Everything You Need to Know About Repairable Phone Charger Sourcing in 2025

Introduction: Navigating the Global Market for repairable phone charger

The surge in consumer demand for sustainable technology has brought repairable phone chargers to the forefront of the global market. Sourcing high-quality, repairable phone chargers presents a unique challenge for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. As businesses seek to align with environmentally responsible practices while ensuring product reliability, understanding the nuances of this emerging category becomes critical.

This comprehensive guide delves into various types of repairable phone chargers, their applications across different industries, and the importance of supplier vetting to ensure quality and sustainability. It also addresses cost considerations, helping international buyers make informed purchasing decisions that balance budget constraints with ethical sourcing.

By leveraging insights from leading manufacturers and industry experts, this guide empowers B2B buyers to navigate the complexities of the repairable phone charger market. Whether you’re looking to enhance your product offerings or fulfill corporate social responsibility goals, the information presented here will equip you with the knowledge needed to choose the right partners and products. Embrace the opportunity to contribute to a more sustainable future while meeting the needs of your customers in a competitive landscape.

Understanding repairable phone charger Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Repairable Charging Cables | User-repairable design, compatible with multiple connectors | Retail, E-commerce, Repair Shops | Pros: Cost-effective, eco-friendly; Cons: Requires user skill for repairs. |

| Sustainable USB Charging Cables | Made from recycled materials, designed for durability | Corporate Gifting, Eco-friendly Brands | Pros: Sustainable, ethical production; Cons: Higher initial cost. |

| Modular Charging Systems | Interchangeable parts, customizable lengths and connectors | Tech Startups, Custom Electronics Firms | Pros: Versatile, tailored solutions; Cons: Complexity in assembly. |

| High-Performance Fast Chargers | Supports high wattage, built for durability | Mobile Device Manufacturers, Distributors | Pros: Fast charging capabilities; Cons: May be overkill for casual users. |

| Multi-Device Charging Stations | Capable of charging multiple devices simultaneously | Offices, Educational Institutions | Pros: Efficient for multiple devices; Cons: Requires more space. |

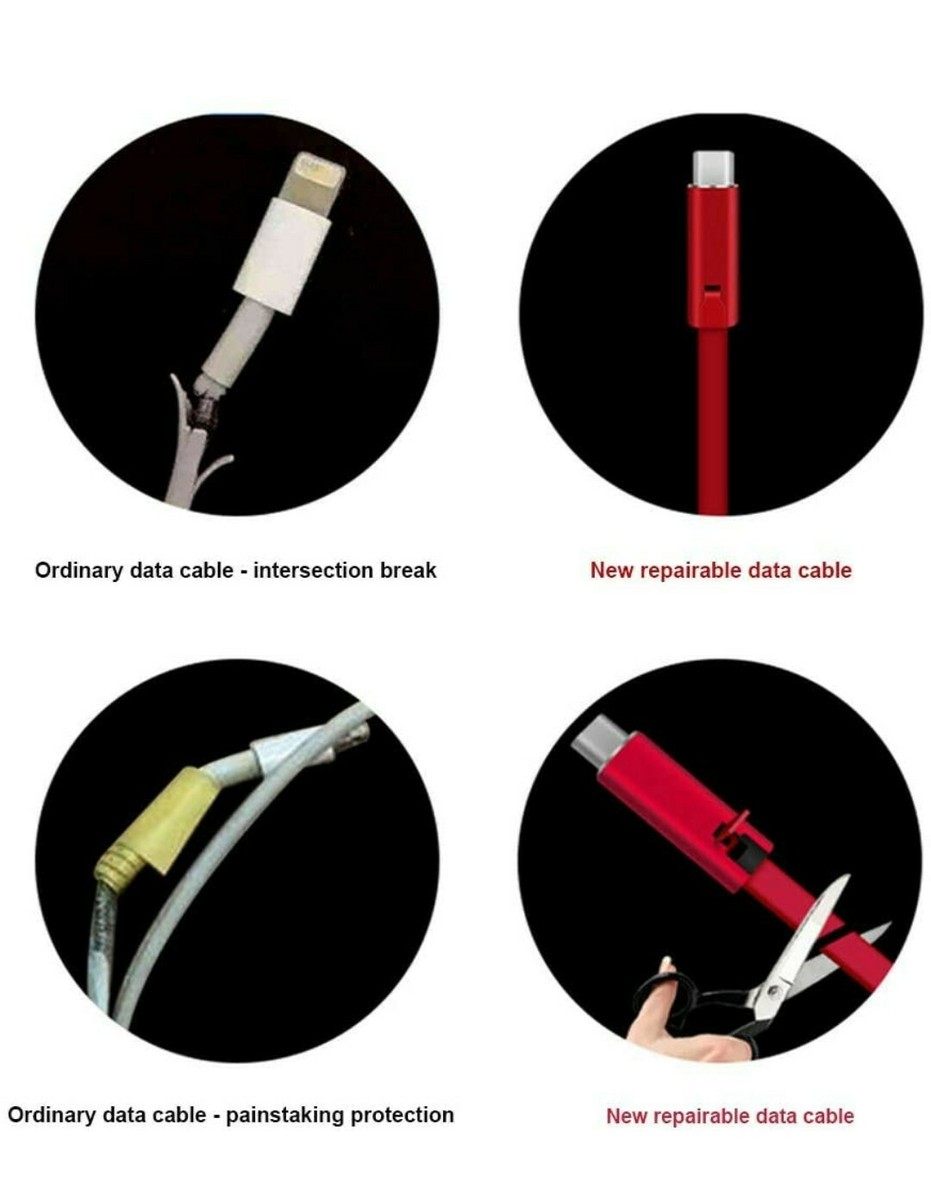

What Are the Characteristics of Repairable Charging Cables?

Repairable charging cables are designed for ease of repair, allowing users to replace broken connectors or damaged sections without discarding the entire cable. This approach is particularly appealing to businesses that prioritize sustainability and cost-effectiveness. In B2B applications, these cables are ideal for retail and e-commerce sectors, where they can be marketed as eco-friendly alternatives. However, they require a certain level of technical skill from users, which may limit their appeal in some markets.

