Everything You Need to Know About Pressure Differential Switch Sourcing in 2025

Introduction: Navigating the Global Market for pressure differential switch

In an increasingly interconnected world, sourcing reliable pressure differential switches is a critical challenge for international B2B buyers. These devices, essential for monitoring pressure differences across various applications—from HVAC systems to industrial processes—serve as the backbone of operational efficiency and safety. However, navigating the global market can be daunting, with numerous options, varying standards, and a plethora of suppliers to evaluate. This guide addresses these complexities by providing a comprehensive overview of the types of pressure differential switches available, their specific applications, and essential criteria for supplier vetting.

Throughout this guide, readers will gain actionable insights into cost considerations, key performance indicators, and compliance standards relevant to their regions, including Africa, South America, the Middle East, and Europe. Whether you’re operating in Nigeria’s burgeoning industrial sector or Germany’s advanced manufacturing landscape, understanding the nuances of pressure differential switches is crucial for informed purchasing decisions. By empowering B2B buyers with the knowledge needed to identify quality products and trustworthy suppliers, this resource aims to facilitate smoother transactions and enhance operational reliability.

Prepare to delve into the essential components of selecting the right pressure differential switch, ensuring your business remains competitive and compliant in today’s global marketplace.

Understanding pressure differential switch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mechanical Pressure Switch | Operates via mechanical components; adjustable setpoints | HVAC systems, industrial equipment | Pros: Reliable, low maintenance. Cons: Limited precision compared to electronic types. |

| Electronic Pressure Switch | Utilizes electronic sensors for enhanced accuracy | Clean rooms, laboratory applications | Pros: High precision, versatile. Cons: Higher cost and complexity. |

| Explosion-Proof Pressure Switch | Designed for hazardous environments; weatherproof construction | Oil & gas, chemical processing | Pros: Safety in explosive atmospheres. Cons: Typically more expensive. |

| Adjustable Differential Pressure Switch | Field-adjustable settings for specific pressure ranges | Air filter monitoring, ventilation systems | Pros: Customizable for varied applications. Cons: May require more user knowledge. |

| Wet/Wet Differential Pressure Switch | Designed for measuring liquids; dual pressure connections | Water treatment, HVAC applications | Pros: Suitable for liquid applications. Cons: Limited to specific media types. |

What Are the Characteristics of Mechanical Pressure Switches?

Mechanical pressure switches are primarily characterized by their use of mechanical components to detect pressure changes. They are often adjustable, allowing operators to set specific thresholds for activation. These switches are commonly employed in HVAC systems and industrial equipment due to their reliability and low maintenance requirements. However, they may lack the precision of electronic alternatives, which can be a consideration for buyers requiring exact measurements.

How Do Electronic Pressure Switches Enhance Accuracy?

Electronic pressure switches leverage advanced sensor technology to provide high accuracy and responsiveness. They are often favored in applications where precise control is essential, such as in clean rooms and laboratory settings. These switches can accommodate a variety of pressure ranges and are typically more versatile than mechanical types. However, their complexity and higher cost might be a drawback for some businesses, particularly those with tighter budgets.

What Makes Explosion-Proof Pressure Switches Essential in Certain Industries?

Explosion-proof pressure switches are specifically designed for use in hazardous environments, such as oil and gas fields or chemical processing plants. Their weatherproof construction and compliance with safety standards make them crucial for ensuring operational safety in explosive atmospheres. While they provide essential protection, the cost and installation requirements can be more significant than standard switches, which is an important consideration for buyers in high-risk industries.

Why Choose Adjustable Differential Pressure Switches?

Adjustable differential pressure switches offer field-adjustable settings, making them ideal for applications requiring flexibility, such as air filter monitoring and ventilation systems. Their ability to be customized for various pressure ranges allows businesses to optimize their operations effectively. However, the need for user knowledge to make adjustments can be a potential barrier for some users, making training and support critical in the purchasing decision.

In What Situations Are Wet/Wet Differential Pressure Switches Preferred?

Wet/wet differential pressure switches are designed to measure pressure in liquid applications, making them suitable for industries like water treatment and HVAC. They feature dual pressure connections that allow for accurate readings in applications involving fluids. While they excel in specific media types, their use is limited to liquids, which may restrict their applicability in other settings. Buyers should consider their specific media requirements when selecting this type of switch.

Key Industrial Applications of pressure differential switch

| Industry/Sector | Specific Application of Pressure Differential Switch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| HVAC | Airflow Monitoring and Control | Ensures optimal airflow, reducing energy costs and improving comfort levels. | Look for switches with adjustable setpoints and high reliability. |

| Oil & Gas | Leak Detection in Pipelines | Enhances safety by detecting leaks early, minimizing environmental impact and financial loss. | Ensure compliance with local regulations and explosion-proof ratings. |

| Pharmaceuticals | Cleanroom Pressure Monitoring | Maintains sterile environments crucial for product integrity and compliance. | Seek switches with precise measurement capabilities and robust materials. |

| Water Treatment | Filter Monitoring | Prevents equipment damage and ensures water quality by monitoring filter conditions. | Consider durability and resistance to corrosive environments. |

| Manufacturing | Process Control in Production Lines | Increases efficiency by ensuring optimal pressure levels in manufacturing processes. | Evaluate for compatibility with various media and operational conditions. |

How is Pressure Differential Switch Used in HVAC Applications?

In HVAC systems, pressure differential switches are essential for monitoring and controlling airflow. They detect pressure differences across filters and ducts, triggering alarms or equipment adjustments when thresholds are exceeded. This functionality helps maintain optimal indoor air quality and energy efficiency, which is particularly valuable for businesses aiming to reduce operational costs. Buyers from regions like Africa and Europe should prioritize switches with adjustable setpoints and robust construction to withstand varying environmental conditions.

What Role Does Pressure Differential Switch Play in Oil & Gas Leak Detection?

In the oil and gas industry, pressure differential switches are crucial for leak detection in pipelines. By monitoring pressure changes, these switches can promptly alert operators to potential leaks, thereby minimizing environmental risks and financial losses. For international buyers, particularly in South America and the Middle East, sourcing switches that comply with stringent safety regulations and have explosion-proof ratings is essential for ensuring operational safety and reliability.

How is Pressure Differential Switch Essential for Pharmaceuticals Cleanroom Monitoring?

In pharmaceutical manufacturing, maintaining sterile environments is vital for product integrity. Pressure differential switches are employed to monitor the pressure in cleanrooms, ensuring that contaminants do not enter the controlled environment. This application is critical for compliance with health regulations. Buyers should focus on switches that offer precise measurement capabilities and are constructed from materials that can withstand the rigorous demands of cleanroom conditions, particularly in European markets.

