Everything You Need to Know About Metal Spur Sourcing in 2025

Introduction: Navigating the Global Market for metal spur

In an increasingly interconnected world, sourcing high-quality metal spur gears can be a daunting challenge for B2B buyers. These essential components play a critical role in various machinery and equipment, impacting performance, durability, and overall operational efficiency. This guide aims to equip international buyers, particularly from regions like Africa, South America, the Middle East, and Europe—including key markets such as Nigeria and Saudi Arabia—with the insights needed to navigate the global market for metal spur gears effectively.

Throughout this comprehensive resource, you will discover detailed information on various types of metal spur gears, their applications across industries, and the nuances of selecting the right products for your specific needs. We will delve into essential supplier vetting processes, offering practical advice to ensure you partner with reputable manufacturers who meet your quality standards. Additionally, this guide will address cost considerations, helping you make budget-conscious decisions without compromising on quality.

By empowering you with the knowledge necessary for informed purchasing decisions, this guide aims to simplify the sourcing process, enhance your supply chain efficiency, and ultimately contribute to your organization’s success in a competitive global marketplace. Whether you’re looking to upgrade existing equipment or fulfill new project requirements, understanding the landscape of metal spur gears will position your business for growth and innovation.

Understanding metal spur Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Spur Gear | Simple cylindrical shape, parallel teeth | Manufacturing, automotive, robotics | Pros: High precision, easy to manufacture. Cons: Can generate noise during operation. |

| Helical Spur Gear | Angled teeth, smoother operation | Gearboxes, conveyors, industrial machinery | Pros: Quieter operation, higher load capacity. Cons: More complex to manufacture, higher cost. |

| Steel Spur Gear | Made from hardened steel, rust-resistant coating | Heavy machinery, automotive upgrades | Pros: Exceptional durability, ideal for high power applications. Cons: Heavier than other materials, potential for wear over time. |

| Plastic Spur Gear | Lightweight, corrosion-resistant, lower cost | Consumer products, small machinery | Pros: Cost-effective, lightweight. Cons: Limited load capacity, may wear out faster than metal. |

| Profile Shifted Gear | Adjusted tooth profile for improved strength | Precision machinery, aerospace | Pros: Enhanced strength and durability, customizable. Cons: More expensive, requires precise manufacturing processes. |

