Everything You Need to Know About Metal Shims Sourcing in 2025

Introduction: Navigating the Global Market for metal shims

In an increasingly competitive global marketplace, sourcing metal shims can pose significant challenges for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe, including key markets like Germany and Saudi Arabia. The right metal shim not only ensures precision in applications ranging from construction to machinery but also plays a critical role in enhancing overall operational efficiency. This guide serves as a comprehensive resource, addressing the complexities of selecting the appropriate types of metal shims, understanding their varied applications, and navigating the intricacies of supplier vetting.

Throughout this guide, we delve into essential topics such as material specifications, cost considerations, and quality assurance measures that are crucial for making informed purchasing decisions. With a focus on the unique requirements of international buyers, we provide actionable insights into evaluating suppliers and negotiating favorable terms. Our goal is to equip you with the knowledge necessary to streamline your sourcing process, mitigate risks, and ultimately enhance the performance of your operations. By leveraging the information presented here, you can confidently navigate the global market for metal shims, ensuring that your business remains competitive and responsive to evolving demands.

Understanding metal shims Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stainless Steel | Corrosion-resistant, durable, available in various thicknesses | Aerospace, automotive, machinery assembly | Pros: High durability, excellent corrosion resistance; Cons: Higher cost compared to carbon steel. |

| Carbon Steel | Strong and cost-effective, available in various grades | Construction, heavy machinery, industrial equipment | Pros: Cost-effective, readily available; Cons: Prone to rust, requires protective coatings. |

| Plastic | Lightweight, non-corrosive, available in various colors and sizes | Electrical applications, plumbing, HVAC systems | Pros: Non-conductive, resistant to chemicals; Cons: Limited load-bearing capacity, not suitable for high-temperature environments. |

| Brass | Good corrosion resistance, aesthetic appeal, malleable | Decorative applications, plumbing fittings | Pros: Attractive finish, good machinability; Cons: More expensive, softer than steel, can deform under heavy loads. |

| Composite | Lightweight, combines strength and flexibility | Aerospace, automotive, and marine applications | Pros: High strength-to-weight ratio, resistant to corrosion; Cons: Can be more expensive, requires specialized handling. |

What Are the Characteristics and Suitability of Stainless Steel Shims?

Stainless steel shims are known for their exceptional corrosion resistance and durability, making them ideal for demanding environments such as aerospace, automotive, and machinery assembly. They come in various thicknesses, allowing for precise adjustments in applications where precision is critical. B2B buyers should consider the initial cost versus long-term benefits, as these shims can significantly enhance the lifespan of equipment and components.

How Do Carbon Steel Shims Compare for Industrial Use?

Carbon steel shims are a popular choice for many industries due to their strength and cost-effectiveness. Commonly used in construction and heavy machinery, they are readily available in various grades, allowing buyers to select the appropriate type for their specific application. However, potential buyers should be aware of their susceptibility to rust and the need for protective coatings, especially in humid or corrosive environments.

When to Choose Plastic Shims for Electrical Applications?

Plastic shims are lightweight and non-corrosive, making them suitable for electrical applications, plumbing, and HVAC systems. They are available in various colors and sizes, providing flexibility in use. However, B2B buyers should note that while they are resistant to chemicals and non-conductive, their limited load-bearing capacity may restrict their use in heavy-duty applications.

What Advantages Do Brass Shims Offer in Decorative Applications?

Brass shims are valued for their aesthetic appeal and good corrosion resistance, making them ideal for decorative applications and plumbing fittings. Their malleability allows for easy machining, providing versatility in design. However, buyers should consider the higher cost and the fact that brass is softer than steel, which may limit its effectiveness in heavy-load scenarios.

Why Consider Composite Shims for Aerospace and Automotive?

Composite shims are gaining traction in aerospace and automotive applications due to their lightweight nature and high strength-to-weight ratio. They offer excellent resistance to corrosion and can withstand harsh environmental conditions. However, B2B buyers should be mindful of their potentially higher costs and the need for specialized handling during installation and maintenance.

Key Industrial Applications of metal shims

| Industry/Sector | Specific Application of metal shims | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Engine alignment and vibration control | Enhances operational efficiency and safety in flight operations | Material certification, precision manufacturing, and compliance with aviation standards |

| Construction | Leveling and supporting structures | Ensures structural integrity and safety in buildings | Load capacity, corrosion resistance, and availability in bulk |

| Automotive | Component spacing and alignment | Improves performance and longevity of vehicles | Compatibility with specific vehicle models and dimensions |

| Machinery Manufacturing | Precision alignment of machinery components | Minimizes wear and tear, enhancing productivity | Custom thickness options and rapid delivery capabilities |

| Oil & Gas | Equipment stabilization in harsh environments | Increases reliability and reduces maintenance costs | Resistance to extreme temperatures and chemical exposure |

How Are Metal Shims Used in Aerospace Applications?

In the aerospace industry, metal shims are critical for engine alignment and vibration control. They help ensure that engines are correctly positioned, which is essential for optimal performance and safety. Given the stringent regulations in this sector, buyers must prioritize sourcing shims that meet specific material certifications and precision manufacturing standards. Additionally, shims must be capable of withstanding high temperatures and pressures, making material selection and quality assurance vital for international buyers.

What Role Do Metal Shims Play in Construction?

In construction, metal shims are widely used for leveling and supporting structures, such as beams and columns. They provide the necessary adjustments to maintain structural integrity, ensuring that buildings are safe and durable. For buyers in Africa, South America, and the Middle East, sourcing shims that meet load capacity requirements and corrosion resistance is essential, especially in regions with varying climate conditions. Bulk availability can also be a key factor for large-scale projects.

