and layering needed based on the unique RF environment. Engaging in a pilot project with a small quantity of fabric can also help buyers evaluate the effectiveness before scaling up.

Scenario 2: Challenges in Fabric Integration for Industrial Applications

The Problem: Integrating RF shielding fabric into existing industrial applications can pose a significant challenge for B2B buyers, particularly in sectors like aerospace or telecommunications. For example, a company in the Middle East may find it difficult to incorporate shielding fabric into a production line without disrupting workflow or compromising equipment safety. This often leads to delays in project timelines and increased costs due to unplanned modifications.

Illustrative image related to rf shielding fabric

The Solution: To facilitate smoother integration, buyers should prioritize sourcing fabrics that are user-friendly and adaptable for industrial applications. Selecting RF shielding fabric that is lightweight yet durable, such as those made from polyester combined with copper and nickel, can ease the installation process. Additionally, employing adhesives or tapes specifically designed for RF shielding can simplify the application process. Before full-scale implementation, conducting trials to assess the fabric’s performance in the intended environment can help identify any potential issues, allowing for necessary adjustments without major disruptions.

Scenario 3: Uncertainty About Compliance and Certifications

The Problem: B2B buyers often face uncertainty regarding compliance with local regulations and industry standards when sourcing RF shielding fabric. Companies in Europe, for example, may be concerned about whether the fabric meets the necessary electromagnetic compatibility (EMC) requirements for their products. This lack of clarity can lead to hesitancy in purchasing decisions, resulting in missed opportunities for enhanced data security and equipment performance.

The Solution: To mitigate compliance concerns, buyers should seek RF shielding fabrics that come with verifiable certifications from accredited laboratories. For instance, fabrics tested for compliance with MIL STD 188-125 and IEEE 299-2006 offer documented proof of their shielding effectiveness. Buyers can also benefit from engaging with suppliers who provide comprehensive documentation and support for compliance issues. Establishing a dialogue with manufacturers to clarify any uncertainties regarding the material’s specifications and performance can further enhance confidence in the procurement process. Additionally, staying informed about local regulations and industry standards will empower buyers to make well-informed decisions that align with their operational needs.

Strategic Material Selection Guide for rf shielding fabric

What Are the Key Materials Used in RF Shielding Fabric?

When selecting RF shielding fabric, understanding the properties and performance of different materials is crucial for B2B buyers. Here, we analyze four common materials used in RF shielding applications, highlighting their key properties, advantages, disadvantages, and considerations for international buyers.

1. Copper-Nickel Alloy Fabric

Key Properties:

Copper-nickel alloys exhibit excellent conductivity and corrosion resistance, making them ideal for RF shielding. They can withstand high temperatures and pressures, ensuring durability in various environments.

Illustrative image related to rf shielding fabric

Pros & Cons:

The primary advantage of copper-nickel alloy fabric is its superior shielding effectiveness against a wide range of frequencies, including Wi-Fi and cellular signals. However, it can be more expensive than other materials and may require specialized manufacturing techniques, increasing production complexity.

Impact on Application:

This material is particularly effective in environments where high-frequency signals are prevalent, such as telecommunications and military applications. Its compatibility with various electronic devices enhances its utility.

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should ensure compliance with relevant standards such as ASTM and IEC. In countries with stringent regulations, the certification of materials may be necessary for importation.

2. Conductive Polyester Fabric

Key Properties:

Conductive polyester combines the flexibility of polyester with conductive additives, providing a lightweight and durable option for RF shielding. It offers moderate temperature resistance and is generally resistant to wear and tear.

Illustrative image related to rf shielding fabric

Pros & Cons:

The main advantage of conductive polyester is its lightweight nature, making it easy to handle and integrate into various applications. However, its shielding effectiveness is lower than that of metals like copper, and it may not perform well in high-frequency environments.

Impact on Application:

This material is suitable for consumer electronics and general RF shielding applications where extreme performance is not critical. Its flexibility allows for diverse applications, including clothing and portable devices.

Considerations for International Buyers:

Buyers should verify the material’s compliance with local regulations, especially in regions like Africa and South America, where standards may differ. Cost-effectiveness is a significant factor, as this material is generally more affordable.

3. Silver-Coated Fabric

Key Properties:

Silver-coated fabrics provide excellent conductivity and antimicrobial properties. They are effective at blocking RF signals and have a high resistance to corrosion.

Pros & Cons:

The key advantage of silver-coated fabric is its superior shielding performance and durability. However, the high cost of silver can be a limiting factor for large-scale applications, making it less accessible for budget-conscious projects.

Impact on Application:

This material is often used in high-end applications, such as medical devices and military equipment, where performance is paramount. Its antimicrobial properties also make it suitable for environments requiring hygiene.

