Everything You Need to Know About Level Switch Sourcing in 2025

Introduction: Navigating the Global Market for level switch

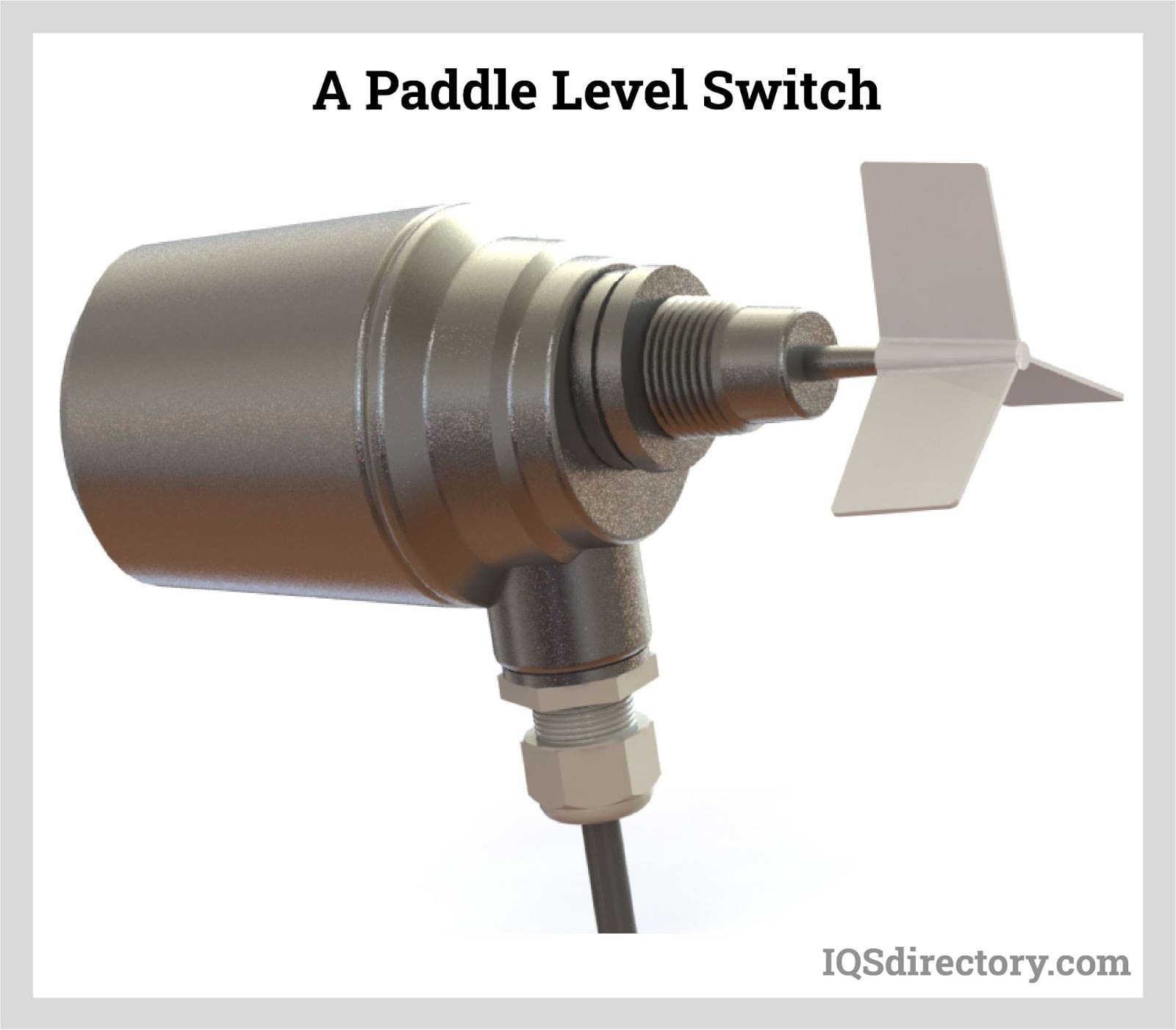

As global industries increasingly rely on precise level measurement for operational efficiency, sourcing the right level switch can pose significant challenges for international B2B buyers. With a diverse array of options available—ranging from float and displacer switches to advanced optical and ultrasonic technologies—making informed decisions is crucial. This guide delves deep into the world of level switches, covering essential topics such as types of switches, their applications across various industries, and the importance of rigorous supplier vetting.

Buyers from regions such as Africa, South America, the Middle East, and Europe will find tailored insights that address their unique market dynamics and requirements. The guide also explores cost considerations, industry certifications, and warranty offerings, enabling stakeholders to evaluate products comprehensively. By providing a structured approach to understanding the complexities of level switch procurement, this resource empowers buyers to navigate the global market with confidence and make purchasing decisions that align with their operational goals.

Whether you are in the petrochemical, manufacturing, or power generation sectors, this guide will equip you with the knowledge needed to select reliable level switches that enhance productivity and ensure safety in your processes.

