Everything You Need to Know About Pulse Jet Dust Collector Sourcing in 2025

Introduction: Navigating the Global Market for pulse jet dust collector

The quest for efficient and effective dust management solutions is a significant challenge faced by manufacturers globally. For businesses in diverse sectors, sourcing a reliable pulse jet dust collector can be pivotal in ensuring compliance with environmental regulations while maintaining operational efficiency. This guide delves into the intricacies of the pulse jet dust collector market, offering invaluable insights tailored for international B2B buyers, particularly those in emerging markets like Nigeria, Vietnam, and across South America, the Middle East, and Europe.

Within these pages, you will discover a comprehensive overview of various types of pulse jet dust collectors, including modular and round configurations, alongside their ideal applications across industries. We will examine the critical factors to consider when vetting suppliers, including their technological advancements and service capabilities. Additionally, the guide will provide a clear analysis of cost implications, enabling businesses to make informed purchasing decisions that align with their budget and operational needs.

By equipping you with the knowledge to navigate this complex landscape, our aim is to empower your organization to select the most suitable pulse jet dust collector for your unique requirements. In a global market that demands efficiency and sustainability, this guide serves as your essential resource for optimizing dust management solutions, ensuring your operations remain compliant and competitive.

Understanding pulse jet dust collector Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

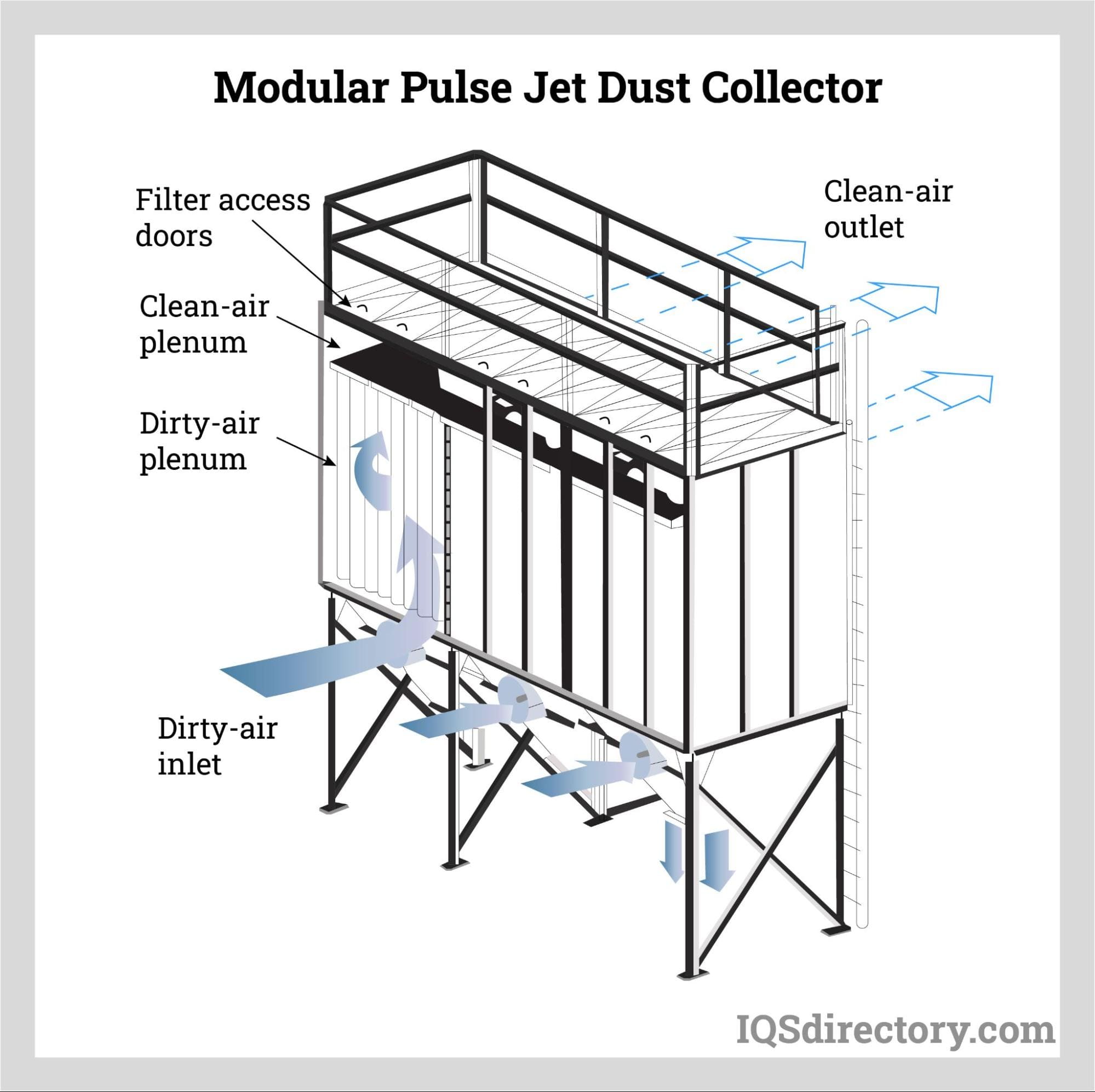

| Modular Pulse Jet Collectors | Flexible design, scalable for various applications | Manufacturing, Food Processing | Pros: Customizable, easy to install. Cons: May require more space. |

| Multi-Modular Pulse Jet Collectors | Prewired sections for large applications, designed for easy transport | Heavy Industry, Mining | Pros: High capacity, efficient. Cons: Higher upfront costs. |