Considerations for International Buyers:

International buyers should be aware of the higher costs associated with silver-coated fabrics and consider the return on investment for their specific applications. Compliance with health and safety standards is also crucial, especially in the medical field.

4. Aluminum Foil Fabric

Key Properties:

Aluminum foil fabric is lightweight and provides good shielding effectiveness against low to mid-frequency RF signals. It is resistant to corrosion and can be easily manipulated for various applications.

Pros & Cons:

The primary advantage of aluminum foil fabric is its low cost and ease of availability. However, it may not provide adequate shielding at higher frequencies and can be less durable compared to other materials.

Impact on Application:

This fabric is commonly used in DIY RF shielding projects and temporary enclosures. Its ease of use makes it popular among hobbyists and small-scale manufacturers.

Considerations for International Buyers:

Buyers should consider the material’s limited performance in high-frequency applications and ensure it meets local standards. Cost-effectiveness is a significant advantage for budget-sensitive projects, especially in developing regions.

Illustrative image related to rf shielding fabric

Summary Table of RF Shielding Fabrics

| Material | Typical Use Case for RF Shielding Fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper-Nickel Alloy Fabric | Telecommunications, Military Applications | Superior shielding effectiveness | Higher cost and manufacturing complexity | High |

| Conductive Polyester Fabric | Consumer Electronics, General RF Shielding | Lightweight and flexible | Lower shielding effectiveness | Low |

| Silver-Coated Fabric | Medical Devices, Military Equipment | Excellent performance and durability | High cost | High |

| Aluminum Foil Fabric | DIY Projects, Temporary Enclosures | Low cost and easy availability | Limited performance at high frequencies | Low |

This guide provides a comprehensive overview of the materials available for RF shielding fabric, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for rf shielding fabric

What are the Key Stages in the Manufacturing Process of RF Shielding Fabric?

The manufacturing of RF shielding fabric involves several critical stages, each designed to ensure the production of high-quality materials that meet stringent performance standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

In the initial phase, the selection of raw materials is paramount. RF shielding fabrics typically utilize a combination of polyester fibers infused with conductive materials like copper and nickel. This blend is crucial for achieving the desired electromagnetic interference (EMI) shielding properties. Quality control begins at this stage, with suppliers often required to provide certifications for the materials, ensuring they meet specified standards for conductivity and durability.

After sourcing, the materials undergo testing to assess their electromagnetic properties, tensile strength, and resistance to corrosion. This testing is essential to ensure that the fabric will perform effectively in its intended applications.

