Everything You Need to Know About Latch Pin Spring Sourcing in 2025

Introduction: Navigating the Global Market for latch pin spring

In today’s global marketplace, sourcing reliable latch pin springs can pose a significant challenge for international B2B buyers. With a myriad of options available, companies must navigate varying quality standards, material specifications, and regional supplier capabilities. This guide aims to streamline that process, offering a comprehensive overview of latch pin springs, including their diverse applications across industries such as automotive, construction, and manufacturing. We will explore different types of latch pin springs, their specific uses, and how to effectively vet suppliers to ensure you receive high-quality products that meet your operational needs.

As businesses in Africa, South America, the Middle East, and Europe look to enhance their supply chains, understanding the nuances of latch pin spring procurement becomes crucial. This guide provides actionable insights into cost considerations, allowing you to make informed purchasing decisions while maximizing value. By equipping you with the knowledge needed to assess product specifications and supplier reliability, we empower you to navigate the complexities of the global market confidently. Whether you are sourcing for immediate projects or planning long-term supply strategies, our guide serves as an essential resource in your procurement toolkit.

Understanding latch pin spring Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Spring-Loaded Latch | Mechanism that automatically engages when released | Automotive, trailers, shipping containers | Pros: Quick release, durable; Cons: May require precise installation. |

| Heavy-Duty Spring Latch | Enhanced strength for demanding environments | Industrial equipment, agricultural machinery | Pros: High load capacity; Cons: Higher cost compared to standard latches. |

| Slam Latch | Designed to automatically latch upon closure | Gates, containers, trailers | Pros: Easy operation; Cons: Potential for wear over time with heavy use. |

| Pull Pin Latch | Allows for manual disengagement with a simple pull | Tool hold downs, seat sliders | Pros: Versatile use, easy to operate; Cons: May not be suitable for high-security applications. |

| Weld-On Latch | Requires welding for installation, providing a permanent fit | Metal fabrication, custom machinery | Pros: Strong, reliable connection; Cons: Permanent installation limits adjustments. |

What Are the Key Characteristics of Spring-Loaded Latches?

Spring-loaded latches are designed to engage automatically when released, making them ideal for applications where quick access is required. Commonly used in automotive and trailer applications, these latches provide reliable performance and durability. When purchasing, buyers should consider the latch’s material, as corrosion resistance is crucial for longevity in various environments. Additionally, the installation process must be straightforward to ensure effective operation.

How Do Heavy-Duty Spring Latches Differ from Standard Versions?

Heavy-duty spring latches are specifically engineered to withstand higher loads and more demanding conditions than standard latches. They are commonly used in industrial equipment and agricultural machinery, where reliability is paramount. Buyers should evaluate the load capacity and material strength when selecting heavy-duty options, as these factors directly impact performance and durability. While they may come at a higher price point, the investment often pays off in longevity and reduced maintenance costs.

What Are the Advantages of Slam Latches in B2B Applications?

Slam latches are designed to automatically engage when a door or gate is closed, making them ideal for high-traffic environments such as shipping containers and trailers. Their ease of use can enhance operational efficiency, as personnel do not need to manually secure each closure. However, buyers should be aware that the mechanism may wear over time, particularly in heavy-use scenarios. Choosing a high-quality slam latch can mitigate this risk and ensure long-term performance.