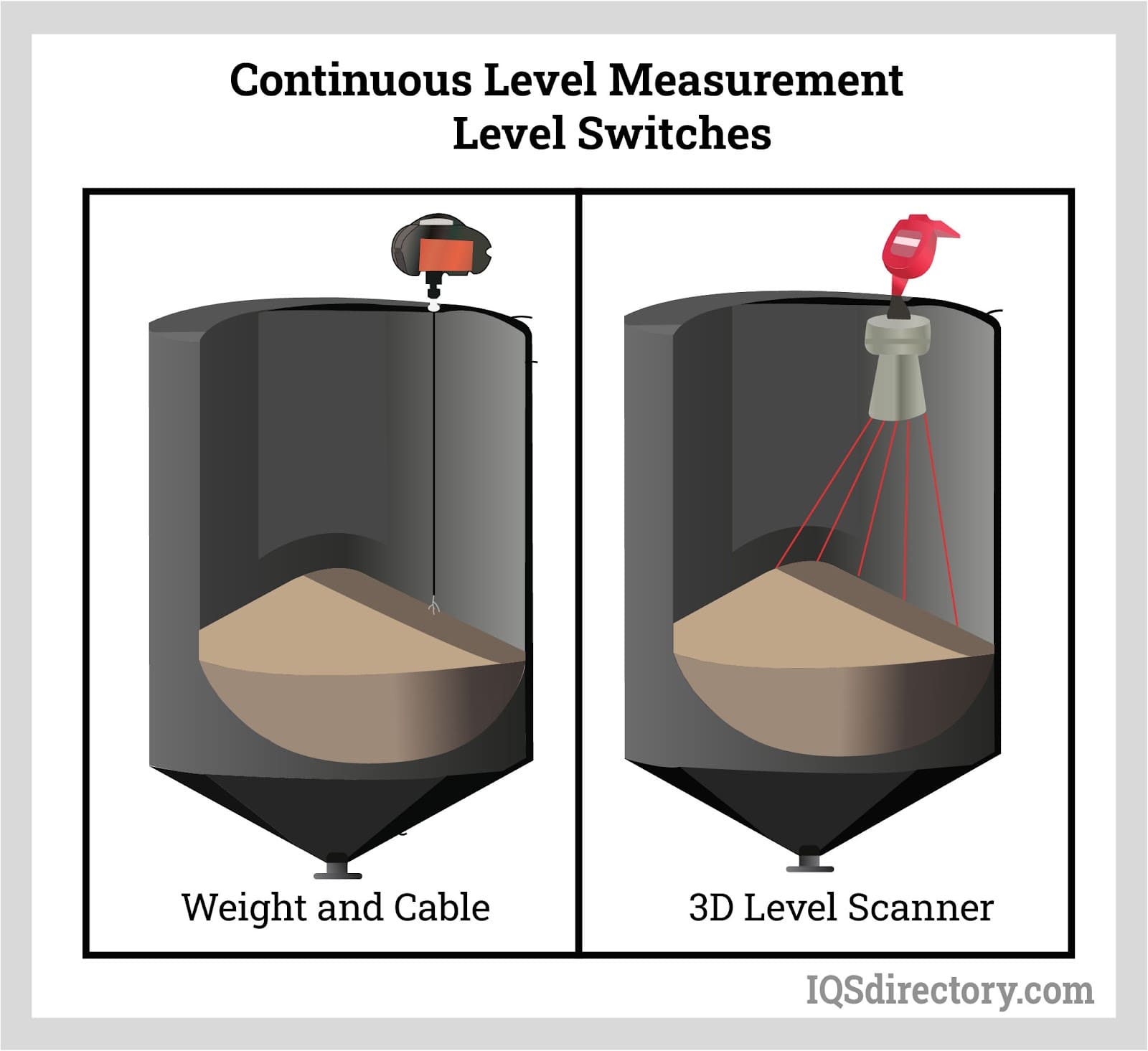

Understanding level switch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Float Level Switch | Utilizes buoyancy to detect liquid levels; available in top and side-mounted configurations. | Oil & gas, water treatment, manufacturing | Pros: Simple design, reliable in various conditions. Cons: Limited to specific media types. |

| Optical Level Switch | Non-contact technology using light refraction; suitable for low-viscosity liquids. | Chemical processing, food & beverage | Pros: High sensitivity, no moving parts. Cons: May not work well with opaque or high-viscosity liquids. |

| Pneumatic Level Switch | Operates using air pressure; available in bleed and non-bleed options. | Industrial automation, HVAC systems | Pros: Versatile, suitable for high-pressure applications. Cons: Requires air supply, potential for leaks. |

| Ultrasonic Level Switch | Uses sound waves to measure levels; suitable for various media types. | Wastewater treatment, bulk storage | Pros: Non-invasive, accurate over long distances. Cons: Can be affected by temperature and vapor. |

| Displacer Level Switch | Measures level based on buoyancy of a displacer; suitable for high-density liquids. | Petrochemical, power generation | Pros: Accurate, reliable in harsh conditions. Cons: Requires more space for installation. |

What Are the Key Characteristics of Float Level Switches?

Float level switches are among the most common types used in various industries. Their operation is based on the buoyancy principle, where a floating device rises or falls with the liquid level. They can be configured as top-mounted or side-mounted units, making them versatile for different tank designs. B2B buyers should consider the environmental conditions of their application, as these switches are particularly effective in clean liquids but may struggle in turbulent or viscous media.

How Do Optical Level Switches Function and Where Are They Used?

Optical level switches operate by sensing changes in light refraction caused by the presence of liquid. They are ideal for low-viscosity, clear liquids and are commonly used in the chemical processing and food and beverage industries. B2B buyers looking for high sensitivity and a non-invasive solution will find these switches advantageous. However, they may not be suitable for opaque or high-viscosity liquids, which could limit their application in certain scenarios.

What Are the Advantages of Pneumatic Level Switches?

Pneumatic level switches utilize air pressure to detect liquid levels, with options for bleed and non-bleed configurations. These switches are particularly beneficial in industrial automation and HVAC systems, where high pressure is often required. Buyers should consider their facility’s air supply capabilities, as these switches need a constant air source. While they offer versatility, potential air leaks can pose maintenance challenges.

Why Choose Ultrasonic Level Switches for Your Applications?

Ultrasonic level switches measure liquid levels using sound waves, making them a non-invasive option suitable for a wide range of media types. They are often employed in wastewater treatment and bulk storage applications. B2B buyers should note that while these switches provide accurate measurements over long distances, their performance can be impacted by temperature fluctuations and vapor presence, which may require additional considerations in specific environments.

What Makes Displacer Level Switches a Reliable Choice?

Displacer level switches operate based on the buoyancy of a displacer immersed in the liquid. They are particularly effective for high-density liquids and are commonly found in the petrochemical and power generation sectors. Buyers should be aware that while these switches offer high accuracy and reliability in harsh conditions, they do require more installation space compared to other types.

Key Industrial Applications of level switch

| Industry/Sector | Specific Application of Level Switch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Monitoring liquid levels in storage tanks | Prevents overflows and spills, ensuring safety and compliance | High-pressure resistance, certifications for hazardous environments |

| Water Treatment | Controlling water levels in treatment plants | Enhances operational efficiency and water quality control | Corrosion resistance, compatibility with various liquids |

| Food and Beverage | Ensuring proper ingredient levels in processing | Maintains product quality and reduces waste | Sanitary design, compliance with food safety regulations |

| Chemical Manufacturing | Managing chemical levels in reactors and storage | Improves safety and reduces the risk of chemical spills | Material compatibility, ATEX and other relevant certifications |

| Pharmaceuticals | Monitoring levels in drug formulation processes | Ensures accurate dosing and quality control | Precision, compliance with pharmaceutical standards |

How is a Level Switch Used in the Oil and Gas Industry?

In the oil and gas sector, level switches are crucial for monitoring liquid levels in storage tanks. These devices help prevent overflows and spills, which can lead to environmental hazards and costly fines. Buyers in this sector should prioritize switches that can withstand high pressures and are certified for hazardous environments, ensuring both safety and compliance with regulatory standards.

What Role Do Level Switches Play in Water Treatment Facilities?

Level switches are extensively used in water treatment plants to control the levels of water in various tanks and reservoirs. By maintaining the optimal water level, these devices enhance operational efficiency and ensure high water quality. International buyers should consider sourcing switches that offer corrosion resistance and compatibility with different types of water, including potable and wastewater.