How Are Metal Shims Essential in Automotive Manufacturing?

Metal shims are employed in the automotive industry primarily for component spacing and alignment. They play a crucial role in enhancing the performance and longevity of vehicles by ensuring that all parts fit together correctly. International buyers need to focus on compatibility with specific vehicle models and precise dimensions when sourcing these shims. Additionally, understanding the application environment—whether it be standard or extreme conditions—can influence the choice of materials used.

Why Are Metal Shims Important in Machinery Manufacturing?

In machinery manufacturing, metal shims are used for the precise alignment of components, which is essential for minimizing wear and tear. This application directly contributes to increased productivity and reduced downtime due to equipment failure. Buyers should consider custom thickness options to meet specific machinery requirements, along with rapid delivery capabilities to avoid project delays. The ability to source shims that meet industry standards for precision can significantly impact operational efficiency.

How Do Metal Shims Benefit the Oil & Gas Industry?

In the oil and gas sector, metal shims are vital for stabilizing equipment in harsh environments. They help maintain operational reliability and reduce maintenance costs, which is crucial for companies operating in remote locations. Buyers in this industry must ensure that the shims sourced are resistant to extreme temperatures and chemical exposure. Additionally, understanding the specific application requirements—such as size and thickness—can help in selecting the right product for their operational needs.

3 Common User Pain Points for ‘metal shims’ & Their Solutions

Scenario 1: Sourcing the Right Type of Metal Shim for Precision Applications

The Problem: Many B2B buyers encounter difficulties in sourcing the appropriate metal shim for specific applications. Whether it’s for machinery alignment, leveling equipment, or structural support, the variations in material, thickness, and size can be overwhelming. Additionally, the risk of using the wrong shim can lead to operational inefficiencies, costly downtimes, or even safety hazards. Buyers often find themselves uncertain about the specifications needed for their projects, leading to frustration and delays.

The Solution: To effectively source the right type of metal shim, buyers should start by clearly defining their application requirements. Understanding the load-bearing capacity, environmental conditions, and tolerances necessary for the application will guide the selection process. For example, stainless steel shims are ideal for corrosion-prone environments, while carbon steel may suffice for less demanding settings. Once specifications are established, utilize reputable suppliers that provide detailed product descriptions, including material properties and dimensional tolerances. It’s also beneficial to request samples or consult with suppliers’ technical support to ensure the chosen shims meet your precise needs before placing a bulk order.

Illustrative image related to metal shims

Scenario 2: Managing Inventory and Avoiding Stockouts

The Problem: B2B buyers often struggle with inventory management, particularly when it comes to metal shims. Fluctuating demand and unexpected project requirements can lead to stockouts, resulting in halted operations and delayed project timelines. Conversely, overstocking can tie up capital and lead to unnecessary storage costs. This balancing act can be particularly challenging for businesses operating in multiple regions with varying demand levels.

The Solution: Implementing a just-in-time (JIT) inventory management system can significantly alleviate these issues. This approach allows companies to order metal shims based on actual consumption patterns rather than forecasts. Collaborating with suppliers who offer flexible ordering options, such as bulk purchasing or consignment inventory, can help ensure that shims are available when needed without overcommitting resources. Additionally, utilizing inventory management software can provide real-time data on stock levels, helping buyers anticipate needs and reorder in a timely manner. Establishing strong communication channels with suppliers to adjust orders based on real-time project demands can further enhance efficiency.

Scenario 3: Ensuring Compliance with Industry Standards

The Problem: Compliance with industry standards and regulations is a significant concern for many B2B buyers of metal shims. Different sectors, such as aerospace, automotive, and construction, have specific requirements regarding material quality, safety, and performance. Failing to adhere to these standards can result in costly penalties, project delays, and damage to reputation. Buyers often find themselves navigating a complex web of certifications and regulations, leading to confusion and potential missteps.

The Solution: To ensure compliance, buyers should first familiarize themselves with the relevant industry standards applicable to their specific sector, such as ISO, ASTM, or SAE standards for metal shims. Engaging with suppliers who can provide certifications and documentation for their products is essential. This not only confirms the quality of the shims but also ensures they meet the necessary regulatory requirements. Additionally, conducting regular audits of suppliers and their materials can help maintain compliance. Joining industry associations or forums can also provide valuable insights and updates regarding changes in regulations, helping buyers stay informed and proactive in their sourcing strategies.

Strategic Material Selection Guide for metal shims

What Are the Key Properties of Different Materials Used for Metal Shims?

Metal shims are essential components in various industrial applications, providing precise spacing and alignment. The choice of material significantly affects their performance, durability, and suitability for specific applications. Here, we analyze four common materials used for metal shims: stainless steel, carbon steel, brass, and aluminum.

How Does Stainless Steel Perform in Metal Shim Applications?

Stainless steel, particularly grades like 304 and 316, is renowned for its excellent corrosion resistance and high-temperature stability. This makes it suitable for applications in harsh environments, such as chemical processing and marine settings. Stainless steel shims can withstand temperatures up to 870°C (1600°F) and are often used in applications requiring stringent hygiene standards, such as food and pharmaceutical industries.

Pros: High durability, excellent corrosion resistance, and good mechanical properties make stainless steel a preferred choice for many applications.

Cons: The primary drawback is its higher cost compared to other materials. Additionally, manufacturing complexity can increase due to the need for specialized tools and processes.

Impact on Application: Stainless steel shims are compatible with various media, including water, oils, and chemicals, making them versatile for different industrial sectors.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM A240 for stainless steel and consider local regulations regarding material sourcing and environmental impact.

What Are the Advantages of Using Carbon Steel for Metal Shims?

