Everything You Need to Know About Is Quartz Conductive Sourcing in 2025

Introduction: Navigating the Global Market for is quartz conductive

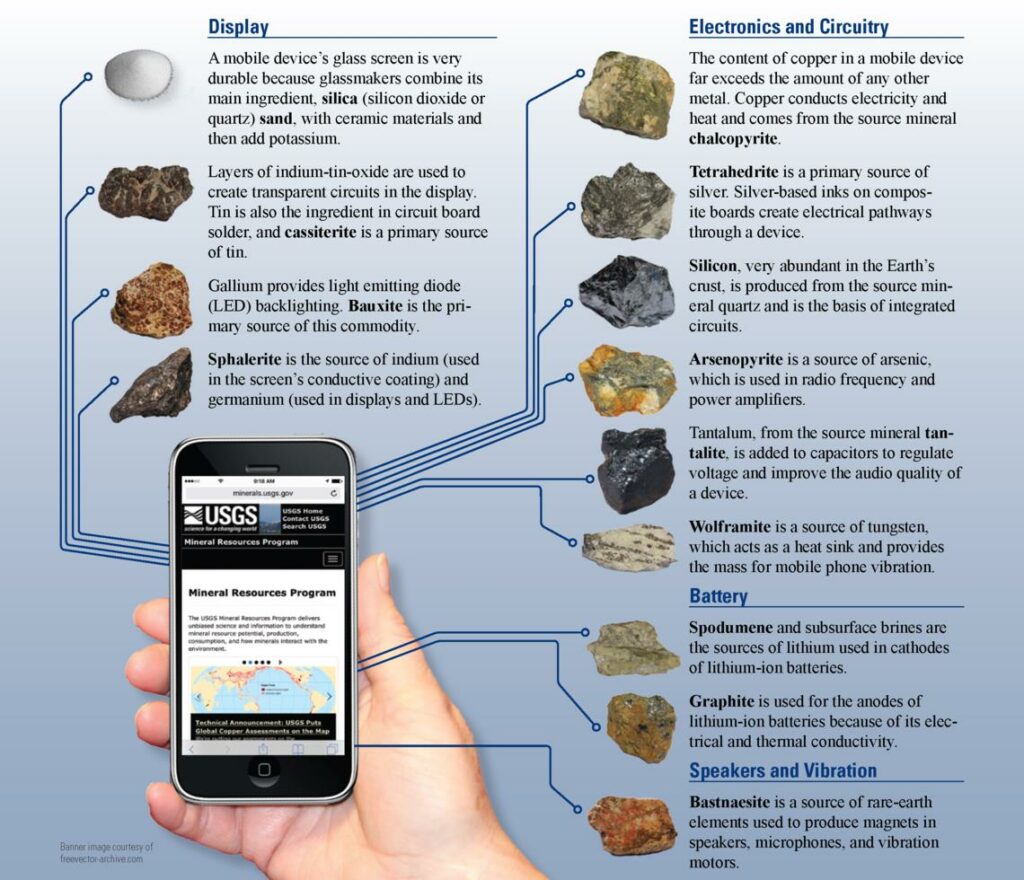

In today’s fast-paced global market, understanding whether quartz is conductive poses a critical challenge for international B2B buyers, particularly in diverse regions such as Africa, South America, the Middle East, and Europe, including Nigeria and Germany. While quartz is widely recognized for its unique properties, it is essential to clarify that quartz itself is not conductive in the traditional sense; however, its piezoelectric characteristics make it invaluable in various electronic applications. This guide aims to empower B2B buyers by providing a comprehensive overview of quartz, including its types, applications, and the nuances of sourcing high-quality quartz for specific needs.

By delving into the intricacies of quartz’s electrical properties, this guide will help you navigate the complexities of supplier vetting, pricing structures, and the overall market landscape. Whether you’re looking to incorporate quartz into cutting-edge electronic devices or seeking reliable materials for manufacturing, understanding the specific qualities of quartz can lead to informed purchasing decisions. With actionable insights tailored to the unique challenges faced by international buyers, this resource serves as an essential tool for optimizing your sourcing strategies and enhancing your competitive edge in the global marketplace.

Understanding is quartz conductive Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Natural Quartz | Found in nature, less pure, and variable in quality | Jewelry, decorative items | Pros: Aesthetic appeal; Cons: Less reliable for precision electronics. |

| Synthetic Quartz | Manufactured for purity and consistency, ideal for electronics | Oscillators, frequency control devices | Pros: High precision; Cons: Higher cost than natural quartz. |

| Piezoelectric Quartz | Exhibits piezoelectric properties, generating voltage under stress | Sensors, actuators, and transducers | Pros: Versatile applications; Cons: Requires specific circuit designs. |

| Fused Quartz | High-purity quartz, resistant to thermal shock and chemicals | Laboratory equipment, semiconductor fabrication | Pros: Excellent durability; Cons: Limited applications outside specialized fields. |

| Quartz Crystal Oscillators | Engineered for specific frequencies, used in timing applications | Telecommunications, consumer electronics | Pros: Reliable frequency control; Cons: Complexity in integration and cost. |

What Are the Characteristics of Natural Quartz and Its B2B Applications?

