Everything You Need to Know About Lafarge And Egge Sourcing in 2025

Introduction: Navigating the Global Market for lafarge and egge

In the competitive landscape of global manufacturing, sourcing precision tube assemblies and welding services from reputable suppliers like Lafarge and Egge can present significant challenges for B2B buyers. Companies in industries such as aerospace, defense, and automotive often struggle to find reliable partners that not only meet stringent quality standards but also deliver on time and within budget. This comprehensive guide aims to empower international buyers, particularly those in Africa, South America, the Middle East, and Europe, by providing insights into the diverse offerings of Lafarge and Egge.

From exploring the intricacies of build-to-print tube assemblies to understanding the nuances of CNC machining and special process welding, this guide covers a wide range of topics crucial for informed purchasing decisions. We will delve into the various applications these services support, the key certifications that ensure product integrity, and effective supplier vetting strategies. Additionally, we will provide actionable insights into cost considerations and best practices for optimizing procurement processes.

By equipping buyers with the knowledge and tools necessary to navigate the complexities of sourcing from Lafarge and Egge, this guide seeks to enhance competitiveness and drive operational efficiency in your projects. Whether you are in Saudi Arabia or Brazil, understanding these key elements will position you to make strategic decisions that align with your business goals.

Understanding lafarge and egge Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tube Bending | Precision bending of high-pressure tubes; custom designs | Aerospace, automotive, medical devices | Pros: Tailored solutions, high durability. Cons: May require longer lead times for custom orders. |

| CNC Machining | Advanced CNC technology for close tolerance machining | Aerospace components, automotive parts | Pros: High precision, repeatability. Cons: Initial setup costs can be high. |

| Fusion Welding | Techniques include TIG and orbital welding; strong joints | Aerospace, defense, medical equipment | Pros: Exceptional strength and reliability. Cons: Requires skilled labor, potentially higher costs. |

| Sheet Metal Fabrication | Precision fabrication of complex shapes and assemblies | Aerospace, military, commercial equipment | Pros: Versatile applications, cost-effective for large runs. Cons: Less suitable for small batch production. |

| Torch Brazing | Joining metals with a flame; suitable for various alloys | Tool & die, automotive, aerospace | Pros: Good for dissimilar metals, lower heat distortion. Cons: Not as strong as welding for critical applications. |

