Everything You Need to Know About Indexing Conveyor Sourcing in 2025

Introduction: Navigating the Global Market for indexing conveyor

In today’s fast-paced manufacturing landscape, sourcing the right indexing conveyor can be a pivotal challenge for B2B buyers looking to enhance operational efficiency and precision. Indexing conveyors are essential for streamlining production processes, ensuring that products are delivered at the right time and in the right order. This comprehensive guide addresses the complexities of navigating the global market for indexing conveyors, offering insights into various types, applications, and key considerations for suppliers.

From understanding the nuances of precision indexing systems to evaluating the specific needs of different industries—such as food processing, metalworking, and automation—this guide serves as a vital resource for international buyers from Africa, South America, the Middle East, and Europe, including countries like Germany and Vietnam. It empowers you to make informed purchasing decisions by highlighting essential factors like supplier vetting, cost structures, and technological advancements in conveyor systems.

By the end of this guide, you will be equipped with actionable knowledge to select the most suitable indexing conveyor solutions that align with your production goals, ultimately leading to improved productivity and reduced operational costs. Whether you are seeking high-volume solutions or custom configurations, our insights will ensure your investment is both strategic and beneficial.

Understanding indexing conveyor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Precision Indexing Conveyors | Positive drive-toothed belts for high accuracy | Automation, Food Processing, Metal Working | Pros: High precision, reduced errors. Cons: Higher initial investment. |

| Timing Belt Conveyors | Step motion control with fixtures for product placement | Assembly Lines, Packaging, Robotics | Pros: Versatile, customizable. Cons: May require more maintenance. |