Natural quartz is the most abundant form of quartz found in nature. It varies in purity and quality, making it suitable for decorative applications like jewelry and art. However, its inconsistencies limit its use in precision electronics. B2B buyers should consider the aesthetic appeal and lower costs associated with natural quartz, but must be cautious of its variability, which can affect product quality.

How Does Synthetic Quartz Differ and What Are Its Key Uses?

Synthetic quartz is manufactured to achieve high purity and uniformity, making it ideal for electronic applications. This type of quartz is extensively used in oscillators and frequency control devices, where precision is paramount. Buyers should weigh the benefits of enhanced performance and reliability against the higher costs associated with synthetic quartz, especially when considering long-term applications in electronics.

Why is Piezoelectric Quartz Valuable for Certain Applications?

Piezoelectric quartz is notable for its ability to generate an electrical charge when subjected to mechanical stress. This property makes it invaluable in sensors, actuators, and various transducer applications. B2B buyers need to consider the specific circuit designs required for piezoelectric materials, as well as their versatility in different technological applications, while also being aware of the potential complexities in integration.

What Advantages Does Fused Quartz Offer in Specialized Fields?

Fused quartz is a high-purity variant that exhibits excellent resistance to thermal shock and chemical corrosion, making it ideal for laboratory equipment and semiconductor fabrication. Its durability and reliability make it a preferred choice in specialized applications. However, B2B buyers should note that its use is often limited to specific industries, which could restrict broader applications.

How Do Quartz Crystal Oscillators Function and What Should Buyers Know?

Quartz crystal oscillators are engineered to operate at specific frequencies, providing reliable timing solutions for telecommunications and consumer electronics. Their ability to maintain precise frequency control makes them essential in modern electronics. Buyers should consider the complexity of integration and associated costs when sourcing these components, as well as the importance of selecting the right oscillator for their specific application needs.

Illustrative image related to is quartz conductive

Key Industrial Applications of is quartz conductive

| Industry/Sector | Specific Application of is quartz conductive | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics | Quartz Crystal Oscillators | Provides stable frequency for timing circuits | Purity of quartz, frequency specifications, and reliability |

| Telecommunications | Signal Processing Components | Enhances signal clarity and reduces interference | Quality control, compliance with international standards |

| Automotive | Sensors and Actuators | Increases precision in vehicle systems | Temperature resistance, durability, and supplier reputation |

| Aerospace | Navigation Systems | Ensures accurate positioning and data transmission | Certification, performance under extreme conditions |

| Renewable Energy | Solar Inverters | Improves efficiency in energy conversion | Cost-effectiveness, scalability, and material sourcing |

How is Quartz Used in Electronics and What Benefits Does It Provide?

In the electronics sector, quartz crystal oscillators are fundamental for maintaining stable frequencies in various devices. They are critical in timing circuits, ensuring accurate clock signals for microprocessors and other electronic components. B2B buyers should focus on the purity of quartz used, as impurities can affect the oscillator’s performance. Additionally, understanding frequency specifications is essential to meet specific application requirements, particularly in regions like Europe and South America, where precision is paramount for compliance with regulatory standards.

What Role Does Quartz Play in Telecommunications?

In telecommunications, quartz is pivotal in signal processing components, where its piezoelectric properties enhance signal clarity and minimize interference. This application is vital for maintaining high-quality communication lines, especially in densely populated urban areas in Africa and the Middle East. Buyers should prioritize sourcing quartz that meets stringent quality control measures and complies with international standards to ensure reliability and performance in critical communication systems.

How is Quartz Beneficial in Automotive Applications?

The automotive industry utilizes quartz in sensors and actuators, which are essential for increasing precision in vehicle systems such as navigation and safety features. The demand for high-performance vehicles necessitates sourcing quartz that can withstand varying temperatures and environmental conditions. B2B buyers must evaluate the durability and reliability of quartz components, especially from suppliers with a strong reputation in the market, to ensure safety and compliance with automotive regulations.

What are the Applications of Quartz in Aerospace Navigation Systems?

In aerospace, quartz is integral to navigation systems, providing accurate positioning and data transmission capabilities. The reliability of quartz components is critical in this sector, where precision is non-negotiable. Buyers should consider the certification of quartz products and their performance under extreme conditions, which are essential for compliance with aerospace industry standards. Sourcing from reputable suppliers ensures that the components meet the rigorous demands of aviation applications.

How Does Quartz Enhance Renewable Energy Solutions?

Quartz plays a significant role in renewable energy, particularly in solar inverters, where it improves efficiency in energy conversion. As the demand for sustainable energy solutions grows, businesses need to ensure that the quartz sourced is cost-effective and scalable for large production runs. B2B buyers should evaluate the material sourcing strategies of suppliers to ensure that they can meet the growing demands of the renewable energy market while maintaining quality and performance standards.