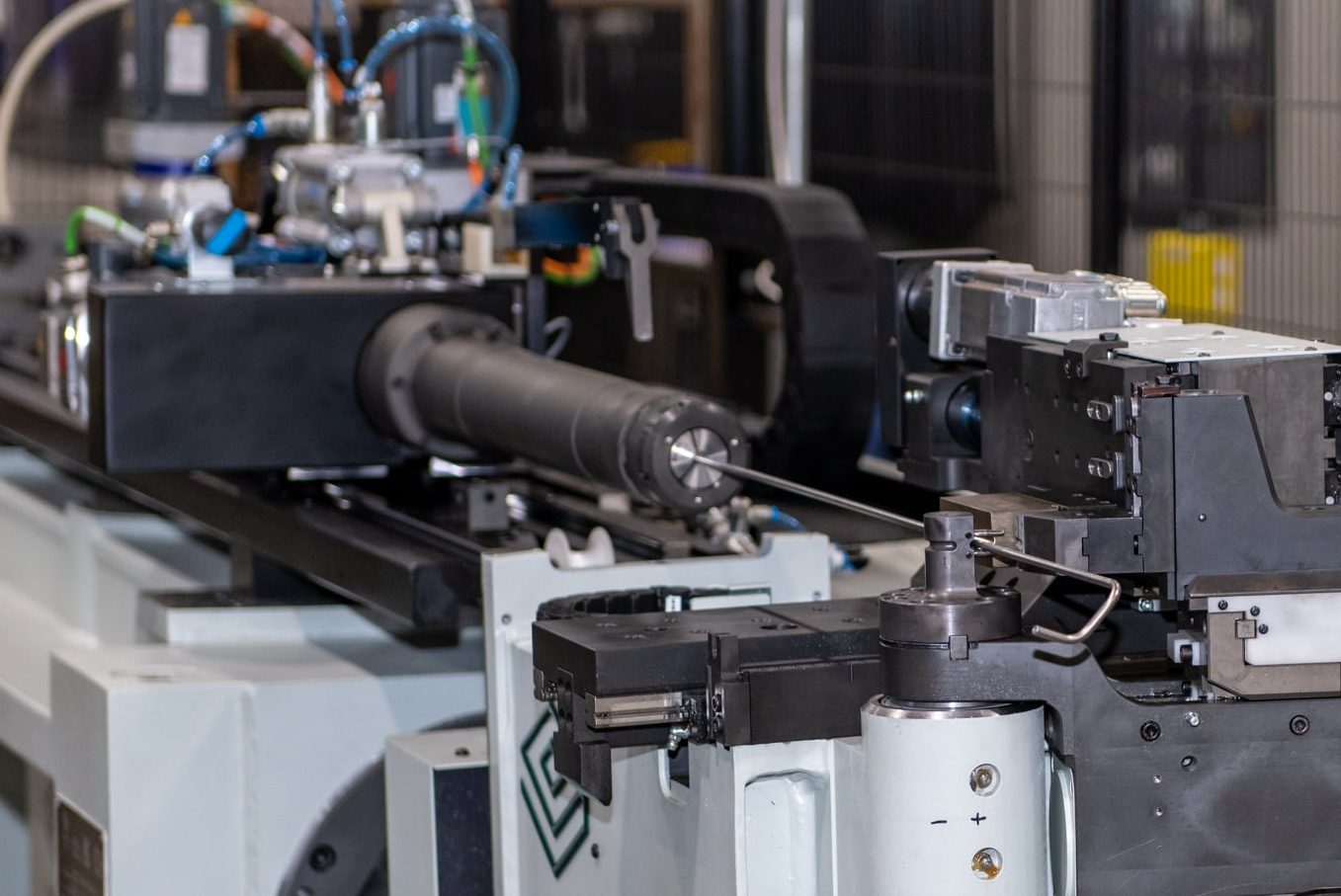

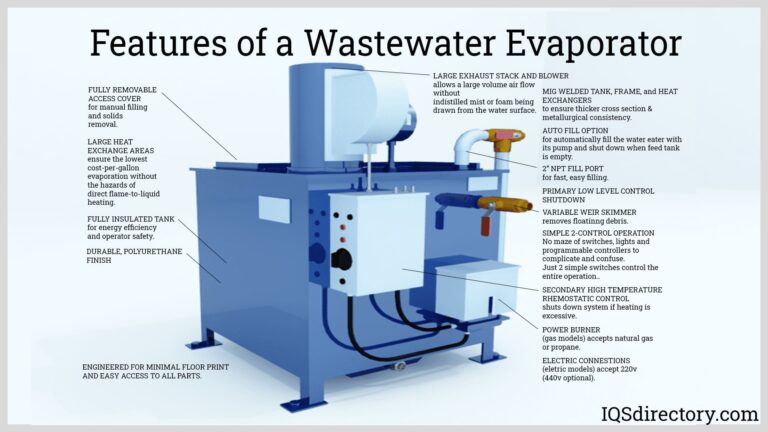

What Are the Key Characteristics of Tube Bending Services?

Tube bending services offered by Lafarge & Egge are characterized by their precision and adaptability. These services are essential for creating high-pressure tube assemblies used in various industries, particularly aerospace and automotive. Buyers should consider the specific requirements of their projects, such as the desired material and bending radius, to ensure optimal performance. The ability to customize tube designs enhances the service’s appeal, but buyers may encounter longer lead times for uniquely tailored solutions.

How Does CNC Machining Benefit B2B Buyers?

CNC machining at Lafarge & Egge utilizes advanced technology to achieve close tolerances and high precision in manufacturing components. This capability is particularly beneficial for industries like aerospace and automotive, where component accuracy is critical. Buyers should weigh the benefits of precision and repeatability against initial setup costs, which may be higher for complex projects. The investment in CNC machining can lead to significant long-term savings through reduced waste and increased efficiency.

What Makes Fusion Welding a Preferred Choice in Manufacturing?

Fusion welding, including TIG and orbital welding, is known for producing exceptionally strong joints essential in high-stress applications such as aerospace and defense. The rigorous standards upheld by Lafarge & Egge ensure that products meet necessary certifications, making them reliable for critical applications. Buyers must consider the skill level of the workforce required for such processes and the associated costs, but the benefits of strength and durability often outweigh the drawbacks.

Why Is Sheet Metal Fabrication Important for Diverse Industries?

Sheet metal fabrication services provide versatility in producing complex shapes and assemblies, making them invaluable for industries like aerospace and military. The ability to handle large production runs efficiently can lead to cost savings for buyers. However, those seeking small batch production may find this method less suitable due to economies of scale. Buyers should evaluate their production needs and budget to determine the best approach for their projects.

What Are the Advantages of Torch Brazing in Metal Joining?

Torch brazing is a metal joining technique that allows for the effective joining of dissimilar metals with minimal heat distortion. This method is particularly useful in industries like tool & die and automotive, where varying material types are common. Buyers should consider the application requirements, as torch brazing may not provide the same strength as welding for critical applications. However, its flexibility and cost-effectiveness make it an attractive option for many projects.

Illustrative image related to lafarge and egge

Key Industrial Applications of lafarge and egge

| Industry/Sector | Specific Application of lafarge and egge | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision tube assemblies for hydraulic systems | Enhanced reliability and performance in aircraft operations | Look for AS9100/ISO 9001 certifications and experience with aerospace standards. |

| Medical | Fabrication of complex tubing for medical devices | Improved patient safety and compliance with medical regulations | Ensure compliance with FDA regulations and certifications for medical applications. |

| Defense | Custom welding and tube bending for military equipment | Increased durability and performance under extreme conditions | Assess capabilities in high-stress environments and certifications relevant to defense contracts. |

| Automotive | CNC machining of automotive components | Cost-effective production with high precision | Evaluate tooling capabilities and experience with automotive industry standards. |

| Space | Tube assemblies for spacecraft systems | Critical support for mission success and safety | Verify experience in space applications and adherence to strict quality standards. |

How Does Lafarge & Egge Support the Aerospace Sector?

In the aerospace industry, Lafarge & Egge specializes in manufacturing precision tube assemblies for hydraulic systems, oxygen conveyance, and de-icing tubes. These assemblies are essential for ensuring the reliability and performance of aircraft operations. B2B buyers in this sector should prioritize suppliers with AS9100/ISO 9001 certifications and a proven track record in meeting stringent aerospace standards to ensure safety and quality in their aircraft components.

What Role Does Lafarge & Egge Play in the Medical Industry?

Lafarge & Egge’s expertise extends to the medical sector, where they fabricate complex tubing for various medical devices. These components are critical for patient safety and must comply with rigorous medical regulations. International buyers from regions like Africa and South America should confirm that their suppliers meet FDA regulations and possess the necessary certifications to ensure the highest quality and safety standards in medical applications.

How is Lafarge & Egge Involved in Defense Manufacturing?

