Everything You Need to Know About Laboratory Benching Sourcing in 2025

Introduction: Navigating the Global Market for laboratory benching

As international B2B buyers seek to establish efficient and effective laboratory environments, sourcing reliable laboratory benching solutions poses a significant challenge. With the diverse needs of laboratories across Africa, South America, the Middle East, and Europe—ranging from chemical resistance to ergonomic design—the task of selecting the right workbench can be daunting. This guide aims to demystify the global market for laboratory benching by providing a comprehensive overview of the various types, applications, and configurations available, alongside strategies for effective supplier vetting and cost considerations.

In this resource, you will find detailed insights into specific bench designs, such as heavy-duty, modular, and adjustable options, tailored to meet the unique demands of your laboratory. The guide also explores the importance of selecting materials that enhance durability and safety, ensuring compliance with international standards. By equipping B2B buyers with the knowledge to navigate this complex landscape, we empower you to make informed purchasing decisions that enhance operational efficiency and promote innovation in your laboratory spaces.

Whether you are based in Nigeria, Saudi Arabia, or elsewhere, understanding the nuances of laboratory benching is crucial for optimizing your lab’s functionality and productivity. This guide serves as your essential companion in sourcing the ideal laboratory workbench, ensuring that you invest wisely in equipment that meets your current and future needs.

Understanding laboratory benching Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Resin Top Lab Workbench | Durable, chemical-resistant resin surface | Chemical labs, industrial settings | Pros: High resistance to chemicals; easy to clean. Cons: Can be more expensive than basic models. |

| Stainless Steel Workbench | Corrosion-resistant, hygienic surface | Biotechnology, medical labs | Pros: Excellent durability and easy maintenance. Cons: Prone to scratching; may require regular polishing. |

| Adjustable Height Workbench | Height adaptability for ergonomic use | Educational institutions, research labs | Pros: Enhances user comfort; accommodates various tasks. Cons: Mechanisms may wear out over time. |

| ESD (Electrostatic Discharge) Workbench | Designed to prevent static electricity build-up | Electronics labs, cleanrooms | Pros: Protects sensitive electronic components. Cons: Limited to specific environments; may be costlier. |

| Modular Lab Benching | Flexible configurations, customizable designs | Research facilities, multi-use labs | Pros: Adaptable to changing needs; efficient space usage. Cons: Initial setup can be complex; may require professional installation. |

What Are the Key Characteristics of Resin Top Lab Workbenches?

Resin top lab workbenches are primarily made from high-density resin, offering exceptional durability and resistance to chemical spills. They are ideal for laboratories that handle corrosive substances, as their surfaces can withstand harsh cleaning agents. When purchasing, consider the load-bearing capacity and whether the bench design meets specific laboratory requirements.

How Do Stainless Steel Workbenches Stand Out?

Stainless steel workbenches are favored for their hygienic properties and resistance to corrosion. They are commonly used in biotechnology and medical labs where cleanliness is paramount. Buyers should evaluate the gauge of the steel to ensure it meets their durability needs, as heavier gauges typically provide better support and longevity.

What Benefits Do Adjustable Height Workbenches Provide?

Adjustable height workbenches cater to ergonomic needs by allowing users to modify the working height, promoting comfort during extended use. These benches are particularly beneficial in educational settings and research labs. When considering these options, buyers should assess the ease of adjustment mechanisms and the stability of the bench at varying heights.

Why Are ESD Workbenches Important for Electronics Labs?

ESD workbenches are specifically designed to dissipate static electricity, protecting sensitive electronic components during assembly or testing. These benches are crucial in electronics labs and cleanroom environments. Buyers should focus on the ESD ratings and ensure compliance with industry standards to safeguard their operations.

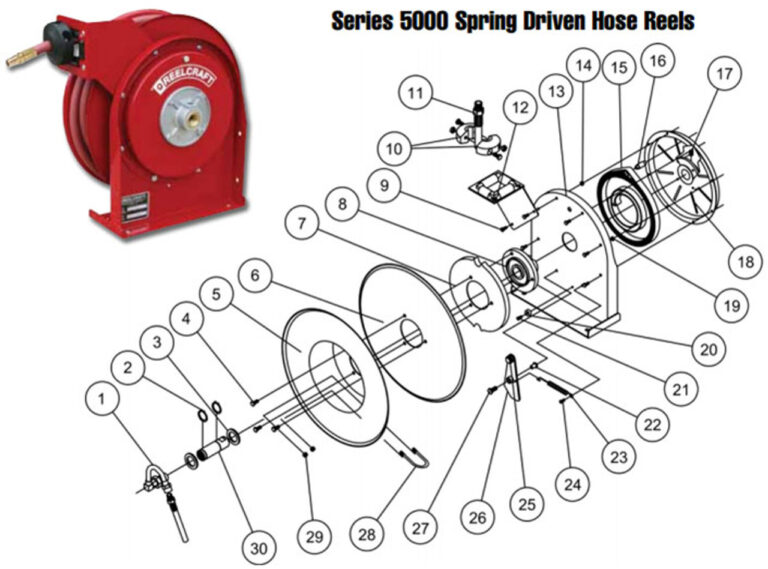

What Makes Modular Lab Benching a Flexible Solution?

Modular lab benching systems offer versatility, allowing laboratories to customize layouts based on specific needs and workflows. This adaptability is particularly valuable in research facilities that may require frequent reconfigurations. When investing in modular systems, consider the ease of assembly and the availability of additional components for future expansions.