How Does Pressure Differential Switch Aid in Water Treatment Filter Monitoring?

In water treatment facilities, pressure differential switches monitor the condition of filters to prevent clogging and ensure water quality. By detecting pressure changes, these switches can indicate when filters need maintenance or replacement, thus protecting downstream equipment and maintaining service quality. Buyers in Africa and South America should consider sourcing switches that are durable and resistant to the corrosive nature of water treatment chemicals.

What is the Importance of Pressure Differential Switch in Manufacturing Process Control?

In manufacturing, pressure differential switches are integral to process control, ensuring that pressure levels remain within specified limits for optimal production efficiency. They help prevent equipment failure and downtime by monitoring pressure in real-time. Businesses should look for switches compatible with various media and capable of functioning in diverse operational conditions, especially in regions with fluctuating environmental factors like the Middle East.

3 Common User Pain Points for ‘pressure differential switch’ & Their Solutions

Scenario 1: Difficulty in Maintaining Accurate Pressure Readings

The Problem: Many B2B buyers face challenges in maintaining accurate pressure readings with differential pressure switches due to environmental factors such as dust, humidity, and temperature fluctuations. These conditions can lead to erratic readings, causing equipment malfunctions and inefficiencies in processes. For instance, in manufacturing facilities, inaccurate pressure readings can result in improper ventilation, leading to unsafe working conditions and affecting product quality.

The Solution: To combat these issues, buyers should invest in pressure differential switches that are designed with robust environmental protections, such as weatherproof enclosures and built-in pressure snubbers for stable readings. Additionally, selecting switches with a wide operating temperature range and materials that resist corrosion can enhance reliability. Regular calibration and maintenance schedules should also be implemented, ensuring that the switches are functioning correctly and providing accurate data. Consider suppliers that offer comprehensive support and guidance on installation and maintenance, enabling your team to optimize the performance of the switches in challenging environments.

Scenario 2: Complications in Setting the Correct Pressure Thresholds

The Problem: Another common issue is the complexity involved in setting the correct pressure thresholds for differential pressure switches. B2B buyers often encounter difficulties in adjusting setpoints accurately, which can lead to either premature activation or delayed responses. This is particularly problematic in industries like HVAC and cleanroom environments, where precise control of pressure is critical for operational efficiency and safety.

The Solution: Buyers should look for pressure differential switches that offer user-friendly, field-adjustable setpoints. Devices equipped with easy-to-read dials or digital displays allow for quick adjustments without the need for specialized tools. Additionally, investing in training for the operational staff on how to properly set and adjust these switches can significantly improve their effectiveness. Engaging with manufacturers that provide detailed user manuals and instructional resources can also facilitate better understanding and usage, ensuring that the equipment operates within the desired parameters.

Scenario 3: Challenges in Compatibility with Existing Systems

The Problem: B2B buyers often struggle with integrating new pressure differential switches into their existing systems. Compatibility issues can arise due to differences in electrical connections, mounting configurations, or operational requirements. This can lead to increased installation costs, project delays, and potential system failures, particularly in industries that rely heavily on automated processes.

The Solution: To mitigate compatibility issues, buyers should conduct a thorough compatibility assessment before purchasing a pressure differential switch. This involves checking specifications such as electrical connection types, process connection sizes, and overall system requirements. Opting for modular or configurable switches can also provide greater flexibility in integration. Collaborating with suppliers who offer customized solutions or technical support during the installation process can further ensure a smooth integration. It’s beneficial to source from manufacturers that provide detailed documentation, including compatibility matrices, which can help streamline the selection process and prevent future disruptions.

Strategic Material Selection Guide for pressure differential switch

What Are the Key Materials Used in Pressure Differential Switches?

When selecting materials for pressure differential switches, it is essential to consider their properties, advantages, and limitations. The choice of material can significantly impact the performance, durability, and suitability of the switch for specific applications. Below, we analyze four common materials used in the manufacturing of pressure differential switches.

How Does Stainless Steel Perform in Pressure Differential Switches?

Key Properties: Stainless steel is renowned for its excellent corrosion resistance and high-temperature tolerance, typically rated up to 500°F (260°C). It can withstand high pressures, making it suitable for demanding environments.

Pros & Cons: The durability of stainless steel is one of its most significant advantages, ensuring a long lifespan even in harsh conditions. However, its higher cost compared to other materials can be a drawback for budget-sensitive projects. Additionally, manufacturing processes for stainless steel components can be complex, requiring specialized tooling.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive fluids and gases. This makes it ideal for applications in industries such as oil and gas, pharmaceuticals, and food processing.

Considerations for International Buyers: Buyers from regions such as Europe (e.g., Germany) should ensure compliance with standards like DIN and ASTM for material specifications. The higher cost may be justified by the material’s longevity and reliability.

What Role Does Brass Play in Pressure Differential Switches?

Key Properties: Brass offers good corrosion resistance and is easy to machine, with a temperature rating typically around 300°F (149°C). It is also capable of handling moderate pressure levels.

Pros & Cons: The primary advantage of brass is its affordability and ease of manufacturing, which can reduce overall production costs. However, brass is less durable than stainless steel and may not be suitable for high-pressure applications or environments with aggressive chemicals.