How Do Sustainable USB Charging Cables Stand Out?

Sustainable USB charging cables are manufactured from recycled materials and emphasize ethical production methods. These cables not only reduce environmental impact but also resonate with brands focused on corporate social responsibility. Businesses that opt for these cables can enhance their brand image while appealing to environmentally conscious consumers. While the initial investment may be higher compared to conventional cables, the long-term benefits of sustainability and consumer loyalty can outweigh these costs.

What Are the Benefits of Modular Charging Systems?

Modular charging systems offer flexibility through interchangeable components, allowing businesses to customize cable lengths and connector types based on specific needs. This adaptability makes them suitable for tech startups and custom electronics firms that require tailored solutions for diverse products. However, the complexity involved in assembling these systems may deter some buyers, necessitating a clear understanding of the target market’s technical capabilities.

Why Choose High-Performance Fast Chargers?

High-performance fast chargers are engineered to support rapid charging, often featuring advanced technology to deliver higher wattage. These chargers are particularly beneficial for mobile device manufacturers and distributors who seek to provide their customers with efficient charging solutions. While they cater to a specific need for speed, businesses should consider the potential for overkill in casual consumer markets, where slower charging options might suffice.

What Are the Advantages of Multi-Device Charging Stations?

Multi-device charging stations are designed to accommodate various devices simultaneously, making them particularly useful in office environments and educational institutions. They enhance efficiency by centralizing charging needs, which can be a significant advantage for businesses managing multiple devices. However, their larger footprint may require careful consideration regarding space allocation in the workplace, which could be a drawback for some buyers.

Key Industrial Applications of repairable phone charger

| Industry/Sector | Specific Application of Repairable Phone Charger | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Charging stations in public areas | Reduces electronic waste and enhances customer satisfaction | Durability, repairability, and compatibility with various devices |

| Education | Charging solutions for schools and universities | Cost-effective, sustainable options for tech-savvy institutions | Bulk purchasing options, warranty, and after-sales support |

| Logistics and Transport | Mobile charging solutions for delivery vehicles | Ensures devices remain operational, improving service efficiency | Quick repair options, robust design, and local sourcing for parts |

| Retail | In-store charging stations for customers | Increases foot traffic and customer engagement | Aesthetic design, ease of use, and adaptability to various environments |

| Hospitality | Charging solutions in hotels and restaurants | Enhances guest experience and promotes sustainable practices | Custom branding options, ease of maintenance, and service agreements |

How is a Repairable Phone Charger Utilized in Telecommunications?

In the telecommunications sector, repairable phone chargers are increasingly deployed in public charging stations. These stations cater to users needing to charge devices on the go, thereby reducing electronic waste through their repairable nature. Businesses benefit from enhanced customer satisfaction as users appreciate the reliability and sustainability of these charging solutions. When sourcing, companies should prioritize durability and compatibility with multiple device types to maximize utility.

What Role Do Repairable Phone Chargers Play in Education?

Educational institutions, from primary schools to universities, utilize repairable phone chargers as part of their technology infrastructure. These solutions provide cost-effective and sustainable charging options for students and staff alike. By investing in such products, educational facilities can minimize their carbon footprint while ensuring that devices remain functional. Bulk purchasing agreements, warranties, and after-sales support are essential considerations for buyers in this sector to ensure long-term viability.

How Can Logistics and Transport Benefit from Repairable Phone Chargers?

In logistics and transport, repairable phone chargers are critical for mobile charging solutions in delivery vehicles. They ensure that essential devices remain operational, directly impacting service efficiency and customer satisfaction. The ability to quickly repair these chargers reduces downtime and enhances overall productivity. When sourcing, companies should focus on options that offer quick repair solutions and robust designs to withstand the rigors of transport environments.

Why Are Repairable Phone Chargers Essential for Retail?

Retail businesses are increasingly incorporating in-store charging stations equipped with repairable phone chargers to engage customers. Such initiatives not only enhance the shopping experience but also promote sustainability by reducing waste. By increasing foot traffic and customer dwell time, retailers can drive sales while demonstrating their commitment to eco-friendly practices. Key sourcing considerations include aesthetic design and adaptability to different retail environments to ensure seamless integration.

What Advantages Do Repairable Phone Chargers Offer in Hospitality?

In the hospitality industry, repairable phone chargers are installed in hotels and restaurants to improve guest experiences. By providing reliable charging solutions, establishments can cater to the needs of tech-savvy guests while promoting sustainability. This not only enhances customer satisfaction but also aligns with the growing demand for eco-friendly practices in the sector. Buyers should look for options that allow for custom branding, ease of maintenance, and comprehensive service agreements to maximize their investment.

3 Common User Pain Points for ‘repairable phone charger’ & Their Solutions

Scenario 1: Ensuring Durability in High-Volume Environments

The Problem: In sectors such as logistics and warehousing, B2B buyers often face the challenge of maintaining functional charging solutions for devices used in demanding environments. Regular chargers tend to wear out quickly due to frequent use, exposure to harsh conditions, or rough handling. This leads to increased downtime, as employees must constantly replace broken chargers, which can be both costly and disruptive to operations.

The Solution: Sourcing repairable phone chargers designed for durability is crucial. Buyers should look for products that emphasize robust materials and construction, such as reinforced connectors and heavy-duty cables capable of withstanding high levels of physical stress. For instance, cables that support up to 70,000 bends and feature high-quality copper cores ensure longevity and reliability. In addition, establishing a clear maintenance schedule to inspect and repair these chargers can extend their lifespan significantly. By investing in repairable chargers, businesses can reduce replacement costs and improve overall productivity.

Scenario 2: Navigating Sustainability and Ethical Sourcing

The Problem: As businesses increasingly prioritize sustainability, B2B buyers are confronted with the challenge of finding charging solutions that align with their environmental and ethical values. Many conventional chargers are made from non-recyclable materials and produced under questionable labor conditions. This not only affects a company’s corporate social responsibility (CSR) image but may also lead to backlash from environmentally conscious consumers.

