Everything You Need to Know About Kiss Wire Sourcing in 2025

Introduction: Navigating the Global Market for kiss wire

In an increasingly interconnected global market, sourcing high-quality kiss wire can pose significant challenges for international B2B buyers. Whether you are in Nigeria, Saudi Arabia, or any part of Europe, understanding the diverse types and applications of kiss wire is crucial to meeting your operational needs. This guide serves as a comprehensive resource, addressing everything from the various types of kiss wire available—such as oil-tempered, galvanized, and superconductive wire—to their specific applications in industries like construction, automotive, and medical technology.

Navigating the complexities of supplier vetting and cost assessment is essential for making informed purchasing decisions. This guide empowers B2B buyers by offering actionable insights into best practices for evaluating suppliers, negotiating prices, and ensuring product quality. By delving into the intricacies of kiss wire sourcing, you can better position your business to capitalize on emerging opportunities in your respective markets.

With a focus on international buyers from Africa, South America, the Middle East, and Europe, this resource is tailored to help you mitigate risks and streamline your procurement processes. As you explore the sections ahead, you’ll gain the knowledge necessary to make strategic decisions that enhance your supply chain and drive competitive advantage in your industry.

Understanding kiss wire Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Oil Tempered Wire | Enhanced durability and flexibility through heat treatment | Automotive springs, industrial machinery | Pros: High fatigue resistance; Cons: Higher cost than standard wire. |

| Galvanized Steel Wire | Coated with zinc for corrosion resistance | Construction, fencing, and cable stays | Pros: Excellent weather resistance; Cons: Coating can wear off over time. |

| Superconducting Wire | Utilizes advanced materials for high efficiency | Medical MRI machines, particle accelerators | Pros: Superior performance in magnetic fields; Cons: Specialized applications limit market. |

| Spring Wire | High tensile strength, designed for elasticity | Automotive, aerospace, and consumer products | Pros: Versatile applications; Cons: Requires precise specifications for optimal performance. |

| Wire Rope | Composed of multiple wires for strength and flexibility | Lifting, rigging, and construction | Pros: High load-bearing capacity; Cons: Can be heavy and require specialized handling. |

What are the Characteristics and Applications of Oil Tempered Wire?

Oil tempered wire is known for its remarkable durability and flexibility, achieved through a specific heat treatment process that enhances its fatigue resistance. This type of wire is predominantly used in automotive springs and various industrial machinery applications. Buyers should consider the higher cost associated with oil tempered wire, which is justified by its longevity and performance in demanding environments.

How Does Galvanized Steel Wire Stand Out in the Market?

Galvanized steel wire is coated with a layer of zinc to provide excellent corrosion resistance, making it ideal for outdoor applications such as construction, fencing, and cable stays. Its weather-resistant properties ensure a longer lifespan in harsh environments. However, buyers should be aware that while the coating is effective, it can wear off over time, potentially leading to rust if not monitored.

Why is Superconducting Wire Important for Advanced Technologies?

Superconducting wire is a specialized product that employs advanced materials to achieve high efficiency in applications requiring strong magnetic fields, such as medical MRI machines and particle accelerators. Its unique properties allow for superior performance, but its specialized nature means it is only suitable for niche markets. Buyers must evaluate the specific requirements of their applications when considering superconducting wire.

What Makes Spring Wire a Versatile Choice for Various Industries?

Spring wire is characterized by its high tensile strength and elasticity, making it suitable for a wide range of applications, including automotive, aerospace, and consumer products. Its versatility is a significant advantage; however, buyers need to ensure they provide precise specifications to manufacturers to achieve optimal performance in their specific applications.

How Does Wire Rope Compare in Terms of Strength and Flexibility?

Wire rope is constructed from multiple wires twisted together, providing exceptional strength and flexibility, making it ideal for lifting, rigging, and construction applications. While its high load-bearing capacity is a key benefit, buyers should also consider the weight of wire rope and the need for specialized handling equipment, which can add to overall operational costs.

Key Industrial Applications of kiss wire

| Industry/Sector | Specific Application of kiss wire | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Tire Manufacturing | Steel Cord and Bead Wire for Tires | Enhances tire durability and performance | Quality certifications, production capacity, and delivery timelines |

| Construction | Galvanized Steel Wire for Reinforcement | Provides structural integrity and longevity | Corrosion resistance, strength specifications, and compliance standards |

| Energy Sector | Superconductive Wire for MRI and Particle Accelerators | Enables high-efficiency energy transmission and advanced medical imaging | Technical specifications, reliability, and sourcing from certified manufacturers |

| Automotive Industry | Oil Tempered Wire for Suspension Systems | Improves vehicle safety and performance | Material properties, fatigue resistance, and compliance with automotive standards |

| Telecommunications | Control and Micro Cables | Ensures reliable data transmission and system efficiency | Cable specifications, compatibility with existing infrastructure, and delivery reliability |

How is kiss wire utilized in tire manufacturing, and what are the benefits?

In tire manufacturing, kiss wire is primarily used as steel cord and bead wire. This application significantly enhances the durability and performance of tires, allowing them to withstand various road conditions and heavy loads. International buyers, especially from regions with diverse climates such as Africa and South America, must consider quality certifications and production capacity to ensure they receive high-performance materials. Additionally, understanding the delivery timelines is crucial to align with manufacturing schedules.

What role does kiss wire play in construction applications?

Kiss wire is extensively utilized in the construction sector, particularly as galvanized steel wire for reinforcement purposes. It provides essential structural integrity and longevity to buildings and infrastructure projects. For international buyers, particularly in the Middle East where construction is booming, sourcing wire with high corrosion resistance and adherence to specific strength specifications is vital. Compliance with local and international construction standards is also a key consideration to avoid project delays.

How does kiss wire contribute to advancements in the energy sector?

In the energy sector, kiss wire is essential for superconductive applications, notably in MRI machines and particle accelerators. This wire allows for high-efficiency energy transmission, which is crucial for both medical and research applications. Buyers in Europe and the Middle East should focus on the technical specifications and reliability of the superconductive wire to ensure compatibility with their systems. Sourcing from certified manufacturers can mitigate risks associated with performance and safety.