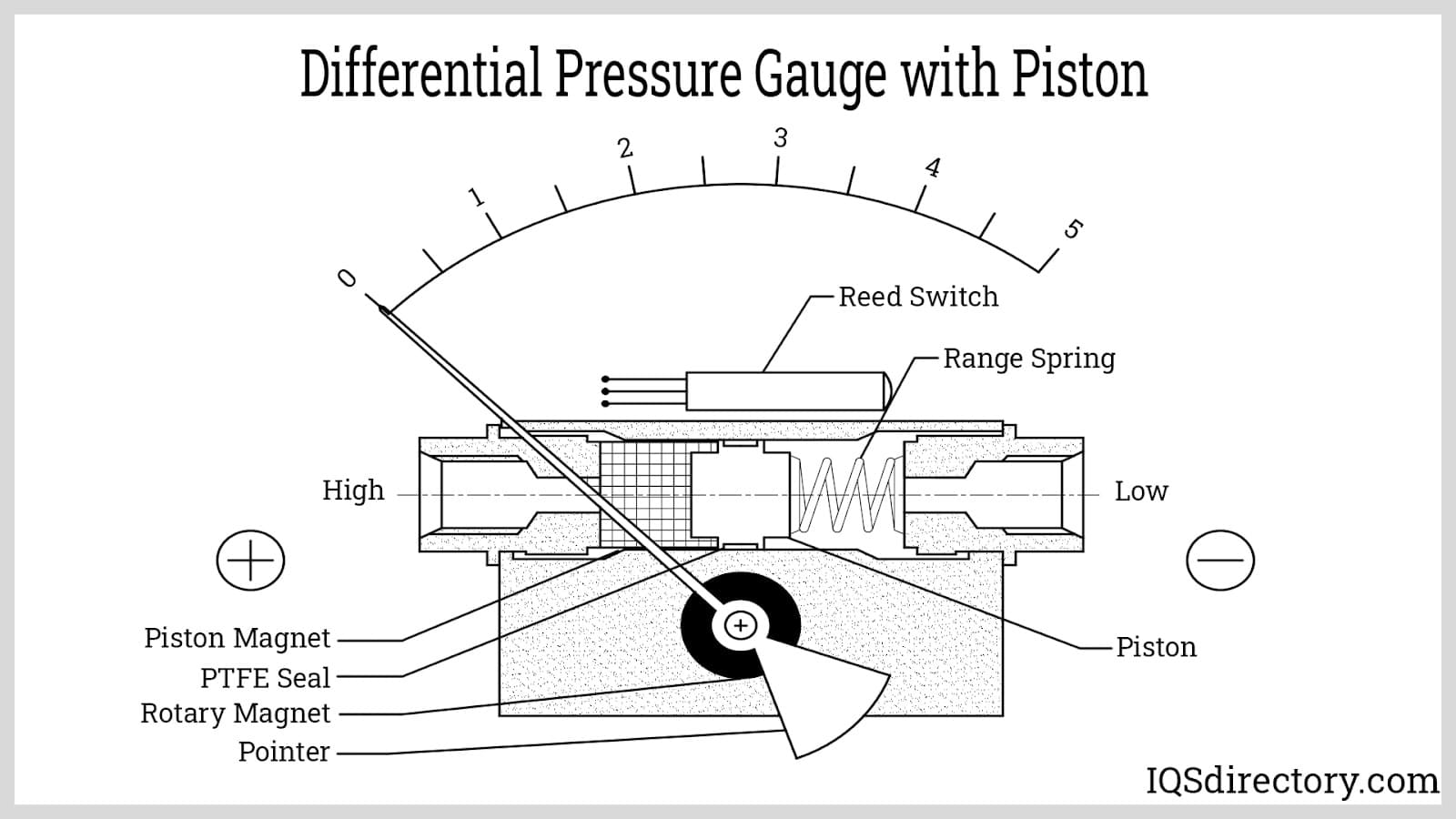

Illustrative image related to pressure differential switch

Impact on Application: Brass is commonly used in applications involving air and non-corrosive gases. It is often favored in HVAC systems and general-purpose applications.

Considerations for International Buyers: Compliance with regional standards is essential, particularly in markets like Africa and South America, where material specifications may vary. The cost-effectiveness of brass can be appealing, but buyers should assess its suitability for specific applications.

How Does Plastic Compare in Pressure Differential Switches?

Key Properties: Plastics, such as polycarbonate or nylon, are lightweight and provide good chemical resistance. They typically have lower temperature ratings, generally up to 200°F (93°C), and can handle low to moderate pressure.

Pros & Cons: The lightweight nature of plastic makes it easy to install, and its cost is significantly lower than metals. However, plastics may not be suitable for high-pressure applications or extreme temperatures, limiting their use in certain industries.

Impact on Application: Plastic pressure switches are often used in low-pressure environments, such as HVAC systems and light industrial applications. Their resistance to moisture and chemicals makes them suitable for specific media.

Considerations for International Buyers: Buyers should be aware of the varying standards for plastics in different regions. Compliance with local regulations is crucial, especially in the Middle East and Africa, where environmental considerations may dictate material choices.

What Advantages Does Aluminum Offer in Pressure Differential Switches?

Key Properties: Aluminum is lightweight, has good corrosion resistance, and can handle moderate temperature and pressure levels, typically rated up to 300°F (149°C).

Pros & Cons: The primary advantage of aluminum is its balance of weight and strength, making it suitable for many applications. However, it is generally more expensive than plastic and may require additional coatings for enhanced corrosion resistance.

Impact on Application: Aluminum is often used in applications where weight is a critical factor, such as in aerospace or automotive industries. Its compatibility with various media makes it versatile.

Considerations for International Buyers: For buyers in Europe, compliance with EU regulations regarding aluminum use is essential. The cost of aluminum may be higher, but its performance can justify the investment.

Summary Table of Material Selection for Pressure Differential Switches

| Material | Typical Use Case for pressure differential switch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Oil and gas, pharmaceuticals, food processing | Excellent durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Brass | HVAC systems, general-purpose applications | Cost-effective and easy to machine | Less durable under high pressure | Medium |

| Plastic | HVAC systems, light industrial applications | Lightweight and low cost | Limited high-pressure capability | Low |

| Aluminum | Aerospace, automotive applications | Good balance of weight and strength | More expensive than plastic | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the various materials used in pressure differential switches, allowing for informed decision-making based on application requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for pressure differential switch