The Solution: To address this, buyers should consider repairable phone chargers made from sustainable materials and produced under fair labor practices. Products that highlight their eco-friendly credentials, such as using recycled plastics and conflict-free metals, can provide a meaningful way to support ethical sourcing. When evaluating suppliers, buyers should ask for certifications that verify sustainable practices and request detailed information about the manufacturing process. This approach not only enhances a company’s reputation but can also attract a growing market segment that values sustainability.

Scenario 3: Managing Compatibility Across Diverse Device Ecosystems

The Problem: In multinational companies, B2B buyers often deal with a plethora of devices that require different charging solutions. This diversity can lead to confusion and inefficiencies, especially when different teams use various types of smartphones and tablets, each needing specific chargers. This not only complicates inventory management but can also lead to increased costs due to the need to stock multiple types of chargers.

The Solution: A strategic approach is to invest in universal repairable phone chargers that accommodate multiple device types through interchangeable connectors, such as Lightning, Type-C, and Micro USB. These versatile solutions can significantly simplify inventory and reduce costs. Additionally, buyers should establish clear guidelines for selecting and using these chargers, ensuring all team members are trained on their compatibility and repair procedures. This not only optimizes inventory management but also enhances user experience by providing a consistent charging solution across the organization. By prioritizing compatibility, companies can streamline their operations and improve efficiency in device management.

Strategic Material Selection Guide for repairable phone charger

What Are the Key Materials for Repairable Phone Chargers?

In the development of repairable phone chargers, selecting the right materials is crucial for ensuring product performance, sustainability, and user satisfaction. Here, we analyze four common materials: thermoplastic elastomers (TPE), polyvinyl chloride (PVC), recycled plastics, and copper. Each material offers unique properties that can influence the durability, cost, and overall effectiveness of the final product.

How Do Thermoplastic Elastomers (TPE) Perform in Repairable Phone Chargers?

Thermoplastic elastomers (TPE) are widely used in the manufacturing of flexible components in phone chargers. They exhibit excellent elasticity, high-temperature resistance, and good chemical stability, making them suitable for environments with varying temperatures and humidity. TPEs can withstand repeated bending and twisting, which is essential for charging cables that undergo frequent manipulation.

Pros: TPE is durable and flexible, allowing for easy repair and customization. Its resistance to UV light and chemicals also enhances its longevity.

Cons: While TPE is generally cost-effective, the manufacturing process can be complex, requiring specialized equipment. Additionally, TPE may not be as environmentally friendly as other materials unless sourced sustainably.

Impact on Application: TPE is compatible with various media and can be used in different environments, making it versatile for international markets.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers from regions like Africa and South America may also prioritize materials that are locally sourced or produced to reduce costs.

What Role Does Polyvinyl Chloride (PVC) Play in Charger Manufacturing?

Polyvinyl chloride (PVC) is another common material used in the insulation of charging cables. PVC has excellent electrical insulation properties and is resistant to abrasion and impact. It can be formulated to meet specific requirements, including flexibility and rigidity.

Pros: PVC is cost-effective and widely available, making it a popular choice for manufacturers. Its durability and resistance to environmental factors enhance the longevity of chargers.

Cons: PVC is less environmentally friendly compared to other materials, as it can release harmful substances during production and disposal. Additionally, it may not withstand extreme temperatures as well as other materials.

Impact on Application: PVC’s excellent insulation properties make it suitable for various electronic applications, ensuring safety during charging.

Considerations for International Buyers: Buyers should be aware of local regulations regarding PVC usage, especially in Europe, where there are stringent environmental standards.