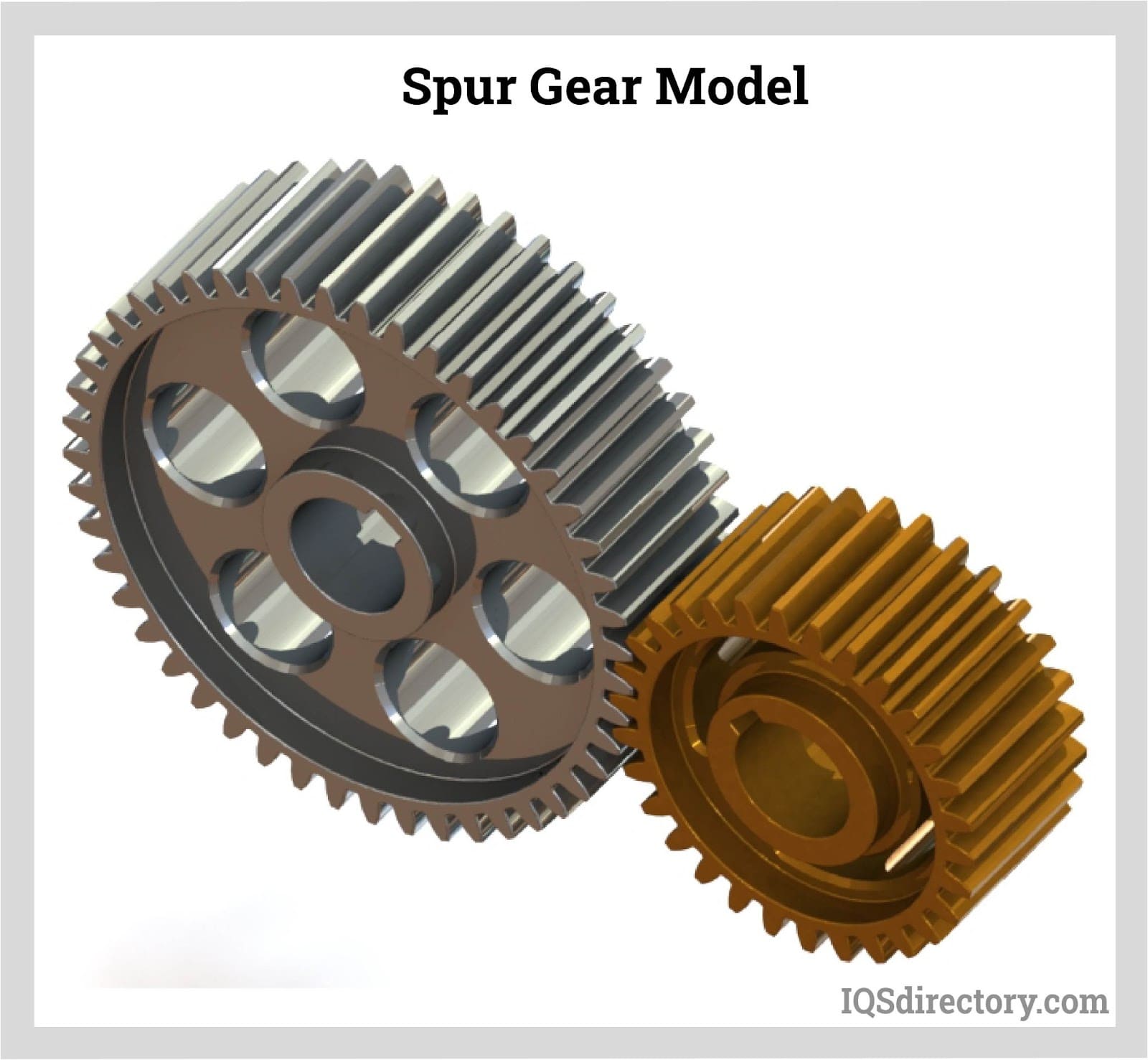

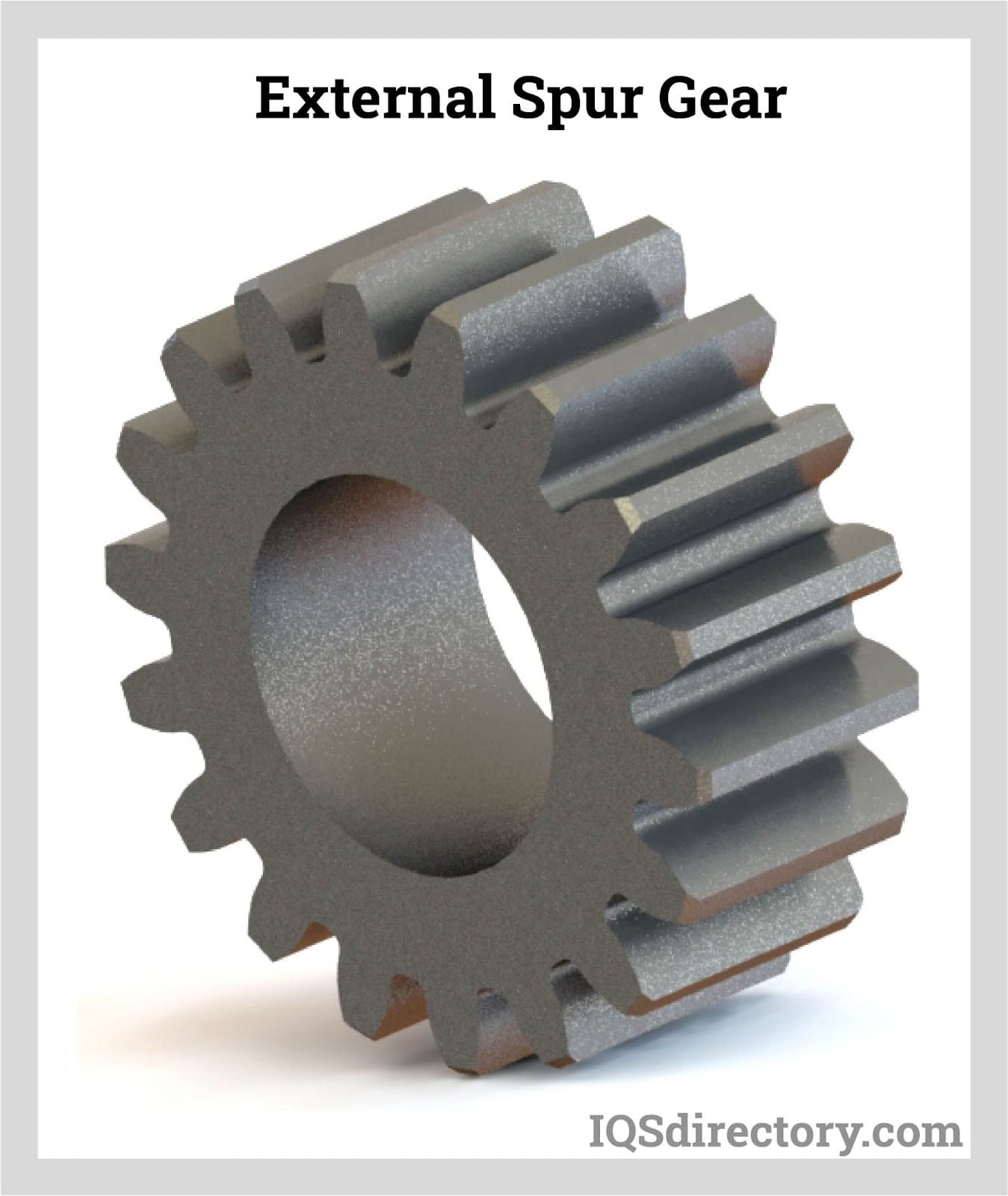

What Are the Characteristics of Standard Spur Gears?

Standard spur gears are the most common type of gear used in various industries. Their design features parallel teeth that mesh directly, allowing for efficient motion transfer between parallel shafts. They are well-suited for applications where space is limited and precision is critical. B2B buyers should consider the potential noise generated during operation, which may necessitate additional sound dampening measures in certain environments.

How Do Helical Spur Gears Differ from Standard Types?

Helical spur gears feature teeth that are angled relative to the gear axis, which allows for smoother engagement and quieter operation compared to standard spur gears. This design is particularly advantageous in applications requiring higher load capacities, such as gearboxes and industrial machinery. Buyers should weigh the increased manufacturing complexity and cost against the operational benefits, especially in high-performance applications.