What benefits does kiss wire offer in the automotive industry?

Kiss wire is used in the automotive industry as oil tempered wire for suspension systems. This application enhances vehicle safety and performance by providing the necessary strength and flexibility to absorb shocks and impacts. Buyers, especially from regions with stringent automotive standards like Europe, must prioritize material properties such as fatigue resistance and compliance with industry regulations when sourcing kiss wire.

How is kiss wire applied in telecommunications?

In telecommunications, kiss wire serves as control and micro cables, which are crucial for reliable data transmission and system efficiency. This application is especially relevant in regions experiencing rapid technological growth, such as Africa and South America. Buyers should consider the specific cable specifications and ensure compatibility with existing infrastructure. Additionally, the reliability of delivery is essential to maintain operational continuity in telecommunications systems.

3 Common User Pain Points for ‘kiss wire’ & Their Solutions

Scenario 1: Difficulty in Ensuring Quality Standards for Kiss Wire Products

The Problem:

B2B buyers often struggle with the variability in quality standards when sourcing kiss wire, especially when working with suppliers across different countries. In regions like Africa and South America, where local manufacturing capabilities may vary significantly, buyers may receive subpar products that fail to meet the rigorous demands of their applications. This not only leads to production delays but can also compromise the integrity of end products, resulting in financial losses and reputational damage.

The Solution:

To overcome this challenge, buyers should implement a robust supplier evaluation process. This involves conducting thorough background checks on potential suppliers, including certifications related to quality management systems such as ISO 9001. Furthermore, establishing clear quality specifications and conducting regular audits can help ensure adherence to these standards. Engaging in a trial order before committing to large purchases allows buyers to assess product quality firsthand. Additionally, consider leveraging third-party quality assurance services that can perform inspections at various stages of the manufacturing process to guarantee compliance with your quality expectations.

Scenario 2: Navigating Import Regulations and Compliance Issues

The Problem:

International buyers often face a labyrinth of import regulations and compliance requirements that can complicate the procurement of kiss wire. For instance, buyers from the Middle East and Europe may encounter stringent customs regulations, tariffs, and documentation requirements that can delay shipments and increase costs. These complications can lead to project delays, strained relationships with clients, and additional unforeseen expenses.

The Solution:

To navigate these complexities, buyers should invest time in understanding the import regulations specific to their region and the countries they are sourcing from. Collaborating with a knowledgeable customs broker can streamline the import process by ensuring that all necessary documentation is in order and compliant with local regulations. Additionally, maintaining open lines of communication with suppliers regarding shipping timelines and potential customs issues can help buyers proactively address any challenges. Staying informed about trade agreements that may affect tariffs can also provide cost-saving opportunities.

Scenario 3: Challenges in Specifying the Right Type of Kiss Wire for Applications

The Problem:

Selecting the appropriate type of kiss wire for specific applications can be daunting for B2B buyers, particularly when faced with a wide array of options, including oil tempered wire, spring wire, and superconductive wire. Miscommunication with suppliers regarding application requirements can lead to the wrong product being sourced, causing operational inefficiencies or even equipment failure.

The Solution:

To ensure the correct specification of kiss wire, buyers should first conduct a thorough analysis of their application needs. This includes understanding factors such as tensile strength, corrosion resistance, and thermal properties. Creating a detailed specification sheet that outlines these requirements can facilitate clearer communication with suppliers. Engaging with the supplier’s technical team for guidance on material selection can provide valuable insights tailored to specific applications. Furthermore, investing in training for procurement teams on the technical aspects of kiss wire can empower them to make informed decisions and reduce the likelihood of sourcing errors.

Strategic Material Selection Guide for kiss wire

What Are the Key Materials Used in Kiss Wire Production?

Kiss wire, utilized in various industrial applications, is manufactured from specific materials that significantly influence its performance and suitability for different environments. Understanding these materials is crucial for international B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe.

How Does Steel Perform as a Material for Kiss Wire?

Steel is the most common material used in kiss wire production due to its excellent tensile strength and durability. It can withstand high temperatures and pressures, making it suitable for demanding applications. Steel’s corrosion resistance can be enhanced through galvanization or coating, which is particularly important in humid or corrosive environments.

Pros: Steel is relatively cost-effective and widely available, making it a preferred choice for many manufacturers. Its strength and durability ensure long-lasting performance in various applications, including automotive and construction.

Cons: The primary drawback of steel is its susceptibility to rust if not properly treated. Additionally, the manufacturing process can be complex, especially when producing specialized wire forms.

Impact on Application: Steel kiss wire is compatible with a wide range of media, including air, water, and various chemicals, depending on the surface treatment applied.

Considerations for International Buyers: Buyers from regions like Nigeria and Saudi Arabia should ensure compliance with local standards such as ASTM or JIS. Additionally, understanding the environmental conditions in their specific markets can guide the selection of the appropriate steel treatment.

What Role Does Stainless Steel Play in Kiss Wire Applications?

Stainless steel is another popular choice for kiss wire, particularly in applications requiring enhanced corrosion resistance. This material is known for its ability to withstand harsh environments, making it ideal for industries such as food processing, pharmaceuticals, and marine applications.

Pros: The primary advantage of stainless steel is its excellent corrosion resistance, which extends the lifespan of the wire in challenging environments. It also offers good mechanical properties and aesthetic appeal.

Cons: Stainless steel is generally more expensive than regular steel, which may affect budget-conscious projects. Additionally, its manufacturing process can be more complex, requiring specialized equipment.

Impact on Application: Stainless steel kiss wire is particularly effective in applications involving exposure to moisture or corrosive substances, ensuring reliability and safety.

Considerations for International Buyers: Buyers in Europe and the Middle East should be aware of compliance with specific standards for food safety and corrosion resistance, such as FDA regulations or EN standards.

How Does Copper Influence Kiss Wire Performance?