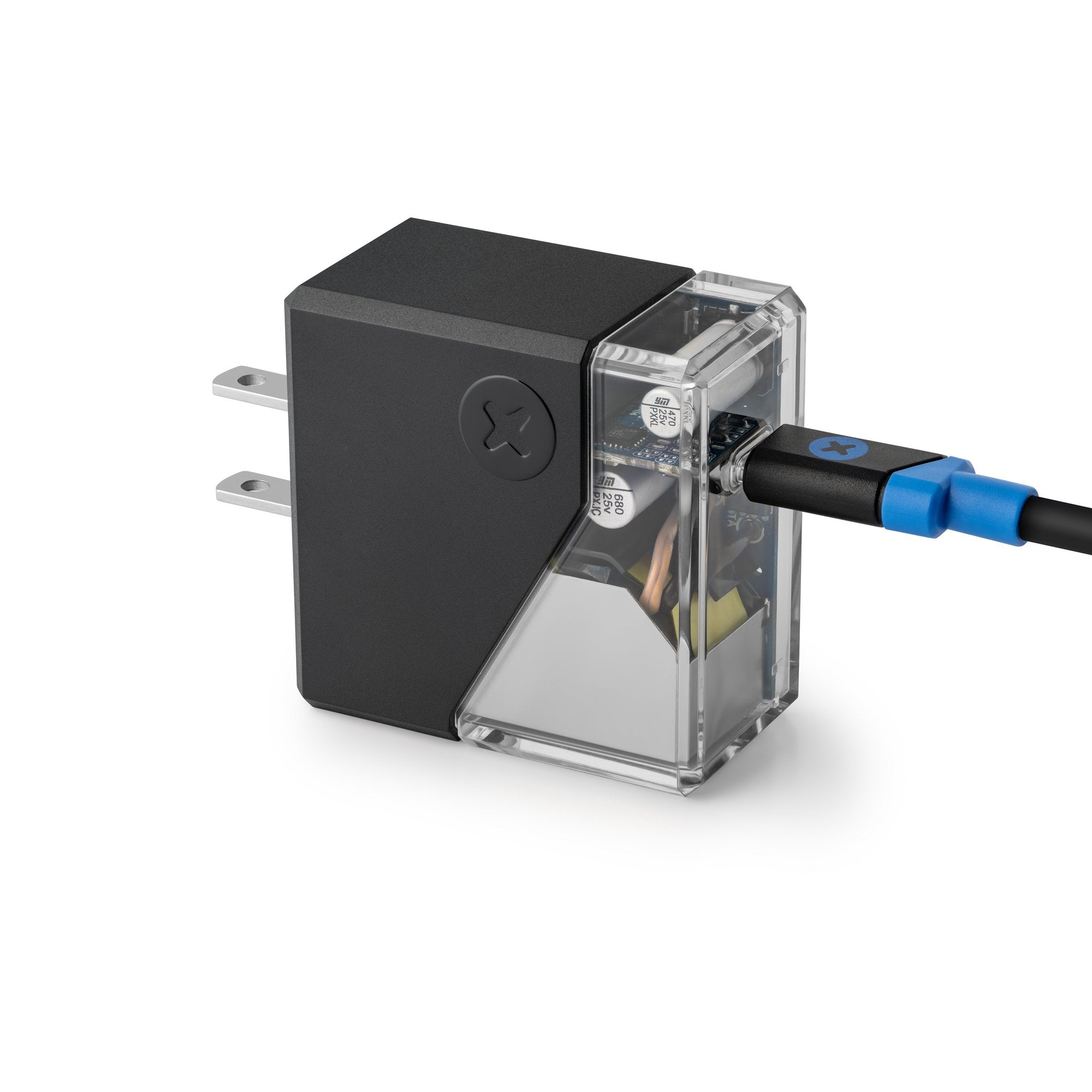

Illustrative image related to repairable phone charger

How Do Recycled Plastics Contribute to Sustainable Charger Design?

Recycled plastics are increasingly being utilized in the production of repairable phone chargers. These materials can include post-consumer waste, which helps reduce environmental impact and promotes sustainability.

Pros: Using recycled plastics can significantly lower the carbon footprint of production. They are often less expensive than virgin materials and can meet various performance standards.

Cons: The quality of recycled plastics can vary, potentially affecting the durability and performance of the end product. Manufacturers must ensure that the recycled materials meet the necessary specifications.

Impact on Application: Recycled plastics can be tailored to fit various applications, making them suitable for diverse markets.

Considerations for International Buyers: Buyers should prioritize suppliers who adhere to recycling certifications and sustainability standards, particularly in regions with a strong focus on environmental responsibility, such as Germany.

What Advantages Does Copper Offer for Electrical Conductivity in Chargers?

Copper is the primary material used for the internal wiring of phone chargers due to its excellent electrical conductivity. It ensures efficient charging and data transfer, which are critical for user satisfaction.

Pros: Copper is highly conductive, allowing for faster charging and improved performance. It is also relatively durable and resistant to corrosion.

Cons: The cost of copper can be high, particularly in regions experiencing supply chain disruptions. Additionally, copper’s weight may be a consideration for portable charger designs.

Impact on Application: Copper is essential for high-performance applications, ensuring that chargers can support rapid charging technologies.

Considerations for International Buyers: Buyers should consider sourcing copper from suppliers who comply with ethical mining practices, particularly in regions where conflict minerals are a concern.

Summary Table of Material Selection for Repairable Phone Chargers

| Material | Typical Use Case for Repairable Phone Charger | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic Elastomers (TPE) | Flexible cable insulation | Excellent elasticity and durability | Complex manufacturing process | Medium |

| Polyvinyl Chloride (PVC) | Insulation for cables | Cost-effective and widely available | Environmental concerns | Low |

| Recycled Plastics | Structural components | Reduces carbon footprint | Variable quality | Medium |

| Copper | Internal wiring | High electrical conductivity | High cost and weight | High |

This analysis provides a comprehensive overview of the materials used in repairable phone chargers, offering actionable insights for B2B buyers in various international markets. Understanding these materials will aid in making informed purchasing decisions that align with both performance requirements and sustainability goals.

In-depth Look: Manufacturing Processes and Quality Assurance for repairable phone charger

What Are the Main Stages in the Manufacturing Process of Repairable Phone Chargers?

The manufacturing process for repairable phone chargers involves several key stages, including material preparation, forming, assembly, and finishing. Each of these stages requires specific techniques and adherence to quality standards to ensure a durable and reliable product.

Material Preparation: What Materials Are Used and How Are They Processed?

The first step in manufacturing involves selecting high-quality materials that align with sustainability goals. Common materials include:

- Conductors: Typically, pure copper is used for its excellent conductivity, allowing for efficient charging. Manufacturers may opt for recycled copper to enhance sustainability.

- Insulation: High-grade thermoplastics are often chosen for their durability and heat resistance. These materials help prevent overheating and ensure user safety.

- Connectors: The connectors must be robust and designed to withstand wear and tear. Manufacturers often use reinforced plastic or metal alloys that provide strength and longevity.

Once materials are selected, they undergo processing to meet the specifications required for further stages. This may include cutting copper wires to length, extruding plastic components, and preparing connectors for assembly.

Illustrative image related to repairable phone charger

How Are the Components Formed and Assembled in Production?

During the forming stage, manufacturers utilize techniques such as injection molding and extrusion.

- Injection Molding: This technique is commonly used for creating plastic components, such as the casing and connectors. It allows for precise shaping and minimizes waste.

- Extrusion: This is employed for producing the cable insulation. Continuous lengths of insulation are extruded around the conductors, ensuring a uniform thickness.

After the components are formed, they move to the assembly stage. Here, skilled workers or automated systems bring together the various parts. The assembly process often includes:

- Soldering Connections: Ensuring that electrical connections are secure and capable of handling high currents.

- Testing Fit and Functionality: Each assembled unit is typically checked for proper fit and functionality before moving on to the finishing stage.

What Finishing Techniques Are Commonly Used in Repairable Charger Manufacturing?

Finishing techniques aim to enhance the product’s aesthetics and durability. Common methods include:

- Surface Treatment: Components may undergo treatments like coating or plating to improve resistance to corrosion and wear.

- Labeling and Branding: Clear labeling is crucial for product identification and compliance with international standards.

- Final Inspection: Each unit is subjected to a final quality check to ensure it meets the specified standards before packaging.

What Quality Control Standards Should B2B Buyers Expect from Repairable Phone Charger Manufacturers?