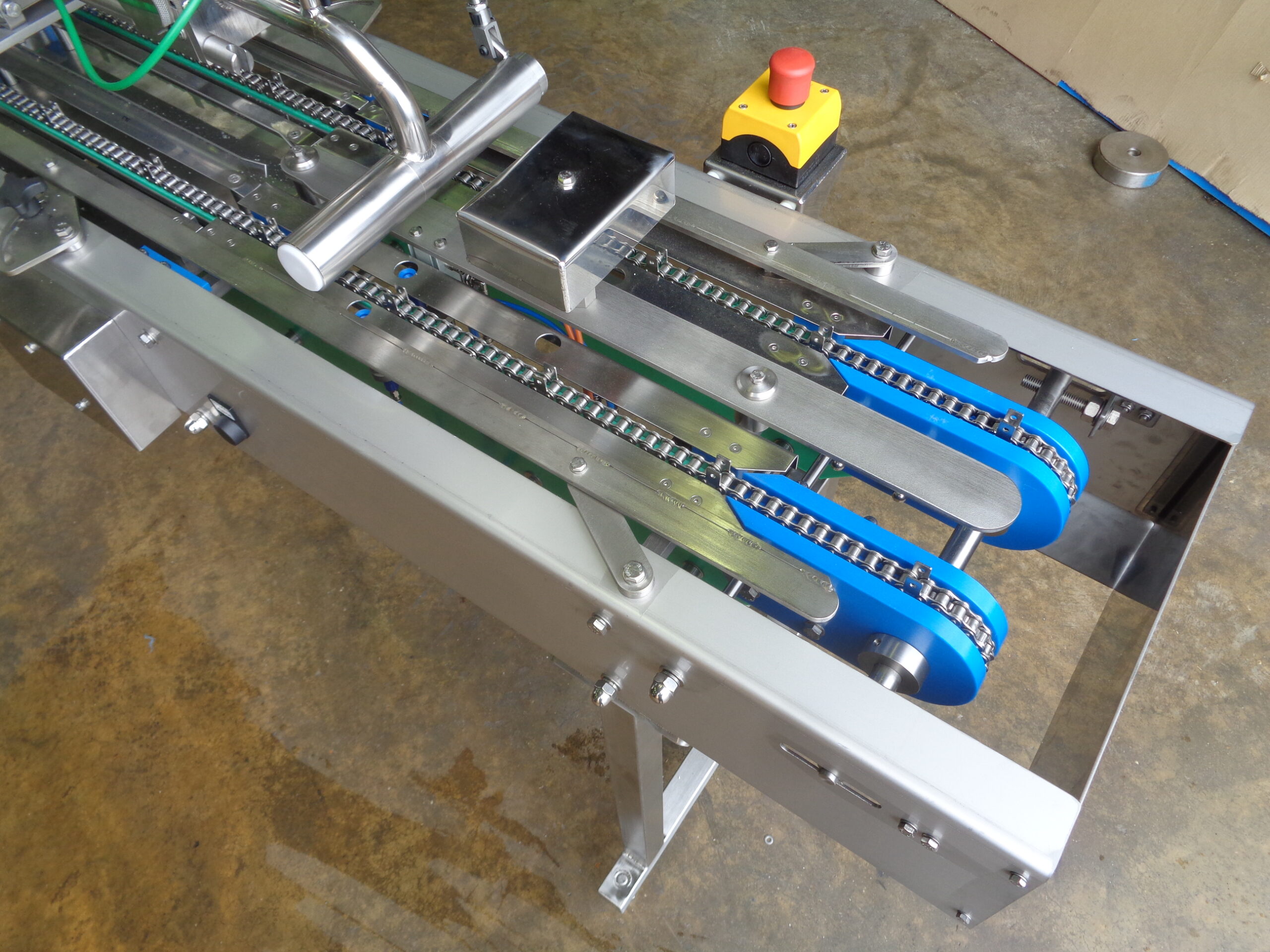

| Chain Conveyors | Durable construction suitable for harsh environments | Food and Pharmaceutical Manufacturing | Pros: Robust, reliable in tough conditions. Cons: Heavier and less flexible. |

| Modular Conveyors | Configurable sections for tailored layouts | Custom Manufacturing, Product Handling | Pros: Highly adaptable, easy to expand. Cons: Complexity in design and setup. |

| Servo Motor Conveyors | High-speed operation with precise control | Automotive, Electronics Assembly | Pros: Fast, precise, reduces cycle time. Cons: Higher cost for advanced technology. |

What Are Precision Indexing Conveyors and Their Benefits for B2B Buyers?

Precision indexing conveyors are designed for applications requiring high accuracy in product placement. Utilizing a positive drive-toothed belt, these conveyors ensure that products are positioned with minimal error, making them ideal for automated systems in sectors like food processing and metal working. When considering a purchase, B2B buyers should evaluate the potential return on investment through increased productivity and reduced error rates, despite the higher initial costs associated with these sophisticated systems.

How Do Timing Belt Conveyors Enhance Assembly Line Efficiency?

Timing belt conveyors are characterized by their ability to move products in a controlled step-wise manner, often incorporating fixtures to hold items in place. This feature makes them particularly useful in assembly lines and packaging applications. Buyers should consider the versatility and customization options available with timing belt conveyors, as they can be tailored to fit specific production needs. However, potential buyers should also be aware of the maintenance requirements that may arise from their use.