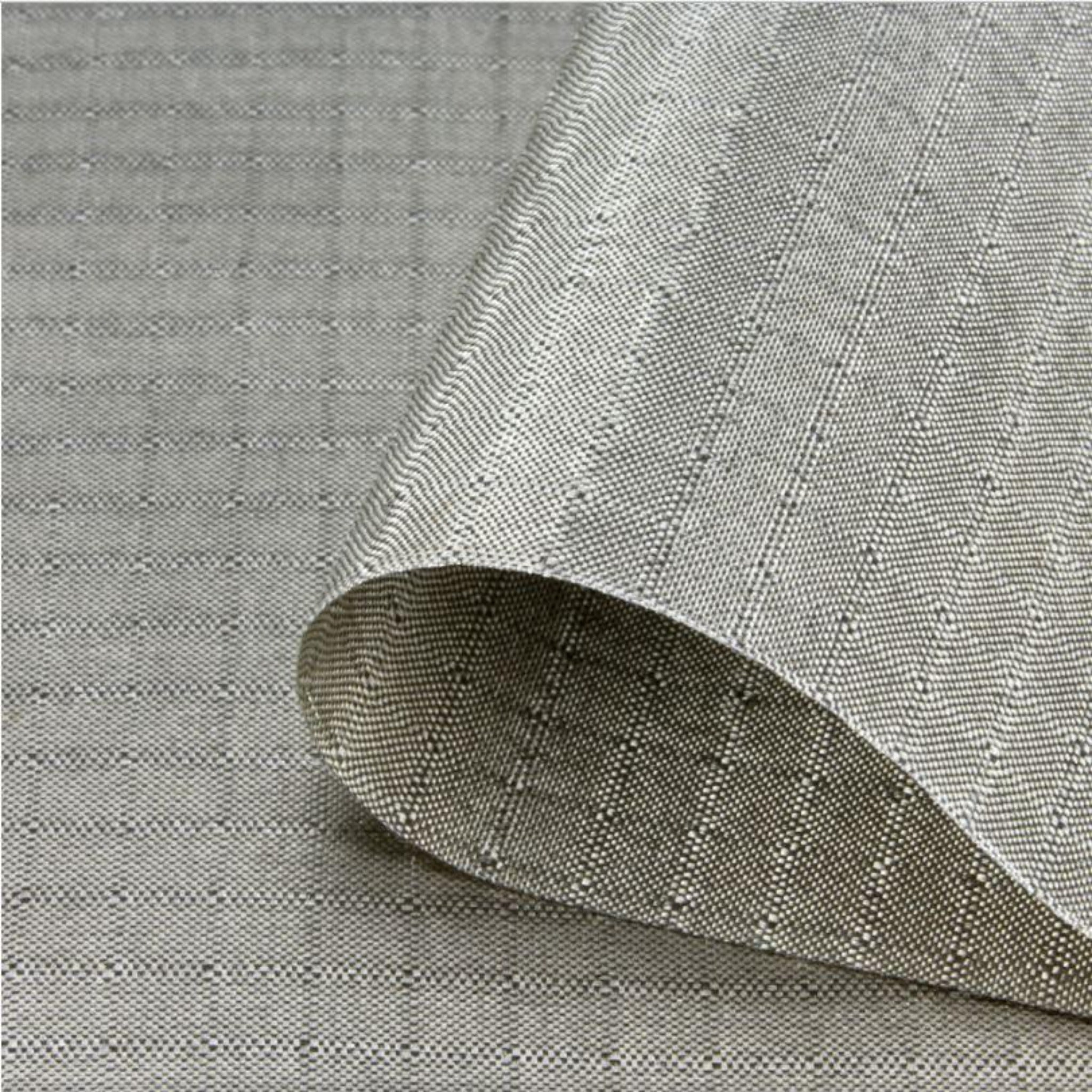

Forming Techniques for RF Shielding Fabric

The forming stage involves weaving the prepared fibers into fabric. Advanced techniques such as warp knitting or weaving are commonly employed to create a fabric that is both flexible and robust. The choice of technique can affect the fabric’s performance, such as its ability to block specific frequency ranges.

Illustrative image related to rf shielding fabric

During this stage, manufacturers may also incorporate additional treatments, such as fire-retardant coatings or anti-static finishes, depending on the intended application. These treatments not only enhance the fabric’s performance but also expand its usability across various industries, including military, telecommunications, and medical devices.

Assembly Processes for Enhanced Functionality

Once the fabric is formed, it may undergo assembly processes where it is cut into specified sizes and shapes based on customer requirements. This stage can involve creating finished products such as Faraday bags, tents, or custom shielding enclosures. Manufacturers often use specialized equipment to ensure precision in cutting and sewing, which is critical for maintaining the fabric’s shielding effectiveness.

Quality checkpoints during assembly include visual inspections for defects, ensuring that seams are secure, and verifying that the fabric meets the dimensional specifications outlined in the design phase.

Finishing Techniques to Ensure Durability

The finishing stage is where the RF shielding fabric is treated to enhance its longevity and usability. This may involve applying additional protective coatings, such as water-resistant finishes or UV protection, to extend the fabric’s lifespan in various environmental conditions.

Illustrative image related to rf shielding fabric

Manufacturers often conduct final testing during this stage to verify that the fabric meets all specifications, including its shielding effectiveness across the required frequency ranges. This testing is crucial for ensuring that the final product adheres to international standards and industry-specific requirements.

What International Standards and Quality Assurance Measures are Important for RF Shielding Fabric?

Quality assurance in the manufacturing of RF shielding fabric is governed by several international standards and industry-specific certifications. These frameworks are designed to ensure that products are consistently produced to meet customer and regulatory expectations.

Which International Standards Should B2B Buyers Be Aware Of?

ISO 9001 is one of the most recognized international quality management standards that manufacturers may adhere to. It focuses on meeting customer requirements and enhancing satisfaction through effective quality management systems. For RF shielding fabric, adherence to ISO 9001 can indicate a commitment to quality throughout the manufacturing process.

In addition to ISO standards, industry-specific certifications, such as CE marking for compliance with European health, safety, and environmental protection standards, are also relevant. For military and defense applications, compliance with standards like MIL-STD-188-125 ensures that the fabric can withstand high-altitude electromagnetic pulses (HEMP).

What Are the Key Quality Control Checkpoints in Manufacturing RF Shielding Fabric?

Quality control checkpoints are essential at various stages of the manufacturing process to ensure product integrity. Common checkpoints include:

Illustrative image related to rf shielding fabric

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is crucial. This may involve periodic testing of fabric samples to assess shielding effectiveness and material integrity.

- Final Quality Control (FQC): At this stage, finished products undergo rigorous testing, including electromagnetic shielding tests and visual inspections for defects.

These checkpoints help identify issues early in the production process, minimizing waste and ensuring that only high-quality products reach the market.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality assurance practices is vital. Here are several actionable strategies:

Conduct Supplier Audits

Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Audits should focus on evaluating compliance with international standards and the effectiveness of their quality management systems.

Request Quality Assurance Reports

Buyers should request documentation that details the quality control processes used by suppliers, including test results and certifications. This documentation should demonstrate adherence to relevant international standards and provide transparency regarding the product’s performance.

