Everything You Need to Know About Modular Belt Conveyors Sourcing in 2025

Introduction: Navigating the Global Market for modular belt conveyors

As global supply chains evolve, sourcing the right modular belt conveyors has become a pivotal challenge for businesses aiming to enhance efficiency and productivity. These versatile systems are essential in various industries, enabling seamless product movement while accommodating diverse operational needs. This comprehensive guide delves into the world of modular belt conveyors, exploring the different types, applications, and configurations available. It also addresses critical factors such as supplier vetting, cost considerations, and maintenance strategies, empowering international B2B buyers from Africa, South America, the Middle East, and Europe—including regions like Germany and Vietnam—to make informed purchasing decisions.

Navigating the complexities of conveyor systems can be daunting, particularly for businesses with unique operational requirements. By providing a detailed overview of the features and benefits of modular belt conveyors, this guide equips buyers with actionable insights to optimize their supply chain processes. Whether you are looking for solutions that enhance flexibility in design, reduce downtime, or improve product handling, this resource will help you identify the best options tailored to your specific needs. With a focus on value-driven decision-making, we aim to support your journey toward selecting the most effective modular belt conveyor systems, ensuring your operations run smoothly and efficiently in a competitive global market.

Understanding modular belt conveyors Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Straight-running Belts | Simple design for linear transport; easy installation | Assembly lines, packaging, and sorting | Pros: Cost-effective; easy maintenance. Cons: Limited in directional flexibility. |

| Curved Modular Belts | Allows for directional changes; can navigate tight spaces | Food processing, warehousing | Pros: Maximizes space efficiency; versatile. Cons: Potentially more complex installation. |

| Chain Belts | High strength; suitable for heavy loads | Heavy manufacturing, automotive | Pros: Robust and durable; excellent for sharp edges. Cons: Heavier and may require more power. |

| Food-safe Belting | Compliant with food safety standards; easy to clean | Food and beverage industries | Pros: Ensures hygiene; maintains product integrity. Cons: Higher initial costs for compliance. |

| Spiral Conveyors | Vertical transport; ideal for cooling or freezing processes | Bakery, dairy, and meat processing | Pros: Space-saving; efficient for temperature control. Cons: More complex design and higher maintenance. |

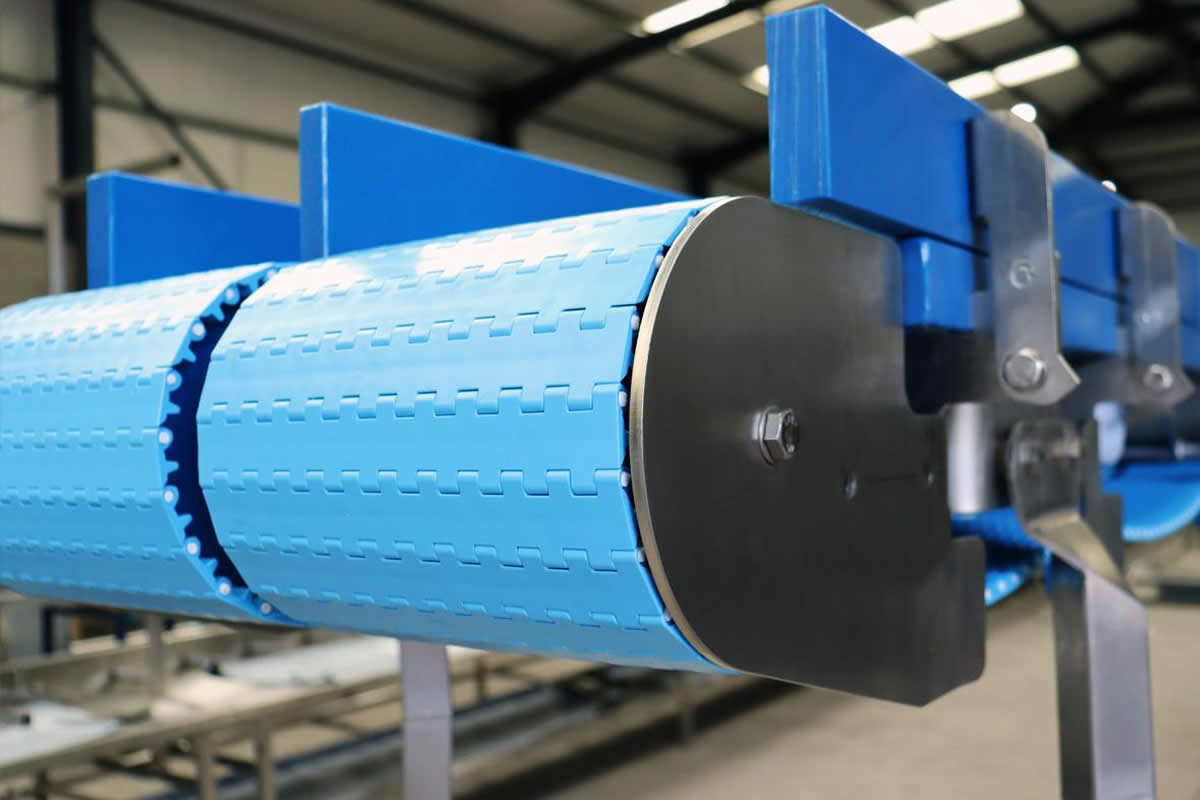

What Are the Key Characteristics of Straight-running Belts?

Straight-running belts are designed for straightforward, linear transport of products. They are particularly suitable for assembly lines, packaging, and sorting applications where space is not a constraint. Their simple construction allows for easy installation and maintenance, making them an attractive option for companies looking to optimize efficiency without significant upfront investment. However, their limitation lies in their inability to navigate curves, which may necessitate additional conveyor systems for complex layouts.