Carbon steel is a cost-effective option for metal shims, offering good strength and durability. It is suitable for applications where corrosion resistance is not a primary concern. Carbon steel shims can handle moderate temperatures and pressures, making them ideal for general-purpose applications in construction and machinery.

Pros: Low cost and good mechanical strength are significant advantages, making carbon steel a popular choice for budget-sensitive projects.

Cons: The major limitation is its susceptibility to rust and corrosion, which can lead to failure in adverse environments. Protective coatings can mitigate this but may add to the overall cost.

Impact on Application: Carbon steel shims are best suited for applications involving dry environments or where exposure to moisture is limited.

Considerations for International Buyers: Buyers should be aware of standards such as ASTM A36 for structural steel and ensure that the material meets local quality requirements.

How Does Brass Compare for Metal Shim Use?

Brass, an alloy of copper and zinc, is often used for metal shims in applications requiring good electrical conductivity and resistance to corrosion. It is particularly valuable in electrical and plumbing applications due to its non-sparking properties.

Pros: Brass shims offer excellent corrosion resistance and are easy to machine, making them suitable for precision applications.

Cons: The main disadvantage is its higher cost compared to carbon steel and its lower strength, which limits its use in high-load applications.

Impact on Application: Brass shims are ideal for use in electrical components and plumbing systems where conductivity and corrosion resistance are critical.

Illustrative image related to metal shims

Considerations for International Buyers: Compliance with standards like ASTM B36 for brass is essential, and buyers should consider the availability of brass alloys in their region.

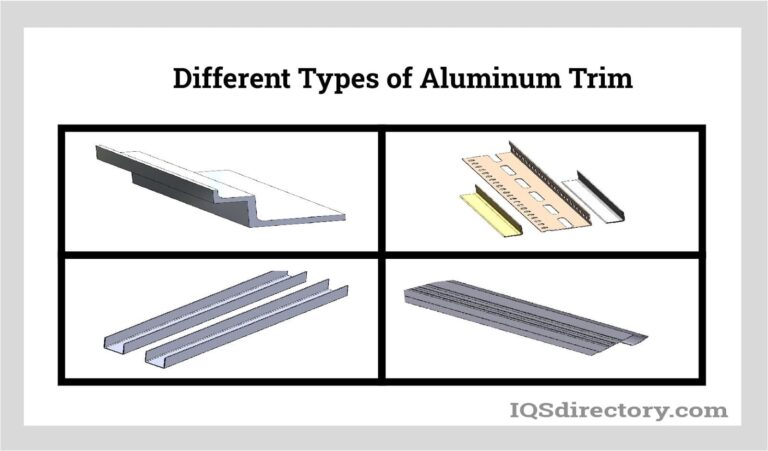

What Benefits Does Aluminum Offer for Metal Shims?

Aluminum is lightweight and corrosion-resistant, making it an excellent choice for applications where weight is a critical factor, such as in aerospace and automotive industries. Aluminum shims can handle moderate temperatures and pressures, making them versatile for various applications.

Pros: The lightweight nature of aluminum helps reduce overall system weight, and its corrosion resistance extends the lifespan of components.

Cons: However, aluminum shims may not be suitable for high-stress applications due to lower strength compared to steel options.

Impact on Application: Aluminum shims are particularly effective in environments where weight savings are prioritized, such as in transportation and aerospace applications.

Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM B221 for aluminum and consider local sourcing options to minimize costs.

Summary Table of Material Selection for Metal Shims

| Material | Typical Use Case for Metal Shims | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Chemical processing, food industry | Excellent corrosion resistance | Higher cost, manufacturing complexity | High |

| Carbon Steel | General construction, machinery | Low cost, good mechanical strength | Susceptible to rust and corrosion | Low |

| Brass | Electrical components, plumbing | Good conductivity, corrosion resistant | Higher cost, lower strength | Med |

| Aluminum | Aerospace, automotive applications | Lightweight, corrosion resistant | Lower strength for high-stress use | Med |

This comprehensive analysis provides B2B buyers with actionable insights into the material selection process for metal shims, helping them make informed decisions based on their specific application needs and regional considerations.

Illustrative image related to metal shims

In-depth Look: Manufacturing Processes and Quality Assurance for metal shims

What Are the Main Stages in the Manufacturing Process of Metal Shims?

The manufacturing process of metal shims involves several critical stages designed to ensure precision and quality. These stages typically include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Metal Shim Manufacturing?

Material preparation is the first step in the manufacturing process. High-quality raw materials, often stainless steel or carbon steel, are sourced from reputable suppliers. These materials are then subjected to rigorous inspections to ensure they meet specified chemical and physical properties. The materials are cut into manageable sizes using techniques such as shearing or laser cutting, which allows for precise dimensions essential for the final product.

What Forming Techniques Are Commonly Used in Metal Shim Production?

The forming stage involves shaping the prepared materials into shim forms. This can be achieved through several methods, including stamping, die-cutting, and waterjet cutting. Stamping is often favored for its efficiency and ability to produce large quantities with consistent quality. For specialized applications requiring intricate designs or specific thicknesses, waterjet cutting is employed due to its precision and ability to cut through various thicknesses without compromising the material’s integrity.

How Is Assembly Conducted for Metal Shims?

In the assembly phase, shims may be combined or layered depending on their intended use. For instance, in applications where varying thicknesses are needed, multiple shims may be stacked together. This process requires careful alignment and, in some cases, welding or fastening to ensure stability and performance under load. Ensuring that the assembly meets the required specifications is crucial for ensuring the shims perform effectively in their applications.

Illustrative image related to metal shims

What Finishing Processes Are Applied to Metal Shims?