Illustrative image related to is quartz conductive

3 Common User Pain Points for ‘is quartz conductive’ & Their Solutions

Scenario 1: Misunderstanding Quartz’s Electrical Properties

The Problem: Many B2B buyers, especially in the electronics sector, often assume that quartz is conductive due to its widespread use in electronic components. This misconception can lead to critical errors in product design and sourcing. For instance, a manufacturer may design a circuit expecting quartz crystals to function as conductive elements, only to discover that they are piezoelectric and non-conductive. Such misunderstandings can result in costly delays, wasted resources, and the need for redesigns.

The Solution: To mitigate this issue, B2B buyers should prioritize education about quartz’s properties. This can be achieved by consulting technical datasheets from reputable suppliers that clearly outline the electrical characteristics of quartz, including its piezoelectric nature. Furthermore, buyers should engage in discussions with manufacturers who can provide insights into the practical applications of quartz in electronics. Implementing training sessions for design teams can also enhance understanding, ensuring that quartz is utilized effectively in applications such as oscillators and sensors without assuming conductivity.

Scenario 2: Difficulty in Sourcing High-Purity Quartz for Electronics

The Problem: Buyers often face challenges when sourcing high-purity quartz necessary for precision electronics. Natural quartz can contain impurities that affect its performance, making it unsuitable for high-frequency applications. This can lead to subpar product performance and reliability issues in critical electronic components, such as timing devices or filters, which rely on the consistent oscillation provided by quartz crystals.

The Solution: To overcome sourcing challenges, it is essential for buyers to establish partnerships with suppliers that specialize in synthetic quartz. Synthetic quartz is engineered to be of higher purity and can be tailored to meet specific frequency requirements. Buyers should request certifications and test results to verify the purity levels of the quartz being supplied. Additionally, investing in long-term relationships with manufacturers can lead to better quality control and supply chain stability, ensuring that the materials meet the necessary specifications for high-performance applications.

Scenario 3: Inability to Effectively Integrate Quartz into Circuit Designs

The Problem: Integration of quartz crystals into electronic circuit designs can be complex due to their unique electrical behavior. Buyers may struggle with understanding how to effectively utilize quartz in oscillator circuits, leading to inefficient designs that do not perform as expected. This can result in increased time-to-market and higher costs associated with troubleshooting and redesigning circuits.

The Solution: To effectively integrate quartz into circuit designs, buyers should leverage the expertise of electronic design engineers who understand the nuances of working with piezoelectric materials. Engaging in collaborative design sessions can facilitate knowledge sharing and foster innovative solutions tailored to specific applications. Additionally, utilizing simulation software can help visualize the behavior of quartz within a circuit before physical implementation. Investing in training for engineering teams on crystal oscillator design will also empower them to create more efficient and reliable circuits, ultimately reducing development time and costs.

Strategic Material Selection Guide for is quartz conductive

What Are the Key Properties of Quartz in Electrical Applications?

Quartz, primarily composed of silicon dioxide (SiO2), is renowned for its piezoelectric properties rather than electrical conductivity. This characteristic allows quartz to generate an electrical charge when subjected to mechanical stress, making it valuable in various electronic applications. Key properties relevant to product performance include its ability to withstand high temperatures (up to 573°C) and pressures, as well as its excellent chemical stability, which ensures durability in diverse environments.

What Are the Pros and Cons of Using Quartz in Electronics?

The advantages of quartz in electronic applications are significant. Its durability and resistance to environmental factors make it suitable for long-term use in devices like oscillators and frequency filters. Additionally, quartz is relatively cost-effective due to its abundance and the established processes for its extraction and refinement. However, the manufacturing complexity can be a drawback; achieving the high purity levels required for electronic-grade quartz necessitates advanced processing techniques, which can increase production costs.

How Does Quartz Impact Specific Applications?

In applications involving oscillators and sensors, quartz’s piezoelectric properties allow for precise frequency control, essential in telecommunications and computing. However, compatibility with specific media must be considered; while quartz is chemically inert, it may not perform optimally in highly corrosive environments. For international B2B buyers, understanding the specific application requirements is crucial, particularly in regions with varying industrial standards.

What Should International Buyers Consider When Sourcing Quartz?

For B2B buyers in Africa, South America, the Middle East, and Europe, compliance with local standards such as ASTM, DIN, or JIS is essential. In Nigeria, for example, adherence to local regulations regarding electronic components can affect market entry. Similarly, German buyers may prioritize quality certifications and environmental sustainability in their sourcing decisions. Understanding these regional preferences can enhance supplier relationships and ensure compliance with local market demands.

| Material | Typical Use Case for is quartz conductive | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Quartz | Frequency control in oscillators | High durability and temperature resistance | Requires high purity for electronic applications | Medium |

| Synthetic Quartz | Precision electronics manufacturing | Consistent quality and purity | Higher production costs due to advanced processing | High |

| Natural Quartz | Basic electronic components | Abundant and cost-effective | Impurities can affect performance | Low |

| Quartz Glass | Optical and electronic applications | Excellent chemical resistance | Limited mechanical strength compared to crystalline forms | Medium |

This analysis provides a comprehensive overview of quartz’s role in electrical applications, focusing on its properties, advantages, and limitations. By understanding these factors, B2B buyers can make informed decisions that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for is quartz conductive

What Are the Key Stages in the Manufacturing Process of Quartz Crystals?

