Everything You Need to Know About Polyurethane Rollers Sourcing in 2025

Introduction: Navigating the Global Market for polyurethane rollers

Navigating the complexities of sourcing polyurethane rollers can be a daunting task for international B2B buyers, especially when considering the diverse applications across various industries. From material handling and automotive to food processing and printing, these specialized components are crucial for enhancing operational efficiency and minimizing downtime. This comprehensive guide is designed to empower decision-makers in Africa, South America, the Middle East, and Europe—regions characterized by unique market demands and challenges—by providing insights into the types of polyurethane rollers available, their specific applications, and essential factors to consider when vetting suppliers.

In the following sections, we will delve into the different types of polyurethane rollers, exploring their performance characteristics and suitability for various environments. Additionally, we will discuss the intricacies of cost considerations, ensuring buyers can make informed budgetary decisions. The guide also emphasizes the importance of supplier vetting, equipping readers with actionable strategies to identify reliable manufacturers who meet quality standards and can deliver customized solutions. By leveraging the knowledge presented here, B2B buyers will be better positioned to navigate the global market effectively, ensuring that their operations benefit from high-quality polyurethane rollers tailored to their specific needs.

Understanding polyurethane rollers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cast Urethane Rollers | Engineered for durability; customizable hardness | Material handling, automotive, food processing | Pros: High abrasion resistance; tailored formulations. Cons: Initial cost may be higher than alternatives. |

| Millable Urethane Rollers | Flexible processing; can be machined post-production | Printing, textile industries | Pros: Versatile; can be modified for specific needs. Cons: Generally less durable than cast options. |

| Polyurethane Coated Rollers | Steel core with polyurethane coating; lightweight | Machinery, packaging, conveyor systems | Pros: Protects surfaces; high load capacity. Cons: May require more frequent replacement. |

| Specialty Urethane Rollers | Custom blends for unique applications; varying hardness | Aerospace, oil & gas, specialized machinery | Pros: Tailored for harsh environments; enhanced performance. Cons: Longer lead times for production. |

| Recovered Urethane Rollers | Refurbished with new urethane; cost-effective | Existing machinery maintenance | Pros: Eco-friendly; cost savings compared to new rollers. Cons: Performance may not match original specifications. |

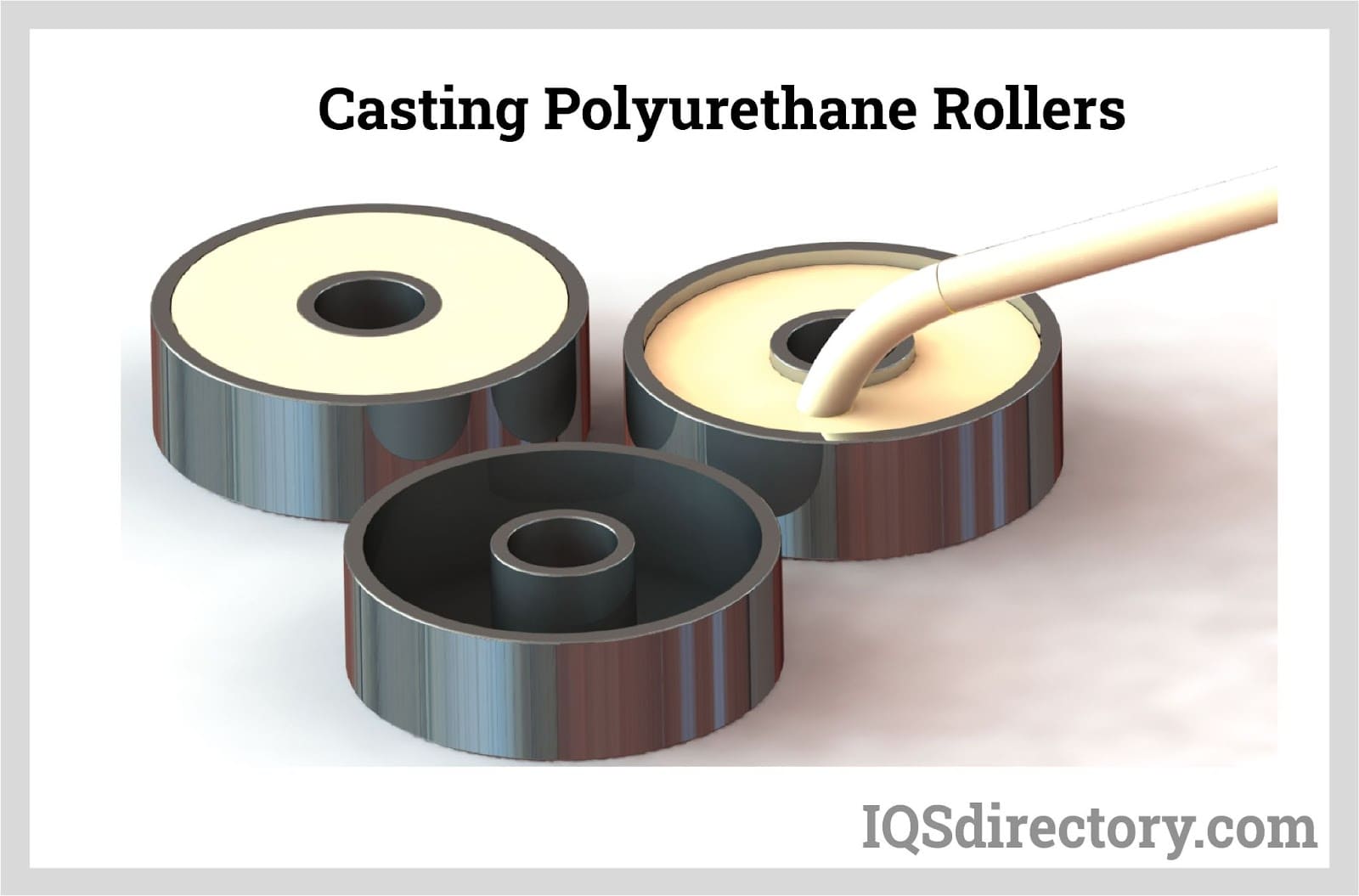

What Are the Characteristics of Cast Urethane Rollers?

