Everything You Need to Know About Kinetic Sand Bulk Sourcing in 2025

Introduction: Navigating the Global Market for kinetic sand bulk

In today’s competitive landscape, international B2B buyers face the pressing challenge of sourcing quality kinetic sand bulk that meets safety, quality, and cost-effectiveness standards. As the demand for innovative play materials rises, businesses across Africa, South America, the Middle East, and Europe—particularly in regions like Saudi Arabia and Vietnam—must navigate a complex market filled with diverse suppliers and product variations. This guide is designed to empower you with the insights necessary to make informed purchasing decisions in the kinetic sand bulk market.

We will delve into a comprehensive exploration of the types of kinetic sand available, their various applications in educational settings, crafts, and recreational activities, and the importance of vetting suppliers to ensure reliability and compliance with international standards. Additionally, we will examine cost factors, shipping logistics, and best practices for procurement, enabling you to streamline your sourcing process.

By equipping you with actionable insights and expert recommendations, this guide aims to facilitate your journey toward successful procurement of kinetic sand bulk, ensuring that your business remains competitive and responsive to market demands. Whether you are looking to enhance your product offerings or seeking a reliable supplier for consistent stock, understanding the dynamics of this market will be crucial for your success.

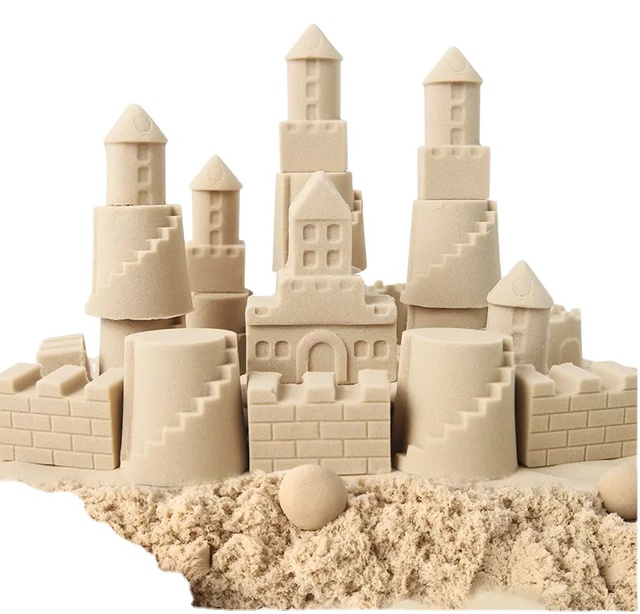

Understanding kinetic sand bulk Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Kinetic Sand | Original formula; moldable and reusable; non-drying | Educational toys, art supplies, sensory kits | Pros: Safe for children; encourages creativity. Cons: May require frequent replenishment. |

| Colored Kinetic Sand | Available in various vibrant colors; visually appealing | Arts & crafts, party supplies, events | Pros: Attracts attention; enhances creative play. Cons: Color may fade over time. |

| All-Natural Kinetic Sand | Made from natural sand; eco-friendly and safe for kids | Eco-conscious markets, educational products | Pros: Appeals to environmentally conscious buyers. Cons: May have a higher price point. |

| Scented Kinetic Sand | Infused with pleasant fragrances; sensory experience | Therapeutic uses, sensory play, gifts | Pros: Engages multiple senses; unique selling point. Cons: Scent may not appeal to all. |

| Bulk Kinetic Sand Sets | Larger quantities for cost-effectiveness; customizable options | Retail, bulk sales, schools | Pros: Economical for large orders; versatile. Cons: Storage space may be a concern. |

What Are the Key Characteristics of Classic Kinetic Sand?

Classic Kinetic Sand is the original formulation that has gained popularity for its unique ability to stick together while remaining easily moldable. It is non-toxic, ensuring safety for children during play. This type is particularly suitable for educational environments where creativity and motor skills development are prioritized. B2B buyers should consider factors such as packaging size and price per unit when purchasing, as these can affect overall cost-effectiveness for resale or distribution.

How Does Colored Kinetic Sand Enhance Creative Applications?

Colored Kinetic Sand offers a visually stimulating alternative to the classic version, making it ideal for arts and crafts projects. The vibrant hues can capture children’s attention, making it a popular choice for events and parties. When sourcing this product, B2B buyers should evaluate the range of colors available and assess whether bulk purchasing options can provide a competitive edge in the market. However, it is important to note that colors may fade with prolonged exposure to sunlight.

Why Choose All-Natural Kinetic Sand for Eco-Conscious Markets?

All-Natural Kinetic Sand is crafted from natural materials, appealing to environmentally conscious consumers. This variant is particularly valuable for educational products and eco-friendly toy lines. B2B buyers should consider the sourcing and sustainability practices of their suppliers, as these factors can enhance brand reputation. However, this type may come at a premium price, so buyers should weigh the benefits against budget constraints.

Illustrative image related to kinetic sand bulk

What Are the Benefits of Scented Kinetic Sand in Therapeutic Settings?

Scented Kinetic Sand introduces an additional sensory element, making it suitable for therapeutic applications and sensory play. The fragrances can create a calming atmosphere, beneficial in therapeutic settings. B2B buyers should assess the variety of scents offered and consider customer preferences, as not all scents will appeal universally. The unique sensory experience can serve as a differentiator in a competitive market, but it is essential to ensure that scents do not irritate sensitive individuals.

How Do Bulk Kinetic Sand Sets Provide Cost-Effective Solutions?