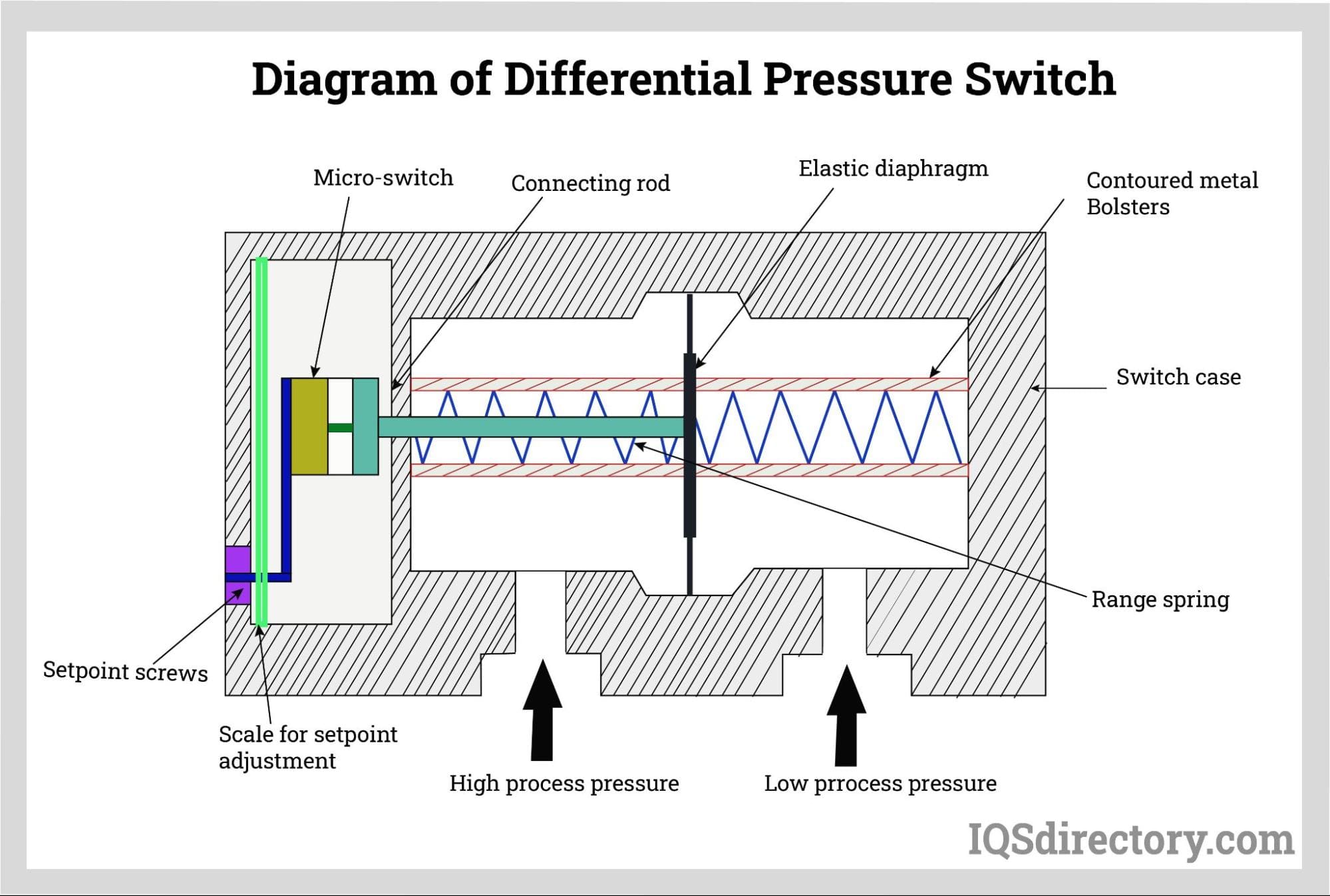

What Are the Main Stages of Manufacturing a Pressure Differential Switch?

The manufacturing process of pressure differential switches involves several critical stages that ensure both functionality and reliability. Understanding these stages helps B2B buyers assess the capabilities of their suppliers.

Material Preparation

The first step in manufacturing pressure differential switches is the selection and preparation of materials. Common materials include stainless steel, brass, and various plastics, which are chosen based on their compatibility with the operating environment and the media being measured. Before production, materials undergo rigorous quality checks to ensure they meet specified standards for strength, corrosion resistance, and durability.

Forming Techniques

Once materials are prepared, they are subjected to forming techniques. Common methods include machining, stamping, and injection molding. Machining is often used for precision components, ensuring tight tolerances essential for accurate pressure readings. Stamping may be employed for creating metal housings, while injection molding is typically used for plastic components. Each technique must be executed with precision to maintain the integrity of the switch’s design.

Illustrative image related to pressure differential switch

Assembly Processes

The assembly stage involves the integration of various components, including sensors, diaphragms, and electrical connections. Automated assembly lines are frequently utilized to enhance efficiency and reduce human error. During assembly, components are meticulously aligned, and connections are secured to ensure reliability in operation. This stage may also include calibration processes, where the switch is adjusted to activate at specific pressure differentials.

Finishing Procedures

The final stage in manufacturing involves finishing processes, which may include surface treatments, painting, or the application of protective coatings. These treatments enhance the durability and aesthetic appeal of the switches. For products intended for harsh environments, additional sealing or weatherproofing may be applied to ensure longevity and reliability.

How Is Quality Assurance Implemented in the Manufacturing of Pressure Differential Switches?

Quality assurance (QA) is a critical aspect of the manufacturing process for pressure differential switches, ensuring that products meet both international and industry-specific standards.

What Are the Relevant International Standards for Quality Control?

International standards, such as ISO 9001, are pivotal in establishing quality management systems across manufacturing processes. Compliance with ISO 9001 ensures that suppliers maintain consistent quality and continual improvement practices. For pressure differential switches, compliance with industry-specific standards such as CE marking for products sold in Europe and API (American Petroleum Institute) standards for oil and gas applications is also essential.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are integrated throughout the manufacturing process, including:

- Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials and components before they enter the production line.

- In-Process Quality Control (IPQC): During manufacturing, IPQC involves regular inspections to monitor the quality of work in progress. This may include checking dimensions, assembly integrity, and calibration of pressure settings.

- Final Quality Control (FQC): After assembly, FQC ensures that the final product meets all specifications. This includes functional testing, where switches are subjected to varying pressure levels to verify their response accuracy.

What Common Testing Methods Are Used for Pressure Differential Switches?

Testing methods play a crucial role in validating the performance of pressure differential switches. Common testing techniques include:

Illustrative image related to pressure differential switch

- Pressure Testing: This method evaluates the switch’s ability to operate under specified pressure conditions. It often involves subjecting the switch to both positive and negative pressures to ensure reliable performance.

- Electrical Testing: Ensures that electrical connections function correctly and that the switch activates at the designated pressure differentials.

- Environmental Testing: Assesses the switch’s performance in different environmental conditions, such as temperature extremes and humidity, ensuring that it can withstand its intended operational environment.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe, must take proactive steps to verify the quality control processes of their suppliers.

What Methods Can Be Used for Supplier Audits?

Conducting supplier audits is an effective way to assess quality control practices. During these audits, buyers can evaluate the supplier’s manufacturing processes, quality management systems, and adherence to international standards. It is advisable to have a checklist based on ISO standards and industry-specific requirements to ensure thorough evaluations.

How Can Buyers Access Quality Reports and Certifications?

Buyers should request quality assurance documentation, including certificates of compliance with relevant international and industry standards. These documents provide insights into the supplier’s commitment to quality and can be pivotal in decision-making.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can further enhance confidence in supplier quality. These independent entities can conduct inspections at various stages of production, providing unbiased assessments of quality control practices and product reliability. This is particularly beneficial for international buyers concerned about compliance with local regulations and standards.

Illustrative image related to pressure differential switch

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate unique challenges related to quality control. Understanding local regulations, standards, and certifications is vital for compliance. For example, products sold in Europe must adhere to CE marking requirements, while those in the Middle East may need to comply with specific local standards.