Finishing processes enhance the durability and aesthetic of metal shims. Common techniques include polishing, coating, or anodizing, which not only improve the surface finish but also protect against corrosion. For stainless steel shims, a passivation process may be applied to enhance corrosion resistance. Quality control during this stage is essential, as any imperfections can significantly affect the shim’s performance.

How Is Quality Assurance Implemented in Metal Shim Manufacturing?

Quality assurance (QA) is a fundamental aspect of metal shim manufacturing, ensuring that the products meet international standards and customer expectations.

What International Standards Govern Quality Assurance in Metal Shim Production?

International standards such as ISO 9001 provide a framework for quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements. In addition, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) are essential for shims used in specific applications, particularly in the construction and oil and gas sectors.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are crucial throughout the manufacturing process. Incoming Quality Control (IQC) checks the raw materials upon arrival, ensuring they meet the specified standards. In-Process Quality Control (IPQC) monitors the production stages to identify and rectify issues early. Finally, Final Quality Control (FQC) involves comprehensive testing of the finished products, verifying dimensions, and ensuring performance under load.

What Testing Methods Are Commonly Used for Metal Shims?

Common testing methods for metal shims include dimensional inspections, tensile strength tests, and corrosion resistance tests. Dimensional inspections ensure that the shims meet the specified thickness and size requirements, while tensile strength tests evaluate the material’s performance under stress. Corrosion resistance tests help determine the longevity of the shims in various environments, which is particularly important for international buyers operating in diverse climates.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should take proactive steps to verify the quality control processes of their suppliers. Conducting audits is one effective approach; these can be either announced or unannounced and should focus on the supplier’s adherence to quality standards. Reviewing quality control reports and certifications can also provide insight into a supplier’s commitment to maintaining high-quality products.

What Role Do Third-Party Inspections Play in Quality Assurance?

Third-party inspections serve as an additional layer of quality assurance. Engaging independent inspection agencies can provide unbiased evaluations of the manufacturing processes and final products. This is particularly valuable for international buyers who may not have the capacity to perform onsite inspections themselves.

What Are the Unique Quality Control Considerations for International Buyers?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, face unique challenges in quality control. Different countries may have varying regulatory requirements, which necessitates a thorough understanding of both local and international standards. Buyers should ensure that their suppliers are compliant with these regulations and possess the necessary certifications.

In summary, the manufacturing processes and quality assurance for metal shims involve meticulous planning and execution. By understanding these processes, B2B buyers can make informed decisions, ensuring that they source high-quality products that meet their specific needs. Engaging with reputable suppliers who adhere to stringent quality standards is crucial for maintaining operational efficiency and reliability in their applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metal shims’

Introduction

Sourcing metal shims can be a complex process, especially for international B2B buyers. This guide aims to provide a clear, actionable checklist to streamline your procurement process, ensuring that you select the right products and suppliers to meet your specific needs.

Step 1: Define Your Technical Specifications

Before initiating your search, it’s essential to clearly outline your technical requirements for the shims. Consider factors such as material type (e.g., stainless steel, carbon steel), thickness, dimensions, and any specific tolerances that must be met. This step is crucial as it helps you communicate effectively with suppliers and ensures that the shims will fit your application needs.

Step 2: Research Supplier Credentials

Conduct thorough research to identify potential suppliers. Look for established companies with a strong reputation in the industry, particularly those with experience in your geographic region. Check for certifications like ISO 9001, which indicate adherence to quality management standards, and ensure they have a history of reliability and customer satisfaction.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Investigate their production capabilities and lead times to ensure they can meet your order requirements. This diligence will help you avoid disruptions in your supply chain.

Step 4: Request Samples

Always request samples of the metal shims before placing a bulk order. This allows you to evaluate the quality, dimensions, and material properties firsthand. Inspect the samples for defects and verify that they meet your technical specifications. This proactive step minimizes the risk of receiving subpar products.

Step 5: Compare Pricing and Payment Terms

Once you have a shortlist of suppliers, compare their pricing structures and payment terms. Look beyond just the unit cost; consider shipping fees, bulk discounts, and payment options. Some suppliers may offer favorable terms for larger orders or longer payment periods, which can significantly impact your cash flow.

Step 6: Assess Delivery Options and Lead Times

Understanding the logistics involved in your order is vital. Discuss delivery options with suppliers to find the most efficient and cost-effective methods. Be sure to clarify lead times, especially if you have tight deadlines. This transparency ensures that you can plan your operations without delays.

Step 7: Verify After-Sales Support and Warranty Policies

Before finalizing your order, inquire about after-sales support and warranty policies. Reliable suppliers should offer assistance in case of defects or issues with the shims. A solid warranty policy can protect your investment and provide peace of mind, ensuring that you can resolve any problems that may arise post-purchase.

Illustrative image related to metal shims

By following this step-by-step checklist, B2B buyers can enhance their sourcing process for metal shims, ensuring they make informed decisions that align with their operational needs and standards.

Comprehensive Cost and Pricing Analysis for metal shims Sourcing

What Are the Key Cost Components in Metal Shims Manufacturing?

When sourcing metal shims, understanding the cost structure is essential for B2B buyers to make informed decisions. The primary cost components include:

-

Materials: The choice of material significantly affects the price. Common materials for shims include stainless steel, carbon steel, brass, and plastic. For instance, 304 stainless steel is often favored for its corrosion resistance, but it comes at a higher cost compared to carbon steel. The fluctuating prices of raw materials can impact overall costs.

-

Labor: Labor costs vary by region and can significantly influence the final price. In regions with higher labor costs, such as parts of Europe, the cost of manufacturing shims will be higher compared to countries with lower labor costs.

-

Manufacturing Overhead: This encompasses costs related to facilities, utilities, and administrative expenses. Efficient manufacturing processes can help reduce these overheads, impacting pricing positively.

