Everything You Need to Know About Pressure Vessel Types Sourcing in 2025

Introduction: Navigating the Global Market for pressure vessel types

In today’s competitive landscape, sourcing the right pressure vessel types is critical for international B2B buyers, particularly those operating in sectors such as oil and gas, pharmaceuticals, and food processing. The challenge lies in navigating a complex market filled with diverse materials, designs, and compliance standards, which can significantly impact operational efficiency and safety. This comprehensive guide demystifies the world of pressure vessels, offering insights into their various types—ranging from storage and process vessels to heat exchangers and boilers—along with their specific applications across industries.

The guide goes beyond mere definitions, equipping buyers with essential knowledge on supplier vetting processes, cost considerations, and regulatory compliance, particularly relevant for regions like Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Germany. Each section is designed to empower decision-makers with actionable insights, enabling them to make informed purchasing decisions that align with their operational needs and budget constraints. By understanding the intricacies of pressure vessel types and their applications, buyers can ensure they select solutions that not only meet their technical specifications but also enhance their overall business performance.

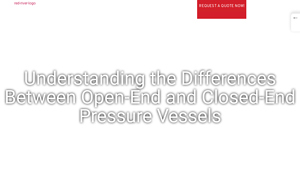

Understanding pressure vessel types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Storage Vessels | Designed to hold liquids, gases, or vapors under pressure. | Oil & gas, chemical storage, water treatment. | Pros: Versatile, reusable. Cons: Risk of leakage if not maintained. |

| Heat Exchangers | Transfers heat between two or more fluids, optimizing thermal efficiency. | Power generation, food processing, HVAC. | Pros: Energy-efficient, essential for many processes. Cons: Complex design can increase costs. |

| Boilers | Converts water into steam using heat energy, critical for various industrial processes. | Power plants, manufacturing, food production. | Pros: High efficiency, essential for steam generation. Cons: Requires regular maintenance to prevent failure. |

| Process Vessels | Large containers used for chemical reactions and mixing operations. | Chemical manufacturing, pharmaceuticals. | Pros: Customizable for specific processes. Cons: High initial investment and operational costs. |

| Spherical Pressure Vessels | Uniform pressure distribution, robust design. | High-pressure gas storage, cryogenics. | Pros: Space-efficient, strong. Cons: Higher manufacturing cost. |