Illustrative image related to laboratory benching

Key Industrial Applications of laboratory benching

| Industry/Sector | Specific Application of Laboratory Benching | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pharmaceuticals | Drug formulation and testing | Ensures compliance with regulatory standards and enhances safety | Need for chemical-resistant materials and customizable designs |

| Food and Beverage | Quality control and testing | Improves product safety and quality assurance | Must meet hygiene standards and be easy to clean |

| Environmental Testing | Sample analysis and reporting | Facilitates accurate data collection and analysis | Requires durable materials and ESD protection for sensitive equipment |

| Education and Research | Lab-based learning and experimentation | Enhances student engagement and practical learning experiences | Flexible configurations and height-adjustable options preferred |

| Biotechnology | Genetic research and development | Supports cutting-edge research and innovation | Need for cleanroom-compatible designs and modularity |

How is Laboratory Benching Used in Pharmaceuticals and What Problems Does It Solve?

In the pharmaceutical sector, laboratory benching is crucial for drug formulation and testing. These workbenches provide a stable and compliant environment for researchers to conduct experiments involving hazardous chemicals and biological materials. Buyers in this industry must consider benches made from chemical-resistant materials to ensure safety and durability. Additionally, customizable designs allow for integration with specialized equipment, helping to streamline workflows and maintain regulatory compliance.

What Role Does Laboratory Benching Play in Food and Beverage Quality Control?

Laboratory benching is essential in the food and beverage industry for quality control and testing processes. These benches facilitate the handling and analysis of samples, ensuring that products meet safety and quality standards. For international buyers, sourcing benches that comply with hygiene regulations is vital. Options that are easy to clean and resistant to spills and contaminants are particularly beneficial, as they help maintain high standards of food safety and reduce the risk of contamination.

How Do Environmental Testing Labs Utilize Laboratory Benching?

Environmental testing laboratories rely on specialized laboratory benching for sample analysis and reporting. These workbenches are designed to accommodate various testing equipment while ensuring accuracy and reliability in data collection. Buyers should prioritize benches made from durable materials that can withstand frequent use and are resistant to chemical exposure. Additionally, ESD (Electrostatic Discharge) protection is critical for safeguarding sensitive electronic devices used in testing processes.

In What Ways Does Laboratory Benching Enhance Education and Research Environments?

In educational and research settings, laboratory benching supports lab-based learning and experimentation. Flexible and height-adjustable workbenches enable students and researchers to engage in hands-on learning experiences, fostering a deeper understanding of scientific principles. International buyers should consider sourcing modular benching systems that can be easily reconfigured to adapt to different teaching methods and research needs. This adaptability not only maximizes space but also enhances the overall learning environment.

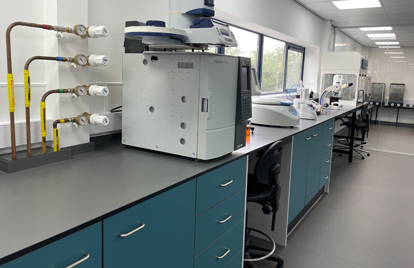

What Specific Needs Do Biotechnology Firms Have Regarding Laboratory Benching?

Biotechnology firms utilize laboratory benching for genetic research and development, requiring highly specialized workspaces. These benches must accommodate advanced equipment and provide a cleanroom-compatible environment to prevent contamination. Buyers in this sector should focus on sourcing modular systems that allow for easy reconfiguration as research needs evolve. Additionally, benches that support proper airflow and filtration systems are essential to maintain the integrity of sensitive experiments and promote innovation in biotechnological advancements.

Illustrative image related to laboratory benching

3 Common User Pain Points for ‘laboratory benching’ & Their Solutions

Scenario 1: Difficulty in Customizing Laboratory Benches for Specific Needs

The Problem:

B2B buyers often struggle with the challenge of finding laboratory benches that meet the specific needs of their unique environments. For instance, a laboratory focused on high-precision chemistry may require benches with specific chemical-resistant materials, while a biology lab may need integrated sink and drainage systems. The one-size-fits-all approach of many suppliers can lead to inefficiencies, safety hazards, and increased costs associated with retrofitting or replacing inadequate benches.

The Solution:

To address this issue, buyers should seek suppliers that offer customizable laboratory benching solutions. Engage in a co-creation process with manufacturers who specialize in modular bench systems, such as the Modulab Connect® system. This allows for the design of benches tailored to specific applications, ensuring that all necessary features are included from the outset. When specifying your needs, consider factors such as load-bearing capacity, material compatibility with chemicals, and any required electrical or plumbing integrations. Conducting a thorough needs assessment will facilitate a smoother procurement process and ensure that the final product meets the laboratory’s operational requirements.

Scenario 2: Ensuring Safety and Compliance in Laboratory Environments

The Problem:

Safety compliance is a paramount concern in laboratory settings, especially when dealing with hazardous materials. B2B buyers often face challenges in sourcing laboratory benches that adhere to local safety regulations and standards. For example, non-compliance can lead to accidents, legal issues, and costly downtime. Many buyers find it difficult to navigate the myriad of regulations governing laboratory equipment, which can vary significantly by region, particularly in international markets such as Africa and the Middle East.

The Solution:

To mitigate this risk, it’s crucial to partner with suppliers who are knowledgeable about local and international safety standards. When sourcing laboratory benches, request documentation that demonstrates compliance with relevant regulations, such as those from ISO or ASTM. Additionally, consider investing in benches that come with built-in safety features, such as anti-slip surfaces, rounded edges, and integrated containment systems for spills. Regular training sessions for laboratory staff on the proper use and maintenance of these benches can further enhance safety and compliance, ensuring that all personnel understand the operational limits and safety protocols associated with the equipment.