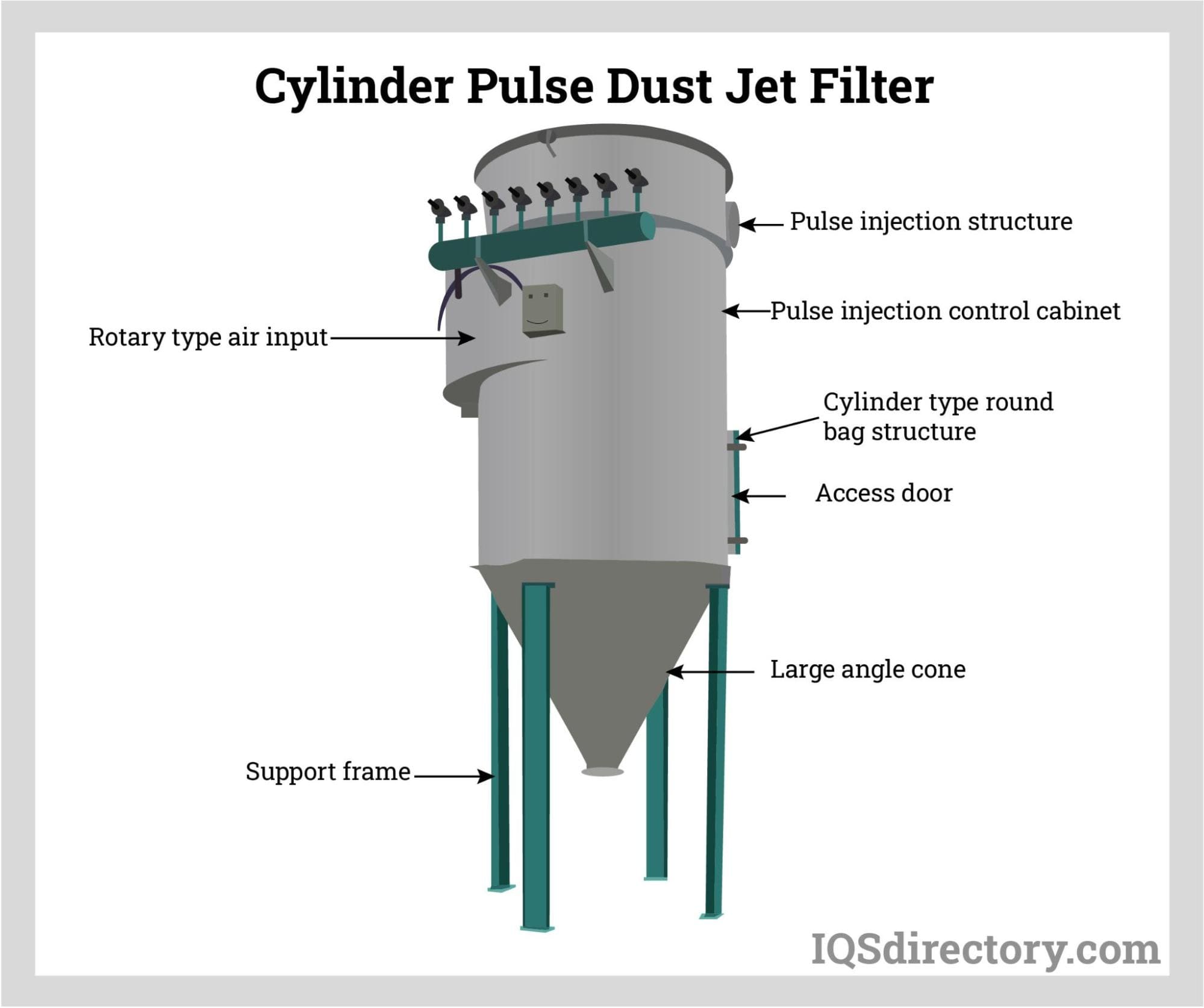

| Round Pulse Jet Collectors | Suitable for high vacuum or pressure, compact design | Chemical Processing, Pharmaceuticals | Pros: Space-saving, effective in tight spaces. Cons: Limited filter area. |

| Flat Bag Pulse Jet Filters | Horizontal layout, efficient cleaning mechanism | Woodworking, Metal Fabrication | Pros: Lower maintenance, easier access. Cons: May have lower airflow capacity. |

| Long Bag Technology | Extended bag length for increased filtration area | Cement, Aggregates, Bulk Material Handling | Pros: Enhanced dust capture, longer filter life. Cons: More complex installation. |

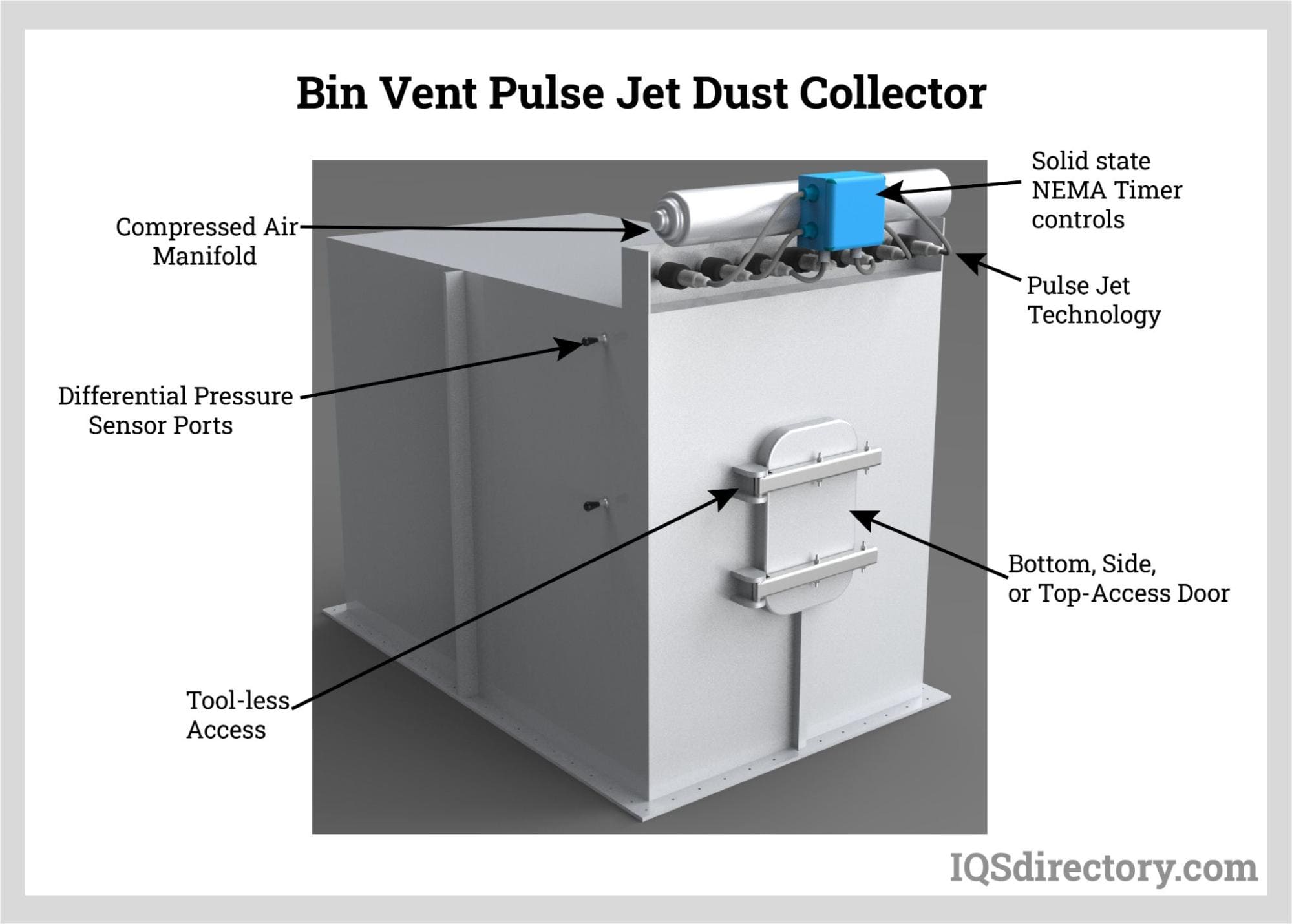

What Are Modular Pulse Jet Collectors and Their Benefits for B2B Buyers?

Modular pulse jet collectors are versatile systems designed for various industrial applications. Their modularity allows businesses to customize the size and capacity according to their specific needs, making them ideal for manufacturing and food processing sectors. Buyers should consider the space available for installation and the scalability of the system as production demands change.

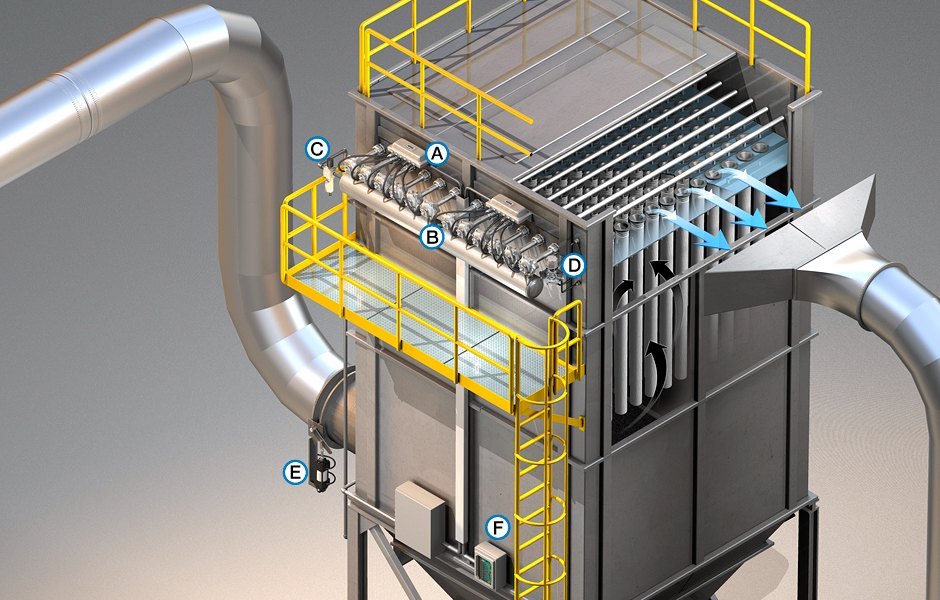

How Do Multi-Modular Pulse Jet Collectors Cater to Large Industries?

Multi-modular pulse jet collectors are engineered for large-scale operations, typically equipped with prewired sections to facilitate transportation and installation. These systems are particularly useful in heavy industries such as mining and construction, where high dust volumes are generated. While they offer excellent efficiency and capacity, businesses should weigh the initial investment against the long-term operational savings.

Illustrative image related to pulse jet dust collector

What Makes Round Pulse Jet Collectors Ideal for Specific Applications?