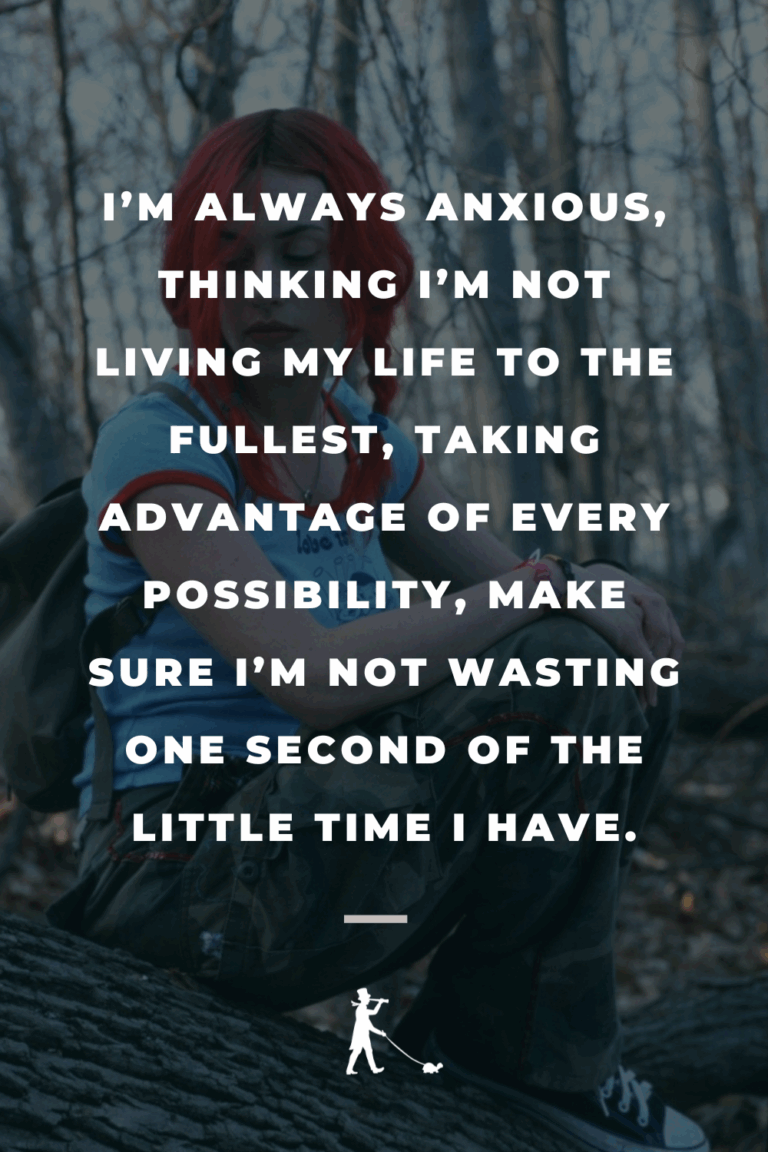

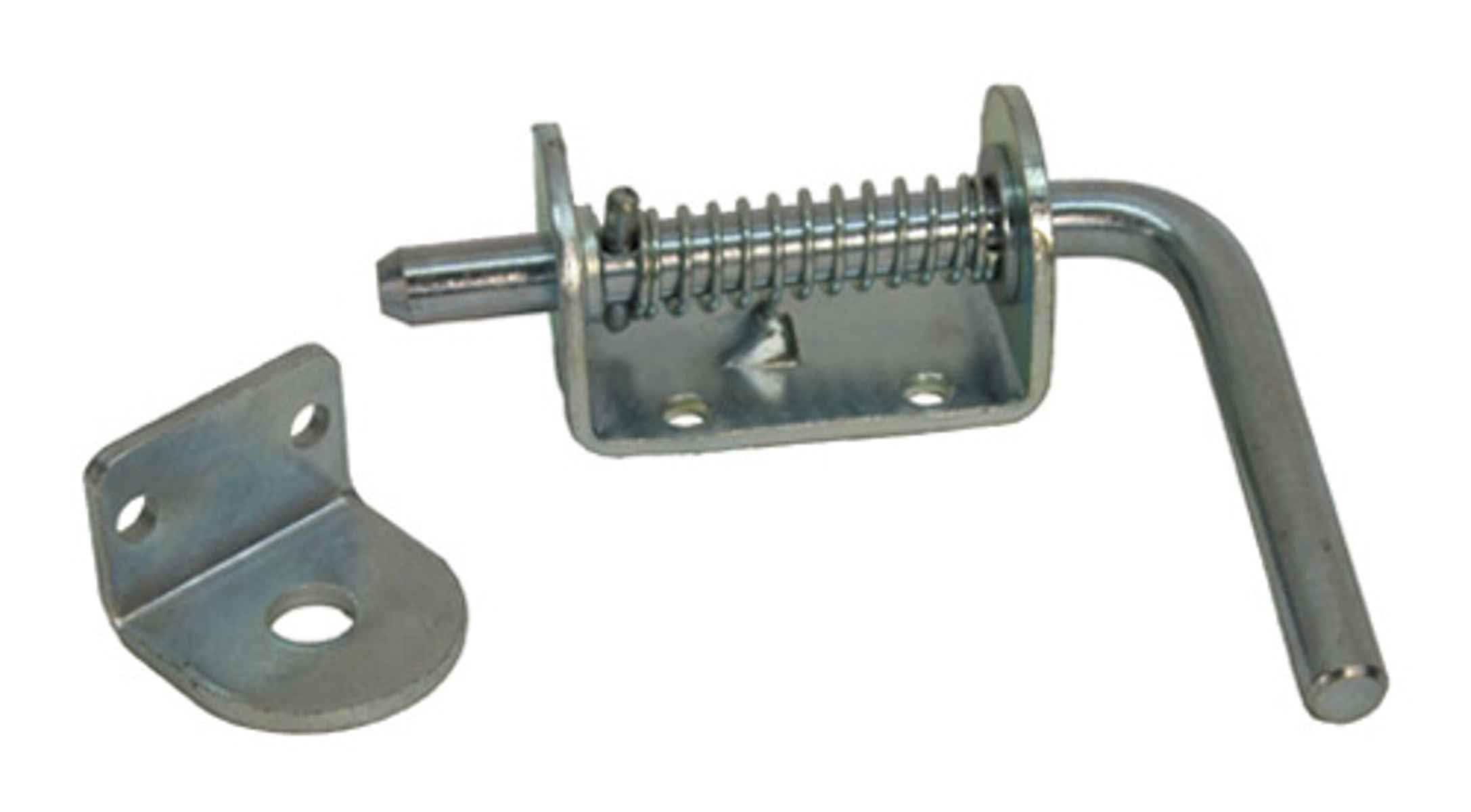

Illustrative image related to latch pin spring

In What Scenarios Are Pull Pin Latches Most Effective?

Pull pin latches are versatile components that allow for quick manual disengagement, making them suitable for applications such as tool hold downs and seat sliders. Their ease of operation is a significant advantage in environments where frequent adjustments are needed. However, buyers should consider the security aspect, as pull pin latches may not provide the same level of security as other types. Selecting a robust design can help enhance their effectiveness in various applications.

Why Choose Weld-On Latches for Custom Machinery?

Weld-on latches offer a permanent solution for securing components in metal fabrication and custom machinery applications. Their installation process involves welding, which creates a strong, reliable connection that can withstand significant stress. Buyers should evaluate the welding compatibility with their materials and consider the permanence of the installation, as adjustments will require additional work. Despite the higher initial effort, weld-on latches provide unmatched stability and reliability for demanding applications.

Key Industrial Applications of latch pin spring

| Industry/Sector | Specific Application of latch pin spring | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Quick-release systems in vehicles | Enables efficient assembly and disassembly, reducing downtime. | Durability, corrosion resistance, and compatibility with vehicle designs. |

| Agriculture | Latches for equipment such as trailers and gates | Ensures secure operation while allowing quick access for maintenance. | Material strength and weather resistance to withstand outdoor conditions. |

| Manufacturing | Fixtures in assembly lines | Increases operational efficiency by facilitating quick adjustments. | Precision engineering and ability to integrate with existing systems. |

| Shipping & Logistics | Securing cargo in containers and racks | Enhances safety and reliability of cargo transport. | Compliance with international shipping standards and ease of installation. |

| Construction | Temporary structures and scaffolding | Provides secure and adjustable connections for safety. | Load-bearing capacity and adaptability to various construction materials. |

How Are Latch Pin Springs Used in Automotive Applications?

In the automotive industry, latch pin springs are crucial for quick-release systems, allowing components such as hoods, doors, and seats to be easily removed or adjusted. This flexibility reduces assembly and maintenance time, leading to improved production efficiency. Buyers should consider sourcing durable materials that can withstand the rigors of automotive environments, including high temperatures and exposure to various chemicals.

Illustrative image related to latch pin spring

What Role Do Latch Pin Springs Play in Agriculture?

In agriculture, latch pin springs are commonly used in trailers and gates, ensuring they operate smoothly while providing secure closure. This application is vital for equipment that needs frequent access, such as livestock trailers or farming equipment. Buyers in this sector should prioritize springs that offer high corrosion resistance and robustness to endure harsh outdoor conditions, ensuring longevity and reliability.

How Do Latch Pin Springs Enhance Manufacturing Efficiency?

Manufacturers utilize latch pin springs in fixtures and machinery setups, allowing for quick adjustments and repositioning of parts during assembly. This adaptability enhances operational efficiency and minimizes production downtime. For B2B buyers, it’s essential to choose springs that are engineered for precision to ensure compatibility with existing manufacturing systems, along with the ability to handle the specific loads and stresses of their applications.

Why Are Latch Pin Springs Essential in Shipping and Logistics?

In shipping and logistics, latch pin springs secure cargo in containers and racks, playing a critical role in ensuring safe transport. They facilitate quick loading and unloading, which is essential for maintaining schedules and reducing labor costs. Businesses should focus on sourcing latch pin springs that meet international shipping standards and are easy to install, thereby enhancing their operational efficiency.

What Benefits Do Latch Pin Springs Provide in Construction?

In the construction sector, latch pin springs are used in temporary structures and scaffolding, providing secure yet adjustable connections that enhance safety. This application is vital for compliance with safety regulations while allowing for quick adjustments as construction progresses. Buyers should look for springs with high load-bearing capacities and the ability to adapt to various construction materials, ensuring they meet the rigorous demands of building sites.

3 Common User Pain Points for ‘latch pin spring’ & Their Solutions

Scenario 1: Difficulty in Ensuring Durability Under Harsh Conditions

The Problem: B2B buyers often face significant challenges in sourcing latch pin springs that can withstand extreme environmental conditions. Industries such as agriculture, transportation, and construction frequently expose these components to moisture, dust, and corrosive materials. A latch pin spring that fails prematurely due to rust or degradation can lead to costly downtime and replacement costs, along with potential safety hazards.