Copper is often used in kiss wire applications where electrical conductivity is paramount. Its excellent conductivity makes it suitable for electrical and electronic applications, such as wiring and connectors.

Pros: Copper kiss wire provides superior electrical conductivity, making it ideal for applications requiring efficient power transfer. It is also relatively ductile, allowing for easy manipulation during installation.

Cons: The primary limitation of copper is its susceptibility to corrosion, particularly in marine environments. Additionally, copper is generally more expensive than steel, which can increase overall project costs.

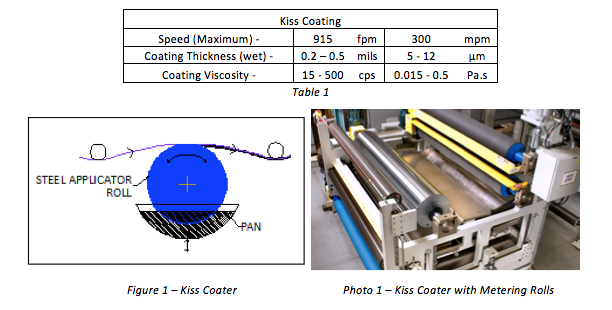

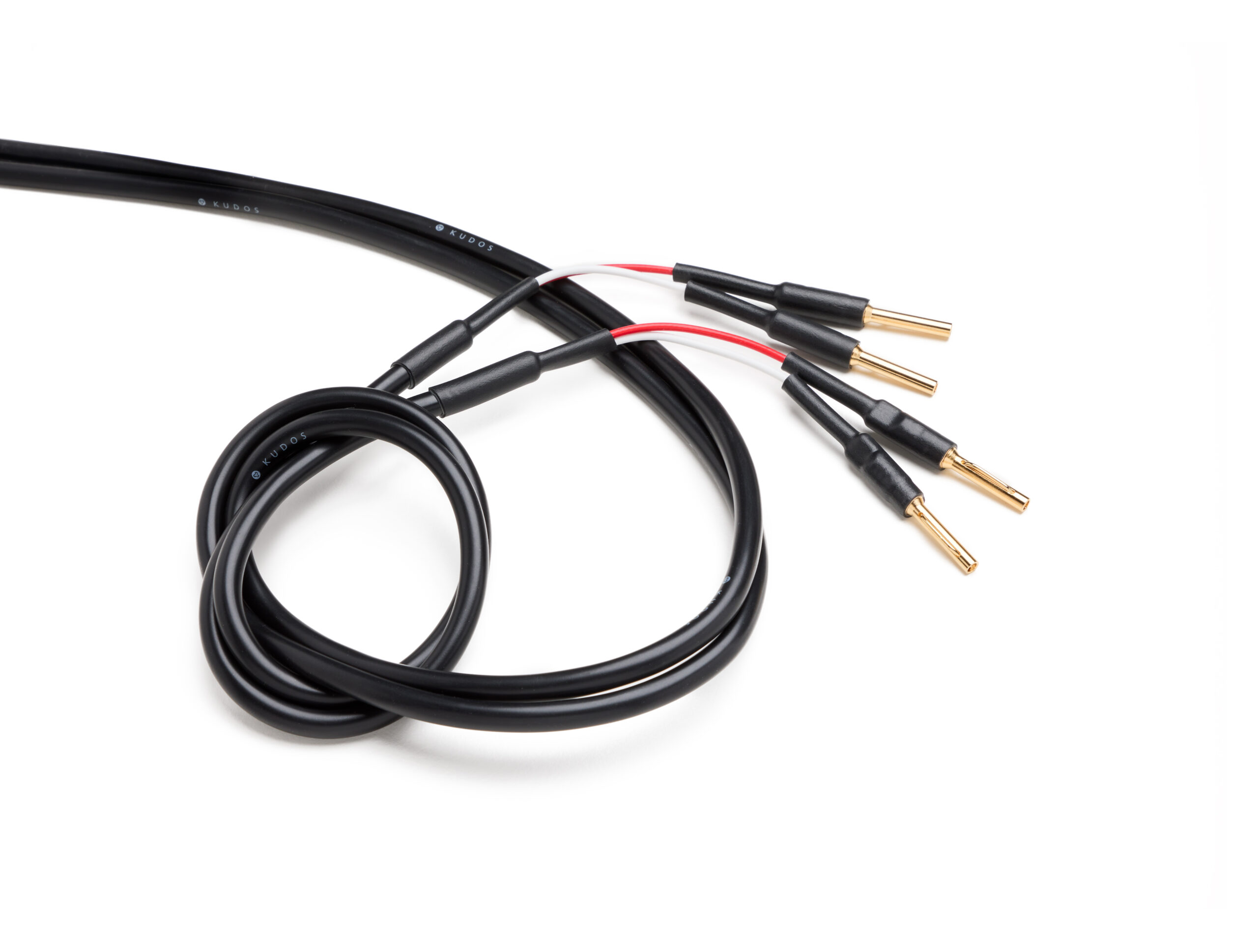

Illustrative image related to kiss wire

Impact on Application: Copper kiss wire is best suited for applications involving electrical connections, where conductivity is critical.

Considerations for International Buyers: Buyers should consider the local availability of copper and its compliance with international electrical standards, such as IEC or UL, particularly in regions with stringent electrical safety regulations.

What Advantages Does Aluminum Offer for Kiss Wire?

Aluminum is increasingly being utilized in kiss wire applications due to its lightweight and corrosion-resistant properties. It is particularly favored in industries where weight reduction is essential, such as aerospace and automotive.

Pros: The lightweight nature of aluminum makes it easier to handle and install, reducing labor costs. Its natural corrosion resistance also contributes to lower maintenance requirements.

Cons: However, aluminum is generally not as strong as steel, which can limit its use in high-stress applications. Additionally, it may require additional treatments to enhance its mechanical properties.

Impact on Application: Aluminum kiss wire is suitable for applications where weight savings are crucial, such as in aerospace components or lightweight structures.