Round pulse jet collectors are designed for high vacuum or pressure applications, making them suitable for industries like chemical processing and pharmaceuticals. Their compact design allows for installation in confined spaces while maintaining effective dust collection. Buyers should assess the specific pressure and vacuum requirements of their processes to determine suitability.

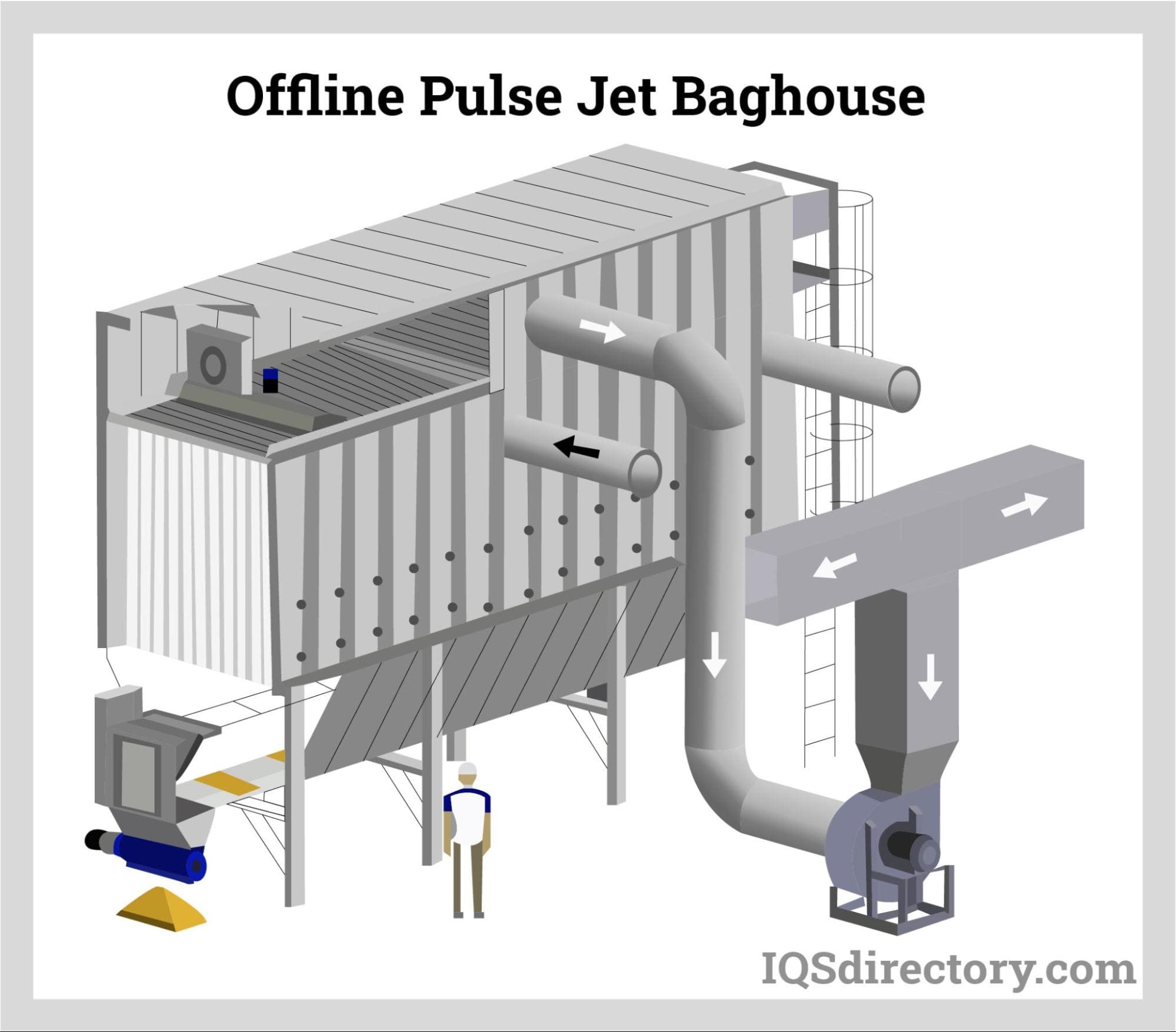

Why Choose Flat Bag Pulse Jet Filters for Your Operations?

Flat bag pulse jet filters feature a horizontal layout, facilitating efficient cleaning and maintenance. They are commonly used in woodworking and metal fabrication industries, where ease of access is crucial. While these filters reduce maintenance efforts, potential buyers should consider their airflow capacity to ensure it meets operational needs.

What Advantages Does Long Bag Technology Offer for Dust Collection?

Long bag technology enhances dust collection efficiency by providing a larger filtration area, making it particularly beneficial in cement and bulk material handling industries. This technology results in longer filter life and improved dust capture rates. However, the complexity of installation may require specialized knowledge, which buyers should account for when considering this option.

Key Industrial Applications of pulse jet dust collector

| Industry/Sector | Specific Application of pulse jet dust collector | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Dust control in metalworking and fabrication | Reduces airborne particulate matter, ensuring a safer workspace and compliance with regulations | Filter efficiency, energy consumption, and ease of maintenance |

| Food Processing | Collection of flour and sugar dust | Minimizes product contamination and maximizes yield | Sanitary design, compliance with food safety standards |

| Pharmaceuticals | Control of hazardous powders and active pharmaceutical ingredients (APIs) | Ensures safe handling of toxic substances and compliance with health regulations | Explosion-proof features, filter material compatibility |

| Mining and Minerals | Dust suppression in mineral extraction | Enhances worker safety and reduces environmental impact | Durability under harsh conditions, modular design for scalability |

| Cement Production | Collection of cement dust during production | Improves air quality and reduces material loss | High filtration efficiency, resistance to high temperatures |

How is a Pulse Jet Dust Collector Used in Manufacturing?