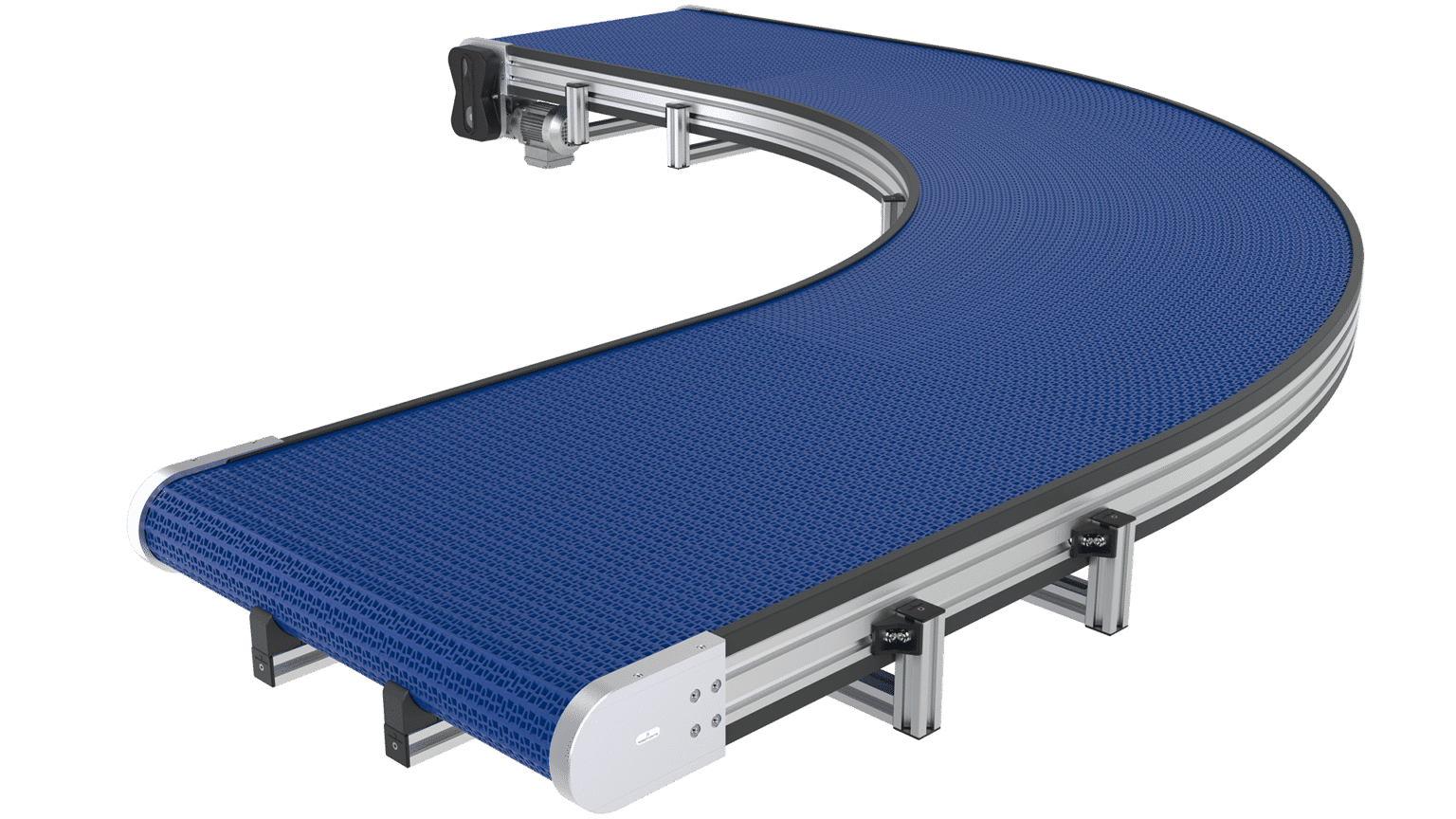

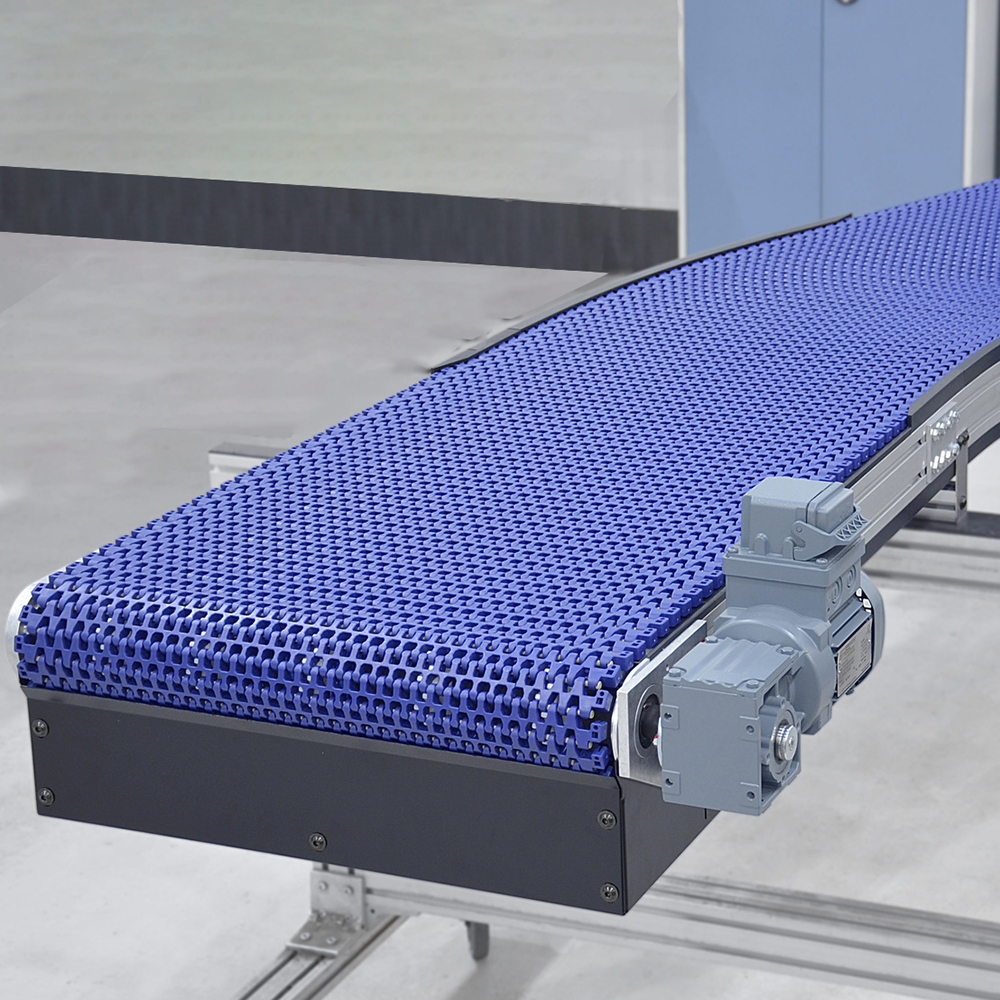

How Do Curved Modular Belts Enhance Operational Flexibility?

Curved modular belts are engineered to facilitate directional changes, making them ideal for applications in food processing and warehousing. Their design allows for smooth transitions through tight spaces, effectively maximizing floor space. While they offer significant flexibility, the installation can be more complex compared to straight-running belts, which may require specialized expertise. Businesses should consider their layout and operational needs when opting for this type of conveyor.