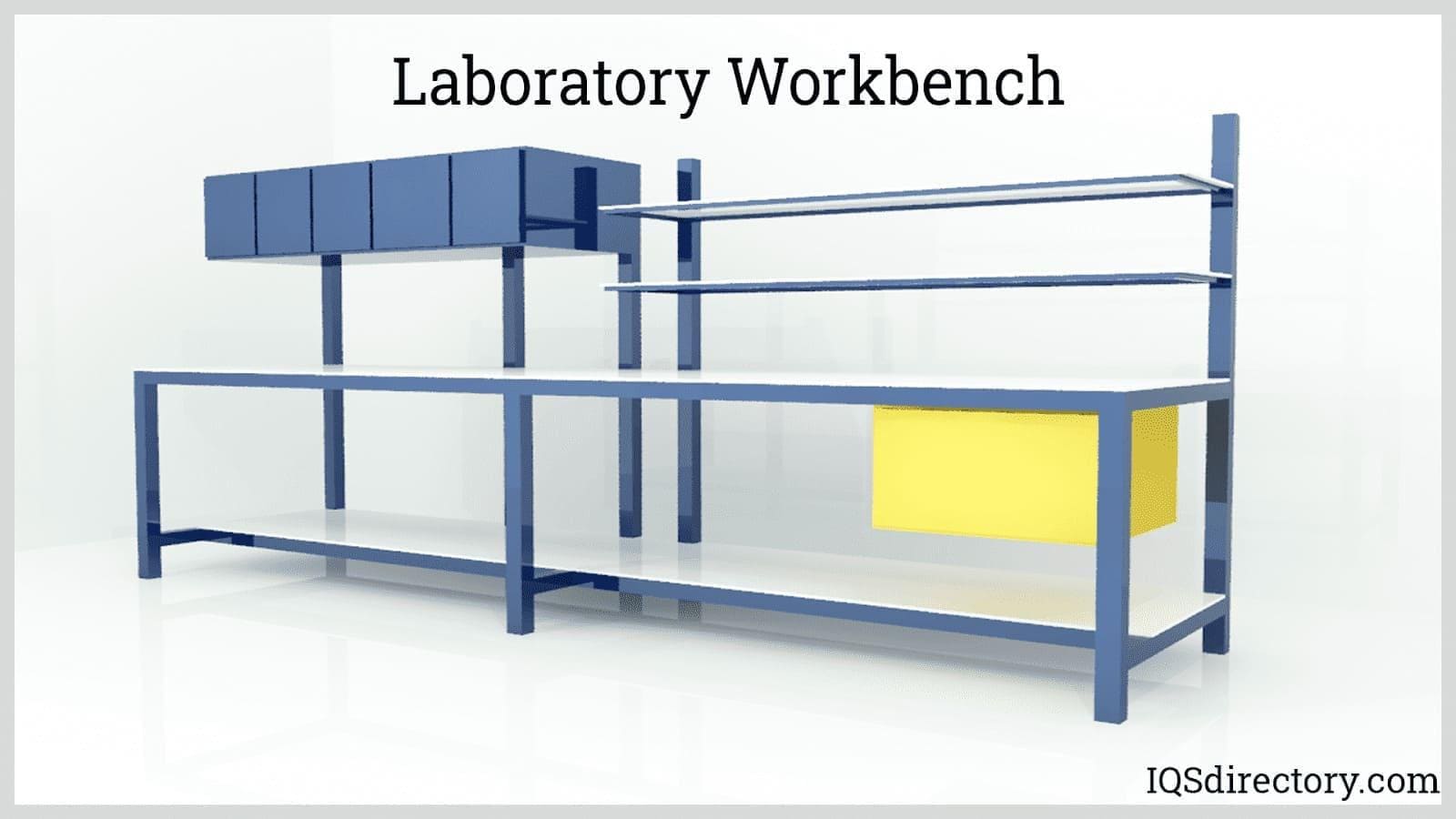

Scenario 3: Managing Space Constraints in Laboratory Design

The Problem:

Space limitations can pose significant challenges for laboratories, especially in urban areas where real estate is at a premium. B2B buyers may find that their existing laboratory space is not conducive to the efficient flow of work, leading to overcrowded conditions and decreased productivity. This situation is exacerbated in regions where laboratories are often retrofitted into smaller, pre-existing structures, resulting in inadequate workspace for staff and equipment.

Illustrative image related to laboratory benching

The Solution:

To effectively manage space constraints, buyers should consider modular and mobile laboratory benching solutions. Modular systems allow for flexible configurations that can be easily adjusted based on the laboratory’s evolving needs. For example, height-adjustable benches can accommodate both standing and seated work, optimizing space usage and improving ergonomics. Furthermore, incorporating mobile benches can facilitate the reconfiguration of laboratory layouts as needed, enhancing workflow and accessibility. When planning a laboratory layout, use 3D design tools offered by some suppliers to visualize the space and test different configurations before making a purchase. This proactive approach will help ensure that the laboratory operates efficiently, even within limited square footage.

Strategic Material Selection Guide for laboratory benching

When selecting materials for laboratory benching, it is crucial to consider the specific requirements of the laboratory environment, including chemical compatibility, durability, and compliance with international standards. Below, we analyze four common materials used in laboratory benching, highlighting their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Phenolic Resin in Laboratory Benching?

Phenolic resin is renowned for its excellent chemical resistance and durability. It can withstand high temperatures and is resistant to various solvents and corrosive substances, making it suitable for laboratories that handle aggressive chemicals. Its non-porous surface also aids in easy cleaning and maintenance.

Pros and Cons:

The primary advantage of phenolic resin is its robustness and resistance to chemicals and heat. However, it can be relatively expensive compared to other materials, which may deter budget-conscious buyers. Additionally, its manufacturing process can be complex, requiring specialized equipment.

Impact on Application:

Phenolic resin is particularly effective in environments dealing with acids, bases, and solvents, ensuring that the benching remains intact and functional over time.

Considerations for International Buyers:

Buyers from regions like Africa and the Middle East should ensure compliance with local safety standards and certifications, such as ASTM or DIN, which may dictate specific performance metrics for laboratory furniture.

How Does Stainless Steel Compare as a Material for Laboratory Benching?

Stainless steel is a popular choice due to its exceptional strength, corrosion resistance, and hygienic properties. It is particularly favored in laboratories that require sterile conditions, such as medical and pharmaceutical environments.