Bulk Kinetic Sand sets are designed for buyers looking for cost-effective solutions for retail or educational use. These sets can be customized in terms of quantity and packaging, catering to various market needs. B2B buyers should evaluate the pricing structure and potential discounts for larger orders, as this can significantly impact profit margins. While bulk purchasing can lead to savings, considerations around storage and inventory management should also be taken into account.

Key Industrial Applications of kinetic sand bulk

| Industry/Sector | Specific Application of kinetic sand bulk | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Education | Classroom Activities & Therapy Tools | Enhances creativity and fine motor skills in children | Quality assurance, safety certifications, and bulk pricing |

| Construction & Landscaping | Sand Casting for Molds and Models | Provides a versatile medium for prototyping and design | Sourcing from reliable suppliers with consistent quality |

| Arts & Crafts | Mixed Media Projects | Enables unique textures and effects in artworks | Availability of natural, non-toxic materials for safety |

| Event Planning | Interactive Installations for Events | Engages audiences and provides a memorable experience | Customization options and logistics for large orders |

| Toy Manufacturing | Product Development for Educational Toys | Supports innovative designs that attract children | Compliance with international safety standards and regulations |

How is Kinetic Sand Bulk Used in Education?

In the education sector, kinetic sand bulk is utilized in classrooms for hands-on activities that promote creativity and fine motor skills. It serves as an interactive tool for children, allowing them to mold, shape, and explore textures, which enhances their cognitive development. For international B2B buyers, especially in regions like Africa and South America, sourcing high-quality, non-toxic kinetic sand is crucial. Ensuring that the product meets local safety standards can also facilitate smoother import processes.

What are the Applications of Kinetic Sand in Construction & Landscaping?

Kinetic sand bulk finds its place in construction and landscaping primarily through sand casting for molds and models. This application allows architects and designers to create prototypes or detailed models that can be easily manipulated and reshaped. For businesses in the Middle East and Europe, it’s essential to source kinetic sand that offers consistent quality and durability. Establishing relationships with reliable suppliers can ensure that businesses receive a product that meets their specific project requirements.

How is Kinetic Sand Beneficial for Arts & Crafts?

In the arts and crafts industry, kinetic sand bulk is a popular choice for mixed media projects, providing unique textures and effects that enhance artistic expression. Artists and crafters appreciate the versatility of kinetic sand, as it can be used in various applications, from sculpture to decorative elements. Buyers in regions like Saudi Arabia and Vietnam should prioritize sourcing natural, non-toxic materials to align with safety regulations and consumer preferences, ensuring a competitive edge in the market.

Why is Kinetic Sand Important for Event Planning?

Event planners use kinetic sand bulk to create interactive installations that engage audiences and enhance the overall experience. Its captivating properties make it an attractive addition to exhibitions, trade shows, and family events. For B2B buyers in South America and Europe, it is important to consider customization options and logistics for large orders, ensuring timely delivery and alignment with event themes. Establishing partnerships with suppliers who can accommodate these needs is crucial for successful event execution.

How Does Kinetic Sand Aid in Toy Manufacturing?

In the toy manufacturing sector, kinetic sand bulk is integral to the development of innovative educational toys that stimulate creativity in children. Its unique texture and moldability make it an appealing option for product designers. For international buyers, compliance with safety standards is paramount, as products must meet regulations in various markets. Ensuring that suppliers are certified and can provide documentation is essential for a successful sourcing strategy.

3 Common User Pain Points for ‘kinetic sand bulk’ & Their Solutions

Scenario 1: Shipping Delays Impacting Inventory Management

The Problem: B2B buyers often face significant challenges with shipping delays when sourcing kinetic sand in bulk. This can be particularly problematic for businesses that rely on just-in-time inventory systems. For instance, a toy retailer in Saudi Arabia may place a large order to prepare for a seasonal spike in demand, only to encounter unexpected shipping delays. This not only affects their ability to meet customer demand but can also lead to lost sales and strained supplier relationships.

The Solution: To mitigate shipping delays, B2B buyers should establish strong relationships with multiple suppliers and logistics partners. It is crucial to conduct thorough due diligence on suppliers regarding their shipping reliability and track record. Additionally, buyers should consider using freight forwarders who specialize in international shipping to navigate customs and expedite delivery. Implementing a system to monitor shipping timelines and communicating proactively with suppliers about potential delays can also help manage expectations and maintain inventory levels. Setting up safety stock levels can provide an additional buffer against unexpected delays, ensuring that businesses can continue to operate smoothly even when challenges arise.

Illustrative image related to kinetic sand bulk

Scenario 2: Quality Control Issues with Bulk Orders

The Problem: Another common pain point for B2B buyers is the inconsistency in the quality of kinetic sand received in bulk orders. For example, a distributor in Europe may receive a shipment that contains varying textures or colors of sand, which can be detrimental when marketing a uniform product to customers. This inconsistency can lead to customer complaints and returns, negatively affecting the distributor’s reputation.

The Solution: To address quality control issues, B2B buyers should prioritize sourcing from reputable manufacturers that offer quality guarantees. Conducting pre-shipment inspections can help ensure that the products meet specified standards before they leave the factory. Establishing clear product specifications and quality benchmarks in the purchase agreement can also serve as a reference for both parties. Additionally, implementing a quality assurance process upon receiving shipments can help identify discrepancies early, allowing for timely resolutions, such as returns or exchanges, which ultimately protects the buyer’s brand integrity.

Scenario 3: Difficulty in Understanding Product Specifications

The Problem: Many B2B buyers encounter confusion regarding the specifications of kinetic sand products, which can lead to incorrect orders and wasted resources. For instance, a school supply company in South America may not fully understand the differences between various types of kinetic sand (e.g., colors, textures, or additives), resulting in purchases that do not meet customer needs. This lack of clarity can hinder sales and complicate inventory management.