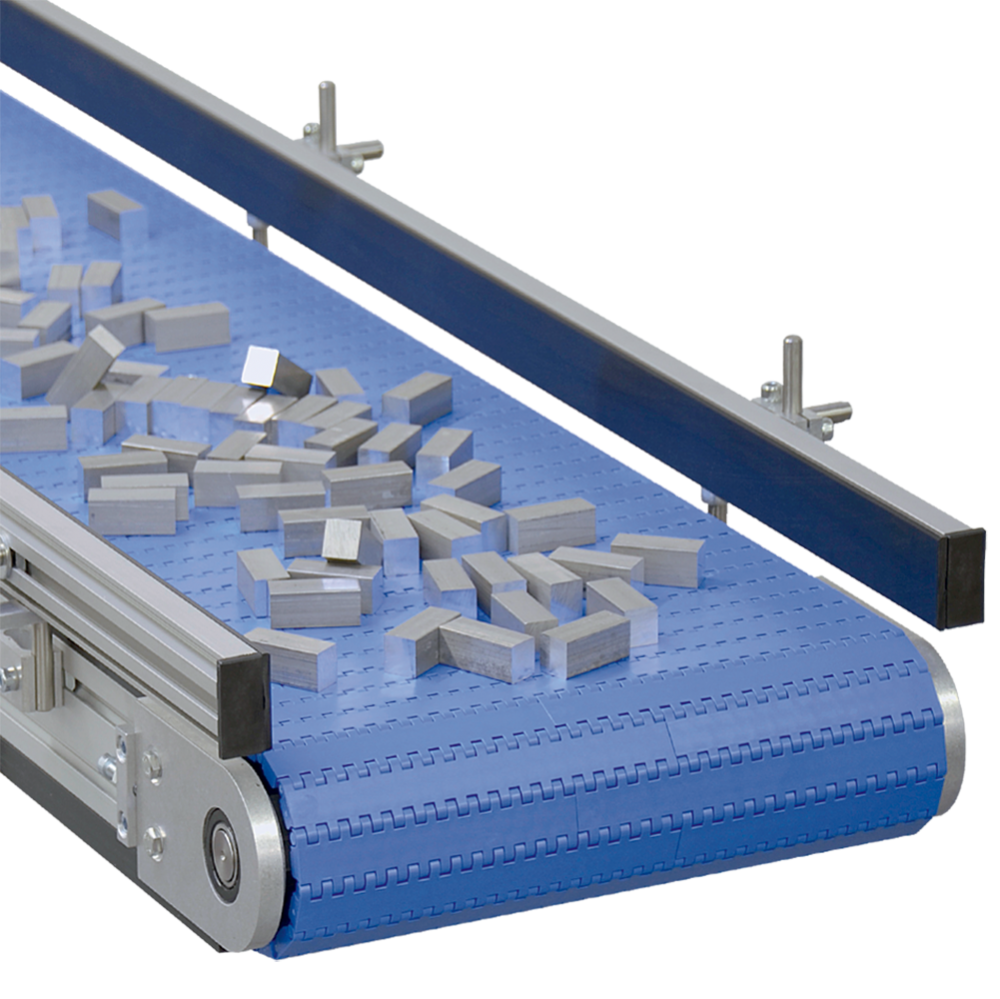

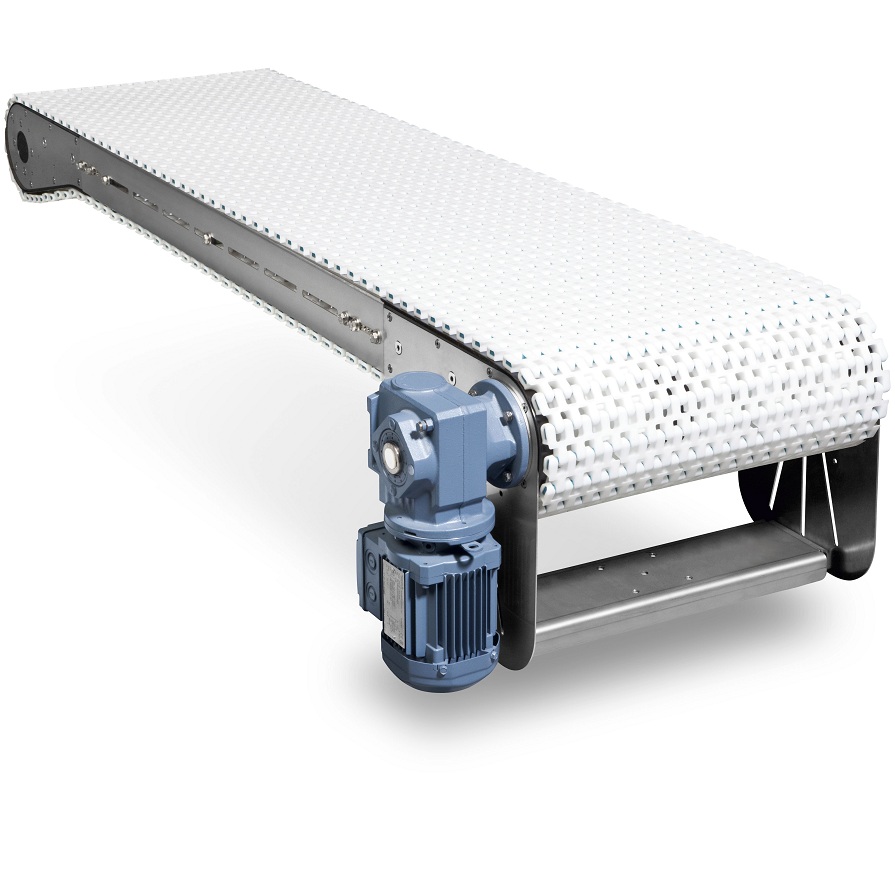

Illustrative image related to modular belt conveyors

Why Choose Chain Belts for Heavy-Duty Applications?

Chain belts are characterized by their high strength and durability, making them suitable for transporting heavy loads and sharp-edged products in industries such as automotive and heavy manufacturing. Their robust construction ensures longevity and reliability under demanding conditions. However, buyers should be aware that chain belts are heavier and may require more power to operate, which can lead to higher energy costs over time.

What Makes Food-safe Belting Essential for the Food Industry?

Food-safe belting is specifically designed to meet stringent hygiene standards, making it crucial for food and beverage industries. These belts are easy to clean and help maintain product integrity, ensuring compliance with health regulations. Although the initial investment may be higher due to compliance requirements, the long-term benefits in terms of safety and quality assurance make them a worthwhile consideration for manufacturers in this sector.

How Do Spiral Conveyors Optimize Space and Efficiency?

Spiral conveyors are unique in their ability to transport products vertically, making them ideal for applications that require cooling or freezing, such as in bakeries and meat processing. Their space-saving design allows for efficient use of vertical space, while their specialized construction ensures that products are transported at controlled temperatures. However, they come with a more complex design that may necessitate higher maintenance efforts, which should be factored into the purchasing decision.

Key Industrial Applications of modular belt conveyors

| Industry/Sector | Specific Application of modular belt conveyors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Transporting packaged goods through processing lines | Ensures food safety compliance and minimizes downtime | Look for food-safe materials, easy cleaning features, and custom configurations. |

| Automotive Manufacturing | Moving heavy parts along assembly lines | Increases efficiency and reduces manual handling | Evaluate load capacity, durability, and adaptability to various layouts. |

| Electronics | Handling delicate components in assembly processes | Prevents damage and enhances operational efficiency | Consider anti-static materials and precision in modular design. |

| Pharmaceuticals | Conveying products in cleanroom environments | Maintains hygiene standards and improves workflow | Ensure compliance with industry regulations and easy integration with existing systems. |

| Packaging | Automating the packaging process | Increases throughput and reduces labor costs | Focus on modularity for reconfiguration and compatibility with various packaging formats. |

How Are Modular Belt Conveyors Used in the Food and Beverage Industry?

In the food and beverage sector, modular belt conveyors are essential for transporting packaged goods through various processing stages, from filling to labeling. These conveyors are designed to meet stringent food safety standards, incorporating materials that are easy to clean and resistant to contamination. By minimizing downtime through quick changeovers and maintenance, they enhance overall operational efficiency. Buyers should prioritize sourcing belts that comply with food safety regulations and offer customizable configurations to suit their specific production lines.

Illustrative image related to modular belt conveyors

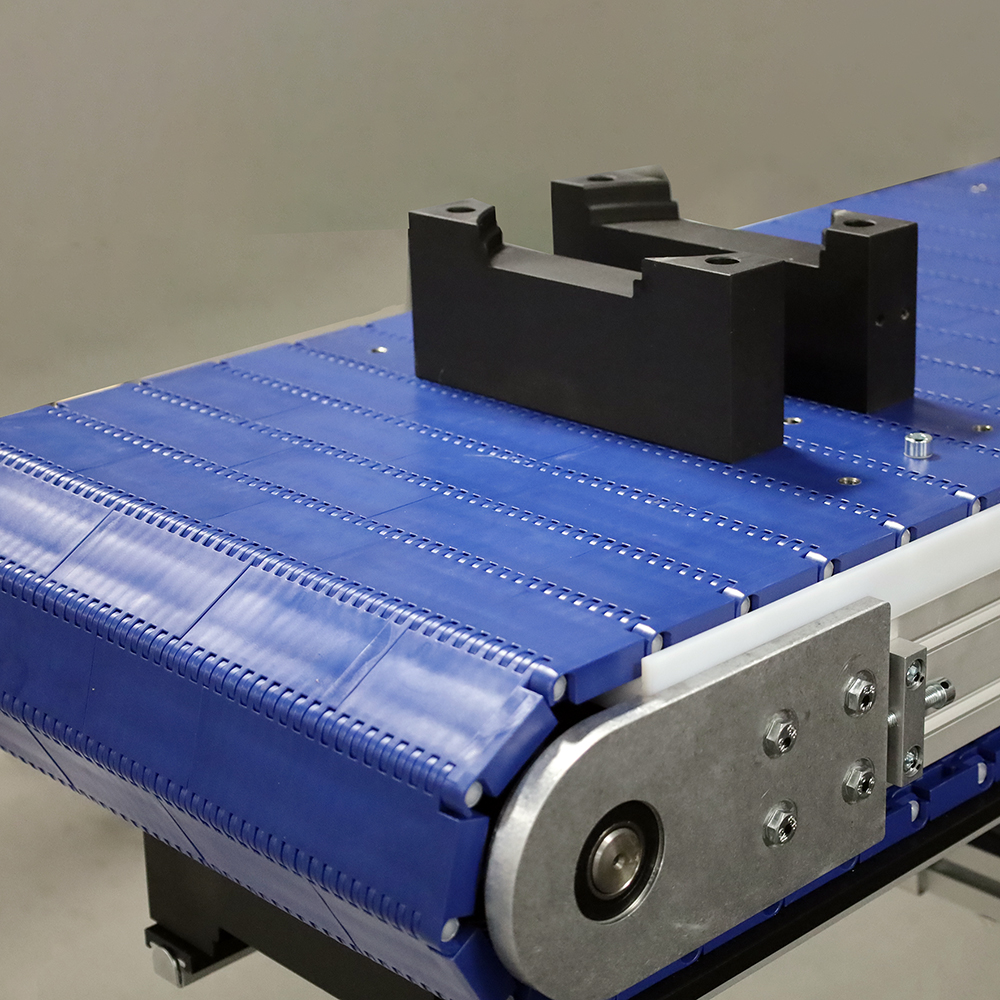

What Role Do Modular Belt Conveyors Play in Automotive Manufacturing?