Pros and Cons:

The key advantage of stainless steel is its durability and ease of cleaning, making it ideal for laboratories with stringent hygiene requirements. However, it can be more expensive than other materials, and its susceptibility to scratching may be a concern in high-impact environments.

Illustrative image related to laboratory benching

Impact on Application:

Stainless steel is compatible with a wide range of media, including biological samples and chemicals, making it versatile for various laboratory applications.

Considerations for International Buyers:

In Europe and South America, there are specific regulations regarding the use of stainless steel in food and pharmaceutical applications, necessitating compliance with standards such as JIS and ISO.

What Are the Benefits of Laminate Surfaces for Laboratory Benching?

Laminate surfaces, often made from materials like Formica, offer a cost-effective solution for laboratory benching. They are available in various colors and finishes, allowing for customization in laboratory design.

Illustrative image related to laboratory benching

Pros and Cons:

Laminate surfaces are relatively inexpensive and easy to install, making them a popular choice for budget-conscious labs. However, they may not withstand harsh chemicals or high temperatures, limiting their use in certain applications.

Impact on Application:

These surfaces are ideal for less demanding laboratory environments, such as educational institutions or basic research labs, where exposure to aggressive chemicals is minimal.

Considerations for International Buyers:

Buyers in regions like Nigeria and Saudi Arabia should be aware of local climate conditions that may affect laminate durability, such as high humidity or extreme temperatures.

Illustrative image related to laboratory benching

Why Choose Butcher Block as a Material for Laboratory Benching?

Butcher block, typically made from hardwoods, offers a warm aesthetic and is often used in laboratories that require a sturdy work surface for manual tasks.

Pros and Cons:

The main advantage of butcher block is its natural resilience and ability to absorb shock, making it suitable for heavy-duty applications. However, it is less resistant to chemicals and moisture, which can lead to warping or degradation over time.

Impact on Application:

Butcher block is well-suited for laboratories focused on physical tasks, such as dissections or woodworking, where chemical exposure is limited.

Considerations for International Buyers:

Buyers should consider the availability of quality hardwoods in their region and ensure compliance with environmental regulations regarding wood sourcing.

Summary Table of Material Selection for Laboratory Benching

| Material | Typical Use Case for laboratory benching | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Phenolic Resin | Chemical handling and storage | Excellent chemical resistance | Higher cost and complex manufacturing | High |

| Stainless Steel | Sterile environments (medical/pharma) | Durable and easy to clean | More expensive, scratches easily | High |

| Laminate | Basic research and educational labs | Cost-effective and customizable | Limited chemical resistance | Low |

| Butcher Block | Heavy-duty physical tasks | Natural shock absorption | Poor chemical and moisture resistance | Medium |

This strategic material selection guide provides valuable insights for B2B buyers in diverse regions, helping them make informed decisions when investing in laboratory benching solutions.

In-depth Look: Manufacturing Processes and Quality Assurance for laboratory benching

What Are the Main Stages of Manufacturing Laboratory Benching?

The manufacturing process of laboratory benching involves several critical stages, each contributing to the final product’s quality and functionality. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves selecting high-quality materials suited for laboratory environments. Common materials include stainless steel, phenolic resin, laminate, and hardwood. Suppliers often conduct rigorous quality checks on incoming materials to ensure compliance with industry standards.

-

Forming: During this phase, the prepared materials are shaped into the desired components. Techniques such as CNC machining, laser cutting, and bending are commonly employed to achieve precise dimensions. These processes ensure that each part meets the specifications required for laboratory benching.

-

Assembly: After forming, components are assembled to create the final product. This may involve welding, bolting, or other fastening techniques. Effective assembly practices are crucial, as they directly influence the durability and stability of the workbench. Automated assembly lines are often used for efficiency, but skilled labor is essential for quality assurance.

-

Finishing: The final stage includes surface treatments and coatings to enhance durability and aesthetics. Common finishing techniques include powder coating, anodizing, and applying protective laminates. These treatments not only improve the appearance of the laboratory benches but also provide resistance to chemicals, moisture, and wear.

How Is Quality Assurance Implemented in Laboratory Benching?

Quality assurance (QA) in the manufacturing of laboratory benching is a structured process that ensures products meet specified standards and customer expectations. It includes adherence to international standards such as ISO 9001 and industry-specific certifications like CE and API.

-

International Standards Compliance: ISO 9001 is a widely recognized standard that outlines the requirements for a quality management system (QMS). Compliance ensures that manufacturers consistently produce high-quality products and enhances customer satisfaction. B2B buyers should verify that their suppliers maintain ISO certifications.

-

Quality Control Checkpoints: Various checkpoints throughout the manufacturing process help maintain quality. These include:

– Incoming Quality Control (IQC): Checks raw materials upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): Monitors production processes to identify defects early.

– Final Quality Control (FQC): Conducts thorough inspections of finished products before they are shipped. -

Common Testing Methods: Several testing methods are employed to assess product performance and safety, including:

– Load testing to ensure the bench can support specified weights.

– Chemical resistance testing to verify that surfaces can withstand exposure to various substances.

– Vibration and stability tests to ensure durability during use.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control processes of their suppliers. This can be achieved through several methods:

-

Supplier Audits: Conducting on-site audits allows buyers to assess manufacturing practices, quality control measures, and compliance with international standards. Audits can reveal insights into the supplier’s operational efficiency and commitment to quality.

-

Quality Reports: Requesting quality assurance documentation, including inspection reports and certification copies, can provide transparency regarding the supplier’s QC processes. These documents should detail any testing performed and results obtained.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased evaluation of a supplier’s products and processes. These inspections can occur at various stages, from raw material sourcing to final product delivery.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers face unique challenges when it comes to quality control in laboratory benching. Understanding these nuances can help mitigate risks and ensure product quality.

-

Regulatory Compliance: Different regions have varying regulations and standards that must be adhered to. For instance, CE marking is crucial for products sold in Europe, while other regions may have specific local certifications. Buyers should ensure that their suppliers understand and comply with these requirements.