Quality assurance is a critical aspect of manufacturing repairable phone chargers, ensuring that products meet international and industry-specific standards. B2B buyers should be familiar with the following:

Which International Standards Are Relevant for Repairable Phone Chargers?

- ISO 9001: This international standard focuses on quality management systems. Manufacturers adhering to ISO 9001 demonstrate their commitment to consistent quality and continuous improvement.

- CE Marking: Required for products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- RoHS Compliance: The Restriction of Hazardous Substances (RoHS) directive is crucial for ensuring that electronic products do not contain harmful materials.

These standards help to establish a baseline for product quality and safety, providing B2B buyers with confidence in their suppliers.

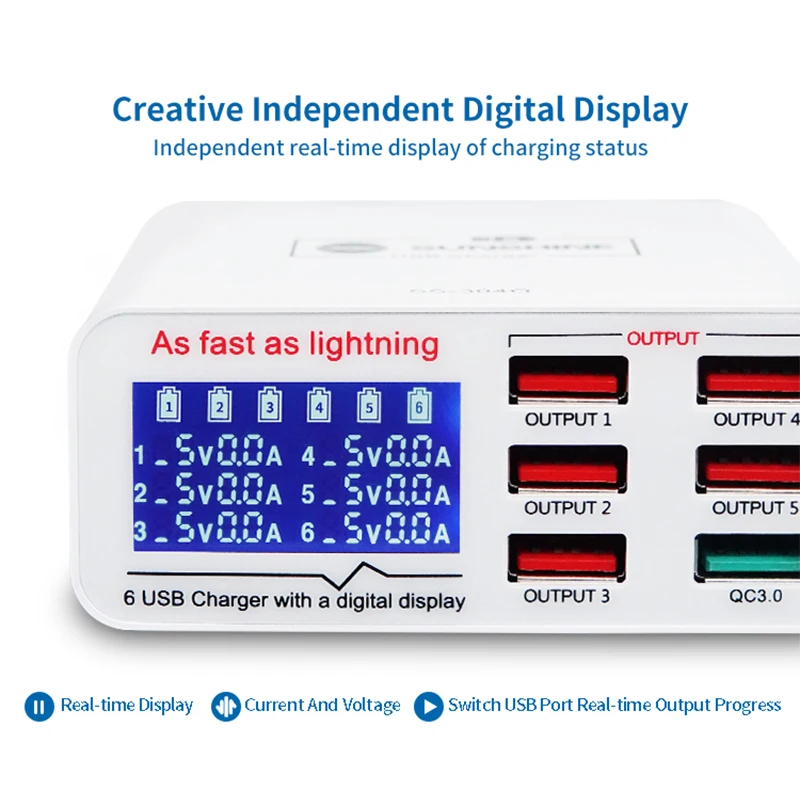

Illustrative image related to repairable phone charger

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are essential for identifying and addressing potential issues throughout the manufacturing process. Typical checkpoints include:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet specifications before processing.

- In-Process Quality Control (IPQC): Throughout the production process, manufacturers conduct regular inspections to monitor processes and identify defects early.

- Final Quality Control (FQC): After assembly, each unit undergoes rigorous testing to ensure it meets all quality and performance standards.

How Can B2B Buyers Verify the Quality Control Processes of Their Suppliers?

B2B buyers can take several steps to verify the quality control processes of potential suppliers:

- Request Documentation: Buyers should ask for quality assurance documents, including ISO certifications, quality control plans, and test reports.

- Conduct Audits: On-site audits allow buyers to assess the manufacturing environment, processes, and adherence to quality standards firsthand.

- Engage Third-Party Inspectors: Utilizing independent inspection agencies can provide an unbiased evaluation of the manufacturer’s quality control practices.

What Are the Unique Quality Control Nuances for International B2B Buyers?

When sourcing from international manufacturers, particularly in regions such as Africa, South America, the Middle East, and Europe, buyers should be aware of specific nuances:

- Cultural Differences in Quality Standards: Different regions may have varying perceptions of quality and acceptable practices. Understanding these cultural differences can aid in effective communication and expectation management.

- Logistical Considerations: International shipping and customs can affect product integrity. B2B buyers should ensure that suppliers have robust logistics plans to protect products during transit.

- Regulatory Compliance: Buyers must verify that products comply with the regulations of their home country, which may differ significantly from those in the manufacturing country.

In conclusion, understanding the manufacturing processes and quality assurance practices associated with repairable phone chargers is essential for B2B buyers. By focusing on material quality, manufacturing techniques, and rigorous quality control standards, businesses can ensure they source reliable, sustainable products that meet market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘repairable phone charger’

Introduction

This guide is designed to assist B2B buyers in sourcing repairable phone chargers, emphasizing sustainable practices and long-term investment. With the rising demand for eco-friendly technology solutions, understanding the key steps in procurement can lead to better decision-making and enhanced supplier relationships.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it is essential to outline your technical requirements. Consider factors such as compatibility with various devices (e.g., Lightning, Type-C, Micro USB), charging speed (aim for at least 3A for fast charging), and durability (look for cables that withstand significant bending). Clear specifications will help streamline your search and ensure that suppliers can meet your needs.

Step 2: Research Market Trends and Innovations

Stay informed about the latest trends in the repairable charger market. Focus on innovations that enhance usability, such as cables that allow for easy repairs or those made from sustainable materials. Understanding these trends will help you identify suppliers who are not only keeping pace with the industry but are also committed to sustainability and ethical practices.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they align with your business values and quality standards. Request detailed company profiles, product specifications, and references from previous clients, especially those within your region or industry. Look for suppliers that offer warranties, as this indicates confidence in their product’s durability.

Step 4: Verify Certifications and Compliance

Ensure that the chargers comply with international safety and environmental standards. Certifications such as CE, RoHS, or ISO can indicate a commitment to quality and sustainability. Additionally, check if the supplier employs fair labor practices and utilizes conflict-free materials, as these factors are increasingly important in today’s market.

Step 5: Assess Cost vs. Value Proposition

While cost is a critical factor, it’s essential to evaluate the overall value proposition of the chargers. Consider the long-term savings from repairable options compared to traditional, single-use chargers. Calculate potential costs associated with replacements and the environmental impact, which can significantly influence your purchasing decision.