Additionally, cultural differences in business practices can impact quality assurance processes. Buyers should foster open communication with suppliers to clarify expectations regarding quality standards and ensure alignment.

Conclusion

Understanding the manufacturing processes and quality assurance measures for pressure differential switches is essential for B2B buyers. By familiarizing themselves with production stages, international standards, testing methods, and verification practices, buyers can make informed decisions when selecting suppliers. This due diligence not only ensures product reliability but also strengthens the overall supply chain in a global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pressure differential switch’

Introduction

Sourcing a pressure differential switch requires careful consideration of various technical and supplier-related factors. This checklist is designed to guide international B2B buyers through a systematic process to ensure that they procure reliable, high-quality switches that meet their specific operational needs. Whether you are in Africa, South America, the Middle East, or Europe, following these steps will help you make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s vital to have a clear understanding of your technical requirements. This includes the pressure range, switch type (e.g., mechanical or electronic), and compatibility with the media involved (air, gas, or liquid). Knowing these specifications helps in selecting the right product that meets your operational criteria and avoids costly errors.

- Pressure Range: Specify the minimum and maximum pressures your application requires.

- Switch Type: Decide between mechanical or electronic based on precision and application needs.

Step 2: Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers who specialize in pressure differential switches. Look for companies with a strong reputation in your industry and region. Creating a shortlist of suppliers allows for a more focused evaluation and facilitates better negotiation.

- Online Reviews: Check platforms like Trustpilot or industry-specific forums for customer feedback.

- Industry Networks: Utilize professional networks to gain insights into reliable suppliers.

Step 3: Evaluate Supplier Certifications

Before proceeding, verify that your shortlisted suppliers hold necessary certifications relevant to your industry. Certifications such as ISO 9001 or UL listing ensure that the products meet international quality and safety standards. This step is crucial for mitigating risks associated with substandard products.

- Quality Assurance: Look for suppliers who can provide documentation for their certifications.

- Regulatory Compliance: Ensure that the product complies with local regulations in your region.

Step 4: Request Samples for Testing

Once you have identified potential suppliers, request samples of the pressure differential switches for testing. This will allow you to assess the product’s performance and reliability in real-world conditions. Testing samples can save time and resources by ensuring the product meets your operational demands before bulk ordering.

Illustrative image related to pressure differential switch

- Performance Metrics: Evaluate the switch’s response time, accuracy, and durability under your specific conditions.

- Installation: Check the ease of installation and compatibility with existing systems.

Step 5: Negotiate Terms and Pricing

Engage in discussions with your chosen suppliers to negotiate terms, including pricing, delivery schedules, and payment terms. A clear agreement will help prevent misunderstandings and ensure a smooth procurement process.

- Volume Discounts: Inquire about pricing reductions for bulk orders.

- Lead Times: Confirm delivery timelines to align with your project schedules.

Step 6: Finalize the Order and Confirm Details

After agreeing on terms, finalize your order and confirm all details in writing. Ensure that the order includes all specifications discussed, including any warranty or support services offered by the supplier. This step is essential to protect your investment and establish clear expectations.

- Documentation: Keep a copy of the purchase order and any agreements for future reference.

- Follow-Up: Maintain communication with the supplier for updates on shipping and delivery.

Step 7: Monitor Performance Post-Purchase

After installation, monitor the performance of the pressure differential switches regularly. This will help you identify any issues early and ensure that the switches continue to meet your operational requirements.

- Feedback Loop: Establish a system for collecting feedback from your team on the switch’s performance.

- Supplier Relationship: Maintain a good relationship with the supplier for future support or replacements.

By following this checklist, you can confidently navigate the sourcing process for pressure differential switches, ensuring that you make informed decisions that support your business objectives.

Comprehensive Cost and Pricing Analysis for pressure differential switch Sourcing

What Are the Key Cost Components for Pressure Differential Switches?

When sourcing pressure differential switches, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The choice of materials significantly affects the cost. High-quality materials that resist environmental factors (such as humidity or corrosive substances) may incur higher upfront costs but can reduce long-term maintenance expenses. For instance, switches designed for harsh environments often utilize durable metals and specialized plastics.

-

Labor: Labor costs vary widely based on the region and the complexity of the manufacturing process. In regions with higher labor costs, like Germany, these expenses can be substantial. Conversely, sourcing from countries with lower labor costs, such as Nigeria or Brazil, may offer savings but can come with trade-offs in terms of quality or lead time.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities and indirect labor. Overhead is typically spread across all products manufactured, meaning that larger production runs can lower the cost per unit.

-

Tooling: Custom tooling for specialized designs can represent a significant upfront investment. However, once established, these tools can produce switches at a lower cost per unit, which is advantageous for larger orders.

-

Quality Control (QC): Implementing stringent QC processes ensures product reliability and compliance with international standards, which is essential for buyers in regulated industries. While this adds to the cost, it can prevent costly failures and recalls in the future.

-

Logistics: Transportation and shipping costs can vary greatly depending on the destination. Incoterms play a vital role in determining who bears these costs, which can impact overall pricing.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This can vary based on market dynamics, competition, and the perceived value of the switch.

How Do Price Influencers Impact Sourcing Decisions?

Several factors can influence the pricing of pressure differential switches, particularly for B2B buyers in Africa, South America, the Middle East, and Europe.

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly impact pricing. Higher volumes generally lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their needs to optimize costs.

-

Specifications and Customization: Custom specifications, such as unique pressure ranges or specific certifications, can increase costs. Buyers should assess whether standard models meet their needs to avoid unnecessary expenses.

-

Materials and Quality/Certifications: Higher quality and certified products often come at a premium. Buyers must evaluate whether the additional cost aligns with their operational requirements and risk management strategies.

-

Supplier Factors: The supplier’s reputation, reliability, and service offerings can influence pricing. A well-established supplier may command higher prices due to their proven track record, while newer entrants might offer competitive pricing to gain market share.

-

Incoterms: Understanding Incoterms is essential for determining the total landed cost, which includes shipping, insurance, and tariffs. This understanding helps buyers accurately assess the final pricing.

What Buyer Tips Can Enhance Cost-Efficiency?

International B2B buyers can adopt several strategies to enhance cost-efficiency when sourcing pressure differential switches:

-

Negotiation: Engaging in negotiations can yield favorable terms, particularly for bulk orders or long-term contracts. Buyers should be prepared to discuss volume, payment terms, and delivery schedules.

-

Total Cost of Ownership (TCO): Assessing the TCO rather than just the upfront cost can reveal hidden expenses, such as maintenance and operational costs over the product’s lifespan. This approach helps buyers make more informed decisions.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa or South America should consider currency fluctuations and import tariffs, which can affect overall costs. Establishing relationships with local suppliers may mitigate some of these risks.

