Everything You Need to Know About Marine Connectors Sourcing in 2025

Introduction: Navigating the Global Market for marine connectors

In an increasingly interconnected world, sourcing high-quality marine connectors presents a significant challenge for international B2B buyers. As businesses expand their maritime operations across Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Germany—they must navigate a complex landscape of product specifications, supplier reliability, and compliance with stringent standards. This guide serves as an essential resource, offering insights into various types of marine connectors, their applications, and the critical factors to consider when selecting the right products for your needs.

The marine industry demands connectors that can withstand harsh environments, including exposure to saltwater, vibration, and extreme temperatures. Understanding the nuances of connector design—such as weatherproofing, conductivity, and material durability—is crucial to ensuring safety and reliability in your operations. Additionally, this guide will delve into the process of vetting suppliers, enabling you to identify trusted manufacturers who adhere to international quality standards.

By consolidating information on cost considerations, performance benchmarks, and industry best practices, this comprehensive resource empowers B2B buyers to make informed purchasing decisions. As you engage with the global market for marine connectors, rely on this guide to streamline your sourcing process and enhance your operational efficiency, ultimately driving success in your maritime endeavors.

Understanding marine connectors Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Heat Shrink Connectors | Dual-wall insulation, heat-activated adhesive, tinned copper barrels for corrosion resistance | Marine, automotive, industrial wiring | Pros: Excellent sealing against moisture; easy installation. Cons: Requires heat application; may need specific tools. |

| Waterproof Connectors | High Ingress Protection (IP) ratings, designed for immersion, robust materials | Marine vessels, offshore equipment | Pros: Reliable in harsh environments; prevents corrosion. Cons: Typically more expensive; may require specialized installation. |

| Terminal Lugs and Rings | Thick copper barrels for strong connections, various sizes for compatibility | Battery connections, electrical panels | Pros: Strong electrical contact; versatile sizing. Cons: Potential for corrosion if not properly sealed; requires appropriate crimping tools. |

| Circular Connectors | Multi-pin configurations, compact design, often weatherproof | Complex electrical systems in vessels | Pros: Space-saving; can handle multiple connections. Cons: Can be complex to install; may require specific mating connectors. |

| Spade and Fork Connectors | Easy attachment and detachment, available in various sizes | General electrical connections in marine systems | Pros: Simplifies maintenance; user-friendly design. Cons: Less secure than crimped connections; may corrode if not protected. |

What Are Heat Shrink Connectors and Why Are They Beneficial for Marine Applications?

Heat shrink connectors are designed with dual-wall insulation and a heat-activated adhesive that ensures a watertight seal. Their tinned copper barrels provide excellent conductivity and resistance to corrosion, making them ideal for marine environments where moisture and vibration are prevalent. B2B buyers should consider their ease of use, as these connectors can significantly speed up installation processes when paired with the right tools, such as a heat gun and a crimping tool. However, the requirement for heat application may deter some buyers who prefer simpler installation methods.

How Do Waterproof Connectors Ensure Longevity in Marine Environments?