The Solution: To ensure that latch pin springs meet durability requirements, buyers should prioritize sourcing components made from high-quality materials such as stainless steel or specially coated alloys. It’s crucial to verify that the supplier provides detailed specifications regarding corrosion resistance and the operational limits of their products. Additionally, buyers should consider working with manufacturers who offer testing certifications that demonstrate the product’s performance in extreme conditions. Investing in latch pin springs designed for heavy-duty use, such as those rated for industrial applications, can significantly enhance longevity and reliability.

Scenario 2: Incompatibility with Existing Systems

The Problem: Many buyers encounter the issue of latch pin springs that do not fit seamlessly with their current mechanisms or systems. This incompatibility can arise from differences in sizes, locking mechanisms, or installation requirements, leading to increased installation time and costs. For example, a company may purchase a spring latch that is too large for their existing frame or one that requires specialized tools for installation, complicating the integration process.

The Solution: To mitigate compatibility issues, it is essential for buyers to conduct a thorough assessment of their existing systems before making a purchase. This includes measuring the dimensions of the latch pin spring housing and the pin diameter, as well as understanding the specific application requirements. Buyers should seek suppliers that provide customizable solutions or a wide range of standard sizes. Engaging in direct communication with the manufacturer can also help clarify installation requirements and ensure that the latch pin springs will be a perfect fit for the intended application.

Scenario 3: Challenges in Achieving Quick Release Mechanism Efficiency

The Problem: In applications where quick release is essential—such as in automotive or machinery settings—buyers often find that the latch pin springs they initially selected do not operate as expected. Slow or unreliable engagement can hinder workflow efficiency, causing delays in operations and increased frustration among operators. This situation is particularly problematic in high-paced environments where time is critical.

The Solution: To enhance the efficiency of quick release mechanisms, buyers should consider latch pin springs designed specifically for rapid engagement and release. It is advisable to look for products that feature a robust spring mechanism capable of quick retraction and reliable locking. Evaluating the spring tension and reviewing user feedback can provide insights into the performance of various models. Additionally, integrating a testing phase into the procurement process can help buyers determine how well a latch pin spring performs under actual operating conditions, thus ensuring optimal efficiency in their applications.

Strategic Material Selection Guide for latch pin spring

What Materials Are Commonly Used for Latch Pin Springs?

When selecting materials for latch pin springs, several factors must be considered, including mechanical properties, environmental resistance, and cost. Below, we analyze four common materials used in the manufacturing of latch pin springs, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high tensile strength, and ability to withstand high temperatures. It typically has a temperature rating of up to 800°F (427°C) and can handle moderate pressure applications.

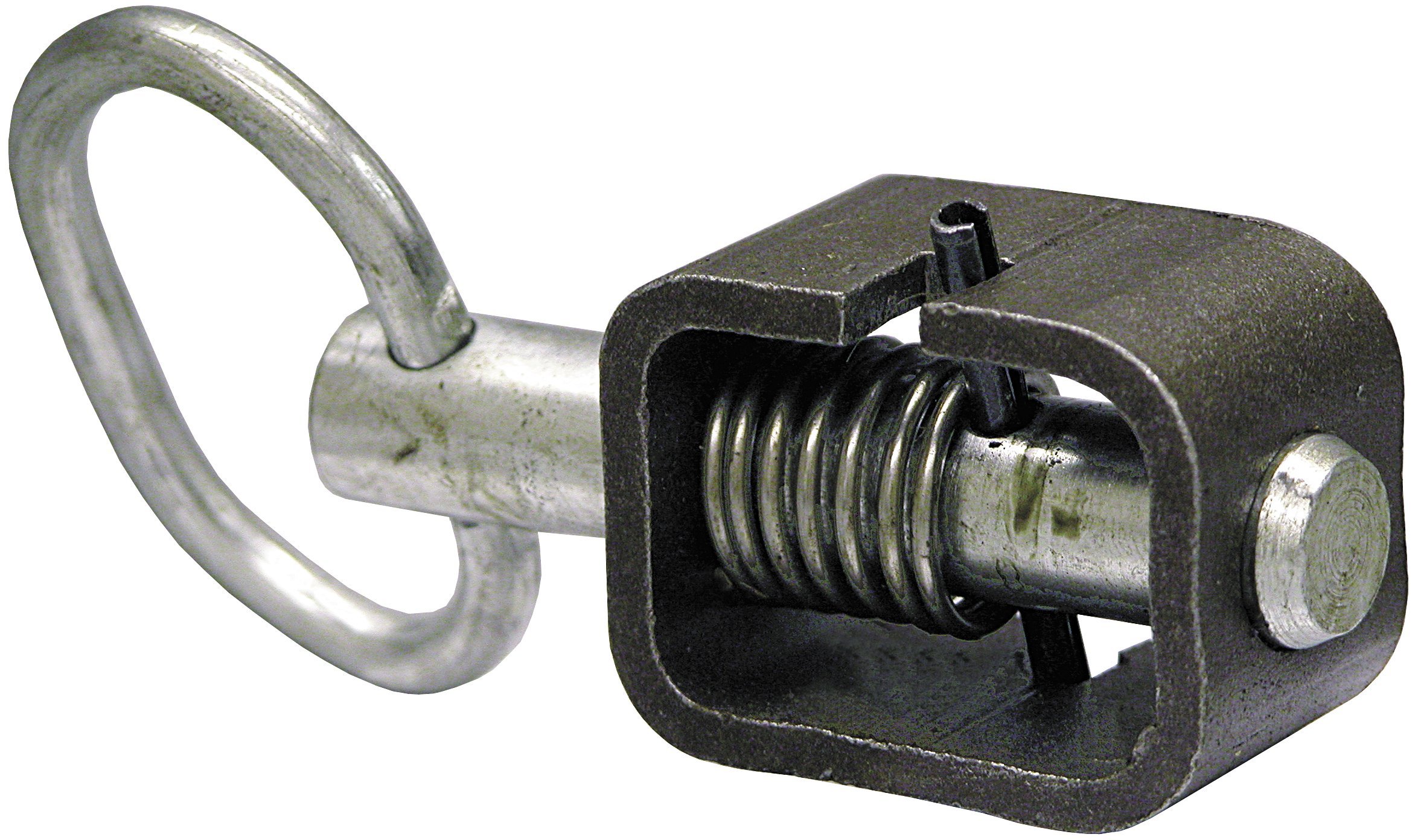

Illustrative image related to latch pin spring

Pros & Cons:

Stainless steel springs are durable and can endure harsh environments, making them ideal for outdoor or marine applications. However, they can be more expensive than other materials, and their manufacturing processes may require specialized equipment, increasing overall production costs.

Impact on Application:

Stainless steel is compatible with a wide range of media, including water and various chemicals, making it suitable for industries like automotive and marine.

Considerations for International Buyers:

For buyers in regions like Africa and the Middle East, compliance with ASTM standards is crucial. Buyers should also consider local sourcing options to mitigate import costs.

2. Carbon Steel

Key Properties:

Carbon steel offers good strength and hardness, with a typical temperature rating of around 400°F (204°C). It is less resistant to corrosion compared to stainless steel, which may limit its use in certain environments.

