Everything You Need to Know About Locks And Latches Sourcing in 2025

Introduction: Navigating the Global Market for locks and latches

In today’s interconnected world, sourcing reliable locks and latches has become increasingly challenging for international B2B buyers. With a diverse range of products available, from residential gate locks to industrial cabinet latches, understanding the nuances of this market is crucial for ensuring security and functionality. This comprehensive guide addresses the complexities of the global locks and latches market, highlighting various types, applications, and key considerations for supplier vetting and cost analysis.

As businesses across Africa, South America, the Middle East, and Europe (including regions like Saudi Arabia and Brazil) seek to enhance their security infrastructure, the importance of informed purchasing decisions cannot be overstated. This guide empowers buyers by providing insights into industry standards, material specifications, and the latest technological advancements in locking solutions. By exploring the diverse applications—ranging from child safety locks to robust industrial latches—international buyers can make choices that meet their unique operational needs.

Furthermore, our guide emphasizes best practices in supplier evaluation, ensuring that buyers can select partners who not only meet quality standards but also align with their business values. Armed with this knowledge, B2B buyers will navigate the global market with confidence, making strategic decisions that enhance their security measures while optimizing costs.

Understanding locks and latches Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Deadbolt Locks | High security, requires a key for locking/unlocking | Commercial buildings, secure residential doors | Pros: Superior security; Cons: More complex installation and cost. |

| Cam Locks | Simple mechanism, often key-operated, versatile in application | Cabinets, lockers, industrial enclosures | Pros: Easy to install; Cons: Limited security compared to deadbolts. |

| Gate Latches | Designed for gates, available in self-closing options | Perimeter security, pools, gardens | Pros: Convenient; Cons: May require regular maintenance. |

| Paddle and Toggle Latches | Quick access with a simple mechanism, often lever-operated | Industrial cabinets, food industry applications | Pros: Fast and easy access; Cons: May not be as secure as other types. |

| Snap Locks | Compact design, often used in lightweight applications | Automotive, furniture, and light machinery | Pros: Lightweight and space-efficient; Cons: Not suitable for high-security needs. |

What are Deadbolt Locks and Their Key Characteristics?

Deadbolt locks are renowned for their robust security features, making them a preferred choice for commercial properties and secure residential doors. They typically require a key for both locking and unlocking, which enhances their security level. For B2B buyers, considerations include the installation complexity and the associated costs, as these locks often require professional installation. Their durability and resistance to forced entry can justify the investment, especially in high-risk areas.

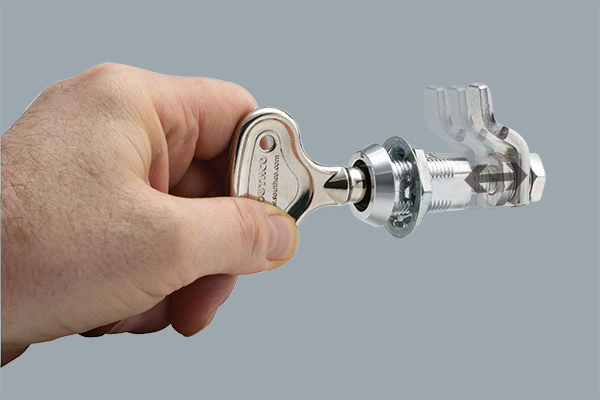

How Do Cam Locks Serve Various Applications?

Cam locks are versatile locking solutions that operate with a simple mechanism, making them suitable for a wide range of applications, including cabinets, lockers, and industrial enclosures. Their ease of installation is a significant advantage for businesses looking to secure storage areas without extensive modifications. However, while they offer convenience, buyers should note that cam locks may not provide the same level of security as deadbolts, making them ideal for low-risk environments.

What Makes Gate Latches Essential for Security?

Gate latches are specifically designed for securing gates and are available in various styles, including self-closing options. They are commonly used in applications such as perimeter security, pools, and gardens. For B2B buyers, the ease of use and convenience of these latches are significant benefits. However, regular maintenance may be necessary to ensure their functionality over time, which should be factored into purchasing decisions.

Why Choose Paddle and Toggle Latches for Industrial Use?

Paddle and toggle latches are designed for quick access, often utilizing a lever-operated mechanism. They are particularly popular in industrial cabinets and applications within the food industry, where easy access is crucial. While these latches provide fast entry, buyers should consider their security limitations compared to more robust locking systems. For businesses that prioritize efficiency over high-security needs, these latches offer an excellent solution.

What are the Advantages of Using Snap Locks in Lightweight Applications?

Snap locks are compact locking devices often used in lightweight applications such as automotive and furniture designs. Their space-efficient design makes them ideal for environments where weight and space are critical considerations. However, snap locks may not be suitable for high-security applications, which is an essential factor for B2B buyers to evaluate based on their specific security requirements.

Key Industrial Applications of locks and latches

| Industry/Sector | Specific Application of locks and latches | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Securing machinery and equipment in production facilities | Enhances safety and prevents unauthorized access | Durability, resistance to industrial conditions, and compliance with safety standards |

| Telecommunications | Locking server cabinets and data centers | Protects sensitive data and ensures operational integrity | Corrosion resistance, ease of access for maintenance, and compatibility with security systems |

| Transportation and Logistics | Securing cargo and freight containers | Reduces theft risk and ensures cargo integrity | Weather resistance, tamper-proof designs, and certification for international shipping |

| Construction | Locking construction site tools and materials | Minimizes theft and unauthorized usage | Robustness, adaptability to various environments, and compliance with local regulations |

| Healthcare | Locking medical storage and sensitive equipment | Ensures patient safety and compliance with hygiene standards | Hygiene compliance, ease of cleaning, and high durability in sterile environments |

How Are Locks and Latches Used in Manufacturing?