Considerations for International Buyers: Buyers should ensure that aluminum kiss wire meets local standards for strength and corrosion resistance, particularly in regions with specific regulatory requirements.

Summary Table of Strategic Material Selection for Kiss Wire

| Material | Typical Use Case for kiss wire | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Construction, automotive | High strength and durability | Susceptible to rust if untreated | Low |

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Copper | Electrical applications | Superior electrical conductivity | Corrosion susceptibility | Medium |

| Aluminum | Aerospace, automotive | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

This strategic material selection guide provides essential insights for B2B buyers, helping them make informed decisions based on the specific needs of their applications and compliance requirements in their respective markets.

In-depth Look: Manufacturing Processes and Quality Assurance for kiss wire

What are the Key Stages in the Manufacturing Process of Kiss Wire?

The manufacturing of kiss wire involves several critical stages that ensure the production of high-quality wire suitable for various industrial applications. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: How is Raw Material Selected and Processed?

The process begins with the selection of high-grade raw materials, typically low-carbon steel or specialty alloys, depending on the application of the kiss wire. The raw materials undergo rigorous quality checks to ensure they meet the required specifications. Once approved, the materials are treated to remove impurities and enhance their mechanical properties.

Next, the materials are cut to length and subjected to processes like annealing, which involves heating and cooling to relieve internal stresses. This step is crucial as it prepares the materials for further processing and enhances their ductility.

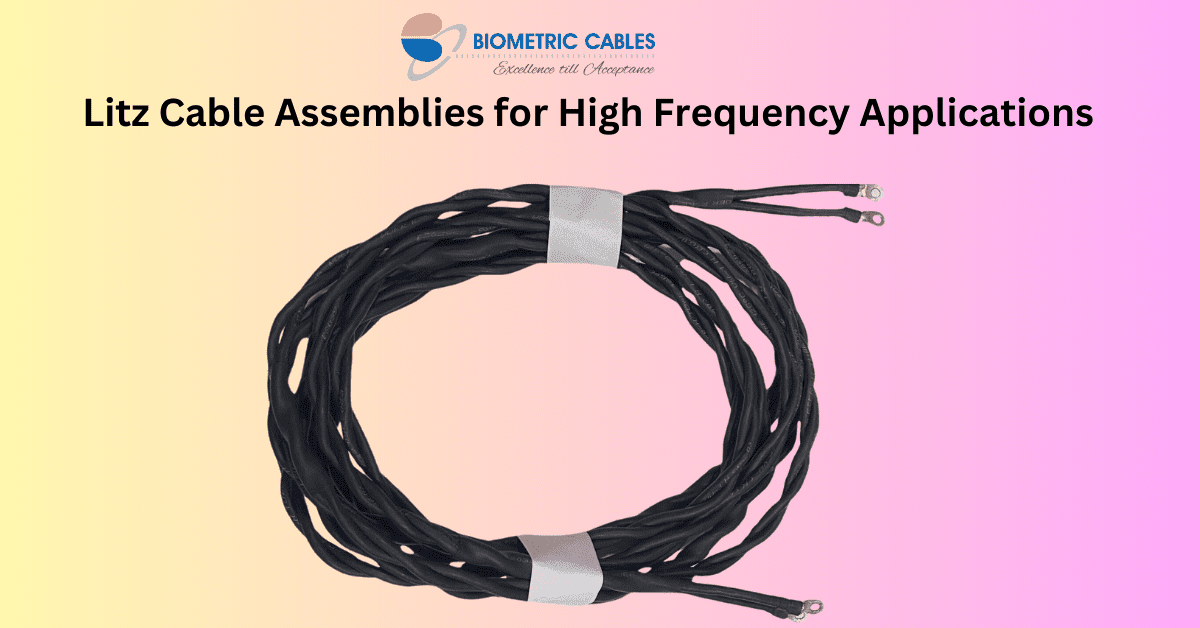

Illustrative image related to kiss wire

What Techniques are Used in the Forming Stage?

The forming stage involves several techniques to shape the wire. Drawing is the primary method, where the prepared wire is pulled through a series of dies to reduce its diameter and increase its length. This process not only shapes the wire but also improves its tensile strength through work hardening.

In addition to drawing, other techniques such as rolling, coiling, and bending may be employed, depending on the specific requirements of the kiss wire being produced. For instance, if the wire is intended for tire reinforcement, specialized coiling techniques are used to create the desired geometry.

How is Kiss Wire Assembled and Finished?

The assembly stage may involve the combination of different wire types or the integration of additional components, such as coatings for corrosion resistance. For kiss wire, this could include applying a protective layer or surface treatment to enhance durability.

The finishing stage is vital for ensuring that the wire meets all aesthetic and functional requirements. This may involve processes such as polishing, coating, or galvanizing to provide additional protection against environmental factors. Each finishing process is carefully monitored to ensure compliance with industry standards.

What Quality Assurance Standards are Relevant for Kiss Wire Production?

Quality assurance is a cornerstone of kiss wire manufacturing. Adhering to international standards, such as ISO 9001, ensures that manufacturers maintain a consistent level of quality throughout the production process. For specific applications, additional certifications such as CE (Conformité Européenne) or API (American Petroleum Institute) may also be required.

Illustrative image related to kiss wire

How are Quality Control Checkpoints Established?

Quality control checkpoints are strategically integrated into the manufacturing process to monitor and verify quality at various stages. These checkpoints typically include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitoring production processes to identify and rectify issues in real-time.

- Final Quality Control (FQC): Conducting thorough inspections of finished products before shipping to ensure they meet all specifications.

By implementing these checkpoints, manufacturers can effectively mitigate the risk of defects and ensure that the kiss wire delivered to clients meets stringent quality standards.

What Common Testing Methods are Used to Ensure Quality?

To validate the quality of kiss wire, various testing methods are employed. These may include:

- Tensile Testing: Measuring the strength and elongation of the wire to ensure it meets required specifications.

- Bend Testing: Assessing the wire’s flexibility and resistance to deformation.