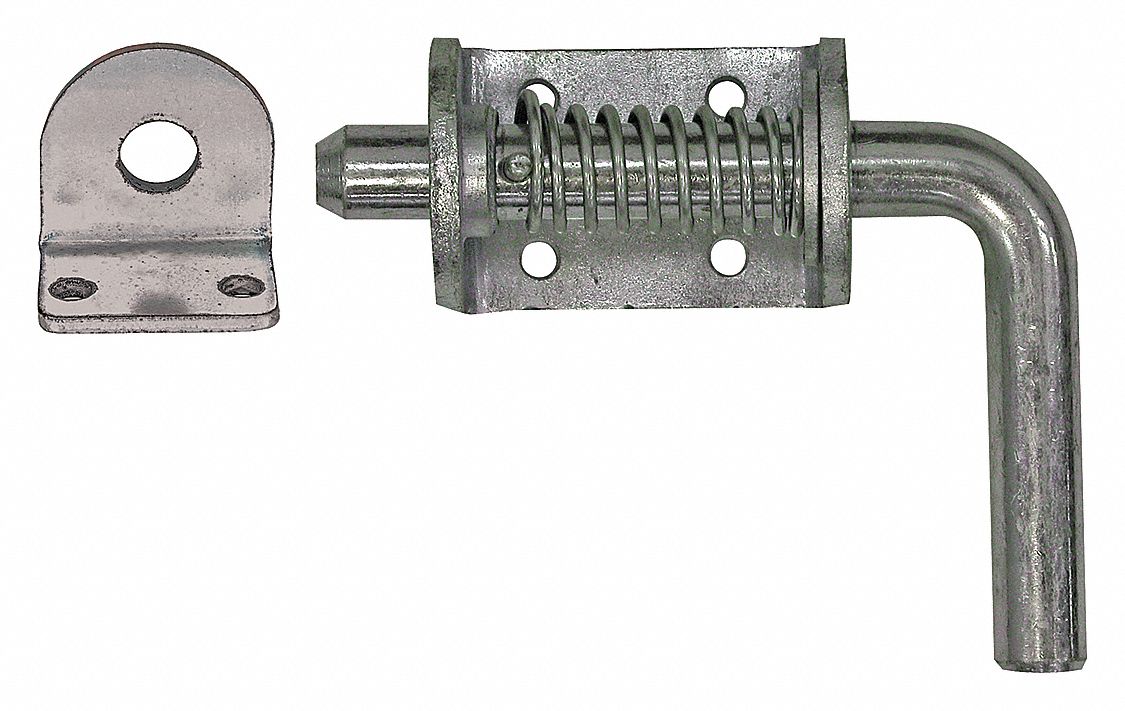

Illustrative image related to latch pin spring

Pros & Cons:

The primary advantage of carbon steel is its lower cost compared to stainless steel, making it a preferred choice for budget-sensitive projects. However, its susceptibility to rust and corrosion can be a significant drawback, especially in humid or corrosive environments.

Impact on Application:

Carbon steel springs are suitable for applications where environmental exposure is minimal, such as indoor machinery.

Considerations for International Buyers:

Buyers should ensure that carbon steel components meet relevant local standards, such as DIN or JIS, to avoid compliance issues.

Illustrative image related to latch pin spring

3. Alloy Steel

Key Properties:

Alloy steel, which includes various elements such as chromium and molybdenum, provides enhanced strength and toughness. It can withstand higher temperatures and pressures, typically rated up to 600°F (316°C).

Pros & Cons:

The main advantage of alloy steel is its superior mechanical properties, making it suitable for high-load applications. However, the cost can be higher than carbon steel, and the manufacturing process may be more complex due to the need for heat treatment.

Impact on Application:

Alloy steel is ideal for demanding applications in automotive and aerospace sectors, where performance under stress is critical.

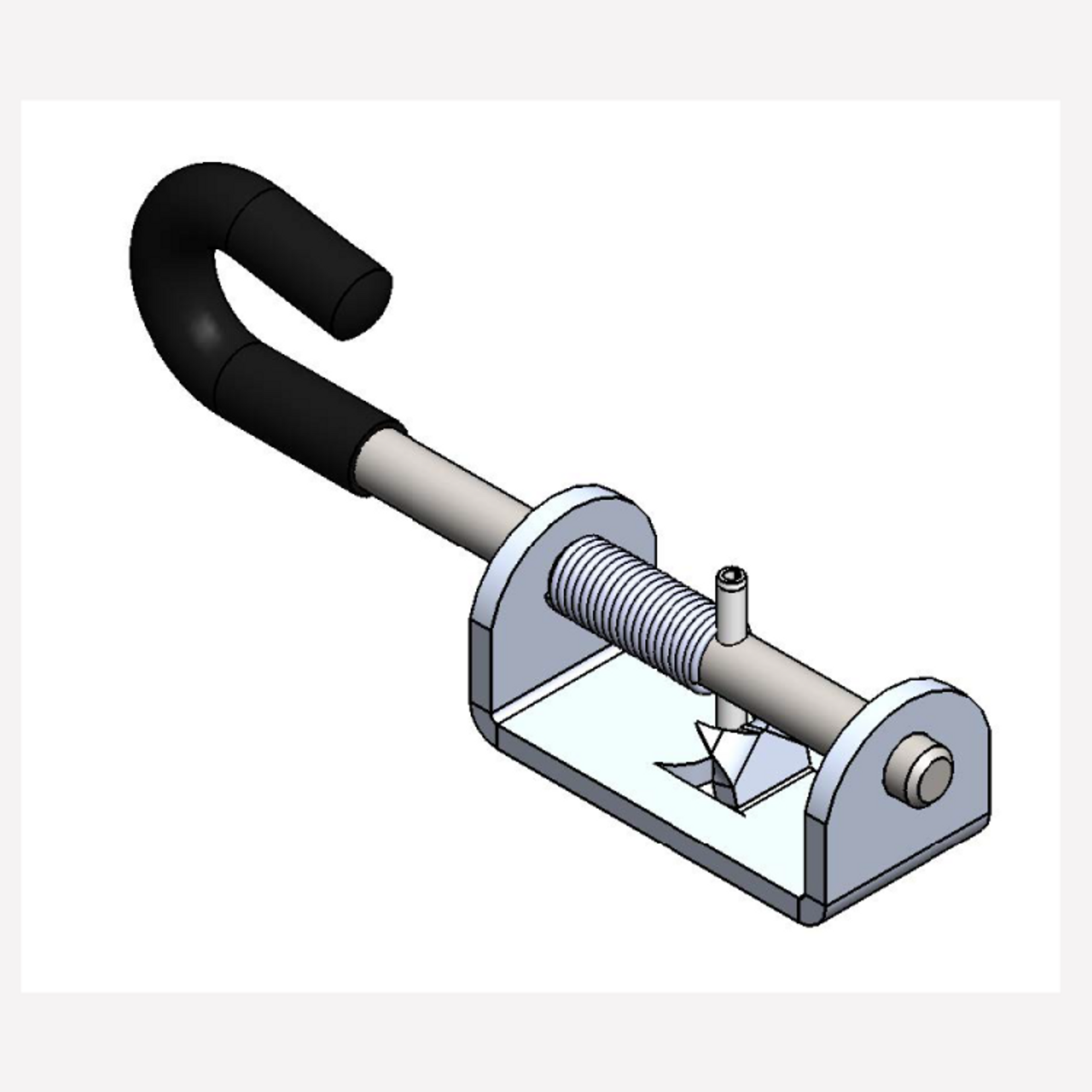

Illustrative image related to latch pin spring

Considerations for International Buyers:

Buyers should verify that alloy steel springs comply with international standards to ensure quality and safety in their applications.