-

Research and Comparison: Conduct thorough market research to compare prices and features from multiple suppliers. This practice can provide leverage during negotiations and help identify the best value for money.

By understanding the complex cost structure and pricing influencers associated with pressure differential switches, B2B buyers can make informed sourcing decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing pressure differential switch With Other Solutions

Exploring Alternative Solutions to Pressure Differential Switches

In the realm of industrial applications, pressure differential switches are widely recognized for their reliability in monitoring pressure changes. However, there are alternative technologies that can also fulfill similar roles in various settings. Understanding these alternatives allows B2B buyers to make informed decisions tailored to their operational needs. This analysis will compare pressure differential switches with two viable alternatives: Pressure Transmitters and Pressure Sensors.

| Comparison Aspect | Pressure Differential Switch | Pressure Transmitter | Pressure Sensor |

|---|---|---|---|

| Performance | High reliability for on/off control at set thresholds | Continuous pressure readings with high accuracy | Good for direct pressure measurement, limited to specific ranges |

| Cost | Generally lower initial cost | Higher initial investment due to advanced technology | Moderate cost, varies based on type and features |

| Ease of Implementation | Simple installation and setup | Requires more complex setup and calibration | Easy to install, but may need calibration for accuracy |

| Maintenance | Low maintenance; periodic checks recommended | Moderate maintenance; recalibration needed periodically | Minimal maintenance; generally stable, but calibration may be required |

| Best Use Case | HVAC systems, filtration monitoring | Industrial process control, automation | General pressure monitoring in various applications |

In-Depth Analysis of Alternatives

What are the Advantages and Disadvantages of Pressure Transmitters?

Pressure transmitters provide continuous pressure monitoring, offering superior accuracy and real-time data transmission. They are ideal for applications requiring precise pressure control, such as in industrial automation and process control systems. However, their higher cost and the complexity involved in installation and calibration can be a drawback for smaller operations or less critical applications. They often require a more extensive setup, which can increase overall project time and costs.

How do Pressure Sensors Compare in Terms of Performance?

Pressure sensors are versatile devices that measure pressure directly and can be used in a variety of applications, from automotive to HVAC. They offer a good balance between cost and performance, making them suitable for general pressure monitoring tasks. However, their performance may be limited to specific pressure ranges, and they may not provide the same level of accuracy as transmitters. While they are relatively easy to install, they may require calibration to ensure accuracy, especially in more demanding environments.

Making the Right Choice: Which Solution is Best for Your Needs?

When evaluating the right solution for your operations, consider the specific requirements of your application. If you require high accuracy and continuous monitoring, a pressure transmitter may be the best choice despite the higher upfront investment. On the other hand, if you are looking for a cost-effective solution for basic on/off control, a pressure differential switch remains a reliable option. For general pressure monitoring with moderate accuracy requirements, pressure sensors can provide a good balance of performance and cost.

Illustrative image related to pressure differential switch

Ultimately, the decision should be based on the operational context, budget constraints, and performance expectations of your specific application. By carefully weighing the pros and cons of each alternative, B2B buyers can ensure they select the most appropriate technology to meet their business needs.

Essential Technical Properties and Trade Terminology for pressure differential switch

Understanding the technical properties and terminology associated with pressure differential switches is crucial for B2B buyers seeking reliable solutions for monitoring and controlling pressure variations in various applications. This section outlines key specifications and common industry terms to facilitate informed decision-making.

What Are the Key Technical Properties of Pressure Differential Switches?

-

Measurement Range

The measurement range indicates the minimum and maximum pressure differentials that the switch can accurately detect. This is critical for ensuring that the switch can operate effectively within the specific conditions of your application. Common ranges may vary from 0.1” to 40” WC (20 to 10,000 Pa). Selecting a switch with the appropriate range helps prevent premature failure and ensures optimal performance. -

Switch Rating

The switch rating specifies the maximum electrical load the switch can handle, typically measured in amperes (A). This is vital for compatibility with the systems being controlled. For instance, a switch rated at 5A is suitable for low-power applications, while higher ratings may be necessary for industrial settings. Ensuring the switch rating matches your application’s requirements can reduce the risk of electrical failures. -

Deadband

Deadband refers to the range of pressure change required to activate or deactivate the switch. A narrower deadband allows for more precise control, while a broader deadband can prevent frequent cycling of the switch. Understanding deadband specifications is essential for applications requiring fine pressure control, as it impacts system responsiveness and stability. -

Operating Temperature Range

This specification outlines the temperature limits within which the switch can function effectively. Operating temperature ranges can vary widely, from -40°F to +180°F (-40°C to +82°C). Selecting a switch with an appropriate operating temperature range ensures reliability in extreme environments, which is particularly important for industries such as HVAC and manufacturing. -

Material Compatibility

The materials used in the construction of a pressure differential switch, especially those in contact with the media, play a significant role in its durability and performance. Common materials include stainless steel, brass, and various plastics. Understanding material compatibility is crucial for applications involving corrosive substances or high pressures, as it affects the longevity and reliability of the switch.

What Are Common Trade Terms in the Pressure Differential Switch Industry?

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of pressure differential switches, OEMs often provide customized solutions tailored to specific applications. B2B buyers should consider OEM options for unique requirements that off-the-shelf products may not meet. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budget-conscious buyers as it can affect overall project costs. Buyers should negotiate MOQs to align with their purchasing needs without incurring unnecessary expenses. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing for specific products or services. This term is vital for B2B buyers as it initiates the procurement process, allowing them to compare costs and terms from multiple suppliers. A well-structured RFQ can streamline negotiations and ensure better pricing. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping and logistics. Understanding Incoterms helps B2B buyers navigate shipping costs, insurance, and risk management, ensuring that both parties are clear on their obligations. -