- Corrosion Resistance Testing: Evaluating the wire’s durability against environmental factors, particularly for applications in harsh conditions.

These tests are crucial for ensuring that the kiss wire will perform as expected in its intended application, providing peace of mind for B2B buyers.

How Can B2B Buyers Verify the Quality Control of Their Suppliers?

For B2B buyers, especially those from diverse markets such as Africa, South America, the Middle East, and Europe, it is essential to verify the quality control processes of potential suppliers. Here are several actionable steps buyers can take:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control systems in place. This firsthand evaluation can provide insights into the supplier’s capabilities and adherence to quality standards.

-

Requesting Quality Reports: Buyers should ask for detailed quality assurance reports that outline the testing methods used, results obtained, and compliance with relevant standards. These reports can be invaluable in assessing a supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. This can be particularly beneficial for buyers who are unable to visit the manufacturing facilities themselves.

What are the Quality Control Nuances for International Buyers?

International B2B buyers must navigate several nuances when it comes to quality control and certification. Understanding the specific requirements for different regions is critical. For instance, European buyers may prioritize CE certification, while buyers in the Middle East might focus on compliance with local standards.

Additionally, language barriers and cultural differences can impact communication regarding quality expectations. Buyers should establish clear channels of communication and ensure that all specifications are documented in detail to avoid misunderstandings.

Finally, it’s advisable for buyers to build relationships with suppliers who have a proven track record in international trade, as this can significantly reduce risks associated with quality control and product reliability.

Conclusion

Understanding the manufacturing processes and quality assurance practices for kiss wire is crucial for B2B buyers seeking reliable suppliers. By focusing on the key stages of production, adhering to recognized quality standards, and implementing robust verification processes, buyers can ensure they receive high-quality products that meet their specific needs. This proactive approach not only enhances supply chain reliability but also fosters long-term partnerships with suppliers in a competitive global market.

Illustrative image related to kiss wire

Practical Sourcing Guide: A Step-by-Step Checklist for ‘kiss wire’

To assist B2B buyers in effectively procuring kiss wire, this guide provides a structured checklist that emphasizes critical steps in the sourcing process. The following steps will help ensure that you select the right products and suppliers for your needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it is vital to have a clear understanding of your technical requirements for kiss wire. This includes specifications such as diameter, tensile strength, and coating types. Defining these parameters will not only streamline your search but also ensure compatibility with your intended applications, whether in construction, manufacturing, or other industries.

Step 2: Conduct Market Research

Engage in thorough market research to identify potential suppliers and understand industry standards. Look for companies with a strong reputation, particularly those that have experience in your target regions, such as Africa, South America, the Middle East, and Europe. Utilize industry reports, trade publications, and online forums to gather insights about pricing, quality, and supplier reliability.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their production capabilities, quality control measures, and customer service responsiveness to ensure they align with your expectations and operational needs.

- Check Certifications: Ensure that potential suppliers hold relevant industry certifications, such as ISO standards, which demonstrate adherence to quality management practices.

Step 4: Request Samples

To assess the quality of kiss wire, request samples from shortlisted suppliers. This step allows you to evaluate the wire’s physical properties, such as flexibility, strength, and finish. Comparing samples from multiple suppliers can help you make an informed decision based on tangible evidence of quality.

Illustrative image related to kiss wire

Step 5: Negotiate Terms and Pricing

Once you have identified a preferred supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Be clear about your expectations and any specific requirements you may have. Strong negotiation can lead to better pricing and terms that can significantly impact your bottom line.

- Consider Volume Discounts: If you plan to order in bulk, inquire about potential discounts or flexible payment options to maximize your investment.

Step 6: Verify Logistics and Delivery Capabilities

Assess the supplier’s logistics capabilities, including shipping methods, lead times, and reliability in meeting deadlines. Understanding their delivery capabilities is crucial, especially if your project timelines are tight. A supplier with robust logistics can prevent delays and ensure that you receive your kiss wire on schedule.

Step 7: Establish a Relationship for Future Orders

After your initial order, foster a relationship with your chosen supplier for future needs. A strong partnership can lead to improved service, better pricing, and more tailored solutions as your requirements evolve. Maintain open lines of communication and provide feedback to strengthen this relationship over time.

By following this checklist, B2B buyers can navigate the complexities of sourcing kiss wire effectively, ensuring they select the right products and suppliers to meet their operational goals.

Illustrative image related to kiss wire

Comprehensive Cost and Pricing Analysis for kiss wire Sourcing

What Are the Key Cost Components in Kiss Wire Sourcing?

When sourcing kiss wire, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials such as high-carbon steel or specialized alloys plays a significant role in overall pricing. Prices can fluctuate based on market demand and availability, impacting your sourcing strategy.

-

Labor: Labor costs encompass wages for skilled workers involved in wire production, which can vary by region. For instance, labor costs may be higher in developed countries compared to emerging markets.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce overhead, directly affecting pricing.

-

Tooling: The investment in specialized tools and machinery for wire production can be substantial. Custom tooling for specific wire designs may lead to higher initial costs but can improve quality and precision.

-

Quality Control (QC): Ensuring product quality is paramount, especially for industries requiring stringent specifications. The costs associated with QC processes, including testing and certification, should be factored into pricing.

-

Logistics: Shipping and handling costs can vary significantly based on the destination. International buyers must consider freight costs, customs duties, and potential delays, which can add to the total expense.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the market landscape can help buyers negotiate better rates.

How Do Pricing Influencers Impact Kiss Wire Costs?

Several factors can influence the pricing of kiss wire, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk often leads to discounted pricing. However, buyers should be mindful of MOQs set by suppliers, which can affect initial investment.

-

Specifications and Customization: Customized wire products, whether in terms of size, shape, or material composition, generally command higher prices. Clear communication of specifications can help avoid unexpected costs.

-

Material Quality and Certifications: Higher-quality materials or those with specific certifications (such as ISO) may incur additional costs. Buyers should assess whether the added expense aligns with their end-use requirements.