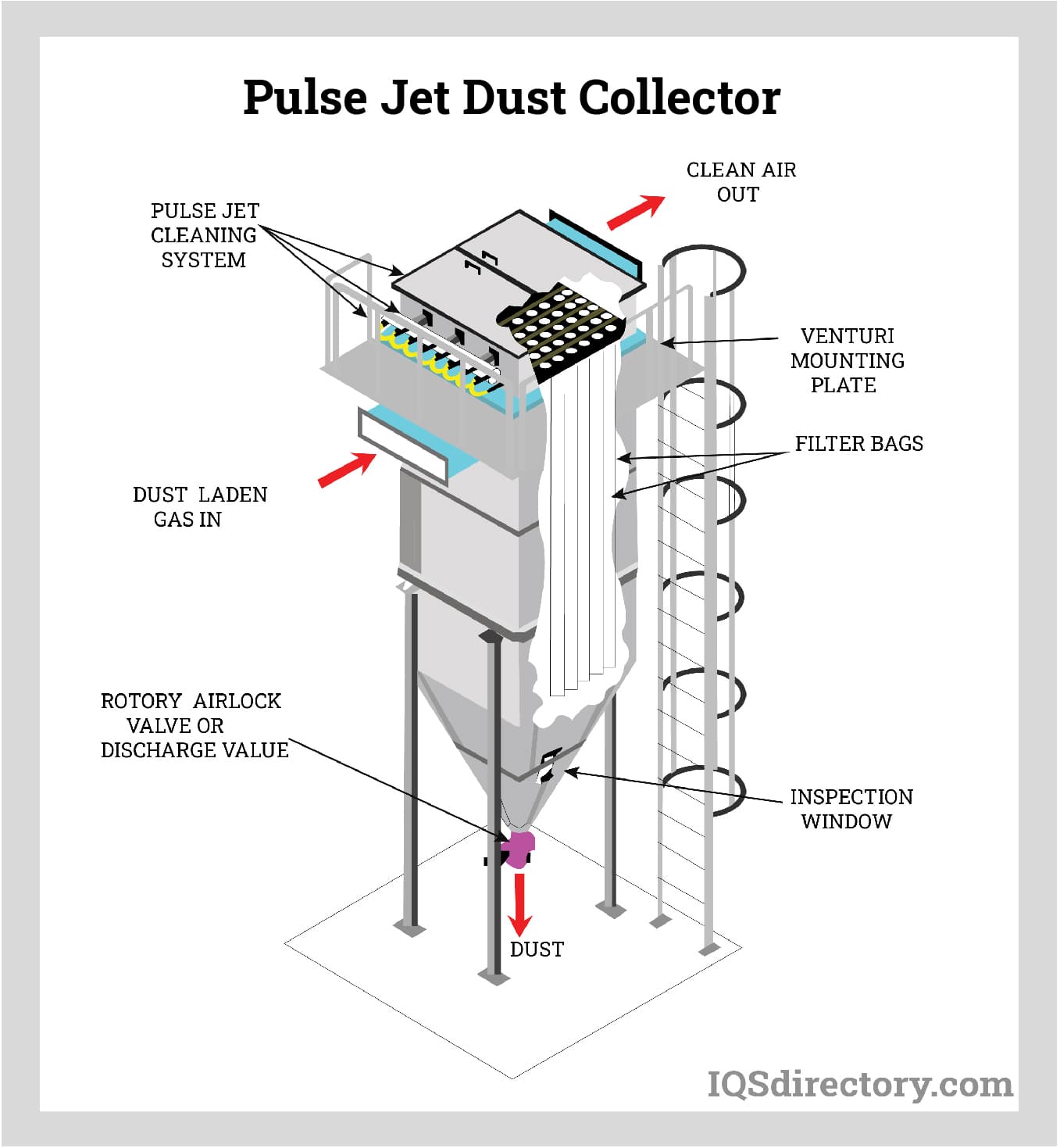

In the manufacturing sector, pulse jet dust collectors are essential for maintaining air quality during metalworking and fabrication processes. These systems utilize bursts of compressed air to dislodge dust from filter bags, ensuring continuous operation without the need for downtime. By effectively capturing harmful particulate matter, manufacturers can comply with health and safety regulations while creating a safer work environment. For international buyers, especially in regions with strict environmental regulations, sourcing a collector that balances filter efficiency and energy consumption is crucial.

What Role Does a Pulse Jet Dust Collector Play in Food Processing?

In food processing, pulse jet dust collectors are vital for managing dust generated from ingredients like flour and sugar. These systems prevent contamination and ensure product quality, which is paramount in this sector. By maintaining a clean environment, companies can maximize yield and comply with food safety standards. Buyers should consider the system’s design to ensure it meets hygiene requirements and operates effectively in high-volume production scenarios, particularly in regions like Africa and South America where food safety regulations are evolving.

Why is a Pulse Jet Dust Collector Critical in Pharmaceuticals?

The pharmaceutical industry often handles hazardous powders, making effective dust control essential. Pulse jet dust collectors help manage these substances, ensuring safe handling and compliance with health regulations. These systems must have explosion-proof features and filter materials compatible with toxic substances. For international buyers, particularly in emerging markets, it’s vital to source equipment that not only meets local compliance standards but is also durable and reliable under various operational conditions.

How Does a Pulse Jet Dust Collector Enhance Safety in Mining and Minerals?

In the mining and minerals sector, dust suppression is critical to worker safety and environmental protection. Pulse jet dust collectors efficiently capture dust generated during mineral extraction, minimizing health risks and environmental impact. Buyers should look for systems that are durable and can withstand harsh conditions, as well as modular designs that allow for scalability as operations grow. This is particularly important in regions like the Middle East, where mining operations are expanding rapidly.

Illustrative image related to pulse jet dust collector

What Benefits Does a Pulse Jet Dust Collector Offer in Cement Production?

Cement production generates significant dust, making effective dust collection systems essential for improving air quality and reducing material loss. Pulse jet dust collectors capture cement dust during production processes, helping to maintain compliance with environmental regulations. When sourcing these systems, businesses should prioritize high filtration efficiency and the ability to resist high temperatures, especially in regions like Europe where environmental standards are stringent.

3 Common User Pain Points for ‘pulse jet dust collector’ & Their Solutions

Scenario 1: Difficulty in Maintaining Optimal Filter Efficiency

The Problem: Many B2B buyers encounter significant challenges with maintaining optimal filter efficiency in pulse jet dust collectors, particularly in industries where dust loads are high. Over time, accumulated dust can lead to increased pressure drop, reduced airflow, and ultimately, diminished performance of the dust collection system. This not only impacts operational efficiency but can also lead to costly downtime and maintenance issues, especially if the system requires frequent shutdowns for cleaning. Buyers often struggle to find effective solutions that allow for continuous operation while ensuring maximum filtration performance.

The Solution: To combat this issue, buyers should consider investing in advanced filter technologies such as Ultra-Web SB pleated bags, which are designed to maintain higher filtration efficiency for longer periods. These filters utilize a unique fiber technology that traps dust on the surface, resulting in less frequent cleaning cycles and extended filter life. Additionally, implementing a remote monitoring system, like Donaldson’s iCue™ Connected Filtration Technology, can provide real-time insights into the dust collector’s performance. This allows operators to schedule maintenance proactively, preventing unplanned downtime and ensuring the system runs at peak efficiency. Regularly reviewing and optimizing the cleaning pulse settings can also help maintain filter performance by effectively dislodging accumulated dust without damaging the filter media.

Scenario 2: High Operational Costs Due to Frequent Filter Changes

The Problem: Another common pain point for B2B buyers is the high operational costs associated with frequent filter replacements in pulse jet dust collectors. Traditional filter bags often have a shorter lifespan and require regular replacements, which can strain budgets and disrupt operations. Companies may find themselves incurring not only the cost of replacement filters but also additional expenses related to labor, downtime, and disposal of used filters. This becomes particularly critical in regions with limited access to replacement parts or where shipping delays can exacerbate operational challenges.

The Solution: To mitigate these costs, buyers should evaluate the benefits of investing in longer-lasting filter options like Dura-Life® filter bags. These bags are engineered to provide twice the lifespan of standard polyester bags, significantly reducing the frequency of replacements. Furthermore, integrating a comprehensive maintenance plan that includes regular inspections and monitoring can help identify potential issues before they escalate, thereby extending the life of the entire dust collection system. Buyers should also consider partnering with suppliers who offer bundled services, including installation, maintenance, and filter replacement, to streamline operations and manage costs more effectively.

Scenario 3: Compliance Challenges with Environmental Regulations

The Problem: Compliance with environmental regulations is a major concern for many B2B buyers using pulse jet dust collectors. As regulations become more stringent, particularly regarding emissions and air quality standards, companies face the risk of penalties or shutdowns if their dust collection systems do not meet compliance requirements. Buyers may struggle with selecting the right equipment that not only adheres to local regulations but also provides adequate performance in capturing fine particulate matter.

The Solution: To address compliance challenges, buyers should focus on selecting pulse jet dust collectors that are specifically designed to meet or exceed regulatory standards. For instance, systems that incorporate advanced filtration technologies, like the Ultra-Web® pleated filters, are proven to capture a higher percentage of fine dust particles, thus reducing emissions. Additionally, implementing a robust data tracking system can help organizations maintain accurate records of their dust collection system’s performance and compliance status. Regular audits and maintenance checks should be scheduled to ensure that the equipment continues to perform optimally and adheres to environmental regulations. Engaging with suppliers that provide compliance support can also be beneficial, as they often have the expertise to guide companies through the regulatory landscape effectively.

Strategic Material Selection Guide for pulse jet dust collector

What Are the Key Materials Used in Pulse Jet Dust Collectors?

When selecting materials for pulse jet dust collectors, understanding the properties and suitability of various options is crucial. Here, we analyze four common materials: polyester, polypropylene, fiberglass, and stainless steel. Each material has unique characteristics that can significantly impact the performance and longevity of dust collection systems.

How Does Polyester Perform in Pulse Jet Dust Collectors?

Polyester is one of the most widely used materials for filter bags in pulse jet dust collectors. It offers excellent filtration efficiency and can withstand temperatures up to 190°C (375°F). Its inherent resistance to moisture and chemicals makes it suitable for a variety of applications, particularly in industries dealing with non-corrosive dust.

Pros: Polyester is durable, cost-effective, and easy to manufacture. It provides a good balance between performance and price, making it a popular choice for many applications.

Illustrative image related to pulse jet dust collector

Cons: However, polyester is not suitable for high-temperature applications beyond its rated limit and can degrade in highly acidic or alkaline environments.