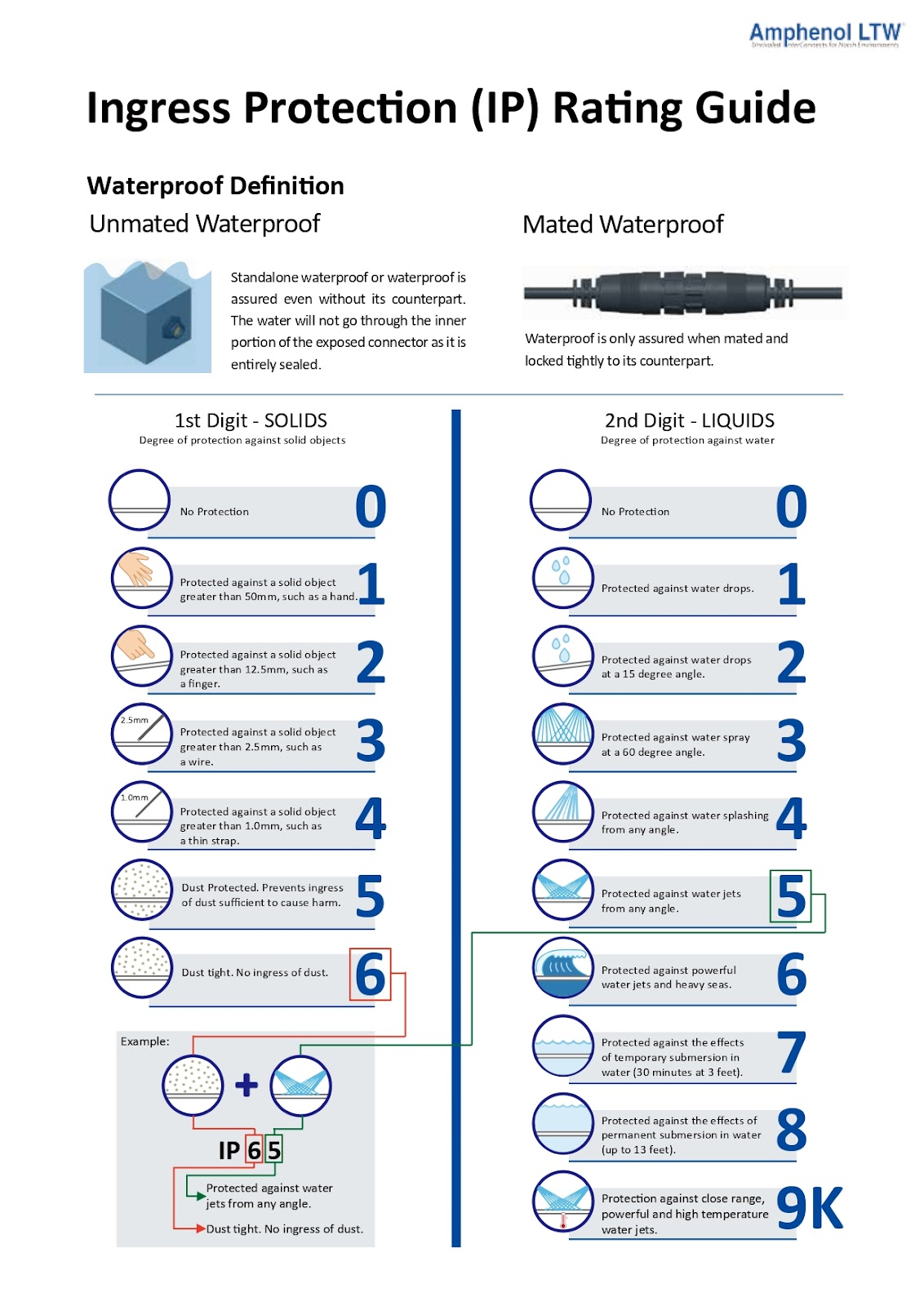

Waterproof connectors are engineered to withstand harsh marine conditions, often featuring high Ingress Protection (IP) ratings that guarantee resistance to water and dust. These connectors are crucial for applications exposed to immersion, such as underwater lighting or navigation systems. Buyers should prioritize connectors that meet industry standards, such as those outlined by the American Boat and Yacht Council (ABYC). While they offer superior protection, the cost and complexity of installation can be higher compared to standard connectors.

What Advantages Do Terminal Lugs and Rings Offer for Electrical Connections?

Terminal lugs and rings are essential components for establishing secure electrical connections, particularly in battery setups and electrical panels. Their thick copper barrels allow for strong and reliable connections that can handle high current loads. B2B buyers should consider the variety of sizes available to ensure compatibility with different wire gauges. However, if not properly sealed or maintained, these connectors can be susceptible to corrosion, which may compromise performance over time.

Why Are Circular Connectors Ideal for Complex Electrical Systems?

Circular connectors are particularly useful in marine applications that require multiple connections in a compact space. They come in various pin configurations, making them versatile for complex electrical systems found in modern vessels. B2B buyers should evaluate the specific requirements of their applications, as these connectors can simplify wiring management but may also necessitate a more intricate installation process. The investment in high-quality circular connectors can lead to enhanced reliability and reduced maintenance.

What Makes Spade and Fork Connectors Popular in Marine Wiring?

Spade and fork connectors are known for their ease of attachment and detachment, which makes them a popular choice for general electrical connections in marine systems. They are available in various sizes, allowing for flexibility in installation. B2B buyers appreciate their user-friendly design, especially during maintenance or repairs. However, it is important to ensure that these connectors are adequately protected against corrosion, as their open design can expose them to harsh environmental factors.

Key Industrial Applications of marine connectors

| Industry/Sector | Specific Application of marine connectors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine Transportation | Power distribution in vessels | Ensures reliable electrical connections under harsh conditions | Waterproof ratings, corrosion resistance, and compliance with ABYC standards |

| Offshore Oil & Gas | Connectivity in drilling platforms | Supports critical communication and power systems | High-temperature tolerance, vibration resistance, and certifications for hazardous environments |

| Renewable Energy (Marine) | Wiring in offshore wind turbines | Facilitates energy transmission in remote locations | UV resistance, reliability in saline environments, and ease of installation |

| Fishing Industry | Electrical systems in commercial fishing vessels | Enhances operational efficiency and safety | Durability against water exposure, ease of maintenance, and compatibility with existing systems |

| Yachting and Recreational | Lighting and navigation systems | Improves safety and enhances user experience | Lightweight design, aesthetic options, and weatherproof capabilities |

How Are Marine Connectors Used in Marine Transportation?

In the marine transportation sector, marine connectors are vital for power distribution systems aboard vessels. They facilitate reliable connections for various electrical systems, such as navigation, communication, and propulsion. Given the harsh marine environment, these connectors must be waterproof and resistant to corrosion, ensuring long-term performance. For international buyers, especially from regions like the Middle East and Europe, compliance with the American Boat and Yacht Council (ABYC) standards is crucial, as it guarantees safety and reliability in their operations.

What Role Do Marine Connectors Play in Offshore Oil & Gas Applications?

In offshore oil and gas operations, marine connectors are essential for ensuring robust connectivity in drilling platforms. They support critical power and communication systems that are exposed to extreme conditions, including high temperatures and vibrations. The connectors must meet stringent safety and durability standards, particularly in hazardous environments. Buyers from regions such as Africa and South America should prioritize sourcing connectors that are certified for use in such challenging applications to mitigate risks and enhance operational efficiency.

How Do Marine Connectors Support Renewable Energy Initiatives?

Marine connectors are increasingly used in the renewable energy sector, particularly in offshore wind turbines. They facilitate the efficient transmission of electricity generated in remote marine locations back to the grid. The connectors must be resistant to UV rays and saline environments, ensuring they can withstand exposure to harsh weather conditions. For B2B buyers in Europe, where renewable energy initiatives are prominent, sourcing high-quality connectors that guarantee durability and reliability is essential for project success.

Why Are Marine Connectors Important in the Fishing Industry?

In the commercial fishing industry, marine connectors are integral to the electrical systems used in fishing vessels. They enhance operational efficiency by ensuring reliable connections for equipment such as sonar systems, lights, and motors. Durability against water exposure is a primary concern for buyers, as is the ease of maintenance in challenging marine environments. Suppliers must offer connectors that withstand the rigors of daily use while providing compatibility with existing systems to ensure seamless integration.

How Do Marine Connectors Enhance Safety in Yachting and Recreational Activities?

For yachting and recreational boating, marine connectors are crucial for lighting and navigation systems, significantly improving safety and user experience. The connectors must be lightweight and aesthetically pleasing while providing the necessary weatherproof capabilities. Buyers from Europe, particularly in countries with a strong boating culture like Germany, should focus on sourcing connectors that combine functionality with design, ensuring that they meet both safety standards and consumer preferences.