In the manufacturing sector, locks and latches are vital for securing machinery and equipment within production facilities. They help prevent unauthorized access, enhancing workplace safety and reducing the risk of accidents. Buyers in this industry should prioritize locks that offer durability and resistance to harsh industrial conditions, as well as compliance with safety regulations. For international buyers, understanding local compliance standards is crucial to ensure that the selected locking solutions meet regional requirements.

What Role Do Locks and Latches Play in Telecommunications?

Locks and latches are essential in the telecommunications industry, particularly for securing server cabinets and data centers. These locking mechanisms protect sensitive data and maintain operational integrity by preventing unauthorized access. Buyers must consider corrosion-resistant materials and designs that allow for easy access during maintenance. Additionally, compatibility with existing security systems is a key factor for B2B buyers looking to enhance their data security measures.

Why Are Locks and Latches Important for Transportation and Logistics?

In the transportation and logistics sector, locks and latches are used to secure cargo and freight containers, significantly reducing the risk of theft and ensuring cargo integrity during transit. Buyers should focus on weather-resistant and tamper-proof designs that can withstand various environmental conditions. Furthermore, certification for international shipping standards is crucial for businesses operating in multiple regions, as it ensures compliance with global security protocols.

How Do Locks and Latches Function in Construction?

Locks and latches serve a critical role in securing tools and materials at construction sites. They minimize the risk of theft and unauthorized usage, which can lead to significant financial losses. Buyers should seek robust locking solutions that can adapt to various environmental conditions and comply with local regulations. Understanding the specific security needs of construction sites in different regions can aid in selecting the most effective locking mechanisms.

What Is the Importance of Locks and Latches in Healthcare?

In the healthcare sector, locks and latches are crucial for securing medical storage and sensitive equipment. They ensure patient safety and compliance with strict hygiene standards. Buyers must prioritize locking solutions that are easy to clean and maintain while offering high durability in sterile environments. For international B2B buyers, it is essential to be aware of local healthcare regulations and standards to ensure that the selected locks meet all necessary compliance requirements.

3 Common User Pain Points for ‘locks and latches’ & Their Solutions

Scenario 1: Securing Perimeter Gates for Commercial Properties

The Problem: Many B2B buyers in sectors such as logistics, manufacturing, and retail face challenges when it comes to securing perimeter gates. These gates are critical for preventing unauthorized access, but traditional locks can be easily bypassed. Additionally, gate latches often fail under heavy use or extreme weather conditions, leading to security vulnerabilities and potential losses. Buyers are often concerned about the durability and reliability of the locking mechanisms, especially in regions with varying climates, such as the Middle East or South America.

The Solution: To address these concerns, businesses should invest in high-quality gate latches and locks that are specifically designed for commercial applications. Opt for products made from robust materials like stainless steel or high-grade aluminum that can withstand harsh environmental conditions. Furthermore, consider self-closing gate latches equipped with tamper-resistant features. When sourcing these products, work with reputable suppliers who can provide detailed specifications and performance testing data. It’s essential to conduct a risk assessment to determine the level of security required and to select locks that meet those needs, such as keyable locks for easy access management. Implementing a regular maintenance schedule for gate hardware will also prolong its lifespan and ensure continued security.

Scenario 2: Ensuring Child Safety with Pool Gates

The Problem: Businesses in the hospitality and recreational sectors, such as hotels and amusement parks, often encounter difficulties in ensuring child safety around pool areas. The challenge lies in installing locks and latches that are both secure and easy for adults to operate while being inaccessible to children. Many standard latch systems do not meet safety regulations, leading to potential liability issues.

The Solution: To effectively mitigate these risks, B2B buyers should invest in pool gate locks specifically designed for child safety. These locks should feature an automatic latching mechanism that secures the gate upon closure, as well as a child-proof release mechanism that requires adult strength to operate. Additionally, ensure compliance with local safety regulations by reviewing the latest guidelines on pool safety equipment. When selecting a supplier, look for those who offer a range of products tailored to different gate materials and configurations, ensuring that you can find a suitable solution for your specific needs. Regular training for staff on the proper use and maintenance of these safety latches is also crucial, as it reinforces safety protocols and keeps guests protected.

Scenario 3: Managing Security in Industrial Settings

The Problem: In industries like telecommunications, transportation, and manufacturing, securing sensitive areas such as server rooms or control cabinets is paramount. B2B buyers often face the challenge of finding locks and latches that provide a high level of security while being easy to use and maintain. Many existing solutions may not meet stringent security standards or may require complex installations that disrupt operations.

The Solution: For industrial applications, it is essential to choose locks and latches designed specifically for high-security environments. Look for products that offer features such as electronic access control or biometric systems, which can enhance security without complicating access for authorized personnel. When sourcing these solutions, prioritize suppliers who provide comprehensive installation support and technical assistance. This ensures that the products are integrated seamlessly into existing systems and that staff are trained on their use. Additionally, conducting a thorough security audit can help identify the most vulnerable areas in your operation, allowing you to tailor your lock and latch solutions to meet specific security needs effectively. Regular evaluations and upgrades to the locking systems should also be part of the security management plan to adapt to evolving threats.

Strategic Material Selection Guide for locks and latches

What Are the Key Properties of Common Materials Used in Locks and Latches?

When selecting materials for locks and latches, it is essential to consider their properties and how they align with the requirements of specific applications. Here, we analyze four common materials: stainless steel, brass, plastic, and zinc alloy.

Stainless Steel: A Durable Choice for Security

Stainless steel is renowned for its strength and corrosion resistance, making it ideal for locks and latches exposed to harsh environments. It typically boasts a high-temperature rating and excellent mechanical properties, ensuring reliable performance under pressure.

Pros: Its durability and resistance to rust and corrosion make stainless steel a preferred choice for outdoor applications and industries requiring high hygiene standards, such as food processing.