The manufacturing of quartz crystals for electronic applications involves several key stages, each critical to ensuring the quality and performance of the final product. Understanding these stages can help B2B buyers identify the right suppliers and ensure that they are sourcing high-quality quartz crystals.

1. Material Preparation

The process begins with the sourcing of high-purity quartz. Natural quartz is abundant, but for electronic applications, it must be refined to remove impurities that could affect its electrical properties. This involves crushing the raw quartz, followed by several purification techniques, such as hydrofluoric acid treatment and flotation processes, which enhance the purity levels to above 99.99% silicon dioxide (SiO2).

2. Forming Techniques

Once purified, the quartz undergoes forming processes to create the desired shapes—typically bars or discs. The most common techniques include:

- Cutting: Using precision saws, the quartz is sliced into specific thicknesses. The thickness directly influences the crystal’s resonant frequency, making this step crucial for achieving the desired electrical characteristics.

- Polishing: After cutting, the surfaces of the quartz pieces are polished to eliminate any surface defects and enhance optical clarity, which is essential for applications like oscillators and filters.

3. Assembly of Electrical Components

In the assembly stage, electrical leads are attached to the quartz crystal. This is typically done using conductive adhesives or soldering techniques, ensuring a reliable electrical connection. The leads are often plated with metals such as gold or silver to improve conductivity and prevent oxidation.

4. Finishing Processes

The final stage of manufacturing involves protective coatings and packaging. A thin layer of protective metal is often applied to shield the crystal from environmental factors. Additionally, crystals are often encapsulated in protective casings to ensure durability during transport and use.

Illustrative image related to is quartz conductive

How Is Quality Assurance Implemented in Quartz Crystal Manufacturing?

Quality assurance (QA) is paramount in the manufacturing process of quartz crystals, especially considering their applications in sensitive electronic devices. B2B buyers should be aware of the relevant international and industry-specific standards, as well as the common quality checkpoints throughout the manufacturing process.

International Standards: Which Ones Should Buyers Be Aware Of?

Manufacturers of quartz crystals typically adhere to international standards like ISO 9001, which sets criteria for a quality management system. This certification indicates that the manufacturer consistently meets customer and regulatory requirements. Additionally, industry-specific certifications like CE mark (Conformité Européenne) and API (American Petroleum Institute) may also apply, especially for crystals used in specialized applications.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is integrated into various stages of the manufacturing process, with key checkpoints typically including:

Illustrative image related to is quartz conductive

-

Incoming Quality Control (IQC): This initial stage involves inspecting the raw materials for purity and quality before they enter the production line. Any substandard materials are rejected at this point.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor critical parameters like thickness, surface quality, and electrical performance. This continuous monitoring helps identify defects early, minimizing waste and rework.

-

Final Quality Control (FQC): Once the crystals are assembled, they undergo rigorous testing to ensure they meet specified performance metrics. Tests may include frequency accuracy, temperature stability, and mechanical integrity.

What Testing Methods Are Commonly Used for Quartz Crystals?

Several testing methods are employed to verify the quality and performance of quartz crystals:

-

Electrical Testing: This includes measuring the resonant frequency, capacitance, and Q factor (quality factor) to ensure the crystal performs as expected in its intended application.

-

Mechanical Testing: This assesses the durability and resistance to physical stress, ensuring that the crystals can withstand the rigors of operation.

-

Environmental Testing: Crystals may be subjected to various environmental conditions, such as temperature and humidity, to evaluate their stability and performance under different circumstances.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive measures to verify the quality control practices of their suppliers. Here are actionable steps to consider:

-

Supplier Audits: Conducting on-site audits can provide direct insight into the supplier’s manufacturing processes, quality control systems, and adherence to international standards.

-

Requesting Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including results from IQC, IPQC, and FQC. These reports should detail the testing methods used and outcomes achieved.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control practices, providing additional assurance regarding the reliability of the products.

What Are the Nuances of QC and Certification for International Buyers?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is crucial. Different regions may have varying standards and regulatory requirements that could impact the import and use of quartz crystals.

-

Regional Compliance: Buyers should familiarize themselves with the specific compliance requirements of their region. For instance, CE marking is essential for products sold in the European market, while other regions may have distinct certification needs.

-

Documentation and Customs: Ensuring that all necessary documentation, including quality certifications and compliance reports, is in order can facilitate smoother customs clearance and reduce the risk of supply chain disruptions.

-

Cultural Considerations: Understanding the cultural and business practices of suppliers in different regions can help build stronger relationships and ensure clearer communication regarding quality expectations.

By grasping the intricacies of the manufacturing processes and quality assurance practices for quartz crystals, B2B buyers can make informed decisions and establish partnerships that align with their quality standards and business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘is quartz conductive’

Introduction

This sourcing guide serves as a practical checklist for B2B buyers interested in procuring quartz for various applications, particularly in electronics. Understanding whether quartz is conductive, along with its piezoelectric properties, is crucial for making informed purchasing decisions. This guide will help you navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of any successful sourcing effort. Determine the specific type of quartz you require, such as purity levels, size, and intended application (e.g., piezoelectric devices, oscillators). This clarity helps ensure that suppliers can meet your needs and allows for better comparison across potential vendors.