Cast urethane rollers are engineered from liquid polyurethane that is poured into molds, ensuring a high level of durability and performance. These rollers can be customized to achieve specific hardness levels ranging from 30 Shore A to 70 Shore D, making them suitable for demanding applications such as material handling and food processing. B2B buyers should consider their operational needs, as the initial investment may be higher, but the long lifespan and resistance to wear can lead to cost savings over time.

How Do Millable Urethane Rollers Differ in Use?

Millable urethane rollers are characterized by their flexibility in production, allowing for post-production machining to meet precise specifications. This makes them ideal for applications in the printing and textile industries, where adaptability is crucial. While they offer versatility, B2B buyers should note that millable urethane generally has lower durability compared to cast options, which may impact long-term performance and replacement frequency.

Why Choose Polyurethane Coated Rollers?

Polyurethane coated rollers feature a robust steel core wrapped in a layer of high-strength polyurethane, providing excellent protection for surfaces and a lightweight solution for various applications. They are commonly used in machinery and packaging, where load capacity is essential. Buyers benefit from the protective properties, but should be aware that these rollers may require more frequent replacement due to wear.

What Are Specialty Urethane Rollers Best Suited For?

Specialty urethane rollers are designed with custom blends that cater to unique industrial requirements, such as those found in aerospace or oil and gas sectors. These rollers can withstand extreme conditions and are engineered for enhanced performance. However, B2B buyers should factor in longer lead times for production and potential costs associated with custom formulations, as these may affect project timelines.

Illustrative image related to polyurethane rollers

How Do Recovered Urethane Rollers Provide Value?

Recovered urethane rollers are refurbished products that have been re-coated with new polyurethane, offering an eco-friendly and cost-effective solution for businesses looking to maintain existing machinery. While they can provide substantial savings compared to purchasing new rollers, buyers should consider that the performance may not match the original specifications, and thorough inspections are necessary to ensure reliability.

Key Industrial Applications of polyurethane rollers

| Industry/Sector | Specific Application of polyurethane rollers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Material Handling | Conveyor systems for transporting goods | Enhanced durability and reduced maintenance costs | Custom hardness and abrasion resistance for specific loads |

| Printing | Printing press rollers for various printing techniques | Improved print quality and reduced noise levels | Compatibility with different inks and solvents |

| Food Processing | Rollers in packaging and processing lines | Compliance with food safety standards | FDA-approved materials and easy cleaning features |

| Automotive | Rollers in assembly lines for vehicle manufacturing | Increased efficiency and reduced downtime | Precision specifications for load-bearing applications |

| Textile Manufacturing | Textile feed rollers in weaving and finishing processes | Enhanced fabric handling and reduced wear | Custom coatings for chemical resistance and durability |

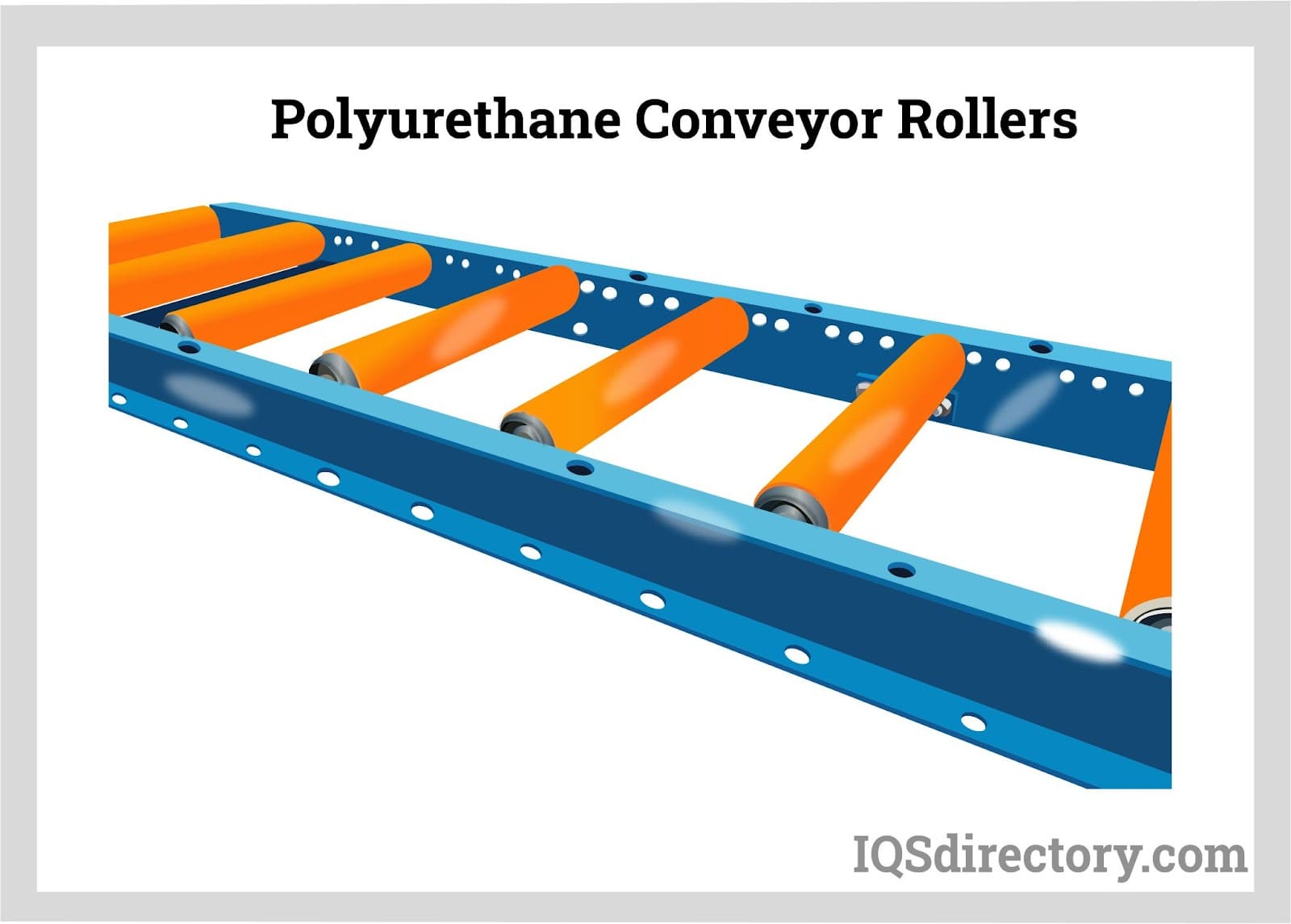

How Are Polyurethane Rollers Used in Material Handling?