Utilize Third-Party Inspection Services

Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality assurance practices. These services can conduct independent testing and audits, ensuring that the products meet the required specifications and standards.

What Nuances Should International B2B Buyers Consider Regarding Quality Assurance?

International B2B buyers must be aware of specific nuances related to quality assurance when sourcing RF shielding fabric.

-

Understanding Regional Compliance Requirements: Different regions may have varying compliance standards. For instance, products sold in Europe must meet CE requirements, while those in the United States may need to comply with FCC regulations. Buyers should ensure that their suppliers are well-versed in the compliance requirements of the regions they serve.

-

Navigating Import Regulations: Buyers should also familiarize themselves with import regulations, including tariffs and duties, which can impact the overall cost of products. Understanding these regulations will help in planning procurement strategies effectively.

-

Cultural and Language Differences: Effective communication is essential when dealing with international suppliers. Language barriers and cultural differences can affect negotiations and the clarity of quality expectations. Establishing clear communication channels and expectations can mitigate these challenges.

By understanding the manufacturing processes, quality assurance standards, and verification methods, B2B buyers can make informed decisions when sourcing RF shielding fabric. This knowledge not only enhances the likelihood of obtaining high-quality products but also fosters strong supplier relationships based on trust and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rf shielding fabric’

This practical sourcing guide provides a step-by-step checklist for B2B buyers looking to procure RF shielding fabric. It aims to streamline your sourcing process, ensuring that you make informed decisions that meet your technical and business needs.

Step 1: Define Your Technical Specifications

Understanding your technical requirements is the foundation of sourcing RF shielding fabric. Determine the frequency range you need to block, typically from low MHz up to 40GHz, and identify the specific applications—whether it’s for military, industrial, or consumer use. Clearly defined specifications help suppliers tailor their offerings to meet your needs effectively.

Step 2: Research Material Composition

The effectiveness of RF shielding fabric largely depends on its composition. Look for fabrics that combine polyester with conductive materials such as copper and nickel, as these have proven to offer superior shielding properties. Ensure the fabric meets military standards (like MIL STD 188-125) for high-altitude electromagnetic pulse (HEMP) protection if your application demands it.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is crucial. Request company profiles, case studies, and references from clients within your industry or region. Pay attention to their experience with similar projects and look for certifications that validate their product quality and compliance with international standards.

Step 4: Verify Supplier Certifications

Certifications are a strong indicator of a supplier’s credibility and product reliability. Ensure that the RF shielding fabric is lab-tested and certified for its shielding effectiveness, such as by organizations like Keystone Compliance. Certifications can also provide assurance that the fabric is suitable for specific applications, such as EMP protection or digital privacy.

Step 5: Assess Customization Options

Different projects may require varying sizes and configurations of RF shielding fabric. Inquire about customization options, including the ability to order specific lengths or kits tailored to your project. Suppliers that offer flexibility can better accommodate unique project demands and enhance your overall satisfaction.

Illustrative image related to rf shielding fabric

Step 6: Request Samples for Testing

Before making a bulk purchase, request samples of the RF shielding fabric. Testing samples allows you to assess the fabric’s performance in your specific application, checking for ease of use, durability, and shielding effectiveness. This step can save you from costly mistakes by ensuring the material meets your expectations.

Step 7: Understand Import Regulations and Duties

If sourcing internationally, familiarize yourself with local import regulations and potential duties applicable to RF shielding fabric. This knowledge helps avoid unexpected costs and delays during shipping. Ensure that the supplier provides all necessary documentation to facilitate smooth customs clearance.

By following this checklist, you can navigate the sourcing process effectively, ensuring you select the right RF shielding fabric that meets your technical requirements and business objectives.

Comprehensive Cost and Pricing Analysis for rf shielding fabric Sourcing

What Are the Key Cost Components in RF Shielding Fabric Sourcing?

When sourcing RF shielding fabric, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly influences the overall price. High-quality RF shielding fabrics typically incorporate metals like copper and nickel, which can increase costs due to their market prices and sourcing challenges. For instance, fabrics that meet military specifications, like MIL STD 188-125, will often command a premium due to their enhanced shielding capabilities.

-

Labor: Labor costs vary based on the manufacturing region. Countries with lower labor costs may offer more competitive pricing but could compromise on quality. Conversely, manufacturers in regions with higher labor costs may provide superior craftsmanship and quality assurance, justifying a higher price point.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Manufacturers with advanced technologies or environmentally friendly processes may have higher overheads, which can be reflected in the fabric pricing.

-

Tooling: Customization often requires specific tooling, which can add to initial costs. Buyers seeking tailored solutions should factor in these tooling costs when negotiating prices.