-

Tooling: The initial investment in tools and dies for producing shims is crucial. Custom tooling for specific shim designs can lead to higher upfront costs but may yield savings in mass production.

-

Quality Control (QC): Ensuring that shims meet specific standards requires investment in quality control processes. Certifications such as ISO can enhance credibility but may add to the cost.

-

Logistics: Transportation and shipping costs vary by region, impacting the final price. Import tariffs and local regulations can also add to logistics costs, particularly for international buyers.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. This margin can vary based on market demand and supplier competition.

How Do Price Influencers Affect Metal Shim Costs?

Several factors influence the pricing of metal shims beyond the basic cost components:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit prices. Suppliers are generally more willing to negotiate on price for bulk purchases, making it advantageous for buyers to consolidate orders.

-

Specifications and Customization: Custom shims with specific dimensions or tolerances may incur additional costs. Standard sizes typically have lower prices due to economies of scale.

-

Quality and Certifications: Higher quality materials and certifications can increase costs. Buyers should assess whether the additional investment aligns with their application needs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their products due to perceived quality and service reliability.

-

Incoterms: The agreed terms of delivery (e.g., FOB, CIF) can significantly impact the total cost. Buyers must understand these terms to evaluate shipping costs accurately.

What Are Effective Buyer Tips for Cost-Efficiency in Sourcing Metal Shims?

Navigating the complexities of metal shim sourcing requires strategic approaches to maximize cost-efficiency:

-

Negotiation: Engage in discussions with suppliers to explore price breaks for larger orders or long-term contracts. Building relationships can lead to favorable terms.

-

Total Cost of Ownership (TCO): Evaluate the TCO, which includes purchase price, shipping, and long-term usage costs. A lower initial price may not always result in overall savings if quality issues arise.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe must be aware of local market conditions, currency fluctuations, and import tariffs that can affect pricing. Understanding these factors can aid in better budget planning.

-

Supplier Comparison: Solicit quotes from multiple suppliers, considering not just price but also delivery times, quality assurances, and customer service. A comprehensive comparison can lead to better sourcing decisions.

-

Stay Informed on Market Trends: Monitor material prices and industry trends. Being aware of market fluctuations can help in timing purchases to achieve better pricing.

Disclaimer on Indicative Prices

Prices for metal shims can vary widely based on the aforementioned factors. The values mentioned in this analysis are indicative and may not reflect current market conditions. Always consult with suppliers for the most accurate and up-to-date pricing information tailored to specific requirements.

Alternatives Analysis: Comparing metal shims With Other Solutions

Introduction: Understanding Alternatives to Metal Shims

In the world of precision engineering and manufacturing, achieving the right alignment and spacing is crucial. Metal shims have long been a go-to solution for these needs, but they are not the only option available. As businesses look to optimize performance, cost, and efficiency, it’s essential to evaluate alternative solutions that can fulfill similar functions. This analysis will compare metal shims with two viable alternatives: composite shims and adjustable spacers, providing insights for B2B buyers.

Comparison Table

| Comparison Aspect | Metal Shims | Composite Shims | Adjustable Spacers |

|---|---|---|---|

| Performance | High strength and durability, excellent for heavy loads | Moderate strength, suitable for lighter applications | Versatile, allows for dynamic adjustments |

| Cost | Generally higher initial cost | Lower cost, budget-friendly | Variable cost, depending on complexity |

| Ease of Implementation | Requires precise placement and handling | Easy to install, often lightweight | User-friendly, can be adjusted on-site |

| Maintenance | Low maintenance, long-lasting | Moderate maintenance, susceptible to wear | Low maintenance, but may require recalibration |

| Best Use Case | Heavy machinery, structural applications | HVAC, electrical installations | Automotive, machinery requiring frequent adjustments |

Detailed Breakdown of Alternatives

Composite Shims: Are They a Cost-Effective Solution?

Composite shims are made from a variety of materials, including plastics and rubber, which makes them lighter and more affordable than metal shims. Their moderate strength makes them suitable for applications where heavy loads are not a concern, such as HVAC systems and electrical installations. The installation process is straightforward, often requiring minimal tools. However, composite materials may wear out faster under high stress and extreme conditions, leading to potential performance issues over time. Buyers should consider the trade-off between initial cost savings and long-term durability when evaluating composite shims.

Adjustable Spacers: Flexibility in Alignment

Adjustable spacers provide a unique advantage in environments where precise alignment is essential but may change over time. These devices allow for on-the-fly adjustments, making them ideal for applications in automotive and machinery settings where components may need frequent realignment. The ease of use is a significant benefit, as workers can quickly adjust the spacer without needing to remove and replace shims. However, adjustable spacers can be more complex and may involve a variable cost structure depending on the design and materials used. This complexity may not be suitable for all applications, particularly in environments where static alignment is preferred.

Conclusion: Choosing the Right Solution for Your Needs

When selecting between metal shims and their alternatives, B2B buyers must consider several factors, including the specific application requirements, budget constraints, and long-term performance expectations. Metal shims excel in high-load environments and provide durability, while composite shims and adjustable spacers offer flexibility and cost-effectiveness for lighter applications. Ultimately, the right choice will depend on the unique needs of the project, making it essential for buyers to thoroughly assess their options before making a decision.

Illustrative image related to metal shims

Essential Technical Properties and Trade Terminology for metal shims

What Are the Essential Technical Properties of Metal Shims?