Step 2: Research Quartz Properties

Familiarize yourself with the properties of quartz, particularly its non-conductive nature and piezoelectric capabilities. Understanding these characteristics will enable you to articulate your needs accurately to suppliers. Remember, while quartz does not conduct electricity like metals, its ability to generate electrical charges under pressure is vital for many electronic applications.

Step 3: Evaluate Potential Suppliers

Before making any commitments, thoroughly vet your potential suppliers. Request company profiles, case studies, and references from other businesses in your sector or region. Focus on suppliers that specialize in high-purity quartz for electronics to ensure you receive quality materials that meet industry standards.

- Check Certifications: Look for ISO certifications or other quality assurance documentation.

- Assess Production Capabilities: Ensure the supplier can meet your volume requirements and deadlines.

Step 4: Request Samples

Always request samples before finalizing any orders. Testing samples allows you to evaluate the quartz’s properties, such as purity and piezoelectric performance, ensuring they meet your technical specifications. This step is crucial for avoiding costly mistakes and ensuring that the material will perform as expected in your applications.

Step 5: Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in discussions about pricing and contract terms. Be transparent about your budget and seek to negotiate favorable conditions, including payment terms, delivery schedules, and warranty provisions. A clear agreement can help mitigate risks associated with supply chain disruptions.

Step 6: Plan for Quality Assurance

Establish a quality assurance process to monitor the quartz you receive. This may include periodic testing of batches for purity and performance characteristics. Consider setting up regular communication with your supplier to address any quality concerns promptly, ensuring that you maintain consistent product standards.

Step 7: Consider Long-term Partnerships

Think about the potential for long-term partnerships with your suppliers. Building strong relationships can lead to better pricing, priority service, and enhanced collaboration on future projects. Evaluate suppliers not just on current needs, but also on their ability to support your business growth over time.

By following this checklist, B2B buyers can streamline their sourcing process for quartz, ensuring they acquire the right materials to meet their technical needs while fostering reliable supplier relationships.

Comprehensive Cost and Pricing Analysis for is quartz conductive Sourcing

What Are the Key Cost Components in Quartz Sourcing?

When considering the sourcing of quartz, particularly for electronic applications, it is essential to understand the various cost components that contribute to the overall pricing structure. The primary cost elements include:

-

Materials: The cost of raw quartz, especially high-purity quartz, forms a significant part of the total expense. The quality and source of the quartz can influence prices, with synthetic quartz generally being more expensive due to its purity and manufacturing processes.

-

Labor: Labor costs vary based on the region of production and the level of expertise required for handling and processing quartz. Skilled labor is essential for tasks such as cutting and shaping quartz crystals to meet specific requirements.

-

Manufacturing Overhead: This includes expenses related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce overhead costs, which can be reflected in pricing.

-

Tooling: The initial investment in specialized tools for cutting and shaping quartz can be substantial. These costs are typically amortized over the production volume, affecting unit costs.

-

Quality Control (QC): Ensuring the purity and precision of quartz crystals involves rigorous QC processes. These costs can vary based on the complexity of the specifications and the required certifications.

-

Logistics: Transporting quartz, especially from different continents, incurs significant shipping and handling costs. Factors such as distance, shipping methods, and customs duties can impact the final price.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit, which can vary widely based on market conditions and competition.

What Influences Pricing for Quartz Sourcing?

Several factors can influence the pricing of quartz in B2B transactions:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Negotiating favorable terms for high volumes can significantly reduce overall costs.

-

Specifications and Customization: Custom-cut quartz crystals or those with specific electrical properties may come at a premium. Buyers should weigh the necessity of customization against cost.

-

Quality and Certifications: Higher quality and certified quartz, especially for high-tech applications, command higher prices. Certifications such as ISO or specific industry standards can also affect cost.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: The terms of shipping and delivery (Incoterms) can significantly affect pricing. For instance, DDP (Delivered Duty Paid) terms may result in higher upfront costs but eliminate unexpected fees later.

How Can Buyers Negotiate Effectively for Quartz?

B2B buyers can adopt several strategies to enhance cost-efficiency in quartz sourcing:

-

Conduct Thorough Market Research: Understanding the market landscape, including pricing trends and competitor offerings, empowers buyers to negotiate better deals.

-

Leverage Total Cost of Ownership (TCO): Instead of solely focusing on the initial purchase price, buyers should consider TCO, including shipping, handling, and quality control costs over the product’s lifecycle.

-

Establish Long-Term Relationships: Building strong relationships with suppliers can yield benefits such as better pricing, priority during shortages, and more favorable terms.

-

Be Flexible with Specifications: If possible, buyers should remain open to slight adjustments in specifications that could lead to cost savings.

-

Consider Alternative Suppliers: Engaging multiple suppliers can foster competition, which may drive down prices while providing options for quality and service.