In automotive manufacturing, modular belt conveyors facilitate the movement of heavy and bulky parts along assembly lines. Their robust construction allows for the transport of sharp-edged components without risk of damage, while their modular design enables easy integration into existing systems. This adaptability is crucial for automotive manufacturers looking to optimize their production processes. Buyers should consider the conveyor’s load capacity, durability, and the ability to configure straight, curved, and inclined sections to meet their unique operational requirements.

Why Are Modular Belt Conveyors Important in the Electronics Sector?

Modular belt conveyors are vital in the electronics industry for handling delicate components during assembly processes. These conveyors minimize the risk of damage to sensitive parts through their precise movement and customizable configurations. Additionally, anti-static materials can be employed to protect electronic components from static discharge. For international buyers, sourcing conveyors that ensure operational efficiency while adhering to specific industry standards is critical, particularly in regions with strict manufacturing regulations.

How Do Modular Belt Conveyors Enhance Pharmaceutical Operations?

In the pharmaceutical sector, modular belt conveyors are used to transport products within cleanroom environments, ensuring that hygiene standards are upheld throughout the production process. These conveyors are designed to facilitate smooth operations while minimizing contamination risks. Buyers must ensure that the conveyors meet industry regulations, offer easy integration with existing systems, and allow for flexibility in design to accommodate changing production needs.

Illustrative image related to modular belt conveyors

What Benefits Do Modular Belt Conveyors Offer in Packaging Applications?

Modular belt conveyors automate the packaging process by streamlining the transport of products from production to packaging stations. This automation increases throughput and significantly reduces labor costs associated with manual handling. For businesses in the packaging industry, it is essential to focus on sourcing modular systems that allow for easy reconfiguration to accommodate various packaging formats and layouts. The ability to adapt to changing production demands is a key consideration for international buyers looking to enhance operational efficiency.

3 Common User Pain Points for ‘modular belt conveyors’ & Their Solutions

Scenario 1: Frequent Downtime Due to Maintenance Issues

The Problem: For many manufacturers, the reliability of modular belt conveyors is critical to maintaining operational efficiency. However, unexpected breakdowns and lengthy maintenance procedures can lead to significant downtime, disrupting production schedules and resulting in lost revenue. Buyers often struggle with identifying the root causes of these issues, which can stem from improper installation, inadequate maintenance practices, or the use of subpar components. This frustration is particularly pronounced in environments where quick adjustments and repairs are essential, such as food processing or automotive manufacturing.

The Solution: To mitigate maintenance-related downtime, companies should prioritize selecting high-quality modular belt conveyors that are designed for easy maintenance. When sourcing these systems, buyers should engage with manufacturers who provide detailed installation guides and ongoing technical support. Implementing a preventive maintenance schedule can also prove invaluable; regular inspections and timely replacements of wear parts can significantly extend the life of the conveyor. Additionally, investing in training for staff on proper maintenance practices ensures that operators are equipped to handle minor issues before they escalate, thereby reducing overall downtime and enhancing productivity.

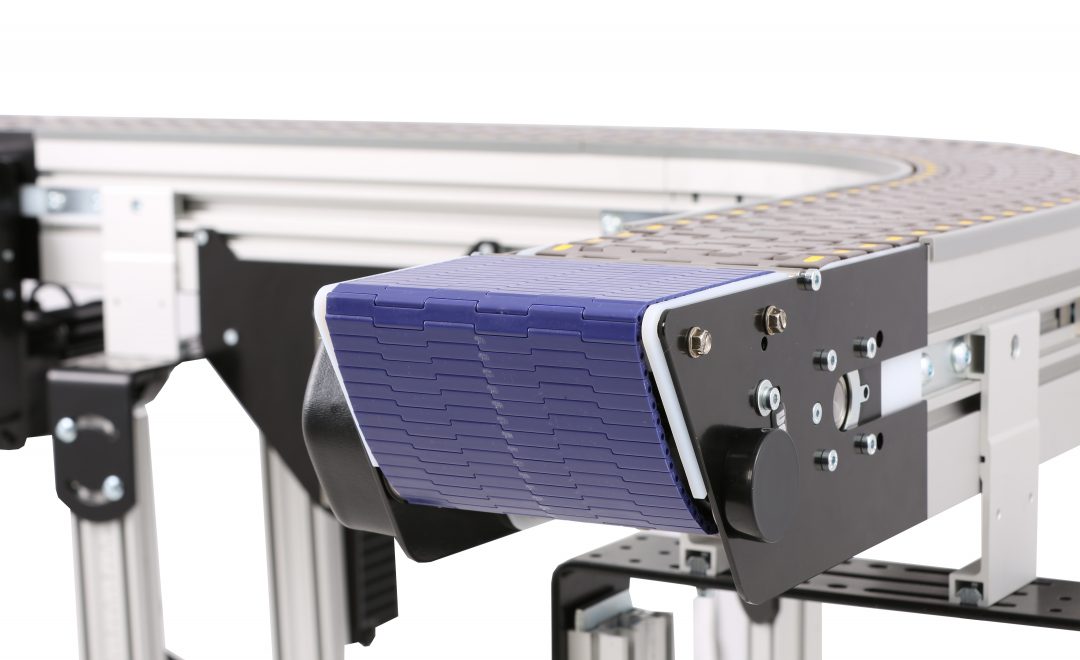

Scenario 2: Inflexibility to Adapt to Changing Production Needs

The Problem: In today’s fast-paced manufacturing environments, flexibility is key. Many businesses face challenges when their existing conveyor systems are unable to adapt to new product lines or changing production layouts. This inflexibility can lead to the need for costly system overhauls or even complete replacements, which can strain budgets and timelines. B2B buyers often feel the pressure to remain agile in response to market demands but find that their current conveyor systems hinder this adaptability.

Illustrative image related to modular belt conveyors

The Solution: Buyers should consider modular belt conveyors that offer customizable configurations and can be easily reconfigured as production needs evolve. When evaluating options, look for systems that allow for simple adjustments in length, angle, and layout without requiring extensive downtime or specialized tools. Engaging with manufacturers who offer modular components enables businesses to expand their conveyor systems incrementally. Furthermore, investing in conveyor systems that integrate well with automation technologies can enhance flexibility and scalability, ensuring that the conveyor system can grow alongside the business without incurring excessive costs.

Scenario 3: Difficulty Ensuring Product Safety and Compliance

The Problem: In industries such as food processing and pharmaceuticals, ensuring product safety and compliance with stringent regulations is paramount. Buyers often encounter challenges related to the materials and design of modular belt conveyors, which can harbor contaminants or fail to meet safety standards. This concern is amplified when transitioning to new products or processes, as existing conveyor systems may not be compliant with updated regulatory requirements, putting the entire production line at risk.

The Solution: To address safety and compliance concerns, B2B buyers should prioritize sourcing modular belt conveyors made from food-grade materials that are easy to clean and maintain. When evaluating options, it is essential to confirm that the conveyor systems are designed to meet relevant industry standards, such as FDA or ISO certifications. Additionally, consider investing in modular systems with features like open frame designs, which facilitate thorough cleaning and minimize the risk of contamination. Working closely with suppliers who have a strong track record in compliance can provide peace of mind and ensure that the conveyor systems meet both current and future regulatory needs. By proactively addressing these concerns, businesses can safeguard their products and maintain trust with their customers.

Strategic Material Selection Guide for modular belt conveyors

When selecting materials for modular belt conveyors, B2B buyers must consider various factors that can significantly impact performance, durability, and cost. Below is an analysis of four common materials used in modular belt conveyors, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers.

Illustrative image related to modular belt conveyors

What Are the Key Properties of Polyethylene in Modular Belt Conveyors?

Polyethylene (PE) is a widely used material in modular belt conveyors due to its favorable properties. It exhibits excellent chemical resistance, making it suitable for various applications, including food processing and packaging. PE can withstand temperatures up to 80°C (176°F) and is lightweight, facilitating easier installation and maintenance.

Pros: Polyethylene is cost-effective and has a low coefficient of friction, which enhances the efficiency of product movement. Its flexibility allows for various configurations, making it adaptable to different layouts.