Understanding the critical technical properties of metal shims is crucial for international B2B buyers. These properties not only affect the performance of the shims but also influence procurement decisions. Here are some key specifications to consider:

1. Material Grade

Metal shims are typically made from various materials, including stainless steel, carbon steel, and brass. The material grade, such as 304 or 316 stainless steel, impacts corrosion resistance, strength, and durability. For industries operating in harsh environments, selecting the appropriate material can prevent premature failure and reduce maintenance costs.

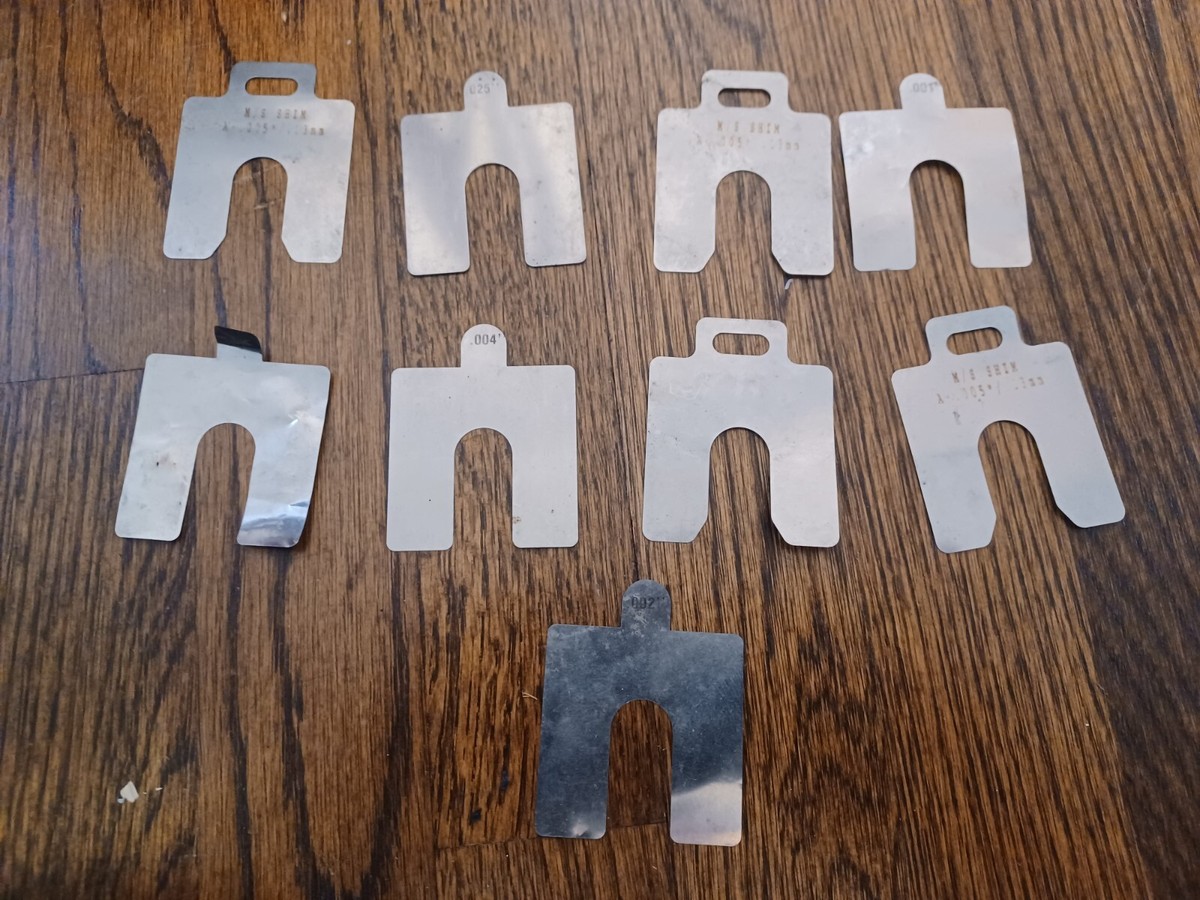

2. Thickness and Tolerance

Thickness is a vital specification for shims, often ranging from a few thousandths of an inch to several millimeters. Tolerance indicates how much variation is acceptable in the thickness. For precision applications, tight tolerances (e.g., ±0.001 inches) are essential to ensure proper fit and function. This is particularly important in sectors like aerospace and automotive, where even minor discrepancies can lead to significant operational issues.

3. Dimensions and Customization Options

Standard dimensions for metal shims typically include sizes like 6″ x 6″ or 12″ x 12″. However, customization is often required to meet specific application needs. Custom shims can be cut to precise dimensions, which is advantageous for businesses that require unique solutions. Understanding available sizes and customization options can streamline your procurement process.

4. Load-Bearing Capacity

The load-bearing capacity of a shim determines how much weight it can support without deforming. This property is critical in applications where shims are used to level machinery or support structural components. Buyers should assess the load requirements of their applications to choose shims that can safely handle expected loads.

5. Surface Finish

The surface finish of metal shims can affect their performance, especially in applications involving friction or contact with other components. Common finishes include polished, brushed, or anodized. A smooth surface finish can enhance wear resistance and reduce friction, which is vital in high-speed machinery.

What Are Common Trade Terms Related to Metal Shims?

Familiarizing yourself with industry jargon is essential for effective communication and negotiation in the B2B space. Here are several key terms relevant to metal shims:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of metal shims, OEMs often require specific shim types to fit their machinery, making it essential for suppliers to understand the OEM specifications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For metal shims, understanding the MOQ is crucial for budgeting and inventory management. Buyers should assess their needs to avoid excess inventory while ensuring they meet the supplier’s requirements.