In material handling, polyurethane rollers are integral to conveyor systems, where they facilitate the smooth transport of goods across various settings. These rollers are designed to withstand heavy loads and harsh environments, significantly reducing maintenance and replacement costs. For international buyers, particularly in regions like Africa and South America, sourcing rollers with specific hardness and abrasion resistance can optimize performance, ensuring longevity even in challenging conditions.

What Role Do Polyurethane Rollers Play in Printing?

Polyurethane rollers are essential in printing applications, where they serve in printing presses for tasks such as ink application and paper feed. Their unique properties help improve print quality by providing consistent pressure and reducing noise during operation. Buyers from the Middle East and Europe should consider sourcing rollers that are compatible with various inks and solvents, as this will enhance the versatility and efficiency of their printing processes.

How Are Polyurethane Rollers Essential in Food Processing?

In the food processing industry, polyurethane rollers are utilized in packaging and processing lines, where they ensure compliance with stringent food safety standards. These rollers are often made from FDA-approved materials, making them suitable for direct contact with food products. For businesses in regions like Africa and Asia, it is crucial to focus on sourcing rollers that not only meet safety standards but also feature designs that facilitate easy cleaning to maintain hygiene.

Why Are Polyurethane Rollers Important in Automotive Manufacturing?

In automotive manufacturing, polyurethane rollers are employed in assembly lines to aid in the efficient movement of vehicle components. These rollers enhance operational efficiency by minimizing downtime and improving the overall production flow. When sourcing for this application, international buyers must prioritize precision specifications and load-bearing capabilities to ensure that the rollers can handle the demands of high-volume production environments.

How Do Polyurethane Rollers Benefit Textile Manufacturing?

Polyurethane rollers are widely used in textile manufacturing, particularly in weaving and finishing processes. They provide excellent fabric handling, reducing wear and tear on textiles while maintaining high-speed production rates. Buyers in emerging markets should look for custom coatings that offer chemical resistance and durability, as these features will significantly improve the longevity and performance of rollers in various textile applications.

3 Common User Pain Points for ‘polyurethane rollers’ & Their Solutions

Scenario 1: Inconsistent Roller Performance Leading to Production Delays

The Problem: In industries such as manufacturing and packaging, the performance of polyurethane rollers is critical for smooth operations. B2B buyers often face the challenge of inconsistent roller performance, which can lead to production delays. This inconsistency may stem from variations in the hardness of the roller material, improper roller selection for specific applications, or even subpar manufacturing processes. As a result, businesses may experience increased downtime, higher operational costs, and a negative impact on their bottom line.

The Solution: To combat this issue, it is essential for buyers to source polyurethane rollers from reputable manufacturers that offer detailed specifications, including hardness ratings and material composition. Buyers should engage in thorough discussions with suppliers to ensure the rollers are tailored for their specific applications. When specifying rollers, consider factors such as load-bearing capacity, temperature tolerance, and environmental conditions. Additionally, conducting regular performance assessments of the rollers in operational environments can help identify any early signs of wear or performance inconsistencies, allowing for proactive maintenance or replacement.

Scenario 2: High Wear and Tear Causing Frequent Replacements

The Problem: Many B2B buyers discover that polyurethane rollers wear out much quicker than anticipated, leading to frequent replacements and escalating costs. This problem is particularly pronounced in environments where rollers are exposed to harsh conditions, such as high temperatures, abrasive materials, or heavy loads. Such rapid wear not only disrupts production schedules but also increases maintenance expenditures, putting pressure on operational budgets.

The Solution: To enhance the longevity of polyurethane rollers, buyers should select rollers with specific formulations designed for high wear resistance. Engaging with manufacturers who offer customized solutions can yield rollers that meet the unique demands of your operational environment. Furthermore, implementing a scheduled maintenance program that includes regular inspections and cleaning can mitigate wear. Consider using rollers with protective coatings or enhanced elastomer blends that can withstand abrasiveness and temperature fluctuations. Investing in quality over cost can lead to significant savings in the long run by reducing replacement frequency.

Scenario 3: Difficulty in Sourcing Custom Roller Solutions

The Problem: Many businesses require custom polyurethane rollers to fit unique machinery or application needs, yet sourcing these custom solutions can be a daunting task. B2B buyers often find themselves frustrated with long lead times, limited options, or a lack of expertise from suppliers, which can stall projects and impact operational efficiency. This challenge is particularly prevalent in specialized industries where standard roller sizes and materials do not suffice.

The Solution: To effectively address this sourcing challenge, buyers should prioritize working with manufacturers that specialize in custom polyurethane roller solutions. Engaging suppliers that have advanced manufacturing capabilities and offer extensive customization options—such as various hardness levels, sizes, and specialized coatings—can streamline the procurement process. It’s beneficial to provide detailed specifications and application requirements upfront to ensure manufacturers can deliver precisely what is needed. Establishing a collaborative relationship with suppliers can lead to quicker turnaround times and more innovative roller designs that cater to specific operational needs. Additionally, utilizing digital tools for communication and design review can expedite the process, ensuring that custom solutions meet expectations without unnecessary delays.

Strategic Material Selection Guide for polyurethane rollers

What Are the Key Properties of Common Materials Used in Polyurethane Rollers?

Polyurethane rollers are integral components in various industrial applications, and the selection of the right material is crucial for performance and longevity. Below, we analyze four common materials used in the manufacturing of polyurethane rollers, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. TDI (Toluene Diisocyanate) Ester Polyurethane

Key Properties: TDI ester polyurethanes offer excellent abrasion resistance, high resilience, and good load-bearing capabilities. They typically perform well at temperatures up to 220°F (105°C) and exhibit superior tear resistance.

Pros & Cons: The primary advantage of TDI ester polyurethanes is their durability in harsh operating conditions, making them suitable for heavy-duty applications. However, they can be more expensive compared to other materials and may require complex manufacturing processes.