Cons: However, PE has limited temperature resistance compared to other materials and can become brittle at lower temperatures. It may not be suitable for heavy-duty applications involving sharp or abrasive materials.

Illustrative image related to modular belt conveyors

Impact on Application: Polyethylene is ideal for food-safe applications, but its limitations in high-temperature environments must be considered.

How Does Polypropylene Compare for Modular Belt Conveyor Applications?

Polypropylene (PP) is another popular choice for modular belt conveyors, known for its high strength-to-weight ratio. It can handle temperatures up to 100°C (212°F) and offers good chemical resistance, particularly against acids and bases.

Pros: The durability of polypropylene makes it suitable for heavy-duty applications, including automotive and packaging industries. It is also resistant to UV radiation, which is advantageous in outdoor settings.

Cons: On the downside, polypropylene can be more expensive than polyethylene and may require more complex manufacturing processes. Its rigidity can limit flexibility in certain configurations.

Impact on Application: PP is suitable for applications requiring higher temperature resistance and durability but may not be the best fit for environments with extreme temperature fluctuations.

Illustrative image related to modular belt conveyors

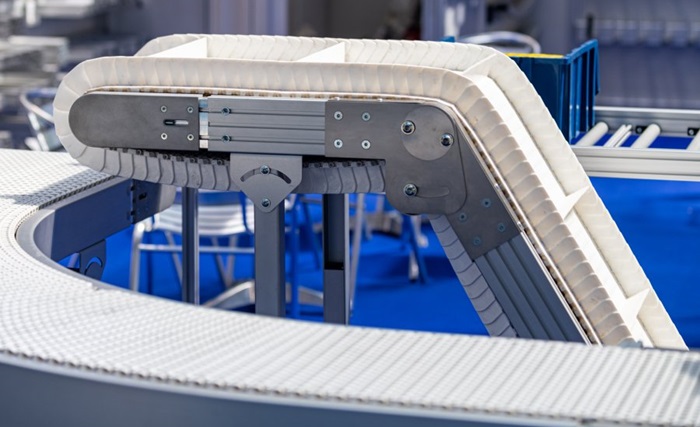

What Are the Benefits of Stainless Steel in Modular Belt Conveyors?

Stainless steel is renowned for its exceptional strength and corrosion resistance, making it a preferred material for modular belt conveyors in industries like food processing, pharmaceuticals, and chemicals.

Pros: Its durability ensures a long lifespan, even in harsh environments. Stainless steel also meets stringent hygiene standards, making it ideal for applications where cleanliness is paramount.

Cons: The primary drawback is the high cost associated with stainless steel, both in terms of material and manufacturing. Additionally, its weight can complicate installation and maintenance.

Impact on Application: Stainless steel is particularly beneficial in applications requiring high hygiene standards and resistance to corrosion, but buyers must account for the associated costs.

Why Choose Engineering Plastics for Modular Belt Conveyors?

Engineering plastics, such as acetal and nylon, offer unique advantages for modular belt conveyors. These materials exhibit high strength and excellent wear resistance, making them suitable for demanding applications.

Illustrative image related to modular belt conveyors

Pros: Engineering plastics can withstand a wide range of temperatures and provide excellent dimensional stability. They are also lightweight, which aids in reducing the overall weight of the conveyor system.

Cons: However, engineering plastics can be more expensive than traditional plastics and may require specific processing techniques. Their chemical resistance varies, necessitating careful selection based on the application.

Impact on Application: These materials are ideal for specialized applications requiring precise tolerances and high wear resistance, but buyers should be aware of their higher costs and processing requirements.

Illustrative image related to modular belt conveyors

Summary Table of Material Selection for Modular Belt Conveyors

| Material | Typical Use Case for modular belt conveyors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene | Food processing, packaging | Cost-effective and lightweight | Limited temperature resistance | Low |

| Polypropylene | Automotive, packaging | High strength and UV resistance | Higher cost and rigidity | Medium |

| Stainless Steel | Food processing, pharmaceuticals | Exceptional durability and hygiene | High cost and weight | High |

| Engineering Plastics | High-wear applications, precision tasks | Excellent wear resistance and stability | Higher cost and specific processing | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the various materials available for modular belt conveyors, helping them make informed decisions based on their specific operational needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for modular belt conveyors

What Are the Main Stages of Manufacturing Modular Belt Conveyors?

The manufacturing process of modular belt conveyors involves several critical stages, each designed to ensure the production of high-quality and durable systems. Understanding these stages helps B2B buyers assess potential suppliers and their capabilities.

Material Preparation: What Materials Are Used in Modular Belt Conveyors?

The first step in manufacturing modular belt conveyors is material preparation. Common materials include high-impact plastics, stainless steel, and other alloys, selected for their strength, durability, and resistance to wear and corrosion. For food-grade applications, materials must comply with FDA and food safety regulations, ensuring that they do not contaminate products during transport.

Illustrative image related to modular belt conveyors

At this stage, suppliers typically source raw materials from certified vendors, ensuring that they meet international standards such as ISO 9001. This certification indicates a commitment to quality management systems, which is crucial for B2B buyers looking for reliable suppliers.

How Are Modular Belt Components Formed?

Once materials are prepared, the next stage is forming the components. This process may involve several techniques, including injection molding, extrusion, and die-cutting.

-

Injection Molding: This technique is frequently used for creating the modular plastic links that make up the belt. By injecting molten plastic into a mold, manufacturers can produce complex shapes that fit together precisely.

-

Extrusion: Used primarily for the conveyor frame, extrusion involves forcing material through a shaped die to create long, continuous sections of the desired profile.

-

Die-Cutting: This method is often applied to create specific features in belt designs, such as perforations or slots, which are essential for particular applications like airflow or drainage.

Each of these techniques is selected based on the desired characteristics of the finished product, such as strength, flexibility, and weight.

What Does the Assembly Process Involve?

After forming, the components move to the assembly stage, where they are put together to create the complete conveyor system. This process can be manual or automated, depending on the manufacturer’s capabilities and production volume.

Key elements of the assembly process include:

-

Joining Components: This may involve mechanical fastening, welding, or adhesive bonding, ensuring that all parts fit together securely.

-

Integration of Accessories: Many modular belt conveyors include additional features such as side guides, sensors, and drives. These components are integrated during assembly to ensure a fully functional system.

-

System Configuration: Manufacturers often provide customizable options, allowing buyers to specify configurations that meet their operational needs. Flexibility in assembly is essential for catering to diverse industry requirements.

How Is the Finishing Stage Conducted?

The final manufacturing stage is finishing, where the conveyor system undergoes treatments that enhance its performance and aesthetics. This may include:

Illustrative image related to modular belt conveyors

-

Surface Treatment: Processes such as anodizing or powder coating improve corrosion resistance and provide a clean finish, which is particularly important for food and pharmaceutical applications.

-

Quality Checks: Before shipment, the finished products are subjected to rigorous quality checks to ensure they meet the required specifications and industry standards.

What Quality Assurance Measures Are Implemented During Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process for modular belt conveyors. It ensures that products meet specified standards and perform reliably in their intended applications.

What International Standards Apply to Modular Belt Conveyor Manufacturing?

B2B buyers should be aware of the various international quality standards that influence the manufacturing of modular belt conveyors:

-

ISO 9001: This standard outlines the criteria for a quality management system. Manufacturers certified under ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

-

CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards. It is essential for buyers in Europe, ensuring that products are safe and reliable.

-

API Standards: For conveyors used in specific industries such as oil and gas, adherence to American Petroleum Institute (API) standards may be necessary. These standards ensure that equipment is safe and effective for demanding applications.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is implemented at various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, periodic inspections are conducted to monitor the quality of components being produced. This helps identify and rectify any issues early in production.

-

Final Quality Control (FQC): Before shipping, the completed conveyor systems undergo comprehensive testing to verify their functionality, durability, and adherence to quality standards. This may include load testing, operational checks, and visual inspections.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

For B2B buyers, verifying a supplier’s quality assurance practices is crucial to ensure reliable product performance. Here are key strategies to assess potential suppliers:

Illustrative image related to modular belt conveyors

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes, quality control measures, and compliance with international standards. This can be done internally or through third-party services.