4. Plastic Composites

Key Properties:

Plastic composites are lightweight and resistant to corrosion and chemicals, with temperature ratings typically around 200°F (93°C).

Pros & Cons:

The primary advantage of plastic composites is their resistance to corrosion and low weight, making them suitable for applications where metal fatigue is a concern. However, they may not offer the same level of mechanical strength as metal springs, limiting their use in high-load applications.

Illustrative image related to latch pin spring

Impact on Application:

These materials are often used in consumer products and applications where weight reduction is essential, such as in the automotive industry.

Considerations for International Buyers:

For buyers in Europe and South America, it is essential to ensure that the plastic composites meet environmental regulations, such as REACH, to avoid compliance issues.

Summary Table of Material Selection for Latch Pin Springs

| Material | Typical Use Case for latch pin spring | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Marine applications, automotive | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Carbon Steel | Indoor machinery | Lower cost | Susceptible to rust and corrosion | Low |

| Alloy Steel | Automotive, aerospace | Superior strength and toughness | Higher cost and complex manufacturing | Med |

| Plastic Composites | Consumer products, lightweight designs | Corrosion resistant and lightweight | Lower mechanical strength | Med |

This guide aims to assist B2B buyers in making informed decisions regarding the material selection for latch pin springs, ensuring compatibility with their specific applications and compliance with international standards.

Illustrative image related to latch pin spring

In-depth Look: Manufacturing Processes and Quality Assurance for latch pin spring

What Are the Key Stages in the Manufacturing Process of Latch Pin Springs?

The manufacturing process of latch pin springs involves several critical stages, ensuring that the final product meets the specific requirements of various applications. Understanding these stages is essential for B2B buyers looking to source high-quality latch pin springs.

Material Preparation: What Materials Are Commonly Used?

The first step in manufacturing latch pin springs is selecting the right materials. Typically, manufacturers use high-carbon steel, stainless steel, or other alloys that provide the necessary strength and corrosion resistance. The choice of material is crucial, as it directly influences the durability and performance of the latch pin spring in different environments.

Once the material is selected, it undergoes preparation, which includes cutting it to the required lengths and treating it to enhance its mechanical properties. Heat treatment, for example, can improve tensile strength and elasticity, making the spring more resilient under load.

How Are Latch Pin Springs Formed?

The forming process is where the spring takes its shape. This can involve several techniques, including:

-

Coiling: This is the most common method, where the wire is coiled around a mandrel to create the spring shape. The coiling process can be automated for efficiency and precision.

-

Stamping: For specific designs, stamping can be used to create flat springs or components of the latch pin spring. This method allows for high-volume production with consistent quality.

-

Bending: In some cases, bending is employed to achieve specific geometries that are required for the latch mechanism.

These forming techniques must adhere to strict tolerances to ensure that the latch pin springs function correctly in their intended applications.

Illustrative image related to latch pin spring

What Assembly Techniques Are Used in Manufacturing Latch Pin Springs?

After forming, the next stage is assembly. This may involve integrating the spring with other components, such as pins or housings. During this stage, manufacturers may use techniques such as welding, riveting, or mechanical fastening to ensure a secure assembly. The choice of assembly method depends on the design requirements and the intended use of the latch pin spring.

It’s essential to note that the assembly process must be performed with precision to maintain the integrity of the spring’s function. Any misalignment can lead to operational failures, which could be detrimental in critical applications.

What Finishing Processes Enhance the Quality of Latch Pin Springs?

The finishing stage is critical for enhancing the durability and aesthetics of latch pin springs. Common finishing processes include:

-

Surface Treatment: This includes processes such as plating, anodizing, or coating to enhance corrosion resistance and wear properties. For example, zinc plating can be applied to steel springs to prevent rust.

-

Quality Inspection: After finishing, a thorough inspection is conducted to ensure that the springs meet the required specifications. This can include visual inspections and dimensional checks.

-

Packaging: Finally, the latch pin springs are packaged in a manner that protects them during shipping and handling, ensuring they reach the buyer in optimal condition.

What Quality Assurance Measures Are Essential for Latch Pin Springs?

Quality assurance is paramount in the manufacturing of latch pin springs, as it ensures the reliability and safety of the final product. B2B buyers must be aware of the international standards and specific quality control measures employed by manufacturers.

Which International Standards Should Buyers Look For?

Manufacturers of latch pin springs often adhere to international quality standards such as ISO 9001. This standard focuses on quality management systems, ensuring that manufacturers consistently produce high-quality products. Additionally, industry-specific certifications, such as CE marking for compliance with European safety standards or API standards for oil and gas applications, may also be relevant.

B2B buyers should inquire about these certifications when assessing potential suppliers to ensure compliance with international safety and quality norms.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are critical at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials before they enter the production line. Ensuring that materials meet specifications can prevent defects later in the process.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular checks should be conducted to ensure that the production remains within defined tolerances. This can include monitoring the coiling process and verifying assembly integrity.

-

Final Quality Control (FQC): Before products are shipped, a final inspection is conducted to ensure that all specifications are met. This includes dimensional checks, functional tests, and surface quality assessments.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control measures can be challenging but is crucial for ensuring product reliability. Here are some actionable steps buyers can take:

-

Supplier Audits: Conducting an on-site audit allows buyers to assess the manufacturing processes, quality control measures, and overall operational practices of the supplier. This firsthand evaluation can provide insights into their commitment to quality.

-

Requesting Quality Reports: Buyers should request quality control documentation, including inspection reports, material certifications, and compliance certificates. This information can help verify that the supplier meets international standards.

-

Engaging Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the manufacturing process and product quality. These inspectors can conduct thorough evaluations at various stages of production.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing latch pin springs from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should be aware of specific nuances:

-

Cultural Differences: Understanding cultural attitudes toward quality and business practices can facilitate better communication and expectations between buyers and suppliers.

-

Regulatory Compliance: Different regions may have varying regulations regarding product safety and quality. Buyers should ensure that suppliers are compliant with local and international laws.

-

Lead Times and Logistics: Quality control processes may impact lead times. Buyers should account for potential delays in production and inspection when planning their supply chain.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for latch pin springs is essential for B2B buyers. By focusing on material selection, manufacturing techniques, and rigorous quality control, buyers can ensure that they source reliable and durable products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘latch pin spring’

Introduction

In the complex world of industrial procurement, sourcing a latch pin spring requires a strategic approach. This guide offers a step-by-step checklist designed specifically for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. By following these steps, you can ensure that you select the right components for your applications while optimizing quality, cost, and supplier reliability.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to outline the technical specifications of the latch pin spring you require. Consider factors such as material (e.g., stainless steel for corrosion resistance), dimensions, load capacity, and specific application requirements. Having clear specifications will help you communicate effectively with suppliers and avoid misunderstandings.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in latch pin springs. Look for manufacturers with a strong reputation in your industry, particularly those who have experience serving clients in your region. Utilize platforms like industry directories and trade shows to gather a list of potential partners.