What Are the Pricing Nuances for International B2B Buyers?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific pricing nuances:

-

Currency Fluctuations: Exchange rates can significantly impact purchasing costs. Buyers should account for potential currency risks in their budgeting.

-

Import Tariffs and Duties: Understanding local import regulations and duties can prevent unexpected costs and influence the final price.

-

Cultural and Communication Differences: Effective communication is crucial in international dealings. Being aware of cultural nuances can enhance negotiation outcomes and build trust with suppliers.

-

Logistical Challenges: Buyers must consider the complexities of international shipping, including potential delays and additional costs associated with customs clearance.

Disclaimer

The prices and cost structures discussed herein are indicative and subject to market fluctuations and specific supplier negotiations. Buyers are encouraged to conduct thorough due diligence and seek multiple quotations to ensure competitive pricing.

Alternatives Analysis: Comparing is quartz conductive With Other Solutions

Exploring Alternatives to Quartz Conductivity: A Comparative Analysis

When evaluating the conductivity of quartz and its applications, it’s essential to consider alternative materials and technologies that can fulfill similar roles in electronic components. This analysis will focus on comparing quartz’s properties with those of two viable alternatives: silicon and piezoelectric ceramics. Understanding the nuances of each option helps B2B buyers make informed decisions based on their specific requirements.

| Comparison Aspect | Is Quartz Conductive | Silicon | Piezoelectric Ceramics |

|---|---|---|---|

| Performance | Non-conductive, piezoelectric properties enhance functionality in oscillators | Highly conductive, supports various electronic applications | Good piezoelectric properties, less precise than quartz |

| Cost | Moderate, varies based on purity and processing | Generally lower, especially for mass production | Can be higher due to specialized manufacturing |

| Ease of Implementation | Requires precise cutting and metallization | Easily fabricated into various forms | Requires specific processing techniques |

| Maintenance | Low maintenance; stable under normal conditions | Low maintenance; stable but can degrade under high temperatures | Moderate; can degrade under certain conditions |

| Best Use Case | Ideal for frequency control in oscillators | Excellent for general semiconductor applications | Suitable for sensors and actuators needing piezoelectric response |

What Are the Benefits and Drawbacks of Silicon as an Alternative?

Silicon is a widely used semiconductor known for its excellent electrical conductivity and versatility in various applications, from microchips to solar cells. Its cost-effectiveness, particularly in large-scale production, makes it a preferred choice for many manufacturers. However, while silicon excels in conductivity, it does not possess the piezoelectric properties that quartz offers, which limits its use in applications requiring precise frequency control. Additionally, silicon devices can be sensitive to high temperatures, potentially affecting performance in extreme conditions.

How Do Piezoelectric Ceramics Compare to Quartz?

Piezoelectric ceramics are another alternative that leverages piezoelectric properties similar to quartz. These materials can generate an electric charge under mechanical stress, making them useful in sensors and actuators. However, they generally lack the precision and stability of quartz crystals, especially in high-frequency applications. The manufacturing process for piezoelectric ceramics can be more complex and costly, which may deter some buyers. Nevertheless, they offer advantages in applications where a robust material is required that can withstand harsher environments.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate material for electronic applications hinges on several factors, including performance, cost, ease of implementation, and maintenance requirements. Quartz remains a top choice for applications demanding high precision and stability, particularly in oscillators. However, silicon may be preferable for cost-sensitive projects that prioritize conductivity over piezoelectric properties. Meanwhile, piezoelectric ceramics present a compelling option for applications requiring robust performance under mechanical stress. By evaluating these alternatives against specific project requirements, B2B buyers can make informed decisions that align with their strategic objectives.

Essential Technical Properties and Trade Terminology for is quartz conductive

What Are the Key Technical Properties of Quartz in Electronics?

When evaluating quartz for electronic applications, understanding its technical properties is crucial for B2B buyers. Here are some essential specifications to consider:

1. Material Grade

Quartz used in electronics is typically of a high purity grade, often referred to as “synthetic quartz” or “optical grade quartz.” This material grade is vital because impurities can significantly affect the performance and reliability of electronic components. High-purity quartz is essential for applications requiring precise frequency stability and low loss, making it a preferred choice for oscillators and filters.

2. Frequency Tolerance

Frequency tolerance defines the allowable deviation from the specified frequency of a quartz crystal. It is typically expressed in parts per million (ppm). For B2B buyers, this specification is critical, as tighter tolerances ensure better performance in timing applications, such as in telecommunications and computer systems. An understanding of frequency tolerance can help buyers choose the right product that meets their specific operational needs.

3. Temperature Coefficient of Frequency (TCF)

The TCF indicates how the frequency of a quartz crystal changes with temperature. This property is particularly important for applications in varying thermal environments. A low TCF means that the crystal will maintain its frequency stability across a range of temperatures, which is essential for high-precision applications. Buyers should look for crystals with a TCF that suits their application’s thermal conditions to ensure optimal performance.