3. RFQ (Request for Quotation)

An RFQ is a formal document issued by a buyer to solicit price quotes from suppliers. This process helps companies compare pricing and terms. When requesting quotes for metal shims, including detailed specifications can lead to more accurate and competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. They clarify who is responsible for shipping, insurance, and tariffs. Understanding these terms is essential for international buyers, especially when sourcing metal shims from different regions, to avoid unexpected costs and delays.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For metal shims, lead times can vary based on material availability and production schedules. Knowing the lead time helps businesses plan their projects and avoid delays in operations.

In summary, understanding the essential properties and trade terminology related to metal shims equips B2B buyers with the knowledge needed to make informed purchasing decisions. This insight not only facilitates smoother transactions but also contributes to operational efficiency across various industries.

Illustrative image related to metal shims

Navigating Market Dynamics and Sourcing Trends in the metal shims Sector

What Are the Key Drivers and Trends in the Global Metal Shims Market?

The global metal shims market is experiencing robust growth driven by several factors, including the rising demand for precision engineering across various industries such as automotive, aerospace, and construction. With a surge in infrastructure development, particularly in emerging markets in Africa and South America, the need for high-quality shimming solutions is escalating. Furthermore, advancements in manufacturing technologies, such as CNC machining and 3D printing, are enabling companies to produce customized shims that meet specific dimensional requirements, thereby enhancing efficiency and reducing waste.

International B2B buyers are increasingly focusing on sourcing strategies that emphasize both quality and cost-effectiveness. The trend towards online procurement platforms is gaining momentum, providing buyers from regions like Europe and the Middle East with easier access to a wider range of suppliers. This shift is complemented by the rise of data analytics tools that allow buyers to make informed decisions based on market trends and supplier performance. Additionally, the integration of IoT in manufacturing processes is facilitating real-time monitoring and quality control, ensuring that the products meet stringent industry standards.

How Can B2B Buyers Embrace Sustainability and Ethical Sourcing in the Metal Shims Sector?

Sustainability is becoming a pivotal consideration in the procurement of metal shims, with businesses increasingly recognizing the environmental impact of their supply chains. The production of metal shims often involves energy-intensive processes and the use of non-renewable resources, prompting buyers to seek suppliers that prioritize sustainable practices. This includes sourcing materials that are recycled or derived from sustainable sources, as well as implementing energy-efficient manufacturing processes.

Ethical sourcing is equally important, with buyers looking for suppliers that adhere to fair labor practices and promote transparency in their operations. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming critical benchmarks for evaluating suppliers. By partnering with certified manufacturers, buyers can enhance their brand reputation and appeal to environmentally-conscious consumers. Moreover, utilizing ‘green’ materials, such as stainless steel with low carbon footprints, can further align procurement strategies with sustainability goals.

How Has the Metal Shims Industry Evolved Over Time?

The evolution of the metal shims industry can be traced back to the industrial revolution, where the need for precision in machinery led to the development of shimming solutions. Initially made from wood or basic metals, shims have transformed into highly engineered products made from advanced materials like stainless steel and composite alloys. This shift has been driven by the demand for higher precision and durability in applications ranging from automotive manufacturing to aerospace engineering.

Over the decades, the introduction of computer-aided design (CAD) and automated manufacturing processes has revolutionized how metal shims are produced. Today, manufacturers can create highly specialized shims tailored to specific applications, enhancing performance and reliability. As industries continue to evolve and demand greater precision and sustainability, the metal shims market is poised for further innovation, catering to the complex needs of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of metal shims

-

How do I solve the issue of misalignment in machinery?

Misalignment in machinery can lead to increased wear and tear, leading to costly downtime. To address this, consider using metal shims to adjust the spacing and level components. Identify the specific areas where misalignment occurs and select shims of appropriate thickness. If necessary, consult with your shim supplier for recommendations on the best type of shim (e.g., stainless steel for durability) and ensure proper installation to achieve optimal alignment. -

What is the best material for metal shims in harsh environments?

For harsh environments, stainless steel shims are often the best choice due to their resistance to corrosion, rust, and high temperatures. Specifically, 304 stainless steel offers good mechanical properties and durability, making it suitable for various industrial applications. If your application involves exposure to chemicals or extreme conditions, consider discussing additional options, such as specialized coatings or different alloy compositions, with your supplier. -

How can I customize metal shims for my specific application?

Customization of metal shims can be achieved by specifying dimensions, thicknesses, and material types according to your needs. Many suppliers offer custom fabrication services, allowing you to order shims tailored to fit unique machinery or equipment. When reaching out to suppliers, provide detailed specifications, including required tolerances and any specific features like slots or tabs, to ensure that the shims meet your application requirements. -

What are the typical minimum order quantities (MOQs) for metal shims?

Minimum order quantities (MOQs) for metal shims can vary significantly among suppliers. Generally, MOQs may range from as low as 50 pieces for standard sizes to several hundred for custom orders. When sourcing internationally, it’s advisable to discuss your project requirements with suppliers upfront to negotiate MOQs that fit your budget and production timeline while ensuring you receive the necessary quantity for your operations. -

What payment terms should I expect when sourcing metal shims internationally?

Payment terms for international purchases of metal shims typically include options such as advance payment, letter of credit, or net 30/60 days after delivery. It is essential to clarify these terms with your supplier before finalizing the order. Factors like order size, your relationship with the supplier, and shipping conditions can influence payment terms. Always ensure that the terms are documented in your purchase agreement to avoid misunderstandings. -

How do I vet suppliers for metal shims?

Vetting suppliers for metal shims involves evaluating their reputation, quality assurance processes, and experience in your industry. Start by checking customer reviews and testimonials, and consider requesting samples to assess product quality. Additionally, inquire about their manufacturing capabilities, certifications (like ISO), and adherence to international standards. Establishing communication and visiting their facility, if possible, can provide valuable insights into their operations and reliability. -

What quality assurance (QA) processes should I expect from a metal shim supplier?