-

Cultural and Operational Differences: Buyers from Africa, South America, the Middle East, and Europe may encounter cultural differences that impact quality expectations and manufacturing practices. Building strong relationships and clear communication with suppliers can help bridge these gaps.

-

Logistical Considerations: International shipping can introduce risks such as damage during transit. Buyers should consider working with suppliers who have robust packaging and shipping protocols to protect products during transport.

-

Post-Sale Support and Warranty: Understanding the supplier’s warranty policies and after-sale support can provide additional assurance regarding product quality. B2B buyers should clarify these details before finalizing contracts.

Conclusion

The manufacturing processes and quality assurance mechanisms for laboratory benching are critical to ensuring that products meet the rigorous demands of laboratory environments. B2B buyers should prioritize suppliers who demonstrate strong quality control practices, adherence to international standards, and a commitment to customer satisfaction. By understanding the manufacturing stages, quality assurance checkpoints, and verification methods, buyers can make informed decisions and establish successful partnerships in the laboratory equipment market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘laboratory benching’

In the competitive landscape of laboratory equipment procurement, sourcing high-quality laboratory benches is essential for optimizing workspace efficiency and ensuring safety. This guide provides a structured checklist to assist B2B buyers in effectively navigating the procurement process, tailored to the specific needs of laboratories in diverse regions.

Illustrative image related to laboratory benching

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for your laboratory benches. Consider factors such as load capacity, material types (e.g., stainless steel, laminate, or phenolic resin), and dimensions to ensure they meet your laboratory’s operational needs. Clearly defined specifications help avoid costly mistakes and ensure that the selected benches will support your intended applications.

Step 2: Assess Compliance and Safety Standards

It is vital to verify that the laboratory benches comply with relevant industry standards and regulations, such as ASTM or ISO certifications. Compliance ensures that the products meet safety and performance benchmarks, which is crucial for avoiding legal issues and ensuring a safe working environment. Ask potential suppliers for documentation that demonstrates their adherence to these standards.

Step 3: Evaluate Potential Suppliers

Before making a purchase, conduct thorough evaluations of potential suppliers. Review company profiles, case studies, and references from other clients, particularly those in similar industries or geographical locations. This due diligence not only helps assess the supplier’s reliability but also provides insight into their customer service and after-sales support.

Illustrative image related to laboratory benching

- Consider Supplier Experience: Look for suppliers with a proven track record in supplying laboratory equipment to your specific sector.

- Request Samples: If possible, request samples or demonstrations of the laboratory benches to evaluate their quality firsthand.

Step 4: Explore Customization Options

Depending on your laboratory’s unique requirements, explore suppliers that offer customizable solutions. Custom benches can be designed to fit specific workflows, ensuring maximum efficiency and usability. Collaborate closely with suppliers to develop a solution that meets your precise specifications while maximizing your return on investment.

Step 5: Analyze Pricing and Payment Terms

Obtain detailed quotes from multiple suppliers and analyze the pricing structures, including any additional costs for shipping, installation, or customization. Ensure that you understand the payment terms, including any financing options, to maintain cash flow and budget compliance. Comparing costs against features can help you identify the best value for your investment.

Step 6: Check Warranty and Support Services

Investigate the warranty and support services offered by potential suppliers. A robust warranty can protect your investment against defects and ensure long-term usability of the benches. Additionally, inquire about the availability of technical support and parts replacement, as this can significantly impact the longevity and performance of your laboratory setup.

Step 7: Finalize the Order and Logistics

Once you have selected a supplier, finalize your order by confirming all specifications, pricing, and delivery timelines. Discuss logistics to ensure timely delivery and installation, especially if your laboratory has specific operational deadlines. Clear communication during this phase can prevent misunderstandings and ensure a smooth procurement process.

By following these steps, B2B buyers can effectively navigate the sourcing of laboratory benches, ensuring that their investments contribute to a productive and safe laboratory environment.

Comprehensive Cost and Pricing Analysis for laboratory benching Sourcing

What are the Key Cost Components in Laboratory Benching Sourcing?

When sourcing laboratory benching, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly influences pricing. Common materials include solid wood, steel, resin, and laminate. Higher-quality materials typically command higher prices but offer better durability and longevity.

-

Labor: Labor costs vary based on the complexity of the benching design and local wage standards. Custom or specialized manufacturing processes may require skilled labor, increasing costs.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help minimize overhead.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. These costs should be amortized over the production volume to determine their impact on unit pricing.

-

Quality Control: Implementing rigorous QC processes ensures that the final product meets specifications and industry standards. This adds to costs but can prevent future liabilities and enhance customer satisfaction.

-

Logistics: Transportation and shipping costs can vary widely based on distance, shipping method, and volume. International buyers should consider these factors when calculating total costs.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. Understanding typical margins in the industry can aid in price negotiations.

How Do Price Influencers Affect Laboratory Benching Costs?

Several factors influence the pricing of laboratory benches, particularly in international markets.

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract significant discounts due to economies of scale. Buyers should assess their needs carefully to optimize order sizes.

-

Specifications and Customization: Custom-designed benches will generally be more expensive than standard models. Buyers should weigh the benefits of customization against the associated costs.

-

Material Quality and Certifications: Products that meet specific certifications (e.g., ESD compliance) or use premium materials will typically have higher prices. Buyers should evaluate the importance of these factors relative to their applications.

-

Supplier Factors: Supplier reputation, reliability, and service level can impact pricing. Established suppliers with a track record of quality may command higher prices but can offer greater peace of mind.

-

Incoterms: Understanding Incoterms is critical for international transactions. Terms like CIF (Cost, Insurance, Freight) or FOB (Free on Board) can affect the total landed cost, impacting the buyer’s budget.

What Tips Can Buyers Use for Cost-Efficiency in Laboratory Benching?