Cons: The primary drawback is its higher cost compared to other materials. Additionally, manufacturing complexity can increase due to the need for specialized tooling.

Impact on Application: Stainless steel locks are suitable for environments with exposure to moisture, chemicals, or extreme temperatures, providing longevity and reliability.

Considerations for International Buyers: Compliance with international standards, such as ASTM or DIN, is crucial. Buyers in regions like the Middle East and Europe may prefer stainless steel for its aesthetic appeal and durability.

Brass: Traditional and Versatile

Brass is a popular choice for locks and latches due to its attractive finish and good corrosion resistance. It offers moderate strength and is easy to machine, making it suitable for various applications.

Pros: Its natural antimicrobial properties make it suitable for applications in healthcare settings. Brass also has a lower cost compared to stainless steel, making it an economical option for many projects.

Cons: While brass is resistant to corrosion, it is not as robust as stainless steel and may tarnish over time, requiring regular maintenance.

Impact on Application: Brass locks are often used in residential settings and decorative applications where aesthetics are essential.

Considerations for International Buyers: Buyers should be aware of local regulations regarding the use of brass in specific applications, especially in regions like Africa and South America, where environmental conditions may influence material choice.

Plastic: Lightweight and Cost-Effective

Plastic materials, such as polyamide and polyethylene, are increasingly used in locks and latches due to their lightweight nature and resistance to corrosion. They offer good flexibility and can withstand various environmental conditions.

Pros: The low cost and ease of manufacturing make plastic an attractive option for high-volume production. Additionally, plastic is resistant to chemicals and UV light, making it suitable for outdoor applications.

Cons: However, plastic lacks the strength of metal materials, which may limit its use in high-security applications.

Impact on Application: Plastic locks are ideal for lighter-duty applications, such as garden gates or indoor cabinets, where high security is not a primary concern.

Considerations for International Buyers: Buyers should consider the environmental impact of plastic and local recycling regulations, especially in Europe, where sustainability is a significant focus.

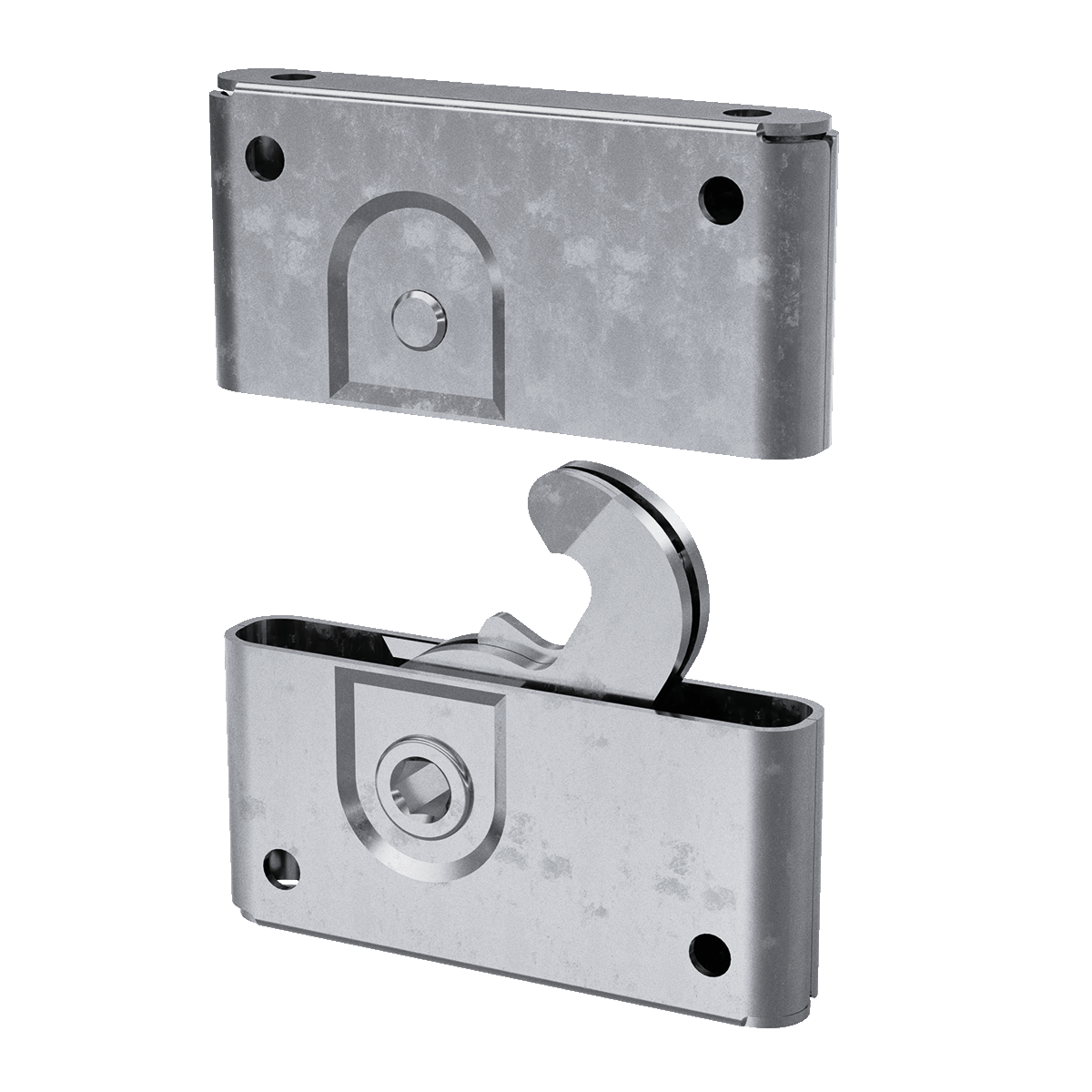

Illustrative image related to locks and latches

Zinc Alloy: A Balance of Strength and Cost

Zinc alloy is another popular material for locks and latches, known for its strength and ability to resist corrosion. It is often used in combination with other materials to enhance performance.