Why Are Level Switches Important in the Food and Beverage Industry?

In the food and beverage industry, level switches are essential for ensuring that ingredient levels are maintained during processing. This helps in maintaining product quality and minimizing waste. Buyers should look for switches with a sanitary design that comply with food safety regulations, ensuring that the materials used do not contaminate food products.

How Do Level Switches Enhance Chemical Manufacturing Processes?

In chemical manufacturing, level switches manage chemical levels within reactors and storage tanks, significantly improving safety by reducing the risk of spills and leaks. Buyers must focus on switches made from materials compatible with various chemicals and look for ATEX certifications, particularly when dealing with flammable substances.

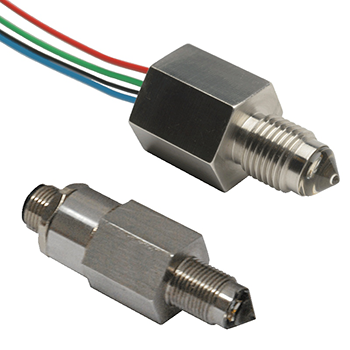

Illustrative image related to level switch

What Benefits Do Level Switches Provide in Pharmaceutical Applications?

In the pharmaceutical industry, level switches are utilized to monitor liquid levels in drug formulation processes. This ensures accurate dosing and compliance with stringent quality control standards. Buyers should seek switches known for their precision and reliability, as well as those that meet the specific regulatory requirements for pharmaceutical manufacturing.

3 Common User Pain Points for ‘level switch’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Level Switch for Specific Applications

The Problem: B2B buyers often face challenges when selecting the appropriate level switch for their unique industrial applications. Factors such as pressure range, temperature limits, and the compatibility of materials can complicate decision-making. For instance, a company in the petrochemical sector may require a switch that can withstand high pressure and extreme temperatures, yet they might not have adequate knowledge of the technical specifications needed for their specific process. This can lead to costly mistakes, such as purchasing equipment that fails to perform as required or, worse, causes operational failures.

The Solution: To effectively select the right level switch, buyers should begin with a thorough assessment of their operational requirements. This includes understanding the specific process conditions such as pressure and temperature ranges, as well as the properties of the media being monitored (e.g., corrosiveness, viscosity). Consulting with manufacturers or suppliers that offer customized solutions can provide valuable insights. For instance, SOR Controls Group offers a range of level switches with various certifications, ensuring they meet stringent industry standards. Engage with a knowledgeable sales engineer to discuss customization options, which can lead to a solution that precisely fits your operational needs.

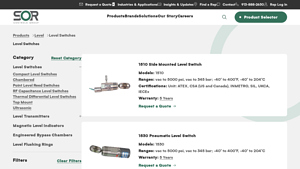

Illustrative image related to level switch

Scenario 2: High Maintenance Costs Due to Equipment Failure

The Problem: Frequent equipment failures and maintenance issues with level switches can significantly increase operational costs for businesses. This is particularly true in industries that rely on continuous processes, such as water treatment or chemical manufacturing. A malfunctioning level switch can lead to unexpected downtime, regulatory compliance issues, and even safety hazards. B2B buyers may struggle with selecting durable products that can withstand harsh conditions, ultimately resulting in high maintenance expenses and reduced productivity.

The Solution: To minimize maintenance costs and equipment failures, it is crucial to invest in high-quality level switches designed for rugged environments. Selecting switches made from durable materials, such as stainless steel, can enhance longevity and resistance to corrosion. Additionally, opting for devices with robust warranties, such as the five-year warranty offered by many reputable manufacturers, can provide peace of mind. Regular maintenance should also be part of the operational protocol—implementing a routine check-up schedule can identify wear and tear before they escalate into major issues. Furthermore, considering advanced technologies like self-testing ultrasonic level switches can help ensure reliability and reduce manual inspection efforts.

Scenario 3: Integration Challenges with Existing Systems

The Problem: Many B2B buyers encounter integration challenges when trying to incorporate new level switch technologies into their existing control systems. This is particularly relevant for companies that have legacy systems or utilize a mix of equipment from various manufacturers. Lack of compatibility can lead to operational disruptions, as the new equipment may not communicate effectively with existing systems, hindering data collection and process automation.

The Solution: To address integration challenges, buyers should prioritize level switches that offer compatibility with a wide range of existing control systems. Before purchasing, conduct a comprehensive review of the specifications, including output signals (e.g., NPN, PNP) and communication protocols. Choosing products from manufacturers that provide detailed integration support can ease this transition. For example, KOBOLD’s optical level switches are designed to be easily integrated into various control systems, which can simplify installation and reduce integration time. It may also be beneficial to engage with system integrators who can provide tailored solutions, ensuring that new level switches work seamlessly with legacy equipment, thus optimizing overall operational efficiency.

Strategic Material Selection Guide for level switch

When selecting materials for level switches, it is crucial to consider the specific requirements of the application, including temperature and pressure ratings, corrosion resistance, and compatibility with the media being monitored. Below, we analyze four common materials used in the manufacturing of level switches, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Stainless Steel for Level Switches?

Stainless steel is a widely used material in level switch applications due to its excellent corrosion resistance and high strength. It typically offers temperature ratings up to 1200°F (649°C) and pressure ratings exceeding 5000 psi (345 bar). The material is non-reactive and can withstand harsh environments, making it suitable for industries like petrochemicals and food processing.

Pros & Cons: The durability of stainless steel ensures a long service life, reducing maintenance costs. However, it can be more expensive than other materials, which may impact the overall cost of the switch. Additionally, manufacturing complexity can increase with the need for specialized machining.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive liquids, making it a versatile choice for various applications.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and IECEx, particularly in regions with strict regulations like Europe and the Middle East.

How Does Polypropylene Perform in Level Switch Applications?

Polypropylene is a thermoplastic material known for its lightweight and chemical resistance properties. It is typically rated for temperatures up to 176°F (80°C) and pressures around 145 psi (10 bar). This material is ideal for applications involving low-viscosity, non-coating liquids.

Pros & Cons: The primary advantage of polypropylene is its low cost and ease of manufacturing, which can lead to lower overall costs for level switches. However, its lower temperature and pressure ratings limit its use in more demanding environments.

Impact on Application: Polypropylene is particularly suited for applications involving water or mild chemicals, but it may not be suitable for high-pressure or high-temperature environments.

Illustrative image related to level switch

Considerations for International Buyers: Buyers in regions like Africa and South America should consider the availability of polypropylene components and ensure that they meet local regulatory standards.

What Are the Benefits of Using Brass in Level Switches?

Brass is another material used in level switches, particularly for its good machinability and moderate corrosion resistance. It typically operates effectively at temperatures up to 400°F (204°C) and pressures around 1500 psi (103 bar).