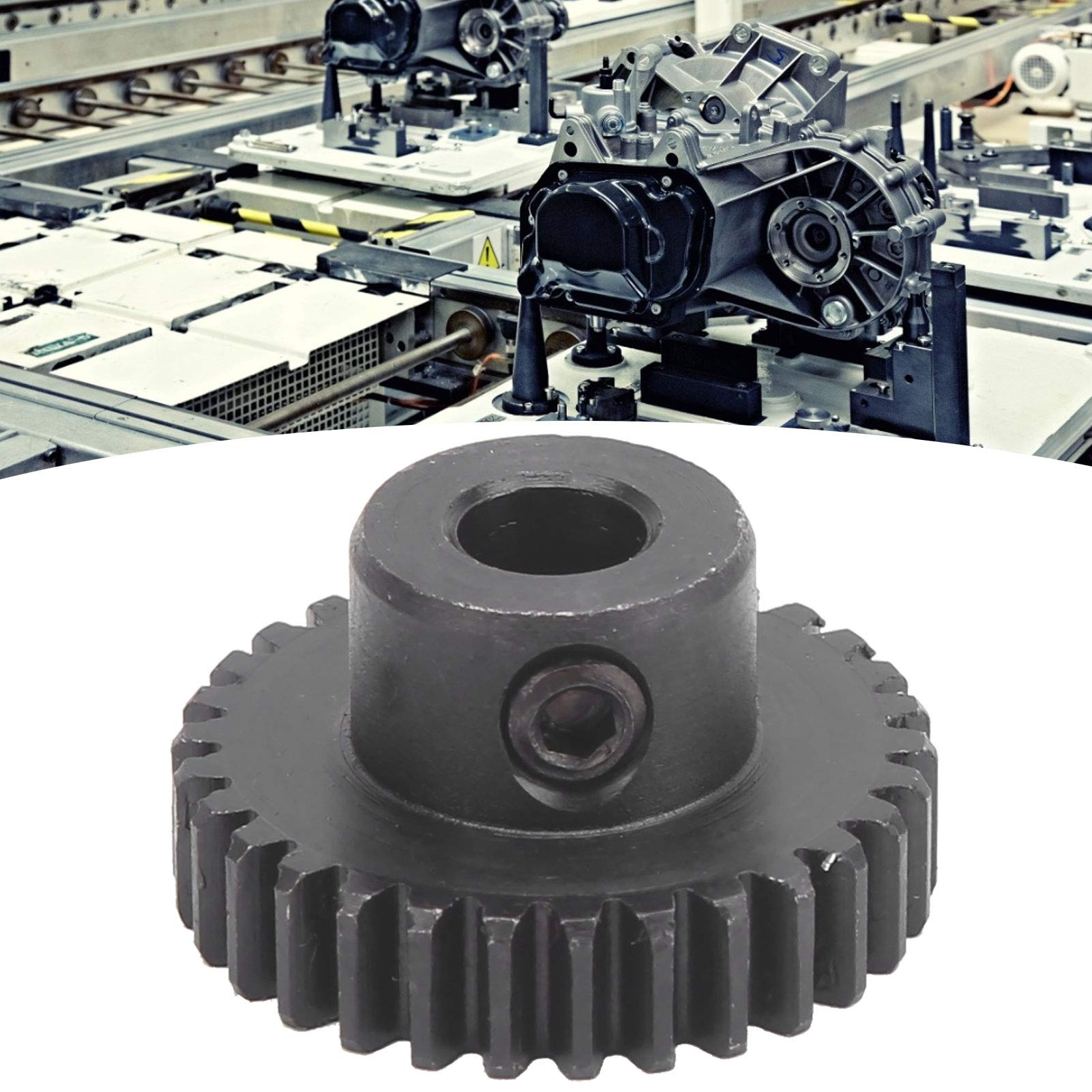

Illustrative image related to metal spur

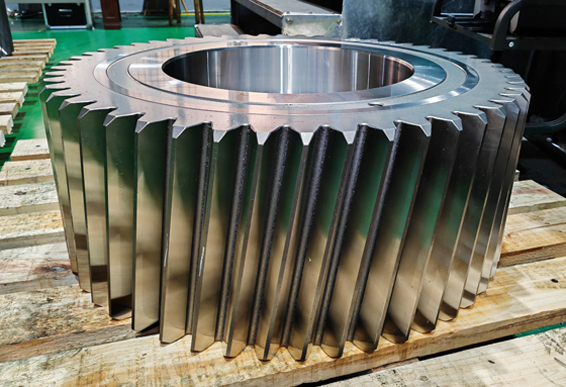

Why Choose Steel Spur Gears for Heavy Machinery?

Steel spur gears are crafted from hardened steel and often feature a rust-resistant coating, making them ideal for heavy-duty applications. Their robust construction provides exceptional durability, which is essential in environments that subject gears to high stress and power loads. B2B purchasers should consider the weight of these gears and their potential wear over time, especially in applications requiring frequent replacements.

What Are the Benefits of Using Plastic Spur Gears?

Plastic spur gears offer a lightweight and cost-effective solution for various applications, particularly in consumer products and small machinery. Their corrosion-resistant properties make them suitable for environments where metal gears might suffer from rust. However, buyers must be mindful of their limited load capacity, which can restrict their use in high-stress applications, necessitating careful consideration of the operational requirements.

What Is the Advantage of Profile Shifted Gears?

Profile shifted gears are designed with an altered tooth profile to enhance strength and durability. This customization allows for improved performance in precision machinery and aerospace applications. While they provide significant advantages in terms of load-bearing capabilities, B2B buyers should be aware that their production can be more complex and costly, which may impact overall project budgets and timelines.

Key Industrial Applications of metal spur

| Industry/Sector | Specific Application of metal spur | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Drive train components in vehicles | Enhances vehicle performance and reliability | Material quality, precision machining capabilities |

| Manufacturing | Gear systems in production machinery | Increases operational efficiency and reduces downtime | Customization options, lead times, and scalability |

| Robotics | Motion control in robotic arms | Improves precision and responsiveness in automation | Compatibility with existing systems, durability |

| Agriculture | Gear systems in farm equipment | Boosts productivity and reliability in operations | Resistance to corrosion, maintenance requirements |

| Aerospace | Gear assemblies in aircraft systems | Ensures safety and performance under extreme conditions | Certifications, weight considerations, and sourcing standards |

How Are Metal Spurs Used in the Automotive Industry?

In the automotive sector, metal spur gears are integral to the drive train components of vehicles, facilitating the transfer of power from the engine to the wheels. These gears are designed to withstand high torque while ensuring smooth operation, which is crucial for vehicle performance. International buyers, particularly from regions like Africa and the Middle East, need to prioritize sourcing high-quality materials to ensure durability and reliability, as well as precision machining capabilities to meet specific design requirements.

What Role Do Metal Spurs Play in Manufacturing?

In manufacturing, metal spur gears are used in various production machinery, including conveyor systems and automated assembly lines. Their ability to transmit motion efficiently reduces operational downtime and enhances productivity. For businesses in South America and Europe, sourcing gears that offer customization options is vital, as they may need to adapt to specific machinery configurations and production demands, ensuring a seamless integration into existing systems.

Illustrative image related to metal spur

How Are Metal Spurs Utilized in Robotics?

In robotics, metal spur gears are essential for motion control in robotic arms and other automated systems. They provide precise movement and responsiveness, which are critical for tasks requiring high accuracy. B2B buyers in the robotics sector should focus on sourcing durable gears that can withstand repetitive motion and environmental stresses. Compatibility with existing robotic systems is also a significant consideration to ensure optimal performance.

Why Are Metal Spurs Important in Agriculture?

Metal spur gears are commonly found in agricultural equipment, such as tractors and harvesters, where they enhance the machinery’s efficiency and reliability. These gears enable the smooth operation of gear systems that drive various functions, from tilling to harvesting. Buyers from regions with significant agricultural activities, such as Nigeria, should consider the corrosion resistance of metal spur gears, as agricultural environments can be harsh, requiring components that can withstand wear and tear.

How Do Metal Spurs Contribute to Aerospace Applications?

In the aerospace industry, metal spur gears are crucial for gear assemblies within aircraft systems. They must meet stringent safety and performance standards, especially under extreme conditions. International buyers in the aerospace sector should look for suppliers that provide certified products with the necessary weight considerations to ensure compliance with industry regulations. Sourcing gears that can withstand high-stress environments while maintaining performance is essential for operational safety.