-

Quality Control (QC): Rigorous testing and certification processes ensure that the fabric meets specific standards. The costs associated with quality control can be substantial, especially for fabrics intended for high-stakes applications like military use or critical infrastructure.

-

Logistics: Shipping and handling costs can vary widely based on the origin and destination. For international buyers, understanding Incoterms is crucial to gauge who bears the cost of shipping, insurance, and customs duties. This can significantly impact the final price.

-

Margin: Suppliers typically add a profit margin to the cost of production. Understanding the market dynamics can help buyers negotiate better margins, especially when dealing with bulk orders.

How Do Price Influencers Affect RF Shielding Fabric Costs?

Several factors can influence the pricing of RF shielding fabric, making it imperative for buyers to be well-informed:

-

Volume/MOQ: Purchasing in bulk often leads to reduced per-unit costs. Manufacturers typically have minimum order quantities (MOQs), and buyers can negotiate better terms by meeting or exceeding these quantities.

-

Specifications and Customization: Custom specifications, such as specific dimensions or additional features, can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Fabrics that are certified for military or industrial use will generally cost more. Buyers should assess whether the added expense for certifications aligns with their intended applications.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers with a track record of quality may charge more but offer peace of mind regarding product reliability and compliance.

-

Incoterms: Understanding international shipping terms can help buyers manage logistics costs effectively. Incoterms dictate responsibilities for shipping, insurance, and tariffs, which can affect the overall cost.

What Are Effective Buyer Tips for Sourcing RF Shielding Fabric?

To navigate the complexities of RF shielding fabric sourcing, buyers should consider the following strategies:

-

Negotiate Effectively: Engaging in negotiations can yield better pricing, particularly for large orders. Building a strong relationship with suppliers can result in favorable terms and conditions.

-

Focus on Cost-Efficiency: Analyze the Total Cost of Ownership (TCO) rather than just the upfront price. Consider factors such as durability, maintenance, and performance over time to determine the best value.

-

Understand Pricing Nuances: International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of regional pricing trends and market conditions. Fluctuations in material costs or currency exchange rates can impact overall pricing.

-

Request Samples: Before committing to large orders, requesting samples can help assess quality and suitability for specific applications. This practice can prevent costly mistakes down the line.

-

Stay Informed on Market Trends: Keeping abreast of market developments, such as changes in material costs or emerging suppliers, can provide leverage during negotiations and sourcing decisions.

In summary, a comprehensive understanding of the cost components, pricing influencers, and effective sourcing strategies can empower B2B buyers to make informed decisions when sourcing RF shielding fabric. This knowledge is particularly vital for international buyers navigating diverse markets.

Alternatives Analysis: Comparing rf shielding fabric With Other Solutions

Exploring Alternatives to RF Shielding Fabric

When considering solutions for RF shielding, it’s essential to evaluate various alternatives that can effectively block or mitigate electromagnetic interference. Understanding the strengths and weaknesses of each option helps B2B buyers make informed decisions tailored to their specific needs.

| Comparison Aspect | Rf Shielding Fabric | Alternative 1: Metal Enclosures | Alternative 2: Conductive Paint |

|---|---|---|---|

| Performance | High shielding effectiveness (up to 65dB) across a wide frequency range (low MHz to 40GHz) | Excellent performance for complete signal isolation | Moderate performance, effective against low-frequency signals |

| Cost | Mid-range pricing; varies by size (e.g., $23 for 11 sq ft) | Higher initial investment due to material and fabrication costs | Lower initial cost, but requires multiple applications for full effectiveness |

| Ease of Implementation | User-friendly; can be cut and sewn for custom applications | Requires professional fabrication, potentially lengthy installation | DIY application possible, but requires careful layering |

| Maintenance | Minimal; durable and corrosion-resistant | Low; however, may require periodic inspections | Moderate; may need reapplication over time |

| Best Use Case | Ideal for custom RF shielding enclosures, secure facilities, and personal data protection | Best for permanent installations requiring high security | Suitable for areas needing low-cost RF shielding, such as home offices |

In-Depth Analysis of Alternatives

Metal Enclosures

Metal enclosures, often made from materials such as aluminum or steel, provide robust shielding against RF signals. They are particularly effective for high-security applications, such as military and government installations, where complete signal isolation is critical. However, the main drawbacks include a higher initial cost and the need for professional installation, which can lead to increased project timelines. Additionally, once installed, these enclosures are not easily adjustable, limiting flexibility.

Conductive Paint

Conductive paint serves as a low-cost alternative for RF shielding, offering an easy-to-apply solution for smaller projects. It can be painted on walls, ceilings, and other surfaces to create a barrier against low-frequency signals. While it is an economical choice, its performance is generally inferior to that of RF shielding fabric and metal enclosures, particularly against high-frequency signals. Moreover, achieving optimal shielding may require multiple coats, increasing labor time and complexity. Maintenance can also be a concern, as the paint may degrade over time and necessitate reapplication.