Pros & Cons: Brass is durable and has a lower cost compared to stainless steel, making it an attractive option for cost-sensitive applications. However, its susceptibility to corrosion in certain environments can be a drawback, especially when exposed to aggressive chemicals.

Impact on Application: Brass is suitable for applications involving water or non-corrosive liquids but may not be ideal for harsh environments.

Considerations for International Buyers: Compliance with standards such as ASTM and local regulations is essential, especially in regions with stringent environmental controls.

How Does PVC Compare as a Material for Level Switches?

PVC (Polyvinyl Chloride) is a versatile plastic material that offers good chemical resistance and is lightweight. It typically operates at temperatures up to 140°F (60°C) and pressures around 150 psi (10 bar).

Illustrative image related to level switch

Pros & Cons: The advantages of PVC include its low cost and ease of installation. However, its limited temperature and pressure ratings restrict its use in more demanding applications.

Impact on Application: PVC is commonly used in applications involving water and mild chemicals, making it suitable for less demanding environments.

Considerations for International Buyers: Buyers should verify that PVC components meet local compliance standards, especially in regions with strict safety regulations.

Summary Table of Material Selection for Level Switches

| Material | Typical Use Case for level switch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Harsh environments, petrochemical industry | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Polypropylene | Low-viscosity, non-coating liquids | Low cost, lightweight | Limited temperature/pressure ratings | Low |

| Brass | Water, non-corrosive liquids | Good machinability, moderate cost | Susceptible to corrosion in harsh environments | Medium |

| PVC | Water, mild chemicals | Low cost, easy installation | Limited temperature/pressure ratings | Low |

This material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for level switch

What Are the Key Stages in the Manufacturing Process of Level Switches?

The manufacturing process of level switches typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is designed to ensure that the final product meets the stringent requirements of various industrial applications.

Material Preparation: The first step involves selecting high-quality materials that can withstand harsh operating conditions. Common materials include stainless steel, which offers excellent corrosion resistance, and specialized alloys for extreme temperatures. The materials are cut to size and treated to remove any impurities that could affect performance.

Forming: After preparation, the materials undergo forming processes such as machining, welding, or molding. For instance, components like float mechanisms may be machined to precise specifications to ensure accurate level detection. For optical level switches, the lens must be formed using materials that facilitate light transmission while maintaining durability.

Assembly: In this stage, various components are assembled, often in a cleanroom environment to prevent contamination. This includes the integration of electrical components, sensors, and mechanical parts. Precision is critical, as any misalignment can lead to performance issues. Automated assembly techniques may be employed to enhance consistency and reduce human error.

Finishing: The final stage involves surface treatments and coatings that enhance the durability and performance of the level switches. This can include anodizing, passivation, or applying protective coatings. Final inspections are conducted to ensure that all specifications are met before the products are packaged for shipment.

How Is Quality Assurance Implemented in Level Switch Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process for level switches, ensuring that each unit performs reliably under specified conditions. This process adheres to various international standards and industry-specific certifications.

International Standards: Most reputable manufacturers comply with ISO 9001, which outlines criteria for a quality management system. This certification signifies that a company consistently provides products that meet customer and regulatory requirements. Additionally, certifications like CE mark and API standards are critical for products used in specific industries, ensuring compliance with safety and performance criteria.

Quality Control Checkpoints: Several checkpoints are established throughout the manufacturing process to maintain quality. Incoming Quality Control (IQC) checks the materials upon arrival, ensuring they meet the necessary specifications. In-Process Quality Control (IPQC) monitors the manufacturing process, identifying defects or deviations in real-time. Finally, Final Quality Control (FQC) involves comprehensive testing of the finished product to verify performance and reliability before shipment.

Illustrative image related to level switch

What Testing Methods Are Commonly Used for Level Switches?

Testing is a vital component of quality assurance for level switches, and several methods are employed to ensure that each unit meets performance standards.

Functional Testing: This involves testing the level switch in conditions that simulate actual operating environments. For example, float switches may be tested in liquid tanks to verify their response to changing levels.

Pressure and Temperature Testing: Given that level switches often operate under extreme conditions, manufacturers conduct pressure and temperature tests to validate their performance limits. This includes exposing switches to maximum pressure conditions and extreme temperatures to ensure they function correctly.

Electrical Testing: For electronic level switches, electrical performance is tested to verify the functionality of sensors and output signals. This includes checking for proper signal transmission and response times.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must ensure that their suppliers adhere to rigorous quality control practices. Here are several strategies to verify supplier QC:

Supplier Audits: Conducting on-site audits of potential suppliers can provide insight into their manufacturing processes and quality control measures. During these audits, buyers can assess compliance with international standards and the effectiveness of quality control systems.

Reviewing Quality Reports: Requesting detailed quality reports, including testing results and compliance certifications, can help buyers evaluate a supplier’s commitment to quality. These documents should provide transparency regarding the supplier’s manufacturing processes and quality assurance practices.

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes. These inspections can occur at various stages of production and provide additional assurance of product quality.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, must navigate specific quality control nuances when sourcing level switches.

Cultural and Regulatory Differences: Different regions may have varying regulations and standards for industrial equipment. Buyers should familiarize themselves with these standards to ensure compliance. For example, equipment sold in Europe must meet CE marking requirements, while products in the Middle East may need to comply with local safety regulations.

Supply Chain Considerations: Understanding the supply chain dynamics is crucial, as logistics can affect product quality. Delays in shipping or handling can compromise the integrity of sensitive equipment. Buyers should work closely with suppliers to establish reliable shipping methods and timelines.

Communication and Documentation: Clear communication regarding quality expectations is essential. Buyers should ensure that suppliers provide all necessary documentation, including certifications, testing reports, and compliance statements. This documentation not only assures quality but also facilitates smoother transactions and reduces the risk of disputes.

Illustrative image related to level switch

Conclusion: Ensuring Quality in Level Switch Manufacturing

For B2B buyers, understanding the manufacturing processes and quality assurance practices for level switches is vital for making informed purchasing decisions. By focusing on material preparation, forming, assembly, finishing, and rigorous quality control measures, buyers can ensure that they select reliable suppliers that meet their operational needs. Engaging in supplier audits, reviewing quality reports, and being aware of international standards can further enhance the procurement process, ensuring that the level switches perform reliably in demanding industrial applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘level switch’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring level switches, essential components for monitoring and controlling liquid levels in various industrial applications. A structured approach will ensure you select the right product that meets your operational needs while minimizing risks and maximizing efficiency.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements for your level switch. Consider factors such as the medium being monitored (liquid type), operating pressure and temperature ranges, and installation type (top-mounted, side-mounted, etc.). This step is crucial as it directly influences the performance and longevity of the switch in your specific application.