3 Common User Pain Points for ‘marine connectors’ & Their Solutions

Scenario 1: Difficulty Ensuring Long-term Durability in Harsh Marine Environments

The Problem: B2B buyers often face challenges when selecting marine connectors that can withstand the harsh conditions typical of marine environments. Corrosion from saltwater, exposure to UV radiation, and constant vibration can lead to premature failure of connectors, resulting in costly repairs and downtime. This is especially critical for businesses operating in regions with extreme weather conditions, such as the Middle East and Africa, where the integrity of electrical systems is paramount.

The Solution: To combat these issues, it is essential to invest in marine-grade connectors that meet stringent industry standards, such as those set by the American Boat and Yacht Council (ABYC). Look for connectors with high Ingress Protection (IP) ratings, specifically IP67 or IP68, which indicate resistance to moisture and dust. Additionally, opt for connectors made from tinned copper, which provides enhanced corrosion resistance. For added durability, choose connectors with heat-shrink technology that seals the connection from environmental elements, ensuring a reliable electrical flow over time. Regularly inspect connectors for signs of wear and replace them proactively to avoid failure during critical operations.

Scenario 2: Challenges with Compatibility and Interchangeability of Connectors

The Problem: A common frustration among B2B buyers is the compatibility of marine connectors with existing systems. Improperly matched connectors can lead to cross-connection issues, particularly in vessels with both AC and DC systems. This can create hazardous situations, as connecting the wrong type can cause electrical failures, potential damage to equipment, or even safety risks for personnel.

The Solution: To mitigate these risks, implement a standardized color-coding system for connectors and wiring throughout the vessel. This will help prevent accidental cross-connections. When sourcing connectors, ensure they are clearly labeled and, where possible, choose manufacturers that offer connectors in distinct colors for AC and DC applications. Additionally, consider investing in connectors that feature non-interchangeable designs to further safeguard against improper connections. Regular training for crew members on the importance of adhering to these standards can also significantly reduce the likelihood of errors.

Scenario 3: Inefficient Installation Processes Leading to Increased Labor Costs

The Problem: B2B buyers often encounter inefficiencies during the installation of marine connectors, leading to increased labor costs and project delays. Traditional connectors can require extensive preparation, crimping, and sealing processes, which not only consume time but also increase the risk of installation errors that may compromise the integrity of the connection.

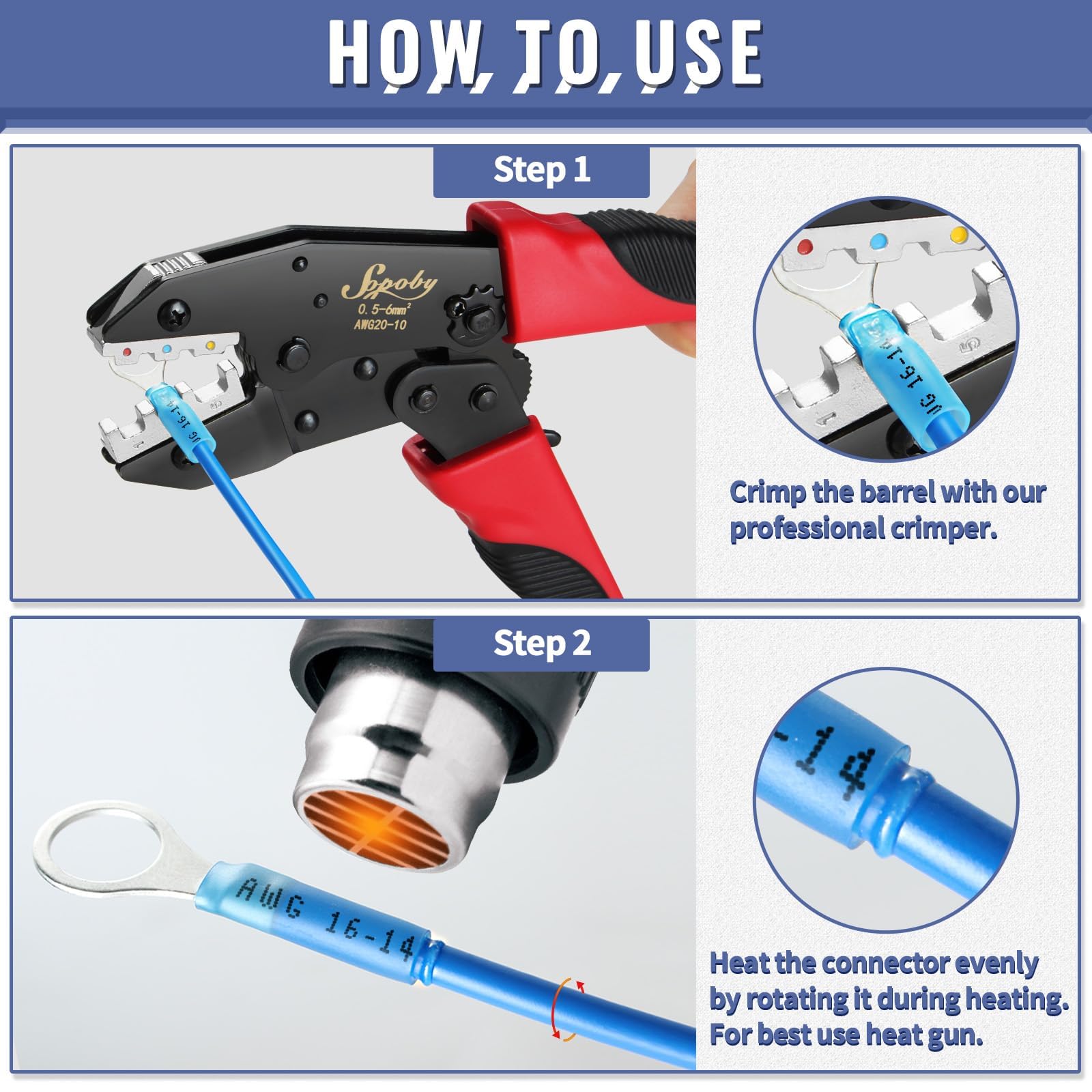

The Solution: To streamline the installation process, consider utilizing heat-shrink connectors that combine both crimping and sealing in one step. These connectors come with built-in adhesive that activates with heat, providing a secure and waterproof seal without the need for additional sealing materials. Investing in a quality heat gun and crimping tools specifically designed for these connectors will further enhance installation efficiency. Additionally, providing installation guides and training to your technicians can improve the overall quality of the connections, ensuring they are completed correctly and reducing the need for costly rework. By adopting these practices, businesses can significantly cut down on labor time and costs, resulting in a more efficient installation process.