In defense applications, Lafarge & Egge provides custom welding and tube bending services for military equipment. These components are designed to withstand extreme conditions, thus enhancing the durability and performance of defense systems. Buyers in this sector must assess the supplier’s capabilities to operate in high-stress environments and ensure that they hold relevant certifications for defense contracts, which can significantly impact project success.

Illustrative image related to lafarge and egge

Why Choose Lafarge & Egge for Automotive Components?

For the automotive industry, Lafarge & Egge offers CNC machining services that produce high-precision automotive components. This capability allows businesses to achieve cost-effective production while maintaining the necessary accuracy required in automotive manufacturing. B2B buyers should evaluate the supplier’s tooling capabilities and experience with automotive industry standards to ensure that they can meet specific project requirements.

How Does Lafarge & Egge Contribute to Space Exploration?

Lafarge & Egge is also involved in the space industry, providing tube assemblies for spacecraft systems. These components are crucial for mission success and safety, requiring adherence to stringent quality standards. Buyers in the space sector should verify the supplier’s experience in space applications and their commitment to maintaining high-quality production standards, as even minor failures can have significant consequences in space missions.

3 Common User Pain Points for ‘lafarge and egge’ & Their Solutions

Scenario 1: Inconsistent Quality in Precision Components

The Problem: A B2B buyer in the aerospace sector often struggles with the variability in quality of precision components from different suppliers. This inconsistency can lead to production delays, safety concerns, and increased costs due to rework or replacements. For a manufacturer reliant on tight tolerances and high-quality standards, such as those in aerospace applications, the risk of using subpar components is significant.

The Solution: To mitigate the risk of inconsistent quality, buyers should leverage Lafarge & Egge’s robust quality assurance processes, which are certified under AS9100 and ISO 9001 standards. When sourcing, it’s crucial to engage in open communication with the supplier about specific quality requirements and standards relevant to the project. Buyers can request detailed documentation on quality control processes, including inspection reports and certifications for materials and processes used. Additionally, establishing a long-term partnership with Lafarge & Egge can foster trust and ensure that the buyer’s expectations are consistently met, thereby reducing variability in the components supplied.

Scenario 2: Complex Supply Chain Management Challenges

The Problem: International buyers, particularly those in regions like Africa and South America, often face complexities in supply chain management, including delays in shipping, customs clearance issues, and fluctuating costs. This unpredictability can disrupt production schedules and affect the overall project timeline, leading to lost revenue and damaged client relationships.

Illustrative image related to lafarge and egge

The Solution: Buyers can alleviate these supply chain challenges by utilizing Lafarge & Egge’s established logistics and distribution networks. It is advisable for buyers to engage with Lafarge & Egge’s logistics team early in the planning process to discuss shipping options and timelines. By doing so, buyers can develop a clear understanding of lead times and potential bottlenecks. Additionally, implementing a just-in-time inventory strategy can help mitigate the risks associated with overstocking or stockouts. Regular communication and updates with Lafarge & Egge regarding order status can further enhance supply chain efficiency and reliability.

Scenario 3: Difficulty in Customization and Prototyping

The Problem: B2B buyers often encounter challenges when seeking customized solutions or rapid prototyping services for specialized applications, particularly in industries like defense or medical technology. The need for tailored solutions can lead to frustration when suppliers lack the flexibility or technical expertise to accommodate unique specifications.

The Solution: Lafarge & Egge’s extensive experience in precision machining and tube bending positions them as an ideal partner for customized projects. Buyers should clearly outline their specific requirements and desired outcomes during the initial discussions. It is beneficial to leverage Lafarge & Egge’s capabilities in prototyping and their advanced CNC machining technologies to create initial designs that can be tested and refined. Buyers can also request a collaborative approach where their engineering teams work alongside Lafarge & Egge’s experts to ensure that all technical specifications are met. This not only streamlines the prototyping process but also reduces the likelihood of costly revisions later in the production phase. Engaging in this collaborative model can lead to innovative solutions tailored to meet the unique needs of the buyer’s projects.

Strategic Material Selection Guide for lafarge and egge

What Are the Key Properties of Stainless Steel for Lafarge and Egge Applications?

Stainless steel is a favored material for Lafarge and Egge due to its excellent mechanical properties and corrosion resistance. It typically exhibits high strength and durability, making it suitable for high-pressure applications in industries such as aerospace and defense. Its temperature rating can exceed 800°C (1472°F), depending on the specific grade used, which is advantageous for applications involving extreme environments. Additionally, stainless steel’s resistance to oxidation and corrosion ensures longevity, reducing maintenance costs over time.

However, stainless steel can be more expensive than other materials, impacting overall project budgets. The manufacturing complexity involved in machining and welding stainless steel can also lead to longer lead times. Despite these challenges, its suitability for critical applications, such as hydraulic systems and structural components, often outweighs the drawbacks.

How Does Aluminum Compare as a Material Choice for Lafarge and Egge?

Aluminum is another material frequently utilized by Lafarge and Egge, particularly in aerospace and automotive applications. Known for its lightweight properties, aluminum reduces the overall weight of assemblies, which is crucial for fuel efficiency in aerospace applications. It also offers good corrosion resistance, especially when anodized, and can withstand temperatures up to 600°C (1112°F) in certain applications.

On the downside, aluminum’s lower strength compared to stainless steel can be a limitation in high-stress environments. Additionally, the cost of aluminum can vary significantly based on market conditions, which may affect project budgets. For international buyers, especially in regions like the Middle East and Africa, compliance with local standards for aluminum alloys (such as ASTM or JIS) is essential to ensure product integrity.

What Are the Advantages of Using Titanium in Lafarge and Egge Products?