Pros: Zinc alloy is cost-effective and offers good durability, making it suitable for a range of applications, including automotive and industrial uses.

Cons: While it provides decent corrosion resistance, it may not perform as well as stainless steel in harsh environments.

Illustrative image related to locks and latches

Impact on Application: Zinc alloy locks are commonly used in commercial and industrial settings where cost and performance are balanced.

Considerations for International Buyers: Buyers should verify compliance with local standards, as different regions may have varying requirements for material specifications.

Summary Table of Material Selection for Locks and Latches

| Material | Typical Use Case for locks and latches | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Outdoor security locks, industrial applications | High durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Brass | Residential locks, decorative applications | Attractive finish and antimicrobial properties | May tarnish and lower strength | Medium |

| Plastic | Garden gates, indoor cabinets | Lightweight and cost-effective | Limited strength for high-security applications | Low |

| Zinc Alloy | Commercial and industrial locks | Good balance of strength and cost | Moderate corrosion resistance | Medium |

This guide provides B2B buyers with essential insights into material selection for locks and latches, allowing for informed decisions based on application requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for locks and latches

What Are the Key Stages in the Manufacturing Process of Locks and Latches?

The manufacturing process of locks and latches involves several critical stages, each essential for ensuring product quality and reliability. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves selecting high-quality raw materials, such as stainless steel, brass, and various plastics. The selection process is crucial, as the materials must meet specific strength, corrosion resistance, and durability standards. Often, suppliers will conduct material tests to verify that these criteria are met before moving on to the next stage.

-

Forming: Once the materials are prepared, they undergo various forming processes. Techniques such as stamping, forging, and machining are commonly used to create the intricate shapes required for locks and latches. Advanced technologies like CNC machining ensure high precision and repeatability, which is vital for components that need to fit together seamlessly.

-

Assembly: After forming, the components are assembled. This may involve manual or automated processes, depending on the complexity of the latch or lock design. Assembly lines are often designed to optimize workflow and minimize the risk of errors. Quality control checks are integrated into this stage to catch any defects early.

-

Finishing: The final stage involves surface treatments such as plating, coating, and polishing to enhance aesthetics and durability. Processes like electroplating can improve corrosion resistance, while powder coating offers a durable finish that can withstand harsh environmental conditions. This stage is also critical for ensuring that the locks and latches meet industry standards for appearance and functionality.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is an integral part of the manufacturing process for locks and latches, ensuring that products meet international standards and customer expectations. Several checkpoints and testing methods are employed throughout the production process.

-

International and Industry-Specific Standards: Compliance with international standards such as ISO 9001 is essential for manufacturers aiming to operate in global markets. ISO 9001 outlines criteria for a quality management system that can enhance customer satisfaction and operational efficiency. Additionally, industry-specific certifications like CE for products in the European market or API for oil and gas applications provide further assurance of quality and safety.

-

Quality Control Checkpoints: Key quality control checkpoints include:

– Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During the manufacturing stages, regular checks are performed to catch defects early in the process. This can involve measuring tolerances and inspecting for surface defects.

– Final Quality Control (FQC): Before products are shipped, a thorough inspection is conducted to ensure that all components function correctly and meet quality standards. -

Common Testing Methods: Various testing methods are utilized to verify the integrity of locks and latches. These can include:

– Functional Testing: Ensuring the lock or latch operates as intended.

– Durability Testing: Simulating long-term use to assess wear and tear.

– Environmental Testing: Evaluating how products withstand extreme temperatures, humidity, and exposure to chemicals.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial to ensure product reliability. Here are actionable steps buyers can take:

-

Conduct Audits: Performing on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control systems. This allows buyers to assess compliance with international standards and identify any areas of concern.

-

Request Quality Reports: Buyers should request detailed quality assurance reports from suppliers. These documents should outline the results of various quality checks, including IQC, IPQC, and FQC results, as well as any certifications the supplier holds.

-

Utilize Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control processes. These inspectors can conduct random checks on production batches, ensuring that the products meet agreed specifications before shipment.

-

Understand Regional Quality Nuances: Different regions may have specific quality requirements or certifications. For example, products destined for the European market must often comply with CE marking regulations, while those for the Middle Eastern market may need to meet local standards. Buyers should familiarize themselves with these requirements to avoid compliance issues.

What Are the Challenges in Maintaining Quality Assurance Across Borders?

Maintaining consistent quality assurance in international supply chains can be challenging due to various factors, including:

-

Regulatory Differences: Different countries have different regulations governing product quality and safety. Understanding these regulations is essential for compliance and to avoid costly recalls or legal issues.

-

Cultural Variations in Quality Standards: Quality expectations may vary significantly from one region to another. What is considered acceptable in one market may not meet the standards of another. B2B buyers should communicate clearly with suppliers about their quality expectations.

-

Logistical Challenges: Transportation and logistics can impact product quality. Delays or improper handling during shipping can lead to damage. Buyers should work with reliable logistics partners and consider using packaging designed to protect sensitive products during transit.

Conclusion

The manufacturing processes and quality assurance systems in place for locks and latches are vital for ensuring product reliability and safety. By understanding the intricacies of these processes, B2B buyers can make informed decisions when selecting suppliers. Adopting a proactive approach to quality verification, including audits and third-party inspections, will help mitigate risks and establish long-term partnerships that align with their business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘locks and latches’

To streamline the procurement process for locks and latches, this guide offers a structured checklist aimed at helping B2B buyers make informed decisions. By following these steps, you can ensure that you select the right products and suppliers that meet your specific needs.