Strategic Material Selection Guide for marine connectors

What Are the Key Materials for Marine Connectors?

When selecting materials for marine connectors, it is essential to consider the unique environmental challenges faced in marine applications. The following analysis covers four common materials: copper, aluminum, stainless steel, and thermoplastics. Each material offers distinct properties, advantages, and limitations that can significantly impact performance and suitability for various applications.

How Does Copper Perform in Marine Connector Applications?

Copper is widely recognized for its excellent electrical conductivity, making it a popular choice for marine connectors. It typically operates effectively in a temperature range from -40°C to 90°C and can handle moderate pressure levels. However, copper is susceptible to corrosion, particularly in saltwater environments, which can compromise its longevity.

Pros: High conductivity ensures minimal electrical resistance, leading to efficient power transmission. Additionally, copper connectors are generally easy to manufacture and can be produced in various forms, such as lugs and terminals.

Cons: The primary drawback is its vulnerability to corrosion, necessitating protective coatings or treatments, which can increase costs. Furthermore, copper’s relatively high price compared to other materials may deter some buyers.

What Advantages Do Aluminum Connectors Offer for Marine Use?

Aluminum connectors are lightweight and resistant to corrosion, particularly when anodized. They can withstand temperatures from -50°C to 150°C, making them suitable for a wide range of marine applications. Aluminum is also less expensive than copper, which can be appealing to budget-conscious buyers.

Pros: The lightweight nature of aluminum reduces overall system weight, which is critical in marine applications. Its corrosion resistance, especially with protective coatings, enhances durability in harsh environments.

Cons: Aluminum has lower conductivity than copper, which may result in higher resistance and potential heat generation in high-current applications. Additionally, it can be more challenging to work with, requiring specialized tools for crimping and assembly.

How Does Stainless Steel Compare in Marine Connector Applications?

Stainless steel connectors are favored for their exceptional strength and corrosion resistance, especially in harsh marine environments. They can withstand extreme temperatures and pressures, making them ideal for heavy-duty applications. Stainless steel typically has a temperature rating of -200°C to 800°C.

Pros: The durability and mechanical strength of stainless steel connectors make them suitable for high-stress applications. They are also resistant to pitting and crevice corrosion, which is vital in saltwater environments.

Cons: The cost of stainless steel is generally higher than that of copper or aluminum, which can be a significant factor for buyers. Additionally, the heavier weight may not be ideal for all marine applications where weight savings are crucial.

What Role Do Thermoplastics Play in Marine Connector Design?

Thermoplastics, such as nylon and polycarbonate, are increasingly used in marine connectors due to their lightweight and corrosion-resistant properties. These materials can operate effectively in temperatures ranging from -40°C to 120°C and are often used in non-load-bearing applications.

Pros: Thermoplastics are typically less expensive and easier to manufacture than metal connectors. They also provide excellent insulation and are resistant to moisture, making them suitable for various marine applications.

Cons: While they are resistant to corrosion, thermoplastics may not withstand extreme mechanical stress and can degrade under prolonged exposure to UV radiation. Their lower thermal and electrical conductivity compared to metals can limit their use in high-power applications.

Summary Table of Material Selection for Marine Connectors

| Material | Typical Use Case for marine connectors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | High-current electrical connections | Excellent conductivity | Susceptible to corrosion | High |

| Aluminum | Lightweight applications | Corrosion-resistant and lightweight | Lower conductivity than copper | Medium |

| Stainless Steel | Heavy-duty applications | Exceptional strength and durability | Higher cost and weight | High |

| Thermoplastics | Insulated connectors | Cost-effective and moisture-resistant | Limited mechanical strength | Low |

This strategic material selection guide serves as a valuable resource for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, helping them make informed decisions based on application-specific requirements and environmental considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for marine connectors

What Are the Main Stages in the Manufacturing Process of Marine Connectors?

The manufacturing of marine connectors involves several critical stages that ensure the final product meets the demanding standards of the marine environment. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used and How Are They Prepared?

The first step in the manufacturing process is the selection and preparation of materials. Marine connectors are typically made from high-quality metals like copper, often tinned to prevent corrosion, and insulated with durable polymers to withstand harsh marine conditions. The preparation process involves sourcing materials that meet industry standards for conductivity and corrosion resistance. This may include conducting chemical analyses to ensure the material’s composition aligns with specifications.

Illustrative image related to marine connectors

Forming: How Are Marine Connectors Shaped and Molded?

Once the materials are prepared, they undergo forming processes. This can involve stamping, die-casting, or extrusion, depending on the design of the connector. The forming stage requires precision equipment to ensure that the components meet exact specifications for size and shape. Advanced techniques like CNC machining may be employed for more complex geometries, ensuring a consistent and high-quality product.

Assembly: What Techniques Are Used to Ensure Reliability?

After forming, the various components are assembled. This may include crimping, soldering, or using specialized adhesives to secure connections. Techniques like automated crimping machines are often used to ensure that connections are strong and reliable. The assembly process is critical, as it directly impacts the performance and longevity of the connectors in challenging marine environments.

Finishing: What Final Touches Are Added for Durability?

The finishing stage involves applying protective coatings or treatments that enhance the durability of marine connectors. This may include electroplating to provide an additional layer of protection against corrosion or applying heat shrink tubing to seal connections against moisture and environmental stressors. Quality finishing techniques contribute to a longer lifespan and better performance under extreme conditions.

What Are the Key Quality Assurance Standards Relevant to Marine Connectors?

Quality assurance in the manufacturing of marine connectors is paramount, especially given the potential risks associated with electrical failures in marine environments. Several international and industry-specific standards guide the quality assurance processes.