Illustrative image related to rf shielding fabric

Choosing the Right RF Shielding Solution

Selecting the appropriate RF shielding solution hinges on several factors, including the specific application, budget constraints, and desired performance level. For projects requiring high levels of shielding and security, RF shielding fabric or metal enclosures may be ideal. Conversely, for smaller, less critical applications, conductive paint could offer an acceptable balance of cost and performance. Ultimately, B2B buyers should assess their unique needs and potential challenges to determine the most effective shielding method for their environment.

Essential Technical Properties and Trade Terminology for rf shielding fabric

What Are the Key Technical Properties of RF Shielding Fabric?

When selecting RF shielding fabric for various applications, understanding its technical specifications is critical for ensuring optimal performance. Here are some essential properties that B2B buyers should be aware of:

1. Material Composition

RF shielding fabrics are typically composed of a blend of conductive materials, such as copper and nickel, integrated into a polyester base. This composition is vital as it determines the fabric’s conductivity, flexibility, and durability. A higher percentage of conductive materials typically leads to better shielding effectiveness against electromagnetic interference (EMI) and radio frequency (RF) signals, making it crucial for industries like telecommunications, military, and healthcare.

2. Shielding Effectiveness (Attenuation)

This metric, often expressed in decibels (dB), indicates how well the fabric can block RF signals across various frequencies. For instance, a fabric with an attenuation of over 65 dB can effectively shield against signals from low MHz to 40 GHz. Understanding this specification helps buyers assess whether the fabric meets their specific shielding requirements, particularly in high-risk environments where signal leakage could compromise sensitive data.

3. Surface Resistance

Surface resistance, typically measured in ohms per square (Ω/sq), indicates how well the fabric can conduct electricity along its surface. A lower surface resistance means better conductivity, which translates to more effective shielding. Buyers should look for fabrics with surface resistance values below 50 MΩ, especially for applications requiring consistent performance under varying environmental conditions.

Illustrative image related to rf shielding fabric

4. Thickness and Weight

The thickness of RF shielding fabric, measured in micrometers (µm), and its weight, measured in grams per square meter (g/m²), affect both its performance and usability. Thicker fabrics generally offer better attenuation but may be less flexible. Buyers should consider the balance between thickness and weight based on their project requirements, such as portability or ease of installation.

5. Certifications and Compliance

Certifications such as MIL STD 188-125 and IEEE 299-2006 provide assurance that the fabric meets established industry standards for shielding effectiveness and durability. These certifications are particularly important for B2B buyers in regulated industries, as they ensure compliance with safety and performance benchmarks.

6. Corrosion Resistance

Corrosion resistance is essential for maintaining the integrity of RF shielding fabric over time, especially in environments prone to moisture or harsh conditions. Fabrics that resist corrosion and tarnishing ensure longevity and reliability, making them a worthwhile investment for businesses that require consistent performance.

What Are Common Trade Terms Associated with RF Shielding Fabric?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions involving RF shielding fabric. Here are some key terms to be familiar with:

Illustrative image related to rf shielding fabric

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of RF shielding fabric, buyers may work directly with OEMs to source custom materials tailored to specific applications, ensuring compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers as it impacts inventory management and costs. For RF shielding fabric, MOQs can vary based on the supplier and the specific fabric type, influencing purchasing decisions.

3. RFQ (Request for Quotation)

An RFQ is a document sent by potential buyers to suppliers to request pricing and terms for a specific quantity of products. This is a standard practice in B2B procurement, helping companies compare costs and negotiate favorable terms for RF shielding fabric.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers, as they clarify who is responsible for shipping, insurance, and tariffs during the importation of RF shielding fabric.

5. EMI (Electromagnetic Interference)

EMI refers to the disruption that electronic devices can experience due to external electromagnetic fields. Understanding EMI is vital for companies looking to mitigate risks through effective RF shielding solutions, ensuring the integrity of sensitive equipment.

6. HEMP (High-Altitude Electromagnetic Pulse)

HEMP is a type of electromagnetic interference that can result from nuclear explosions at high altitudes. Knowing the implications of HEMP is essential for industries that require robust shielding solutions, particularly in defense and critical infrastructure sectors.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when sourcing RF shielding fabric, ensuring it meets their operational needs and industry standards.

Navigating Market Dynamics and Sourcing Trends in the rf shielding fabric Sector

What Are the Current Market Dynamics and Key Trends in the RF Shielding Fabric Sector?

The RF shielding fabric sector is witnessing robust growth driven by increasing demand for data protection and privacy across various industries. As digital transformation accelerates globally, businesses are increasingly aware of the vulnerabilities posed by electromagnetic interference (EMI) and radio frequency interference (RFI). This has led to a surge in applications for RF shielding fabrics in sectors such as telecommunications, healthcare, military, and consumer electronics, particularly in regions like Africa, South America, the Middle East, and Europe.