The Solution: To alleviate this issue, buyers should invest time in thoroughly researching product specifications and understanding the unique attributes of different kinetic sand options. Engaging directly with manufacturers and suppliers for detailed product descriptions, samples, and demonstrations can provide invaluable insights. Attending trade shows or industry conferences can also offer opportunities to connect with experts who can clarify specifications and trends. Finally, creating a comprehensive product guide that outlines the features and benefits of each type of kinetic sand can serve as a useful resource for sales teams, ensuring they can effectively communicate with customers and make informed purchasing decisions.

Strategic Material Selection Guide for kinetic sand bulk

When selecting materials for kinetic sand bulk production, it is crucial to consider properties that directly impact product performance, cost, and suitability for various applications. Here, we analyze four common materials used in the production of kinetic sand, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Natural Sand in Kinetic Sand Production?

Natural sand is the primary ingredient in kinetic sand, known for its unique ability to stick together when wet. Key properties include:

- Temperature Resistance: Natural sand can withstand high temperatures, making it suitable for various climates.

- Corrosion Resistance: Being inert, natural sand does not corrode, ensuring longevity in products.

Pros: Natural sand is abundant and cost-effective, providing excellent moldability and texture. It is non-toxic and safe for children, making it a preferred choice for educational and recreational applications.

Cons: The quality of natural sand can vary based on its source, leading to inconsistencies in texture and performance. Additionally, sourcing from specific regions may involve logistical challenges, especially in remote areas.

For international buyers, especially in regions like Africa and the Middle East, compliance with local safety standards is crucial. Buyers should ensure that the sand meets ASTM or DIN standards for safety and quality.

How Does Synthetic Polymer Impact Kinetic Sand Performance?

Synthetic polymers, such as polydimethylsiloxane (PDMS), are often added to enhance the properties of kinetic sand.

- Temperature/Pressure Ratings: Synthetic polymers can perform well under a variety of conditions, maintaining their integrity even at elevated temperatures.

- Corrosion Resistance: These materials are generally resistant to chemical corrosion, ensuring durability.

Pros: Synthetic polymers improve the sand’s flowability and moldability, allowing for more intricate designs. They also provide a longer shelf life since they do not dry out.

Illustrative image related to kinetic sand bulk

Cons: The cost of synthetic polymers can be significantly higher than natural sand, impacting the overall price of the final product. Additionally, the manufacturing process can be more complex, requiring specialized equipment.

International buyers should consider the environmental regulations regarding synthetic materials in their respective regions. For instance, compliance with REACH regulations in Europe is essential for the import of synthetic products.

What Role Does Colorant Play in Kinetic Sand Bulk?

Colorants are often added to kinetic sand to enhance its visual appeal.

- Compatibility: Most colorants used are compatible with both natural and synthetic sand.

- Durability: High-quality colorants can withstand various environmental conditions without fading.

Pros: The addition of colorants can significantly increase the marketability of kinetic sand, appealing to a broader audience, especially in educational and recreational sectors.

Cons: Some colorants may not be non-toxic, which can limit their use in products aimed at children. Moreover, the cost of high-quality, safe colorants can add to the overall expense.

For buyers in regions like South America and Africa, it is essential to verify that colorants comply with local safety standards, particularly for children’s products.

How Do Additives Affect Kinetic Sand’s Performance and Safety?

Additives such as anti-clumping agents and preservatives are often included in kinetic sand formulations.

- Performance: These additives can enhance the sand’s texture and prevent clumping, improving user experience.

- Safety: The safety profile of additives is critical, especially for products intended for children.

Pros: Additives can improve the functional properties of kinetic sand, making it easier to mold and shape while extending its shelf life.

Cons: The introduction of additives can complicate the manufacturing process and may increase costs. Additionally, there is a risk of regulatory scrutiny regarding the safety of certain additives.

Illustrative image related to kinetic sand bulk

International buyers should ensure that any additives used comply with local regulations, particularly in regions with strict safety standards like Europe.

Summary Table of Material Selection for Kinetic Sand Bulk

| Material | Typical Use Case for kinetic sand bulk | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Sand | Basic kinetic sand production | Abundant and cost-effective | Quality can vary by source | Low |

| Synthetic Polymer | Enhanced moldability and durability | Improves flowability and shelf life | Higher cost and complex manufacturing | High |

| Colorant | Aesthetic enhancement | Increases market appeal | Potential toxicity issues | Medium |

| Additives | Improved texture and performance | Enhances user experience | Regulatory scrutiny and increased costs | Medium |

This strategic material selection guide provides critical insights for B2B buyers looking to source kinetic sand bulk. Understanding these materials’ properties and implications can lead to informed purchasing decisions that align with market demands and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for kinetic sand bulk

What Are the Main Stages of Kinetic Sand Bulk Manufacturing?

The manufacturing process for kinetic sand bulk typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage plays a crucial role in ensuring the final product meets quality standards and customer expectations.

Illustrative image related to kinetic sand bulk

Material Preparation: Sourcing and Processing Raw Ingredients

The primary ingredient in kinetic sand is natural sand, which is often sourced locally to minimize costs and environmental impact. Manufacturers ensure that the sand is clean and free from contaminants. This stage may also involve the addition of polymer additives that give kinetic sand its unique properties, such as its moldability and ability to stick together.

Quality assurance begins here, as the selection and testing of raw materials can significantly impact the final product. Suppliers should provide certificates of analysis for the sand and additives, confirming they meet the necessary safety and performance standards.