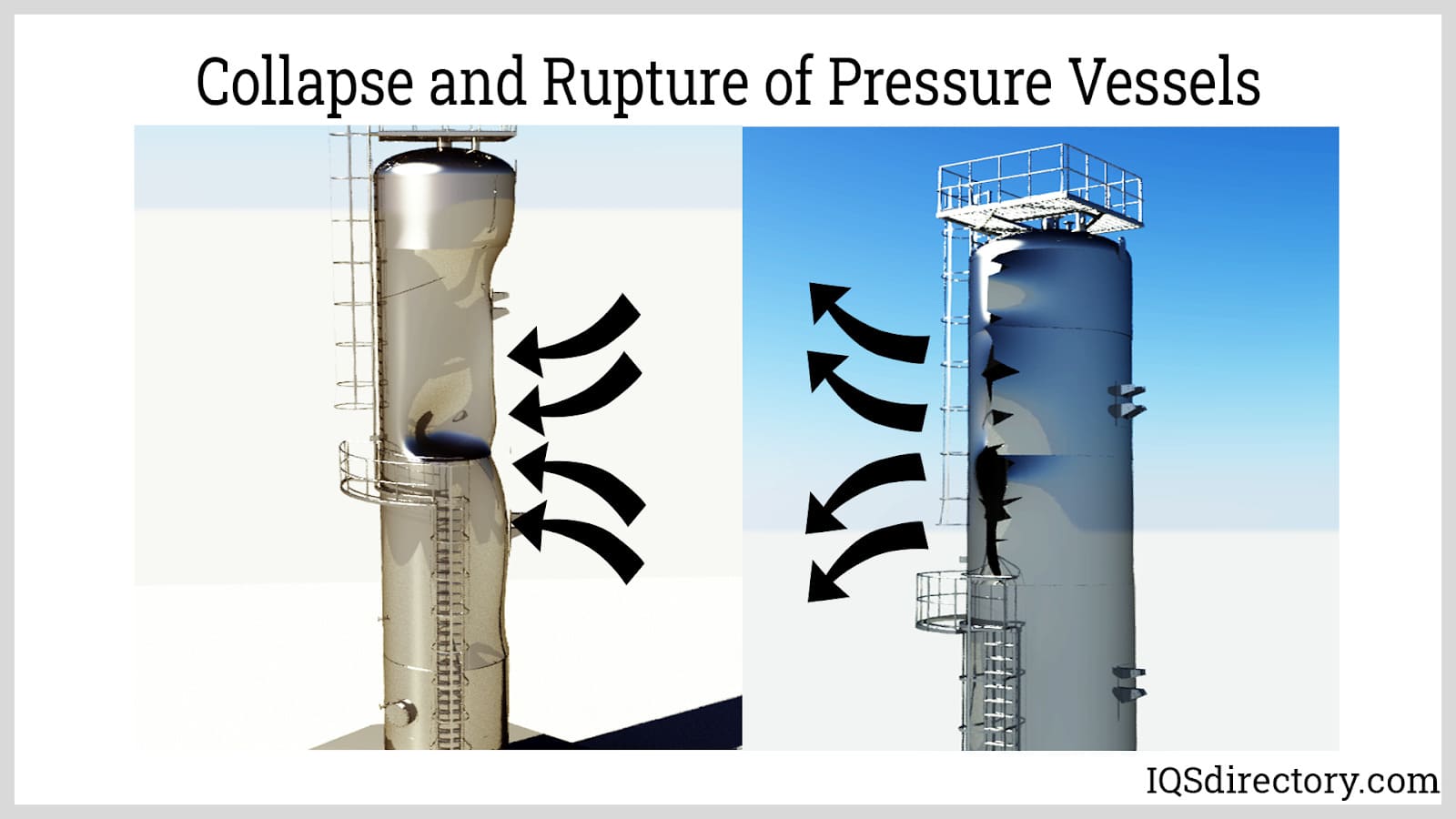

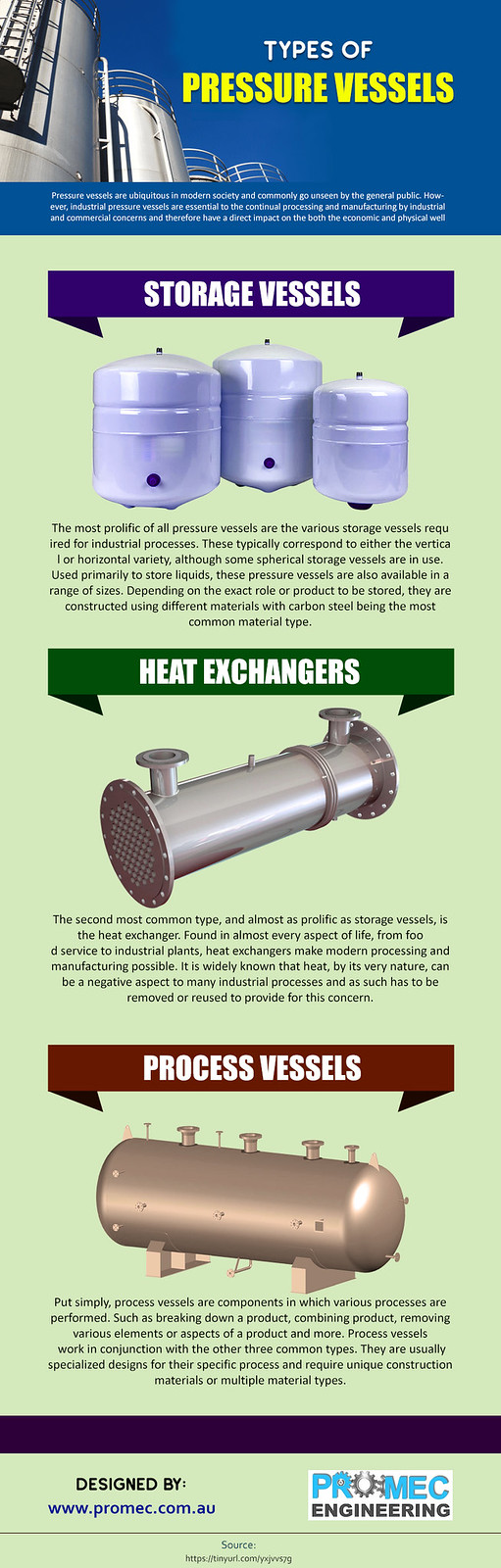

What Are Storage Vessels and Their B2B Relevance?

Storage vessels serve as crucial components in various industries, designed to safely contain liquids, gases, and vapors under pressure. Their versatility allows them to be reused for different processes, making them ideal for sectors like oil and gas, chemical storage, and water treatment. When considering purchasing storage vessels, B2B buyers should focus on the vessel’s material compatibility, capacity, and safety features to mitigate risks of leakage and ensure compliance with local regulations.

How Do Heat Exchangers Optimize Industrial Processes?

Heat exchangers are vital for transferring heat between fluids, significantly enhancing energy efficiency in processes across power generation, food processing, and HVAC systems. Their design can be complex, tailored to specific thermal and flow properties of the involved fluids. B2B buyers should assess the heat exchanger’s thermal performance, material durability, and ease of maintenance. This ensures long-term operational efficiency while minimizing downtime.

Why Are Boilers Essential for Industry Operations?

Boilers play a critical role in converting water into steam through heat energy, serving industries such as power generation, manufacturing, and food production. They are designed to operate under high pressure and require robust materials to withstand the intense conditions. Buyers in the B2B space must evaluate boiler efficiency ratings, maintenance requirements, and safety features, as regular upkeep is essential to prevent operational failures and ensure compliance with industry standards.

What Are the Characteristics of Process Vessels?

Process vessels are large containers integral to chemical reactions, mixing, and other industrial processes. Their design can be customized to meet specific operational needs, making them particularly valuable in chemical manufacturing and pharmaceuticals. B2B buyers should consider the process vessel’s size, material composition, and adaptability to different chemical processes. The initial investment may be high, but the long-term benefits often justify the cost.

Why Choose Spherical Pressure Vessels for High-Pressure Applications?

Spherical pressure vessels are engineered to handle high-pressure environments effectively, with their design allowing for uniform pressure distribution. This makes them particularly suitable for storing gases and cryogenic liquids. While they are more space-efficient and robust than other vessel types, the higher manufacturing costs may be a consideration for B2B buyers. It’s essential to evaluate the specific application needs and potential long-term savings in operational efficiency when investing in spherical vessels.

Key Industrial Applications of pressure vessel types

| Industry/Sector | Specific Application of Pressure Vessel Types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Storage Vessels for Natural Gas | Safe and efficient storage of volatile gases, ensuring supply continuity. | Compliance with ASME standards; material selection for corrosion resistance. |

| Pharmaceutical | Process Vessels for Drug Manufacturing | Enables precise chemical reactions and mixing, improving product quality. | Need for high-purity materials; strict adherence to regulatory standards. |

| Power Generation | Boilers for Steam Production | Efficient energy conversion, reducing operational costs. | Consideration of thermal efficiency and pressure ratings; material durability. |

| Food and Beverage | Heat Exchangers for Pasteurization | Maintains product safety and quality while enhancing operational efficiency. | Compliance with food safety regulations; ease of cleaning and maintenance. |

| Water Treatment | Pressure Vessels for Filtration Systems | Ensures safe drinking water supply through effective contaminant removal. | Durability against corrosive substances; adherence to safety standards. |

How are Pressure Vessels Used in the Oil and Gas Industry?

In the oil and gas sector, storage vessels are essential for safely containing natural gas and other volatile substances. These vessels are designed to withstand high pressures and prevent leaks, which is crucial for operational safety and environmental protection. Buyers must ensure compliance with ASME standards and select materials that resist corrosion due to the harsh operational environment. Additionally, they should consider the vessel’s capacity and the specific gas composition to optimize storage efficiency.

What Role do Pressure Vessels Play in Pharmaceutical Manufacturing?

Pressure vessels in pharmaceutical manufacturing are primarily used as process vessels where critical chemical reactions occur. These vessels facilitate precise mixing and temperature control, which are vital for producing high-quality medications. For international buyers, especially in regions with stringent regulations, sourcing high-purity materials is essential to meet safety standards. Moreover, adherence to regulatory requirements ensures that the vessels can be validated for use in drug production, minimizing the risk of contamination.

Why are Boilers Important in Power Generation?

Boilers are a type of pressure vessel that plays a vital role in power generation by converting water into steam, which drives turbines to produce electricity. The efficiency of energy conversion directly impacts operational costs, making the selection of high-quality materials and designs crucial. Buyers should prioritize vessels that can withstand high temperatures and pressures while maintaining structural integrity over time. Additionally, considerations for maintenance and inspection processes are essential to ensure reliable operation and compliance with safety regulations.

How Do Heat Exchangers Benefit the Food and Beverage Industry?

In the food and beverage industry, heat exchangers are critical for processes like pasteurization, where they help maintain product safety while optimizing energy use. These pressure vessels transfer heat between fluids without direct contact, preserving product integrity. Buyers must ensure that the heat exchangers comply with food safety regulations, which may vary by region. Additionally, ease of cleaning and maintenance is paramount, as it affects operational efficiency and product quality.