-

Supplier Factors: Supplier reputation, reliability, and production capacity can all influence pricing. Engaging with established manufacturers may provide cost benefits due to their economies of scale.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) applicable to your purchase is vital. Terms like FOB (Free on Board) or CIF (Cost, Insurance, Freight) can significantly affect landed costs and overall pricing strategies.

What Buyer Tips Can Enhance Cost Efficiency in Kiss Wire Sourcing?

To optimize sourcing strategies, buyers should consider the following tips:

-

Negotiation: Effective negotiation can lead to significant savings. Establishing long-term relationships with suppliers may provide leverage for better pricing and terms.

-

Total Cost of Ownership (TCO): Beyond the initial purchase price, consider ongoing costs such as maintenance, quality assurance, and logistics. A comprehensive TCO analysis can reveal hidden costs and help in making informed decisions.

-

Pricing Nuances for International Buyers: Different regions may have varying pricing structures due to economic conditions, labor costs, and material availability. For buyers in Africa, South America, the Middle East, and Europe, it’s essential to conduct thorough market research and possibly engage local sourcing experts.

-

Stay Informed on Market Trends: Regularly monitoring market trends and material prices can help buyers anticipate changes and adjust their sourcing strategies accordingly.

Disclaimer on Indicative Prices

While this analysis aims to provide a comprehensive overview of cost structures and pricing factors, it is essential to note that prices can vary widely based on supplier, location, and market conditions. Buyers are encouraged to conduct their own research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing kiss wire With Other Solutions

When evaluating solutions for wire applications, especially in industries like construction, automotive, and electronics, it is essential to consider various alternatives to kiss wire. Each alternative brings unique benefits and challenges, making it crucial for B2B buyers to analyze their options based on specific project requirements.

| Comparison Aspect | Kiss Wire | Alternative 1: Oil Tempered Wire | Alternative 2: Galvanized Steel Wire |

|---|---|---|---|

| Performance | High tensile strength and flexibility | Excellent fatigue resistance | Corrosion resistance and durability |

| Cost | Moderate pricing | Generally higher cost due to treatment | Cost-effective for large quantities |

| Ease of Implementation | Straightforward with standard tools | Requires specialized handling | Easy to work with, widely available |

| Maintenance | Low maintenance needs | Moderate; periodic inspections needed | Low; corrosion-resistant properties reduce upkeep |

| Best Use Case | High-stress applications, such as springs | Heavy-duty applications, like automotive | Outdoor applications, construction, and fencing |

What are the Advantages and Disadvantages of Oil Tempered Wire Compared to Kiss Wire?

Oil tempered wire is known for its superior fatigue resistance, making it ideal for applications where repeated stress is a factor, such as in automotive components and springs. Its treatment process enhances performance, but it typically comes at a higher price point. Additionally, oil tempered wire may require specialized handling and installation techniques, which could complicate implementation for some users. Despite these challenges, its performance in demanding applications often justifies the investment.

How Does Galvanized Steel Wire Offer a Different Solution?

Galvanized steel wire provides a cost-effective alternative with excellent corrosion resistance, making it suitable for outdoor and marine environments. Its durability ensures longevity in applications such as fencing and construction. However, while it is easy to work with and widely available, it may not offer the same tensile strength or flexibility as kiss wire. Therefore, while galvanized steel wire is appropriate for many general uses, it may not be the best choice for high-stress applications where performance is critical.

Conclusion: How Can B2B Buyers Choose the Right Wire Solution?

Selecting the right wire solution involves assessing the specific needs of your project. Factors such as the operational environment, mechanical stress, and budget constraints will guide your decision. Kiss wire excels in high-performance applications, while oil tempered wire is suited for fatigue-intensive uses, and galvanized steel wire offers corrosion resistance at a lower cost. By carefully analyzing these alternatives, B2B buyers can make informed choices that align with their operational goals and project requirements.

Illustrative image related to kiss wire

Essential Technical Properties and Trade Terminology for kiss wire

What Are the Key Technical Properties of Kiss Wire?

When evaluating kiss wire, several essential technical properties are critical for ensuring the wire meets the specific needs of various applications. Understanding these properties can significantly influence purchasing decisions, especially for B2B buyers in industries such as construction, automotive, and manufacturing.

1. Material Grade

Kiss wire is often made from high-carbon steel, which provides strength and durability. The material grade determines the wire’s tensile strength, ductility, and resistance to corrosion. For B2B buyers, selecting the right material grade is crucial as it impacts the wire’s performance under stress and environmental conditions, thereby affecting the longevity of the final product.

2. Tolerance

Tolerance refers to the permissible variation in the wire’s diameter and mechanical properties. For kiss wire, tight tolerances are vital in applications where precision is key, such as in automotive components or high-performance machinery. Ensuring the wire meets the specified tolerances can reduce the risk of product failure and enhance overall safety.

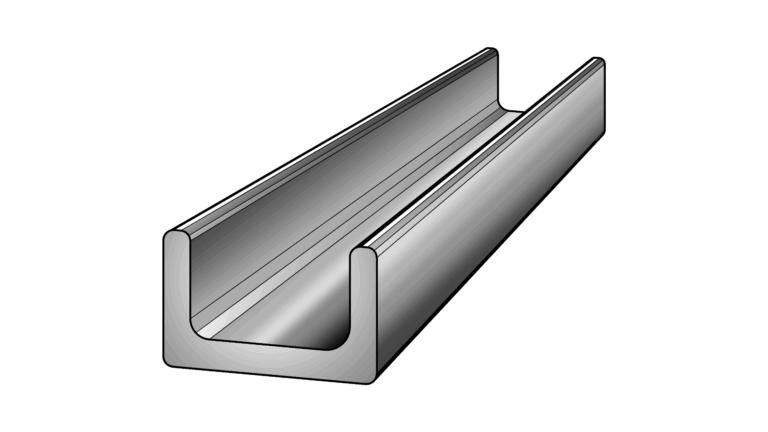

3. Coating Type

Kiss wire can come with various coatings, such as galvanization, which protects against rust and corrosion. The choice of coating type affects the wire’s durability and suitability for different environments. B2B buyers must consider the operational environment of their products to select the appropriate coating, thereby ensuring longevity and minimizing maintenance costs.