Illustrative image related to polyurethane rollers

Impact on Application: These materials are particularly effective in environments where rollers are subjected to high wear and tear, such as in printing and packaging industries. Their compatibility with various media types, including solvents and oils, enhances their versatility.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers from regions like Africa and South America should be aware of local regulations regarding chemical safety and environmental impact.

2. MDI (Methylenediphenyl Diisocyanate) Ester Polyurethane

Key Properties: MDI ester polyurethanes are known for their excellent chemical resistance and high-temperature stability, withstanding temperatures up to 220°F (105°C). They also provide good mechanical properties and resilience.

Pros & Cons: The key advantage of MDI-based formulations is their exceptional performance in environments with exposure to harsh chemicals. However, they can be more challenging to process and may require specialized equipment, increasing manufacturing complexity.

Illustrative image related to polyurethane rollers

Impact on Application: MDI polyurethanes are ideal for applications in the automotive and food processing industries, where chemical exposure is common. Their resistance to solvents and oils makes them suitable for various operational conditions.

Considerations for International Buyers: Buyers should ensure that MDI formulations meet local and international compliance standards. For example, in Europe, adherence to REACH regulations is critical for chemical safety.

3. Ether-Based Polyurethane

Key Properties: Ether-based polyurethanes provide good elasticity and flexibility, making them suitable for applications requiring shock absorption. They typically perform well at temperatures up to 220°F (105°C) and offer moderate chemical resistance.

Pros & Cons: The main advantage of ether-based polyurethanes is their cost-effectiveness and ease of processing. However, they may not offer the same level of durability as ester-based formulations, particularly in highly abrasive environments.

Illustrative image related to polyurethane rollers

Impact on Application: These materials are commonly used in light-duty applications, such as conveyor systems and light material handling. Their flexibility allows for effective shock absorption, which is beneficial in various operational settings.

Considerations for International Buyers: Buyers should evaluate the specific application requirements and ensure that ether-based materials comply with local standards. In regions like the Middle East, understanding the climatic conditions can also impact material selection.

4. Millable Urethane

Key Properties: Millable urethanes are characterized by their ability to be processed using traditional rubber manufacturing techniques. They typically have a hardness range of 20-95 Shore A and offer good abrasion resistance.

Pros & Cons: The primary advantage of millable urethanes is their versatility in manufacturing, allowing for lower upfront tooling costs. However, they may not provide the same performance characteristics as cast urethanes, particularly in terms of durability.

Impact on Application: Millable urethanes are suitable for applications that require custom shapes and sizes, making them ideal for specialized industries. However, their performance may be limited in high-stress environments.

Considerations for International Buyers: Buyers should consider the availability of manufacturing capabilities in their region. In emerging markets, such as Nigeria, investing in local production can reduce lead times and costs.

Summary Table of Material Selection for Polyurethane Rollers

| Material | Typical Use Case for Polyurethane Rollers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| TDI Ester Polyurethane | Heavy-duty applications in printing | Excellent abrasion resistance | Higher cost and complex manufacturing | High |

| MDI Ester Polyurethane | Automotive and food processing | Exceptional chemical resistance | Processing complexity | High |

| Ether-Based Polyurethane | Light-duty material handling | Cost-effective and easy to process | Lower durability in harsh conditions | Medium |

| Millable Urethane | Custom shapes for specialized industries | Versatile manufacturing options | Limited performance in high-stress | Low |

This guide provides a comprehensive overview of the strategic material selection for polyurethane rollers, equipping international B2B buyers with the insights necessary to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for polyurethane rollers

Polyurethane rollers are widely utilized across various industries due to their durability, versatility, and performance characteristics. Understanding the manufacturing processes and quality assurance protocols associated with these rollers is crucial for B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe. This section provides an in-depth exploration of the typical manufacturing processes and the quality assurance measures that ensure the reliability and performance of polyurethane rollers.

What Are the Main Stages in the Manufacturing Process of Polyurethane Rollers?

The manufacturing process of polyurethane rollers consists of several key stages, each critical to achieving the desired performance and quality.

Material Preparation

The first stage involves the careful selection and preparation of raw materials. Polyurethane is typically formulated from polyols and isocyanates, which can be tailored to meet specific hardness and performance requirements. This stage may include the mixing of additives to enhance properties such as abrasion resistance, chemical stability, and temperature tolerance. Manufacturers often use advanced mixing equipment to ensure a homogeneous blend of materials.

Forming Techniques: How Are Polyurethane Rollers Shaped?

Once the materials are prepared, the next step is forming the rollers. Common techniques include:

-

Casting: In this method, the polyurethane mixture is poured into molds. This allows for intricate shapes and customized designs. Cast polyurethane rollers exhibit superior durability and performance compared to those made from millable urethane.

-

Molding: This includes various methods such as compression, transfer, and injection molding, depending on the specific requirements of the roller. Mold design is crucial, as it influences the final dimensions and surface finish of the rollers.

-

Extrusion: For certain applications, extrusion may be used to produce continuous lengths of polyurethane material, which can then be cut to size.

Assembly Process: How Are Polyurethane Rollers Constructed?

In some cases, polyurethane rollers may require assembly, especially if they consist of multiple components, such as a steel core and the polyurethane coating. This stage involves precise alignment and secure fastening to ensure optimal performance. Manufacturers often employ automated machinery to enhance precision and efficiency during assembly.

Finishing Touches: What Are the Final Steps?

The final stage includes finishing processes such as grinding, polishing, and surface treatment. This ensures that the rollers meet specified tolerances and surface quality requirements. Some manufacturers may also apply coatings or treatments to enhance resistance to abrasion, chemicals, or UV exposure.

What Quality Assurance Measures Are Typically Implemented?

Quality assurance is critical to ensuring that polyurethane rollers meet industry standards and customer expectations.

What Are the Relevant International Standards for Polyurethane Rollers?

B2B buyers should look for manufacturers who adhere to international quality standards such as ISO 9001. This standard outlines a framework for quality management systems that emphasize continuous improvement and customer satisfaction. Additionally, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) for oil and gas applications may be relevant.

What Are the Key Quality Control Checkpoints?

Quality control is typically implemented at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified quality standards before production begins.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, checkpoints are established to monitor critical parameters such as temperature, pressure, and material consistency. This helps identify any deviations early in the production cycle.