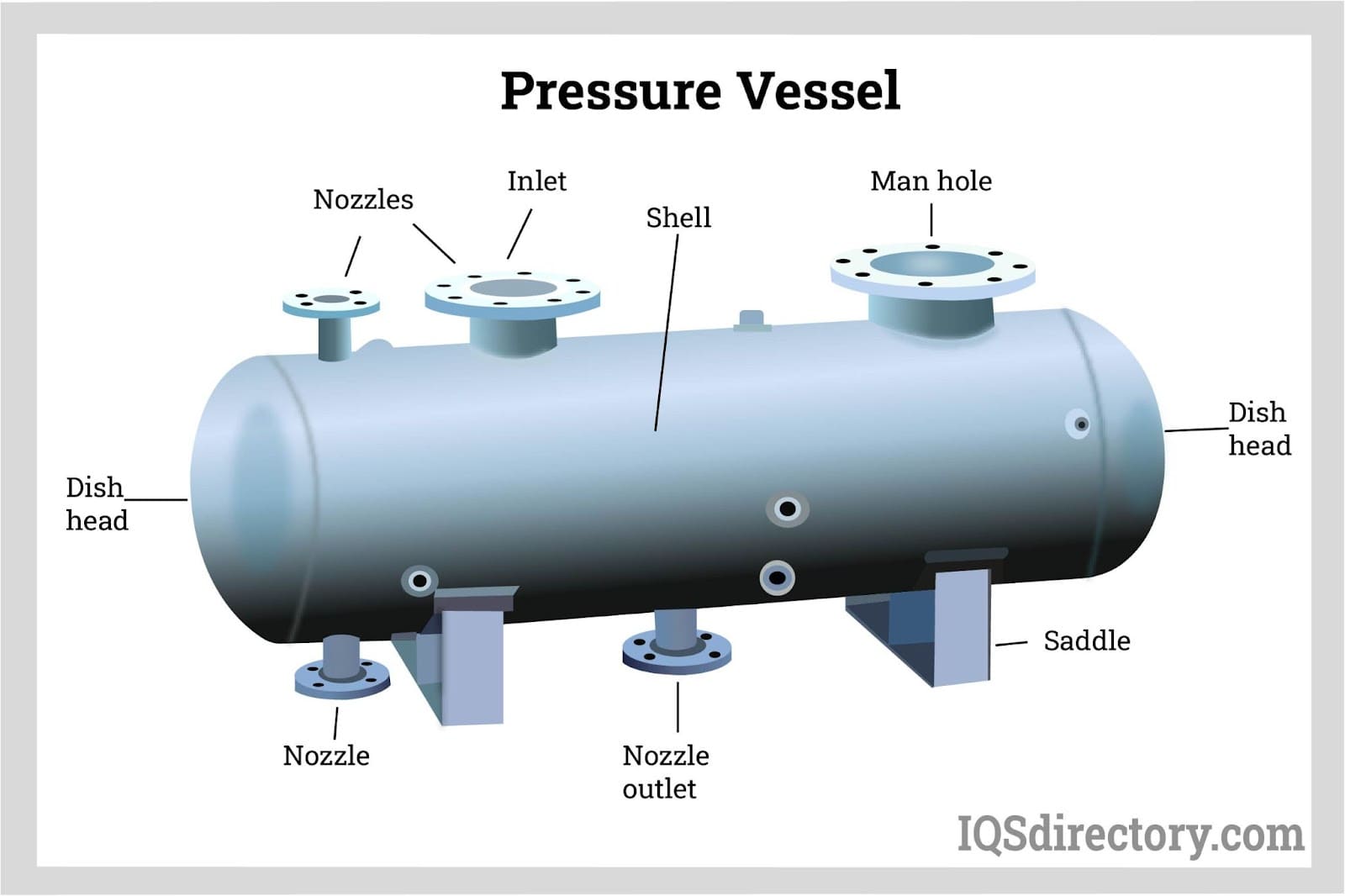

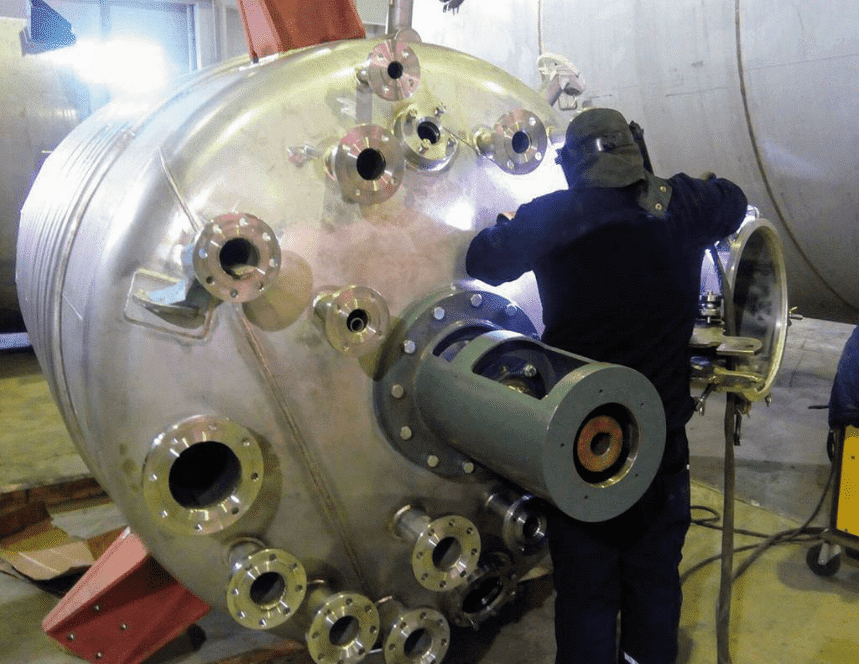

Illustrative image related to pressure vessel types

What is the Importance of Pressure Vessels in Water Treatment?

Pressure vessels are integral to water treatment systems, particularly in filtration processes that ensure safe drinking water. These vessels must be designed to withstand the corrosive nature of various contaminants while maintaining structural integrity. International buyers need to consider the durability of materials used and ensure compliance with local and international safety standards. The ability to effectively remove contaminants while ensuring longevity and reliability of the vessel is crucial for maintaining a consistent supply of clean water.

3 Common User Pain Points for ‘pressure vessel types’ & Their Solutions

Scenario 1: Navigating Compliance with Pressure Vessel Regulations

The Problem:

B2B buyers in industries such as oil and gas, pharmaceuticals, and food processing often face the daunting task of ensuring compliance with stringent regulatory standards for pressure vessels. The complexities of international standards like the ASME Boiler and Pressure Vessel Code (BPVC) or regional regulations can be overwhelming, especially for companies operating across multiple countries. This uncertainty can lead to costly delays in production, potential fines, or even operational shutdowns if a vessel fails to meet safety standards.

The Solution:

To navigate these regulatory challenges effectively, buyers should invest in comprehensive training for their engineering and compliance teams. This includes familiarizing them with the specific requirements of the ASME BPVC, API 510, and local regulations relevant to their operations. Additionally, sourcing pressure vessels from manufacturers who provide clear documentation of compliance, including inspection certificates and material traceability, can streamline the procurement process. Regular audits of suppliers can also ensure ongoing adherence to these standards. Engaging with a consultant specializing in pressure vessel compliance can further enhance understanding and mitigate risks.