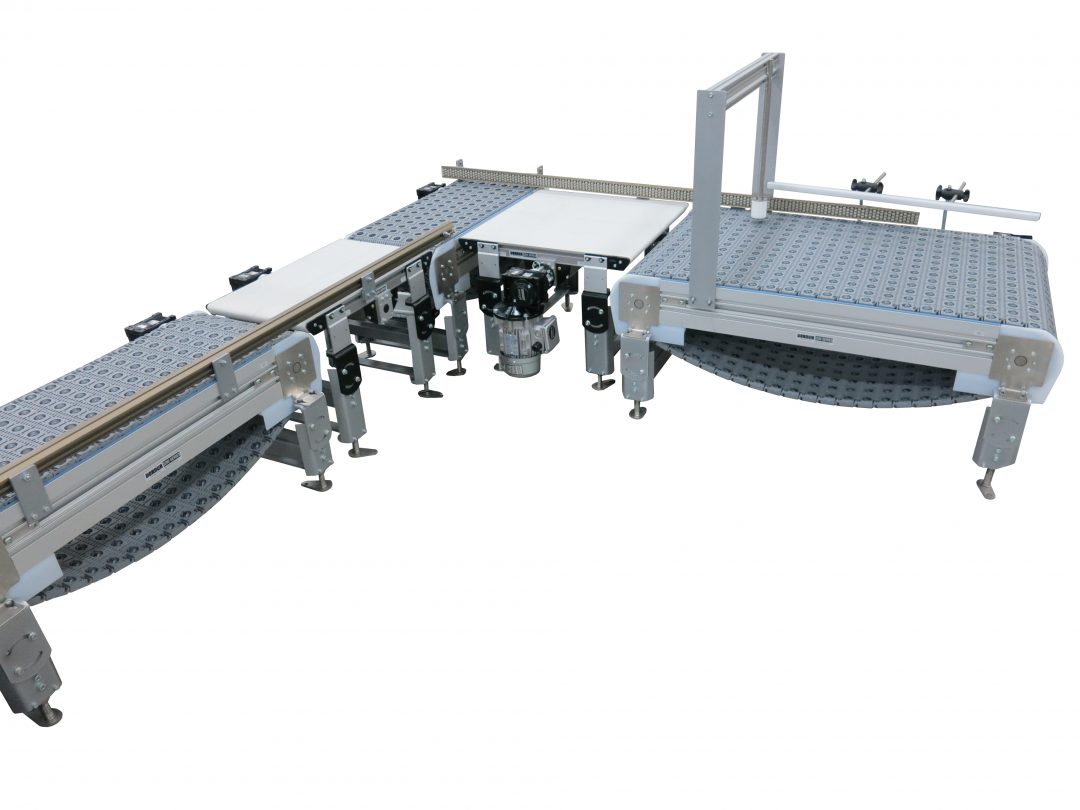

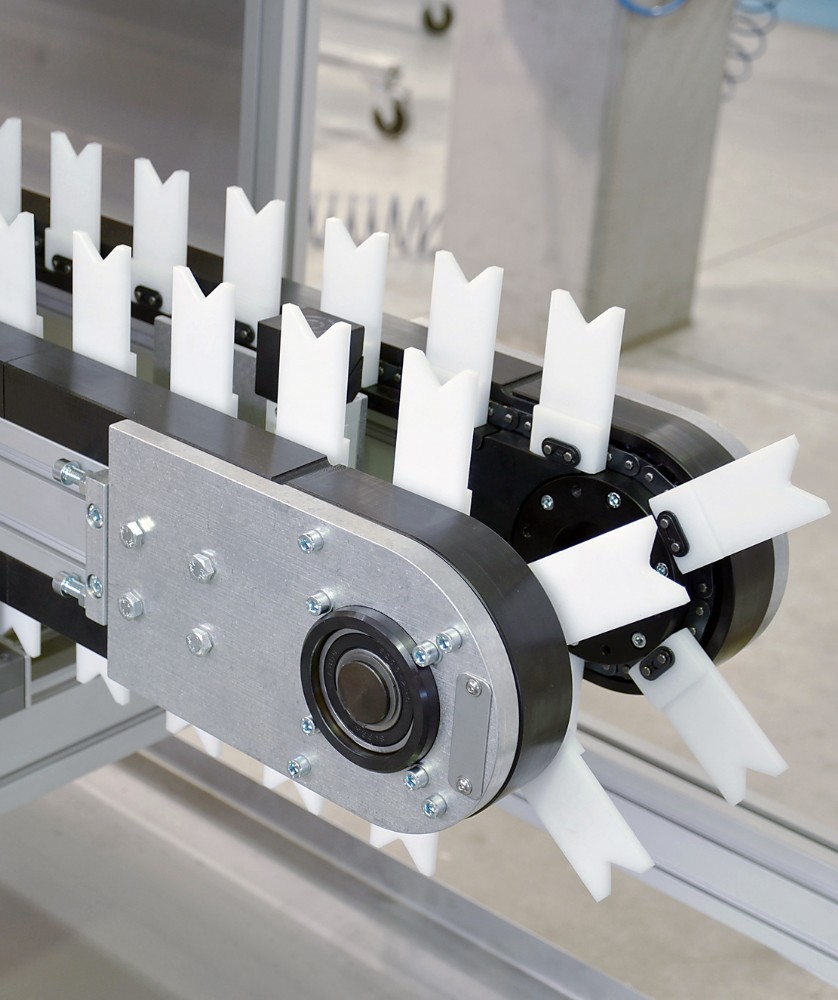

Illustrative image related to indexing conveyor

Why Choose Chain Conveyors for Harsh Environments?

Chain conveyors are built for durability, making them suitable for harsh industrial environments, such as food and pharmaceutical manufacturing. Their robust construction allows them to handle heavy loads and resist wear and tear. When purchasing chain conveyors, B2B buyers should assess the operational conditions and expected load capacities. While these conveyors provide reliability, they may be heavier and less flexible than other types, which could impact installation and layout flexibility.

What Are the Advantages of Modular Conveyors for Custom Manufacturing?

Modular conveyors consist of configurable sections that allow for tailored layouts to meet specific operational needs. This adaptability makes them ideal for custom manufacturing and product handling. Buyers should consider the ease of expansion and modification as their production requirements evolve. However, the complexity in design and setup can be a drawback, necessitating careful planning and potential investment in engineering support.

How Do Servo Motor Conveyors Improve Assembly Speed and Precision?

Servo motor conveyors are known for their high-speed operation and precise control, which are crucial in industries such as automotive and electronics assembly. These conveyors can significantly reduce cycle times and enhance overall productivity. B2B buyers should weigh the benefits of speed and precision against the higher costs associated with this advanced technology. Investing in servo motor conveyors can lead to considerable efficiency gains, making them a worthy consideration for businesses focused on competitive production rates.

Key Industrial Applications of indexing conveyor

| Industry/Sector | Specific Application of indexing conveyor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Automated assembly lines for packaging food products | Increases throughput and reduces labor costs | Compliance with food safety standards and hygiene |

| Automotive Manufacturing | Precision part handling for assembly processes | Enhances accuracy and reduces assembly errors | Ability to integrate with robotics and automation systems |

| Pharmaceutical | Controlled dispensing and packaging of medications | Ensures accuracy in dosages and improves operational efficiency | Compliance with regulatory standards and traceability |

| Metalworking | Indexing for machining and fabrication processes | Improves workflow efficiency and reduces waste | Robust construction for harsh environments and durability |

| Electronics Assembly | Automated placement of components on PCBs | Increases speed and precision in manufacturing | Customization options for different component sizes and shapes |

How Are Indexing Conveyors Used in Food Processing?

In the food processing industry, indexing conveyors facilitate the automated assembly and packaging of food products. They allow for precise positioning and movement of items along the production line, which is essential for maintaining hygiene and efficiency. For international buyers, especially in regions like Africa and South America, sourcing indexing conveyors that comply with local food safety regulations is crucial. Additionally, the ability to handle various product sizes and types can significantly impact operational flexibility and throughput.