Titanium is lauded for its exceptional strength-to-weight ratio and outstanding corrosion resistance, making it an ideal choice for high-performance applications in aerospace and medical industries. It can withstand temperatures up to 600°C (1112°F) while maintaining structural integrity, which is vital for components exposed to extreme conditions. Titanium’s biocompatibility also makes it suitable for medical applications.

However, titanium is one of the more expensive materials, which can pose a challenge for budget-conscious projects. Its manufacturing complexity is also higher, requiring specialized techniques for machining and welding. International buyers should be aware of specific certifications and compliance requirements for titanium products, particularly in regions with stringent aerospace regulations.

What Role Does Carbon Steel Play in Lafarge and Egge’s Offerings?

Carbon steel is commonly used in various applications due to its strength and affordability. It is suitable for less critical components where high corrosion resistance is not a primary concern. Carbon steel can handle moderate temperatures and pressures, making it a versatile choice for many applications, including automotive and general manufacturing.

The primary disadvantage of carbon steel is its susceptibility to rust and corrosion, which can lead to higher maintenance costs over time. Additionally, it may not be suitable for high-performance applications where weight and strength are critical. For international buyers, understanding the specific grades of carbon steel and their compliance with local standards (such as ASTM or DIN) is essential to ensure product suitability.

Summary Table of Material Selection for Lafarge and Egge

| Material | Typical Use Case for Lafarge and Egge | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Aerospace hydraulic systems | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Automotive components | Lightweight and good corrosion resistance | Lower strength in high-stress applications | Medium |

| Titanium | Aerospace and medical applications | Exceptional strength-to-weight ratio | High cost and complex manufacturing | High |

| Carbon Steel | General manufacturing components | Cost-effective and strong | Susceptible to corrosion | Low |

This guide provides a strategic overview of material selection for Lafarge and Egge, equipping international B2B buyers with the insights needed to make informed decisions based on application requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for lafarge and egge

What Are the Key Stages in the Manufacturing Process at Lafarge & Egge?

Lafarge & Egge employs a systematic approach to manufacturing that ensures high-quality output tailored to the specific needs of its clients. The manufacturing process can be broadly divided into four main stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Manufacturing?

The first stage involves meticulous material preparation, which is critical for ensuring the integrity and performance of the final product. Lafarge & Egge sources high-grade materials such as stainless steel, aluminum, and titanium, which are essential for industries like aerospace and medical. The materials undergo a thorough inspection upon arrival, ensuring they meet specified standards before proceeding to the next stage.

Lafarge & Egge utilizes advanced inventory management systems to track material specifications and ensure compliance with international standards. This attention to detail mitigates the risk of defects in the final product, aligning with the company’s commitment to quality.

What Forming Techniques Are Utilized?

The forming stage includes processes such as tube bending and CNC machining. Lafarge & Egge is particularly renowned for its tube bending capabilities, which cater to complex applications in hydraulic plumbing and air conveyance systems. The company employs both manual and automated methods to achieve precise bends and contours, ensuring that every component meets stringent dimensional tolerances.

CNC machining complements tube bending by enabling the production of intricate parts with high precision. The facility is equipped with state-of-the-art CNC machinery that allows for close tolerance machining, which is vital for applications in industries such as defense and aerospace.

How Does Assembly Take Place at Lafarge & Egge?

In the assembly phase, components are integrated to form complete systems. This step may involve kitting services, where multiple parts are grouped together for streamlined assembly. Lafarge & Egge emphasizes collaboration with its clients during this phase to ensure that the assembled products meet specific operational requirements.

Quality control checkpoints are embedded throughout the assembly process. This includes in-process quality checks to verify that each assembly meets the required standards before moving on to the next stage. These checks help in identifying and addressing issues early in the process, reducing the likelihood of defects in the final product.

What Finishing Techniques Are Employed?

The finishing stage focuses on enhancing the aesthetic and functional qualities of the products. This may involve surface treatments, coatings, or additional machining processes to achieve the desired finish. Lafarge & Egge utilizes advanced techniques such as laser welding and micro-welding, which not only enhance the strength of the assemblies but also ensure high-quality finishes that meet the aesthetic demands of clients.

What Quality Assurance Practices Are Essential at Lafarge & Egge?

Quality assurance is a cornerstone of Lafarge & Egge’s manufacturing philosophy. The company adheres to internationally recognized standards such as ISO 9001 and AS9100, which are crucial for maintaining quality in aerospace and other critical industries.

How Does Lafarge & Egge Ensure Compliance with International Standards?

Lafarge & Egge’s commitment to quality is evident in its comprehensive quality management system, which integrates the following key components:

- Incoming Quality Control (IQC): This involves inspecting raw materials to ensure they meet predefined specifications before they enter the manufacturing process.

- In-Process Quality Control (IPQC): Throughout the manufacturing stages, regular inspections are conducted to monitor compliance with quality standards. This helps to detect any deviations from specifications early on.

- Final Quality Control (FQC): Before products are shipped, they undergo rigorous final inspections to ensure they meet all customer and regulatory requirements.

What Testing Methods Are Commonly Used?

Lafarge & Egge employs a range of testing methods to validate the quality and performance of its products. Common techniques include:

- Pressure Testing: Used for tube assemblies to ensure they can withstand operational pressures without failure.

- Dimensional Inspection: Utilizing advanced measurement tools to confirm that products meet the specified tolerances.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or X-ray inspection are used to detect internal flaws without damaging the components.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers like Lafarge & Egge is vital. Here are actionable steps buyers can take:

-

Conduct Audits: Regular audits can provide insights into the supplier’s quality management systems and practices. This helps ensure compliance with industry standards and uncover any potential issues.