Key trends shaping the market include the rising adoption of advanced materials that offer superior shielding capabilities. Innovations such as composites of copper, nickel, and polyester are gaining traction, as they not only provide effective signal blockage but also enhance durability and flexibility. The emergence of smart materials—those that can change properties in response to external stimuli—presents new opportunities for tailored solutions in RF shielding.

Illustrative image related to rf shielding fabric

Moreover, international buyers are increasingly gravitating towards suppliers that offer customizable options to meet specific project requirements. As businesses become more project-centric, the ability to procure RF shielding fabric in various sizes and compositions is paramount. Additionally, the focus on e-commerce platforms is facilitating easier access to a broader range of products, enabling buyers in diverse geographical regions to source materials more efficiently.

How Are Sustainability and Ethical Sourcing Addressed in the RF Shielding Fabric Industry?

Sustainability is becoming a pivotal consideration for international B2B buyers in the RF shielding fabric sector. The environmental impact of manufacturing processes and materials is under scrutiny, prompting companies to seek suppliers that prioritize eco-friendly practices. Sustainable sourcing involves not just the materials used but also the manufacturing processes, which should minimize waste and carbon footprints.

Ethical supply chains are essential, especially for buyers in regions like Europe, where regulatory frameworks around sustainability are tightening. Certifications such as ISO 14001 for environmental management and adherence to REACH regulations for chemical safety are becoming prerequisites for suppliers. Buyers should look for manufacturers that utilize ‘green’ materials, such as recycled metals or organic fibers, to align with their sustainability goals.

Moreover, the trend towards transparency in supply chains is gaining momentum. Companies that can demonstrate responsible sourcing practices and provide traceability of their materials will likely have a competitive edge. This not only enhances brand reputation but also builds trust with consumers who are increasingly concerned about the origins of the products they use.

How Has the RF Shielding Fabric Sector Evolved Over Time?

The evolution of the RF shielding fabric sector can be traced back to the mid-20th century when the military first recognized the need for effective shielding against electromagnetic interference. Initially, materials were rudimentary, often limited to heavy metals that were difficult to work with. However, advancements in material science have led to the development of lightweight, flexible fabrics that maintain excellent shielding properties.

In recent decades, the proliferation of wireless technology has accelerated demand for RF shielding solutions across various sectors. The rise of consumer electronics, coupled with heightened awareness of data privacy issues, has expanded the market beyond traditional applications. Today, RF shielding fabrics are not just vital for military and aerospace applications but have found their way into everyday products, from mobile devices to smart home technologies.

As the industry continues to mature, the focus is shifting towards innovation and customization, enabling suppliers to meet the dynamic needs of their B2B clients. The integration of smart technology and sustainable practices in manufacturing processes is set to further revolutionize the sector, making it more responsive to the challenges of a rapidly evolving technological landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of rf shielding fabric

1. How do I ensure the RF shielding fabric meets my specific project requirements?

To ensure the RF shielding fabric meets your project needs, start by defining your shielding goals, such as frequency range and level of attenuation required. Consult product specifications, such as MIL STD 188-125 and IEEE 299-2006 certifications, which validate the fabric’s performance. Additionally, consider the fabric’s composition, thickness, and layering options, as these factors influence its effectiveness. Engage with suppliers to discuss your application, and request samples for testing before making a bulk order.

2. What is the best RF shielding fabric for protecting electronic devices?

The best RF shielding fabric for protecting electronic devices is one that provides comprehensive coverage across the frequency spectrum relevant to your application, typically from low MHz to 40 GHz. Fabrics like Mission Darkness TitanRF, which includes copper and nickel for superior conductivity and shielding effectiveness, are highly recommended. Look for materials that are lightweight yet durable, allowing for easy installation in various configurations, such as enclosures or wall coverings, to ensure effective signal blocking.

3. What are the typical minimum order quantities (MOQs) for RF shielding fabric?

Minimum order quantities (MOQs) for RF shielding fabric can vary significantly based on the supplier and the type of fabric. Generally, MOQs can range from a few yards for small projects to several hundred yards for larger industrial applications. When sourcing internationally, consider potential shipping constraints and costs that could impact your order size. It’s advisable to discuss your specific needs with suppliers to negotiate MOQs that align with your project requirements while ensuring cost-effectiveness.

4. How can I vet suppliers of RF shielding fabric?

To effectively vet suppliers of RF shielding fabric, start by researching their reputation in the market. Look for customer reviews, case studies, and testimonials that highlight their experience in the industry. Check if they have relevant certifications and compliance with international standards. Additionally, request samples of their products to assess quality firsthand. Engaging in direct communication about your needs and observing their responsiveness can also provide insights into their reliability and customer service.