-

Requesting Quality Reports: Suppliers should be willing to provide documentation of their quality control processes, including results from IQC, IPQC, and FQC. This transparency can build trust and assure buyers of product reliability.

-

Third-Party Inspections: Engaging third-party inspection services can provide an objective assessment of a supplier’s manufacturing capabilities and adherence to quality standards. This can be particularly beneficial when sourcing from international suppliers.

What Are the Quality Control Nuances for International Buyers?

When sourcing modular belt conveyors from international suppliers, B2B buyers must consider several nuances related to quality control:

-

Cultural Differences: Different regions may have varying standards for quality control and manufacturing practices. Understanding these cultural differences can help buyers set realistic expectations and foster better communication.

-

Regulatory Compliance: Buyers must ensure that the products comply with local regulations in their respective markets. This includes understanding any additional certifications that may be required for specific industries.

-

Logistics and Supply Chain Management: Ensuring quality in the supply chain is vital. Buyers should consider how logistics and transportation may affect product integrity and what measures suppliers have in place to mitigate these risks.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for modular belt conveyors is essential for B2B buyers. By focusing on these aspects, businesses can make informed purchasing decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘modular belt conveyors’

Introduction

This guide provides a structured approach for B2B buyers seeking to procure modular belt conveyors. By following this checklist, you can ensure that you make informed decisions that align with your operational needs, budget, and long-term business goals.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the foundation of your procurement process. Consider factors such as the type of materials you will be transporting, the weight of the loads, and the specific layout of your facility. This will help in selecting a conveyor that meets your operational demands and minimizes potential downtime.

- Material Compatibility: Ensure the belt material is suitable for your products, especially in industries like food processing where food-safe materials are essential.

- Load Capacity: Assess the maximum weight and dimensions of the items to be transported to avoid underperformance or damage.

Step 2: Identify Potential Suppliers

Research potential suppliers who specialize in modular belt conveyors. Look for companies with a proven track record and extensive experience in the industry. This step is vital for finding partners who can deliver quality products and reliable service.

- Industry Reputation: Check online reviews, industry forums, and case studies to gauge the supplier’s reputation.

- Geographical Presence: Consider suppliers with a local or regional presence to facilitate easier communication and support.

Step 3: Evaluate Supplier Capabilities

Before committing, assess the capabilities of your shortlisted suppliers. This includes their manufacturing processes, design flexibility, and ability to customize solutions according to your needs.

- Customization Options: Ensure the supplier can provide modular designs that can be easily reconfigured or expanded as your needs evolve.

- Technical Support: Confirm that the supplier offers robust technical support, including installation and maintenance services.

Step 4: Verify Certifications and Compliance

Check that the suppliers hold relevant certifications and comply with industry standards. This is crucial for ensuring that the conveyors are safe and reliable for your operations.

- Quality Certifications: Look for ISO certifications or other quality management standards that indicate a commitment to product excellence.

- Regulatory Compliance: Ensure that the conveyors meet local regulations, especially if operating in highly regulated industries like food or pharmaceuticals.

Step 5: Request Samples and Demonstrations

Before making a purchase, request samples or arrange for demonstrations of the conveyor systems. This hands-on approach allows you to assess the product’s performance and suitability for your specific applications.

- Trial Runs: Engage in trial periods to evaluate how the conveyor integrates with your existing systems.

- Performance Metrics: Ask for data on throughput rates, energy efficiency, and maintenance needs during the demonstration.

Step 6: Analyze Total Cost of Ownership

Consider the total cost of ownership (TCO) rather than just the initial purchase price. This includes installation costs, maintenance, energy consumption, and potential downtime.

- Lifecycle Costs: Evaluate the long-term costs associated with repairs and parts replacement to understand the overall financial impact.

- Warranty and Support: Assess the warranty terms and after-sales support offered by the supplier to mitigate future expenses.

Step 7: Finalize Contract Terms

Once you have selected a supplier, ensure that all contract terms are clear and comprehensive. This includes delivery timelines, payment terms, and after-sales support commitments.

Illustrative image related to modular belt conveyors

- Negotiation Points: Be prepared to negotiate terms that align with your operational needs and budget constraints.

- Clarity in Deliverables: Ensure the contract specifies all aspects of the delivery, including installation and training for your team.

By following these steps, you can streamline your procurement process and select the right modular belt conveyor that will enhance your operational efficiency and productivity.

Comprehensive Cost and Pricing Analysis for modular belt conveyors Sourcing

What Are the Key Cost Components in Modular Belt Conveyor Sourcing?

When sourcing modular belt conveyors, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials significantly impacts the overall cost. Modular plastic belts, for instance, are often made from high-impact polycarbonate or other durable plastics. Suppliers may offer various options that can affect price, such as food-safe materials for the food industry or heavy-duty materials for industrial applications.

-

Labor: Labor costs can vary depending on the complexity of the conveyor system and the location of manufacturing. In regions with higher labor costs, such as Europe, expect to pay more for skilled labor involved in assembly and quality assurance.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities and facility maintenance. Suppliers with advanced manufacturing techniques may have lower overheads, potentially passing those savings on to buyers.

-

Tooling: Customization often requires specialized tooling, which can add to initial costs. Suppliers may charge for the design and production of unique components tailored to specific operational needs.

-

Quality Control: Ensuring the durability and reliability of modular conveyors requires robust QC processes. Investments in quality assurance can lead to higher upfront costs but result in lower long-term maintenance expenses.

-

Logistics: Shipping and handling costs are critical, especially for international buyers. Factors such as distance, freight methods, and import duties can significantly influence the total cost.

-

Margin: Suppliers typically mark up prices to cover their costs and profit. Understanding the average margins in the industry can help buyers negotiate better deals.

How Do Price Influencers Affect Modular Belt Conveyor Costs?

Several factors can influence the pricing of modular belt conveyors, making it crucial for buyers to consider them during sourcing.

-

Volume/MOQ (Minimum Order Quantity): Ordering in bulk can lead to significant discounts. Suppliers often provide better pricing tiers for larger orders, which is beneficial for companies planning extensive installations.

-

Specifications and Customization: Custom features, such as unique dimensions or specialized materials, can increase costs. Buyers should clarify their needs upfront to avoid unexpected expenses later.

-

Material Quality and Certifications: Higher quality materials or those meeting specific industry certifications (like FDA compliance for food handling) typically come at a premium. However, investing in quality can reduce total ownership costs by minimizing downtime and maintenance.

-

Supplier Factors: Different suppliers may have varying pricing strategies based on their operational efficiencies, market positioning, and brand reputation. It’s advisable to compare multiple suppliers to gauge the best value.

-

Incoterms: Understanding the agreed Incoterms (International Commercial Terms) can impact overall costs. For example, “FOB” (Free on Board) pricing may include different transportation responsibilities, affecting logistics costs.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

B2B buyers can adopt several strategies to ensure cost-effective sourcing of modular belt conveyors.

-

Negotiate Terms: Leverage your purchasing power by negotiating prices, payment terms, and warranties. Suppliers may be willing to offer discounts for long-term contracts or larger orders.

-

Focus on Total Cost of Ownership (TCO): Assess not only the initial purchase price but also the long-term costs associated with maintenance, energy consumption, and potential downtime. A lower initial price may lead to higher overall expenses if quality is compromised.

-

Be Aware of Pricing Nuances in International Markets: Buyers from regions such as Africa, South America, and the Middle East should factor in local economic conditions, currency fluctuations, and import regulations that could affect pricing. Understanding these nuances can lead to more strategic sourcing decisions.

-

Request Prototypes: When considering custom solutions, ask for prototypes or pilot projects. This can help assess quality and functionality before committing to larger orders.

-

Research and Compare Suppliers: Conduct thorough research to compare different suppliers based on their product offerings, customer service, and reputation. Utilizing online resources and case studies can provide insights into supplier capabilities.

Conclusion

In summary, a comprehensive understanding of the cost structure and pricing influencers in the modular belt conveyor market can empower B2B buyers to make informed decisions. By considering the outlined components and employing strategic sourcing tips, businesses can achieve greater cost-efficiency while ensuring the reliability and performance of their conveyor systems. Always remember that indicative prices may vary based on specific requirements and market conditions, so maintaining flexibility and open communication with suppliers is essential.