Step 6: Request Samples for Quality Testing

Before finalizing any orders, request samples of the chargers for quality assessment. Conduct tests to evaluate their performance, durability, and user-friendliness. This step is crucial to ensure that the products meet your technical specifications and quality expectations before committing to a larger purchase.

Illustrative image related to repairable phone charger

Step 7: Establish Clear Communication Channels

Once you’ve selected a supplier, establish clear communication channels to facilitate ongoing collaboration. Discuss order fulfillment timelines, support for product issues, and processes for handling repairs or returns. Strong communication will enhance your supplier relationship and ensure a smoother procurement process, leading to better service and support over time.

By following this checklist, B2B buyers can make informed decisions when sourcing repairable phone chargers, aligning with sustainability goals while ensuring product quality and supplier reliability.

Comprehensive Cost and Pricing Analysis for repairable phone charger Sourcing

What are the Key Cost Components in Repairable Phone Charger Sourcing?

When sourcing repairable phone chargers, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials directly affects the quality and price of the chargers. For example, using high-quality copper for conductors ensures better performance but increases costs. Sustainable materials, such as recycled plastics and conflict-free metals, may also command a premium.

-

Labor: Labor costs vary significantly based on geographic location. In regions with higher labor costs, such as Europe, manufacturers may pass these costs onto buyers. Conversely, sourcing from countries with lower labor costs can reduce expenses but may raise concerns about quality and working conditions.

-

Manufacturing Overhead: This includes costs related to factory maintenance, utilities, and administrative expenses. Efficient manufacturing processes can help minimize these overheads, thereby lowering the overall cost.

-

Tooling: Investment in specialized tooling for production can impact initial costs. However, high-quality tooling can enhance manufacturing efficiency and product quality, leading to long-term savings.

-

Quality Control (QC): Implementing robust QC processes ensures that only high-quality products reach the market, which can reduce returns and enhance customer satisfaction. However, these processes add to the overall cost.

-

Logistics: Shipping and handling costs can vary widely based on distance, volume, and chosen transport methods. Buyers should consider these expenses when evaluating total costs.

-

Margin: Suppliers will typically apply a margin on their costs to ensure profitability. Understanding the supplier’s margin expectations can aid in negotiation.

How Do Price Influencers Affect Repairable Phone Charger Costs?

Several factors influence the pricing of repairable phone chargers:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to lower unit prices. Buyers should negotiate MOQs that align with their inventory capabilities to maximize cost-efficiency.

-

Specifications and Customization: Custom features, such as unique lengths or connectors, can increase costs. Buyers must balance the need for customization with budget constraints.

-

Material Quality and Certifications: Premium materials and certifications (e.g., for sustainability or safety) can elevate costs. Buyers should evaluate the importance of these factors based on their target markets.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their proven track record but can offer better service and quality assurance.

-

Incoterms: Understanding Incoterms is essential for determining who bears shipping costs and risks. This knowledge can influence total pricing and should be factored into negotiations.

What Negotiation Tips Can Help Buyers Optimize Costs?

B2B buyers should adopt strategic negotiation tactics to achieve better pricing:

-

Leverage Volume Discounts: Communicate your purchasing potential to negotiate better rates based on higher order volumes.

-

Consider Long-Term Partnerships: Establishing long-term relationships with suppliers can lead to more favorable pricing and terms.

-

Evaluate Total Cost of Ownership (TCO): Focus on the TCO rather than just upfront costs. This includes maintenance, repairability, and potential savings from using durable, repairable products.

-

Be Aware of Pricing Nuances: International buyers, especially from regions like Africa and South America, may face additional costs related to tariffs, taxes, and currency fluctuations. Understanding these nuances can prevent unexpected expenses.

-

Research Market Prices: Stay informed about market rates and competitors’ pricing to strengthen your negotiation position.

Conclusion: Why is It Important to Understand Cost and Pricing Dynamics?

Understanding the cost and pricing dynamics of repairable phone chargers is essential for B2B buyers aiming to make informed purchasing decisions. By analyzing cost components, recognizing price influencers, and employing effective negotiation strategies, buyers can optimize their sourcing processes. Keep in mind that prices fluctuate, and the figures discussed here are indicative, reflecting the current market landscape.

Alternatives Analysis: Comparing repairable phone charger With Other Solutions

In the evolving landscape of mobile technology, the demand for sustainable and efficient charging solutions has never been higher. As businesses seek to balance performance with environmental responsibility, comparing repairable phone chargers to alternative solutions is crucial. This analysis will explore two viable alternatives: traditional disposable chargers and sustainable charging cables that are not repairable but offer eco-friendly features.

Comparison Table

| Comparison Aspect | Repairable Phone Charger | Traditional Disposable Charger | Sustainable Non-Repairable Charger |

|---|---|---|---|

| Performance | High durability, customizable | Basic functionality, often less durable | Good performance, eco-friendly materials |

| Cost | Moderate initial investment, potential long-term savings | Low upfront cost, frequent replacements add up | Higher initial cost, but sustainable |

| Ease of Implementation | Requires user understanding for repairs | Plug-and-play, no special skills needed | Simple to use, no repairs necessary |

| Maintenance | Requires user involvement for repairs | Minimal maintenance, but leads to waste | Low maintenance, but non-repairable |

| Best Use Case | Businesses focused on sustainability and cost-saving over time | Short-term needs, low-budget solutions | Companies prioritizing eco-friendly practices without repair options |

Detailed Breakdown of Alternatives

1. Traditional Disposable Charger

Traditional chargers are widely available and are typically the least expensive option upfront. However, their lack of durability means they often need to be replaced frequently, resulting in higher long-term costs and increased electronic waste. For businesses with a low budget and short-term needs, these chargers may seem attractive, but they are not a sustainable solution.

2. Sustainable Non-Repairable Charger

These chargers are designed with eco-friendliness in mind, utilizing recycled materials and sustainable manufacturing practices. While they do not offer the repairability of a repairable phone charger, they provide solid performance and are often built to last longer than traditional disposable options. Their higher initial cost can be offset by their reduced environmental impact, making them suitable for companies looking to enhance their sustainability credentials without the complexity of repairs.