5. What payment terms should I expect when purchasing RF shielding fabric internationally?

Payment terms for international purchases of RF shielding fabric typically vary by supplier and can include options such as advance payment, letters of credit, or payment upon delivery. Common terms may involve a deposit upfront (20-50%) with the balance due upon shipment or delivery. It’s essential to clarify these terms during negotiations to avoid misunderstandings. Additionally, consider using secure payment methods to protect your transaction, and be aware of any currency conversion fees that may apply.

6. What quality assurance measures should I look for in RF shielding fabric?

When sourcing RF shielding fabric, look for suppliers that implement stringent quality assurance measures. This includes lab testing certifications, such as those from accredited compliance laboratories, which verify the fabric’s shielding effectiveness and durability. Inquire about their manufacturing processes, materials sourcing, and any quality control protocols in place. A reputable supplier should provide documentation and test results to support their claims, ensuring that the fabric meets your project’s specifications and standards.

7. What logistical considerations should I keep in mind when importing RF shielding fabric?

When importing RF shielding fabric, consider logistics factors such as shipping methods, customs clearance, and potential import duties or taxes. Choose a reliable freight forwarder familiar with your destination country’s regulations to facilitate smooth transport. Ensure you have all necessary documentation, including invoices, packing lists, and certificates of origin, to avoid delays at customs. Additionally, factor in lead times for production and shipping when planning your project timeline to ensure timely delivery.

Illustrative image related to rf shielding fabric

8. Can I customize RF shielding fabric for specific applications?

Yes, many suppliers offer customization options for RF shielding fabric to meet specific application needs. Customization can include variations in size, thickness, and material composition to enhance shielding effectiveness or adaptability for particular environments. When discussing your requirements with suppliers, be clear about your project specifications and desired outcomes. Some manufacturers may also provide tailored solutions, including pre-cut pieces or specific configurations for easy integration into your projects.

Top 4 Rf Shielding Fabric Manufacturers & Suppliers List

1. Aaronia – Shielding Solutions

Domain: aaronia.com

Registered: 2010 (15 years)

Introduction: Aaronia Shield – Shielding solution by Aaronia AG. Key features include: 50dB RF Shielding-Fabric, very transparent RFI screening solution for windows, clothes, screening tents, and medical applications with high damping up to 50dB (99.999%). Made from patented high-tech shielding-fibre, it is highly transparent, washable, antiseptic, and effective against RF “electrosmog” especially in the high G…

2. Aaronia – RF and EMF Shielding Solutions

Domain: aaroniausa.com

Registered: 2008 (17 years)

Introduction: Aaronia offers a range of RF and EMF shielding products with the following key details:

– **Protection Levels:** Up to 108 dB for RF and LF electric fields.

– **Applications:** Suitable for RF test chambers, shielded faraday cages, electronics shielding, and protective clothing.

– **Product Types:**

– **Lightweight RF Shielding Fabrics:** 50dB (SHIELD) and 70dB (SHIELD ULTRA), breathable, wa…

3. WOREMOR – TüllX Semi-Transparent Shielding Fabric

Domain: emrss.com

Registered: 2013 (12 years)

Introduction: WOREMOR TüllX: Semi-transparent, silver-plated knit fabric for HF and LF shielding. Price: $33.00. 3 reviews.

HF+ LF – SILVER Elastic Shielding Fabric: Compact, full silvered spandex fabric for HF+LF shielding, ideal for clothing. Price: $34.99.

EMF shielding fabric STEEL-GRAY: Cotton/polyester/stainless-steel fabric for HF+LF shielding, suitable for curtains, floor mats, blankets. Price: $29.00….

4. Safe Living Technologies – EMF Shielding Fabric

Domain: safelivingtechnologies.com

Registered: 2006 (19 years)

Introduction: This company, Safe Living Technologies – EMF Shielding Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for rf shielding fabric

As the demand for RF shielding fabric continues to grow, strategic sourcing becomes increasingly vital for international B2B buyers. By partnering with reputable manufacturers like Mission Darkness, businesses can ensure access to high-quality, certified materials that meet military standards. This not only enhances product reliability but also provides peace of mind against various electromagnetic threats, including EMPs and data breaches.

Investing in RF shielding fabric can yield significant returns, particularly in sectors such as telecommunications, medical technology, and security. Buyers should prioritize suppliers that offer extensive product support, including guidance on fabric applications and project specifications. This approach will facilitate successful implementations, whether for DIY projects or large-scale industrial applications.

Looking ahead, the RF shielding fabric market is poised for expansion, driven by increasing global awareness of electromagnetic interference and data security. We encourage B2B buyers from Africa, South America, the Middle East, and Europe to explore strategic partnerships that not only meet their immediate shielding needs but also position them for future challenges. Engage with trusted suppliers today to secure the best materials for your projects and stay ahead in a rapidly evolving landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.