To achieve cost-efficiency, buyers should consider the following strategies:

-

Negotiate Pricing: Engage suppliers in discussions about pricing, especially for larger orders. Understanding the supplier’s cost structure can provide leverage during negotiations.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, durability, and replacement costs over time. Investing in higher-quality benches may yield lower TCO.

-

Research and Compare Suppliers: Conduct thorough market research to compare prices and offerings. This can help identify the best value options and avoid overpaying.

-

Understand Pricing Nuances in International Markets: Buyers from regions such as Africa, South America, and the Middle East should be aware of regional pricing differences influenced by local demand, import tariffs, and currency fluctuations.

-

Plan for Lead Times: Factor in lead times when ordering to avoid rushed purchases, which can lead to higher costs. Adequate planning can also allow for bulk purchasing opportunities.

Disclaimer on Indicative Prices

While this analysis provides a comprehensive overview of the cost and pricing landscape for laboratory benching, the prices mentioned are indicative and may vary based on specific supplier offerings, regional factors, and market conditions. It is advisable for buyers to obtain detailed quotes and conduct due diligence before making purchasing decisions.

Illustrative image related to laboratory benching

Alternatives Analysis: Comparing laboratory benching With Other Solutions

Exploring Alternative Solutions to Laboratory Benching

In the laboratory environment, selecting the right work surface is crucial for optimizing workflow, enhancing safety, and ensuring compliance with industry standards. While laboratory benching is a popular choice, several alternative solutions exist that can fulfill similar roles. This analysis will compare laboratory benching with modular workstations and mobile lab tables, providing insights that can help B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Laboratory Benching | Modular Workstations | Mobile Lab Tables |

|---|---|---|---|

| Performance | High durability; customizable for various tasks | Flexible configurations for different setups | Good for temporary setups; easy to relocate |

| Cost | Moderate to high, depending on materials | Typically higher initial investment | Generally lower; budget-friendly options |

| Ease of Implementation | Requires significant setup and space | Quick assembly; can be adapted on-site | Simple installation; minimal space required |

| Maintenance | Regular cleaning; durable materials reduce wear | May require more frequent adjustments | Easy to clean; portable design minimizes wear |

| Best Use Case | Ideal for permanent laboratory settings | Excellent for evolving lab environments | Suitable for educational or temporary use |

Detailed Breakdown of Alternatives

Modular Workstations

Modular workstations offer flexibility and adaptability, allowing laboratories to reconfigure their layouts as needs change. This solution is particularly beneficial for research facilities where workflows may evolve over time. The downside is that the initial investment can be higher, and these systems may require more frequent adjustments to maintain optimal performance. However, they provide a robust solution for labs anticipating growth or changes in focus.

Mobile Lab Tables

Mobile lab tables are designed for versatility, enabling quick rearrangement of laboratory spaces. These tables are typically lightweight and can be moved easily, making them ideal for educational settings or labs needing to adapt quickly to different projects. While they are generally more budget-friendly, their performance may not match that of fixed laboratory benches, especially in high-demand environments. Mobile tables may also have limited load-bearing capacities, which can be a concern for heavy equipment or extensive use.

Conclusion: How to Choose the Right Solution for Your Laboratory Needs

When selecting the right laboratory work surface, consider the specific requirements of your facility. Laboratory benching provides durability and customization, making it suitable for permanent installations where heavy use is expected. Modular workstations are ideal for labs that require flexibility and anticipate changes, while mobile lab tables offer an economical and versatile option for temporary setups. Evaluate your space, budget, and future needs to determine the most effective solution for your laboratory environment. This strategic approach will help ensure a well-functioning lab that meets both current and evolving requirements.

Essential Technical Properties and Trade Terminology for laboratory benching

What Are the Key Technical Properties of Laboratory Benching?

When selecting laboratory benches, understanding specific technical properties is crucial for ensuring that the workspace meets both safety and operational requirements. Here are some essential specifications to consider:

-

Material Grade

Laboratory benches are typically made from materials like stainless steel, phenolic resin, or solid wood. The material grade determines the bench’s durability, resistance to chemicals, and ability to withstand high loads. For instance, stainless steel benches are ideal for environments where cleanliness and corrosion resistance are paramount. Choosing the right material helps minimize maintenance costs and ensures longevity. -

Load Capacity

The load capacity indicates how much weight a bench can safely support. For example, some laboratory benches can handle loads ranging from 1,200 lbs to over 20,000 lbs, depending on their construction and materials. Understanding load capacity is vital for ensuring that the bench can accommodate laboratory equipment, samples, and other materials without compromising safety. -

Height Adjustability

Benches that offer adjustable heights provide ergonomic benefits, allowing users to work comfortably while reducing the risk of strain or injury. This feature is especially important in collaborative environments where multiple users may have different height preferences. Investing in adjustable benches can enhance productivity and worker satisfaction. -

Surface Finish

The surface finish of a laboratory bench can affect its resistance to chemicals, stains, and abrasions. For instance, a phenolic resin top provides excellent chemical resistance, making it suitable for handling corrosive substances. Selecting the right surface finish not only impacts the bench’s functionality but also its maintenance and cleaning requirements. -

Static Control Features

In environments sensitive to static electricity, such as electronics labs, ESD (Electrostatic Discharge) control features become crucial. Benches designed with static control materials help prevent damage to sensitive equipment. This property is particularly important for laboratories involved in research and development of electronic components. -

Modularity

Modular benches allow for flexible configurations and can adapt to changing laboratory needs. This adaptability can lead to cost savings and efficient use of space, as laboratories can reconfigure their setups without the need for complete replacement. Understanding modularity helps organizations future-proof their investments in lab furniture.