- Medium Characteristics: Ensure compatibility with the chemical composition and viscosity of the liquid.

- Environmental Conditions: Consider the temperature extremes and pressure levels the switch will be subjected to.

Step 2: Research Different Types of Level Switches

Familiarize yourself with the various types of level switches available in the market, such as float, optical, and ultrasonic switches. Each type has its unique advantages depending on the application.

- Float Switches: Ideal for a wide range of applications, including harsh environments.

- Optical Switches: Best for non-contact detection and clear liquids.

Step 3: Evaluate Supplier Certifications

Prioritize suppliers that possess relevant industry certifications, such as ATEX, CSA, or SIL. These certifications demonstrate compliance with safety and quality standards, which is particularly important in regions with stringent regulations.

- Quality Assurance: Certifications assure you of the product’s reliability and safety.

- Geographic Compliance: Ensure the certifications are recognized in your region of operation.

Step 4: Assess Warranty and Support Options

Investigate the warranty terms offered by suppliers as this reflects their confidence in their products. A robust warranty, typically ranging from 3 to 5 years, can mitigate risks associated with potential failures.

- Customer Support: Check if the supplier offers technical support and quick response times for any operational issues.

- Return Policy: Understand the terms for product returns or exchanges in case of non-compliance with specifications.

Step 5: Request Samples or Demonstrations

Whenever possible, request samples or live demonstrations of the level switches. This allows you to evaluate the product’s performance in a controlled environment relevant to your operations.

- Performance Testing: Use the opportunity to test the switch under actual working conditions.

- Installation Ease: Assess the installation process and compatibility with your existing systems.

Step 6: Compare Pricing and Total Cost of Ownership

Gather quotes from multiple suppliers and compare not only the initial purchase price but also the total cost of ownership. Consider factors such as installation costs, maintenance expenses, and the expected lifespan of the switch.

Illustrative image related to level switch

- Long-term Value: A cheaper initial price may not always equate to lower overall costs if maintenance or failure rates are high.

- Bulk Purchase Discounts: Inquire about volume discounts if you plan on purchasing multiple units.

Step 7: Finalize Your Supplier Selection

After thorough evaluation, select a supplier that meets your criteria and aligns with your business goals. Establish clear terms of agreement, including delivery timelines and payment conditions, to ensure a smooth procurement process.

- Contractual Clarity: Ensure all specifications, warranties, and service agreements are documented.

- Ongoing Relationship: Consider establishing a long-term partnership for future needs and better pricing.

By following these steps, you can effectively navigate the sourcing process for level switches, ensuring you make an informed and strategic purchase decision.

Comprehensive Cost and Pricing Analysis for level switch Sourcing

What Are the Key Cost Components in Level Switch Manufacturing?

Understanding the cost structure of level switches is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials greatly influences cost. High-quality stainless steel and specialized polymers for sensors can increase initial expenses but enhance durability and performance. Cost-effective options may include plastic or lower-grade metals, but these can compromise reliability.

-

Labor: Labor costs vary significantly based on geographic location. Regions with lower labor costs can provide competitive pricing, but this may come at the expense of skilled workmanship, which is essential for producing reliable level switches.

-

Manufacturing Overhead: This encompasses operational costs including utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can reduce overhead, positively impacting pricing.

-

Tooling: Custom tooling for unique designs or specifications can be a significant upfront investment. However, this cost can be amortized over larger production runs, making it essential for buyers to consider the long-term benefits of customized solutions.

-

Quality Control: Rigorous QC processes ensure product reliability and compliance with certifications like ATEX and IECEx, which are vital for industries such as oil and gas, food processing, and pharmaceuticals. These processes add to the cost but are critical for maintaining safety and performance standards.

-

Logistics: Shipping and handling costs can vary based on the supplier’s location and the chosen Incoterms. Efficient logistics planning can minimize these costs, especially for international shipments.

-

Margin: Suppliers typically apply a margin based on their operational costs and market demand. Understanding the competitive landscape can help buyers gauge whether pricing is fair.

How Do Price Influencers Affect Level Switch Sourcing?

Several factors influence the pricing of level switches, making it vital for buyers to be informed:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Higher volumes often lead to lower per-unit costs due to economies of scale. Negotiating favorable terms can reduce overall expenditures.

-

Specifications/Customization: Custom designs tailored to specific applications may incur additional costs. Buyers should weigh the benefits of customization against their budget constraints.

-

Materials: As mentioned, the choice of materials directly impacts cost. Opting for specialized materials can enhance performance but will also elevate prices.

-

Quality and Certifications: Products that meet international standards or have specific certifications typically command higher prices due to the assurance of quality and compliance.

-

Supplier Factors: Supplier reputation, reliability, and historical performance can influence pricing. Established suppliers with a track record of quality may charge a premium, but they often provide better long-term value.

-

Incoterms: Understanding Incoterms is crucial for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect total landed costs, influencing overall pricing.

What Buyer Tips Can Help Optimize Costs in Level Switch Procurement?

To navigate the complexities of sourcing level switches effectively, consider the following strategies:

-

Negotiation: Engage suppliers in discussions regarding pricing and terms. Leverage volume purchases to negotiate lower prices or favorable payment terms.

-

Cost-Efficiency: Analyze the total cost of ownership (TCO), which includes purchase price, maintenance, and operational costs over the product’s lifecycle. A higher initial investment may lead to lower TCO if the product offers superior performance and reliability.

-

Pricing Nuances for International Buyers: Understand local market conditions and currency fluctuations that may impact pricing. Building relationships with local suppliers can also provide insights into more favorable terms.

-

Market Research: Conduct thorough research on multiple suppliers to compare prices and terms. This not only aids in negotiation but also helps identify the best value propositions.

-

Disclaimer for Indicative Prices: Be aware that prices can fluctuate based on market dynamics, supplier changes, and material costs. Always request updated quotes and consider the potential for price changes in long-term contracts.

By understanding these dynamics, international B2B buyers can make informed decisions that optimize their procurement processes for level switches, ensuring they achieve the best value and reliability for their applications.

Alternatives Analysis: Comparing level switch With Other Solutions

Exploring Alternatives to Level Switches for Liquid Level Management

In the realm of industrial automation, selecting the right technology for liquid level management is crucial for operational efficiency. While level switches are a popular choice due to their reliability and versatility, various alternative solutions can achieve similar objectives. This section explores these alternatives, comparing their performance, costs, ease of implementation, maintenance requirements, and best use cases.