-

Request Quality Reports: Buyers should request quality assurance reports, including details of inspections, testing results, and any corrective actions taken. This transparency can build trust and confidence in the supplier’s capabilities.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of the supplier’s quality processes and product integrity. This is particularly beneficial when dealing with complex regulatory environments.

-

Understand Certification Nuances: Buyers should familiarize themselves with the specific certifications required in their region and how they align with international standards. This knowledge will aid in evaluating suppliers effectively.

Conclusion: Why Quality Assurance Matters for B2B Buyers

In a competitive global market, the manufacturing processes and quality assurance practices at Lafarge & Egge are critical for ensuring that products meet the highest standards of quality and reliability. By understanding these processes, B2B buyers can make informed decisions, fostering partnerships that enhance operational efficiency and product performance in their respective industries. As a result, investing time in verifying supplier capabilities and quality controls will ultimately lead to better outcomes for both parties.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lafarge and egge’

This practical sourcing guide aims to provide B2B buyers with a structured approach to procuring services and products from Lafarge & Egge, a renowned manufacturer specializing in precision welding and tube bending. By following this checklist, you can ensure that your procurement process is efficient, effective, and aligned with your specific project needs.

Illustrative image related to lafarge and egge

Step 1: Define Your Technical Specifications

Begin by clearly outlining your project requirements, including dimensions, materials, tolerances, and any specific industry standards that must be met. This is critical as it sets the groundwork for your interactions with potential suppliers. Be specific about the types of tube assemblies or welding processes you need, such as CNC machining or fusion welding, to facilitate accurate quotes and capabilities assessments.

Step 2: Research and Identify Qualified Suppliers

Conduct thorough research to identify suppliers that specialize in the areas you require. Focus on companies with a proven track record in the aerospace, defense, or medical industries, as these sectors often have stringent quality requirements. Use industry databases, trade shows, and professional networks to compile a list of potential suppliers that align with your needs.

Step 3: Verify Supplier Certifications

Certifications play a crucial role in ensuring that the supplier meets industry standards. Look for ISO 9001 and AS9100 certifications, which indicate a commitment to quality management systems. Additionally, check for Nadcap accreditation for special processes like welding, as these certifications demonstrate the supplier’s capability to meet specific technical requirements.

Step 4: Request Detailed Proposals

Once you have shortlisted potential suppliers, request detailed proposals that outline their capabilities, timelines, and pricing structures. A comprehensive proposal should include information on their manufacturing processes, quality control measures, and past project examples. This will help you compare options effectively and understand the value each supplier brings.

Step 5: Conduct Site Visits or Virtual Tours

If feasible, arrange for site visits to the supplier’s facilities or request virtual tours. Observing their operations firsthand will give you insights into their production capabilities, quality control processes, and overall work environment. Pay attention to the equipment used, cleanliness, and safety standards, as these factors can impact product quality.

Illustrative image related to lafarge and egge

Step 6: Evaluate Customer Support and Communication

Assess the level of customer support and communication offered by each supplier. Effective communication is essential for addressing issues that may arise during production. Ensure that your chosen supplier has a responsive team that can provide updates and handle inquiries promptly, as this will enhance your overall experience.

Step 7: Establish Clear Terms and Agreements

Before finalizing your order, ensure that all terms and agreements are clearly established. This includes payment terms, delivery schedules, and warranty policies. A well-defined agreement protects both parties and sets expectations for quality and timelines, reducing the risk of misunderstandings later in the project.

By following this checklist, you will be well-equipped to select a supplier that not only meets your technical specifications but also aligns with your business objectives, ensuring a successful partnership with Lafarge & Egge.

Comprehensive Cost and Pricing Analysis for lafarge and egge Sourcing

What Are the Key Cost Components for Lafarge & Egge’s Products?

When sourcing from Lafarge & Egge, understanding the cost structure is vital for effective budgeting and financial planning. The primary cost components include:

-

Materials: The cost of raw materials significantly impacts pricing. Lafarge & Egge utilizes high-quality alloys and materials suitable for aerospace and defense applications. Prices may vary based on market conditions and the specific materials chosen.

-

Labor: Skilled labor is essential for precision welding and machining. The costs associated with labor include not only wages but also training and certification processes, particularly for specialized tasks such as Nadcap-approved welding.

-

Manufacturing Overhead: This encompasses facility costs, utilities, and equipment maintenance. Given the advanced machinery used in CNC machining and welding, overhead can be substantial, especially for small batch production.

-

Tooling: Custom tooling is often required for specific projects. The initial investment in tooling can be significant, but it is amortized over the production run, affecting the overall cost per unit.

-

Quality Control (QC): Rigorous QC processes are necessary to meet industry certifications like AS9100 and ISO 9001. This includes testing and inspection costs, which are integral to maintaining product integrity.

-

Logistics: Shipping costs can vary widely depending on the destination and shipping method. International buyers should account for customs duties and potential delays, which can impact delivery timelines.

-

Margin: The profit margin applied by Lafarge & Egge will depend on the complexity of the project and the overall demand for their products. Margins may be tighter for high-volume contracts and more flexible for custom or low-volume orders.

How Do Price Influencers Impact Sourcing Decisions?

Several factors can influence the pricing of products from Lafarge & Egge, including:

-

Volume and Minimum Order Quantities (MOQ): Higher order volumes typically lead to lower per-unit costs. Understanding the MOQ for specific products can help buyers negotiate better pricing.

-

Specifications and Customization: Custom specifications often incur additional costs due to the need for specialized tooling and processes. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: The choice of materials and required certifications can significantly influence pricing. Products requiring higher-grade materials or additional testing may be priced at a premium.