Step 3: Evaluate Supplier Certifications

Supplier certifications are vital indicators of quality and compliance. Verify that your potential suppliers hold relevant certifications, such as ISO 9001, which ensures consistent quality management systems. Additionally, check for any industry-specific certifications that may apply, which can be particularly important in sectors like automotive or aerospace.

Illustrative image related to latch pin spring

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples of the latch pin springs from your shortlisted suppliers. Testing samples allows you to evaluate their performance, durability, and compatibility with your applications. Ensure that the samples meet your technical specifications and are tested under realistic operating conditions.

Step 5: Assess Pricing and Payment Terms

Once you’ve identified a few qualified suppliers, compare their pricing structures and payment terms. Be cautious of unusually low prices that may indicate compromised quality. Look for transparency in pricing, including details on shipping costs, taxes, and possible discounts for bulk orders.

Step 6: Check Customer Reviews and References

Customer feedback provides valuable insights into a supplier’s reliability and product quality. Request references from other businesses that have sourced latch pin springs from the suppliers you are considering. Pay attention to reviews that highlight aspects such as customer service, delivery times, and the performance of the products.

Illustrative image related to latch pin spring

Step 7: Negotiate Terms and Finalize the Order

After selecting your preferred supplier, engage in negotiations to finalize terms that work for both parties. Discuss lead times, warranties, and after-sales support to ensure you have a comprehensive understanding of the relationship. Once all terms are agreed upon, proceed to place your order confidently.

By following this checklist, you can streamline your sourcing process for latch pin springs, ensuring you make informed decisions that meet your business needs effectively.

Comprehensive Cost and Pricing Analysis for latch pin spring Sourcing

What Are the Key Cost Components in Latch Pin Spring Sourcing?

When sourcing latch pin springs, understanding the cost structure is critical for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the price. Stainless steel is commonly used for its durability and corrosion resistance, but variations such as carbon steel or specialty alloys may also be considered depending on the application. The cost of raw materials fluctuates based on global market trends and regional availability.

-

Labor: Labor costs vary by region and the complexity of the manufacturing process. In countries with lower labor costs, such as certain regions in Africa or South America, the overall production cost may be reduced. However, higher-quality, skilled labor may be necessary for precision components, affecting the final pricing.

-

Manufacturing Overhead: This encompasses costs associated with facility maintenance, utilities, and administrative expenses. Suppliers in regions with higher operational costs may pass these expenses onto buyers, making it essential to consider the location of the manufacturer.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. These costs are typically amortized over the production run, so larger orders can significantly reduce the per-unit price.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability, which is critical for applications that demand high performance. Suppliers may charge more for products that undergo stringent testing and certification.

-

Logistics: Shipping costs, including freight and handling, can vary dramatically based on the distance from the supplier to the buyer, as well as chosen shipping methods. Incoterms will also play a role in determining who bears these costs.

-

Margin: Suppliers will typically add a profit margin based on their operational costs, market demand, and competitive landscape. This margin can vary widely between manufacturers.

How Do Price Influencers Affect Latch Pin Spring Costs?

Several factors influence the pricing of latch pin springs:

-

Volume/MOQ: Minimum order quantities (MOQs) often dictate pricing. Larger orders can lead to lower per-unit costs due to economies of scale. Negotiating MOQs can be crucial for cost-effective sourcing.

-

Specifications and Customization: Custom designs or specific technical requirements can increase costs. Buyers should clearly define their needs to avoid unexpected price hikes.

-

Material Choices: As previously mentioned, the selection of materials can significantly affect cost. For instance, opting for high-performance materials may yield better durability but at a higher initial cost.

-

Quality and Certifications: Certifications such as ISO or industry-specific standards can add to costs but may be necessary for compliance in certain markets, especially in Europe and the Middle East.

-

Supplier Factors: The reputation, reliability, and location of suppliers can influence pricing. Established suppliers with a history of quality may charge premium prices, but this can often lead to lower total costs due to reduced failure rates.

-

Incoterms: The chosen Incoterms will determine the responsibilities for shipping costs, insurance, and risks. Buyers should understand how these terms impact their total landed costs.

What Are Essential Buyer Tips for Cost-Efficient Sourcing?

B2B buyers, especially from diverse regions like Africa, South America, and the Middle East, should consider the following strategies to optimize sourcing:

-

Negotiate Effectively: Building strong relationships with suppliers can lead to better pricing and terms. Leverage volume purchases or long-term contracts to negotiate favorable deals.

-

Assess Total Cost of Ownership (TCO): Beyond initial prices, consider the TCO, which includes maintenance, operational efficiency, and potential failure costs. A higher-quality latch pin spring might have a higher upfront cost but could save money over time through durability and reliability.

-

Understand Pricing Nuances: Be aware that prices can vary significantly based on geographic location and market conditions. Engaging with multiple suppliers can provide a clearer picture of the pricing landscape.

-

Stay Informed on Market Trends: Regularly monitor market trends and material costs to better predict future pricing and adjust sourcing strategies accordingly.

-

Consider Local Suppliers: For buyers in Africa and South America, sourcing from local manufacturers can reduce logistics costs and lead times, enhancing supply chain efficiency.

By understanding the complex interplay of cost components and pricing influencers, international B2B buyers can make informed decisions when sourcing latch pin springs, ensuring they achieve both quality and value in their purchases.

Alternatives Analysis: Comparing latch pin spring With Other Solutions

Understanding the Landscape of Latch Solutions

In the realm of mechanical fastening solutions, various technologies serve similar purposes as the latch pin spring. Identifying the most suitable option requires a thorough analysis of performance, cost, ease of implementation, maintenance, and specific use cases. Below, we compare latch pin springs with two viable alternatives: Heavy-Duty Spring-Loaded Latches and Pneumatic Latches.

Comparison Table

| Comparison Aspect | Latch Pin Spring | Heavy-Duty Spring-Loaded Latch | Pneumatic Latch |

|---|---|---|---|

| Performance | Reliable for quick-release needs | High durability, strong holding | Fast operation, adjustable force |

| Cost | Moderate pricing | Competitive pricing | Higher upfront costs |

| Ease of Implementation | Simple installation process | Requires welding | Requires air supply |

| Maintenance | Low maintenance | Moderate; check for wear | Higher; needs regular checks |

| Best Use Case | Applications needing frequent access | Heavy-duty applications like trailers | Environments needing rapid actuation |

Heavy-Duty Spring-Loaded Latch: Pros and Cons

Heavy-duty spring-loaded latches are designed for robust applications, providing strong holding power and durability. They are ideal for environments where heavy machinery or components require secure fastening. The competitive pricing makes them an attractive option for businesses seeking reliable performance. However, installation may necessitate welding, which could increase labor costs and complexity. Additionally, while maintenance is generally low, users should periodically check for wear and tear to ensure optimal performance.

Pneumatic Latch: Pros and Cons

Pneumatic latches offer rapid actuation and are often used in high-speed environments where quick access is critical. They can be adjusted for varying levels of force, providing flexibility in applications ranging from automotive assembly lines to packaging machinery. However, the initial investment is typically higher due to the need for an air supply system and regular maintenance checks. This makes pneumatic latches less suitable for low-volume applications or environments where air supply is not feasible.