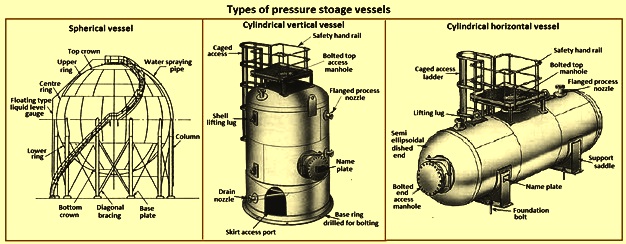

Scenario 2: Managing the Lifecycle of Pressure Vessels

The Problem:

Managing the lifecycle of pressure vessels presents significant challenges, particularly regarding maintenance, inspections, and timely replacements. B2B buyers often struggle to balance operational efficiency with the need for regular inspections and maintenance to prevent costly downtimes. Neglecting these aspects can lead to catastrophic failures, damaging equipment and putting personnel at risk.

The Solution:

Implementing a robust Asset Management System (AMS) can greatly enhance lifecycle management. This system should include scheduled maintenance alerts, detailed inspection logs, and a replacement timeline based on the manufacturer’s specifications and industry standards. Buyers should also consider investing in predictive maintenance technologies, such as IoT sensors, which can monitor the health of pressure vessels in real-time and provide data analytics for proactive decision-making. Collaborating with experienced service providers for regular inspections and maintenance will ensure that the vessels remain compliant and functional throughout their operational life.

Scenario 3: Selecting the Right Type of Pressure Vessel for Specific Applications

The Problem:

Choosing the appropriate type of pressure vessel for specific applications can be a significant pain point for B2B buyers. With various options like storage vessels, heat exchangers, and process vessels available, the decision-making process can become overwhelming. Misalignment between vessel type and application requirements can lead to inefficiencies, increased operational costs, and potential safety hazards.

The Solution:

To alleviate this challenge, buyers should engage in a thorough needs assessment before purchasing. This involves understanding the specific application requirements, including the type of media being stored or processed, temperature and pressure conditions, and space constraints. Collaborating with a knowledgeable supplier who can provide tailored recommendations based on industry best practices can be invaluable. Additionally, investing in simulation tools can help visualize how different vessel types will perform under various conditions, allowing for informed decision-making. Ensuring that suppliers offer customization options can also help in aligning the pressure vessel design with operational needs.

Strategic Material Selection Guide for pressure vessel types

What Are the Key Properties of Carbon Steel for Pressure Vessels?

Carbon steel is one of the most commonly used materials for pressure vessels due to its excellent mechanical properties and cost-effectiveness. It typically exhibits good strength and toughness, making it suitable for high-pressure applications. Carbon steel pressure vessels can withstand temperatures up to approximately 400°C (752°F) and pressures exceeding 15 psig, depending on the specific grade used. However, carbon steel has limited corrosion resistance, which can be a significant drawback in harsh environments.

Illustrative image related to pressure vessel types

Pros and Cons of Carbon Steel

The primary advantage of carbon steel is its affordability and availability, which significantly reduces manufacturing costs. It is also relatively easy to fabricate and weld, allowing for efficient production. However, its susceptibility to corrosion necessitates protective coatings or linings, which can add to long-term maintenance costs. Additionally, in applications involving aggressive chemicals or high humidity, carbon steel may not be the best choice due to potential degradation.

Impact on Application

Carbon steel is widely used in oil and gas, chemical processing, and power generation industries. It is compatible with various media, including water, steam, and hydrocarbons. However, buyers must consider environmental factors, as carbon steel may not perform well in corrosive or high-temperature applications without appropriate protective measures.

How Does Stainless Steel Compare for Pressure Vessel Applications?

Stainless steel is renowned for its excellent corrosion resistance, making it ideal for pressure vessels that handle aggressive media or operate in harsh environments. It can withstand temperatures up to 800°C (1472°F) and pressures similar to those of carbon steel. The alloying elements, particularly chromium and nickel, enhance its durability and resistance to oxidation.

Pros and Cons of Stainless Steel

The key advantage of stainless steel is its longevity and minimal maintenance requirements due to its corrosion-resistant properties. This makes it a preferred choice for industries such as pharmaceuticals, food processing, and petrochemicals. However, stainless steel is more expensive than carbon steel, which can impact the overall project budget. Additionally, its fabrication can be more complex, requiring specialized welding techniques.

Impact on Application

Stainless steel pressure vessels are particularly suitable for applications involving corrosive substances, such as acids and chlorides. International buyers must ensure compliance with standards such as ASTM A312 or DIN 17440, which govern the use of stainless steel in pressure vessel construction.

Illustrative image related to pressure vessel types

What Are the Advantages of Using Aluminum in Pressure Vessels?

Aluminum is a lightweight alternative for pressure vessels, especially in applications where weight is a critical factor. It typically has a pressure rating of up to 300 psi and can withstand temperatures around 150°C (302°F). Aluminum’s natural corrosion resistance makes it suitable for various environments.

Pros and Cons of Aluminum

One of the main advantages of aluminum is its low density, which can lead to reduced transportation costs and easier installation. It is also highly resistant to corrosion, reducing the need for protective coatings. However, aluminum has lower strength compared to carbon and stainless steel, which may limit its use in high-pressure applications. Additionally, it can be more expensive to fabricate due to the need for specialized welding techniques.

Impact on Application

Aluminum pressure vessels are commonly used in aerospace and automotive applications, as well as in portable gas storage. Buyers must consider the specific media compatibility, as certain chemicals can react adversely with aluminum. Compliance with standards such as ASTM B221 is essential for international procurement.

What Role Do Nickel Alloys Play in Pressure Vessel Material Selection?

Nickel alloys are specialized materials designed for extreme conditions, offering superior strength and corrosion resistance. They can handle temperatures exceeding 1000°C (1832°F) and high pressures, making them suitable for challenging applications like chemical processing and power generation.

Pros and Cons of Nickel Alloys

The primary advantage of nickel alloys is their exceptional performance in corrosive environments and high-temperature applications. They are highly durable and can withstand significant stress. However, they are among the most expensive materials available, which can be a limiting factor for budget-conscious projects. Additionally, the complexity of fabrication can lead to longer lead times.

Impact on Application

Nickel alloys are often used in the aerospace, marine, and chemical industries where extreme conditions are prevalent. Buyers must be aware of compliance with standards such as ASTM B163 and ASME Section II, which dictate the use of nickel alloys in pressure vessel applications.

Summary Table of Material Selection for Pressure Vessels

| Material | Typical Use Case for pressure vessel types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Oil and gas, chemical processing | Cost-effective and widely available | Susceptible to corrosion | Low |

| Stainless Steel | Pharmaceuticals, food processing | Excellent corrosion resistance | Higher cost and complex fabrication | High |

| Aluminum | Aerospace, portable gas storage | Lightweight and corrosion-resistant | Lower strength than steel | Medium |

| Nickel Alloys | Chemical processing, power generation | Superior strength and durability | High cost and complex fabrication | High |

In-depth Look: Manufacturing Processes and Quality Assurance for pressure vessel types

What Are the Main Stages in the Manufacturing Process of Pressure Vessels?

The manufacturing of pressure vessels involves several critical stages, each designed to ensure the final product meets the stringent requirements for safety and performance. Understanding these stages can help B2B buyers assess potential suppliers and ensure they adhere to high manufacturing standards.

Material Preparation: What Materials Are Commonly Used?