Forming: Shaping the Kinetic Sand

Once the raw materials are prepared, the next step is forming. This involves mixing the sand with the polymer additives in precise proportions to achieve the desired consistency and texture. The mixture is then subjected to specific processes such as kneading or blending in industrial mixers to ensure uniformity.

During this stage, manufacturers often utilize advanced machinery to automate the mixing process, ensuring consistent quality across batches. Automation not only improves efficiency but also reduces the potential for human error.

Assembly: Packaging for Distribution

After forming, the kinetic sand is packaged for distribution. This involves filling bulk containers or bags, labeling, and preparing the product for shipping. Manufacturers must adhere to strict packaging guidelines to ensure the product maintains its quality during transportation.

Illustrative image related to kinetic sand bulk

For international shipping, it’s crucial to comply with regulations that vary by region, especially regarding labeling and safety information. Packaging also plays a role in branding, making it essential for manufacturers to consider aesthetics along with functionality.

Finishing: Quality Control Checks

The finishing stage includes final quality control checks before the product is shipped. This can involve visual inspections, texture assessments, and functionality tests to ensure that the kinetic sand meets the required specifications.

Manufacturers often implement a series of quality checkpoints throughout the production process to catch any potential issues early, minimizing waste and rework.

How Is Quality Assurance Implemented in Kinetic Sand Production?

Quality assurance (QA) is a critical aspect of the manufacturing process for kinetic sand. Ensuring that products meet both international standards and specific customer requirements is essential for maintaining a competitive edge in the global market.

What International Standards Should B2B Buyers Be Aware Of?

For kinetic sand manufacturers, adhering to international quality standards such as ISO 9001 is vital. This standard provides a framework for effective quality management systems, ensuring that products consistently meet customer and regulatory requirements.

Illustrative image related to kinetic sand bulk

In addition to ISO standards, specific certifications like CE marking (for products sold in Europe) and ASTM standards (for safety and performance) can enhance a supplier’s credibility. These certifications indicate that the product has been tested and meets the necessary safety and performance benchmarks.

What Are the Key Quality Control Checkpoints?

Manufacturers typically implement several quality control checkpoints throughout the production process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified criteria.

- In-Process Quality Control (IPQC): During production, samples are taken at various stages to monitor consistency and quality.

- Final Quality Control (FQC): Before packaging, the finished product undergoes a thorough inspection to confirm it meets all quality standards.

Common testing methods include particle size analysis, moisture content testing, and tensile strength assessments. These tests help verify that the kinetic sand maintains its unique properties throughout its lifecycle.

How Can B2B Buyers Verify Supplier Quality Control?

When sourcing kinetic sand bulk, B2B buyers should take proactive steps to verify the quality assurance practices of potential suppliers. Here are some actionable strategies:

Conducting Supplier Audits

One of the most effective ways to ensure a supplier meets quality standards is to conduct an audit of their facilities. This can involve a physical inspection of the manufacturing process, reviewing quality control records, and assessing compliance with relevant standards.

Buyers should look for transparency in the supplier’s operations, including their handling of raw materials and adherence to quality checkpoints.

Illustrative image related to kinetic sand bulk

Requesting Quality Assurance Documentation

Buyers should request documentation related to the supplier’s quality assurance processes. This includes quality control reports, test results, and certifications. Such documents provide insight into the supplier’s commitment to maintaining high standards and can help in making informed purchasing decisions.

Engaging Third-Party Inspection Services

For added assurance, buyers may consider employing third-party inspection services. These independent entities can perform quality checks and verify compliance with international standards before the products are shipped. This step is particularly crucial for international transactions, where buyers may not have the ability to inspect products on-site.

What Are the Unique Quality Control Challenges for International Buyers?

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, there are specific nuances in quality control that must be navigated.

Understanding Regional Regulations

Each region has its own regulations governing product safety and quality. Buyers should familiarize themselves with these regulations to ensure compliance. For instance, products sold in Europe must meet CE marking requirements, while certain countries may have additional local safety standards.

Managing Logistics and Shipping Risks

International shipping introduces various risks that can affect product quality, including exposure to moisture and temperature fluctuations. Buyers should ensure that suppliers use appropriate packaging materials that protect the product during transit.

Conclusion

In-depth knowledge of the manufacturing processes and quality assurance practices for kinetic sand bulk is essential for B2B buyers looking to make informed decisions. By understanding the stages of production, international standards, quality control checkpoints, and verification methods, buyers can effectively evaluate potential suppliers. This diligence not only ensures the purchase of high-quality products but also fosters long-term relationships with reliable manufacturers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘kinetic sand bulk’

This guide serves as a comprehensive checklist for B2B buyers looking to source kinetic sand in bulk. Whether you are a distributor, retailer, or educational supplier, following these steps will help you navigate the procurement process efficiently, ensuring you select the right product and supplier for your needs.

1. Identify Your Target Market Needs

Understanding your target market is essential for selecting the right type of kinetic sand. Different regions may have varying preferences for colors, textures, and packaging sizes. Conduct market research to determine what your customers in Africa, South America, the Middle East, and Europe are looking for in kinetic sand products.

Illustrative image related to kinetic sand bulk

2. Define Your Technical Specifications

Before reaching out to suppliers, outline the technical specifications for the kinetic sand you wish to procure. This includes factors such as:

– Material Composition: Ensure the sand is made from natural materials and is safe for children.

– Packaging Options: Decide if you require bulk packaging or individual retail packs.

Defining these specifications will streamline the sourcing process and prevent miscommunication with potential suppliers.