-

Final Quality Control (FQC): After the rollers are completed, a thorough inspection is conducted. This may include dimensional checks, visual inspections, and performance testing to ensure that the rollers meet both customer specifications and industry standards.

What Common Testing Methods Are Used?

Manufacturers employ a range of testing methods to evaluate the performance of polyurethane rollers, including:

-

Hardness Testing: Measured using Shore durometers to ensure the rollers have the required hardness for their intended application.

-

Abrasion Resistance Testing: Conducted to assess how well the rollers can withstand wear and tear in their operational environment.

-

Load-Bearing Tests: To verify that the rollers can support the required weight without deformation or failure.

-

Chemical Resistance Testing: Evaluates the rollers’ ability to withstand exposure to various chemicals, especially in industries like food processing and automotive.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control practices is essential for ensuring product reliability.

Illustrative image related to polyurethane rollers

What Steps Can Buyers Take to Conduct Due Diligence?

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide insight into their manufacturing processes, quality control measures, and adherence to industry standards.

-

Requesting Quality Reports: Buyers should ask for detailed quality reports, including testing results and compliance certifications. This documentation should reflect the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices and product quality.

-

Understanding Certification Nuances: Buyers should be aware of the specific certifications relevant to their region and industry. This understanding will help them evaluate whether the supplier meets necessary compliance requirements for international trade.

What Are the Unique Quality Control Considerations for Buyers in Different Regions?

B2B buyers from Africa, South America, the Middle East, and Europe may face unique challenges when sourcing polyurethane rollers. Understanding local regulations, market expectations, and cultural factors can significantly impact supplier selection and quality assurance processes.

-

Regional Standards: Different regions may have varying standards for product safety and performance. Buyers should familiarize themselves with local regulations to ensure compliance.

-

Cultural Expectations: Building relationships with suppliers can be crucial in regions where trust and communication are paramount. Regular engagement and transparency about quality control practices can foster stronger partnerships.

-

Logistical Considerations: International shipping and customs processes may affect delivery timelines and product integrity. Buyers should consider suppliers who have experience navigating these challenges.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for polyurethane rollers is essential for B2B buyers. By focusing on key stages of production, relevant quality standards, and verification practices, buyers can ensure they select reliable suppliers that meet their operational needs and expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘polyurethane rollers’

In the competitive landscape of industrial procurement, acquiring polyurethane rollers requires a strategic approach. This guide provides a detailed checklist to ensure you make informed decisions when sourcing these essential components for your operations.

Illustrative image related to polyurethane rollers

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements for the polyurethane rollers you need. Consider factors such as hardness (measured in Shore A/D), load-bearing capacity, resistance to abrasion, and specific environmental conditions like temperature or exposure to solvents. Establishing these parameters upfront will help you narrow down your options and ensure compatibility with your machinery.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in polyurethane rollers. Look for companies with a strong industry reputation and a diverse product range. Utilize online resources, industry directories, and trade shows to compile a list of potential partners. Pay attention to their experience in your specific application area, whether it’s material handling, printing, or automotive.

Step 3: Evaluate Supplier Certifications

Before making any commitments, verify that potential suppliers hold relevant industry certifications and adhere to quality standards. Certifications such as ISO 9001 indicate a commitment to quality management and operational excellence. This step is critical to ensuring that the products you receive meet international standards and are reliable for your applications.

Step 4: Request Samples for Testing

Once you have shortlisted suppliers, request samples of their polyurethane rollers for testing. This allows you to assess the performance, durability, and suitability of the rollers in your specific environment. Testing samples can reveal critical insights into how well the product meets your operational needs and can prevent costly mistakes later on.

Step 5: Analyze Pricing and Terms of Sale

Evaluate the pricing structure of the shortlisted suppliers, including bulk order discounts and shipping costs. Compare the total cost of ownership, which includes not just the purchase price but also expected longevity and maintenance costs. Understanding the terms of sale, including payment options and delivery timelines, is also vital to ensure smooth procurement.

Step 6: Review Customer Feedback and Case Studies

Investigate customer feedback and case studies to gauge the satisfaction level of other businesses that have procured from your shortlisted suppliers. Look for testimonials that highlight product performance, reliability, and customer service. Engaging with existing customers can provide valuable insights into what you can expect from the supplier.

Step 7: Finalize Your Order and Establish Communication Channels

After selecting a supplier, finalize your order with clear communication about your requirements. Establish communication channels for ongoing support and inquiries, ensuring that you can easily reach out for technical assistance or order updates. A strong partnership with your supplier can lead to better service and support over time.

By following this structured checklist, you can streamline your sourcing process for polyurethane rollers, ensuring you select the best products and suppliers to meet your operational needs.

Comprehensive Cost and Pricing Analysis for polyurethane rollers Sourcing

What are the Key Cost Components in Sourcing Polyurethane Rollers?

When sourcing polyurethane rollers, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of polyurethane type—such as TDI or MDI—affects cost significantly. Higher-grade materials with enhanced properties like abrasion resistance or temperature tolerance typically command a premium price. Custom formulations may also incur additional costs.

-

Labor: Labor costs encompass the skilled workforce needed for manufacturing, especially for complex designs or custom specifications. Automated processes may reduce labor costs but require significant upfront investment.

-

Manufacturing Overhead: This includes costs associated with the production facility, machinery maintenance, utilities, and administrative expenses. Efficient processes can help lower overheads, but this can vary widely depending on the supplier’s operational efficiency.

-

Tooling: For custom or high-volume orders, tooling costs for molds and production equipment can be substantial. These costs are usually amortized over the production run but can lead to higher initial costs for lower quantities.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes can add to the cost. This is especially important for industries with strict compliance requirements, such as food processing or automotive.

-

Logistics: Transportation and shipping costs vary based on the supplier’s location and the buyer’s destination. International shipping can introduce complexities, such as customs duties and tariffs, which should be factored into the total cost.

-

Margin: Suppliers typically add a profit margin based on their operational costs and market positioning. Buyers should be aware that margins can vary widely among suppliers.

How Do Price Influencers Impact Polyurethane Roller Costs?

Several factors can influence the pricing of polyurethane rollers:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs. Suppliers may have Minimum Order Quantities (MOQs) that can impact pricing, especially for small businesses or startups.