Which International Standards Should B2B Buyers Be Aware Of?

ISO 9001 is the primary international standard for quality management systems. Manufacturers of marine connectors should be ISO 9001 certified, which indicates their commitment to maintaining high-quality processes and continuous improvement. B2B buyers should verify this certification as part of their supplier evaluation.

What Industry-Specific Standards Are Critical for Marine Connectors?

In addition to ISO standards, marine connectors often need to comply with specific industry standards such as CE marking, which indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area. Additionally, the American Boat and Yacht Council (ABYC) provides guidelines that are essential for ensuring the safety and reliability of marine electrical systems.

How Is Quality Control Implemented Throughout the Manufacturing Process?

Quality control (QC) is implemented at various checkpoints throughout the manufacturing process to ensure that products meet the required standards.

What Are the Key QC Checkpoints in Manufacturing Marine Connectors?

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon delivery to ensure they meet predefined specifications. Any non-conforming materials are rejected or returned.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, various inspections are conducted to monitor compliance with specifications. This may include dimensional checks and functional testing at various stages of assembly.

-

Final Quality Control (FQC): Before products are packaged and shipped, a final inspection is conducted. This includes testing for electrical conductivity, insulation integrity, and environmental sealing.

What Common Testing Methods Are Used to Ensure Quality in Marine Connectors?

Testing methods play a crucial role in the quality assurance of marine connectors, ensuring they can withstand the demanding conditions they will face.

Illustrative image related to marine connectors

Which Testing Methods Are Standard for Marine Connectors?

-

Electrical Testing: This includes continuity tests to ensure that connections are solid and free of shorts or breaks. Insulation resistance testing is also performed to verify that the connectors can resist electrical leakage.

-

Environmental Testing: Connectors are subjected to salt spray testing to simulate exposure to marine conditions, ensuring they resist corrosion. Additionally, temperature cycling tests are conducted to evaluate performance under extreme heat and cold.

-

Mechanical Testing: This includes vibration and shock tests to ensure connectors can withstand the physical stresses encountered in marine applications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to ensure that their suppliers adhere to stringent quality control practices.

What Actions Can Buyers Take to Verify QC Processes?

-

Supplier Audits: Conducting on-site audits allows buyers to assess manufacturing practices and quality control systems directly. This can provide insights into the supplier’s commitment to quality.

-

Requesting Quality Reports: Buyers should ask for documentation that outlines quality control procedures, testing results, and certifications. This documentation can help confirm that the supplier meets necessary standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality practices. These services can conduct audits and testing to ensure compliance with international and industry standards.

What Are the Nuances of Quality Control for International Buyers?

For B2B buyers from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential.

How Do Regional Differences Affect Quality Control?

Different regions may have varying standards and regulations that impact the quality control processes. Buyers should familiarize themselves with local regulations that may apply to marine connectors and ensure that suppliers can meet these requirements.

Additionally, language barriers and cultural differences may affect communication regarding quality standards and expectations. Therefore, establishing clear communication channels and understanding local practices can enhance the buyer-supplier relationship and ensure compliance with quality expectations.

In conclusion, the manufacturing processes and quality assurance measures for marine connectors are multifaceted and essential for ensuring product reliability and performance in demanding environments. B2B buyers must be diligent in their evaluation of suppliers, ensuring adherence to both international and industry-specific standards to mitigate risks and ensure the longevity of their marine electrical systems.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘marine connectors’

In the quest for reliable marine connectors, it’s vital to have a structured approach to sourcing. This guide provides a step-by-step checklist designed for B2B buyers aiming to procure high-quality marine connectors that meet industry standards and specific operational needs.

Step 1: Define Your Technical Specifications

Understanding the technical requirements of your project is the foundation of effective sourcing. Identify the voltage, current ratings, and environmental conditions that the connectors will face, including exposure to moisture, saltwater, and temperature variations. This clarity will help you filter out unsuitable options and focus on connectors that meet your operational demands.

Step 2: Research Industry Standards and Certifications

Before selecting a supplier, familiarize yourself with relevant industry standards such as those set by the American Boat and Yacht Council (ABYC). Look for certifications that indicate compliance with these standards, such as Ingress Protection (IP) ratings for weatherproofing. This ensures that the connectors you choose can withstand harsh marine environments, thus enhancing durability and reliability.

Step 3: Evaluate Potential Suppliers

Conduct thorough due diligence on potential suppliers. Request detailed company profiles, case studies, and references from other buyers in similar industries or regions. Assess their experience with marine connectors, including their ability to provide customized solutions. A supplier’s reputation can significantly impact the quality and reliability of the connectors you procure.

Step 4: Examine Product Quality and Specifications

Once you shortlist suppliers, request product samples to evaluate their quality. Check for materials used—look for tinned copper barrels for corrosion resistance and heat shrink tubing for additional protection against moisture and abrasion. Ensure that the connectors are designed for ease of use, such as those that require minimal heat to shrink, providing a secure and reliable connection.

Step 5: Verify Warranty and Support Policies

Understanding the warranty and after-sales support offered by suppliers is crucial. A strong warranty can indicate confidence in product quality and provide peace of mind. Inquire about technical support availability and return policies in case of defects or issues, as this can save time and resources in the long run.

Step 6: Assess Pricing and Bulk Purchase Options

Pricing is an essential factor, but it should not be the sole criterion for selection. Compare prices among different suppliers while considering the quality and warranty of the products. Additionally, ask about bulk purchase discounts or long-term contract options that can lead to cost savings while ensuring a steady supply of connectors.

Step 7: Finalize Your Order and Confirm Delivery Terms

After selecting a supplier, confirm all order details, including quantities, specifications, and delivery timelines. Ensure that the terms of delivery align with your project timelines to avoid delays. Clear communication at this stage can prevent misunderstandings and ensure a smooth procurement process.

By following this checklist, B2B buyers can ensure they make informed decisions when sourcing marine connectors, ultimately leading to reliable and efficient electrical systems in their marine applications.

Comprehensive Cost and Pricing Analysis for marine connectors Sourcing

What Are the Key Cost Components in Marine Connectors Sourcing?