The first step in the manufacturing process is material selection and preparation. Common materials used for pressure vessels include carbon steel, stainless steel, aluminum, and specialty alloys such as Hastelloy and titanium. Each material is chosen based on specific application requirements, including pressure, temperature, and corrosion resistance.

Once the appropriate material is selected, it undergoes cutting and shaping. This may involve processes such as shearing, laser cutting, or water jet cutting to produce plates or sheets that meet the design specifications. The quality of the raw materials is critical, and buyers should verify the material certification to ensure compliance with standards like ASTM or EN.

Illustrative image related to pressure vessel types

How Are Pressure Vessels Formed During Production?

The forming stage involves transforming the flat sheets into the desired shape, typically cylindrical or spherical. This is achieved through techniques such as rolling, bending, and welding.

-

Rolling: Plates are rolled into a cylindrical shape, creating the shell of the vessel. This process requires precise machinery to maintain uniform thickness and curvature.

-

Welding: After forming, the edges are welded together. Common welding methods include MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding. The choice of welding technique depends on the material and thickness of the vessel.

What Assembly Techniques Are Employed for Pressure Vessels?

Following the forming process, the next step is assembly. This may involve adding components such as nozzles, flanges, and supports. Each component must be designed to withstand the operational pressures and temperatures expected during service.

The assembly process also includes the installation of internal fittings such as baffles or trays in process vessels. Precision in assembly is crucial, as any misalignment can lead to operational failures.

What Finishing Processes Are Necessary for Pressure Vessels?

Finishing processes are essential to enhance the vessel’s durability and performance. Common finishing techniques include:

-

Surface Treatment: This may involve sandblasting, painting, or applying corrosion-resistant coatings to protect against environmental factors.

-

Heat Treatment: Some vessels undergo heat treatment processes to relieve stresses induced during welding and forming, ensuring structural integrity.

-

Nondestructive Testing (NDT): This is often performed at this stage to detect any defects that may not be visible to the naked eye. Methods include ultrasonic testing, radiographic testing, and magnetic particle inspection.

How Is Quality Assurance Ensured Throughout the Manufacturing Process?

Quality assurance (QA) is integral to the manufacturing of pressure vessels, ensuring they meet safety and performance standards. B2B buyers should be aware of the international standards and industry-specific certifications that govern these processes.

What Are the Relevant International Standards for Pressure Vessels?

International standards such as ISO 9001 are critical for ensuring consistent quality management systems in manufacturing. In addition, industry-specific standards like the ASME Boiler and Pressure Vessel Code (BPVC) and API 510 (for in-service inspection) provide guidelines for the design, fabrication, and inspection of pressure vessels.

B2B buyers should inquire about suppliers’ adherence to these standards, as compliance indicates a commitment to quality and safety.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process, including:

-

Incoming Quality Control (IQC): This stage verifies the quality of raw materials before they are used in production. It includes checking material certifications and conducting initial tests.

-

In-Process Quality Control (IPQC): During manufacturing, periodic inspections ensure processes are being followed correctly. This may include monitoring weld quality and dimensional accuracy.

-

Final Quality Control (FQC): Once the pressure vessel is completed, a final inspection is conducted to ensure it meets all specifications and regulatory requirements. This may include hydrostatic testing to check for leaks and pressure integrity.

What Testing Methods Are Commonly Used to Ensure Pressure Vessel Integrity?

Various testing methods are employed to verify the integrity and performance of pressure vessels. Some of the most common methods include:

-

Hydrostatic Testing: The vessel is filled with water and pressurized to a specified level to check for leaks and structural integrity.

-

Pneumatic Testing: Similar to hydrostatic testing, but air is used instead of water. This method requires careful handling due to the risks associated with high-pressure gases.

-

Nondestructive Testing (NDT): Techniques like ultrasonic and radiographic testing ensure there are no hidden defects in the material without damaging the vessel.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control measures of potential suppliers. This includes:

-

Supplier Audits: Conducting on-site audits can provide insights into the supplier’s manufacturing processes, quality control systems, and adherence to standards.

-

Requesting Quality Reports: Buyers should request detailed quality reports, including inspection and testing results, to assess compliance with international standards.

-

Third-Party Inspections: Engaging independent third-party inspectors can provide an unbiased assessment of the supplier’s quality control processes and the integrity of the finished product.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, it is crucial to understand the nuances of quality control and certification.

Illustrative image related to pressure vessel types

-

Regulatory Compliance: Buyers should ensure that their suppliers are compliant with both local and international regulations. This may include CE marking in Europe or other regional certifications.

-

Cultural and Regional Considerations: Different regions may have varying expectations and requirements for pressure vessels. Understanding these can help buyers select suppliers that align with their operational needs.

-

Documentation and Traceability: Maintaining thorough documentation of all quality control processes is essential for international transactions. Buyers should ensure that suppliers can provide traceability for materials and processes used in the manufacturing of pressure vessels.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing pressure vessels, ensuring they receive high-quality products that meet their operational requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pressure vessel types’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure various types of pressure vessels. Given the critical role these vessels play in diverse industries—from chemical processing to energy production—understanding the nuances of sourcing is paramount. This guide will walk you through essential steps to ensure that your procurement process is effective, compliant, and aligned with your operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in sourcing pressure vessels. Identify the required dimensions, pressure ratings, and material types based on the intended application. This step is crucial as it directly impacts performance and safety, ensuring that the vessel meets your operational requirements.

- Consider factors such as temperature ranges and compatibility with stored substances.

- Ensure specifications align with relevant industry standards and regulations.

Step 2: Research Different Pressure Vessel Types

Understanding the various types of pressure vessels is essential for making an informed decision. Familiarize yourself with categories such as storage vessels, heat exchangers, and process vessels, as well as their specific applications in your industry. This knowledge will guide you in selecting the most suitable vessel for your needs.

- Explore the advantages and limitations of each type.

- Assess how different designs may influence operational efficiency and safety.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to conduct a thorough evaluation. Request company profiles, case studies, and references from buyers within your industry or region. A reliable supplier should demonstrate a proven track record in delivering quality pressure vessels that meet industry standards.

- Verify their certifications, such as ASME and API compliance.

- Check for customer reviews and testimonials to gauge their reputation.

Step 4: Assess Material Selection Criteria

The material used in pressure vessel construction significantly influences performance and longevity. Ensure that the materials chosen can withstand the specific pressures, temperatures, and corrosive environments they will encounter. This step is vital for reducing maintenance costs and enhancing vessel durability.

- Look for materials with high corrosion resistance if applicable.

- Consider the availability of materials locally to minimize lead times.

Step 5: Understand Regulatory Compliance and Safety Standards

Compliance with regulatory standards is non-negotiable in pressure vessel procurement. Familiarize yourself with relevant local and international regulations, such as the ASME Boiler and Pressure Vessel Code. This knowledge ensures that the vessels you procure are safe and legally compliant.

- Review the supplier’s quality assurance processes.

- Ensure that the vessels undergo rigorous testing and inspection as mandated by regulatory bodies.

Step 6: Request Quotes and Compare Pricing

Once you have shortlisted potential suppliers, request detailed quotes. Compare pricing not only based on initial costs but also consider factors such as delivery timelines, warranty terms, and after-sales support. This comprehensive approach will help you make a cost-effective decision.