4. Q Factor (Quality Factor)

The Q factor measures the energy loss of a vibrating system, reflecting how underdamped the crystal is. A higher Q factor indicates lower energy losses and better performance. For B2B buyers, selecting a quartz crystal with a high Q factor is essential for applications that require high-frequency stability and efficiency, such as in RF circuits.

5. Physical Dimensions

The physical dimensions of quartz crystals—such as length, thickness, and cut orientation—directly influence their resonant frequency. Customization of these dimensions allows for the tailoring of the crystal’s performance to specific application needs. Understanding these specifications helps buyers ensure compatibility with their existing systems.

What Are Common Trade Terms Related to Quartz in Electronics?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for B2B buyers, as sourcing components from reputable OEMs can ensure product quality and reliability.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For buyers, being aware of MOQ is important for budgeting and inventory management, especially when dealing with high-value components like quartz crystals.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price and availability information for specific products. For B2B buyers, submitting an RFQ helps in comparing offers and negotiating better terms, ensuring that they get the best value for their purchases.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is essential for B2B buyers to understand shipping responsibilities, costs, and risks associated with their purchases.

5. Lead Time

Lead time refers to the amount of time it takes for an order to be processed and delivered. Understanding lead times is crucial for B2B buyers to manage their supply chains effectively and ensure that production schedules are met.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions regarding quartz for their electronic applications, fostering smoother transactions and successful partnerships.

Navigating Market Dynamics and Sourcing Trends in the is quartz conductive Sector

What Are the Current Market Dynamics and Key Trends in the Quartz Sector?

The quartz sector is experiencing significant growth driven by the increasing demand for electronic components across various industries, including telecommunications, automotive, and consumer electronics. As a fundamental material in the production of piezoelectric devices, quartz is essential for oscillators and resonators, which are critical for maintaining signal integrity in modern electronic applications. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are particularly focused on sourcing high-quality synthetic quartz, which offers greater purity and consistency than natural quartz.

Emerging trends indicate a shift towards advanced manufacturing techniques, including the use of artificial intelligence and automation in the production of quartz crystals. This transition not only enhances precision but also reduces lead times, making it easier for companies to meet the fast-paced demands of the global market. Additionally, the rise of the Internet of Things (IoT) is creating new opportunities for quartz suppliers, as more devices require precise timing and frequency control. Buyers should also be aware of the increasing focus on supply chain transparency, as stakeholders seek reliable suppliers who can demonstrate quality and compliance with international standards.

How Does Sustainability Influence Sourcing Decisions in the Quartz Sector?

The environmental impact of quartz extraction and processing is a growing concern for B2B buyers. Sustainable sourcing practices are becoming increasingly important, with companies prioritizing suppliers who adhere to ethical guidelines and environmental standards. This includes minimizing waste, reducing energy consumption, and ensuring safe working conditions in mining operations.

Buyers are encouraged to seek out suppliers who can provide certifications that demonstrate their commitment to sustainability, such as ISO 14001 for environmental management and other ‘green’ certifications. These certifications not only enhance a company’s reputation but also ensure compliance with increasingly stringent regulations in various markets. Furthermore, sourcing from suppliers who utilize recycled materials or innovative processes that reduce the carbon footprint can provide a competitive edge in an environmentally conscious marketplace.

What Is the Historical Context of Quartz in Electronics?

Quartz has a long-standing history in electronics, dating back to the early 20th century when it was first utilized in radio technology. Its unique piezoelectric properties were discovered, leading to its adoption in various electronic devices for frequency stabilization and timing applications. Over the decades, advancements in quartz manufacturing techniques have transformed the sector, moving from natural quartz to synthetic options that offer superior quality and reliability.

As electronic devices have evolved, so too has the role of quartz, becoming indispensable in contemporary technologies, including smartphones, GPS systems, and medical devices. This evolution underscores the importance of understanding both the historical context and the current trends in the quartz market, providing valuable insights for B2B buyers looking to make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of is quartz conductive

1. Is quartz conductive and how does it function in electronics?

Quartz is not conductive in the traditional sense; it does not carry electricity like metals. However, it exhibits piezoelectric properties, meaning it can generate small electrical charges when subjected to mechanical stress. This unique characteristic makes quartz valuable in various electronic applications, such as oscillators and sensors, where it serves as a frequency stabilizer. Understanding this property is crucial for B2B buyers looking to source materials for electronic components.

2. What are the primary applications of quartz in electronic devices?

Quartz is primarily used in the production of oscillators, resonators, and sensors due to its stable frequency and piezoelectric properties. These applications are vital in devices such as watches, smartphones, and communication equipment. For B2B buyers, selecting high-quality quartz ensures the reliability and precision of electronic products, which is essential for maintaining competitive advantages in the market.

3. How can I verify the quality of quartz suppliers?

When vetting quartz suppliers, it’s essential to assess their certification and quality control processes. Look for suppliers that adhere to international standards such as ISO 9001, ensuring that their production processes are consistent and reliable. Additionally, request samples to evaluate the quartz’s purity and performance in your specific applications. Conducting site visits, if possible, can also provide insights into their manufacturing capabilities and quality assurance practices.