Alternatives Analysis: Comparing modular belt conveyors With Other Solutions

Introduction to Conveyor Alternatives

In the realm of material handling and product transportation, selecting the right conveyor solution is paramount for operational efficiency. Modular belt conveyors offer unique advantages, but it’s essential to evaluate them against viable alternatives to ensure the best fit for your business needs. This section compares modular belt conveyors with two other popular conveyor systems: roller conveyors and belt conveyors. By analyzing key aspects such as performance, cost, ease of implementation, maintenance, and best use cases, B2B buyers can make informed decisions.

Comparison Table

| Comparison Aspect | Modular Belt Conveyors | Roller Conveyors | Belt Conveyors |

|---|---|---|---|

| Performance | High throughput, flexible design for various loads | Suitable for heavy loads but limited flexibility | Continuous flow, ideal for bulk materials |

| Cost | Higher initial investment but lower long-term maintenance | Generally lower upfront costs | Moderate costs, variable based on belt type |

| Ease of Implementation | Requires skilled assembly, customizable layout | Easy to install, less complex | Straightforward installation but limited adaptability |

| Maintenance | Low maintenance, easy to clean and repair | Moderate, requires regular checks | Varies widely, can be high for certain types |

| Best Use Case | Food processing, packaging, and small part handling | Heavy-duty applications, warehouses | Bulk material handling in mining, agriculture |

Detailed Breakdown of Alternatives

Roller Conveyors

Roller conveyors are an efficient solution for transporting heavy items across short to medium distances. These systems operate on a series of rollers that allow products to move with minimal effort. The primary advantage of roller conveyors is their cost-effectiveness and ease of installation, making them a popular choice in warehouses and distribution centers. However, their flexibility is limited; they are less suited for handling products of varying shapes and sizes compared to modular belt conveyors.

Belt Conveyors

Belt conveyors are a traditional method of transporting materials, especially bulk goods. They are characterized by a continuous loop of material that moves along a defined path. One of the primary benefits of belt conveyors is their ability to handle large volumes of bulk materials, making them ideal for industries like mining and agriculture. However, belt conveyors can be less adaptable than modular systems, often requiring more significant modifications or replacements to change configurations. Maintenance can also be a concern, especially with certain types of belts that may wear out faster under heavy loads.

Conclusion: How to Choose the Right Conveyor Solution

When selecting a conveyor system, B2B buyers must consider their specific operational requirements, including the types of materials being transported, the layout of the facility, and budget constraints. Modular belt conveyors excel in environments requiring flexibility, hygiene, and high throughput, particularly in food processing or packaging industries. In contrast, roller conveyors may be more suitable for straightforward, heavy-duty applications, while belt conveyors are best for bulk material handling. By evaluating these alternatives against the unique demands of their operations, businesses can make a strategic investment that enhances efficiency and productivity.

Illustrative image related to modular belt conveyors

Essential Technical Properties and Trade Terminology for modular belt conveyors

What Are the Key Technical Properties of Modular Belt Conveyors?

Understanding the essential technical properties of modular belt conveyors is crucial for B2B buyers looking to invest in efficient material handling solutions. Here are several critical specifications to consider:

-

Material Grade

Modular belts are typically constructed from high-grade plastics like polypropylene or polyethylene. The material choice affects durability, chemical resistance, and suitability for specific environments, such as food processing or heavy-duty industrial applications. Selecting the right material can significantly impact the longevity and maintenance needs of the conveyor system. -

Belt Width and Thickness

The width and thickness of the conveyor belt are vital for determining the load capacity and operational efficiency. Wider belts can handle larger products, while thicker belts provide increased strength and durability. It’s essential to match these dimensions with the specific requirements of your application to ensure optimal performance. -

Belt Configuration

Modular belts can be configured in various ways, including straight, curved, or inclined setups. This versatility allows businesses to design conveyor systems tailored to their workflow and space constraints. Selecting the appropriate configuration can enhance product flow and reduce the risk of jams or downtime. -

Temperature Tolerance

Different applications may require belts that can operate under extreme temperatures. Understanding the temperature tolerance of the belt material is crucial for industries like food processing, where belts may encounter hot or cold products. Choosing a belt with the appropriate temperature range ensures consistent performance and avoids premature wear. -

Load Capacity

The load capacity of a modular belt conveyor refers to the maximum weight it can transport without compromising safety or efficiency. This specification is critical for industrial applications where heavy materials are common. Knowing the load capacity helps in selecting the right conveyor system to avoid potential breakdowns or safety hazards. -

Belt Life and Maintenance Requirements

Evaluating the expected lifespan of the belt and the associated maintenance needs is essential for cost-effectiveness. Some modular belts are designed for longer operational life and require less frequent maintenance, which can reduce downtime and operating costs. Understanding these factors can assist in making informed purchasing decisions.

What Are Common Trade Terms Related to Modular Belt Conveyors?

Familiarity with industry terminology can streamline communication and negotiations between B2B buyers and suppliers. Here are some common trade terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of modular belt conveyors, working with OEMs ensures that you receive high-quality components that meet industry standards. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest amount of a product that a supplier is willing to sell. Understanding MOQ is critical for budget planning and inventory management, particularly for international buyers who may face shipping and storage challenges. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and availability for specific products or services. For modular belt conveyors, submitting an RFQ can provide comparative insights, helping buyers make informed decisions based on cost and specifications. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping and delivery. Knowing Incoterms is vital for understanding who bears the risk and cost during transportation, especially for international transactions involving modular belt conveyors. -

Lead Time

Lead time is the period between placing an order and receiving the product. Understanding lead times for modular belt conveyors is crucial for project planning and ensuring that production schedules are met without delays. -

Customization Options

This term refers to the ability to tailor modular belt conveyors according to specific operational requirements. Customization can include modifications in belt size, material, and configuration, providing flexibility to meet unique business needs.

By comprehending these technical properties and trade terms, B2B buyers can navigate the modular belt conveyor market more effectively, ensuring they select the right solutions for their operational challenges.

Navigating Market Dynamics and Sourcing Trends in the modular belt conveyors Sector

What Are the Current Market Dynamics and Key Trends Impacting Modular Belt Conveyors?

The modular belt conveyors market is experiencing significant growth driven by the increasing demand for automation across various industries such as food and beverage, automotive, and pharmaceuticals. The rise of e-commerce and the need for efficient material handling systems in warehouses are further propelling this demand. In emerging markets like Africa and South America, the adoption of modular conveyor systems is accelerating as businesses seek to enhance operational efficiency and reduce labor costs. International buyers are particularly focused on solutions that offer flexibility, allowing for easy reconfiguration and scalability in production lines.

Technological advancements are shaping sourcing trends in this sector. Innovations such as IoT integration for real-time monitoring and predictive maintenance are becoming commonplace, enabling companies to minimize downtime and optimize performance. Additionally, the trend towards customization is gaining traction, with manufacturers offering a wide array of belt configurations and materials tailored to specific applications. This is particularly relevant for buyers in Europe and the Middle East, where stringent regulations on food safety and hygiene necessitate specialized conveyor solutions.

How Is Sustainability and Ethical Sourcing Influencing the Modular Belt Conveyors Market?

Sustainability is increasingly becoming a focal point for international B2B buyers, who are now prioritizing eco-friendly practices in their sourcing strategies. The environmental impact of manufacturing processes and the lifecycle of materials used in modular belt conveyors are crucial considerations. Manufacturers are responding by utilizing recycled and recyclable materials in their products, which not only reduces waste but also aligns with global sustainability goals.

Ethical sourcing is equally important, as buyers seek to ensure that their supply chains are transparent and socially responsible. Certifications such as ISO 14001 (Environmental Management) and ISO 9001 (Quality Management) are gaining prominence, offering assurance that suppliers adhere to high standards of environmental stewardship. Moreover, the use of “green” materials, such as biodegradable plastics or energy-efficient manufacturing processes, is becoming a key differentiator in the market. This trend is particularly strong among European buyers, who are increasingly demanding suppliers that demonstrate a commitment to sustainability.

What Is the Brief Evolution and History of Modular Belt Conveyors?

The concept of modular belt conveyors originated in the late 20th century as manufacturers sought more efficient and flexible material handling solutions. Initially developed to address the limitations of traditional conveyor systems, modular belts provided a solution that was easier to install, maintain, and customize. Over the decades, advancements in materials and engineering have transformed these systems, making them lighter, more durable, and capable of handling a wider range of applications.