-

Supplier Factors: The relationship with Lafarge & Egge and their reputation for quality can also affect pricing. Long-term partnerships may lead to more favorable terms.

-

Incoterms: International buyers should consider the Incoterms agreed upon in their contracts, as these define the responsibilities for shipping, insurance, and tariffs, impacting the total cost.

What Are the Best Tips for Negotiating with Lafarge & Egge?

-

Understand Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the lifetime costs associated with the product, including maintenance, logistics, and potential downtime. This holistic view can strengthen your negotiation position.

-

Leverage Volume Discounts: If your business can commit to larger orders, use this leverage to negotiate better pricing structures or payment terms.

-

Be Clear on Specifications: Providing detailed and clear specifications upfront can minimize misunderstandings and reduce costs associated with revisions or custom tooling.

-

Build a Relationship: Establishing a strong relationship with Lafarge & Egge can lead to better pricing and service. Regular communication can help both parties understand each other’s needs and constraints.

-

Stay Informed on Market Trends: Being aware of fluctuations in material costs and industry standards can give you an edge in negotiations, enabling you to make informed decisions.

Conclusion: What Should International Buyers Consider?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, it’s crucial to factor in additional costs such as tariffs and shipping delays when evaluating quotes from Lafarge & Egge. Always request a detailed breakdown of pricing to understand what influences the final cost. Keep in mind that indicative prices can vary based on current market conditions and specific project needs, so regular engagement with Lafarge & Egge will be key to optimizing your sourcing strategy.

Alternatives Analysis: Comparing lafarge and egge With Other Solutions

Understanding the Landscape of Alternatives in Precision Manufacturing

In the realm of precision manufacturing, particularly within the aerospace and medical sectors, businesses often seek the most effective solutions for tube bending and welding. Lafarge & Egge stands out with over six decades of experience, but potential buyers should also consider alternative solutions that might align better with their specific operational needs. This analysis will compare Lafarge & Egge with two alternative providers: Miller Electric and Lincoln Electric, both recognized for their welding and fabrication technologies.

Comparison Table

| Comparison Aspect | Lafarge And Egge | Miller Electric | Lincoln Electric |

|---|---|---|---|

| Performance | High precision, versatile across industries | Reliable for various applications, strong in welding | Excellent for heavy-duty applications, high efficiency |

| Cost | Mid-range, competitive pricing for high-quality output | Generally lower initial cost, but may require higher maintenance | Higher upfront investment, but long-term savings in efficiency |

| Ease of Implementation | Tailored solutions, may require longer onboarding | User-friendly, quick setup for standard applications | Requires skilled operators for optimal use |

| Maintenance | Regular maintenance needed for high standards | Low maintenance with durable equipment | Moderate maintenance, parts readily available |

| Best Use Case | Aerospace, medical, and complex assemblies | General welding tasks, small to medium projects | Heavy-duty industrial applications, high-volume production |

An In-Depth Look at Alternatives

Miller Electric

Miller Electric is renowned for its user-friendly welding equipment, which is particularly appealing for businesses looking to implement welding solutions quickly. Its products often come at a lower initial cost, making them accessible for smaller operations. However, while Miller’s machines are reliable for various applications, they may not deliver the same level of precision as Lafarge & Egge’s specialized services, particularly in highly regulated industries like aerospace and medical. Over time, maintenance costs could accumulate, potentially offsetting initial savings.

Lincoln Electric

Lincoln Electric offers robust welding solutions that excel in heavy-duty applications. While the upfront investment can be significant, their machines are designed for high efficiency and durability, making them ideal for companies engaged in high-volume production. The downside is that Lincoln Electric’s equipment may require skilled operators to maximize its potential, which can lead to increased labor costs. Additionally, while their focus is on heavy industrial applications, they may not cater as effectively to specialized needs in sectors like aerospace or medical, where precision is paramount.

Making the Right Choice for Your Business Needs

Selecting the appropriate manufacturing solution hinges on understanding your specific operational requirements and long-term goals. For B2B buyers, it is essential to consider factors such as the complexity of projects, budget constraints, and the skill level of available personnel. Lafarge & Egge shines in precision and specialized applications, making it suitable for industries where quality cannot be compromised. Conversely, if a business prioritizes cost-efficiency and flexibility for general welding tasks, alternatives like Miller Electric or Lincoln Electric may offer compelling benefits. Ultimately, the right choice will align with your production needs and operational strategy, ensuring that you maximize both efficiency and quality in your manufacturing processes.

Essential Technical Properties and Trade Terminology for lafarge and egge

What Are the Key Technical Properties That B2B Buyers Should Know About Lafarge & Egge?

Understanding the essential technical properties of products from Lafarge & Egge is crucial for B2B buyers, especially when considering specifications for aerospace, defense, medical, and automotive applications. Here are some critical specifications to keep in mind:

-

Material Grade

– Definition: Material grade refers to the classification of materials based on their composition and mechanical properties. Common materials include stainless steel, titanium, inconel, and aluminum.

– Importance: Selecting the right material grade is vital to ensure that the components meet the required strength, durability, and corrosion resistance for specific applications, particularly in high-stakes industries like aerospace and defense. -

Tolerance

– Definition: Tolerance is the permissible limit or limits of variation in a physical dimension or measured value, such as diameter or wall thickness.

– Importance: Precision machining requires tight tolerances to ensure that components fit together correctly and function as intended. This is especially critical in applications where safety and performance are paramount. -

Pressure Rating

– Definition: Pressure rating indicates the maximum pressure a component can withstand without failure, typically measured in psi (pounds per square inch).