Step 1: Define Your Technical Specifications

Before diving into the procurement process, clearly outline the technical specifications required for your locks and latches. Consider factors such as material type (e.g., stainless steel, plastic), locking mechanisms (e.g., cam locks, paddle latches), and application environment (e.g., outdoor, industrial). This clarity helps in narrowing down options and communicating effectively with suppliers.

Step 2: Assess Compliance and Standards

Ensure that the locks and latches comply with relevant industry standards and certifications. Look for products that meet ANSI (American National Standards Institute) or ISO (International Organization for Standardization) certifications, which guarantee quality and reliability. Compliance not only enhances safety but also ensures long-term durability and functionality.

Step 3: Evaluate Potential Suppliers

Conduct a thorough evaluation of potential suppliers to gauge their reliability and product quality. Request detailed company profiles, including information on their manufacturing capabilities, quality control processes, and previous projects. Additionally, seek references from other B2B buyers in similar industries or regions to understand their experiences with the supplier.

Step 4: Request Samples for Testing

Before placing a bulk order, always request samples of the locks and latches you are considering. Testing samples allows you to assess the functionality, durability, and overall quality of the products firsthand. Pay close attention to the ease of installation and operation, as these factors can significantly impact your overall satisfaction.

Step 5: Negotiate Terms and Pricing

Engage in negotiations with your shortlisted suppliers to discuss pricing, payment terms, and delivery schedules. Ensure that you understand the total cost of ownership, including shipping and installation costs. A well-negotiated agreement can lead to cost savings and better service terms, enhancing the overall procurement experience.

Step 6: Verify Warranty and After-Sales Support

Before finalizing your purchase, confirm the warranty and after-sales support offered by the supplier. A robust warranty signifies the supplier’s confidence in their products and provides peace of mind regarding future issues. Additionally, inquire about their customer support services, as prompt assistance can be crucial for resolving any post-purchase concerns.

Step 7: Plan for Long-Term Partnerships

Consider establishing a long-term relationship with a reliable supplier who can meet your ongoing needs. A trusted supplier can provide insights into new products and technologies and offer favorable terms for future orders. Building such partnerships enhances your supply chain efficiency and fosters mutual growth.

By following these steps, you can navigate the procurement process for locks and latches with confidence, ensuring that you secure the best products for your specific requirements.

Comprehensive Cost and Pricing Analysis for locks and latches Sourcing

What Are the Key Cost Components in Locks and Latches Manufacturing?

Understanding the cost structure of locks and latches is critical for international B2B buyers. The primary cost components include:

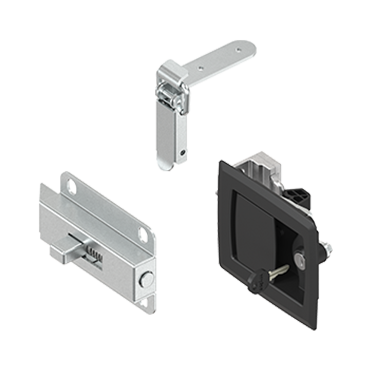

Illustrative image related to locks and latches

-

Materials: The choice of materials significantly impacts the overall cost. High-quality materials like stainless steel offer durability and corrosion resistance but come at a higher price. Plastic alternatives may reduce costs but could compromise longevity and security.

-

Labor: Labor costs vary by region and manufacturing processes. Skilled labor in developed countries may lead to higher production costs compared to lower-wage regions, but quality assurance can justify the expense.

-

Manufacturing Overhead: This includes costs associated with utilities, rent, and equipment maintenance. Efficient production processes can help minimize these expenses, impacting the final pricing.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. These costs are amortized over production runs, meaning higher volume orders can result in lower per-unit costs.

-

Quality Control (QC): Ensuring product reliability and safety is non-negotiable in the locks and latches industry. Effective QC processes add to production costs but are essential for maintaining market reputation.

-

Logistics: Shipping costs vary based on distance, weight, and delivery methods. For international buyers, understanding Incoterms is crucial to determine who bears the shipping costs and risks.

-

Margin: Manufacturers typically mark up prices to cover their costs and generate profit. This margin can fluctuate based on market demand, competition, and the perceived value of the product.

How Do Price Influencers Affect Locks and Latches Sourcing?

Several factors can significantly influence the pricing of locks and latches:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often yield better pricing due to economies of scale. Negotiating favorable terms for bulk purchases can lead to substantial savings.

-

Specifications and Customization: Customized products may come with higher costs due to unique tooling and material requirements. Buyers should evaluate whether customization aligns with their needs and budget.

-

Material Choices: Premium materials not only increase costs but also enhance product performance. Buyers must weigh the benefits of higher-quality materials against their budget constraints.

-

Quality and Certifications: Products that meet specific quality standards or certifications may carry a higher price tag. However, they can also offer assurance of reliability and compliance with industry regulations.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with a track record of quality may charge more, but their reliability can reduce overall costs related to returns and replacements.

-

Incoterms: Understanding the terms of shipping is crucial. Different Incoterms (e.g., FOB, CIF) can affect the total landed cost, including shipping and insurance, which are essential for accurate budgeting.

What Are the Best Negotiation Strategies for International Buyers?

For B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to better pricing and terms:

-

Understand Total Cost of Ownership (TCO): Evaluate the long-term costs associated with a product, including maintenance and replacement, rather than focusing solely on the purchase price. This perspective can justify a higher initial investment if the product offers greater longevity.

-

Leverage Market Research: Knowledge of market prices and competitor offerings empowers buyers during negotiations. This information can help secure more favorable terms.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better pricing and priority treatment in production schedules. Long-term partnerships often yield mutual benefits.

-

Be Open to Alternative Solutions: If a supplier cannot meet your desired price, be willing to explore alternative products or materials that meet your specifications at a lower cost.

-

Clarify Payment Terms: Negotiating favorable payment terms can help manage cash flow and reduce financial strain, especially for large orders.