What Are Common Trade Terms in Laboratory Benching?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are several key terms relevant to laboratory benching:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In laboratory benching, buyers often source benches from OEMs that specialize in specific materials or designs, ensuring they receive high-quality products tailored to their needs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to assess whether they can meet the supplier’s requirements without overcommitting resources. This term is especially relevant for large-scale laboratory setups where multiple units are needed. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products or services. Including detailed specifications in an RFQ ensures that suppliers provide accurate pricing and availability, streamlining the procurement process. -

Incoterms

Incoterms, or International Commercial Terms, define the responsibilities of buyers and sellers in international trade. Familiarity with these terms helps buyers understand who bears the risk and cost of shipping, insurance, and customs clearance, which is crucial for international transactions involving laboratory equipment. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. In laboratory benching, lead times can vary significantly based on customization and manufacturing processes. Understanding lead times aids in project planning and ensures that laboratories can maintain operational continuity. -

Warranty

A warranty is a promise from the manufacturer regarding the condition of the product and the terms of repair or replacement. Knowing the warranty period and conditions can protect buyers from unexpected costs and ensure peace of mind regarding the durability of their laboratory benches.

By understanding these technical properties and trade terminologies, international B2B buyers can make informed decisions when investing in laboratory benching solutions, ensuring they meet their operational needs while maximizing return on investment.

Illustrative image related to laboratory benching

Navigating Market Dynamics and Sourcing Trends in the laboratory benching Sector

What Are the Current Market Dynamics and Key Trends in Laboratory Benching?

The laboratory benching sector is experiencing a transformative phase driven by several global factors. First, the increasing demand for advanced laboratory setups in biotechnology, pharmaceuticals, and research institutions is propelling market growth. B2B buyers from regions like Africa, South America, the Middle East, and Europe (e.g., Nigeria, Saudi Arabia) are particularly interested in high-quality, durable workbenches that can withstand rigorous laboratory conditions. Furthermore, technological advancements such as modular and adjustable workbenches are gaining traction, offering flexibility and adaptability to various laboratory tasks.

Emerging trends include the integration of smart technology into laboratory furniture. Features such as adjustable height, built-in power sources, and data connectivity enhance usability and productivity. Buyers are also showing a preference for custom solutions tailored to specific laboratory needs, allowing them to maximize efficiency while minimizing space constraints. Additionally, the rapid growth of e-commerce platforms has simplified sourcing processes, enabling international buyers to access a wider range of products and suppliers with ease.

How Is Sustainability and Ethical Sourcing Influencing the Laboratory Benching Sector?

Sustainability is becoming a pivotal consideration in the sourcing of laboratory benching solutions. The environmental impact of manufacturing processes and the materials used in laboratory furniture has led buyers to prioritize products that are eco-friendly. This includes the use of recycled materials, sustainable wood sources, and finishes that minimize harmful emissions. For B2B buyers, choosing suppliers that demonstrate a commitment to sustainable practices not only aligns with global environmental goals but also enhances their corporate social responsibility profile.

Ethical sourcing is equally critical, as it ensures that the supply chain adheres to fair labor practices and responsible resource management. Certifications such as Forest Stewardship Council (FSC) for wood products or ISO 14001 for environmental management systems are increasingly sought after by buyers looking to validate their suppliers’ claims. By opting for certified products, businesses can mitigate risks associated with unethical practices and contribute positively to the global sustainability agenda.

What Is the Brief Evolution and History of Laboratory Benching?

The evolution of laboratory benching can be traced back to the early days of scientific experimentation, where simple tables were used for various tasks. As scientific disciplines advanced, so did the need for specialized furniture that could accommodate complex equipment and provide safe working environments. By the mid-20th century, laboratory benches began to incorporate materials resistant to chemicals and corrosion, reflecting the growing sophistication of laboratory work.

Illustrative image related to laboratory benching

In recent years, the focus has shifted towards modular designs and customization, allowing laboratories to adapt their spaces to meet changing needs. This evolution is indicative of a broader trend towards flexibility and efficiency in laboratory environments, where the layout and functionality of benching solutions can significantly impact productivity and safety. As global demands continue to evolve, the laboratory benching sector is poised for further innovation, driven by the need for sustainability, efficiency, and technological integration.

Frequently Asked Questions (FAQs) for B2B Buyers of laboratory benching

-

1. How do I choose the right laboratory bench for my needs?

Choosing the right laboratory bench involves assessing your specific requirements, including the type of work being conducted, the materials being used, and the space available. Consider the bench’s load capacity, resistance to chemicals, and any necessary features like height adjustability or mobility. It’s also essential to evaluate whether a standard model suffices or if customization is necessary to maximize efficiency. Consulting with suppliers who offer a range of options, including modular systems, can help ensure that the bench meets your operational needs. -

2. What are the benefits of modular laboratory benching systems?

Modular laboratory benching systems offer flexibility, adaptability, and scalability. They can be reconfigured or expanded as laboratory needs change, making them ideal for evolving research environments. Additionally, these systems often allow for quick assembly and disassembly, reducing downtime during renovations. Investing in modular solutions can lead to long-term cost savings and improved laboratory efficiency, especially in dynamic settings where space and function may need to be adjusted frequently. -

3. What customization options are available for laboratory benches?

Customization options for laboratory benches can include varying materials (e.g., stainless steel, phenolic resin), dimensions, and features like integrated storage or specialized surfaces for specific applications. Suppliers often offer bespoke solutions tailored to the unique requirements of your laboratory. Collaborating with manufacturers during the design phase can enhance the functionality and aesthetic of the space, ensuring that the bench aligns with your workflow and equipment needs. -

4. What are the typical minimum order quantities (MOQs) for laboratory benching?

Minimum order quantities (MOQs) for laboratory benches vary by supplier and product type. While some manufacturers may have MOQs as low as one unit for standard models, customized benches often require larger orders to justify production costs. It’s advisable to discuss MOQs directly with suppliers, especially if you’re looking to procure multiple units or custom designs. Negotiating terms may be possible, particularly for long-term partnerships or bulk orders. -