3. Evaluate Potential Suppliers

Vetting suppliers is a critical step in ensuring product quality and reliability. Request detailed company profiles, including:

– Certifications: Look for safety certifications relevant to your market.

– References: Seek testimonials from other businesses that have sourced from them.

This evaluation helps ensure that the suppliers can meet your quality standards and fulfill your order on time.

4. Request Samples

Before placing a bulk order, always request samples of the kinetic sand. This allows you to:

– Test Quality: Assess the texture, moldability, and overall quality of the product.

– Check Compliance: Ensure it meets any local safety regulations or standards.

Reviewing samples helps mitigate the risk of dissatisfaction with the bulk order.

Illustrative image related to kinetic sand bulk

5. Negotiate Pricing and Terms

Pricing can vary widely among suppliers, so it’s vital to negotiate effectively. Consider the following:

– Bulk Discounts: Inquire about pricing tiers for larger quantities.

– Payment Terms: Look for favorable payment options like Net 30 or Net 60 to manage cash flow.

Negotiating these aspects can significantly affect your profit margins.

6. Understand Shipping Logistics

When sourcing internationally, understanding shipping logistics is crucial. Pay attention to:

– Shipping Costs: Get a clear estimate of shipping fees, especially for large volumes.

– Customs Regulations: Familiarize yourself with any import duties or taxes that may apply to your region.

This knowledge will help you avoid unexpected costs and delays.

7. Establish a Clear Communication Channel

Finally, set up a robust communication channel with your supplier. Regular updates regarding order status, shipping schedules, and any issues will enhance collaboration. Establishing this communication can help you quickly address any concerns that may arise during the procurement process.

By following this checklist, B2B buyers can ensure a smooth and successful sourcing experience for kinetic sand in bulk, ultimately leading to satisfied customers and a thriving business.

Comprehensive Cost and Pricing Analysis for kinetic sand bulk Sourcing

What Are the Key Cost Components in Kinetic Sand Bulk Sourcing?

When sourcing kinetic sand in bulk, understanding the cost structure is crucial for effective budgeting and procurement strategy. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The primary ingredient in kinetic sand is natural sand combined with a polymer that gives it its unique properties. Prices for these raw materials can fluctuate based on availability and geographic location, significantly impacting the overall cost.

-

Labor: Labor costs encompass the workforce involved in production, packaging, and quality assurance. These costs can vary by region; for instance, sourcing from countries with lower labor costs may be more economical, but could also affect quality.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, equipment maintenance, and administrative costs. Efficient manufacturing processes can reduce overhead, benefiting bulk buyers.

-

Tooling: Initial setup costs for molds and machinery can be substantial, particularly for customized products. Buyers should inquire about tooling costs, especially if they require specific shapes or sizes for their markets.

-

Quality Control: Ensuring that the product meets safety and quality standards often requires additional investment in QC processes. Certifications and compliance with international standards may also incur costs, but they are essential for market acceptance.

-

Logistics: Shipping and handling costs depend on the geographic location of the supplier and the destination. Factors such as freight rates, tariffs, and customs duties can significantly influence total costs, particularly for international shipments.

-

Margin: The profit margin that suppliers add to their costs can vary widely. Understanding the typical margins in the industry can help buyers negotiate better pricing.

How Do Price Influencers Impact Kinetic Sand Bulk Sourcing?

Several factors can influence the pricing of kinetic sand in bulk:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit costs. Suppliers may offer tiered pricing, encouraging bulk purchases.

-

Specifications and Customization: Custom formulations or colors can increase costs. Buyers should weigh the benefits of customization against potential price increases.

-

Materials and Quality Certifications: The choice of materials can affect pricing. Premium materials may command higher prices, and products that meet specific certifications (e.g., ASTM, EN71) may also be priced higher due to the added assurance of safety and quality.

-

Supplier Factors: The supplier’s reputation, reliability, and production capacity can impact pricing. Well-established suppliers may charge a premium but offer better quality assurance and reliability.

-

Incoterms: Understanding the shipping terms (e.g., FOB, CIF) can affect total costs. Buyers should clarify who bears the shipping and insurance responsibilities to avoid unexpected expenses.

What Are the Best Negotiation Tips for International B2B Buyers?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, there are several strategies to enhance cost-efficiency:

-

Negotiate Terms: Always negotiate payment terms and delivery schedules. Opting for longer payment terms can improve cash flow, while shorter delivery times may incur additional costs.

-

Consider Total Cost of Ownership: Evaluate not just the purchase price but also associated costs like shipping, customs duties, and potential tariffs. This holistic approach helps in making informed decisions.

-

Be Aware of Pricing Nuances: Understand the local market dynamics of the supplier’s country. Currency fluctuations and local economic conditions can impact pricing.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better terms and potential discounts on future orders. Regular communication and trust can enhance cooperation.

-

Request Samples: Before committing to large orders, request samples to assess quality and ensure that the product meets your specifications.

Conclusion

In summary, the comprehensive cost and pricing analysis of kinetic sand bulk sourcing involves a multifaceted understanding of cost components, price influencers, and strategic negotiation tactics. B2B buyers should conduct thorough due diligence, considering not just the immediate costs but also the long-term implications of their sourcing decisions. Always remain adaptable and informed to navigate the complexities of international trade effectively.