Reputable metal shim suppliers typically implement rigorous quality assurance (QA) processes to ensure product consistency and reliability. These processes may include material inspections, dimensional checks, and testing for mechanical properties. Ask suppliers about their QA certifications, such as ISO 9001, and request documentation of testing procedures and results. A robust QA process not only guarantees the quality of the shims but also assures compliance with industry standards. -

How can logistics impact my sourcing of metal shims?

Logistics plays a critical role in the sourcing of metal shims, affecting delivery times and overall costs. Factors such as shipping methods, customs clearance, and regional regulations can influence logistics. When sourcing internationally, consider partnering with suppliers who have experience in your target market to navigate these challenges effectively. Additionally, evaluate shipping costs and delivery timelines to ensure that they align with your project schedules and budget constraints.

Top 7 Metal Shims Manufacturers & Suppliers List

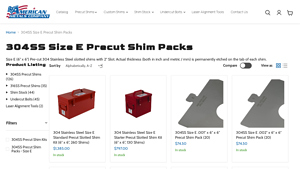

1. Metal Shims – 304SS Size E Precut Shim Packs

Domain: metalshims.com

Registered: 1999 (26 years)

Introduction: 304SS Size E Precut Shim Packs – 6″ x 6″ with 2″ Slot. Available in various thicknesses: .001″, .002″, .003″, .004″, .005″, .010″, .015″, .020″. Each pack contains 20 shims. Total of 260 shims in the standard kit. Original prices range from $74.50 to $1,385.00.

2. McMaster – Steel Shims

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Steel Shims, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. AllFasteners – Metal Shims

Domain: allfasteners.com

Registered: 2002 (23 years)

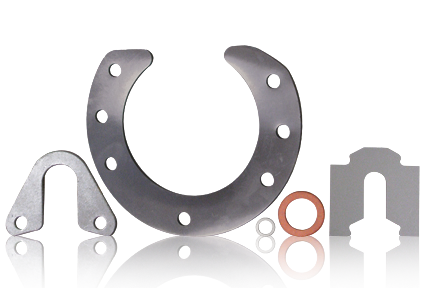

Introduction: Metal shims are thin horseshoe-shaped plates designed for leveling uneven structural steel, particularly in communication tower modifications. They facilitate simple and quick installation, featuring breakaway tabs that are removed once the shim is tightened into position. AF tower metal shims are galvanized and stackable in 1/16 inch increments, allowing for easy fitting and enabling larger gaps …

4. SPIROL – Metal Shims

Domain: spirolshims.com

Registered: 2011 (14 years)

Introduction: SPIROL manufactures Metal Shims from an extensive inventory of raw materials including steel, stainless steel, aluminum, brass, copper, and exotic materials. Thicknesses range from 25.4mm (1.000″) to as thin as 0.02mm (.001″). They offer standard materials such as Carbon Steel (grades 1008, 1010, 1018, 1075, 1095, 4130), Stainless Steel (grades 301, 302, 304, 316, 321), Aluminum (grades 1100, 1145…

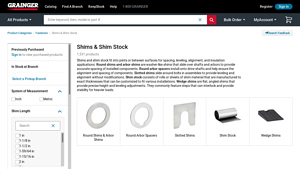

5. Grainger – Shims and Shim Stock

Domain: grainger.com

Registered: 1994 (31 years)

Introduction: This company, Grainger – Shims and Shim Stock, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Shim Shack – Metal Shims

Domain: theshimshack.com

Registered: 2006 (19 years)

Introduction: Metal Shims are available in various materials, each with unique properties suitable for different applications. Key materials include:

1. **Aluminum**: Excellent strength-to-weight ratio, highly formable, corrosion-resistant.

2. **Copper**: Ductile, high conductivity, corrosion-resistant, ideal for electrical applications.

3. **Bronze**: Highly formable, copper alloy, corrosion-resistant, goo…

7. Steel Supply Co – Steel Shims

Domain: thesteelsupplyco.com

Registered: 2008 (17 years)

Introduction: {“Product Name”: “Steel Shims | Metal Shims”, “Part Number”: “150A x 1/32”, “Dimensions”: “3” x 3″ x 1/32″ thick”, “Slot Dimensions”: “1-1/16″ wide x 2″ deep”, “Material”: “Carbon Steel”, “Finish”: “Plain”, “Customization”: “Shims can be made to order in any size and configuration, and be made from any material.”, “Available Materials”: [“Low Carbon Steel”, “Hot Dip Galvanized Steel”, “Stainless S…

Strategic Sourcing Conclusion and Outlook for metal shims

In today’s competitive marketplace, effective strategic sourcing for metal shims is essential for optimizing operations and ensuring product integrity. By leveraging a diverse range of materials—such as stainless steel, plastic, and composite shims—buyers can enhance their supply chain resilience and adapt to specific application needs. Understanding the nuances of shim types and their applications allows international B2B buyers to make informed decisions that align with their operational goals.

Illustrative image related to metal shims

As industries across Africa, South America, the Middle East, and Europe continue to evolve, the demand for high-quality metal shims is expected to rise. Buyers should focus on establishing strong relationships with reliable suppliers who can provide consistent quality and timely deliveries. This not only mitigates risks but also fosters collaboration that can lead to innovation and cost savings.

Looking ahead, companies should prioritize sustainability and efficiency in their sourcing strategies, considering the environmental impact of their choices. Embrace the opportunity to streamline your procurement processes by integrating advanced technologies and data analytics. By doing so, you position your business for success in an increasingly interconnected global market. Engage with trusted suppliers today to secure the best solutions for your metal shim needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.