Impact on Application: Polyester is compatible with a wide range of dust types, making it versatile for various industries.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards (e.g., ASTM) and consider the availability of polyester bags in their markets.

What Advantages Does Polypropylene Offer?

Polypropylene is another synthetic material used in pulse jet dust collectors, particularly for applications involving moisture-laden dust. It can withstand temperatures up to 82°C (180°F) and is highly resistant to chemical corrosion.

Pros: Polypropylene is lightweight, making it easier to handle and install. Its cost is generally lower than polyester, making it an attractive option for budget-conscious buyers.

Illustrative image related to pulse jet dust collector

Cons: The temperature limitation of polypropylene restricts its use in high-heat applications. Additionally, it may not be suitable for all types of dust, particularly those that are abrasive.

Impact on Application: Its chemical resistance makes it ideal for industries like food processing and pharmaceuticals.

Considerations for International Buyers: Buyers should verify compliance with local regulations and the availability of polypropylene options in their specific regions.

Why Choose Fiberglass for High-Temperature Applications?

Fiberglass is an excellent choice for high-temperature applications, withstanding temperatures up to 260°C (500°F). It is often used in industries such as metalworking and cement production, where high heat is prevalent.

Pros: Fiberglass offers exceptional durability and can handle abrasive dust particles without significant wear.

Cons: The manufacturing process for fiberglass can be more complex and expensive, leading to higher costs compared to synthetic alternatives.

Impact on Application: Its high-temperature resistance makes it suitable for environments where other materials would fail.

Considerations for International Buyers: Compliance with industry standards such as DIN or JIS is vital, particularly in regions like Europe and the Middle East where such regulations are stringent.

What Role Does Stainless Steel Play in Dust Collector Design?

Stainless steel is primarily used in the construction of dust collector frames and housings rather than filter media. It offers excellent corrosion resistance and can withstand harsh environmental conditions.

Pros: Its durability and strength make stainless steel a long-lasting option, reducing the need for frequent replacements.

Cons: The cost of stainless steel is significantly higher than that of synthetic materials, which may be a barrier for some buyers.

Illustrative image related to pulse jet dust collector

Impact on Application: Stainless steel is ideal for applications involving corrosive materials or extreme environmental conditions.

Considerations for International Buyers: Buyers should consider the cost-benefit ratio and availability of stainless steel options in their regions, particularly in developing markets.

Summary Table of Material Selection for Pulse Jet Dust Collectors

| Material | Typical Use Case for pulse jet dust collector | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | General dust collection | Cost-effective and durable | Limited high-temperature resistance | Medium |

| Polypropylene | Moisture-laden dust applications | Lightweight and low cost | Low temperature limit | Low |

| Fiberglass | High-temperature environments | Excellent durability | Higher manufacturing complexity | High |

| Stainless Steel | Corrosive or harsh environments | Exceptional strength and longevity | Higher initial cost | High |

This strategic material selection guide provides valuable insights for B2B buyers, enabling informed decisions tailored to specific industrial needs and regional compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for pulse jet dust collector

What Are the Main Stages in the Manufacturing Process of Pulse Jet Dust Collectors?

The manufacturing process for pulse jet dust collectors involves several critical stages that ensure the final product meets high-quality standards and performance expectations. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Are Components Selected and Processed?

The first step in manufacturing pulse jet dust collectors is selecting the appropriate materials, typically high-grade steel or aluminum, to ensure durability and resistance to corrosion. The material is often pre-treated to enhance its properties; for instance, steel may undergo galvanization or coating to improve its resistance to rust and wear.

Once the materials are sourced, they are cut and shaped according to the specifications of the dust collector design. Advanced techniques such as laser cutting or water jet cutting are often employed to achieve precise dimensions, which is crucial for the subsequent assembly process.

Forming: What Techniques Are Used to Shape the Dust Collector Components?

After material preparation, the forming stage begins. This involves shaping the cut materials into the various components of the dust collector, such as the hopper, filter housing, and ducting. Techniques such as bending, welding, and stamping are commonly used.

For instance, the use of robotic welding ensures strong, consistent joints that enhance the structural integrity of the dust collector. Additionally, forming processes may include the creation of custom features, such as access panels and mounting points, to facilitate easier maintenance and installation.

Assembly: How Are Components Joined to Form the Final Product?

Once the individual components are shaped, they move to the assembly stage. This is a critical phase where all parts are combined to create the final pulse jet dust collector. The assembly process often employs modular approaches, allowing for flexibility and scalability in production.

During assembly, components like the filter bags, fans, and electronic controls are integrated. This stage is also where quality checks begin, ensuring each part fits correctly and operates as intended. A focus on ergonomic design can enhance ease of use and maintenance, which is particularly valuable for international buyers who may face logistical challenges.

Finishing: What Processes Ensure the Dust Collector Meets Standards?

The finishing stage involves applying protective coatings and treatments to enhance the dust collector’s longevity and aesthetic appeal. This can include painting, powder coating, or applying specialized finishes that improve resistance to various environmental factors.

In addition, the final inspection occurs during this stage, where each unit is checked for compliance with design specifications and quality standards before being packaged for shipment.

What Quality Assurance Measures Are Implemented in Manufacturing Pulse Jet Dust Collectors?

Quality assurance (QA) is vital in ensuring that pulse jet dust collectors perform reliably and meet international standards. Various QA measures are employed throughout the manufacturing process to maintain product integrity.

Which International Standards Are Relevant for Quality Assurance?

Manufacturers typically adhere to internationally recognized quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards indicates that the manufacturer has established processes to ensure consistent quality and customer satisfaction.

Additionally, industry-specific certifications such as CE marking (indicating conformity with European health, safety, and environmental protection standards) or API standards (for manufacturers in the oil and gas sector) may also apply, depending on the end-use of the dust collector.

What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) checkpoints are integrated into various stages of the manufacturing process. These checkpoints typically include:

Illustrative image related to pulse jet dust collector

-

Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival at the facility to ensure they meet specified standards before processing begins.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor the quality of the work being performed. This can include checking welds, dimensions, and component fit.

-

Final Quality Control (FQC): Before shipping, the completed dust collectors undergo a thorough final inspection to verify that they meet all design specifications and functional requirements.

What Common Testing Methods Are Used to Ensure Quality?

Various testing methods are employed to validate the performance of pulse jet dust collectors. These can include:

- Performance Testing: Assessing airflow rates, pressure drops, and filtration efficiency to ensure the dust collector operates effectively under expected conditions.

- Durability Testing: Subjecting components to stress tests to evaluate their resilience under operational scenarios.

- Leak Testing: Checking for any potential leaks in the system that could compromise performance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is crucial. Here are several actionable strategies:

What Steps Can Buyers Take to Conduct Supplier Audits?

Buyers should conduct regular supplier audits to assess compliance with quality standards and practices. This may involve visiting the manufacturing facility to observe processes, review documentation, and evaluate the effectiveness of quality control measures.

How Can Buyers Request Quality Control Reports?

Requesting detailed quality control reports can provide insights into a supplier’s manufacturing processes and outcomes. These reports should include data on inspection results, testing outcomes, and compliance with international standards.

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can add an extra layer of assurance for buyers. Independent inspectors can evaluate the manufacturing process, conduct tests, and provide unbiased reports on the quality of the dust collectors. This is particularly beneficial for buyers unfamiliar with local suppliers or those operating in regions with varying quality standards.

Illustrative image related to pulse jet dust collector

What Are the Quality Certification Nuances for International Buyers?

International buyers need to be aware of the nuances associated with quality certifications. Different regions may have varying requirements for certifications, which can impact the import and use of pulse jet dust collectors.

Understanding these nuances helps buyers ensure compliance with local regulations and standards, potentially avoiding costly delays or penalties. It is advisable to consult with industry experts or legal advisors familiar with the specific requirements of the target market.

In conclusion, the manufacturing processes and quality assurance practices for pulse jet dust collectors are multifaceted and critical to ensuring product reliability and performance. By understanding these processes, B2B buyers can make informed decisions when sourcing dust collectors, ensuring that they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pulse jet dust collector’

Introduction

Acquiring a pulse jet dust collector is a significant investment that requires careful consideration of various factors. This guide serves as a practical checklist to help B2B buyers navigate the procurement process effectively. By following these steps, you can ensure that you select the right equipment tailored to your operational needs while maximizing efficiency and minimizing costs.