- Analyze the total cost of ownership, including maintenance and operational costs.

- Look for hidden costs that may arise during installation or operation.

Step 7: Plan for Installation and Maintenance Support

Finally, consider the installation and ongoing maintenance support offered by your supplier. A reliable supplier should provide guidance on proper installation procedures and maintenance schedules to ensure optimal vessel performance. This step is critical for long-term operational success.

Illustrative image related to pressure vessel types

- Inquire about training for your staff on proper vessel handling and maintenance.

- Discuss warranty terms and the supplier’s ability to provide timely support if issues arise.

By following this checklist, B2B buyers can navigate the complexities of sourcing pressure vessels, ensuring they select the right products for their specific needs while adhering to industry standards.

Comprehensive Cost and Pricing Analysis for pressure vessel types Sourcing

What Are the Key Cost Components in Sourcing Pressure Vessels?

When sourcing pressure vessels, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. Common materials such as carbon steel and stainless steel vary in price depending on market conditions. Advanced materials like Hastelloy or titanium, while offering superior performance, come at a premium.

-

Labor: Labor costs encompass both manufacturing and assembly processes. Skilled labor is essential for the precise fabrication of pressure vessels, particularly when custom specifications are involved. The cost can also vary based on geographic location, with labor rates differing significantly between regions.

-

Manufacturing Overhead: This includes expenses related to the production facility, utilities, equipment maintenance, and administrative costs. Efficient manufacturing processes can help mitigate these overhead costs, making it important for buyers to assess supplier capabilities.

-

Tooling: Custom tooling may be necessary for specialized designs, which can add to the initial investment. Buyers should consider whether a supplier has the necessary tools for their specific requirements, as this can affect lead times and costs.

-

Quality Control (QC): Ensuring compliance with safety standards such as the ASME Boiler and Pressure Vessel Code incurs costs related to inspections, testing, and certification. Investing in robust QC processes can prevent costly failures and liabilities in the long run.

-

Logistics: Transporting pressure vessels, especially large or heavy units, can be expensive. Logistics costs can be influenced by distance, mode of transport, and any special handling requirements, particularly for international shipments.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary widely based on the competitive landscape and the perceived value of their products.

How Do Price Influencers Impact the Cost of Pressure Vessels?

Several factors can influence the pricing of pressure vessels, including:

-

Volume/MOQ: Purchasing larger volumes often results in lower per-unit costs. Buyers should negotiate minimum order quantities (MOQs) to optimize their pricing strategy.

-

Specifications and Customization: Custom designs or specific performance requirements can drive up costs. Buyers should clearly outline their needs to avoid unexpected price increases during production.

-

Materials: As previously mentioned, the choice of materials directly affects pricing. Opting for standard materials can be more cost-effective than specialized options.

-

Quality and Certifications: Suppliers that offer higher quality and relevant certifications may charge more. However, investing in certified products can reduce long-term risks and maintenance costs.

-

Supplier Factors: The supplier’s reputation, experience, and geographical location can impact pricing. Established suppliers with a track record of reliability may command higher prices but can also provide peace of mind.

-

Incoterms: The terms of shipping (e.g., FOB, CIF) can significantly affect the total cost. Buyers should be aware of these terms to accurately calculate their expenses and responsibilities during shipping.

What Are the Best Practices for Negotiating Pressure Vessel Prices?

To achieve cost-efficiency in sourcing pressure vessels, buyers should consider the following strategies:

-

Understand Total Cost of Ownership (TCO): Beyond initial purchase price, assess the TCO, which includes maintenance, operational costs, and potential downtime. This holistic view can guide better purchasing decisions.

-

Leverage Volume Discounts: If possible, consolidate purchases or collaborate with other buyers to negotiate better rates based on higher volume commitments.

-

Request Multiple Quotes: Solicit quotes from various suppliers to gauge the market rate. This can provide leverage during negotiations and help identify the best offers.

-

Focus on Long-term Relationships: Building strong relationships with suppliers can lead to favorable pricing arrangements and better service over time. Consider establishing contracts that reflect ongoing business rather than one-off purchases.

-

Be Aware of Pricing Nuances for International Procurement: Different regions may have varying standards and regulations affecting pricing. Understanding these nuances, especially in markets like Africa, South America, the Middle East, and Europe, can help in negotiating better terms.

Conclusion

Sourcing pressure vessels involves navigating a complex landscape of costs and pricing factors. By understanding the underlying cost components and leveraging effective negotiation strategies, international B2B buyers can optimize their procurement processes and ensure they receive the best value for their investment. Always remember that indicative prices can fluctuate based on market conditions, so staying informed and flexible is key to successful sourcing.

Illustrative image related to pressure vessel types

Alternatives Analysis: Comparing pressure vessel types With Other Solutions

Understanding Alternatives to Pressure Vessel Types

When considering solutions for storing and transporting gases and liquids under pressure, pressure vessels are a widely accepted choice. However, there are alternative technologies that may meet similar needs, depending on specific operational requirements and constraints. This section provides a comparative analysis of pressure vessel types against two viable alternatives: membrane tanks and atmospheric storage tanks.

Comparison Table

| Comparison Aspect | Pressure Vessel Types | Membrane Tanks | Atmospheric Storage Tanks |

|---|---|---|---|

| Performance | High pressure tolerance; reliable for various applications | Effective for cryogenic applications; flexible design | Suitable for low-pressure applications; less robust |

| Cost | Higher initial investment; long-term durability | Moderate cost; installation can be complex | Generally lower cost; simpler construction |

| Ease of Implementation | Requires skilled labor for installation and maintenance | Installation may require specialized teams | Easy to install and maintain; less specialized labor needed |

| Maintenance | Regular inspections and testing required; more complex | Minimal maintenance; periodic inspections | Low maintenance; simple upkeep |

| Best Use Case | Ideal for high-pressure systems and critical processes | Best for storing liquefied gases at cryogenic temperatures | Suitable for large volume storage of liquids under atmospheric conditions |

Detailed Breakdown of Alternatives

Membrane Tanks

Membrane tanks are specialized structures designed to store liquefied gases at very low temperatures. Their flexible design allows for a reduction in material costs and weight. The primary advantage of membrane tanks is their effectiveness in cryogenic applications, such as storing liquefied natural gas (LNG). However, they typically require specialized installation teams and can be more complex to implement than traditional pressure vessels. While they are generally less expensive than high-pressure vessels, the initial setup may involve significant investment.

Atmospheric Storage Tanks

Atmospheric storage tanks are large containers designed to store liquids at atmospheric pressure. They are less robust than pressure vessels and are primarily used for lower-pressure applications. Their primary benefits include lower construction costs and ease of maintenance, making them a popular choice for bulk storage of chemicals and water. However, they are not suitable for high-pressure applications and may require additional safety measures in terms of containment and environmental protection.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a solution for storing or transporting gases and liquids under pressure, B2B buyers must consider several factors, including operational requirements, budget constraints, and maintenance capabilities. Pressure vessels offer robustness and reliability for high-pressure applications but come with higher costs and maintenance requirements. Conversely, membrane tanks may provide flexibility for specific low-temperature applications, while atmospheric storage tanks offer a cost-effective solution for bulk storage at lower pressures. Ultimately, the choice depends on the specific needs of the business, including the nature of the materials being stored and the operational environment.