4. Mechanical Properties

Key mechanical properties include tensile strength, yield strength, and elongation. These properties determine how the wire behaves under load. For B2B applications, understanding these characteristics is essential for ensuring that the wire can withstand the intended use without failing, which is critical for maintaining operational efficiency.

5. Surface Finish

The surface finish of kiss wire can influence its performance in applications such as tire reinforcement or construction. A smooth finish may reduce friction and wear, while a rougher finish can enhance bonding in composite materials. Buyers should evaluate the required surface finish based on the end-use application to optimize performance.

6. Heat Treatment

Heat treatment processes, such as oil tempering, can enhance the mechanical properties of kiss wire. This process affects toughness and strength, making it suitable for high-stress applications. B2B buyers should consider whether heat treatment is necessary for their specific applications to ensure optimal performance.

What Are Common Trade Terms Used in the Kiss Wire Industry?

Understanding industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some common trade terms associated with kiss wire:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the kiss wire industry, buyers often collaborate with OEMs to ensure that the wire meets specific requirements for their products. Understanding OEM relationships can streamline sourcing and production processes.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. For kiss wire, MOQs can vary significantly between suppliers. B2B buyers must be aware of MOQs to optimize inventory management and avoid excess stock, which can tie up capital.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. When sourcing kiss wire, issuing an RFQ helps buyers obtain competitive quotes and evaluate potential suppliers. It is a critical step in the procurement process.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers involved in importing kiss wire, as they dictate shipping costs, risk, and liability.

Illustrative image related to kiss wire

5. Lead Time

Lead time refers to the time taken from placing an order to delivery. In the kiss wire industry, understanding lead times is vital for effective project planning and inventory management. Buyers should factor in lead times when scheduling production and ensuring timely delivery of materials.

6. Certification

Certification indicates that a product meets specific industry standards or regulations. For kiss wire, relevant certifications can include ISO, ASTM, or other quality assurance standards. Buyers should look for certified products to ensure compliance and quality assurance in their applications.

By comprehensively understanding the essential technical properties and trade terminology associated with kiss wire, B2B buyers can make informed decisions that enhance their purchasing strategies and operational efficiencies.

Navigating Market Dynamics and Sourcing Trends in the kiss wire Sector

What Are the Current Market Dynamics and Key Trends in the Kiss Wire Sector?

The kiss wire sector is currently experiencing significant growth driven by several global factors. The demand for high-quality wire products is surging, particularly in industries such as automotive, construction, and aerospace. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek reliable suppliers, understanding the market dynamics becomes crucial. Key trends include the increased adoption of advanced manufacturing technologies, which enhance production efficiency and product quality. For instance, companies are leveraging automation and data analytics to streamline operations and improve supply chain transparency.

Moreover, the globalization of supply chains is reshaping sourcing strategies, making it essential for buyers to establish robust relationships with manufacturers that can meet stringent quality and delivery requirements. Sustainability is also becoming a central theme, with buyers increasingly prioritizing suppliers that demonstrate environmental responsibility and ethical practices. This trend is particularly pronounced in Europe and parts of the Middle East, where regulatory frameworks are becoming more stringent regarding environmental compliance.

Emerging technologies such as the Internet of Things (IoT) and artificial intelligence (AI) are also influencing the kiss wire market. These technologies facilitate better inventory management and predictive analytics, allowing companies to optimize their sourcing decisions. As a result, B2B buyers are encouraged to engage with suppliers that are not only technologically advanced but also capable of adapting to rapidly changing market conditions.

Illustrative image related to kiss wire

How Is Sustainability and Ethical Sourcing Impacting the Kiss Wire Industry?

The environmental impact of manufacturing processes in the kiss wire sector is drawing increasing scrutiny. B2B buyers are now more aware of the ecological footprint associated with their sourcing decisions. As a result, ethical sourcing has become a critical factor in supplier selection. Companies are expected to adhere to sustainable practices, such as reducing waste, conserving energy, and minimizing emissions throughout their production processes.

Certifications related to sustainability, such as ISO 14001 for environmental management systems, are becoming essential for suppliers aiming to attract international buyers. Additionally, the use of “green” materials in kiss wire production is gaining traction. This includes sourcing raw materials that are either recycled or produced through sustainable methods, which not only reduces environmental impact but also enhances brand reputation.

For buyers, integrating sustainability into sourcing strategies can lead to long-term cost savings and improved compliance with international regulations. Engaging with suppliers that demonstrate a commitment to ethical practices not only aligns with corporate social responsibility goals but also positions companies favorably in the eyes of consumers increasingly concerned about sustainability.

Illustrative image related to kiss wire

How Has the Kiss Wire Industry Evolved Over Time?

The kiss wire industry has a rich history, evolving significantly since its inception. Founded in 1945, KISWIRE Ltd. has been at the forefront of this evolution, transitioning from traditional wire manufacturing techniques to advanced, technology-driven processes. The integration of modern materials science and engineering has allowed manufacturers to produce specialized wires, such as superconductive wire, which are critical for high-tech applications in medical and energy sectors.

Over the decades, the demand for high-performance wire products has expanded, particularly in the automotive and construction industries. This growth has prompted continuous innovation in product design and manufacturing processes, allowing suppliers to meet diverse customer needs across different regions. As the industry continues to adapt to technological advancements and changing market demands, the kiss wire sector is poised for further growth, offering numerous opportunities for B2B buyers worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of kiss wire

-

How do I choose the right type of kiss wire for my project?

Selecting the appropriate kiss wire involves understanding your specific application requirements, such as tensile strength, diameter, and material type. Review the technical specifications provided by manufacturers, focusing on factors like corrosion resistance, fatigue strength, and thermal properties. Additionally, consider any industry standards that may apply to your project. Consulting with an experienced supplier can provide insights tailored to your needs, ensuring optimal performance and longevity of the wire in its intended use. -

What is the best kiss wire for tire reinforcement applications?