– Importance: For applications in hydraulic and fluid systems, understanding the pressure rating is essential to prevent leaks or catastrophic failures, thereby ensuring operational safety and reliability. -

Weld Quality Standards

– Definition: This refers to the specific criteria that welding must meet, which can include visual inspections, non-destructive testing, and adherence to codes like D1.1 or AWS D17.1.

– Importance: High-quality welds are crucial for structural integrity in applications like aerospace and automotive. Ensuring compliance with recognized standards helps mitigate risks associated with weld failures. -

Dimensional Specifications

– Definition: Dimensional specifications outline the exact measurements required for components, including length, width, height, and diameter.

– Importance: Accurate dimensions are necessary for proper assembly and function. Misalignment due to incorrect dimensions can lead to costly reworks and delays.

What Are Common Trade Terms Relevant to B2B Transactions with Lafarge & Egge?

Familiarity with industry jargon can enhance communication and negotiation with Lafarge & Egge. Here are some key trade terms:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Many clients of Lafarge & Egge fall under this category, as they rely on high-quality components for their products, making it essential to ensure compatibility and compliance with specifications. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell.

– Relevance: Understanding the MOQ can help buyers plan their budgets and inventory effectively. It also affects pricing and the feasibility of placing orders. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services.

– Relevance: Issuing an RFQ is a standard practice in B2B transactions, allowing buyers to compare offers and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

– Relevance: Knowledge of Incoterms is crucial for international transactions, as it helps both parties understand their obligations and reduces the risk of disputes. -

Lead Time

– Definition: Lead time refers to the amount of time it takes from placing an order until the product is delivered.

– Relevance: Understanding lead times is vital for project planning and scheduling, particularly in industries where delays can have significant repercussions on production timelines.

By grasping these technical properties and trade terms, B2B buyers can engage more effectively with Lafarge & Egge, ensuring that their procurement processes align with industry standards and project requirements.

Navigating Market Dynamics and Sourcing Trends in the lafarge and egge Sector

What Are the Key Market Trends Impacting the Lafarge and Egge Sector?

The Lafarge and Egge sector is currently experiencing significant shifts driven by global demand for precision manufacturing in industries such as aerospace, medical, and automotive. The rise of advanced manufacturing technologies, including CNC machining and precision welding, is streamlining operations, enhancing product quality, and reducing lead times. International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are increasingly prioritizing suppliers who can deliver high-quality products with rapid turnaround times.

Emerging trends also include the integration of digital tools such as IoT and AI in manufacturing processes, which facilitate real-time data analysis and predictive maintenance. This not only improves operational efficiency but also helps in meeting the stringent quality standards required in sectors like aerospace. Furthermore, as the global market evolves, there is a noticeable shift towards local sourcing strategies. Buyers are seeking to minimize supply chain risks by collaborating with manufacturers who have a strong local presence, thus ensuring timely delivery and reduced logistics costs.

How Are Sustainability and Ethical Sourcing Influencing B2B Decisions in the Lafarge and Egge Sector?

Sustainability has become a critical consideration for B2B buyers in the Lafarge and Egge sector. The environmental impact of manufacturing processes, particularly in terms of emissions and waste, is under scrutiny. Buyers are increasingly inclined to partner with manufacturers who demonstrate a commitment to sustainable practices, such as using eco-friendly materials and adhering to ‘green’ certifications like ISO 14001.

Moreover, ethical sourcing is gaining traction as companies aim to ensure that their supply chains are transparent and responsible. This includes verifying that suppliers maintain fair labor practices and minimize environmental harm. As buyers demand more sustainable and ethical products, Lafarge and Egge can enhance their market position by adopting sustainable practices in their operations and supply chains. This not only meets regulatory requirements but also aligns with the values of conscientious consumers and businesses, fostering long-term relationships built on trust and shared goals.

What Is the Historical Context of Lafarge and Egge in the B2B Landscape?

Founded in 1962, Lafarge and Egge began as a specialized tube bending supplier for aerospace giants like Boeing. Over the decades, the company has evolved into a diversified manufacturer known for its precision welding, CNC machining, and complex tube assembly capabilities. With over 60 years of industry experience, Lafarge and Egge has established itself as a reliable partner across multiple sectors, including aerospace, defense, and medical.

Illustrative image related to lafarge and egge

The company’s commitment to quality and customer service has earned it several accolades, including the GE Aviation Supplier Development Award and the Boeing Supplier Performance Award. This history not only reflects the company’s growth but also its adaptability to market changes and technological advancements, making it a valuable resource for international B2B buyers seeking quality and reliability in manufacturing partnerships.

Frequently Asked Questions (FAQs) for B2B Buyers of lafarge and egge

-

How do I ensure the quality of products from Lafarge & Egge?

To ensure the quality of products from Lafarge & Egge, verify their certifications such as AS9100 and ISO 9001, which indicate adherence to international quality management standards. Additionally, request detailed information about their quality assurance processes, including inspections and testing protocols. Engaging in direct communication with their quality assurance team can provide insights into their commitment to product integrity. It’s also advisable to read testimonials or case studies from other clients in your industry to gauge their satisfaction with product quality. -

What is the best approach for sourcing tube bending and welding services?

The best approach for sourcing tube bending and welding services is to conduct a thorough supplier assessment. Start by identifying your specific project requirements, such as material types and tolerances. Evaluate potential suppliers based on their expertise, industry certifications, and previous project experiences. Request samples or prototypes to assess their manufacturing capabilities. Building a strong relationship with the supplier can also facilitate better communication, ensuring that your project specifications are fully understood and met. -

How can I customize my order with Lafarge & Egge?