Alternatives Analysis: Comparing kinetic sand bulk With Other Solutions

Exploring Alternatives to Kinetic Sand Bulk

In the world of creative play and educational materials, kinetic sand bulk is a popular choice for many businesses. However, there are several alternatives that offer varying benefits depending on specific use cases and objectives. Understanding these alternatives can help B2B buyers make informed decisions that align with their needs and budget.

| Comparison Aspect | Kinetic Sand Bulk | Play Dough | Natural Play Sand |

|---|---|---|---|

| Performance | Sticks together, easy to mold, non-toxic | Soft, pliable, can dry out | Granular, may create mess |

| Cost | Moderate ($49.99 for 11lbs) | Low ($5-$15 per unit) | Low to Moderate ($10-$30 for bulk) |

| Ease of Implementation | Ready to use, minimal setup | Requires kneading, may need conditioning | Requires a setup area, may need tools |

| Maintenance | Minimal, does not dry out | Needs replacement, can dry out | Requires cleanup, may attract pests |

| Best Use Case | Arts and crafts, motor skill development | Creative play, educational activities | Outdoor play, sensory experiences |

In-Depth Analysis of Alternatives

Play Dough

Play dough is a widely recognized alternative that is often less expensive and readily available. It provides a soft, pliable texture that is ideal for creative projects and educational activities. However, one major downside is that it can dry out if not stored properly, requiring businesses to frequently replace stock. Play dough is excellent for younger children and can be used for various learning activities, but its short lifespan may not justify the frequent repurchase for bulk buyers.

Natural Play Sand

Natural play sand is a more traditional option that is often used in outdoor play areas and sandboxes. It is cost-effective, especially when purchased in larger quantities, making it attractive for organizations with significant space and outdoor play areas. However, it can create messes and requires more maintenance, such as regular cleaning and potential pest control. While natural sand offers a sensory experience, it lacks the unique moldable properties of kinetic sand, which may limit creative uses.

Making the Right Choice for Your Business

When deciding between kinetic sand bulk and its alternatives, B2B buyers should consider their specific use cases, target audience, and budget constraints. Kinetic sand is particularly advantageous for environments that prioritize creativity and fine motor skill development, while play dough may appeal to those seeking a low-cost solution for short-term projects. On the other hand, natural play sand is best suited for outdoor settings where sensory play is encouraged, but it requires more upkeep.

In conclusion, the choice between kinetic sand bulk and its alternatives hinges on understanding the unique needs of your business and the preferences of your end-users. By carefully evaluating the performance, cost, ease of implementation, maintenance requirements, and best use cases, you can select the product that best aligns with your strategic goals.

Essential Technical Properties and Trade Terminology for kinetic sand bulk

What Are the Essential Technical Properties of Kinetic Sand Bulk?

Understanding the technical properties of kinetic sand bulk is crucial for B2B buyers, especially those involved in manufacturing, retail, or educational products. Here are some key specifications to consider:

-

Material Composition

Kinetic sand is primarily made from natural sand combined with a proprietary polymer that gives it its unique properties. This combination ensures that the sand is non-toxic, safe for children, and provides an engaging tactile experience. For B2B buyers, knowing the material composition is vital for compliance with safety standards and regulations in different markets. -

Moisture Content

The moisture content of kinetic sand affects its texture and usability. Ideal moisture levels help maintain the sand’s moldability and prevent it from becoming too dry or clumpy. B2B buyers should ensure that the moisture content is consistent for quality assurance and to meet customer expectations. -

Granulation Size

The granulation size refers to the particle size of the sand. Kinetic sand typically features a fine granulation that enhances its moldability and flow characteristics. For manufacturers, understanding granulation size is essential for maintaining product consistency and performance across different batches. -

Color Stability

Kinetic sand can come in various colors, and color stability is a critical property that ensures the hues remain vibrant over time, even with extensive use. This is particularly important for educational and recreational products, where visual appeal can influence customer satisfaction. Buyers should assess the color stability of the product to avoid issues related to fading or discoloration. -

Packaging Specifications

Kinetic sand is often sold in bulk packages, such as 11 lbs (5 kg) boxes. Understanding packaging specifications, including dimensions and weight, is essential for logistics planning, shipping costs, and shelf space allocation in retail settings. Buyers should consider how packaging can affect transportation and storage efficiency. -

Durability

Kinetic sand is designed to withstand repeated use without drying out or degrading. This durability is crucial for both educational settings and retail environments where the product needs to maintain its quality over time. B2B buyers should evaluate the durability of the sand to ensure it meets the demands of their target market.

What Common Trade Terms Should B2B Buyers Know in the Kinetic Sand Industry?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of kinetic sand, an OEM might supply the raw materials or the final product to retailers or educational suppliers. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory levels and ensure cost-effectiveness. For kinetic sand, MOQs can vary significantly between suppliers, impacting purchasing decisions. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request pricing and terms from suppliers. For B2B buyers of kinetic sand, issuing an RFQ can help in comparing offers and negotiating better deals. -

Incoterms (International Commercial Terms)

These are a set of rules that define responsibilities for shipping, insurance, and tariffs between buyers and sellers. Familiarity with Incoterms is essential for international buyers to understand their obligations and risks when importing kinetic sand. -

Lead Time

This term refers to the time it takes from placing an order to receiving the product. For businesses relying on timely delivery of kinetic sand, knowing lead times can help in planning inventory and ensuring that they meet customer demand without delays. -

Drop Shipping

This method allows retailers to sell products without holding inventory, as the supplier ships directly to the customer. Understanding drop shipping arrangements can be beneficial for B2B buyers looking to streamline operations and reduce overhead costs in the kinetic sand market.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they procure high-quality kinetic sand that meets their business needs.

Navigating Market Dynamics and Sourcing Trends in the kinetic sand bulk Sector

What are the Current Market Dynamics and Key Trends in the Kinetic Sand Bulk Sector?