-

Specifications and Customization: Unique specifications or customized designs can significantly increase costs. Buyers should clearly communicate their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher quality materials with relevant certifications (e.g., FDA approval for food-grade applications) usually cost more but may offer better performance and longevity, impacting the Total Cost of Ownership (TCO).

-

Supplier Factors: Supplier reputation, location, and production capabilities play a critical role in pricing. Established suppliers may charge more due to their reliability and quality assurance processes.

-

Incoterms: The choice of Incoterms affects shipping responsibilities and costs. For instance, using CIF (Cost, Insurance, and Freight) may provide clarity on total costs, while EXW (Ex Works) places more responsibility on the buyer.

What Negotiation Tips Can Help Buyers Achieve Cost-Efficiency?

To optimize sourcing costs, buyers should consider the following negotiation strategies:

-

Leverage Volume: When possible, consolidate orders to meet MOQs or negotiate bulk discounts. Suppliers may be more willing to offer better pricing for larger commitments.

-

Evaluate TCO: Consider not just the upfront cost but also the TCO, which includes maintenance, replacement, and operational costs over the roller’s lifespan. Sometimes a higher initial investment can lead to lower long-term costs.

-

Request Multiple Quotes: Solicit quotes from several suppliers to gauge market rates. This can provide leverage in negotiations and help identify competitive pricing.

-

Clarify Specifications Early: Ensure that all specifications and requirements are clear to avoid misunderstandings that could lead to increased costs later in the process.

-

Explore Alternative Suppliers: Investigating suppliers from emerging markets may yield cost savings due to lower labor and material costs. However, it is essential to evaluate their quality assurance processes thoroughly.

What Should International Buyers from Regions Like Africa, South America, and the Middle East Consider?

International buyers must navigate various challenges when sourcing polyurethane rollers. Here are key considerations:

-

Currency Fluctuations: Be aware of currency risks that can affect pricing. It may be beneficial to negotiate contracts in a stable currency or establish pricing mechanisms to mitigate risk.

-

Customs and Duties: Understand the import regulations and tariffs in your region. These can significantly affect the landed cost of goods.

-

Supplier Reliability: Ensure that suppliers have a proven track record of delivering quality products on time. This is especially critical for businesses in regions where supply chain disruptions are more common.

-

Cultural and Communication Nuances: Establishing a good rapport with suppliers can facilitate smoother transactions. Understanding cultural differences can enhance negotiation outcomes.

Disclaimer on Indicative Prices

Prices for polyurethane rollers can vary widely based on the aforementioned factors and market conditions. Buyers should treat any indicative prices as a starting point and conduct thorough market research to obtain accurate quotes tailored to their specific needs.

Alternatives Analysis: Comparing polyurethane rollers With Other Solutions

Exploring Alternatives to Polyurethane Rollers for Industrial Applications

In the quest for efficient material handling and manufacturing solutions, polyurethane rollers have established themselves as a preferred choice due to their durability and versatility. However, businesses often face the challenge of selecting the most suitable roller type for their specific applications. This section examines viable alternatives to polyurethane rollers, providing B2B buyers with insights to make informed decisions.

| Comparison Aspect | Polyurethane Rollers | Rubber Rollers | Metal Rollers |

|---|---|---|---|

| Performance | High abrasion resistance; customizable hardness levels; excellent shock absorption. | Moderate abrasion resistance; softer, providing good grip but less durability. | Excellent durability; high load-bearing capacity but poor shock absorption. |

| Cost | Moderate initial investment with potential for long-term savings due to durability. | Generally lower upfront cost but may require more frequent replacements. | Higher upfront costs due to material; long lifespan can justify investment. |

| Ease of Implementation | Relatively easy to install; available in various sizes and configurations. | Simple installation; widely available in standard sizes. | Installation may require specialized equipment or tools for heavy-duty applications. |

| Maintenance | Low maintenance; resistant to wear and chemicals; easy to clean. | Moderate maintenance; can degrade faster in harsh conditions. | Low maintenance; corrosion-resistant coatings can extend lifespan. |

| Best Use Case | Ideal for applications requiring noise reduction, vibration dampening, and exposure to harsh chemicals. | Best suited for applications needing a softer touch, such as printing and packaging. | Optimal for heavy-duty applications in manufacturing and construction, where weight support is critical. |

What Are the Advantages and Disadvantages of Rubber Rollers?

Rubber rollers are a common alternative, particularly in industries that prioritize a softer touch, such as printing and packaging. They provide a good grip and are generally less expensive upfront compared to polyurethane rollers. However, their moderate abrasion resistance and susceptibility to wear in harsh environments limit their lifespan. Businesses in these sectors may find rubber rollers suitable for applications where high levels of durability are not critical, but they may incur higher replacement costs over time.

How Do Metal Rollers Compare to Polyurethane Rollers?

Metal rollers are renowned for their robustness and ability to support substantial loads, making them ideal for heavy-duty applications in manufacturing and construction. They excel in environments where durability is paramount. However, they typically lack the shock absorption and noise reduction properties of polyurethane rollers. Additionally, their higher initial costs can deter some businesses, although their long lifespan may offset this investment. Organizations that require consistent heavy-duty performance may find metal rollers advantageous, but they must be prepared for the potential lack of flexibility in application.

How Can B2B Buyers Choose the Right Roller Solution?

When selecting the appropriate roller solution, B2B buyers should carefully consider their specific operational needs and environmental conditions. Polyurethane rollers excel in versatility, offering customization and durability for a variety of applications, particularly where noise reduction and chemical exposure are concerns. Conversely, rubber rollers may serve well in lower-stress environments, while metal rollers are ideal for heavy-duty applications requiring superior load-bearing capabilities.

Ultimately, the decision should align with the operational context, budget constraints, and performance expectations of the business. By evaluating these factors against the unique characteristics of each alternative, companies can enhance their material handling processes and optimize their investments.

Essential Technical Properties and Trade Terminology for polyurethane rollers

Understanding the essential technical properties and terminology of polyurethane rollers is crucial for B2B buyers, particularly those involved in industries such as manufacturing, logistics, and food processing. This section outlines the key specifications and trade terms that can significantly impact purchasing decisions and operational efficiency.

Illustrative image related to polyurethane rollers

What Are the Key Technical Properties of Polyurethane Rollers?