Illustrative image related to pressure vessel types

Essential Technical Properties and Trade Terminology for pressure vessel types

What Are the Key Technical Properties of Pressure Vessel Types?

Understanding the essential technical properties of pressure vessels is crucial for B2B buyers, especially when selecting the right equipment for specific applications. Here are some critical specifications:

-

Material Grade

The material grade of a pressure vessel determines its strength, durability, and resistance to corrosion and temperature variations. Common materials include carbon steel, stainless steel, and exotic alloys like Hastelloy. Selecting the right material is vital for ensuring compliance with safety standards and optimizing the lifespan of the vessel, which directly impacts maintenance costs and operational efficiency. -

Design Pressure

Design pressure refers to the maximum pressure that a vessel can safely withstand during its intended operation. This specification is critical for ensuring the safety and reliability of the vessel. It is often governed by industry standards like the ASME Boiler and Pressure Vessel Code (BPVC). Understanding design pressure helps buyers assess whether a vessel is suitable for their specific application, preventing costly failures or accidents. -

Wall Thickness

Wall thickness is a crucial factor that affects the vessel’s ability to handle internal pressures. Thicker walls provide more strength but also add weight and cost. Buyers must balance the need for strength with budgetary constraints, ensuring that the selected pressure vessel meets industry safety requirements without incurring unnecessary expenses. -

Tolerance

Tolerance defines the permissible deviation in the dimensions of the pressure vessel. It is essential for ensuring proper fit and function, particularly in applications where multiple components must work together seamlessly. Understanding tolerance levels helps buyers avoid compatibility issues and ensures that the vessel meets specific operational needs. -

Temperature Rating

The temperature rating indicates the maximum temperature at which a pressure vessel can operate safely. This specification is vital for applications involving high-temperature processes, such as in the chemical or energy sectors. Selecting a vessel with an appropriate temperature rating ensures operational safety and efficiency. -

Testing Standards

Pressure vessels undergo various testing methods, such as hydrostatic testing and radiographic testing, to ensure their integrity and safety. Knowledge of testing standards helps buyers understand the quality assurance measures in place, which is essential for compliance with regulatory requirements.

What Are Common Trade Terms Related to Pressure Vessels?

Familiarity with industry terminology is crucial for effective communication and negotiation in the pressure vessel market. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces components that are used in another company’s end product. Understanding OEM relationships can help buyers identify trusted manufacturers and ensure that they are sourcing quality components for their pressure vessels. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is important for buyers to understand as it can affect inventory costs and supply chain planning. Knowing the MOQ helps in negotiating better terms and ensuring that orders align with operational needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing information for specific products or services. This process allows buyers to compare offers from different manufacturers, ensuring they receive the best value for their investment in pressure vessels. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for effective logistics and cost management, especially when sourcing pressure vessels from international suppliers. -

BOM (Bill of Materials)

A BOM is a comprehensive list of all materials, components, and assemblies required to manufacture a product. For pressure vessels, a detailed BOM helps ensure that all necessary parts are accounted for, facilitating efficient production and assembly processes. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. Understanding lead times is essential for planning and can help buyers manage their inventory and production schedules effectively.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when selecting pressure vessels, ensuring they meet their operational needs while complying with industry standards.

Illustrative image related to pressure vessel types

Navigating Market Dynamics and Sourcing Trends in the pressure vessel types Sector

What Are the Key Market Trends Influencing the Pressure Vessel Sector?

The pressure vessel market is undergoing significant transformation driven by global economic recovery, increased industrial activity, and stringent safety regulations. Key trends include the rising demand for advanced materials that enhance durability and corrosion resistance, particularly in sectors such as oil and gas, chemical processing, and energy. Innovations in manufacturing technologies, such as 3D printing and advanced welding techniques, are also emerging, allowing for more efficient production processes and customized solutions.

International B2B buyers, especially in Africa, South America, the Middle East, and Europe, are increasingly seeking suppliers who can provide not only high-quality products but also robust technological support. The shift towards automation and digitalization in manufacturing processes enables real-time monitoring and predictive maintenance, enhancing operational efficiency. Furthermore, as industries become more interconnected, the need for standardized quality certifications, such as ASME and API, has become crucial for ensuring compliance and reliability in pressure vessel applications.

Emerging markets are also witnessing a surge in infrastructure projects, driving demand for diverse pressure vessel types, including storage vessels, heat exchangers, and boilers. This presents a unique opportunity for international buyers to engage with suppliers who can offer scalable solutions tailored to specific project requirements while adhering to local safety standards.

How Can Sustainability and Ethical Sourcing Shape the Pressure Vessel Industry?

The environmental impact of manufacturing processes in the pressure vessel sector is increasingly under scrutiny, prompting buyers to prioritize sustainability in their sourcing decisions. The production of pressure vessels typically involves energy-intensive processes and the use of raw materials that can have a substantial carbon footprint. As a result, there is a growing emphasis on ethical sourcing practices and the utilization of ‘green’ materials.

Buyers are encouraged to seek suppliers who demonstrate a commitment to sustainability through certifications such as ISO 14001 (Environmental Management) and adherence to the principles of the Circular Economy. This may involve sourcing recycled materials or opting for pressure vessels designed for energy efficiency and reduced emissions. Additionally, suppliers offering innovative technologies, such as heat recovery systems integrated into pressure vessels, can provide significant operational cost savings and enhance environmental performance.

Illustrative image related to pressure vessel types

Ethical supply chains are not only a moral imperative but also a competitive advantage in the global marketplace. Buyers who align with suppliers committed to sustainability can enhance their brand reputation and meet the increasing demands of environmentally conscious consumers and regulatory bodies alike.

What Has Been the Evolution of Pressure Vessel Technology?

The evolution of pressure vessel technology is marked by significant advancements in materials science and engineering practices. Initially, pressure vessels were predominantly constructed from carbon steel, which provided adequate strength but had limitations in corrosion resistance. Over the decades, the introduction of stainless steel, titanium, and composite materials has transformed the sector, enabling the production of vessels that can withstand extreme conditions while minimizing maintenance costs.

The development of sophisticated design codes, such as the ASME Boiler and Pressure Vessel Code, has also played a crucial role in enhancing safety and performance standards across the industry. These regulations ensure that pressure vessels are rigorously tested and certified, thereby instilling confidence in buyers regarding their reliability and operational safety.

In recent years, the integration of digital technologies, such as IoT sensors and AI-driven analytics, has further revolutionized pressure vessel monitoring and maintenance practices. These innovations facilitate proactive management of vessel integrity, reducing downtime and extending service life, which is particularly beneficial for international B2B buyers operating in dynamic and demanding environments.

Frequently Asked Questions (FAQs) for B2B Buyers of pressure vessel types

-

How do I ensure compliance with international pressure vessel standards?