What Should International Buyers Keep in Mind Regarding Pricing Nuances?

International buyers must navigate various pricing nuances that can affect sourcing decisions:

-

Currency Fluctuations: Exchange rate variations can impact pricing, especially when dealing with suppliers in different currencies. Buyers should consider locking in exchange rates when possible.

-

Tariffs and Duties: Import duties can add to the total cost of products sourced internationally. Understanding these costs upfront is crucial for accurate budgeting.

-

Cultural Differences in Negotiation: Different cultures may have unique approaches to business negotiations. Being aware of these differences can facilitate smoother interactions and better outcomes.

Disclaimer on Indicative Prices

While indicative prices can provide a general sense of market trends, they are subject to change based on various factors, including market demand, supplier pricing strategies, and geopolitical influences. Buyers are encouraged to conduct thorough research and engage directly with suppliers for the most accurate pricing information.

Alternatives Analysis: Comparing locks and latches With Other Solutions

Exploring Alternatives to Locks and Latches: What Are Your Options?

When it comes to securing assets, businesses often rely on locks and latches. However, there are alternative solutions that may better suit specific needs or environments. This section compares locks and latches against two viable alternatives: electronic access control systems and biometric security solutions. Each option has its own set of advantages and challenges, which can significantly impact decision-making for international B2B buyers.

| Comparison Aspect | Locks And Latches | Electronic Access Control Systems | Biometric Security Solutions |

|---|---|---|---|

| Performance | Reliable physical security | High-level security with remote access | High accuracy, unique identification |

| Cost | Generally low cost | Moderate to high initial investment | Higher cost due to technology and installation |

| Ease of Implementation | Simple installation | Requires technical setup and integration | Complex installation and training needed |

| Maintenance | Low maintenance required | Regular software updates needed | Maintenance of devices and software |

| Best Use Case | Residential and commercial gates | Offices, secure facilities, remote access points | High-security environments, sensitive data areas |

What Are the Pros and Cons of Electronic Access Control Systems?

Electronic access control systems offer a modern approach to security, allowing users to control access remotely through keypads, card readers, or mobile apps. One of the main advantages is the flexibility in granting and revoking access, which is invaluable for businesses that experience high staff turnover or need to manage access for contractors. However, these systems can require a significant initial investment and ongoing maintenance costs, including software updates and potential repairs. They may also be susceptible to hacking if not properly secured.

How Do Biometric Security Solutions Work and What Are Their Benefits?

Biometric security solutions utilize unique physical characteristics, such as fingerprints or facial recognition, to grant access. The primary advantage of this technology is its accuracy; it significantly reduces the risk of unauthorized access since it relies on inherent traits. Biometric systems can be particularly beneficial in high-security environments, such as data centers or laboratories. On the downside, these solutions can be expensive to implement and maintain. Additionally, they require user training and may face challenges in high-traffic areas where quick access is needed.

Illustrative image related to locks and latches

How Should B2B Buyers Choose the Right Security Solution?

Choosing the right security solution involves carefully evaluating the specific requirements of your business environment. Factors such as the level of security needed, budget constraints, ease of implementation, and maintenance capabilities should all be considered. For instance, businesses requiring quick access for multiple users might favor electronic access control systems, while those prioritizing high-security measures may opt for biometric solutions. Ultimately, understanding the unique needs of your organization will guide you in selecting the most effective security method.

Essential Technical Properties and Trade Terminology for locks and latches

What Are the Key Technical Properties of Locks and Latches?

Understanding the essential technical properties of locks and latches is crucial for B2B buyers, particularly those sourcing products for specific applications. Here are some critical specifications that you should consider:

-

Material Grade

Locks and latches are commonly made from various materials, including stainless steel, brass, and high-grade plastics. The material grade directly impacts durability, corrosion resistance, and overall performance. For instance, stainless steel (such as AISI 304 or AISI 316) offers superior corrosion resistance, making it ideal for outdoor or humid environments. Choosing the right material ensures longevity and reliability, reducing replacement costs. -

Security Rating

Security ratings, often defined by industry standards like ANSI/BHMA, provide insights into the lock’s resistance to forced entry and tampering. Ratings range from Grade 1 (highest security) to Grade 3 (basic security). For B2B buyers, selecting a lock with an appropriate security rating is essential to meet specific regulatory or operational security needs, particularly in high-risk sectors like finance or data protection. -

Tolerance Levels

Tolerance refers to the allowable variation in dimensions during manufacturing. For locks and latches, tight tolerances ensure proper fit and function, which are crucial for operational efficiency. Poor tolerance can lead to misalignment, security vulnerabilities, and increased wear over time. In industrial applications, precise tolerances can enhance equipment reliability and operational safety. -

Installation Type

Locks and latches can be surface-mounted, mortised, or integrated into the design of the door or gate. Understanding the installation type is vital for compatibility with existing infrastructure. B2B buyers should consider ease of installation and potential retrofit requirements, which can affect project timelines and costs. -

Load Capacity

The load capacity indicates how much weight a latch or lock can effectively handle without compromising performance. This specification is particularly important in commercial or industrial settings where doors or gates may be subjected to heavy use. Selecting a product with the right load capacity ensures operational efficiency and minimizes the risk of mechanical failure. -

Environmental Resistance

Locks and latches may be exposed to various environmental conditions, such as moisture, extreme temperatures, or chemicals. Environmental resistance specifications detail how well a product can withstand these conditions, impacting its lifespan and functionality. For buyers in diverse climates, selecting products with adequate environmental resistance is essential for ensuring long-term performance.

What Are Common Trade Terms Relevant to Locks and Latches?