-

Material Grade

Polyurethane rollers are typically made from either ester or ether-based urethanes, each offering distinct advantages. Ester-based urethanes provide excellent abrasion resistance and durability, while ether-based urethanes offer superior weather resistance and low-temperature performance. Understanding the appropriate material grade helps buyers select rollers that meet their specific application requirements, ensuring longevity and performance. -

Hardness (Shore A/D)

The hardness of polyurethane rollers is measured using the Shore A or Shore D scales, ranging from soft (30 Shore A) to very hard (70 Shore D). A roller’s hardness affects its load-bearing capacity, wear resistance, and shock absorption properties. Buyers should consider the operational environment and load requirements when selecting the appropriate hardness to optimize performance. -

Tolerances

Tolerance specifications dictate the allowable variations in roller dimensions, which are critical for ensuring proper fit and function in machinery. Tight tolerances (e.g., ±0.005 inches) are often necessary for precision applications, while looser tolerances may suffice for general use. Understanding tolerances is essential for maintaining efficiency and minimizing downtime due to misalignment or fit issues. -

Temperature Resistance

Polyurethane rollers exhibit varying degrees of temperature resistance, with maximum service temperatures typically reaching up to 250°F (121°C). Buyers must assess their operational conditions, particularly if the rollers will be exposed to extreme heat or cold, to prevent premature wear or failure. -

Abrasion Resistance

The abrasion resistance of polyurethane rollers is a key factor in their longevity and performance. Rollers designed with high abrasion resistance are ideal for applications involving heavy wear, such as in material handling or packaging. This property is often quantified on a scale, allowing buyers to compare options effectively. -

Custom Formulations

Many manufacturers offer custom formulations tailored to specific applications, such as enhanced oil resistance or improved traction. Understanding the availability of these custom options can help buyers procure rollers that better suit their unique operational challenges.

Which Trade Terms Should B2B Buyers Be Familiar With?

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are used in another company’s end products. Understanding OEM relationships can help buyers identify reliable suppliers who adhere to industry standards and specifications. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Buyers should be aware of MOQ requirements to avoid overcommitting to purchases that do not align with their operational needs or inventory capacity. -

RFQ (Request for Quote)

An RFQ is a document that buyers send to suppliers to request pricing for specific products or services. Utilizing RFQs allows buyers to compare costs and specifications effectively, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help buyers understand shipping costs, risk transfer, and delivery obligations, crucial for international procurement. -

Lead Time

Lead time is the time taken from placing an order to receiving the product. Knowing the lead times associated with different suppliers can help buyers plan their production schedules and inventory management more effectively. -

Dynamic Balancing

This term refers to the process of adjusting the weight distribution of rollers to ensure smooth operation and minimize vibration during use. Understanding this process is important for buyers looking to enhance the performance and lifespan of their equipment.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions regarding polyurethane rollers, ultimately leading to improved operational efficiency and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the polyurethane rollers Sector

What Are the Current Market Dynamics and Key Trends in Polyurethane Rollers?

The polyurethane rollers market is experiencing robust growth, driven by the increasing demand from various industries, including material handling, automotive, printing, and food processing. Globalization and the expansion of manufacturing hubs in emerging markets like Africa, South America, and Southeast Asia, particularly Vietnam and Nigeria, are significant factors contributing to this growth. Businesses are increasingly looking for durable and versatile solutions, which polyurethane rollers provide due to their superior abrasion resistance, shock absorption, and customized formulations.

Emerging technologies such as Industry 4.0 and the Internet of Things (IoT) are reshaping sourcing strategies. Companies are leveraging data analytics and predictive maintenance tools to enhance the operational efficiency of polyurethane rollers, leading to reduced downtime and cost savings. Additionally, automated manufacturing processes are enabling suppliers to offer more customized solutions, thus meeting specific client requirements more efficiently.

As buyers from different regions navigate these market dynamics, they must consider local supply chain conditions, pricing fluctuations, and regulatory compliance. The increasing focus on quality and performance means that buyers should prioritize suppliers who can demonstrate advanced manufacturing capabilities and a track record of reliability.

How Does Sustainability and Ethical Sourcing Impact the Polyurethane Rollers Sector?

Sustainability has become a crucial consideration for B2B buyers in the polyurethane rollers market. As environmental regulations tighten globally, companies are under pressure to minimize their ecological footprint. The production of polyurethane materials often involves processes that can be harmful to the environment, making it imperative for buyers to seek suppliers who prioritize sustainable practices.

Ethical sourcing is not just about compliance; it enhances brand reputation and consumer trust. Buyers should look for suppliers who provide transparency in their supply chains and demonstrate a commitment to reducing waste and energy consumption. Additionally, many manufacturers are now offering ‘green’ polyurethane options, made from bio-based materials or using environmentally friendly processes. Certifications such as ISO 14001 (Environmental Management) or the Global Recycle Standard (GRS) can also serve as indicators of a supplier’s commitment to sustainability.

By prioritizing ethical sourcing, companies can align their purchasing decisions with corporate social responsibility goals, ultimately benefiting their bottom line while contributing positively to the environment.

What Is the Brief Evolution and History of Polyurethane Rollers in B2B Applications?

The evolution of polyurethane rollers dates back to the mid-20th century when the versatility of polyurethane materials began to be recognized. Initially, these rollers were primarily used in niche applications due to their specialized properties. However, as manufacturing processes advanced, so did the applications of polyurethane rollers across various industries.

By the 1980s, the adoption of polyurethane rollers gained momentum in sectors such as printing and packaging, where their durability and resistance to wear were highly valued. Over the years, innovations in polymer chemistry have allowed for the development of customized formulations, enabling manufacturers to produce rollers that meet specific performance requirements.

Today, polyurethane rollers are integral to numerous industrial processes, enhancing efficiency and productivity while catering to the diverse needs of global markets. As this sector continues to evolve, the focus on customization and sustainability will likely shape its future trajectory.

Frequently Asked Questions (FAQs) for B2B Buyers of polyurethane rollers

-

How do I choose the right polyurethane roller for my application?