For tire reinforcement, high carbon steel wire is often the best choice due to its superior strength and flexibility. Look for products specifically designed for tire applications, such as steel cord and bead wire, which are engineered to withstand the demanding conditions of tire manufacturing. Ensure that the wire meets industry standards and has undergone rigorous testing for quality assurance. Engaging with suppliers who specialize in tire reinforcement wire can help you access the best options available. -

What are the minimum order quantities (MOQ) for kiss wire products?

Minimum order quantities can vary significantly between suppliers and product types. Typically, manufacturers may set MOQs based on production costs and inventory considerations. For standard products, MOQs may range from a few hundred kilograms to several tons. It’s advisable to discuss your specific needs with potential suppliers to negotiate MOQs that align with your purchasing capabilities, especially if you require customized solutions. -

How do I verify the reliability of a kiss wire supplier?

To vet a kiss wire supplier, start by researching their industry reputation and customer reviews. Request references from current clients to gain insights into their reliability and product quality. Check for certifications that demonstrate adherence to international quality standards, such as ISO certifications. Finally, consider visiting their manufacturing facilities, if feasible, to assess their production processes and quality control measures firsthand. -

What are the typical payment terms for kiss wire purchases?

Payment terms for kiss wire can differ based on the supplier and the scale of the order. Common arrangements include payment in advance, letters of credit, or payment upon delivery. Some suppliers may offer net terms, allowing payment within 30 to 90 days post-delivery. Discussing payment terms upfront with your supplier is crucial to ensuring clarity and building a strong business relationship. -

How does international shipping affect kiss wire procurement?

International shipping can significantly impact the procurement process for kiss wire, affecting lead times, costs, and logistics. It’s essential to understand the shipping terms, including Incoterms, which define responsibilities for shipping, insurance, and tariffs. Additionally, factor in customs regulations and potential delays at border crossings. Collaborating with logistics experts can streamline the shipping process, ensuring timely delivery and compliance with all legal requirements. -

What quality assurance measures should I expect from kiss wire manufacturers?

Reputable kiss wire manufacturers implement rigorous quality assurance processes, including material testing, dimensional inspections, and performance evaluations. Look for suppliers that provide detailed documentation of their quality control practices, such as test reports and certificates of compliance. Additionally, inquire about their adherence to international quality standards, which can provide further assurance of product reliability and consistency. -

Can kiss wire be customized to meet specific project requirements?

Yes, many manufacturers offer customization options for kiss wire to meet specific project requirements. This can include variations in wire diameter, tensile strength, coatings, and packaging. When discussing customization, provide detailed specifications and any relevant standards your project must meet. Collaborating closely with the supplier during the design phase can lead to optimized solutions that enhance performance in your specific application.

Top 3 Kiss Wire Manufacturers & Suppliers List

1. KISWIRE – Wire Products

Domain: kiswire.com

Registered: 1997 (28 years)

Introduction: KISWIRE LTD. offers a variety of wire products including: Oil Tempered Wire, Shaped Wire, Flat Wire, Spring Wire, Hard Drawn Steel Wire, Music Wire, Piano Wire, Tire Reinforcement Bead Wire, Steel Cord, Hose Wire, Saw Wire, Bridge Cable, Galvanized PC Wire and Strand for Cabled Stayed Bridge, Galvanized Wire for Suspension Bridge, Galvanized Steel Wire & Strand, PC Wire & Strand, Unbonded PC Wire …

2. KISWIRE GROUP – Wire Ropes & Automotive Wire

Domain: kiswire-nhy.com

Registered: 2021 (4 years)

Introduction: KISWIRE GROUP manufactures 150,000 tons of wire rope per annum, including 50,000 tons each of Oil & Gas field ropes, Crane Ropes, and Elevator Ropes, as well as Engineering Ropes and Fishing Ropes. KISWIRE AUTOMOTIVE WIRE is produced in three plants for major automotive brands like Mercedes-Benz, BMW, VW, Toyota, Volvo, and Peugeot, focusing on valve springs and suspension springs. KISWIRE TYRE CO…

3. Kiswire, Inc. – Steel Cord Manufacturing

Domain: thsconstructors.com

Registered: 2005 (20 years)

Introduction: Kiswire, Inc. manufactures steel cord and bead wire. They constructed a 166,000 SF steel cord manufacturing facility in Newberry, SC, which included the preparation of a 50-acre site, a 20-foot-deep, 3,600-square-foot concrete lubrication oil pit, and pre-cast concrete feeder trenches to support the bead wire manufacturing process.

Strategic Sourcing Conclusion and Outlook for kiss wire

What Are the Key Takeaways for Strategic Sourcing in Kiss Wire?

In summary, effective strategic sourcing of kiss wire offers significant advantages for international B2B buyers. By leveraging the diverse product range from manufacturers like KISWIRE, including oil tempered wire, superconductive wire, and galvanized steel wire, buyers can ensure they meet specific application needs while optimizing cost efficiency. The ability to source high-quality products from a reputable global supplier not only enhances product reliability but also strengthens supply chain resilience.

How Can B2B Buyers Enhance Their Procurement Strategy?

Investing in strategic sourcing for kiss wire entails understanding market trends and supplier capabilities. Buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize establishing long-term partnerships with manufacturers who demonstrate innovation and adaptability. This approach ensures access to cutting-edge technologies and tailored solutions that align with regional demands, particularly in industries such as automotive and construction.

What Does the Future Hold for Kiss Wire Sourcing?

As the global market evolves, the emphasis on sustainable practices and technological advancements will shape the future of kiss wire sourcing. B2B buyers are encouraged to proactively engage with suppliers to explore new opportunities and solutions that drive efficiency and sustainability. By doing so, they position themselves to capitalize on emerging trends and secure a competitive edge in their respective markets. Take the next step in your sourcing strategy by exploring partnerships with leading manufacturers and ensuring your supply chain is primed for future growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.