Comparison Table of Level Switch and Alternatives

| Comparison Aspect | Level Switch | Ultrasonic Level Sensors | Optical Level Sensors |

|---|---|---|---|

| Performance | Reliable and rugged; works in harsh conditions | Non-contact measurement; effective for varying media | High sensitivity; precise detection of small level changes |

| Cost | Moderate to high initial investment | Generally lower initial cost | Typically lower initial cost |

| Ease of Implementation | Requires mechanical installation; moderate complexity | Simple installation; minimal calibration | Easy to integrate; no moving parts |

| Maintenance | Low maintenance; needs periodic checks | Low maintenance; robust design | Minimal maintenance; self-cleaning features in some models |

| Best Use Case | Ideal for high-pressure environments | Suitable for bulk storage tanks, liquids with varying densities | Best for clear, low-viscosity liquids |

Ultrasonic Level Sensors: Pros and Cons

Ultrasonic level sensors utilize sound waves to measure liquid levels without direct contact with the media. Their non-invasive nature makes them suitable for various applications, especially in tanks where contact with the liquid is not feasible. Pros include lower installation costs and the ability to measure in challenging environments. However, they can be less accurate in conditions with foam or vapor, which can interfere with the ultrasonic signal. Additionally, they may not perform well in high-temperature or high-pressure applications compared to traditional level switches.

Optical Level Sensors: Pros and Cons

Optical level sensors operate by detecting changes in light refraction when a liquid comes into contact with the sensor. These sensors are known for their high sensitivity and can detect small changes in liquid levels, making them ideal for precise applications. They are particularly effective for clear, low-viscosity liquids and require minimal maintenance due to their lack of moving parts. However, optical sensors may not be suitable for opaque or viscous liquids, and their performance can be affected by contaminants on the sensor surface, necessitating regular cleaning.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting a liquid level management solution, B2B buyers must consider several factors, including the specific application requirements, environmental conditions, and budget constraints. Level switches offer robust performance in challenging environments and are ideal for high-pressure applications, while ultrasonic sensors provide cost-effective, non-contact solutions suitable for a variety of media. Optical sensors excel in precision and low-maintenance scenarios, particularly with clear liquids. By evaluating these aspects, buyers can make informed decisions that align with their operational goals and ensure optimal performance in their processes.

Essential Technical Properties and Trade Terminology for level switch

What Are the Key Technical Properties of Level Switches?

When evaluating level switches, several critical specifications must be considered to ensure they meet operational needs. Here are some essential technical properties:

Illustrative image related to level switch

-

Material Grade

Level switches are typically made from materials such as stainless steel or high-grade plastics. Stainless steel is preferred for its corrosion resistance and durability in harsh environments. The material grade affects the switch’s lifespan and performance, especially in industries like petrochemical or food processing, where exposure to aggressive substances is common. -

Pressure Range

The pressure range indicates the maximum pressure the level switch can withstand. Common ranges are from vacuum to 5000 psi (or higher), making it essential for applications in high-pressure environments, such as oil and gas or water treatment. Understanding the pressure requirements is vital for ensuring the switch operates reliably without failure. -

Temperature Tolerance

Temperature tolerance defines the range of temperatures the level switch can handle, often spanning from -40°F to 700°F. This specification is critical for applications in extreme conditions, as exceeding the temperature limits can lead to malfunctions or inaccuracies. Buyers must match the temperature tolerance to their specific application to ensure optimal performance. -

Certification and Compliance

Certifications like ATEX, CSA, or SIL indicate that the level switch meets safety and performance standards required for specific industries. These certifications are crucial for ensuring compliance with regulatory requirements and for minimizing risks in hazardous environments, particularly in regions with stringent safety regulations. -

Response Time

The response time of a level switch is the duration it takes to detect changes in liquid level and signal an alert. Fast response times are essential in critical applications where timely alerts can prevent overflow or other hazardous situations. Understanding this specification helps buyers select switches that align with their operational responsiveness needs. -

Warranty Period

The warranty period offered by manufacturers typically ranges from 3 to 5 years. This is a significant factor for B2B buyers, as a longer warranty indicates confidence in the product’s durability and reliability. A solid warranty can also reduce the total cost of ownership over time, making it a key consideration in purchasing decisions.

What Are Common Trade Terms Related to Level Switches?

Familiarity with industry jargon is essential for effective communication and negotiation. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces components or products that are used in another company’s final product. In the context of level switches, OEMs may offer customized solutions tailored to specific applications, which can be particularly valuable for businesses needing specialized equipment. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management, as it can affect the overall cost and procurement strategy for businesses looking to integrate level switches into their operations. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. Sending an RFQ allows buyers to compare offers from different manufacturers, ensuring they make informed purchasing decisions based on price, specifications, and lead times. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs, which is essential for B2B buyers engaging with international suppliers for level switches. -

Lead Time

Lead time is the time taken from placing an order until the product is delivered. Understanding lead times is vital for project planning and inventory management, especially in industries that require just-in-time delivery to maintain operational efficiency. -

SIL (Safety Integrity Level)

SIL is a measure of the reliability of safety-related systems. It indicates the level of risk reduction provided by a safety function. Knowing the SIL rating of a level switch is crucial for industries where safety is paramount, as it helps ensure that the equipment meets necessary safety standards.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing level switches for their operations, ensuring they select the right products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the level switch Sector

What Are the Key Drivers and Trends Influencing the Level Switch Market?

The global level switch market is currently experiencing transformative dynamics driven by technological advancements and increasing demand across various industries. Key drivers include the rise of automation in manufacturing processes, where precise level control is critical to operational efficiency. Emerging technologies, such as IoT integration and smart sensors, are reshaping how level switches function, providing real-time data and remote monitoring capabilities. This trend is particularly relevant for international B2B buyers in regions like Africa, South America, the Middle East, and Europe, where industries are rapidly modernizing.

Moreover, the market is seeing a shift towards more compact and energy-efficient solutions. Buyers are increasingly favoring level switches with features such as non-contact sensing technologies, which minimize maintenance and enhance reliability. For example, optical level switches are gaining traction for their precision and low environmental impact. Additionally, the demand for customizable solutions that cater to specific industry requirements is on the rise, reflecting a growing need for adaptability in diverse operational environments.

As industries evolve, international buyers should also be aware of the regulatory landscape influencing product certifications, particularly in regions with stringent safety and environmental standards. Compliance with certifications such as ATEX, CSA, and SIL is becoming essential for suppliers aiming to penetrate these markets.

How Is Sustainability Shaping B2B Sourcing in the Level Switch Sector?

Sustainability is increasingly becoming a cornerstone of B2B sourcing strategies in the level switch sector. As businesses worldwide face mounting pressure to reduce their environmental impact, the focus on ethical sourcing and sustainable practices is paramount. International buyers are now prioritizing suppliers who demonstrate a commitment to sustainable manufacturing processes and materials.