Choosing the Right Solution for Your Needs

When selecting between latch pin springs and their alternatives, B2B buyers should consider their specific operational requirements. For businesses focused on frequent access to components with moderate durability needs, latch pin springs are an excellent choice. Conversely, if your operations demand heavy-duty performance, investing in heavy-duty spring-loaded latches may yield long-term benefits. For high-speed applications requiring rapid actuation, pneumatic latches stand out as the most effective solution, albeit at a higher cost.

Ultimately, the decision hinges on balancing performance, cost, and maintenance requirements with the specific needs of your operations. By carefully evaluating these factors, buyers can choose the most appropriate latching mechanism to enhance their operational efficiency.

Essential Technical Properties and Trade Terminology for latch pin spring

What Are the Key Technical Properties of Latch Pin Springs?

When sourcing latch pin springs, understanding their technical specifications is essential for ensuring they meet your application requirements. Here are some critical properties to consider:

-

Material Grade

Latch pin springs are typically made from high-quality materials such as stainless steel or carbon steel. Stainless steel offers superior corrosion resistance, making it ideal for outdoor applications or environments with moisture. Carbon steel, while less resistant to rust, provides excellent strength and durability. Choosing the right material is crucial as it directly impacts the longevity and performance of the spring. -

Spring Force

This refers to the amount of force required to compress or extend the spring. It is measured in pounds or newtons and is a vital specification for ensuring that the latch engages and disengages properly. Understanding the required spring force helps in selecting a latch pin spring that can handle the specific load conditions of your application, thereby preventing premature failure. -

Tolerance

Tolerance specifies the allowable variation in the dimensions of the spring. It is crucial for ensuring proper fit and function within the assembly. A tighter tolerance may be necessary for precision applications, while a looser tolerance may suffice for more general uses. Knowing the required tolerances helps in maintaining quality control and performance reliability. -

Finish

The finish of the latch pin spring can influence its performance and resistance to environmental factors. Common finishes include zinc plating, powder coating, or passivation for stainless steel components. The right finish not only enhances aesthetic appeal but also provides additional protection against corrosion and wear, especially important for components exposed to harsh conditions. -

Dimensions

The size of the latch pin spring, including its diameter and length, is critical for ensuring compatibility with your application. Different applications may require specific dimensions for optimal performance, making it essential to verify these measurements before procurement. -

Load Rating

This property indicates the maximum load that a latch pin spring can handle without deforming or failing. It is essential for applications where safety and reliability are paramount. Understanding load ratings helps in selecting the appropriate spring for your operational needs.

What Are the Common Trade Terms Used in the Latch Pin Spring Industry?

Familiarizing yourself with industry-specific terminology can streamline communication and decision-making. Here are some essential terms:

Illustrative image related to latch pin spring

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of latch pin springs, OEMs are crucial as they set the standards for quality and specifications that other manufacturers must meet. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is vital for inventory management and cost-effectiveness. When sourcing latch pin springs, knowing the MOQ can help you plan your orders effectively to avoid excess inventory or stockouts. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific quantities of products. This is a common practice in B2B transactions, allowing buyers to compare costs and terms from various suppliers before making purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for managing logistics, shipping costs, and risk exposure when sourcing latch pin springs from international suppliers. -

Lead Time

Lead time refers to the time taken from placing an order to receiving it. This is a critical factor in production planning, as long lead times can impact project timelines. Knowing the lead times for latch pin springs helps in scheduling and inventory management. -

Certification Standards

These are industry-specific benchmarks that products must meet to ensure quality and safety. Common certifications for latch pin springs include ISO 9001 for quality management systems. Being aware of certification standards helps in evaluating the reliability and performance of suppliers.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the right latch pin springs for their applications while optimizing procurement processes.

Navigating Market Dynamics and Sourcing Trends in the latch pin spring Sector

What Are the Current Market Trends in the Latch Pin Spring Sector?

The global latch pin spring market is witnessing significant growth driven by several key factors. The demand for durable, efficient, and versatile latch mechanisms is rising across multiple industries, including automotive, aerospace, and construction. As international trade expands, particularly in regions like Africa, South America, the Middle East, and Europe, manufacturers are increasingly sourcing latch pin springs that meet specific industry standards. Notably, the trend toward customization is gaining momentum, with companies seeking tailored solutions to fit unique applications, such as quick-release mechanisms in automotive shipping and agricultural equipment.

Emerging technologies are reshaping the landscape of the latch pin spring sector. The integration of advanced manufacturing techniques, such as 3D printing and automated processes, allows for rapid prototyping and production of complex designs. This technological advancement not only reduces lead times but also enhances product quality and consistency. Furthermore, the rise of e-commerce platforms has made it easier for international B2B buyers to access a wider range of suppliers, enabling them to compare products and prices effectively.

Illustrative image related to latch pin spring

As sustainability becomes a priority globally, manufacturers are increasingly adopting eco-friendly practices. This includes sourcing materials responsibly and implementing energy-efficient production methods. Buyers are encouraged to consider suppliers that demonstrate a commitment to sustainability, as this not only aligns with corporate social responsibility goals but can also improve brand reputation in the marketplace.

How Important Is Sustainability and Ethical Sourcing in the Latch Pin Spring Industry?

Sustainability and ethical sourcing are critical considerations for B2B buyers in the latch pin spring sector. The environmental impact of manufacturing processes, particularly in metalworking and fabrication, has led to increased scrutiny from consumers and regulatory bodies alike. Buyers must prioritize suppliers that adopt sustainable practices, such as minimizing waste, reducing emissions, and utilizing recyclable materials. This not only helps in mitigating environmental impact but also fulfills corporate sustainability goals.

Additionally, the importance of ethical supply chains cannot be overstated. Suppliers who engage in fair labor practices and demonstrate transparency in their operations are increasingly favored by buyers. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) signal a supplier’s commitment to ethical standards. Buyers should actively seek out partners that hold these certifications to ensure compliance with international standards and to foster responsible sourcing practices.

The use of ‘green’ materials, such as stainless steel and other recyclable components, is becoming more prevalent in the latch pin spring market. By selecting products that utilize these materials, buyers can contribute to a circular economy, reducing the overall carbon footprint associated with their supply chains. This focus on sustainability not only enhances brand image but also meets the growing consumer demand for environmentally responsible products.

How Has the Latch Pin Spring Sector Evolved Over Time?

The latch pin spring sector has undergone significant evolution since its inception, adapting to changing industrial needs and technological advancements. Initially used in basic mechanical applications, latch pin springs have evolved into sophisticated components essential for various industries, including automotive, aerospace, and industrial manufacturing. The introduction of new materials and manufacturing processes has enhanced their durability and functionality, allowing for a broader range of applications.

In recent years, the demand for latch pin springs that support quick-release mechanisms has surged, driven by the need for efficiency in assembly and disassembly processes. This evolution reflects the broader trend of automation and efficiency in manufacturing, where the ability to quickly and securely fasten components is crucial. As industries continue to innovate, the latch pin spring sector is expected to keep pace, offering increasingly advanced solutions to meet the diverse needs of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of latch pin spring

-

How do I choose the right latch pin spring for my application?