Customization options with Lafarge & Egge can include material selection, dimensions, and specific fabrication techniques tailored to your project requirements. To initiate the customization process, discuss your needs directly with their engineering team, who can provide insights on feasibility and design considerations. Providing detailed specifications and drawings will help the team understand your requirements more effectively. Additionally, inquire about any limitations in customization based on their current manufacturing capabilities. -

What are the minimum order quantities (MOQs) for products?

Minimum order quantities (MOQs) for products at Lafarge & Egge typically depend on the specific service or product being ordered. It’s essential to communicate your needs directly with the sales team to understand any MOQ requirements that may apply to your project. Discussing your project scope can help them provide tailored solutions, especially for unique or large-scale production runs. Understanding MOQs upfront can assist in budgeting and planning your procurement strategy effectively. -

What payment terms does Lafarge & Egge offer for international buyers?

Lafarge & Egge generally offers flexible payment terms for international buyers, which may include options such as upfront payments, net 30, or net 60 terms, depending on the order size and relationship with the buyer. It’s advisable to confirm specific terms directly with their finance department, as these can vary based on project scope and client history. Additionally, discussing payment methods, including wire transfers or letters of credit, can facilitate smoother transactions for international orders. -

How does Lafarge & Egge handle logistics for international shipping?

Lafarge & Egge has established logistics protocols for international shipping that include collaborating with trusted freight forwarders to ensure timely and safe delivery of products. They can assist in providing necessary documentation for customs clearance, which is crucial for international shipments. Discuss your shipping requirements and timelines with their logistics team to ensure that your products arrive as scheduled. Understanding their logistics process can help mitigate potential delays and enhance your overall procurement experience. -

What industries does Lafarge & Egge serve, and how does this affect their capabilities?

Lafarge & Egge serves a diverse range of industries, including aerospace, defense, automotive, medical, and commercial sectors. This broad industry focus enhances their manufacturing capabilities, allowing them to adapt to various project specifications and technical challenges. Their experience across multiple sectors means they can apply best practices and innovative solutions from one industry to another, providing clients with a competitive edge. Understanding their industry expertise can help you assess how well they can meet your specific needs. -

What should I look for when vetting suppliers like Lafarge & Egge?

When vetting suppliers like Lafarge & Egge, consider factors such as industry certifications, years of experience, and client testimonials. Assess their technical capabilities, including machinery and technology used in production. It’s also vital to evaluate their financial stability and responsiveness to inquiries. Engaging in a site visit or requesting a factory tour can provide firsthand insight into their operations. Lastly, ensure they have a strong customer support system to address any issues that may arise during the partnership.

Top 5 Lafarge And Egge Manufacturers & Suppliers List

1. Lafarge & Egge – Tube Bending and Welding Services

Domain: lafargeandegge.com

Registered: 2017 (8 years)

Introduction: Lafarge & Egge is an AS9100/ISO 9001 manufacturer with over 60 years of experience in tube bending and welding services. They offer build-to-print tube assemblies, CNC machining, fusion welding (TIG, orbital), Nadcap and D1-4426 special process welding, and torch brazing services. Their capabilities include high pressure tube assemblies for industries such as aerospace, space, medical, defense, au…

2. Lafarge & Egge – Precision Tube Assemblies

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: This company, Lafarge & Egge – Precision Tube Assemblies, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. LaFarge & Egge, Inc. – Precision Tube Bending Services

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: LaFarge & Egge, Inc. provides high quality precision tube bending and fabrication for tubes up to 1-1/2″ diameter in materials including aluminum, stainless steel, titanium, inconel, and steel. Their services include flaring, beading, pressure testing, internal swaged fittings, and cryo fitting installation.

4. LaFarge & Egge – Precision Tubes & Sheet Metal Parts

Domain: pitchbook.com

Registered: 2004 (21 years)

Introduction: LaFarge & Egge manufactures precision tubes and sheet metal parts for airplane production. They offer precision sheet metal fabrication and tube bending services, supplying products to aerospace, government, military, medical, and commercial industries, enabling clients to meet diverse project needs at a cost-effective price.

5. Lafarge & Egge – Precision Tube Assemblies

Domain: rocketreach.co

Registered: 2015 (10 years)

Introduction: Lafarge & Egge specializes in small diameter precision tube assemblies and kits for the aerospace industry. They offer capabilities in precision engineering, aerospace components, precision tubing, precision machining, tube assemblies, metal tubing, mechanical assemblies, and tube bending. Their services include kitting, assembly, and supply chain engineering services. They are accredited in Nadca…

Strategic Sourcing Conclusion and Outlook for lafarge and egge

In navigating the complexities of global supply chains, strategic sourcing with Lafarge & Egge presents a compelling opportunity for international B2B buyers. With over 60 years of expertise in precision tube bending, welding, and CNC machining, Lafarge & Egge stands out as a reliable partner across various industries, including aerospace, medical, and automotive. Their commitment to quality, evidenced by numerous industry certifications and awards, ensures that clients receive not only superior products but also exceptional service tailored to their specific needs.

For businesses in Africa, South America, the Middle East, and Europe, leveraging Lafarge & Egge’s capabilities can significantly enhance operational efficiency and competitiveness. By choosing a supplier that prioritizes problem-solving and client-centric approaches, organizations can better navigate market demands and technological advancements.

As you consider your strategic sourcing options, engage with Lafarge & Egge to explore how their innovative solutions can meet your unique project requirements. The future of your supply chain could benefit immensely from a partnership that values integrity, quality, and responsiveness. Take the next step towards optimizing your sourcing strategy and contact Lafarge & Egge today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.