Familiarity with trade terminology can enhance communication and negotiations between B2B buyers and suppliers. Here are several common terms you should know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the locks and latches industry, OEMs often create specialized products tailored to specific needs, enabling businesses to offer unique solutions under their brand. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management, as it can affect cash flow and storage space for businesses. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. B2B buyers use RFQs to gather competitive pricing and assess supplier capabilities, making it a vital step in the procurement process. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC). They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for international transactions, particularly for businesses operating in regions like Africa and South America. -

Lead Time

Lead time refers to the amount of time it takes for an order to be fulfilled from the moment it is placed until the product is delivered. Understanding lead times is crucial for project planning and inventory management, especially in industries where timely delivery is critical. -

Certification Standards

Certification standards, such as ISO or ANSI/BHMA, ensure that products meet specific quality and safety criteria. Familiarity with these standards helps buyers select reliable products and ensures compliance with industry regulations.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions that enhance operational efficiency and security.

Navigating Market Dynamics and Sourcing Trends in the locks and latches Sector

What Are the Key Market Dynamics and Trends in the Locks and Latches Sector?

The locks and latches market is experiencing significant evolution driven by various global factors. One of the primary drivers is the increasing emphasis on security across residential, commercial, and industrial sectors. This heightened demand for security solutions is particularly pronounced in regions like Africa and the Middle East, where urbanization and infrastructural development are accelerating. In South America and Europe, regulatory frameworks around safety and security are also influencing market dynamics, pushing companies to invest in advanced locking technologies.

Emerging technologies such as smart locks and digital access control systems are reshaping sourcing trends. International B2B buyers are increasingly looking for innovative solutions that offer enhanced security features, remote access capabilities, and integration with smart home systems. Furthermore, the rise of e-commerce has led to a surge in demand for secure shipping and delivery solutions, prompting manufacturers to diversify their product offerings. Buyers should be aware of the growing importance of cybersecurity in locking mechanisms, as digital solutions can be vulnerable to breaches without proper safeguards.

The market is also witnessing a shift toward customized solutions to meet specific client needs, whether for residential applications or specialized industrial use. This trend is particularly relevant for buyers in developing regions, where tailored solutions can address unique security challenges. As competition intensifies, manufacturers are focusing on quality, reliability, and performance, ensuring that their products meet or exceed industry standards.

How Is Sustainability Influencing B2B Sourcing in the Locks and Latches Sector?

Sustainability is becoming a central theme in the locks and latches sector, compelling buyers to prioritize environmentally friendly products and ethical sourcing practices. The environmental impact of manufacturing processes and materials used in locks and latches is under scrutiny, prompting companies to adopt greener alternatives. B2B buyers are increasingly seeking products made from recycled materials or those that comply with environmental standards, which can significantly reduce the carbon footprint.

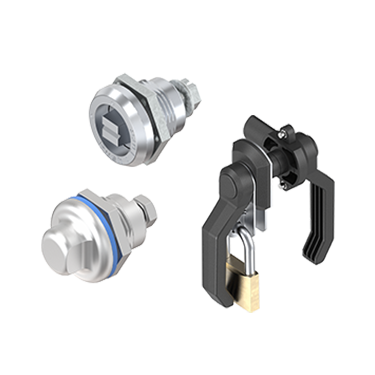

Illustrative image related to locks and latches

Ethical supply chains are also gaining importance, particularly in regions such as Europe and North America, where consumers demand transparency and accountability from manufacturers. Buyers are encouraged to assess their suppliers not only on product quality but also on their commitment to sustainable practices. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) can serve as indicators of a manufacturer’s dedication to sustainability.

Additionally, the demand for ‘green’ materials, such as biodegradable plastics and sustainably sourced metals, is on the rise. Companies like EMKA and KIPP USA are leading the charge by offering products that meet high environmental standards. By prioritizing sustainability, B2B buyers can not only meet regulatory requirements but also enhance their brand reputation in an increasingly eco-conscious market.

How Have Locks and Latches Evolved Over Time?

The evolution of locks and latches reflects broader technological advancements and changing security needs. Historically, locking mechanisms were simple devices, primarily made from wood and metal, serving basic functions of securing entry points. The Industrial Revolution marked a significant turning point, introducing more complex designs and materials that improved security and durability.

In the 20th century, the advent of electronic locking systems began to reshape the landscape, leading to the development of smart locks and keyless entry systems. Today, the integration of IoT technology has further transformed locks and latches, allowing for remote access and enhanced security features. As a result, B2B buyers are now faced with a diverse array of options, from traditional mechanical locks to advanced digital solutions that cater to a wide range of security needs across various industries.

This historical context is crucial for buyers looking to understand the trajectory of the market and make informed sourcing decisions that align with current trends and future innovations.

Illustrative image related to locks and latches

Frequently Asked Questions (FAQs) for B2B Buyers of locks and latches

-

How do I solve security issues with locks and latches for my business?

To address security concerns, assess your specific needs based on the type of facility and the assets you need to protect. Consider high-security locks, which offer advanced features like pick resistance and drill resistance. Additionally, evaluate latch types such as deadbolts or electronic locks that provide enhanced security. Collaborating with reputable suppliers can also ensure you receive products that meet industry standards and regulations, enhancing your overall security posture. -

What is the best type of lock for commercial applications?

For commercial applications, consider using ANSI Grade 1 or Grade 2 locks, which are recognized for their durability and reliability. Deadbolts are often recommended for exterior doors, while electronic locks provide added convenience and security for high-traffic areas. It’s essential to evaluate your specific requirements, such as access control needs and environmental conditions, before selecting the best lock type for your business. -

How can I ensure the quality of locks and latches from international suppliers?

To ensure quality, conduct thorough research on potential suppliers. Look for certifications like ISO 9001, which indicates adherence to quality management standards. Request samples to evaluate the product’s durability and functionality firsthand. Additionally, consider suppliers with a strong reputation and positive reviews from previous clients, and establish clear quality assurance protocols in your purchase agreement to mitigate risks. -

What customization options are available for locks and latches?