4. What customization options are available for quartz products?

Many quartz suppliers offer customization options, including specific dimensions, shapes, and frequency specifications tailored to your needs. Engaging with suppliers early in the sourcing process can help you define your requirements clearly. Be prepared to discuss your application and performance criteria to ensure the customized product meets your expectations. Customization can enhance the functionality of your final products, making it a valuable consideration.

5. What are the typical minimum order quantities (MOQ) for quartz?

Minimum order quantities for quartz products can vary significantly among suppliers and depend on the type of product. Generally, smaller quantities may be available for standard items, while customized products might require higher MOQs. It’s advisable to clarify MOQs during initial discussions with suppliers to avoid potential bottlenecks in your supply chain. Understanding these terms can help you manage inventory and production schedules more effectively.

6. What payment terms should I expect when sourcing quartz internationally?

Payment terms for international purchases of quartz can differ based on supplier policies and the buyer’s negotiating power. Common arrangements include upfront payments, letters of credit, or net payment terms (e.g., 30 or 60 days after shipment). It’s crucial to establish clear payment terms before finalizing contracts to mitigate financial risks. Consider using escrow services for larger orders to ensure mutual trust and security during the transaction.

7. How can I ensure quality assurance (QA) for quartz products?

To guarantee quality assurance for quartz products, establish a clear QA process with your supplier. This process should include detailed specifications, sampling methods, and testing protocols to verify the products meet your standards. Request regular quality reports and conduct audits if possible. Additionally, consider third-party testing to validate performance and compliance with industry standards, ensuring the products you receive are reliable and meet your application needs.

8. What logistics considerations should I keep in mind when sourcing quartz?

Logistics plays a critical role in the successful sourcing of quartz. Consider factors such as shipping methods, lead times, and customs regulations in your country. It’s essential to work with suppliers experienced in international shipping to navigate these complexities. Additionally, assess the supplier’s ability to provide tracking information and support throughout the shipping process to ensure timely delivery and reduce the risk of delays.

Top 6 Is Quartz Conductive Manufacturers & Suppliers List

1. Quartz – Key Properties

Domain: lateblt.tripod.com

Registered: 1994 (31 years)

Introduction: Quartz is silicon dioxide (SiO2) and is the world’s most common mineral. It is piezoelectric, generating electricity under pressure and deforming when electricity is applied. Artificially-made quartz is used in electronics due to its precision. The crystal is cut into bar or disc shapes, has two electrical leads, and is plated with a protective metal coating. Crystals are rated for a specific freq…

2. Quartz – Technical Mineral

Domain: quartzpage.de

Introduction: Quartz is a technically important mineral valued for its combination of electrical and optical properties, along with great physical strength and chemical resistance. It exhibits anisotropic behavior due to its crystalline structure, which affects various physical properties such as refraction, birefringence, and piezoelectricity. Quartz has a simple chemical formula but a complex internal structu…

3. All About Circuits – 6mm Quartz Crystal Sphere

Domain: forum.allaboutcircuits.com

Registered: 2003 (22 years)

Introduction: 6mm Quartz Crystal Sphere, Natural Quartz Gemstone, used in experiments related to electrical conductivity and piezoelectric properties.

4. Sciencing – Quartz Crystal

Domain: sciencing.com

Registered: 2005 (20 years)

Introduction: Quartz crystal is the most widely used crystal for conducting electricity due to its resistance to wear and heat, and its ability to regulate electricity. It is commonly found around the world and is used in radios, computers, televisions, and watches. Additionally, crystals can generate electricity under pressure (piezoelectricity), and are believed to hold physical or emotional energy in metaphy…

5. Wiley Online Library – Enhanced Conductivity in Quartz Crystals

Domain: onlinelibrary.wiley.com

Registered: 1994 (31 years)

Introduction: This company, Wiley Online Library – Enhanced Conductivity in Quartz Crystals, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Brainly – Quartz Properties

Domain: brainly.in

Registered: 2012 (13 years)

Introduction: Quartz is the world’s most common mineral and the main component of common sand. It is not a good conductor of electricity like metals such as copper, but it possesses certain electrical properties that make it useful in electronics, particularly its piezoelectric properties.

Strategic Sourcing Conclusion and Outlook for is quartz conductive

In summary, quartz, while not electrically conductive in the traditional sense, possesses valuable piezoelectric properties that make it indispensable in modern electronics. For B2B buyers, understanding these nuances is crucial for sourcing high-quality quartz materials that meet specific electronic requirements. The importance of strategic sourcing cannot be overstated; it enables companies to secure reliable, high-purity quartz that can enhance product performance and innovation.

As international markets evolve, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for precision electronic components is expected to rise. Buyers in these regions should prioritize partnerships with reputable suppliers who can provide the necessary technical specifications and quality assurance.

Looking ahead, companies that leverage effective sourcing strategies for quartz will be well-positioned to thrive in the competitive landscape of the electronics industry. Engage with suppliers who understand the intricacies of quartz applications, ensuring that your business remains at the forefront of technological advancements. Take the next step in optimizing your sourcing strategy today to capitalize on the future of electronics.

Illustrative image related to is quartz conductive

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.