Selecting the appropriate polyurethane roller involves understanding the specific requirements of your application. Consider factors such as load capacity, environmental conditions (temperature, exposure to chemicals), and the type of surface the roller will interact with. It’s crucial to assess the hardness level (measured in Shore A or D) that best suits your needs, as this affects durability and performance. Consulting with manufacturers or suppliers who offer customization options can also help tailor the roller to your specifications for optimal functionality. -

What is the best type of polyurethane roller for heavy-duty applications?

For heavy-duty applications, cast polyurethane rollers are often the best choice due to their superior strength and durability compared to millable urethane options. They can be engineered to withstand high loads and harsh conditions, making them ideal for industries like material handling, automotive, and manufacturing. Look for rollers with a hardness rating between 60 Shore A and 70 Shore D, as these provide excellent wear resistance and longevity. Always confirm the roller specifications align with your operational requirements before purchasing. -

How do I verify the credibility of a polyurethane roller supplier?

To ensure the credibility of a polyurethane roller supplier, start by researching their industry reputation through online reviews and testimonials. Verify their certifications, such as ISO standards, which indicate adherence to quality management systems. Request case studies or references from previous clients in your industry to gauge their experience and reliability. Additionally, visiting the supplier’s facility, if feasible, can provide firsthand insight into their manufacturing processes and quality control measures. -

What are typical minimum order quantities (MOQs) for polyurethane rollers?

Minimum order quantities (MOQs) for polyurethane rollers can vary significantly based on the supplier and the level of customization required. Standard products may have lower MOQs, often ranging from 10 to 50 units, while custom-designed rollers may require higher quantities, sometimes exceeding 100 units. It is advisable to discuss your needs with potential suppliers to find flexible options that suit your budget and operational demands, especially when considering international shipping and lead times. -

What payment terms should I expect when sourcing polyurethane rollers internationally?

Payment terms for international sourcing of polyurethane rollers typically include options such as advance payment, letters of credit, or payment upon delivery. Many suppliers may request a deposit (usually 30-50%) upfront, with the balance due upon shipment or delivery. It’s essential to clarify payment terms in the initial agreement and ensure they align with your financial processes. Additionally, consider using secure payment methods that provide buyer protection, especially for larger transactions. -

How do I ensure quality assurance (QA) for polyurethane rollers?

To ensure quality assurance for polyurethane rollers, request detailed specifications and certifications from the supplier, including material data sheets and compliance with industry standards. Implementing a thorough inspection process upon receipt of the rollers is crucial; this can include checking for dimensional accuracy, hardness, and overall quality. Consider establishing a quality control agreement with your supplier that outlines testing procedures and acceptable tolerances to maintain consistent product quality throughout your orders. -

What logistics considerations should I keep in mind when importing polyurethane rollers?

When importing polyurethane rollers, consider logistics factors such as shipping methods, customs regulations, and lead times. Choose a reliable freight forwarder experienced in handling industrial goods to navigate customs clearance efficiently. Be aware of potential tariffs and import duties that could impact your overall costs. Also, ensure that the supplier provides proper documentation, including invoices and certificates of origin, to facilitate smooth transit and compliance with local regulations. -

Can I customize polyurethane rollers for specific applications?

Yes, many suppliers offer customization options for polyurethane rollers to meet specific application needs. Customization can include adjusting the hardness, color, and chemical resistance of the material, as well as altering dimensions and surface finishes. When discussing your requirements with a supplier, provide detailed information about your application, including load conditions and environmental factors, to help them recommend the best formulations and designs for your specific use case.

Top 3 Polyurethane Rollers Manufacturers & Suppliers List

1. Mappcaster – HPR-00350 Roller

Domain: mappcaster.com

Registered: 1997 (28 years)

Introduction: {“Part Number”: “HPR-00350”, “Diameter”: “3-1/2 inches”, “Length”: “3-5/8 inches”, “Material”: “Polyurethane coated with a steel core”, “Price”: “$94.40”, “Availability”: “Usually ships in 3-5 Business Days”, “Capacity Information”: “Rollers are not individually rated for capacity. Check the Parts Breakdown Sheet for compatibility with Hevi-Haul Model(s).”, “Bearings”: “Sold separately”}

2. PolyProd – Custom Polyurethane Rollers and Wheels

Domain: polyprod.com

Registered: 1996 (29 years)

Introduction: Custom Polyurethane Rollers and Wheels made from solid polyurethane and custom cast urethane wheels with a thin coating of polyurethane bonded to metal hubs. Applications include: Applicator Rolls, Bridle Rolls, Coating Rolls, Contact Rolls, Conveyor Rolls, Feeding Rolls, Idler Rolls, Laminating Rolls, Pinch Rolls, Printing Rolls, Scoring Rolls, Snubber Rolls, Squeegee Rolls, Escalator Wheels, Ele…

3. Sunray – Cut-to-Width Polyurethane Rollers

Domain: sunray-inc.com

Registered: 1997 (28 years)

Introduction: Sunray’s cut-to-width polyurethane rollers are ideal for multiple applications. Key features include:

– Outer diameters ranging from 1″ to 3″

– Inner diameters (axle diameters) ranging from .375″ to .5″

– Tolerances of +/-.030 (except bore-bore tolerance: -0/+0.10)

– Fully customizable durometers (hardness levels)

– Fully customizable colors and lengths

– Standard lengths of 20″ with a hard …

Strategic Sourcing Conclusion and Outlook for polyurethane rollers

In navigating the complex landscape of polyurethane roller procurement, strategic sourcing emerges as a critical component for international B2B buyers. By prioritizing high-quality materials and reliable suppliers, businesses can enhance operational efficiency and reduce long-term costs. Customization options, such as tailored hardness levels and chemical resistance, enable organizations to meet specific application needs across diverse industries, from automotive to food processing.

Moreover, the importance of roller re-covering services cannot be overstated. This cost-effective approach not only extends the lifespan of existing equipment but also contributes to sustainability initiatives by minimizing waste. As markets in Africa, South America, the Middle East, and Europe continue to evolve, businesses that leverage strategic sourcing will gain a competitive edge by ensuring their operations are equipped with durable and high-performing rollers.

Illustrative image related to polyurethane rollers

Looking ahead, now is the time for buyers to engage with trusted suppliers who can provide innovative solutions tailored to their unique challenges. By adopting a proactive sourcing strategy, organizations can position themselves for success in an increasingly demanding marketplace. Take the next step—explore your options and invest in quality polyurethane rollers that will drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.