When selecting a latch pin spring, consider the specific requirements of your application, including load capacity, environmental conditions, and frequency of use. Assess the materials used in the spring, such as stainless steel for corrosion resistance or high-strength alloys for heavy-duty applications. Additionally, evaluate dimensions like pin diameter and housing size to ensure compatibility with your existing systems. Consulting with suppliers about your application’s needs can provide valuable insights and help you make an informed decision. -

What are the common applications for latch pin springs?

Latch pin springs are versatile components used in various applications, including automotive, industrial machinery, and agricultural equipment. They are commonly employed in quick-release mechanisms, tool hold-downs, and locking systems, enhancing functionality and safety. In sectors like shipping and logistics, they secure containers and packaging systems, while in the automotive industry, they can be found in seat adjusters and door latches. Understanding these applications can help you identify the right product for your needs. -

What is the typical minimum order quantity (MOQ) for latch pin springs?

Minimum order quantities for latch pin springs can vary significantly depending on the manufacturer and the complexity of the design. Generally, MOQs range from 100 to 1,000 pieces for standard products, while custom designs may require higher quantities. It is essential to discuss your specific requirements with potential suppliers to negotiate terms that fit your purchasing strategy and ensure cost-effective sourcing. -

What customization options are available for latch pin springs?

Most suppliers offer customization options for latch pin springs, allowing you to tailor dimensions, materials, and finishes to meet specific application requirements. Customization may include altering pin length, diameter, or incorporating specific coatings for enhanced durability. Some manufacturers also provide design services and CAD files to facilitate the development of bespoke solutions. Engaging early with your supplier can streamline the customization process and ensure timely delivery. -

How can I verify the reliability of a latch pin spring supplier?

To verify a supplier’s reliability, start by checking their industry certifications and quality management systems, such as ISO 9001. Request references or case studies from previous clients to gauge their experience and performance. Conducting on-site visits or audits can provide deeper insights into their manufacturing processes and capabilities. Additionally, consider suppliers who offer warranties or guarantees on their products, as this reflects their confidence in quality. -

What payment terms should I expect when sourcing latch pin springs internationally?

Payment terms for international orders typically vary by supplier and region but often include options such as advance payment, letters of credit, or net payment terms (e.g., net 30 or net 60 days). Discuss payment options early in negotiations to ensure they align with your financial processes. Be aware of any additional costs, such as customs duties or international shipping fees, which can impact your overall budget. -

What quality assurance measures should be in place for latch pin springs?

Quality assurance for latch pin springs should include rigorous testing procedures to assess performance under load, fatigue resistance, and durability. Suppliers should have a documented quality control process, including inspections at various production stages and final testing before shipment. Requesting a certificate of conformity or inspection reports can provide additional assurance of product quality. Regular communication with suppliers about quality standards will foster a strong partnership. -

What logistics considerations should I be aware of when importing latch pin springs?

When importing latch pin springs, consider logistics factors such as shipping methods, lead times, and customs regulations specific to your country. Ensure that your supplier can provide accurate shipping documents and comply with international trade regulations. Evaluate the total landed cost, including shipping, insurance, and tariffs, to avoid unexpected expenses. Partnering with a reliable freight forwarder can streamline the import process and help you navigate any challenges efficiently.

Top 5 Latch Pin Spring Manufacturers & Suppliers List

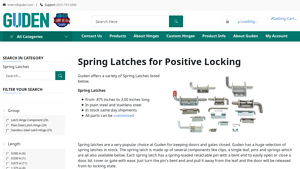

1. Guden – Spring Latches

Domain: guden.com

Registered: 1995 (30 years)

Introduction: Guden offers a variety of Spring Latches ranging from .875 inches to 3.00 inches long, available in plain steel and stainless steel. All parts can be customized and are in stock for same-day shipments. Spring latches feature a spring-loaded retractable pin with a bent end for easy operation, allowing for the quick release of doors, lids, covers, or gates. Guden’s spring latches are also referred t…

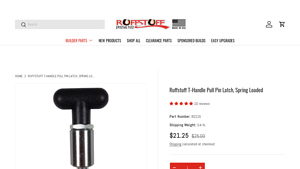

2. Ruffstuff – T-Handle Pull Pin Latch

Domain: ruffstuffspecialties.com

Registered: 2005 (20 years)

Introduction: {“Product Name”: “Ruffstuff T-Handle Pull Pin Latch, Spring Loaded”, “Part Number”: “R2215”, “Shipping Weight”: “0.4 lb”, “Price”: “$21.25”, “Original Price”: “$25.00”, “Material”: “Stainless steel”, “Dimensions”: {“Pin Diameter”: “1/2 inch”, “Pin Length”: “1/2 inch”, “Overall Height”: “3.5 inches”}, “Design”: “Spring-loaded mechanism with 1 inch O.D. weld-in housing”, “Key Features”: [“Heavy-duty…

3. Maxum Hardware – Latches and Fasteners

Domain: maxumhardware.com

Registered: 2007 (18 years)

Introduction: This company, Maxum Hardware – Latches and Fasteners, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Buyers Products – Heavy Duty Spring Latch

Domain: buyersproducts.com

Registered: 1997 (28 years)

Introduction: This company, Buyers Products – Heavy Duty Spring Latch, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

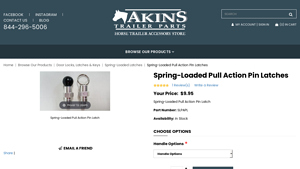

5. Horse Trailer Accessory Store – Spring-Loaded Pull Action Pin Latch

Domain: horsetraileraccessorystore.com

Registered: 2003 (22 years)

Introduction: {“Product Name”: “Spring-Loaded Pull Action Pin Latch”, “Part Number”: “SLPAPL”, “Price”: “$9.95”, “Availability”: “In Stock”, “Handle Options”: [{“Type”: “Split Ring Pull Handle”, “Pin Length”: “1/2 inch”}, {“Type”: “Round Knob Pull Handle”, “Pin Length”: “3/8 inch”, “Additional Cost”: “$1.00”}], “Material”: [{“Body”: “Aluminum”, “Bolt”: “Stainless Steel”, “Handle”: “1 inch diameter HD SPLIT RING…

Strategic Sourcing Conclusion and Outlook for latch pin spring

In the realm of latch pin springs, strategic sourcing emerges as a critical driver of operational efficiency and product quality. By aligning with reputable suppliers, businesses can ensure they are sourcing durable, high-performance components that meet their specific application needs. The versatility of latch pin springs across industries—from automotive to agricultural equipment—underscores the importance of selecting the right product for the right application.

International B2B buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize partnerships with manufacturers that offer robust product lines and customization options. This approach not only enhances supply chain resilience but also fosters innovation in product development.

As the market evolves, staying ahead of trends in material science and manufacturing processes will be essential. Companies that invest in strategic sourcing today will not only benefit from superior products but will also secure a competitive edge in their respective markets. Embrace the opportunity to connect with trusted suppliers, explore new technologies, and leverage the full potential of latch pin springs to drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to latch pin spring

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.