Step 1: Define Your Technical Specifications

Before you start searching for suppliers, it’s essential to outline the specific technical requirements of your dust collection system. Consider factors such as airflow capacity, filter media type, and application environment.

– Airflow Capacity: Determine the volume of air that needs to be filtered to ensure adequate performance.

– Filter Media: Decide between different filter options, such as pleated bags or traditional bags, based on your dust type and desired efficiency.

Step 2: Assess Your Budget Constraints

Establishing a budget is crucial to avoid overspending while ensuring you acquire a high-quality dust collector. Take into account not just the purchase price but also long-term operational costs, including maintenance and energy consumption.

– Cost of Ownership: Factor in the lifespan of filter media and potential energy savings from more efficient systems.

– Total Cost of Installation: Include costs for installation, training, and any necessary accessories.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they meet industry standards and have a proven track record. Request detailed company profiles, case studies, and references from clients in similar sectors or regions.

– Supplier Experience: Look for suppliers with extensive experience in your industry to ensure they understand specific challenges.

– Customer Support: Assess the level of post-purchase support and service offerings, including maintenance and troubleshooting assistance.

Step 4: Verify Compliance and Certifications

Ensure that the dust collector complies with local and international regulations, as well as industry-specific standards. This is vital for both legal compliance and operational safety.

– Certifications: Look for certifications such as ISO, CE, or specific environmental standards relevant to your region.

– Safety Features: Confirm that the equipment includes necessary safety features, such as explosion vents or spark mitigation systems.

Step 5: Review Maintenance and Replacement Parts Availability

A dust collector’s long-term performance heavily relies on its maintenance and the availability of replacement parts. Ensure that the supplier offers easy access to parts and support.

– Maintenance Plans: Inquire about recommended maintenance schedules and available service contracts.

– Part Availability: Verify that replacement filters and components can be easily sourced locally or through the supplier.

Step 6: Consider Technological Features

Modern pulse jet dust collectors often come equipped with advanced technology that enhances performance and monitoring. Assess these features based on your operational needs.

– Smart Monitoring: Look for options like remote monitoring systems that provide real-time data on collector performance.

– Energy Efficiency: Evaluate features that can reduce energy consumption, such as variable speed fans or efficient filter designs.

Step 7: Finalize Your Decision

After completing the previous steps, compile all gathered information and compare your options. Consider not just the initial costs but also the total value each option provides, including operational efficiency and reliability.

– Stakeholder Input: Involve key team members in the decision-making process to ensure all perspectives are considered.

– Trial Periods: If possible, negotiate trial periods or demonstrations to evaluate performance before finalizing your purchase.

Illustrative image related to pulse jet dust collector

By following this structured checklist, you can streamline the sourcing process for a pulse jet dust collector, ensuring you make an informed and strategic investment for your business.

Comprehensive Cost and Pricing Analysis for pulse jet dust collector Sourcing

What Are the Key Cost Components in Pulse Jet Dust Collector Sourcing?

When sourcing pulse jet dust collectors, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The quality of materials used significantly impacts the overall cost. For instance, advanced filter technologies, such as Dura-Life or Ultra-Web SB pleated bags, can increase initial costs but offer longer life and lower maintenance expenses.

-

Labor: Labor costs vary based on the complexity of manufacturing processes and the expertise required. Skilled labor may command higher wages, especially in regions with limited availability of qualified workers.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities and equipment depreciation. Efficient manufacturing processes can help reduce overhead, allowing suppliers to offer competitive pricing.

-

Tooling: Customization often necessitates specialized tooling, which can add to the upfront costs. Buyers should consider the tooling requirements when requesting custom specifications.

-

Quality Control (QC): Rigorous QC processes are essential to ensure that dust collectors meet industry standards and performance specifications. Enhanced QC measures may incur additional costs but can lead to improved product reliability.

-

Logistics: Shipping and handling costs, influenced by distance, weight, and packaging, can significantly affect total expenses. Buyers should factor in these costs, especially when sourcing from international suppliers.

-

Margin: Supplier margins can vary widely based on market conditions and the supplier’s positioning. Understanding these margins helps buyers gauge the overall value offered.

How Do Price Influencers Affect the Cost of Pulse Jet Dust Collectors?

Several factors can influence pricing when sourcing pulse jet dust collectors, particularly for international B2B buyers:

-

Volume/MOQ: Purchasing in bulk can lead to significant discounts, making it advantageous for companies with high demand. Minimum order quantities (MOQ) can also affect pricing, with lower MOQs often resulting in higher per-unit costs.

-

Specifications/Customization: Custom features, such as specific filter media or unique configurations, can drive up costs. Buyers should assess whether the added functionality justifies the expense.

-

Materials: The choice of materials directly correlates with durability and performance. High-grade materials may increase initial costs but can result in long-term savings through reduced maintenance and downtime.

-

Quality and Certifications: Compliance with international standards (e.g., ISO certifications) may raise costs but can be crucial for regulatory compliance in certain markets. Buyers should weigh the importance of these certifications against their budget constraints.

-

Supplier Factors: The reputation, reliability, and financial stability of suppliers can impact pricing. Established suppliers may offer higher prices due to their proven track record, while newer entrants might provide lower prices to gain market share.

-

Incoterms: Understanding Incoterms is vital for international transactions. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, directly affecting the total landed cost.

What Are Effective Buyer Tips for Cost-Efficiency in Sourcing?

To maximize cost-efficiency in sourcing pulse jet dust collectors, buyers should consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing, especially for bulk orders or long-term contracts. Effective negotiation can yield better pricing and terms.

-

Total Cost of Ownership (TCO): Evaluate the TCO, which includes purchase price, operational costs, maintenance, and disposal. A lower upfront cost may not always translate to savings if operational efficiency is compromised.

-

Pricing Nuances for International Buyers: For buyers from regions like Africa, South America, the Middle East, and Europe, understanding local market dynamics, currency fluctuations, and import tariffs is crucial for accurate cost estimation.

-

Request for Quotes (RFQs): Sending RFQs to multiple suppliers can help compare pricing and services. Ensure that RFQs are detailed to receive comparable quotes.

-

Long-Term Relationships: Building long-term partnerships with suppliers can lead to better pricing and service levels over time, as suppliers may offer loyalty discounts or favorable terms.

Disclaimer

Prices for pulse jet dust collectors can vary significantly based on the factors discussed above. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing pulse jet dust collector With Other Solutions

Introduction: Exploring Alternatives to Pulse Jet Dust Collectors

When considering effective dust collection solutions, it’s essential to explore various alternatives to pulse jet dust collectors. Each technology has its own set of advantages and limitations that can influence operational efficiency, maintenance costs, and overall effectiveness. In this analysis, we will compare pulse jet dust collectors against two viable alternatives: cartridge dust collectors and cyclonic dust collectors. This comparison aims to equip B2B buyers with actionable insights to make informed decisions tailored to their specific industrial needs.

| Comparison Aspect | Pulse Jet Dust Collector | Cartridge Dust Collector | Cyclonic Dust Collector |

|---|---|---|---|

| Performance | High filtration efficiency; ideal for high dust loads | Excellent for fine dust; requires less space | Good for larger particles; less effective for fine dust |

| Cost | Moderate initial investment; lower long-term maintenance costs | Generally lower initial cost; higher filter replacement costs | Low initial cost; minimal ongoing costs |

| Ease of Implementation | Moderate complexity; requires space for ducting and installation | Easier to install; compact design | Simple installation; minimal space requirements |

| Maintenance | Regular maintenance needed; efficient bag cleaning reduces downtime | Frequent filter replacements; can lead to higher operational costs | Low maintenance; minimal parts to replace |

| Best Use Case | Heavy-duty industrial applications with high dust loads | Facilities with limited space and fine particulate matter | Operations dealing with larger, heavier dust particles |

Detailed Breakdown of Alternatives

Cartridge Dust Collectors

Cartridge dust collectors utilize cylindrical filter cartridges that capture dust and particulates. They are ideal for environments with limited space, offering a compact design that can fit into smaller facilities. Their ease of installation and low upfront costs make them appealing for smaller operations. However, they require more frequent filter replacements, which can escalate operational costs over time. While they perform well for fine dust, they may not handle high dust loads as efficiently as pulse jet systems.