Understanding the cost structure of marine connectors is essential for B2B buyers looking to make informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The choice of materials significantly impacts costs. Marine connectors typically require high-quality materials like tinned copper for corrosion resistance and durable plastics for housings. The use of heat-shrink tubing further enhances longevity but may add to material costs.

-

Labor: Labor costs can vary based on the region and the complexity of the connector design. Skilled labor is necessary for assembly, especially for connectors requiring precise crimping and sealing processes.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help reduce these overheads.

-

Tooling: Custom tooling for unique connector designs can incur significant upfront costs. Buyers should consider whether the tooling expenses can be amortized over a large production run to reduce per-unit costs.

-

Quality Control (QC): Ensuring that connectors meet international standards, such as those set by the American Boat and Yacht Council (ABYC), involves rigorous testing and quality assurance processes. These QC measures are crucial for reliability in harsh marine environments but can also raise costs.

-

Logistics: Shipping and handling costs are influenced by distance, mode of transport, and packaging requirements. For international buyers, logistics can significantly affect the total cost, especially when considering customs duties and taxes.

-

Margin: Suppliers will apply a margin based on their operational costs and market demand. Understanding the competitive landscape can help buyers negotiate better pricing.

How Do Price Influencers Affect Marine Connector Costs?

Several factors influence pricing beyond the basic cost components. Volume and minimum order quantities (MOQs) can lead to significant discounts; larger orders often result in lower per-unit costs. Customization and specifications also play a critical role; bespoke connectors designed for specific applications typically command higher prices.

Material quality and certifications impact pricing as well. Connectors with higher Ingress Protection (IP) ratings or specific industry certifications will generally be priced higher due to the additional testing and manufacturing standards required.

Supplier factors, such as reputation and reliability, can also influence costs. Established suppliers may charge more for their experience and proven track record, while newer suppliers might offer lower prices to gain market entry.

Additionally, Incoterms affect the pricing structure, as they determine who bears the shipping costs and risks. Familiarity with these terms can help buyers negotiate better deals and understand the total cost of ownership.

What Buyer Tips Can Enhance Cost-Efficiency in Marine Connector Procurement?

To achieve cost-efficiency, buyers should focus on negotiation tactics. Building a long-term relationship with suppliers can lead to better pricing and terms. It’s beneficial to communicate projected volumes and future needs, which can help suppliers plan their production schedules and offer more competitive pricing.

Understanding the total cost of ownership (TCO) is crucial. Buyers should consider not only the upfront costs but also the long-term implications of durability, maintenance, and replacement frequency. Investing in higher-quality connectors may yield cost savings over time due to reduced failures and maintenance.

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, it is essential to be aware of pricing nuances. Currency fluctuations and local regulations can affect costs, so working with suppliers who understand these dynamics can mitigate risks.

Finally, always request indicative pricing and compare quotes from multiple suppliers. This practice allows buyers to benchmark costs and make more informed decisions, ensuring they receive the best value for their investment in marine connectors.

Alternatives Analysis: Comparing marine connectors With Other Solutions

In the realm of marine applications, selecting the right connection solution is crucial for ensuring durability and reliability in challenging environments. While marine connectors are specifically designed to withstand harsh conditions, several alternatives can also serve similar purposes. This analysis will compare marine connectors against two viable alternatives: heat shrink wire connectors and waterproof terminal blocks.

| Comparison Aspect | Marine Connectors | Heat Shrink Wire Connectors | Waterproof Terminal Blocks |

|---|---|---|---|

| Performance | High resistance to saltwater, vibration, and temperature extremes | Excellent insulation and corrosion resistance | Reliable in wet environments, with multiple connection options |

| Cost | Typically higher due to specialized materials | Generally lower, with bulk options available | Moderate, depending on configuration and features |

| Ease of Implementation | Requires specific tools and training for proper installation | User-friendly; can be installed quickly with basic tools | Moderate; may need professional installation for complex setups |

| Maintenance | Low maintenance; durable over time | Minimal; replaceable if damaged | Moderate; requires inspection and potential replacement of connectors |

| Best Use Case | Marine vessels, outdoor equipment | Automotive, marine, and home electrical applications | Marine, industrial, and automotive environments requiring multiple connections |

What are the advantages and disadvantages of heat shrink wire connectors?

Heat shrink wire connectors offer a versatile solution suitable for various applications, including marine settings. Their primary advantage lies in their superior sealing capability, protecting against moisture and corrosion. This type of connector is user-friendly and allows for quick installations, making them ideal for projects requiring efficiency. However, while they provide excellent insulation, they may not be as robust in extreme marine conditions compared to marine connectors specifically designed for those environments.

Illustrative image related to marine connectors

How do waterproof terminal blocks compare in performance and application?

Waterproof terminal blocks are a reliable option for creating multiple connections in environments prone to moisture. They are designed to ensure safety and performance under wet conditions, making them a strong alternative for marine and industrial applications. The main advantages include their modularity and ease of adding or changing connections without extensive rewiring. However, they may require more maintenance and inspection to ensure continued integrity over time, especially if exposed to harsh conditions.

How can B2B buyers choose the right connector solution for their needs?

When deciding on a connector solution, B2B buyers should consider several factors, including the specific environmental conditions of their application, budget constraints, and the required performance levels. Marine connectors are ideal for high-performance, long-lasting needs in extreme marine environments. Conversely, heat shrink wire connectors may suit applications where cost and ease of installation are more critical, while waterproof terminal blocks may be best for systems requiring multiple connections. By evaluating these aspects, buyers can select the most appropriate solution tailored to their operational requirements.

Essential Technical Properties and Trade Terminology for marine connectors

What Are the Key Technical Properties of Marine Connectors?