Ensuring compliance with international pressure vessel standards involves familiarizing yourself with the relevant regulations, such as the ASME Boiler and Pressure Vessel Code (BPVC) and API 510 for inspection. Engage with suppliers who are certified and experienced in these standards. Request documentation of their compliance certifications and inquire about their quality assurance processes. Additionally, consider hiring third-party inspectors to verify that the vessels meet the required safety and operational standards before shipping. -

What is the best pressure vessel type for storing hazardous materials?

For storing hazardous materials, spherical pressure vessels are often the best choice due to their structural integrity and ability to evenly distribute pressure, reducing the risk of failure. These vessels are designed to withstand higher pressures and are less prone to leaks. However, cylindrical pressure vessels with reinforced walls can also be suitable, depending on the specific materials and pressure conditions. Always consult with your supplier to determine the most appropriate design and materials based on the specific requirements of the materials being stored. -

How can I evaluate the reliability of a pressure vessel supplier?

Evaluating the reliability of a pressure vessel supplier requires thorough vetting. Start by checking their reputation through industry reviews and customer testimonials. Verify their certifications, such as ISO or ASME, and assess their production capabilities, including quality control processes. Engage in direct communication to gauge their responsiveness and willingness to address your specific needs. Request references and, if possible, visit their facilities to observe their manufacturing processes firsthand. -

What customization options are typically available for pressure vessels?

Customization options for pressure vessels include variations in size, shape, material, and design features such as insulation or specific fittings. Suppliers can often tailor vessels to meet unique operational requirements, including pressure ratings and corrosion resistance. Discuss your specific application needs with potential suppliers to explore the extent of their customization capabilities and any associated costs. Ensure that all modifications comply with relevant safety standards. -

What are the typical minimum order quantities (MOQs) for pressure vessels?

Minimum order quantities (MOQs) for pressure vessels vary significantly based on the supplier, the complexity of the vessel, and the materials used. Some manufacturers may have MOQs as low as one unit for standard designs, while custom vessels often require larger orders to justify production costs. When engaging with suppliers, clarify their MOQ policies and negotiate terms that align with your project needs, especially if you’re looking to start with a smaller pilot project. -

What payment terms should I expect when sourcing pressure vessels internationally?

Payment terms for international sourcing of pressure vessels can vary widely. Common arrangements include upfront deposits (typically 30-50%), followed by balance payments upon completion or prior to shipment. Some suppliers may offer letter of credit options or payment upon delivery. Always clarify payment terms during negotiations, ensuring they align with your cash flow capabilities and risk management strategies. Consider using escrow services for large transactions to enhance security. -

How do I ensure the quality assurance of pressure vessels before delivery?

To ensure quality assurance before delivery, request detailed inspection reports and certifications from your supplier. Establish a clear quality control agreement that outlines inspection processes, including visual inspections, non-destructive testing, and pressure testing. If feasible, consider conducting a pre-shipment inspection with a third-party inspection service to verify compliance with specifications and safety standards. This proactive approach helps mitigate risks associated with product quality and reliability. -

What logistics considerations should I take into account for transporting pressure vessels?

When transporting pressure vessels, consider the dimensions, weight, and fragility of the units, which may require specialized handling. Ensure compliance with international shipping regulations, including any specific documentation for hazardous materials. Discuss logistics with your supplier to coordinate packaging, loading, and transportation methods that minimize the risk of damage. Additionally, factor in customs clearance processes and potential tariffs or duties, especially when importing into regions with strict regulations.

Top 6 Pressure Vessel Types Manufacturers & Suppliers List

1. SafetyCulture – Pressure Vessels

Domain: safetyculture.com

Registered: 2002 (23 years)

Introduction: Pressure vessels are specialized containers used to store or transport gases and liquids under pressure. They must meet strict safety standards and can be made from materials like steel, aluminum, or composites. Common types include storage vessels, heat exchangers, boilers, and process vessels. They can be spherical or cylindrical in shape. Key standards include the ASME Boiler and Pressure Vesse…

2. IQS Directory – Pressure Vessels

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Pressure vessels are enclosed structures designed to hold liquids, gases, or vapors at pressures significantly differing from the surrounding atmosphere. They are crucial in industries such as petrochemical, oil and gas, chemical processing, and food manufacturing. Key types of pressure vessels include: 1. Storage Vessels: Designed for temporary or long-term holding of liquids, vapors, and gases u…

3. T. Bailey – Pressure Vessels

Domain: blog.tbailey.com

Registered: 1999 (26 years)

Introduction: Pressure vessels are containers designed to store liquids, gases, or vapors at pressures greater than 15 PSI. They can be categorized into three main types: storage vessels, heat exchangers, and process vessels. Storage vessels are tailored for specific products like propane, ammonia, and chlorine. Heat exchangers transfer heat between fluids without direct contact, commonly used in waste processi…

4. Yena Engineering – Pressure Vessels

Domain: yenaengineering.nl

Registered: 2018 (7 years)

Introduction: Pressure vessels are enclosed containers used to store or transfer liquids and gases under pressure. They can be designed in various shapes, with the most common being cylinders, spheres, and cones. Types of pressure vessels include: 1. Storage Vessels – for storing products like petroleum and chemicals. 2. Heat Exchangers – for removing or storing heat. 3. Process Vessels – for conducting chemica…

5. NPROXX – Type 4 Hydrogen Storage Vessels

Domain: nproxx.com

Registered: 2018 (7 years)

Introduction: NPROXX designs and manufactures high-quality Type 4 pressure vessels for hydrogen storage under high pressures. Type 4 pressure vessels are made of all carbon fibre with an inner liner of polyamide or polyethylene plastic, offering much lower weight and very high strength. They provide advantages such as reduced transport costs due to lower weight, increased strength, enhanced corrosion and fatigu…

6. Red River – Open-End Pressure Vessel

Domain: redriver.team

Introduction: Open-End Pressure Vessel: Characterized by at least one open end for easy access; used in food industry, chemical reactors, and water treatment. Materials include stainless steel, carbon steel, and certain plastics. Maintenance involves routine cleaning and inspections. Closed-End Pressure Vessel: Sealed on all sides for maximum containment; used in nuclear reactors, aerospace components, and high…

Strategic Sourcing Conclusion and Outlook for pressure vessel types

As industries across Africa, South America, the Middle East, and Europe continue to evolve, the strategic sourcing of pressure vessels will play a pivotal role in ensuring operational efficiency and compliance with safety standards. Understanding the diverse types of pressure vessels—such as storage, heat exchangers, boilers, and process vessels—enables buyers to make informed decisions tailored to their specific needs.

Illustrative image related to pressure vessel types

Investing in high-quality materials and adhering to rigorous testing protocols are essential for longevity and reliability. By prioritizing suppliers who align with international standards like ASME and API, businesses can mitigate risks associated with pressure vessel failures, which can lead to costly downtimes and safety hazards.

Looking ahead, the demand for innovative pressure vessel solutions will only increase, driven by advancements in technology and the need for sustainable practices. B2B buyers are encouraged to engage with manufacturers who can offer customized solutions that not only meet current requirements but also anticipate future industry trends. By doing so, they can secure a competitive advantage in their respective markets. Embrace the opportunity to enhance your operations through strategic sourcing—your commitment to quality today will yield significant benefits tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.