3 Common User Pain Points for ‘metal spur’ & Their Solutions

Scenario 1: Sourcing Quality Metal Spurs for High-Performance Applications

The Problem: B2B buyers often face challenges in sourcing high-quality metal spurs that can withstand heavy loads and high-speed operations. In industries such as automotive or machinery manufacturing, using subpar spurs can lead to premature wear, increased downtime, and costly repairs. Buyers may struggle to identify suppliers who provide reliable products that meet specific industry standards, especially when dealing with international suppliers.

The Solution: To overcome this issue, buyers should develop a clear set of criteria that includes material specifications, manufacturing processes, and performance benchmarks. When sourcing metal spurs, prioritize suppliers that offer detailed product documentation, including material certifications and test results. Additionally, consider establishing partnerships with manufacturers that have a proven track record in your industry. Engaging in direct communication with suppliers can help clarify product capabilities and ensure that the spurs meet the required specifications. Leveraging industry networks or trade shows can also connect buyers with reputable manufacturers, providing opportunities to evaluate products firsthand.

Scenario 2: Ensuring Compatibility Between Metal Spurs and Existing Machinery

The Problem: Another common pain point for B2B buyers is ensuring that the metal spurs they purchase are compatible with their existing machinery. Incompatible components can lead to inefficient operations, increased wear, and even mechanical failure. This issue is particularly pronounced in sectors where machinery has been retrofitted or customized, complicating the selection of suitable parts.

The Solution: To address compatibility concerns, buyers should conduct a thorough analysis of their existing systems before making a purchase. This includes documenting specifications such as gear ratios, shaft sizes, and mounting configurations. Utilizing CAD software to simulate the integration of new metal spurs can also be beneficial. Buyers should seek suppliers that provide comprehensive technical support, including guidance on compatibility and installation. Additionally, investing in customizable spur options can help tailor products to meet specific machinery requirements, ensuring seamless integration and optimal performance.

Scenario 3: Managing Lead Times and Inventory Levels for Metal Spurs

The Problem: B2B buyers frequently encounter challenges related to lead times and inventory management, particularly when dealing with overseas suppliers. Long lead times can disrupt production schedules, while inadequate inventory levels may lead to halted operations and lost revenue. This issue is exacerbated in industries that rely on just-in-time manufacturing practices, where timing is critical.

The Solution: To mitigate these challenges, buyers should adopt a proactive approach to inventory management. This involves establishing strategic relationships with multiple suppliers to diversify sourcing options and reduce dependency on a single source. Implementing a vendor-managed inventory (VMI) system can also help maintain optimal stock levels, allowing suppliers to monitor inventory and automatically replenish as needed. Furthermore, consider negotiating favorable terms with suppliers for expedited shipping options, particularly during peak production seasons. By forecasting demand accurately and maintaining open communication with suppliers, buyers can better manage lead times and ensure continuous production flow.

By addressing these common pain points with actionable solutions, B2B buyers can enhance their procurement strategies for metal spurs, ultimately leading to improved operational efficiency and reduced costs.

Illustrative image related to metal spur

Strategic Material Selection Guide for metal spur

What Are the Key Properties of Common Materials Used for Metal Spurs?

When selecting materials for metal spurs, it is essential to consider their mechanical properties, manufacturing processes, and suitability for specific applications. Here, we analyze four common materials—carbon steel, stainless steel, aluminum, and brass—highlighting their performance characteristics and implications for international B2B buyers.

How Does Carbon Steel Perform as a Material for Metal Spurs?

Carbon steel is a popular choice for metal spurs due to its excellent strength and hardness. It typically exhibits high tensile strength and can withstand significant mechanical stress, making it suitable for high-load applications. However, carbon steel is prone to rust and corrosion if not properly coated or treated.

Pros: Carbon steel is durable and cost-effective, making it ideal for applications where performance is critical but budget constraints exist. Its manufacturing process is relatively straightforward, allowing for mass production.

Cons: The susceptibility to corrosion necessitates protective coatings, which can add to the overall cost. Additionally, carbon steel may not be suitable for environments with high humidity or exposure to corrosive substances.

Illustrative image related to metal spur

Impact on Application: Carbon steel spurs are well-suited for heavy machinery and automotive applications, where strength is paramount. However, they may not perform well in marine or chemical environments.

Considerations for International Buyers: Compliance with local standards such as ASTM or DIN is crucial. Buyers from regions like Nigeria and Saudi Arabia should ensure that suppliers can provide documentation for material specifications.

What Advantages Does Stainless Steel Offer for Metal Spurs?

Stainless steel is renowned for its corrosion resistance and aesthetic appeal. It is often used in applications where hygiene is a concern, such as food processing and medical devices. Stainless steel spurs can withstand a wide range of temperatures and pressures, making them versatile.

Pros: The primary advantage of stainless steel is its resistance to rust and staining, which prolongs the lifespan of the product. It also requires minimal maintenance and is suitable for various environments.

Cons: Stainless steel can be more expensive than carbon steel, and its manufacturing processes may be more complex, leading to higher production costs. Additionally, it may not provide the same level of strength as carbon steel in high-stress applications.

Impact on Application: Stainless steel spurs are ideal for applications in corrosive environments, such as marine or chemical processing industries. They are also preferred in sectors where cleanliness is paramount.

Considerations for International Buyers: Buyers should verify compliance with international standards and certifications, especially in Europe, where regulations on material quality are stringent.

Why Choose Aluminum for Metal Spurs?

Aluminum is lightweight and offers good corrosion resistance, making it a suitable choice for applications where weight reduction is crucial. It is often used in aerospace and automotive industries.

Pros: The primary advantage of aluminum is its low weight, which can improve the efficiency of machinery. It also has good thermal conductivity and is resistant to corrosion.

Cons: Aluminum is generally less strong than steel, which may limit its use in high-load applications. It is also more expensive than carbon steel.

Impact on Application: Aluminum spurs are particularly useful in applications where weight savings are essential, such as in the aerospace industry. However, they may not be suitable for heavy-duty machinery.

Considerations for International Buyers: Buyers should be aware of the specific grades of aluminum that meet their application needs and ensure compliance with international standards.

What Role Does Brass Play in Metal Spur Applications?

Brass, an alloy of copper and zinc, is known for its excellent machinability and corrosion resistance. It is often used in applications requiring good electrical conductivity.

Pros: Brass spurs are easy to machine and offer good resistance to corrosion, making them suitable for various applications, including plumbing and electrical components.