Marine connectors must adhere to stringent standards due to their exposure to harsh environmental conditions. Here are critical specifications that should be considered:

-

Material Grade

Marine connectors are typically made from corrosion-resistant materials such as tinned copper or stainless steel. Tinned copper enhances conductivity while providing protection against oxidation, which is essential in saltwater environments. Understanding material grade is vital for B2B buyers, as it directly influences the longevity and reliability of the connectors in marine applications. -

Ingress Protection (IP) Rating

The IP rating indicates how well a connector can resist water and dust ingress. For marine applications, connectors should ideally have an IP67 or higher rating, ensuring they are waterproof and suitable for submersion. This specification is crucial for buyers to ensure that the connectors will perform reliably under the specific conditions they will face. -

Temperature Tolerance

Marine connectors must operate efficiently across a range of temperatures. Many connectors are designed to function in extreme conditions, often with a tolerance ranging from -40°C to +85°C. Understanding temperature tolerance helps buyers select connectors that will not fail under thermal stress, thus safeguarding the entire electrical system. -

Vibration Resistance

Marine environments are subject to constant movement and vibrations, which can loosen connections. Connectors designed for marine use often feature locking mechanisms or robust designs that enhance vibration resistance. This property is essential for ensuring a secure connection, minimizing maintenance costs, and enhancing operational safety. -

Crimping and Termination Method

The method used for crimping and terminating connectors can significantly affect their performance. High-quality marine connectors often utilize crimping techniques that ensure a strong mechanical connection, which is less prone to failure under stress. Buyers should prioritize connectors that are easy to install and offer reliable terminations, reducing the risk of electrical failures. -

Current Rating

Each marine connector has a specific current rating, indicating the maximum amount of electrical current it can safely carry. This rating is vital for preventing overheating and potential failures. Buyers must match the current rating of connectors with the electrical requirements of their marine systems to ensure operational safety and efficiency.

What Are Common Trade Terms in the Marine Connector Industry?

Understanding industry-specific terminology can facilitate smoother transactions and communication. Here are several key terms relevant to marine connectors:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are used in another company’s end products. In the marine industry, knowing whether a connector is OEM can assure buyers of its compatibility and reliability within specific marine applications. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. For B2B buyers, understanding MOQ is crucial for budgeting and inventory management, especially when dealing with large-scale projects or specific connector types. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit a price for specific products or services. For marine connector procurement, submitting an RFQ can help buyers obtain competitive pricing and terms, ensuring they are making informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized international shipping terms that define the responsibilities of buyers and sellers in a transaction. Familiarity with Incoterms is essential for B2B buyers to understand shipping costs, risks, and delivery responsibilities, particularly when sourcing from international suppliers. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the products. In the marine industry, where timely procurement can be critical, understanding lead times helps buyers plan their projects more effectively. -

Certification Standards

Many marine connectors must meet specific certification standards, such as those set by the American Boat and Yacht Council (ABYC) or the International Electrotechnical Commission (IEC). Awareness of these standards ensures that buyers select connectors that comply with safety and performance regulations, minimizing risks associated with non-compliance.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing marine connectors, ultimately enhancing the reliability and safety of their marine systems.

Illustrative image related to marine connectors

Navigating Market Dynamics and Sourcing Trends in the marine connectors Sector

What Are the Key Market Trends Influencing the Marine Connectors Sector?

The marine connectors market is experiencing significant growth driven by several global factors. The increasing demand for recreational boating, coupled with advancements in marine technology, is propelling the need for high-performance connectors that can withstand harsh marine environments. Key trends include the rise of electric and hybrid boats, which require specialized connectors for energy efficiency and safety. Furthermore, as international regulations become stricter regarding safety and environmental standards, manufacturers are responding by developing connectors that meet these compliance requirements, such as those set by the American Boat and Yacht Council (ABYC).

Emerging technologies like IoT and smart marine systems are also influencing sourcing strategies. B2B buyers in regions such as Africa, South America, the Middle East, and Europe are increasingly seeking connectors that support integrated systems for navigation, communication, and monitoring. As these technologies evolve, the demand for connectors with enhanced features—such as waterproofing and corrosion resistance—will continue to grow. In addition, the global supply chain landscape is shifting, with buyers looking for suppliers that can offer flexibility, rapid delivery, and competitive pricing without compromising quality.

How Are Sustainability and Ethical Sourcing Shaping the Marine Connectors Market?

Sustainability has become a central theme in the marine connectors sector, as buyers are increasingly aware of the environmental impact of their procurement choices. The marine industry is under pressure to minimize waste and reduce its carbon footprint, prompting manufacturers to adopt eco-friendly practices. B2B buyers are now prioritizing suppliers who utilize sustainable materials and production methods, such as connectors made from recyclable materials or those that meet recognized environmental certifications.

Ethical sourcing is also gaining traction, as companies strive to ensure that their supply chains are transparent and responsible. This involves verifying that materials are sourced from suppliers who adhere to labor standards and environmental regulations. Certifications such as ISO 14001 for environmental management and RoHS compliance for hazardous substances are becoming essential for buyers looking to align their procurement strategies with global sustainability goals. By choosing ethically sourced marine connectors, companies not only enhance their brand image but also contribute to a more sustainable marine ecosystem.

What Is the Historical Context of Marine Connectors and Their Evolution?

The evolution of marine connectors has been largely influenced by technological advancements and changing industry standards. Initially, marine connectors were basic and primarily focused on functionality. However, as the marine industry expanded and diversified, the demand for more sophisticated connectors grew. Over the years, manufacturers have responded by developing connectors that offer enhanced durability, waterproofing, and resistance to corrosion, crucial for applications exposed to harsh marine conditions.

The introduction of industry standards, such as those from the ABYC and the International Electrotechnical Commission (IEC), has further shaped the development of marine connectors. These standards ensure safety, reliability, and performance, prompting manufacturers to innovate continuously. As a result, today’s marine connectors are not only more efficient and reliable but also better suited to accommodate the integration of advanced technologies, making them indispensable in modern marine applications.