Today, modular belt conveyors are recognized for their versatility and adaptability, catering to diverse industries. Their evolution reflects a broader trend towards automation and efficiency in manufacturing, with a focus on reducing operational costs while enhancing productivity. As the market continues to grow, innovations in design and technology will likely shape the future of modular belt conveyors, further solidifying their role in modern industrial applications.

Illustrative image related to modular belt conveyors

Frequently Asked Questions (FAQs) for B2B Buyers of modular belt conveyors

-

How do I solve issues with downtime in my modular belt conveyor system?

To minimize downtime, first assess the common causes such as misalignment, wear and tear, or inadequate maintenance. Implement a routine inspection schedule focusing on critical components like sprockets and belts. Additionally, consider using modular belts designed for easy installation and maintenance, which can significantly reduce repair time. Collaborating with a supplier who offers expert support can also help identify issues early and implement effective solutions tailored to your operational needs. -

What is the best modular belt conveyor for heavy-duty applications?

For heavy-duty applications, look for modular belt conveyors constructed from high-strength materials with robust designs that can handle sharp edges and heavy loads. Options like curved or inclined modular belt conveyors are ideal for flexible layouts in industrial environments. Consult with suppliers to evaluate configurations that optimize your production flow while ensuring durability and performance under demanding conditions. -

How can I customize my modular belt conveyor to fit my specific needs?

Customization options for modular belt conveyors are extensive. You can choose from various belt materials, widths, and configurations, including straight, curved, and inclined designs. Many manufacturers offer engineering support to help you design a system that meets your operational requirements. Be sure to discuss your specific application needs, such as load capacities and environmental considerations, to ensure the conveyor system is tailored to your processes. -

What are the minimum order quantities (MOQs) for modular belt conveyors?

Minimum order quantities can vary significantly by supplier and the complexity of the conveyor system required. Some manufacturers may offer flexibility for smaller orders, especially for customization. Always inquire about MOQs during the sourcing process, as negotiating terms could lead to more favorable conditions, particularly for first-time buyers or smaller businesses looking to test systems before scaling up. -

What payment terms should I expect when purchasing modular belt conveyors internationally?

Payment terms for international purchases typically range from upfront payment to net 30 or net 60 days after delivery. It’s crucial to discuss payment options with your supplier early in the negotiation process. Factors influencing these terms include the supplier’s policies, your order size, and your previous purchasing history. Consider using secure payment methods and letters of credit to safeguard your transactions. -

How can I ensure quality assurance (QA) in my modular belt conveyor purchase?

To ensure quality assurance, partner with reputable suppliers who adhere to international standards and certifications. Request documentation related to quality control processes, such as material specifications and testing protocols. Additionally, consider visiting manufacturing facilities or requesting samples to evaluate product quality firsthand. Establishing clear communication regarding your quality expectations will also help align supplier deliverables with your standards. -

What logistics considerations should I keep in mind when importing modular belt conveyors?

Logistics are crucial when importing modular belt conveyors, including shipping methods, lead times, and customs regulations. Evaluate different shipping options to find the most cost-effective and timely solution. Be aware of import duties and taxes specific to your country, as these can impact total costs. Collaborating with logistics experts can streamline the process, ensuring compliance with regulations and timely delivery. -

What are the best practices for maintaining modular belt conveyors?

Regular maintenance is key to prolonging the lifespan of your modular belt conveyors. Implement a preventive maintenance schedule that includes routine inspections, cleaning, and lubrication of moving parts. Train your staff on operational best practices to minimize wear and tear. Additionally, keep a stock of essential spare parts to quickly address any issues that may arise, reducing potential downtime and ensuring continuous operation.

Top 6 Modular Belt Conveyors Manufacturers & Suppliers List

1. Intralox – Modular Plastic Conveyor Belts

Domain: intralox.com

Registered: 1996 (29 years)

Introduction: Modular Plastic Conveyor Belts by Intralox are designed for optimal performance and longevity, with over 50 years of industry experience. Key features include:

– Hundreds of thousands of configurations available

– Modular construction for easier installation, repair, cleaning, and maintenance

– Increased throughput while minimizing downtime

– Longer belt life, up to three times longer in some …

2. Robot Units – Straight Modular Belt Conveyor

Domain: robotunits.com

Registered: 1998 (27 years)

Introduction: {“Modular_Belt_Conveyor”:{“products”:[{“name”:”Straight Modular Belt Conveyor”,”product_num”:”C8M”,”link”:”https://robotunits.com/en-us/shop/conveyor-technology/modular-belt-conveyor/straight-modular-belt-conveyor/”,”image”:”https://robotunits.com/wp-content/uploads/2022/02/C8M_Modulbandfoerderer-300×169.png”},{“name”:”Curved Modular Belt Conveyor”,”product_num”:”C8MC”,”link”:”https://robotunits.c…

3. DynaCon – Modular Conveyors

Domain: dynamicconveyor.com

Registered: 1998 (27 years)

Introduction: DynaCon Modular Conveyors are designed for flexibility and reconfiguration, allowing businesses to adapt their conveyor systems as needs change. Key features include:

– Configurations: Available in flat, vertical, and Z-style incline modules, with lengths up to 100 feet and widths from 4″ to 72″.

– Portability: Lightweight, high-impact polycarbonate construction with options for casters for easy…

4. Dorner – Conveyor Solutions

Domain: dornerconveyors.com

Registered: 2007 (18 years)

Introduction: Dorner offers a variety of conveyors including:

– Industrial & Automation Conveyors:

– Fabric & Modular Belt

– 1100 Miniature Conveyors

– 2200 Low Profile Conveyors

– 2700 Medium Duty Conveyors

– 3200 Heavy Duty Conveyors

– DCMove Heavy Duty Steel Precision Move

– Compact Curve Conveyor

– Flexible Chain FlexMove

– FlexMove Helix

– FlexMove Stainless Pallet Systems

…

5. Habasit – HabasitLINK Plastic Modular Belts

Domain: habasit.com

Registered: 1999 (26 years)

Introduction: HabasitLINK Plastic Modular Belts have over 20 years of proven industry performance with a portfolio of over 150 different belt styles in various materials and colors. Key advantages include: positive drive and tracking without pre-tensioning, resistance to extreme conditions (-70°C to +240°C), quick repair and maintenance, suitability for aggressive chemical agents, longer lifetime with minimal m…

6. Midwest Rubber – Plastic Modular Conveyor Belts

Domain: midwestrubber.com

Registered: 1998 (27 years)

Introduction: Plastic Modular Conveyor Belts – Midwest Rubber

Key Product Details:

1. **Straight Running Pitch:**

– Sizes: .375, .5, 1, 1.5, 2, 2.5 inches

– Colors: Blue, White, Gray, Natural

– Materials: Acetal, Polypropylene, Polyethylene, Nylon, Ultra Tuff (Proprietary material formulation)

– Additives: Metal, X-Ray, Dual Detectable

– Styles: Flat Top, Grip Top, Roller Top, Dimple Top, Cone…

Strategic Sourcing Conclusion and Outlook for modular belt conveyors

How Can Strategic Sourcing Enhance Your Modular Belt Conveyor Solutions?

In the ever-evolving landscape of modular belt conveyors, strategic sourcing is key to achieving optimal efficiency and cost-effectiveness. By collaborating with reputable manufacturers, businesses can access innovative solutions tailored to their specific needs, ensuring that they remain competitive in their respective markets. Key takeaways include the importance of selecting modular systems that offer flexibility, ease of maintenance, and longevity, which can significantly reduce total ownership costs.

Investing in high-quality modular belt conveyors not only enhances operational performance but also aligns with sustainability goals by minimizing waste and energy consumption. As you navigate the complexities of sourcing, consider leveraging the expertise of established suppliers who can provide customized solutions and unparalleled support.

Looking ahead, now is the time for international B2B buyers, especially from Africa, South America, the Middle East, and Europe, to embrace the advantages of modular belt conveyors. By making informed sourcing decisions today, you can position your business for growth and innovation in the future. Reach out to industry experts to explore the latest technologies and configurations that can propel your operations forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to modular belt conveyors

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.