The environmental impact of level switches can be significant, particularly in terms of materials used and the lifecycle of the products. Buyers should seek manufacturers that utilize recyclable materials and adhere to eco-friendly production methods. Certifications such as ISO 14001 for environmental management systems can serve as indicators of a supplier’s commitment to sustainability.

Moreover, as companies strive to meet their corporate social responsibility goals, the importance of ethical supply chains is magnified. Suppliers that maintain transparency about their sourcing practices and labor conditions will be more appealing to conscientious buyers. Engaging with manufacturers that have a proven track record of social and environmental responsibility can enhance brand reputation and customer loyalty.

What Is the Historical Context Behind the Development of Level Switch Technologies?

The evolution of level switch technologies can be traced back to the need for effective level monitoring in various industries, including oil and gas, water treatment, and manufacturing. Initially, mechanical float switches dominated the market, offering a simple yet effective solution for level detection. However, as industrial processes became more complex and demanding, the limitations of mechanical systems became apparent.

Illustrative image related to level switch

The introduction of electronic and non-contact technologies marked a significant turning point in the sector. Innovations such as capacitive, ultrasonic, and optical level switches emerged, providing enhanced accuracy, reliability, and versatility. These advancements have enabled industries to adopt more sophisticated level control systems, reducing downtime and improving operational efficiency.

Today, level switches are integral components in automated processes, reflecting the continuous push towards innovation and efficiency in industrial applications. Understanding this historical context helps international B2B buyers appreciate the technological advancements available and the potential for future developments in the sector.

Frequently Asked Questions (FAQs) for B2B Buyers of level switch

-

How do I choose the right level switch for my application?

Choosing the right level switch involves assessing your specific application requirements, including the type of media (liquid or solid), operating pressure and temperature ranges, and the installation environment. Consider the certifications needed for compliance with local regulations, such as ATEX for hazardous environments. It’s also crucial to evaluate the switch’s response time, accuracy, and maintenance needs. Consulting with manufacturers or suppliers can provide insights into the best options tailored to your operational needs. -

What types of level switches are available for industrial applications?

There are several types of level switches suitable for industrial applications, including float switches, displacer switches, capacitive, optical, and ultrasonic level switches. Float switches are commonly used for liquids, while displacer switches are effective in various densities. Capacitive switches can work with different media, and optical switches are ideal for non-contact applications. Ultrasonic switches provide non-invasive level detection, making them versatile for a range of industries. Your choice should depend on the specific properties of the media and the operational conditions. -

What are the key certifications I should look for in level switches?

When sourcing level switches, key certifications to consider include ATEX (for explosive atmospheres), CSA (Canadian Standards Association), IECEx (international standards for electrical equipment), and SIL (Safety Integrity Level) certifications. Depending on your location, you may also want to check for compliance with INMETRO in Brazil or UKCA in the UK. These certifications ensure that the level switches meet safety and performance standards, which is critical for maintaining operational integrity and regulatory compliance. -

How can I customize a level switch for my specific needs?

Customization options for level switches often include adjustments in size, material, and sensing technology to meet specific application requirements. Many manufacturers offer tailored solutions based on your operational parameters, such as temperature ranges, pressure ratings, and media types. It’s advisable to discuss your unique specifications with potential suppliers to ensure they can provide a solution that meets your operational demands while adhering to industry standards. -

What is the minimum order quantity (MOQ) for level switches?

Minimum order quantities can vary widely among suppliers, often depending on the type of level switch and the manufacturing process. Typically, MOQs range from a single unit for standard products to larger quantities for customized or specialized switches. It’s essential to clarify these terms with suppliers during the inquiry process, especially if you are managing a tight budget or require a specific number of units for a project. -

What payment terms should I expect when sourcing level switches internationally?

Payment terms for international orders can vary based on the supplier and the buyer’s creditworthiness. Common terms include advance payment, partial payment upon order confirmation, or letters of credit. Ensure to negotiate terms that align with your cash flow and project timelines. Additionally, consider the implications of currency exchange rates and transaction fees when dealing with international suppliers, as these can impact the overall cost. -

How do I ensure quality assurance when purchasing level switches?

To ensure quality assurance, request detailed documentation from suppliers, including product specifications, testing procedures, and certification reports. It’s also beneficial to inquire about the manufacturer’s quality management systems, such as ISO 9001 certification. Conducting factory visits or audits can provide further assurance of the production processes and quality control measures. Additionally, consider sourcing samples for testing before placing large orders to confirm product performance. -

What logistics considerations should I keep in mind when importing level switches?

When importing level switches, logistics considerations include shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder familiar with your region’s import/export requirements to minimize delays. Be aware of any tariffs or duties that may apply to your products, which can affect overall costs. Additionally, plan for potential shipping delays by allowing ample time for delivery, especially if sourcing from suppliers located in different continents.

Top 8 Level Switch Manufacturers & Suppliers List

1. SOR Controls Group – Level Switches

Domain: sorinc.com

Registered: 1997 (28 years)

Introduction: Level Switches from SOR Controls Group are designed for high quality and rugged construction, suitable for demanding applications in industries such as power generation, refining, and petrochemical. Key models include: 1510 Side Mounted Level Switch (ranges: vac to 5000 psi, -40° to 400°F, certifications: ATEX, CSA, SIL), 1530 Pneumatic Level Switch (ranges: vac to 5000 psi, -40° to 400°F), 1540 S…

2. Emerson – Level Switch Technology

Domain: emerson.com

Registered: 1995 (30 years)

Introduction: This company, Emerson – Level Switch Technology, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

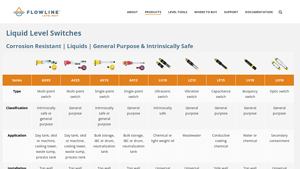

3. Flowline – Level Switches

Domain: flowline.com

Registered: 1996 (29 years)

Introduction: Level Switches: Flowline offers a range of liquid and solid level sensors, switches, and controllers. Key product details include:

– **Types of Switches**: Multi-point switch, Single-point switch, Ultrasonic switch, Vibration switch, Capacitance switch, Buoyancy switch, Optic switch.

– **Classification**: Intrinsically safe or general purpose.

– **Applications**: Suitable for day tanks, cooling t…

4. Vega – Level Switches for Point Level Measurement

Domain: vega.com

Registered: 1994 (31 years)

Introduction: Level switches for point level measurement: Vibration, Capacitive, Conductive, Radar, Radiation-based. Key features include:

– Detects predefined levels in tanks, silos, or containers.

– Outputs binary signals for integration into process control systems.