Illustrative image related to metal spur

Cons: Brass is typically more expensive than carbon steel and may not be as strong, limiting its use in high-load applications.

Impact on Application: Brass is ideal for applications where electrical conductivity is essential, such as in electronic devices. However, its strength limitations may restrict its use in heavy machinery.

Considerations for International Buyers: Buyers should ensure that the brass alloy used complies with relevant standards and is suitable for their specific applications.

Summary of Material Selection for Metal Spurs

| Material | Typical Use Case for Metal Spur | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Heavy machinery, automotive applications | High strength and durability | Prone to corrosion without coating | Medium |

| Stainless Steel | Marine, food processing, medical devices | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Aerospace, automotive (weight-sensitive) | Lightweight and good corrosion resistance | Lower strength compared to steel | Medium |

| Brass | Plumbing, electrical components | Excellent machinability and conductivity | Higher cost and lower strength | Medium |

This guide provides a comprehensive overview of the materials used for metal spurs, enabling B2B buyers to make informed decisions based on their specific application needs and regional compliance requirements.

Illustrative image related to metal spur

In-depth Look: Manufacturing Processes and Quality Assurance for metal spur

What Are the Key Stages in the Manufacturing Process of Metal Spurs?

The manufacturing of metal spurs involves several critical stages that ensure the final product meets the required specifications for strength, durability, and functionality. Understanding these stages is essential for B2B buyers, especially those sourcing from diverse regions such as Africa, South America, the Middle East, and Europe.

How Is Material Prepared for Metal Spur Production?

The process begins with material selection, typically involving high-strength steel or other durable alloys. The chosen material undergoes a thorough inspection to ensure it meets the required mechanical properties. This includes checking for chemical composition, hardness, and tensile strength, which are vital for the performance of the spur.

Once the material is approved, it is cut into manageable sizes using techniques like shearing or sawing. This initial step sets the foundation for further processing, ensuring that the dimensions are accurate for subsequent operations.

Illustrative image related to metal spur

What Forming Techniques Are Commonly Used in Metal Spur Manufacturing?

After material preparation, the forming stage begins. Common techniques for creating metal spurs include:

-

CNC Machining: This method utilizes computer-controlled machines to precisely shape the spur. CNC machining allows for high accuracy and repeatability, making it ideal for producing complex geometries.

-

Forging: This technique involves shaping the metal through compressive forces, which improves the material’s grain structure and enhances its mechanical properties. Forging can be done either hot or cold, depending on the required characteristics of the final product.

-

Casting: In some cases, spurs may be produced through casting, where molten metal is poured into a mold. This method can be advantageous for large production runs but may require additional machining to achieve the desired finish.

What Finishing Processes Are Necessary for Metal Spurs?

Finishing processes are crucial to enhance the surface quality and performance of metal spurs. Common finishing techniques include:

-

Heat Treatment: This process improves the hardness and strength of the spur through controlled heating and cooling. Heat treatment is vital for ensuring that the spur can withstand operational stresses.

-

Surface Coating: Applying coatings such as black oxide or galvanization helps prevent rust and corrosion, extending the lifespan of the spur. Coatings can also improve aesthetics, which may be important for certain applications.

-

Polishing and Deburring: These steps remove any sharp edges or imperfections from the spur’s surface, ensuring safe handling and optimal performance during use.

How Is Quality Assurance Managed in Metal Spur Production?

Quality assurance is integral to the manufacturing process, ensuring that every metal spur meets industry standards and customer expectations. For B2B buyers, understanding the quality control measures in place is essential for making informed purchasing decisions.

What International Standards Are Relevant for Metal Spur Quality Assurance?

Manufacturers often adhere to international standards such as ISO 9001, which outlines the requirements for a quality management system. Compliance with ISO standards demonstrates a commitment to quality and continuous improvement. Additionally, specific industries may require compliance with standards such as CE marking for products sold in Europe or API specifications for oil and gas applications.

What Are the Key QC Checkpoints During the Manufacturing Process?

Quality control checkpoints are strategically placed throughout the manufacturing process to monitor quality at various stages:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials to ensure they meet specified criteria before production begins. Any non-conforming materials are rejected at this stage.

-

In-Process Quality Control (IPQC): During manufacturing, various checks are performed to monitor the production process. This includes dimensional checks and inspections after each major operation, ensuring adherence to specifications.

-

Final Quality Control (FQC): Once the metal spurs are completed, a final inspection is conducted to ensure that all products meet the established quality standards before they are shipped. This may include functional testing, dimensional verification, and visual inspections.

How Can B2B Buyers Verify Supplier Quality Control?

When sourcing metal spurs, B2B buyers should take proactive steps to verify the quality control processes of potential suppliers:

-

Supplier Audits: Conducting audits of the manufacturing facility can provide insights into the quality management system, production capabilities, and adherence to safety and environmental standards.

-

Requesting Quality Reports: Suppliers should be able to provide detailed quality reports, including inspection results and compliance certifications. Reviewing these documents can help buyers assess the supplier’s reliability.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality control processes. This is especially important for international transactions, where buyers may not have direct oversight of the manufacturing process.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate additional complexities when it comes to quality assurance:

-

Cultural Differences: Understanding the local manufacturing culture and practices in regions like Africa or the Middle East can affect quality. Establishing clear communication and expectations is vital.

-

Regulatory Compliance: Different regions may have varying regulations regarding product safety and quality. B2B buyers should ensure that suppliers are compliant with both local and international regulations relevant to their industry.

-

Logistical Considerations: The quality of transportation and handling can also impact the final product. Buyers should consider how products are packaged and transported to minimize risks during shipping.

In conclusion, understanding the manufacturing processes and quality assurance measures for metal spurs is crucial for B2B buyers. By being informed about these aspects, buyers can make better decisions, ensuring they partner with reliable suppliers who meet their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metal spur’

To successfully procure metal spurs for your business needs, following a structured sourcing guide is essential. This checklist will help you navigate the complexities of sourcing high-quality metal spurs, ensuring you make informed decisions that align with your operational requirements and standards.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the specifications for the metal spur you require. This includes dimensions, material type (such as steel or aluminum), and any specific tolerances or performance characteristics needed for your application. By establishing precise requirements, you can streamline the sourcing process and ensure that the products meet your operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in metal spurs. Look for manufacturers with a strong reputation in the industry, especially those who have experience serving markets similar to yours. Consider factors such as:

– Geographic location: Proximity can affect shipping costs and lead times.

– Industry experience: Suppliers with a track record in your specific industry can better understand your needs.