Cyclonic Dust Collectors

Cyclonic dust collectors operate by using centrifugal force to separate larger particles from the air stream. This technology is simple and cost-effective, making it an attractive option for many industries. The low initial investment and minimal ongoing maintenance are significant advantages. However, cyclonic collectors are less effective for fine dust and may not meet the stringent filtration requirements of certain applications. They are best suited for operations that primarily deal with larger dust particles, making them a less versatile option than pulse jet collectors.

Conclusion: Choosing the Right Dust Collection Solution

Selecting the right dust collection solution requires a careful evaluation of your specific operational needs and constraints. Pulse jet dust collectors are optimal for heavy-duty applications with high dust loads, offering superior filtration efficiency and lower long-term maintenance costs. In contrast, cartridge dust collectors provide a space-efficient solution for fine dust but may incur higher ongoing costs. Cyclonic dust collectors, while cost-effective and low-maintenance, are best suited for larger particles and may not meet all filtration requirements. By assessing factors such as performance, cost, ease of implementation, and maintenance, B2B buyers can make an informed decision that aligns with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for pulse jet dust collector

What Are the Key Technical Properties of Pulse Jet Dust Collectors?

When selecting a pulse jet dust collector, understanding its technical specifications is essential for optimizing performance and ensuring compliance with industry standards. Here are some critical specifications that international B2B buyers should consider:

-

Filter Media Area: This refers to the total surface area of the filter bags within the collector. A larger filter media area enhances dust collection efficiency and extends the time between necessary maintenance. For example, collectors with media areas ranging from 14 m² to 766 m² can accommodate various applications, ensuring that operational needs are met without frequent downtime.

-

Airflow Capacity: Measured in cubic feet per minute (CFM) or cubic meters per hour (m³/h), airflow capacity indicates the volume of air the dust collector can handle. It is crucial for determining the collector’s suitability for specific industrial applications. A pulse jet collector must match the system’s airflow requirements to maintain optimal dust filtration and avoid system overload.

-

Pressure Drop: This specification measures the resistance to airflow through the filter media, typically expressed in inches of water gauge (in. wg) or pascals (Pa). A lower pressure drop is desirable as it indicates that the system operates efficiently, reducing energy costs and minimizing wear on fans and motors. Buyers should look for systems that balance effective filtration with minimal pressure drop.

-

Material Construction: The construction material of a dust collector significantly impacts its durability and performance. Common materials include carbon steel and stainless steel, each offering different benefits. Stainless steel is ideal for corrosive environments, while carbon steel is often more cost-effective. Understanding material properties helps in selecting a collector suited for specific operational conditions.

-

Cleaning Mechanism: The pulse jet cleaning mechanism is a defining feature of these dust collectors, using compressed air to dislodge dust from filter bags. This capability allows for continuous operation without the need for manual cleaning. Knowing the efficiency of the cleaning mechanism can help buyers evaluate the total cost of ownership, including maintenance and downtime.

-

Compliance Standards: Dust collectors must meet various environmental and safety regulations, such as those set by the EPA or local authorities. Compliance ensures that the system operates within legal limits for emissions and safety standards, which is crucial for avoiding penalties and maintaining a good reputation.

What Are Common Trade Terms Related to Pulse Jet Dust Collectors?

Understanding industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some key terms commonly used in the dust collector market:

-

OEM (Original Equipment Manufacturer): Refers to a company that produces components or equipment that are sold under another company’s brand. Buyers should consider OEM parts for reliability and compatibility, especially when sourcing replacement filters or parts.

-

MOQ (Minimum Order Quantity): This term indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budget planning and inventory management, particularly for buyers in regions with limited suppliers.

-

RFQ (Request for Quotation): An RFQ is a document issued by a buyer to solicit price offers from suppliers for specific products or services. Crafting a detailed RFQ ensures that potential suppliers provide accurate and comparable quotes, facilitating informed decision-making.

-

Incoterms: Short for International Commercial Terms, these are standardized terms used in international trade to define the responsibilities of buyers and sellers. Familiarity with Incoterms is crucial for understanding shipping costs, risk transfer, and delivery obligations.

-

Turnkey Solutions: This term refers to a complete product or service package that is ready for immediate use upon delivery. Buyers seeking integrated dust collection systems may prefer turnkey solutions to streamline installation and reduce time to operation.

-

Technical Support: This encompasses assistance provided by manufacturers or suppliers regarding product installation, operation, and maintenance. Reliable technical support is critical for minimizing downtime and ensuring that the dust collector operates efficiently throughout its lifespan.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency, compliance, and cost-effectiveness in their dust collection processes.

Navigating Market Dynamics and Sourcing Trends in the pulse jet dust collector Sector

What Are the Current Market Dynamics and Key Trends in the Pulse Jet Dust Collector Sector?

The pulse jet dust collector market is experiencing significant growth driven by increasing industrialization, stringent environmental regulations, and heightened awareness of workplace safety. Global markets, particularly in Africa, South America, the Middle East, and Europe, are witnessing a surge in demand for efficient dust collection solutions that comply with regulatory standards while enhancing operational productivity. Key trends include the adoption of smart technologies such as IoT-enabled monitoring systems that provide real-time insights into equipment performance, allowing businesses to optimize maintenance schedules and minimize downtime.

Moreover, as industries evolve, there is a growing emphasis on modular designs that facilitate scalability and adaptability to diverse operational needs. For international buyers, particularly in developing regions like Nigeria and Vietnam, sourcing pulse jet dust collectors equipped with advanced filtration technologies, such as pleated filter bags that offer longer life and lower emissions, is becoming a priority. This shift not only supports operational efficiency but also aligns with global sustainability goals.

How Is Sustainability and Ethical Sourcing Influencing the Pulse Jet Dust Collector Market?

Sustainability is increasingly shaping the procurement strategies of B2B buyers in the pulse jet dust collector market. Companies are under pressure to reduce their environmental impact, which has led to a demand for equipment that not only meets performance standards but also adheres to eco-friendly practices. Buyers are now prioritizing manufacturers who utilize sustainable materials and processes, thus ensuring that their supply chains are ethically sound.

In this context, certifications such as ISO 14001 for environmental management and adherence to EU regulations on emissions are becoming critical factors in supplier selection. Moreover, manufacturers are innovating with ‘green’ materials in their filter media, such as those derived from recycled sources, to enhance performance while reducing waste. By choosing suppliers who prioritize sustainability, B2B buyers can enhance their corporate responsibility profile and meet the growing expectations of stakeholders and consumers alike.

What Has Been the Evolution of the Pulse Jet Dust Collector Technology?

The evolution of pulse jet dust collector technology can be traced back to the early industrial revolution when the need for effective dust control in manufacturing processes first emerged. Initially, these systems were rudimentary, relying on gravity and basic filtration methods. However, as industries expanded and regulatory pressures increased, the technology advanced significantly.

Today, modern pulse jet collectors utilize sophisticated mechanisms such as compressed air pulses for efficient bag cleaning, enhancing filter life and operational efficiency. Innovations in filter materials, such as pleated designs and advanced coatings, have further improved dust capture capabilities while reducing energy consumption. This evolution reflects a broader trend towards integrating technology in industrial processes, ensuring that dust collection systems are not only effective but also responsive to the dynamic needs of modern manufacturing environments. For B2B buyers, understanding this historical context helps in making informed decisions about future investments in dust collection technology.

Frequently Asked Questions (FAQs) for B2B Buyers of pulse jet dust collector

-

How do I solve dust collection inefficiencies in my facility?

To address dust collection inefficiencies, start by assessing the existing system’s performance, including filter conditions and airflow rates. Implementing a pulse jet dust collector can significantly enhance efficiency by using bursts of compressed air to clean filter bags without shutting down operations. Additionally, consider upgrading to advanced filter media, such as pleated bags or Dura-Life bags, which offer longer service life and lower pressure drops. Regular maintenance and monitoring are also essential to ensure optimal performance and compliance with environmental regulations. -

What is the best pulse jet dust collector for high-volume applications?