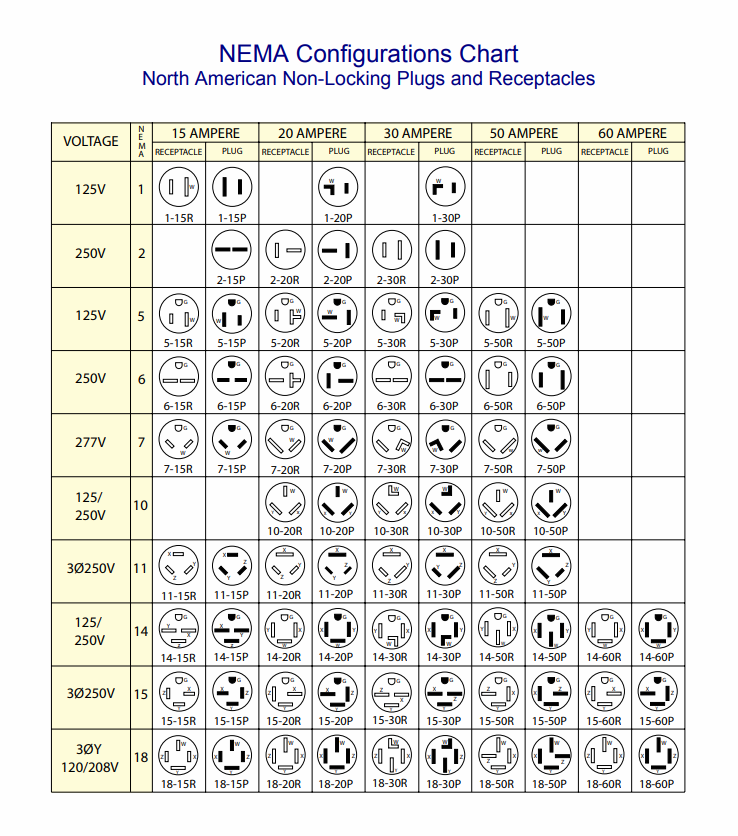

NEMA Ratings (National Electrical Manufacturers Association)

NEMA ratings classify the degree of protection provided by enclosures against environmental conditions. This is particularly relevant for pressure differential switches used in harsh environments. Knowing the NEMA rating ensures that buyers select switches capable of withstanding specific environmental challenges, enhancing reliability and performance.

By understanding these technical properties and industry terminology, B2B buyers can make informed decisions that align with their operational requirements and ensure long-term reliability in their applications.

Navigating Market Dynamics and Sourcing Trends in the pressure differential switch Sector

What Are the Key Market Trends Influencing Pressure Differential Switches?

The pressure differential switch market is experiencing significant growth, driven by increasing demand across various sectors, including HVAC, industrial automation, and medical equipment. Global drivers include the push for energy efficiency, stringent safety regulations, and advancements in technology that enhance the functionality of these devices. As industries strive to optimize processes and improve safety protocols, the integration of smart technologies, such as IoT capabilities, is emerging as a key trend. This allows for real-time monitoring and predictive maintenance, which are crucial for international buyers looking to minimize downtime and operational costs.

Emerging sourcing trends indicate a shift towards localized supply chains, especially in regions like Africa and South America, where logistics and transportation costs can be prohibitive. B2B buyers are increasingly prioritizing suppliers that offer customization and quick turnaround times. Additionally, the demand for high-quality, durable products that can withstand harsh environmental conditions is rising, particularly in the Middle East and Europe. This has led manufacturers to focus on developing products with enhanced materials and compliance certifications to meet diverse regulatory standards.

How Does Sustainability Influence B2B Sourcing for Pressure Differential Switches?

Sustainability is becoming a crucial factor in sourcing decisions for pressure differential switches. The environmental impact of manufacturing processes, from raw material extraction to waste management, is under scrutiny. B2B buyers are increasingly aware of the importance of ethical supply chains and are seeking suppliers who prioritize sustainable practices. This includes using recyclable materials, reducing energy consumption during production, and minimizing emissions.

Furthermore, certifications such as ISO 14001 for environmental management and RoHS compliance for hazardous substances are becoming essential for suppliers targeting international markets. These certifications not only demonstrate a commitment to sustainability but also enhance the credibility of the product in the eyes of discerning buyers. As global regulations tighten around environmental standards, manufacturers that adopt ‘green’ practices will be better positioned to compete and meet the expectations of environmentally-conscious buyers.

How Have Pressure Differential Switches Evolved Over Time?

The evolution of pressure differential switches can be traced back to their initial use in simple mechanical applications. Over the decades, advancements in technology have transformed these devices into sophisticated instruments capable of precise pressure monitoring and control. Early models relied on basic mechanical principles, while modern switches integrate electronic components and smart technology, allowing for enhanced functionality such as remote monitoring and automated alerts.

This evolution has been driven by the increasing complexity of industrial processes and the need for greater efficiency and safety. Today, pressure differential switches are crucial in various applications, from HVAC systems to critical medical devices, highlighting their adaptability and importance in the global market. As technology continues to advance, the future will likely see even more innovative solutions that cater to the specific needs of diverse industries, further solidifying the role of pressure differential switches in modern operations.

Frequently Asked Questions (FAQs) for B2B Buyers of pressure differential switch

-

How do I choose the right pressure differential switch for my application?

Choosing the right pressure differential switch involves evaluating your specific application requirements, such as the pressure range, media compatibility, and environmental conditions. Consider the switch’s operating temperature range, durability, and compliance with relevant standards (e.g., UL, CE). Additionally, assess whether you need features like adjustable setpoints or explosion-proof ratings. Consulting with suppliers for detailed specifications and potential applications can also help you make an informed decision. -

What is the best pressure differential switch for HVAC applications?

For HVAC applications, look for pressure differential switches designed for air flow monitoring and filter status alerts. Models with adjustable setpoints, such as those ranging from 0.1” to 40” WC, are particularly effective. Choose switches with built-in pressure snubbers for stable readings and robust enclosures to withstand environmental factors. Ensure the selected switch is compliant with local regulations and standards to guarantee reliability and safety in HVAC systems. -

What customization options are available for pressure differential switches?

Many manufacturers offer customization options for pressure differential switches, including tailored pressure ranges, specific electrical connections, and unique enclosure designs. You can request features like adjustable setpoints, various output types (e.g., SPDT, DPDT), and materials suitable for your media. Before placing an order, discuss your requirements with the supplier to ensure they can accommodate your needs and provide a solution that fits your application perfectly. -

What are the typical minimum order quantities (MOQs) for pressure differential switches?

Minimum order quantities (MOQs) for pressure differential switches can vary significantly among suppliers. Generally, MOQs may range from 10 to 100 units, depending on the manufacturer and product type. For specialized or custom switches, MOQs might be higher. When sourcing from international suppliers, consider discussing your needs to negotiate more favorable terms, especially if you’re testing a new product or entering a new market. -

What payment terms should I expect when sourcing pressure differential switches internationally?

Payment terms can vary widely among suppliers and regions. Common terms include upfront payments, letters of credit, or payment upon delivery. It’s important to clarify payment conditions before finalizing orders, as factors like order size, supplier reputation, and shipping terms may influence negotiations. Additionally, consider using secure payment methods to protect your transactions, especially when dealing with international suppliers. -

How do I ensure quality assurance for pressure differential switches?