5. What payment terms should I expect when sourcing laboratory benches internationally?

Payment terms for international orders can vary widely based on the supplier, order size, and relationship. Common terms include upfront deposits (often 30-50%), with the balance due prior to shipping. Some suppliers may offer net payment terms (e.g., net 30 or net 60) for established clients. Always clarify payment methods accepted (e.g., bank transfer, letters of credit) and ensure that terms are documented in the purchase agreement to avoid misunderstandings. -

6. How can I ensure quality assurance (QA) for my laboratory benches?

To ensure quality assurance (QA) when sourcing laboratory benches, request product specifications, certifications, and compliance documentation from suppliers. Many reputable manufacturers follow international standards (like ISO certifications) to ensure durability and safety. It can be beneficial to visit the manufacturing facility if possible or request third-party inspection services to verify the quality before shipment. Establishing clear QA protocols in your contract can help safeguard against subpar products. -

7. What logistics considerations should I keep in mind when importing laboratory benches?

When importing laboratory benches, consider logistics factors such as shipping methods, customs duties, and delivery timelines. Evaluate whether the supplier can handle shipping and customs clearance or if you need to arrange this independently. Ensure that your logistics partner is experienced in handling laboratory equipment to avoid damage during transit. Additionally, familiarize yourself with import regulations in your country to ensure compliance and a smooth delivery process. -

8. How do I vet suppliers for laboratory benching products?

Vetting suppliers for laboratory benching products involves researching their reputation, experience, and client reviews. Look for suppliers with a proven track record in the laboratory equipment industry and those who can provide references from previous clients. It’s beneficial to assess their product range, customization capabilities, and quality certifications. Engaging in direct communication can also provide insight into their responsiveness and customer service, which are crucial for long-term partnerships.

Top 6 Laboratory Benching Manufacturers & Suppliers List

1. Uline – Lab Workbenches

Domain: uline.com

Registered: 1995 (30 years)

Introduction: Lab Workbenches designed for labs, chemical plants, and science classrooms. Features include:

– Stands up to corrosive chemicals

– Phenolic top resists heat up to 350°F

– Non-porous, scratch and impact resistant

– 1″ thick

– Withstands harsh acids, moisture, and bacteria

– Heavy-gauge steel frame with sturdy square tube legs

– Adjustable height from 29 to 39″ in 2″ increments

– Capacity with botto…

2. FormaSpace – Modular Lab Bench Solutions

Domain: formaspace.com

Registered: 2006 (19 years)

Introduction: Lab Bench – Sample, Specimen Processing Furniture

– Modular specimen processing furniture designed for laboratories.

– Integrates heavy-duty sample processing and automation equipment.

– Offers mobility options and height adjustability for ergonomic use.

– Features biosafety cabinets for safe handling of hazardous materials.

– Canopy hoods and snorkels for venting non-toxic gases.

– Customizable s…

3. New England Lab – Optima Freestanding Benches

Domain: newenglandlab.com

Registered: 1997 (28 years)

Introduction: Optima freestanding benches are adaptable lab furniture designed for flexibility in laboratory settings. Key features include:

– Moveable, freestanding bench system

– Configurations: single or double-sided with shared post

– Fixed or adjustable height work surfaces

– Optional suspended, mobile, or cabinets on glides

– Quick connect to building mechanicals

– Pre-plumbed and pre-wired

Produc…

4. Genie Scientific – Lab Benches

Domain: geniescientific.com

Registered: 2001 (24 years)

Introduction: Lab benches are classified into three subsections: Purpose, Function, and Structure. Purpose includes specialized designs like cleanroom benches, sink lab benches, and island lab benches. Function covers dry lab benches for non-reactive activities and wet lab benches for handling chemicals and biological samples. Structure includes suspended, floor-mounted, and mobile lab benches. Dry lab benches …

5. Loc Scientific – Laboratory Workstations

Domain: locscientific.com

Registered: 1998 (27 years)

Introduction: Laboratory Benches & Workstations include: “ERGO-LINE” Workbench, “Millennium II” Workbench, “HD” Modular Workbench, “BASICS” Modular Workbench, “DIMENSION NEXT” Expandable Workbench, “HDL” Workbench, and “ELECTRIC WIRE HARNESS” Workbench. These products are designed for durability, adaptability, and performance in laboratory environments, offering advanced electrical integration, high-durability …

6. Thomas Scientific – Lab Workbenches and Tables

Domain: thomassci.com

Registered: 1995 (30 years)

Introduction: Lab workbenches and work tables are essential components in any laboratory setting, designed for versatility and durability. They provide a stable, sturdy surface for conducting experiments, handling lab equipment, and facilitating data analysis. Typically constructed with materials like stainless steel or chemically resistant laminates, these tables ensure longevity and ease of maintenance. Key d…

Strategic Sourcing Conclusion and Outlook for laboratory benching

In today’s rapidly evolving laboratory landscape, strategic sourcing for laboratory benching is paramount for optimizing operational efficiency and maximizing return on investment. By understanding the diverse range of available workbench types—from chemical-resistant models to modular systems—buyers can make informed decisions that align with their specific laboratory needs. Emphasizing customization and adaptability, suppliers are now offering innovative solutions that cater to the unique challenges faced by laboratories across various sectors.

For international B2B buyers, especially those in regions such as Africa, South America, the Middle East, and Europe, the importance of sourcing high-quality, durable laboratory benches cannot be overstated. Investing in the right infrastructure not only enhances productivity but also supports compliance with safety and regulatory standards.

Illustrative image related to laboratory benching

As you consider your next procurement strategy, explore the latest offerings in laboratory benching that can future-proof your operations. Engage with suppliers who prioritize co-creation and can tailor solutions to your requirements. By doing so, you position your laboratory for success in a competitive global market. Take the next step in enhancing your laboratory’s capabilities and ensure your sourcing strategy is both strategic and forward-looking.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to laboratory benching

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.