Many manufacturers offer customization options, including specific sizes, finishes, and functionalities to meet your unique requirements. Custom locks can be designed for specialized applications, such as weather resistance for outdoor use or tamper-proof features for heightened security. When sourcing, communicate your needs clearly to suppliers and inquire about their ability to accommodate custom orders and associated lead times. -

What are the typical minimum order quantities (MOQ) for locks and latches?

Minimum order quantities can vary significantly by supplier and product type. Generally, MOQs range from 50 to 500 units for standard items, while custom products may have higher MOQs due to additional manufacturing processes. Always verify the MOQ before placing an order to ensure it aligns with your purchasing capabilities and budget. Suppliers may also offer flexibility for bulk orders or repeat business. -

What payment terms should I expect when sourcing locks and latches internationally?

Payment terms can vary widely among suppliers, but common arrangements include payment upfront, partial payment upon order confirmation, or payment upon delivery. For international transactions, consider using secure payment methods like letters of credit or escrow services to protect your investment. Always clarify payment terms in your contract to avoid misunderstandings and ensure a smooth transaction. -

How do logistics impact the sourcing of locks and latches?

Logistics play a crucial role in the timely delivery of locks and latches. Factors such as shipping methods, lead times, and customs clearance can affect your overall supply chain efficiency. Work closely with suppliers to understand their shipping capabilities and inquire about their experience with international shipments. Establishing a reliable logistics plan can help minimize delays and ensure you receive your products when needed. -

What are the key regulations and standards for locks and latches in international markets?

Understanding regulations is vital when sourcing locks and latches internationally. Different regions may have specific standards, such as EN 12209 in Europe or ANSI/BHMA standards in the U.S. Familiarize yourself with these regulations to ensure compliance and avoid potential legal issues. Consult with suppliers who are knowledgeable about regional standards and can provide certification for their products, ensuring that they meet the necessary safety and performance criteria.

Top 7 Locks And Latches Manufacturers & Suppliers List

1. D&D – Gate Latches and Locks

Domain: gatehardwarecenter.com

Registered: 2017 (8 years)

Introduction: Gate Latches and Locks provide safe and reliable perimeter security. D&D Latches and Locks are top-of-the-line, exceeding industry standards. Available styles include privacy and security latches, child safety latches, pool gate locks, and models for commercial and residential gates. They cater to different gate materials, with options for self-closing and non-self-closing models, keyable locks, a…

2. Hartville Hardware – Door Latches

Domain: hartvillehardware.com

Registered: 2000 (25 years)

Introduction: This company, Hartville Hardware – Door Latches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. KIPP USA – Latches and Locks

Domain: kippusa.com

Registered: 2012 (13 years)

Introduction: Latches, snap locks, slam latches from KIPP USA. Available in metric sizes. Features include manufacturing competence, fast delivery, and excellent service. Located at 4305 N. Roosevelt Rd., Stevensville, MI 49127. Contact: +1 269 932 1100, +1 269 932 1015, [email protected]

4. EMKA – Industrial Locks and Latches

Domain: emka.com

Registered: 1996 (29 years)

Introduction: EMKA offers a wide range of locks and latches specifically designed for industrial cabinets and casing construction. Key product categories include: 1. Quarter Turns and Compression Latches: – Quarter turns with insert, modular options, safety features, and pre-assembled variants. – Compression latches with insert and handle options. – Accessories like cams, rods, and keys. 2. Locks and Latches fo…

5. Ace Hardware – Door Latches

Domain: acehardware.com

Registered: 1995 (30 years)

Introduction: Door latches are used in interior and exterior applications to keep doors closed. Ace Hardware carries a large inventory of latches from brands like National Hardware, Prime-Line, and Larson. Door latches are typically made from metals like stainless steel, zinc, and aluminum, with options for chrome or brass coatings for visibility. Common types of door latches include: Pocket door latches, Door …

6. D&D Technologies – MagnaLatch® Safety Gate Latch

Domain: us.ddtech.com

Registered: 1998 (27 years)

Introduction: D&D Technologies offers a range of gate latches and locks, including the MagnaLatch® Safety Gate Latch, LokkLatch® privacy and security gate latches, T-Latch® toggle latch, and specialist Stainless Steel and Wood Gate latches. The products are designed for child safety, swimming pool safety, and pet safety, and are known for their reliability and key lockability. D&D Technologies utilizes industri…

7. National Hardware – Gate Latches and Locks

Domain: national-hardware.com

Registered: 2019 (6 years)

Introduction: Gate Latches and Locks are essential security hardware for gates, available in various finishes, features, and styles. Options include basic latches and padlock versions.

Strategic Sourcing Conclusion and Outlook for locks and latches

In the ever-evolving landscape of locks and latches, strategic sourcing emerges as a pivotal approach for international B2B buyers. By prioritizing quality, reliability, and innovation, organizations can ensure they meet the diverse security needs across various sectors, from residential to industrial applications. Leveraging advanced materials and technologies not only enhances security but also aligns with sustainability goals, a crucial consideration for modern buyers.

Understanding regional market dynamics is essential. Buyers from Africa, South America, the Middle East, and Europe must consider local regulations, cultural preferences, and economic conditions when sourcing locks and latches. This comprehensive approach not only mitigates risks but also fosters long-term partnerships with suppliers, ensuring a steady supply chain and competitive pricing.

Looking ahead, the demand for customized locking solutions will continue to grow, driven by emerging technologies and heightened security concerns. Now is the time for businesses to evaluate their sourcing strategies and embrace innovative solutions that cater to evolving market needs. Engage with suppliers who offer flexibility and adaptability, and position your organization to thrive in this dynamic environment. Take the next step in securing your operations—explore strategic sourcing opportunities today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to locks and latches

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.