– Applications include minimum/maximum detection, leak detection, and overfill protection in process tanks, storage tanks, silos, and pipelin…

5. FCI – Liquid Level Switches

Domain: fluidcomponents.com

Registered: 1996 (29 years)

Introduction: FCI Liquid Level Switches detect, monitor, and alarm for all liquids. They utilize mechanical or electronic techniques to automate operations such as opening or closing valves, draining or filling, and sending alarm signals. Key features include:

– Accurate, highly repeatable trip-point sensitivity for water, oils, and chemicals.

– No moving parts for exceptional reliability and no maintenance. …

6. KROHNE – Level Switches for Point Level Detection

Domain: krohne.com

Registered: 1995 (30 years)

Introduction: Level switches for point level detection and interface measurement, including vibration forks and capacitance level switches. Suitable for liquids and solids, designed for extreme pressure and temperature conditions, hazardous and hygienic applications, and safety integrity systems (SIS). Products include: OPTISWITCH 3100 (vibration level switch for solid applications), OPTISWITCH 3200 (vibration …

7. Gems Sensors – Liquid Level Switches

Domain: gemssensors.com

Registered: 1995 (30 years)

Introduction: Liquid Level Switches: Various technologies to detect liquid presence or absence. Key considerations for selection include: Mounting Orientation (Horizontal or Vertical), Media Type (Water, Oil, Chemical), Chemical Compatibility, Environmental Conditions (Humidity, Temperature), Switching Method (Relay or Solid State), Available Mounting & Tank Space, and Media Properties (Temperature, Specific Gr…

8. IQS Directory – Level Switches

Domain: iqsdirectory.com

Registered: 2004 (21 years)

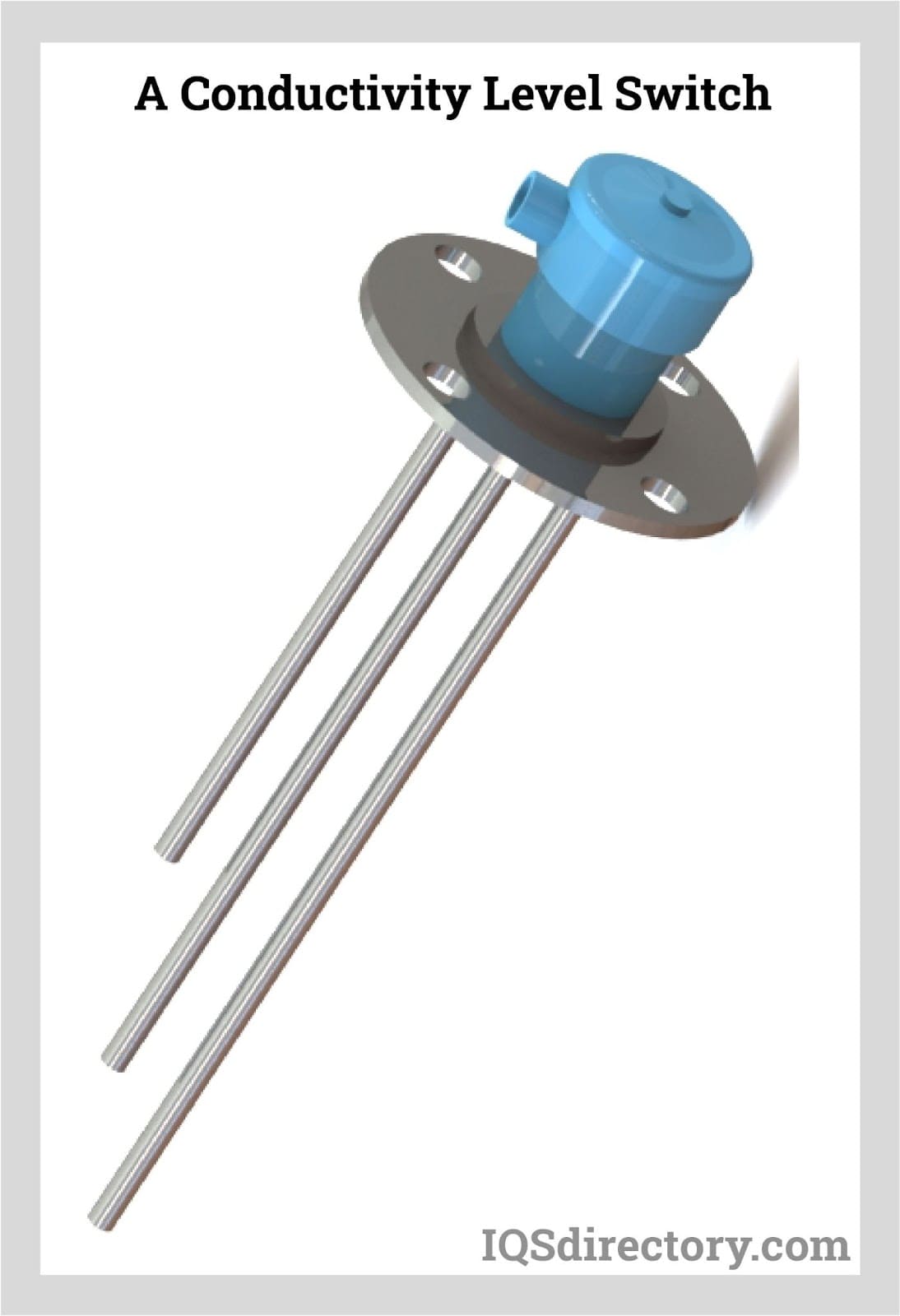

Introduction: Level switches are devices used to monitor the levels of liquids, powders, or bulk materials, activating alerts when predetermined heights or depths are reached. They are crucial in production processes, especially in extreme environments. Key types include: 1. Capacitive Level Switch: Measures corrosive liquids and high temperatures, effective for non-contact detection. 2. Conductivity Level Swit…

Strategic Sourcing Conclusion and Outlook for level switch

How Can Strategic Sourcing Enhance Your Level Switch Procurement?

In the dynamic landscape of industrial equipment, strategic sourcing of level switches is crucial for optimizing operational efficiency and ensuring reliable performance. By carefully evaluating suppliers, considering certifications, and understanding the unique requirements of your applications, B2B buyers can secure high-quality products that align with their specific needs. The diverse range of level switches available—spanning float, displacer, and optical technologies—offers solutions for various industries, from petrochemical to manufacturing.

Leveraging strategic sourcing not only mitigates risks associated with procurement but also fosters partnerships that can enhance innovation and reduce costs over time. As markets in Africa, South America, the Middle East, and Europe continue to evolve, the ability to source tailored solutions becomes increasingly important.

Looking ahead, international buyers should engage proactively with manufacturers, explore customizable options, and capitalize on technological advancements in level switch design. By doing so, they position themselves to meet future challenges effectively while ensuring compliance with safety standards. Now is the time to reassess your sourcing strategy and take the next step towards securing the best level switch solutions for your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to level switch

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.