Conclusion

When selecting the right charging solution, B2B buyers should consider their specific operational needs and sustainability goals. Repairable phone chargers present an excellent option for companies committed to reducing waste and ensuring long-term cost savings, albeit with a higher initial investment and maintenance requirement. In contrast, traditional disposable chargers serve a more immediate need but may lead to higher costs and environmental concerns over time. Sustainable non-repairable chargers strike a balance, offering eco-friendly features without the repair complexity, albeit at a higher price point. Ultimately, the decision should align with the organization’s values, budget, and commitment to sustainability.

Essential Technical Properties and Trade Terminology for repairable phone charger

What Are the Key Technical Properties of Repairable Phone Chargers?

Understanding the technical properties of repairable phone chargers is crucial for B2B buyers to make informed purchasing decisions. Here are some essential specifications to consider:

1. Material Grade

The material used in the construction of charging cables significantly affects durability and performance. Common materials include high-grade PVC, TPE (thermoplastic elastomer), and reinforced braided nylon. Higher-grade materials can provide better resistance to wear and tear, which is essential for products marketed as repairable. For B2B buyers, choosing cables made from premium materials can enhance customer satisfaction and reduce return rates.

2. Current Rating (Amperage)

The current rating indicates the maximum amount of current a charger can safely handle. For example, cables rated for 3A or 4A can support fast charging for devices, significantly reducing charging time. This is particularly important for businesses aiming to offer fast charging solutions to customers. Knowing the amperage allows buyers to select chargers that meet specific performance needs.

3. Heat Dissipation Efficiency

Repairable phone chargers should have high heat dissipation capabilities to prevent overheating during use. Cables with excellent heat management can enhance battery life and reduce the risk of damage to both the charger and the device. For buyers, ensuring that chargers have good heat dissipation properties can lead to fewer issues and increased reliability, fostering trust among end-users.

4. Bend Lifespan

Bend lifespan refers to the number of times a cable can be flexed before it begins to show signs of wear. High-quality cables may be rated for 30,000 bends or more. Understanding this property is vital for businesses targeting consumers who frequently use their chargers on the go. A longer bend lifespan can justify a higher price point and enhance brand reputation for durability.

5. Compatibility

Compatibility with various devices (e.g., Lightning, USB-C, Micro USB) is essential for repairable phone chargers. Offering multi-connector options can cater to a wider customer base, especially in diverse markets. For B2B buyers, this flexibility can translate into higher sales volumes and customer satisfaction, as consumers appreciate the convenience of using a single charger for multiple devices.

Illustrative image related to repairable phone charger

What Are Common Trade Terms in the Repairable Phone Charger Industry?

Navigating the B2B landscape requires familiarity with specific trade terminology. Here are some essential terms relevant to the repairable phone charger sector:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of phone chargers, understanding OEM relationships can help businesses ensure product quality and reliability. Buyers often look for OEM partnerships to guarantee that the chargers meet specific industry standards.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest order size that a supplier is willing to process. Knowing the MOQ is crucial for buyers, especially when budgeting for inventory. Understanding this term helps companies plan their purchases effectively and avoid overstock situations.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for a specific quantity of goods. In the context of repairable phone chargers, using an RFQ can streamline the procurement process, allowing businesses to compare offers efficiently.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms is vital for B2B transactions involving cross-border purchases of repairable phone chargers, as they clarify who bears the risks and costs during transportation.

5. Sustainability Certification

This term refers to documentation that verifies a product’s adherence to environmental and ethical standards. For businesses focused on sustainability, sourcing repairable chargers with recognized certifications can enhance brand image and attract eco-conscious customers.

Understanding these technical properties and trade terms equips B2B buyers with the knowledge necessary to make strategic decisions in the competitive market of repairable phone chargers.

Navigating Market Dynamics and Sourcing Trends in the repairable phone charger Sector

What Are the Key Drivers and Trends Influencing the Repairable Phone Charger Market?

The global market for repairable phone chargers is witnessing significant growth, driven by increasing consumer awareness regarding sustainability and the rising demand for eco-friendly products. Key markets in Africa, South America, the Middle East, and Europe are particularly responsive to these trends, as businesses and consumers alike prioritize environmental responsibility. A notable shift towards repairability is emerging, as brands recognize the potential for reducing electronic waste (e-waste) and fostering a circular economy.

Technological advancements are also playing a pivotal role in this sector. The introduction of versatile charging solutions, such as multi-connector cables compatible with various devices, enhances market appeal. As international B2B buyers seek cost-effective sourcing options, the competitive pricing of repairable chargers is becoming a strategic advantage. Additionally, the rise of e-commerce platforms facilitates easier access to these products, allowing buyers from diverse regions to explore innovative solutions tailored to local market needs.

Moreover, a growing focus on durability and performance is evident, with manufacturers emphasizing enhanced specifications such as faster charging capabilities and resistance to wear and tear. This trend not only meets consumer expectations but also aligns with the sustainability narrative, as longer-lasting products contribute to reduced waste.

How Does Sustainability and Ethical Sourcing Impact the Repairable Phone Charger Sector?

Sustainability is no longer just a buzzword; it is a critical factor influencing purchasing decisions in the B2B landscape. The environmental impact of electronic waste is prompting businesses to seek out suppliers who prioritize ethical sourcing and sustainable manufacturing practices. For repairable phone chargers, this involves utilizing recyclable materials and ensuring that production processes minimize carbon footprints.

B2B buyers are increasingly interested in suppliers who can provide transparency regarding their supply chains. Certifications such as ISO 14001 for environmental management and Fair Trade certifications can significantly influence purchasing decisions. These green credentials not only enhance brand reputation but also offer a competitive edge in markets where consumers are willing to pay a premium for sustainable products.

Furthermore, the adoption of repairable designs aligns with the principles of the circular economy, where products are designed for longevity and recyclability. This approach not only reduces waste but also fosters customer loyalty, as businesses that demonstrate a commitment to sustainability can differentiate themselves in a crowded marketplace.