Step 3: Evaluate Supplier Certifications

Before making any commitments, verify that potential suppliers hold the necessary certifications. Common certifications to look for include ISO 9001 for quality management and other industry-specific standards. These certifications are critical as they reflect the supplier’s commitment to quality and adherence to international standards.

Step 4: Request Samples and Conduct Quality Checks

Once you have narrowed down your options, request samples of the metal spurs. Assess these samples for quality, durability, and adherence to your specifications. Key aspects to evaluate include:

– Material integrity: Check for any defects or inconsistencies.

– Dimensional accuracy: Ensure that the spurs meet your specified dimensions precisely.

Step 5: Review Pricing and Terms

Compare pricing among your shortlisted suppliers, but remember that the lowest price may not always equate to the best value. Consider factors such as:

– Minimum order quantities: Ensure that the supplier can meet your required volume.

– Payment terms: Understand the payment structure and any potential discounts for bulk orders.

Illustrative image related to metal spur

Step 6: Consider After-Sales Support and Warranty

Evaluate the level of after-sales support provided by the supplier. A reliable supplier should offer warranties on their products and be willing to assist with any issues that may arise post-purchase. This includes:

– Technical support: Access to assistance for installation or troubleshooting.

– Return policy: Understand the terms for returns or exchanges in case of defects.

Step 7: Finalize Your Order and Establish Communication

Once you have made your selection, finalize your order with clear communication regarding delivery timelines and expectations. Establish a point of contact for ongoing communication to address any potential issues or questions that may arise during the procurement process. This proactive approach will help ensure a smooth transaction and foster a positive supplier relationship.

By following this checklist, you can streamline your sourcing process for metal spurs, ensuring that you select a supplier who meets your technical and operational needs while maintaining quality and reliability.

Comprehensive Cost and Pricing Analysis for metal spur Sourcing

What Are the Key Cost Components in Metal Spur Manufacturing?

Understanding the cost structure involved in sourcing metal spurs is crucial for B2B buyers aiming to optimize their procurement processes. The primary cost components include:

-

Materials: The choice of raw materials significantly affects pricing. Common materials for metal spurs include carbon steel, stainless steel, and specialty alloys. Each material has its own cost implications based on market fluctuations, availability, and performance characteristics.

-

Labor: Skilled labor is required for precision machining and assembly of metal spurs. Labor costs vary by region; thus, international buyers should consider the location of their suppliers. Countries with lower labor costs may offer competitive pricing but may also come with quality trade-offs.

-

Manufacturing Overhead: This includes utilities, rent, and equipment maintenance. High overhead costs can drive up the final price, making it essential for buyers to understand a supplier’s operational efficiency.

-

Tooling: Initial tooling costs for creating molds or specialized machinery can be significant, especially for custom designs. Buyers should account for these costs in their overall budget, particularly if they require unique specifications.

-

Quality Control (QC): Ensuring product quality can incur additional expenses. Rigorous QC processes may be necessary to meet industry standards, impacting the overall cost of the spurs.

-

Logistics: Shipping and handling costs can vary significantly based on the supplier’s location, chosen shipping methods, and delivery timelines. Import duties and taxes also need to be factored in for international shipments.

-

Margin: Suppliers will typically add a profit margin to their costs. Understanding the margin structure can help buyers negotiate better deals.

How Do Volume and Specifications Affect Metal Spur Pricing?

Pricing for metal spurs is influenced by several key factors:

-

Volume/MOQ: Minimum order quantities (MOQs) often dictate pricing tiers. Larger orders generally lead to lower per-unit costs due to economies of scale. Buyers should assess their consumption patterns to negotiate favorable terms.

-

Specifications and Customization: Custom designs will typically incur higher costs due to the need for specialized tooling and additional engineering time. Buyers should clearly communicate their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials or those that meet specific certifications (e.g., ISO standards) can lead to increased costs. Buyers should weigh the benefits of premium materials against their application needs.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities play a significant role in pricing. Conducting thorough supplier evaluations can help ensure that buyers are not only getting competitive prices but also quality products.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for international transactions. These terms define the responsibilities of buyers and sellers in shipping, which can significantly affect total costs.

What Strategies Can Buyers Use to Optimize Their Metal Spur Procurement?

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiation: Leverage volume commitments to negotiate better pricing or payment terms. Building long-term relationships with suppliers can also provide leverage for discounts.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price, but also the long-term costs associated with maintenance, failure rates, and logistics. A slightly higher upfront cost may be justified if it leads to lower TCO.

-

Pricing Nuances: Be aware of regional pricing differences and market conditions that can affect costs. Currency fluctuations can also impact the pricing landscape, so consider hedging strategies for larger orders.

-

Supplier Diversity: Engaging multiple suppliers can create competitive tension, potentially driving down prices and increasing service levels. However, ensure that quality remains consistent across different suppliers.

Conclusion

Sourcing metal spurs requires a nuanced understanding of the various cost components and pricing influencers. By strategically evaluating these factors and employing effective negotiation tactics, international B2B buyers can achieve significant cost savings while ensuring high-quality products that meet their operational needs. Always remember to request indicative prices as they can fluctuate based on market conditions and specific requirements.

Alternatives Analysis: Comparing metal spur With Other Solutions

Understanding Alternative Solutions to Metal Spur

In the realm of industrial applications, selecting the right gear mechanism is critical for optimal performance. While metal spur gears are widely recognized for their efficiency and reliability, exploring alternatives can provide B2B buyers with options that may better suit specific needs or budgets. This section compares metal spur gears to two viable alternatives: plastic spur gears and helical gears, highlighting their unique characteristics and applications.

Comparison of Metal Spur with Alternative Solutions

| Comparison Aspect | Metal Spur | Plastic Spur Gear | Helical Gear |

|---|---|---|---|

| Performance | High strength, low noise | Moderate strength, noisier | Smooth, quiet operation |

| Cost | Higher initial investment | Lower cost | Higher cost than spur gears |

| Ease of Implementation | Standardized, easy to install | Simple installation | More complex installation |

| Maintenance | Durable, low maintenance | Wear and tear over time | Requires precise alignment |

| Best Use Case | Heavy machinery, automotive | Lightweight applications | High-speed and heavy-load applications |

In-depth Analysis of Alternatives

What Are the Benefits and Drawbacks of Plastic Spur Gears?