For high-volume applications, modular pulse jet dust collectors are recommended due to their scalability and efficient cleaning capabilities. These systems can accommodate larger filter media areas, which are essential for handling substantial dust loads. Brands like Donaldson and Nederman MikroPul offer tailored solutions that can be configured based on specific operational needs. Evaluate factors such as airflow requirements, space constraints, and the type of dust being collected to determine the most suitable model for your application. -

What customization options are available for pulse jet dust collectors?

Many manufacturers provide customization options for pulse jet dust collectors, including variations in filter media, size, and discharge configurations. You can also choose features like integrated monitoring systems, explosion vents, and specialized fan systems. Discussing your specific operational requirements with suppliers can lead to tailored solutions that enhance performance and meet regulatory standards. Always inquire about the potential for future scalability and adaptability to accommodate changing production needs. -

What are the minimum order quantities (MOQs) for pulse jet dust collectors?

Minimum order quantities can vary significantly between manufacturers and depend on the complexity of the equipment. Typically, standard models may have lower MOQs, while customized solutions could require larger orders. It’s advisable to engage with multiple suppliers to compare MOQs and explore options for smaller trial orders if you’re testing a new design or technology. This approach can help mitigate financial risks while ensuring you receive the necessary equipment for your operations. -

What payment terms should I expect when purchasing a pulse jet dust collector?

Payment terms can differ widely based on the supplier and region. Common arrangements include upfront deposits, progressive payments during manufacturing, and final payments upon delivery or installation. Some suppliers may offer financing options or extended payment plans for larger purchases. It is crucial to clarify these terms in advance to avoid misunderstandings and ensure a smooth transaction process. Always review the supplier’s credit terms and policies to align with your company’s financial practices. -

How can I ensure the quality of the pulse jet dust collector I purchase?

To ensure quality, conduct thorough research on potential suppliers, including their manufacturing processes, certifications, and customer reviews. Request product samples or case studies demonstrating the performance of their dust collectors in similar applications. Additionally, inquire about quality assurance processes, warranties, and after-sales support. Engaging with suppliers who have a strong track record in your industry can provide added confidence in the reliability of their equipment. -

What logistics considerations should I keep in mind when sourcing pulse jet dust collectors internationally?

When sourcing pulse jet dust collectors internationally, consider shipping times, customs regulations, and import duties that may apply to your region. Collaborate with suppliers who have experience in international trade to streamline the logistics process. It’s also vital to evaluate the supplier’s ability to provide support during the installation and commissioning phases. Establishing clear communication regarding delivery timelines and responsibilities can help mitigate potential delays and ensure a successful project completion. -

How do I vet suppliers of pulse jet dust collectors for international purchases?

To effectively vet suppliers, start by checking their credentials, such as industry certifications and compliance with international standards. Seek recommendations from industry peers and review case studies or references from similar projects. Conduct site visits if feasible or request virtual tours of their manufacturing facilities. Additionally, assess their customer service responsiveness and support capabilities to ensure they can address your needs throughout the purchasing process. An informed decision can lead to a more successful partnership and better equipment performance.

Top 8 Pulse Jet Dust Collector Manufacturers & Suppliers List

1. Donaldson – FT Pulse Jet Baghouse Dust Collector

Domain: donaldson.com

Registered: 1995 (30 years)

Introduction: FT Pulse Jet Baghouse Dust Collector by Donaldson Torit offers easy and dependable operation for high-volume dust collection applications. Key features include: 1. Dura-Life® Filter Bags – Twice the life over standard polyester bags, engineered with a hydroentanglement process for better pulse cleaning and longer bag life. 2. Ultra-Web SB Pleated Bags – Provide longer life and reduced emissions, w…

2. Nederman MikroPul – Pulse Jet Dust Collectors

Domain: nedermanmikropul.com

Registered: 2015 (10 years)

Introduction: Nederman MikroPul Pulse Jet Dust Collectors are designed for applications where it is impractical to shut down the dust collector for bag cleaning. Key features include:

– Modular Pulse Jet Dust Collector: Ideal for filter media area between 151 – 8,246 ft² (14 m² – 766 m²).

– Multi-Modular Pulse Jet Dust Collectors: Suitable for large applications over 4,500 ft² (440 m²), provided in prewired s…

3. CamCorp Inc – Pulse Jet Baghouse

Domain: camcorpinc.com

Registered: 1998 (27 years)

Introduction: Pulse Jet Baghouse – Industrial dust collection system designed for high-vacuum, high-pressure, and explosion-containment applications. Customizable designs available in various shapes (round, square, rectangle) and sizes to fit specific space constraints. Features include heavy-duty all-welded construction, structural supports engineered for local codes, materials of construction (carbon steel, s…

4. Sly – Pulse Jet Top Bag Removal Collectors

Domain: slyinc.com

Registered: 1997 (28 years)

Introduction: Sly Pulse Jet Top Bag Removal Collectors and CBR Side Bag Removal Units are available in top bag removal design (CTR) or side bag removal design (CBR). Key specifications include: 50-25,000+ ACFM capacities, design pressures from 20″ w.g. to 17″ Hg, full vacuum ASME code stamped housings, and construction to 500°F design temperature. Features include superior cleanability due to cylindrical design…

5. Micronics Inc – Baghouse Cleaning Solutions

Domain: micronicsinc.com

Registered: 1996 (29 years)

Introduction: Pulse-Jet Baghouse Cleaning System Parts, High-Temp Fabric Solutions for P-J Baghouses, Extended Surface Area Solutions, Filter Fabrics, Pleated Filter Bags, Cartridges, AeroPulse® Baghouse Parts, Leak Detection, Powder & Inspection Lights, Precoat Filter Aid, Blast Cabinet Gloves, Filter Bag Cages and Venturis, Installation Hardware.

6. IQS Directory – Pulse Jet Dust Collectors

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Pulse Jet Dust Collectors are high-efficiency dust collection systems known for low maintenance, superior filtration, and ability to handle dense dust particles. They are used in various applications including product recovery, dust capture, filtering hazardous media, metalworking chip extraction, central vacuum cleaning systems, and pneumatic conveying. Types include: 1. Cylindrical Pulse Jet Dus…

7. Griffin Filters – Pulse Jet Dust Collectors

Domain: griffinfilters.com

Registered: 2005 (20 years)

Introduction: Pulse Jet Dust Collectors are designed for efficiency, durability, and versatility in various dust collection applications. Key models include: 1. Jet-Aire Pulse Jet Baghouse Dust Collectors – Effective for solids processing and product recovery, built as stand-alone or modular units for unlimited airflow. 2. Jet Vent Dust Collectors – Easy to install and maintain, providing continuous fabric filt…

8. Baghouse – Optimized Compressed Air Solutions

Domain: baghouse.com

Registered: 1999 (26 years)

Introduction: Compressed air pressure for pulse jet dust collectors should be optimized for filter life, efficiency, and airflow. Recommended pressures are: 70 PSI for most applications using felted filter media, 100-120 PSI for difficult applications, and lower pressures for special circumstances like cartridges or pleated filters. Guidelines suggest starting at 60 PSI and not exceeding 100 PSI without expert …

Strategic Sourcing Conclusion and Outlook for pulse jet dust collector

As industries across Africa, South America, the Middle East, and Europe increasingly prioritize efficient dust management, the strategic sourcing of pulse jet dust collectors becomes paramount. These advanced systems not only enhance operational efficiency but also reduce maintenance costs and downtime through technologies such as the Dura-Life® filter bags and iCue™ monitoring systems. By adopting pulse jet collectors, businesses can benefit from superior filtration capabilities, leading to lower emissions and compliance with environmental regulations.

Investing in high-quality pulse jet dust collectors allows companies to streamline their operations and ensure a safer working environment. The modular designs and customizable features of these collectors provide flexibility to meet the specific needs of diverse industrial applications.

Looking ahead, international B2B buyers should consider forming partnerships with reputable suppliers that offer innovative solutions tailored to their unique operational challenges. By prioritizing strategic sourcing, organizations can not only improve their dust collection processes but also position themselves as leaders in sustainability and operational excellence in their respective markets. Engage with your suppliers today to explore the latest advancements and maximize your dust management strategies for a cleaner, more efficient future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to pulse jet dust collector

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.