Frequently Asked Questions (FAQs) for B2B Buyers of marine connectors

-

1. How do I choose the right marine connectors for my application?

Selecting the appropriate marine connectors involves assessing several factors, including the environmental conditions they will face. Look for connectors with a high Ingress Protection (IP) rating, indicating their resistance to water and dust. Consider the material, as tinned copper connectors resist corrosion better in marine environments. Additionally, ensure that the connectors meet industry standards, such as those set by the American Boat and Yacht Council (ABYC). Finally, evaluate the size and pin configuration based on your specific wiring requirements. -

2. What is the best type of marine connector for harsh environments?

For harsh marine environments, look for connectors that are waterproof and corrosion-resistant, such as those made from marine-grade materials. Heat shrink connectors with adhesive linings are excellent choices, as they provide a secure seal against moisture and contaminants. Additionally, connectors with a robust locking mechanism can withstand vibrations and movement. Products that comply with industry standards, such as ABYC or IEC, are typically reliable for demanding applications. -

3. How can I verify the quality of marine connectors from suppliers?

To ensure the quality of marine connectors, request certifications from suppliers that demonstrate compliance with industry standards. Look for third-party testing results, such as those from UL or CE, which validate the connectors’ performance in marine conditions. Additionally, consider conducting a sample order to evaluate the product firsthand. Reading customer reviews and testimonials can also provide insights into the reliability of the supplier’s products. -

4. What are the typical minimum order quantities (MOQs) for marine connectors?

Minimum order quantities for marine connectors can vary widely depending on the supplier and the type of connector. Generally, MOQs may range from 100 to 1,000 units, especially for specialized or custom connectors. It’s advisable to discuss your requirements with suppliers, as some may offer flexible MOQs for new customers or bulk orders. Understanding your own inventory needs will help you negotiate favorable terms. -

5. What payment terms should I expect when sourcing marine connectors internationally?

Payment terms for international purchases of marine connectors can differ by supplier and region. Common terms include upfront payments, net 30, or net 60 days after delivery. It’s essential to clarify payment methods accepted, such as bank transfers, letters of credit, or online payment systems. Negotiating favorable payment terms can help manage cash flow, particularly for larger orders. Always ensure that terms are outlined in a formal purchase agreement. -

6. How does international shipping affect the sourcing of marine connectors?

International shipping can significantly impact the sourcing process, influencing delivery times and costs. Factors such as shipping method (air vs. sea), customs clearance, and import duties should be considered. Ensure your supplier has experience with international logistics and can provide accurate shipping estimates. Additionally, inquire about their policies on handling delays or damages during transit to mitigate risks associated with international orders. -

7. Can I customize marine connectors to meet specific requirements?

Many suppliers offer customization options for marine connectors, allowing you to tailor specifications such as size, color, and pin configuration to suit your application. Customization can enhance functionality and improve integration with your existing systems. Be sure to communicate your requirements clearly and discuss any potential impacts on MOQs and lead times. Some suppliers may provide design assistance to ensure compatibility with your needs. -

8. What quality assurance measures should I look for in marine connector suppliers?

When evaluating suppliers of marine connectors, prioritize those with robust quality assurance protocols. Look for suppliers who follow ISO standards and have in-place testing procedures for their products. Certifications, such as ISO 9001, indicate a commitment to quality management. Additionally, inquire about their return policy and warranty options, as these can reflect the supplier’s confidence in their product quality and customer service commitment.

Top 4 Marine Connectors Manufacturers & Suppliers List

1. Boat Wire USA – Marine Wire Connectors

Domain: boatwireusa.com

Registered: 2022 (3 years)

Introduction: Wire Connectors for marine wiring installations, including larger battery terminals and lugs, smaller AWG wire ring terminals, and butt splices. High-quality parts designed for marine grade longevity, suitable for non-marine wiring as well. Discounts available: 5% on orders over $500, 10% on orders over $1,000. Trolling Motor Repair services offered. Categories include Marine Grade Wire, Marine El…

2. Wirefy – Heat Shrink Wire Connectors Kit

Domain: wirefyshop.com

Registered: 2016 (9 years)

Introduction: Heat Shrink Wire Connectors Kit – Marine Grade Electrical Connectors

– Available Styles: 1080 PCS, 540 PCS, 270 PCS, 120 PCS

– Price: $109.99 (originally $164.99, save $4.00 or 18%)

– Free delivery on orders over $30.00 & free returns

– Includes a variety of connectors: rings, butt splices, spades, hooks, and forks

– Super strong crimps with thick copper barrels for a tight grip

– Tinned copper ba…

3. Ecomate – Aquarius Series Connector

Domain: connectorsupplier.com

Registered: 2003 (22 years)

Introduction: 1) ecomate Aquarius Series: IP67/69K waterproof rating, multiple coupling options, pin counts from 3 to 32 positions. 2) Amphenol Sine AT series: Color-coded receptacles available in green, black, white, red, blue, brown, and yellow. 3) AT series connector: Built-in strain relief to prevent wire bending. 4) 12-Way ATM connector series: Locking tab ensuring disengagement force exceeding six pounds….

4. Appleton – C2KX Marine Cable Connectors

Domain: appleton.emerson.com

Registered: 1995 (30 years)

Introduction: This company, Appleton – C2KX Marine Cable Connectors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for marine connectors

In navigating the complex landscape of marine connectors, strategic sourcing emerges as a pivotal approach for international B2B buyers. By prioritizing quality and reliability, businesses can ensure that their electrical connections withstand harsh marine environments, which are characterized by moisture, vibration, and temperature fluctuations. Key considerations include selecting connectors that meet industry standards, such as the American Boat and Yacht Council (ABYC) guidelines, ensuring waterproof designs, and utilizing high-conductivity materials like tinned copper.

Moreover, the versatility of products such as heat shrink wire connectors enhances operational efficiency, allowing for quick and secure installations that promise long-term performance. As the marine industry continues to evolve, staying ahead of technological advancements and market trends is essential for maintaining a competitive edge.

Looking forward, international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are encouraged to engage with reputable suppliers who can provide tailored solutions to meet their unique needs. By leveraging strategic sourcing, businesses can not only optimize their supply chains but also enhance their overall operational resilience in the dynamic marine sector. Take proactive steps today to secure the quality connectors that will support your growth and success in the future.

Illustrative image related to marine connectors

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to marine connectors