To ensure quality assurance, request detailed product specifications, certifications, and test reports from suppliers. Look for manufacturers with ISO certifications or similar quality management systems in place. Additionally, consider ordering samples for testing before committing to larger orders. Establishing a clear communication channel with your supplier about quality expectations and conducting periodic audits can further enhance product reliability. -

What logistics considerations should I keep in mind when importing pressure differential switches?

When importing pressure differential switches, consider logistics factors such as shipping methods, delivery timelines, and customs regulations. Ensure your supplier provides accurate shipping documents to facilitate smooth customs clearance. Factor in potential tariffs and taxes, which can impact overall costs. Collaborating with a logistics partner familiar with international trade can streamline the process and help mitigate any unforeseen challenges. -

What should I know about warranty and after-sales support for pressure differential switches?

Before purchasing, inquire about the warranty terms and after-sales support offered by the supplier. Understand the duration of the warranty, what it covers, and the process for claiming it. Reliable suppliers will provide comprehensive after-sales support, including troubleshooting assistance and access to spare parts. This support is critical in maintaining operational efficiency and minimizing downtime in your applications.

Top 8 Pressure Differential Switch Manufacturers & Suppliers List

1. Dwyer – Differential Mechanical Pressure Switch

Domain: dwyeromega.com

Registered: 2022 (3 years)

Introduction: {“product_name”: “Differential Mechanical Pressure Switch”, “brand”: [“Dwyer”, “Omega”], “measurement_pressure_max”: [“0.02 inH₂O”, “0.5 inH₂O”, “0.15 inH₂O”, “0.22 inH₂O”, “1 inH₂O”, “1 kPa”, “1.2 inH₂O”, “1.5 inH₂O”, “1.6 inH₂O”, “2 inH₂O”, “2 psi”, “3 inH₂O”, “3 kPa”, “4 inH₂O”, “4 kPa”, “5 inH₂O”, “5 psi”, “5.5 inH₂O”, “6 inH₂O”, “6 mmHg”, “6 psi”, “8 inH₂O”, “8 psi”, “9 inH₂O”, “10 inH₂O”, “1…

2. BAPI – Differential Pressure Switch

Domain: bapihvac.com

Registered: 1996 (29 years)

Introduction: {“Product Name”: “Differential Pressure Switch”, “Price Range”: “$84.00 – $98.00”, “Pressure Range Options”: [“0.1” to 0.8” WC (20 to 200 Pa)”, “0.5” to 1.2” WC (120 to 300 Pa)”, “0.7” to 2.2” WC (180 to 550 Pa)”, “3.2” to 10.4” WC (800 to 2600 Pa)”, “8.8” to 24” WC (2200 to 6000 Pa)”, “12” to 40” WC (3000 to 10000 Pa)”], “Setpoint Adjustment”: “Field adjustable from 0.1” to 40” WC (20 to 10,000 P…

3. Alps Controls – Differential Pressure Switches

Domain: alpscontrols.com

Registered: 2000 (25 years)

Introduction: Differential Pressure Switches from Alps Controls, available in various setpoint ranges, connection types, and switch types. Setpoint ranges include options from 0.00..0.05 w.c. to 50.00..500.00 psi. Connection types include 0.125 IN. FEMALE NPT, 0.25 IN. BARBED, and more. Switch types available are DPDT, SPDT, and SPST. Options for automatic and manual reset types are also available.

4. IQS Directory – Differential Pressure Switches

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Differential pressure switches are used to measure the disparity in pressure between two locations, triggering alarms or disrupting circuits when specified limits are exceeded. They are essential in industries dealing with fluids and gases, providing accurate control and precise measurements. Types of differential pressure measurement devices include manometers, bourdon tube pressure gauges, diaph…

5. SOR Controls Group – Differential Pressure Switches

Domain: sorinc.com

Registered: 1997 (28 years)

Introduction: Differential Pressure Switches from SOR Controls Group are designed for various applications including filter maintenance and high static pressure flow monitoring. Key features include:

– Models: Big Hermet, Dual Opposed Diaphragm, High Static Operation, Low Pressure Switch, etc.

– Ranges: 0.5 to 2500 psid, 2.5 in wcd to 75 psid, and more.

– Certifications: INMETRO, SIL, UL/CSA, ATEX, CSA, IECEx, …

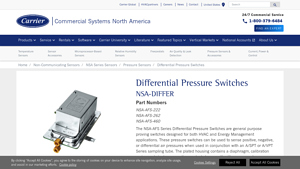

6. Carrier – Differential Pressure Switches NSA-DIFFER

Domain: carrier.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Differential Pressure Switches NSA-DIFFER”, “Part Numbers”: [“NSA-AFS-222”, “NSA-AFS-262”, “NSA-AFS-460”], “Applications”: [“Monitoring Filter Blockage”, “Proof of Flow”, “Prove Excessive or Insufficient Flow”, “Alarms and Control”], “Specifications”: {“Input Pressure Range”: {“NSA-AFS-222”: “0.05 +/- 0.02\” to 12\” wc”, “NSA-AFS-262”: “0.05 +/- 0.02\” to 2.0\” wc”, “NSA-AFS-460″…

7. KRIWAN – Delta-P II Oil Differential Pressure Switches

Domain: kriwan.com

Registered: 1998 (27 years)

Introduction: KRIWAN Delta-P II oil differential pressure switches are designed for use in reciprocating compressors to ensure reliable oil lubrication. They feature a unique two-component system that allows for flexible application. The switches provide precise and reliable measurements to prevent errors and extend the service life of the system.

8. McMaster – Differential Pressure Solutions

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Differential Pressure Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for pressure differential switch

How Can Strategic Sourcing Enhance Your Procurement of Pressure Differential Switches?

In the evolving landscape of industrial automation and HVAC systems, pressure differential switches play a critical role in ensuring operational efficiency and safety. For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, strategic sourcing is not merely a procurement tactic; it is a pathway to securing quality, reliability, and cost-effectiveness. By leveraging supplier relationships and understanding regional compliance requirements, businesses can enhance their sourcing strategies to meet specific operational needs.

Investing in high-quality pressure differential switches can lead to improved system performance, reduced downtime, and enhanced safety measures. Buyers should prioritize suppliers that offer robust support, customizable solutions, and compliance with international standards. The market is ripe with opportunities for those who are proactive in their sourcing strategies, enabling companies to gain a competitive edge.

Looking ahead, it is essential for buyers to stay informed about technological advancements and market trends in pressure differential switches. Engaging with suppliers who can provide insights into innovations and best practices will be crucial. Embrace the future of procurement by exploring strategic partnerships that drive value and sustainability in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.