The global market for kinetic sand bulk is experiencing significant growth driven by increasing demand for sensory play materials and creative educational products. As parents and educators recognize the developmental benefits of tactile play, the market has expanded, particularly in regions such as Africa, South America, the Middle East, and Europe. The rise of e-commerce platforms has also facilitated access to these products, enabling international B2B buyers to source kinetic sand in bulk more conveniently.

Emerging technologies, such as advanced logistics solutions and supply chain management software, are reshaping sourcing strategies. Buyers are increasingly leveraging data analytics to forecast demand and optimize inventory levels, ensuring they can meet consumer needs without overstocking. Furthermore, the trend towards customization is gaining momentum; businesses are looking for suppliers who can offer unique colors, textures, or packaging options to differentiate their products in competitive markets.

Illustrative image related to kinetic sand bulk

In addition, environmental consciousness among consumers is influencing purchasing decisions. B2B buyers are increasingly focused on partnering with suppliers that prioritize sustainable practices and can demonstrate compliance with international safety standards. This shift is particularly evident in regions like Europe, where regulatory frameworks are becoming more stringent.

How is Sustainability and Ethical Sourcing Impacting the Kinetic Sand Bulk Market?

Sustainability and ethical sourcing have become paramount in the kinetic sand bulk sector. The environmental impact of production processes is under scrutiny, prompting suppliers to adopt more sustainable practices. This includes using non-toxic, biodegradable materials and ensuring that the sourcing of raw materials is ethical and responsible. For instance, kinetic sand often incorporates natural sand and polymers; thus, transparency in sourcing these materials is crucial for building trust with B2B partners.

Buyers are increasingly seeking suppliers with certifications that affirm their commitment to sustainability. Certifications such as the Forest Stewardship Council (FSC) for packaging materials or the Global Organic Textile Standard (GOTS) for any organic additives can significantly enhance a supplier’s marketability. These certifications not only mitigate environmental risks but also appeal to a consumer base that is becoming more eco-conscious, particularly in markets like the Middle East and Europe.

Moreover, ethical supply chains are essential for compliance with international labor standards. Buyers must ensure that their suppliers adhere to fair labor practices, which can enhance brand reputation and customer loyalty. This focus on ethical sourcing is not just a trend; it is becoming a fundamental expectation from consumers and businesses alike.

Illustrative image related to kinetic sand bulk

What is the Evolution of Kinetic Sand Bulk and Its Significance for B2B Buyers?

Kinetic sand has evolved significantly since its inception in the early 2000s. Originally marketed as a simple play material, it has transformed into a multifunctional product that supports educational and therapeutic applications. The unique properties of kinetic sand—its ability to mold easily and its non-drying characteristics—have led to its widespread adoption in schools, therapy centers, and homes.

For B2B buyers, understanding this evolution is essential for making informed sourcing decisions. The transition from a novelty item to an educational tool has opened new market segments, providing opportunities for businesses to align their products with educational curricula and developmental goals. This evolution underscores the importance of innovation in product offerings, as buyers seek to remain competitive in an increasingly saturated market.

In conclusion, the kinetic sand bulk sector is characterized by dynamic market trends, a strong emphasis on sustainability, and a rich history that continues to shape its future. B2B buyers who stay informed about these trends and prioritize ethical sourcing will be better positioned to capitalize on the growing demand for this unique product.

Frequently Asked Questions (FAQs) for B2B Buyers of kinetic sand bulk

-

How do I solve issues with shipping kinetic sand bulk orders internationally?

To address shipping issues with international orders of kinetic sand, ensure you work with a reliable logistics provider experienced in customs regulations for your target region. Verify that all necessary documentation, including commercial invoices and packing lists, is prepared accurately to avoid delays. Establish clear communication with your supplier regarding shipping options, lead times, and tracking procedures. Additionally, consider using freight forwarders who can facilitate smoother customs clearance and provide tailored solutions for your specific shipping needs. -

What is the best way to vet suppliers for kinetic sand bulk purchases?

To effectively vet suppliers for bulk kinetic sand, start by researching their reputation through online reviews and industry references. Request samples to assess product quality, and ensure they comply with safety standards relevant to your market. Check for certifications or memberships in trade organizations that indicate professionalism and reliability. Additionally, engage in direct communication to evaluate their responsiveness, willingness to address your concerns, and ability to meet your specific requirements. -

What customization options are available for bulk kinetic sand orders?

Many suppliers offer customization options for bulk kinetic sand, including color variations, packaging types, and branding opportunities. When discussing customization, clearly outline your requirements, such as specific colors or scents, and inquire about any minimum order quantities (MOQs) associated with these customizations. Be aware that custom orders may require additional lead time and costs, so factor these into your planning and budgeting. -

What are common payment terms for international bulk orders of kinetic sand?

Payment terms for international bulk orders can vary widely among suppliers. Common practices include letters of credit, wire transfers, or payment upon delivery. Many suppliers may offer Net 30 or Net 60 terms for established clients, allowing for payment after receipt of goods. Always clarify payment terms upfront and ensure they align with your company’s cash flow management strategies. Additionally, be cautious about any upfront deposits, particularly for large custom orders. -

What are the minimum order quantities (MOQ) for bulk kinetic sand?

Minimum order quantities (MOQ) for bulk kinetic sand can differ based on the supplier and the type of sand requested. Typically, MOQs range from 100 kg to 1000 kg or more, depending on the supplier’s production capabilities. It’s essential to discuss these quantities with potential suppliers upfront to avoid misunderstandings and to ensure your order meets their production requirements. Some suppliers may offer flexibility on MOQs for repeat customers or large contracts. -

How do I ensure quality assurance for my kinetic sand orders?