Plastic spur gears are a lightweight alternative that can be beneficial for applications where weight is a concern. They typically come at a lower cost than metal spur gears, making them an attractive option for budget-sensitive projects. However, their moderate strength means they may not withstand heavy loads or high-stress environments as well as metal spurs. Additionally, plastic gears can be noisier during operation, which may not be suitable for applications requiring quiet operation.

How Do Helical Gears Compare to Metal Spur Gears?

Helical gears offer a unique advantage with their design, which allows for smoother and quieter operation compared to traditional spur gears. This makes them ideal for high-speed applications and scenarios where noise reduction is paramount. However, helix gears are more complex to manufacture and install, often resulting in a higher cost compared to metal spur gears. Furthermore, their precision alignment requirements can lead to increased maintenance needs, which may not be ideal for all users.

Choosing the Right Gear Solution for Your Needs

When deciding between metal spur gears and their alternatives, B2B buyers should consider the specific requirements of their application. Factors such as load capacity, noise tolerance, cost constraints, and installation complexity play significant roles in making the right choice. Metal spur gears excel in durability and performance for heavy machinery, while plastic spur gears can be more cost-effective for lighter applications. Helical gears, on the other hand, are ideal for high-speed environments where noise reduction is critical. Ultimately, a thorough evaluation of these aspects will guide buyers in selecting the most appropriate gear solution for their operational needs.

Essential Technical Properties and Trade Terminology for metal spur

What Are the Key Technical Properties of Metal Spurs?

When sourcing metal spurs for various industrial applications, understanding their technical properties is crucial. Here are several essential specifications that B2B buyers should consider:

-

Material Grade

Metal spurs are typically made from steel, aluminum, or specialized alloys. The material grade determines the spur’s strength, weight, corrosion resistance, and overall performance. For instance, hardened steel is preferred for its durability in high-torque applications, while aluminum may be chosen for lighter applications. Selecting the appropriate material grade ensures that the spur can withstand the operational demands of its intended use. -

Tooth Profile and Pitch

The tooth profile, often involute, and the pitch (distance between teeth) are critical for ensuring proper meshing with other gears. The tooth design affects how efficiently power is transmitted and how much noise is generated during operation. Precision in tooth profile and pitch is essential to minimize backlash and wear, which can lead to gear failure or performance issues. -

Tolerance

Tolerance indicates the allowable deviation from specified dimensions. Tight tolerances are essential for applications requiring high precision, such as in automotive or aerospace sectors. A higher tolerance level reduces the risk of misalignment and mechanical failure, ensuring smooth operation and longevity of the spur gear. -

Surface Treatment

Surface treatments, such as black oxide coating or nitriding, enhance the spur’s resistance to rust and wear. These treatments can also improve the aesthetic appeal of the gear. For B2B buyers, understanding the type of surface treatment applied can help in assessing the longevity and maintenance needs of the metal spur. -

Load Capacity

Load capacity refers to the maximum load that a spur gear can handle without failure. This property is vital for ensuring that the spur can operate effectively under expected loads. Buyers should match the load capacity to their application requirements to prevent premature gear failure.

What Are Common Terms Used in the Metal Spur Industry?

In the B2B landscape, familiarity with industry terminology can significantly enhance communication and procurement processes. Here are some common terms that are beneficial for decision-makers:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are used in the manufacturing of a final product. In the context of metal spurs, an OEM may supply custom spur gears for specific machinery. Knowing whether a supplier is an OEM can help buyers ensure that they are getting high-quality, compatible parts. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ helps buyers gauge the financial commitment needed for a purchase. For businesses looking to maintain lower inventory levels, negotiating MOQs can lead to more flexible purchasing options. -

RFQ (Request for Quotation)

An RFQ is a formal document used to solicit price quotes from suppliers. Including specific details about the required metal spur, such as dimensions and material specifications, can lead to more accurate quotes. This process helps buyers compare offers and select the best supplier based on price and quality. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) clarify who is responsible for shipping costs and risk during transit. Understanding Incoterms is essential for managing logistics and ensuring smooth international transactions. -

Backlash

Backlash refers to the play or clearance between mating gears. It is a crucial factor in gear design as it affects the precision of movement and the overall performance of the machinery. Managing backlash is vital to avoid noise and mechanical failure, making it an important consideration for buyers.

Understanding these properties and terms will equip B2B buyers with the knowledge needed to make informed purchasing decisions regarding metal spurs, leading to enhanced operational efficiency and reduced downtime.

Navigating Market Dynamics and Sourcing Trends in the metal spur Sector

What are the Current Market Dynamics and Key Trends for Metal Spur Sourcing?

The global market for metal spurs is driven by several key factors, including the rising demand for precision components in various industries such as automotive, aerospace, and industrial machinery. As manufacturers increasingly focus on efficiency and durability, the need for high-quality spur gears made from advanced materials has surged. Emerging technologies such as CNC machining and additive manufacturing are revolutionizing production methods, allowing for greater customization and rapid prototyping. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are keen on leveraging these advancements to enhance their product offerings.

Additionally, the shift towards automation and smart manufacturing is influencing sourcing trends. Companies are increasingly looking for suppliers that can provide integrated solutions, including gear design, testing, and after-sales support. This trend is particularly significant in markets like Nigeria and Saudi Arabia, where industrial growth is accelerating. As businesses seek to optimize their supply chains, strategic partnerships with reliable manufacturers that offer competitive pricing and quality assurance are becoming essential.

Moreover, the ongoing globalization of the metal spur industry means that buyers must navigate varying regulations and trade agreements, which can impact sourcing decisions. Understanding these dynamics is crucial for B2B buyers to remain competitive and responsive to market changes.

How is Sustainability and Ethical Sourcing Reshaping the Metal Spur Sector?

Sustainability is increasingly becoming a focal point in the procurement of metal spurs, with buyers prioritizing suppliers who adhere to ethical sourcing practices. The environmental impact of manufacturing processes, including carbon emissions and waste generation, is under scrutiny. As such, international buyers are encouraged to seek out suppliers who utilize eco-friendly materials and energy-efficient manufacturing techniques.

The importance of ethical supply chains cannot be overstated. Buyers are now more aware of the social implications of their sourcing decisions, including labor practices and community engagement. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming critical in supplier evaluations. These certifications not only assure compliance with international standards but also demonstrate a commitment to sustainability.

Furthermore, the use of ‘green’ materials, such as recycled metals and biodegradable lubricants, is gaining traction. Buyers in regions like Europe are particularly keen on sourcing products that contribute to their sustainability goals. By aligning their purchasing strategies with sustainability initiatives, B2B buyers can enhance their brand reputation and meet the growing consumer demand for responsible business practices.