What Is the Evolution of the Repairable Phone Charger Market?

The repairable phone charger market has evolved significantly over the past decade. Initially, the focus was primarily on affordability and basic functionality. However, as environmental concerns gained prominence, manufacturers began to explore innovative solutions that prioritize repairability and sustainability.

Illustrative image related to repairable phone charger

This shift has been characterized by the introduction of modular designs that allow users to replace broken components rather than discarding entire products. Companies like Fairphone have led the charge in demonstrating that repairability can coexist with high performance and durability. As the market matures, the emphasis on ethical sourcing and sustainability is expected to intensify, further reshaping consumer expectations and driving demand for repairable technology solutions.

In conclusion, international B2B buyers must stay attuned to these evolving dynamics, as the interplay between sustainability, technology, and market demand will continue to shape the repairable phone charger sector for years to come.

Frequently Asked Questions (FAQs) for B2B Buyers of repairable phone charger

-

How do I address quality concerns when sourcing repairable phone chargers?

To mitigate quality concerns, it’s essential to conduct thorough supplier vetting. Start by requesting samples to evaluate the product’s durability and performance. Look for certifications that indicate compliance with international safety and quality standards, such as ISO or CE markings. Additionally, consider visiting the manufacturing facility if feasible, or rely on third-party audits. Establishing a clear quality assurance protocol, including regular inspections during production, can further ensure that the products meet your specifications. -

What factors should I consider when choosing a supplier for repairable phone chargers?

When selecting a supplier, prioritize their experience in manufacturing electronic accessories and their commitment to sustainability. Evaluate their production capabilities, lead times, and flexibility in meeting your demands. Research customer reviews and testimonials to gauge their reliability and service quality. Additionally, consider their logistics network, especially for international shipping, to ensure timely delivery. Transparency in communication and a willingness to collaborate on product customization can also indicate a strong partnership. -

What customization options are available for repairable phone chargers?

Many manufacturers offer customization options, including cable lengths, connector types (e.g., USB-C, Lightning, Micro USB), and branding elements like colors or logos. Discuss your specific requirements with potential suppliers to understand their capabilities. Some may also provide bespoke designs tailored to your target market’s preferences. Ensure that any customization aligns with your brand values, particularly regarding sustainability and ethical sourcing. -

What is the minimum order quantity (MOQ) for repairable phone chargers?

The minimum order quantity for repairable phone chargers can vary significantly between suppliers, often ranging from 100 to 1,000 units. Factors influencing MOQ include the manufacturer’s production capacity, the complexity of customization, and material availability. If you are a smaller business, inquire about flexible ordering options or consider consolidating orders with other businesses to meet MOQ requirements. Negotiating MOQ can also be possible, especially if you establish a long-term partnership. -

What payment terms are typically offered for international B2B transactions?

Payment terms can vary, but common practices include a 30% deposit upfront and the remaining 70% before shipment. Some suppliers may offer net 30 or net 60 terms, allowing for payment after delivery. It’s important to discuss and agree upon terms that suit both parties, considering the risks associated with international trade. Utilizing secure payment methods like letters of credit or escrow services can also protect your interests in cross-border transactions. -

How can I ensure timely logistics and delivery for my orders?

To ensure timely logistics, collaborate closely with your supplier to establish clear shipping timelines and methods. Discuss potential shipping options, including air freight for faster delivery or sea freight for cost-effectiveness. Consider working with a freight forwarder who specializes in international shipping to navigate customs and regulations. Regular communication with your supplier regarding order status and anticipated delivery dates can help mitigate any unexpected delays. -

What are the environmental considerations when sourcing repairable phone chargers?

Sourcing repairable phone chargers entails understanding their environmental impact, including the materials used and the manufacturing process. Opt for suppliers who prioritize sustainable practices, such as using recycled materials and ethical sourcing. Verify their commitment to environmental standards and certifications. Additionally, consider the product’s end-of-life recyclability and the supplier’s take-back programs, which contribute to a circular economy and reduce electronic waste. -

How do I handle warranty and after-sales support for repairable phone chargers?

Establish clear warranty terms with your supplier, including the duration and coverage for defects. Many suppliers offer warranties ranging from 1 to 3 years for electronic products. Ensure that the warranty includes repair or replacement options for faulty items. Additionally, discuss after-sales support services, such as technical assistance or return handling procedures. Providing your customers with robust after-sales support will enhance their satisfaction and loyalty, promoting repeat business.

Top 1 Repairable Phone Charger Manufacturers & Suppliers List

1. techong – Repairable Phone Charger BOTH ENDS

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Repairable Phone Charger BOTH ENDS”, “Condition”: “New”, “Price”: “US $30.00”, “Brand”: “techong”, “Type”: “3 in 1 Charging Cable”, “Shipping”: “May not ship to Israel”, “Returns”: “Seller does not accept returns”, “Location”: “Richmond, Texas, United States”, “eBay Item Number”: “363796874892”}

Strategic Sourcing Conclusion and Outlook for repairable phone charger

In the evolving landscape of sustainable technology, the repairable phone charger emerges as a pivotal product for B2B buyers seeking to align with eco-friendly practices. By prioritizing strategic sourcing of repairable chargers, businesses can not only reduce electronic waste but also enhance their brand reputation among environmentally conscious consumers. The ability to repair these chargers extends their life cycle, offering significant cost savings and reducing the need for frequent replacements.

Investing in repairable technology aligns with global sustainability trends, particularly in regions like Africa, South America, the Middle East, and Europe, where regulatory pressures and consumer demand for sustainable products are increasing. Companies such as Fairphone and recable exemplify how high-quality, repairable accessories can provide robust performance while supporting ethical manufacturing processes.

As you consider your procurement strategies, focus on suppliers who emphasize durability, sustainability, and repairability. This approach not only meets market expectations but also positions your business as a leader in the transition towards sustainable technology solutions. Embrace the opportunity to invest in repairable phone chargers and contribute to a more sustainable future while enhancing your competitive edge.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.