To ensure quality assurance for your kinetic sand orders, request detailed product specifications and quality control processes from your supplier. Consider implementing a third-party inspection service to evaluate the product before shipment, especially for large orders. Establish clear quality criteria and communicate these expectations to your supplier. Additionally, maintaining a consistent relationship with your supplier can foster trust and improve quality over time. -

What logistics considerations should I be aware of when importing kinetic sand?

When importing kinetic sand, consider logistics factors such as shipping methods, customs duties, and local regulations in your destination country. Familiarize yourself with the import taxes and tariffs that may apply, as these can significantly impact your overall costs. Additionally, ensure that your shipping partner has experience handling bulk goods and is capable of managing the logistics from port to warehouse. Proper planning can mitigate delays and unexpected expenses. -

How can I find reliable suppliers for kinetic sand in different regions?

To find reliable suppliers of kinetic sand across various regions, leverage online B2B marketplaces such as Alibaba or Global Sources, where you can filter suppliers by region and product type. Attend industry trade shows or exhibitions relevant to toys and educational materials, which provide opportunities for face-to-face interactions. Additionally, networking within industry-specific forums and groups can lead to valuable recommendations and insights into reputable suppliers in your target regions.

Top 6 Kinetic Sand Bulk Manufacturers & Suppliers List

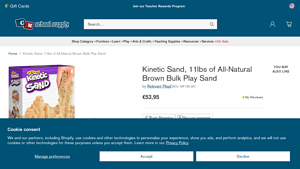

1. Kinetic Sand® – Soft & Mess-Free Play

Domain: lakeshorelearning.com

Registered: 1997 (28 years)

Introduction: Product Name: Kinetic Sand®

Price Range: $13.19 – $37.19 (Regular Price: $21.99 – $61.99)

Available Options: 2.2-Pound Bag, 11-Pound Bag

Recommended Age: 3 years – 8 years (Preschool – 3rd grade)

Description: Soft to the touch and virtually mess-free, Kinetic Sand® feels and moves as if it were wet but is completely dry, inspiring hours of hands-on, tactile exploration. Tub sold separately.

Item N…

2. Relevant Play – Kinetic Sand 11lbs

Domain: shopcmss.com

Registered: 2019 (6 years)

Introduction: Kinetic Sand, 11lbs of All-Natural Brown Bulk Play Sand by Relevant Play. SKU: WF150-201. Regular price: $49.99. Description: 5KG (11LB) of natural brown Kinetic Sand to mix, mold, squish, cut, and more. Encourages creativity and helps develop motor skills. Made with natural sand that sticks together for easy cleanup. Suitable for ages 3 and up. Covered by the Spin Master Care Commitment.

3. Magic Sand Factory – Kinetic Sand in Bulk

Domain: magicsandfactory.com

Registered: 2023 (2 years)

Introduction: Kinetic Sand in Bulk – Available in multiple vibrant colors including Brown, Yellow, Blue, Green, Purple, Red, Orange, and Pink. Crafted with non-toxic and eco-friendly materials. Ideal for educational purposes, art projects, therapy sessions, and creative play. Unique texture that moves and molds like wet beach sand but leaves surfaces dry and mess-free. Easy maintenance as it sticks to itself an…

4. Child Therapy Toys – Kinetic Sand Jumbo Box

Domain: childtherapytoys.com

Registered: 2003 (22 years)

Introduction: Kinetic Sand, Jumbo Box (11 lbs) – Product Number: 100794000 – Price: $59.95 – Composition: 98% pure sand, naturally gluten free – Features: No mess, easy-to-shape, molds into simple designs, provides a relaxing experience for all ages.

5. Kinetic Sand – SquishPizza and Sandy Farm Set

Domain: kineticsand.com

Registered: 2013 (12 years)

Introduction: Kinetic Sand is a unique product made with natural sand and a hint of magic, allowing for endless creative possibilities. Key products include: 1. SquishPizza – A set for shaping and customizing pizzas with tools and toppings. 2. Sandy Farm Set – An introductory set with 6 tools and a reusable barn storage case for imaginative play. 3. Café Case – A coffee shop play set with cappuccino cups and la…

6. NATIONAL GEOGRAPHIC – Play Sand 24 LB

Domain: thinkbluemarble.com

Registered: 2019 (6 years)

Introduction: {“product_name”: “NATIONAL GEOGRAPHIC Play Sand”, “weight”: “24 LB”, “type”: “Bulk Sand Kit”, “price”: “$54.99”}

Strategic Sourcing Conclusion and Outlook for kinetic sand bulk

In conclusion, the strategic sourcing of kinetic sand in bulk offers significant opportunities for B2B buyers across diverse markets, particularly in Africa, South America, the Middle East, and Europe. By focusing on suppliers that prioritize quality, sustainability, and reliable delivery, businesses can enhance their product offerings and meet growing consumer demand for innovative play materials. The unique properties of kinetic sand—such as its ability to stimulate creativity and support motor skill development—make it an attractive addition to educational and recreational products.

Moreover, as the global market continues to evolve, leveraging strategic sourcing can help mitigate supply chain risks and capitalize on cost efficiencies. International buyers should actively seek partnerships with reputable manufacturers who can ensure consistent quality and compliance with local regulations.

Looking ahead, the demand for kinetic sand is expected to rise, driven by trends in educational play and therapeutic uses. Now is the time for B2B buyers to explore sourcing options that align with their strategic objectives, ensuring they remain competitive in this dynamic landscape. Engage with suppliers today to secure favorable terms and position your business for future growth in the kinetic sand market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.