What is the Historical Context of Metal Spurs in B2B Markets?

The history of metal spurs can be traced back to the early days of industrialization when the need for efficient mechanical motion transmission became paramount. Initially crafted from basic materials, spur gears evolved with advancements in metallurgy and manufacturing processes. The introduction of CNC machining in the late 20th century marked a significant turning point, allowing for precision engineering and higher production volumes.

As industries expanded globally, the demand for standardized components like metal spurs grew, leading to the establishment of international standards that govern gear manufacturing today. This evolution has made it easier for B2B buyers to source high-quality spur gears from diverse markets, ensuring compatibility and performance across various applications. Understanding this historical context can provide valuable insights for modern buyers seeking reliable suppliers in an increasingly competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of metal spur

-

How do I select the right metal spur for my application?

Choosing the right metal spur involves considering several factors, including the material, size, and gear type. For applications requiring high durability, opt for spur gears made from hardened steel or other robust materials. Assess the gear’s module, which indicates the size, and ensure compatibility with your existing machinery. Additionally, evaluate the tooth profile and pressure angle for efficiency. Engaging with suppliers who offer customization can also help tailor the spur to your specific needs. -

What is the best material for metal spur gears in high-stress environments?

In high-stress environments, hardened steel is often the best material for metal spur gears due to its superior strength and wear resistance. This material can withstand heavy loads and harsh conditions, making it ideal for industrial applications. Other options include stainless steel for corrosion resistance or alloy steel for improved toughness. Always consult with your supplier to determine the most suitable material based on your operational requirements and environmental conditions. -

What are the typical minimum order quantities (MOQs) for metal spur purchases?

Minimum order quantities for metal spur gears can vary significantly by supplier, typically ranging from 50 to 500 units. Factors influencing MOQs include manufacturing capabilities, material types, and customization options. If you’re a smaller buyer, some suppliers may offer flexibility, especially if you negotiate terms in advance. Always clarify MOQs with potential suppliers to ensure they align with your purchasing needs. -

How can I ensure the quality of metal spur gears from international suppliers?

To ensure quality when sourcing metal spur gears internationally, start by vetting suppliers thoroughly. Look for manufacturers with ISO certifications, as these indicate adherence to international quality standards. Request samples to evaluate the gear’s performance and durability before placing larger orders. Additionally, consider using third-party quality assurance services to inspect products before shipping, ensuring they meet your specifications. -

What payment terms should I expect when purchasing metal spur gears?

Payment terms can vary widely among suppliers, but common arrangements include a 30% deposit upon order confirmation and the balance upon shipment. Some suppliers may offer net 30 or net 60 terms for established relationships. It’s essential to clarify payment terms before finalizing contracts, especially when dealing with international transactions, to avoid any misunderstandings. -

What shipping options are available for importing metal spur gears?

Shipping options for importing metal spur gears typically include air freight for faster delivery and sea freight for cost-effectiveness. The choice depends on your urgency and budget. Ensure to discuss logistics with your supplier, including packaging standards to prevent damage during transit. Additionally, consider customs regulations and duties in your country to avoid unexpected costs. -

How can I customize metal spur gears for my specific needs?

Most manufacturers offer customization options for metal spur gears, including size, tooth design, and material type. To initiate customization, provide detailed specifications regarding your application’s requirements. Engaging in open communication with the supplier about your needs can lead to tailored solutions that enhance performance. Always request prototypes or samples to validate the customizations before placing larger orders. -

What are the common applications of metal spur gears in various industries?

Metal spur gears are widely used across various industries, including automotive, aerospace, manufacturing, and robotics. They play a crucial role in transmitting motion and power between parallel shafts in machinery. Specific applications include conveyor systems, gearboxes, and industrial equipment. Understanding the specific requirements of your industry will help in selecting the appropriate gear type and configuration for optimal performance.

Top 3 Metal Spur Manufacturers & Suppliers List

1. PS Kaufman – Metal Spur

Domain: pskaufman.com

Registered: 2010 (15 years)

Introduction: Product Name: Metal Spur

Price: $42.00

Type: Accessories

Size: Adjustable

Availability: Notify when available option

Additional Information: Contact for fit inquiries regarding specific shoes.

2. Proline Racing – Steel Spur Gear Upgrade for PRO-MT 4×4

Domain: prolineracing.com

Registered: 2000 (25 years)

Introduction: {“name”: “Steel Spur Gear Upgrade: PRO-MT 4×4”, “item_no”: “PRO631802”, “price”: “$32.99”, “availability”: “In Stock”, “key_features”: [“Adds Strength and Durability to Your PRO-MT’s Drive Train”, “CNC Machined from Hardened Steel”, “Black Oxide Coated to Avoid Rust”, “Narrow and Lightweight for Smooth Performance”, “A Must Have Upgrade for Insane Power Lovers”], “in_the_box”: “Steel Spur Gear Upg…

3. KHK Gears – Spur Gears

Domain: khkgears.net

Registered: 2015 (10 years)

Introduction: Spur Gears are cylindrical gears that transmit motion between two parallel shafts without generating thrust force in the axial direction. They are produced with high precision and have an involute tooth shape, which is the most common due to its ability to absorb small center distance errors and simplify manufacturing. Key specifications include:

– Module: Commonly specified by ISO, typically set…

Strategic Sourcing Conclusion and Outlook for metal spur

In conclusion, strategic sourcing of metal spurs represents a critical opportunity for international B2B buyers aiming to enhance their supply chain efficiency and product quality. By prioritizing suppliers who offer durable, high-performance spurs—such as those made from CNC machined hardened steel—businesses can ensure reliability and longevity in their applications. Additionally, understanding the specifications and performance characteristics of different spur gears enables buyers to make informed decisions that align with their operational needs.

The growing demand for metal spurs across diverse industries, especially in emerging markets in Africa, South America, the Middle East, and Europe, underscores the importance of forging strong partnerships with suppliers. By leveraging local insights and global best practices, buyers can optimize their sourcing strategies, reduce lead times, and improve overall product performance.

Looking ahead, businesses are encouraged to explore innovative sourcing solutions and invest in relationships that foster collaboration and mutual growth. This proactive approach will not only enhance competitiveness but also pave the way for sustainable success in the dynamic global marketplace. Engage with reliable suppliers today to secure your competitive edge in the evolving landscape of metal spur applications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.