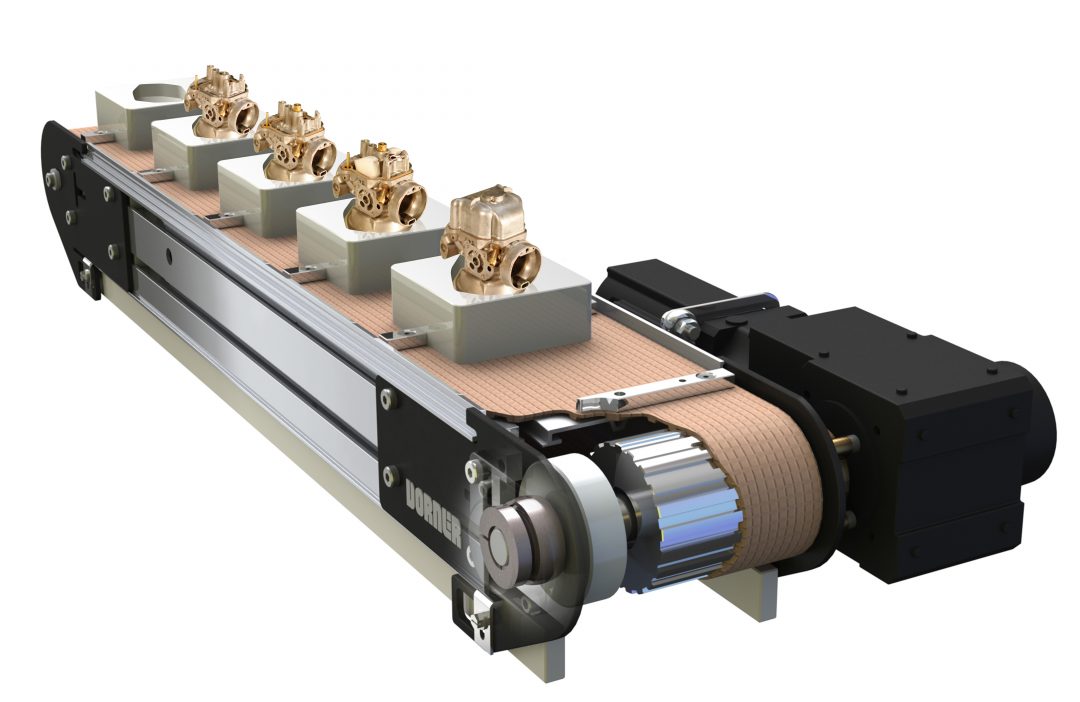

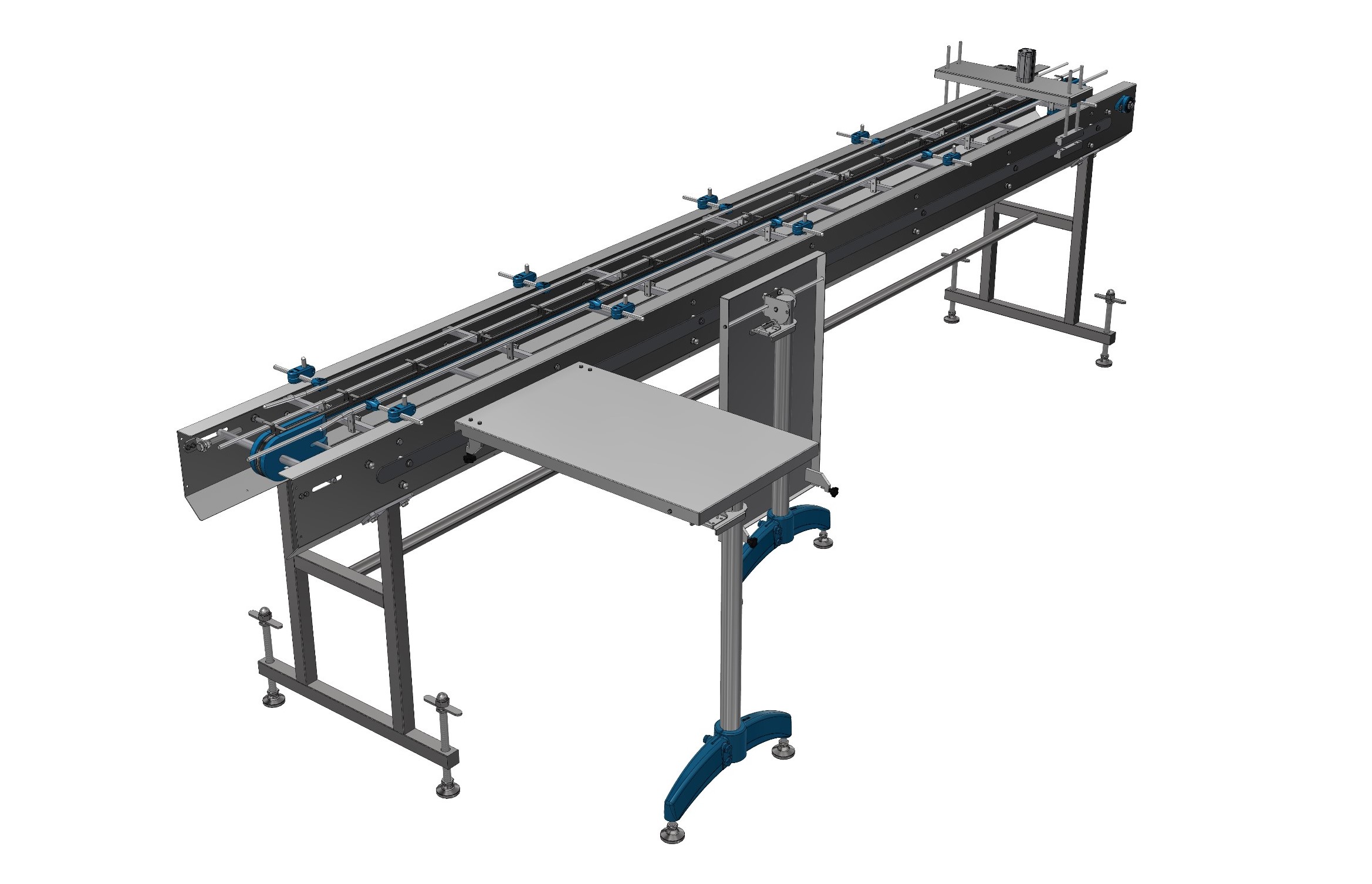

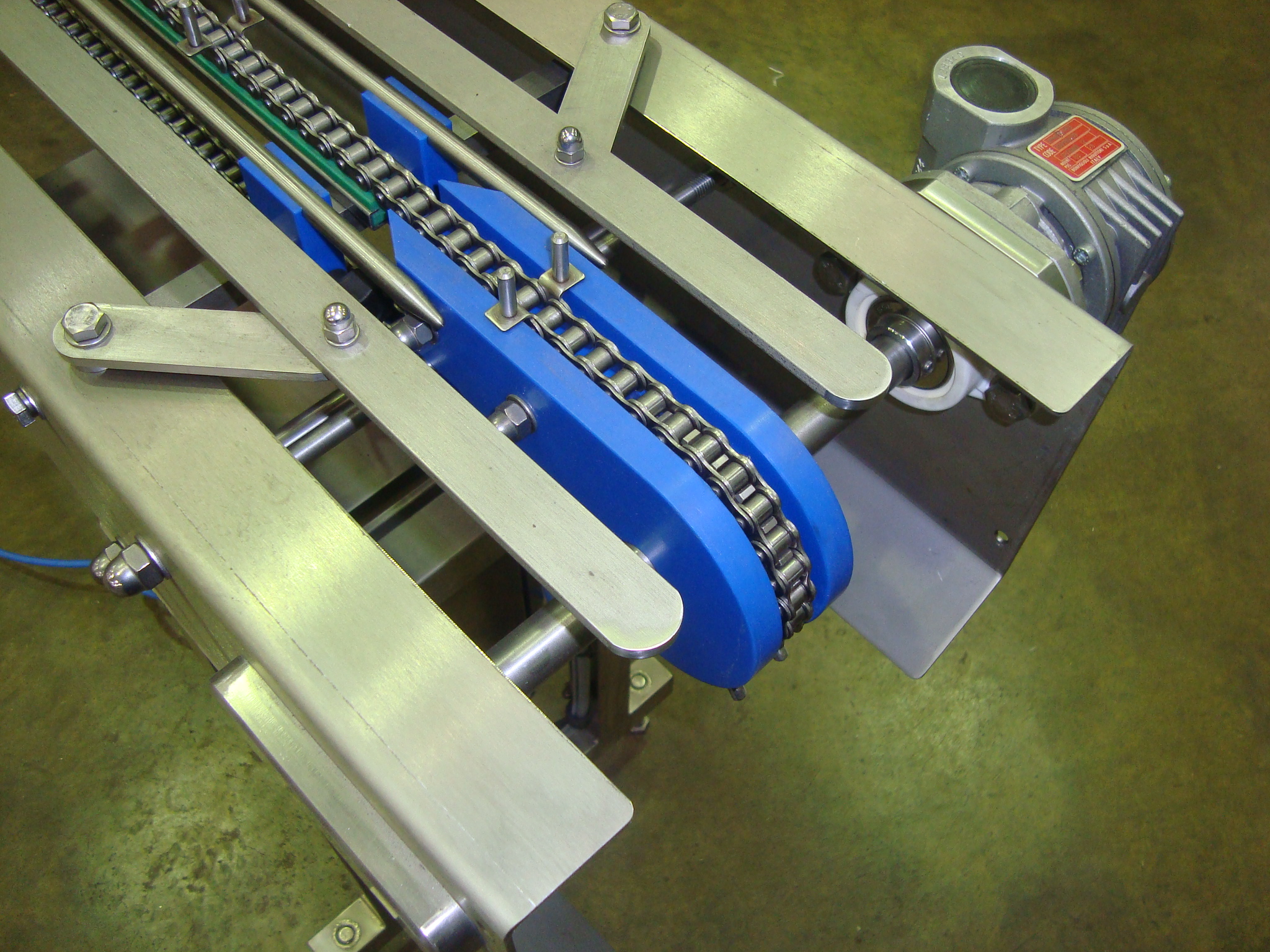

Illustrative image related to indexing conveyor

What Role Do Indexing Conveyors Play in Automotive Manufacturing?

In automotive manufacturing, indexing conveyors are integral for moving parts through assembly lines with high precision. They enable manufacturers to position components accurately, which reduces the likelihood of errors during assembly. For buyers in Europe, particularly in Germany, the emphasis on quality and precision means that selecting conveyors with advanced motor and control systems is vital. Understanding the integration capabilities with existing robotics and automation technologies is also essential for optimizing production processes.

How Are Indexing Conveyors Used in the Pharmaceutical Sector?

Indexing conveyors in the pharmaceutical sector are crucial for the controlled dispensing and packaging of medications. They ensure that dosages are accurate and that products are packaged efficiently, which is vital for compliance with regulatory standards. Buyers from the Middle East and Europe must consider suppliers that provide conveyors with features like traceability and hygiene compliance. The ability to adapt to varying batch sizes and product types is also a significant requirement in this sector.

What Benefits Do Indexing Conveyors Offer in Metalworking?

In metalworking, indexing conveyors streamline machining and fabrication processes by facilitating the precise handling of heavy or complex parts. They improve workflow efficiency, minimize waste, and enhance safety in environments where heavy machinery is in use. For international buyers, especially in regions with stringent industrial regulations, it is essential to source conveyors that can withstand harsh conditions and provide long-term durability. Customization options for specific applications can further enhance operational effectiveness.

How Are Indexing Conveyors Used in Electronics Assembly?

In the electronics assembly sector, indexing conveyors are employed for the automated placement of components on printed circuit boards (PCBs). This application increases manufacturing speed and precision, crucial for meeting high demand and maintaining quality standards. Buyers from diverse markets, including Africa and South America, should look for conveyors that offer customization for various component sizes and shapes. Ensuring compatibility with existing assembly lines and automation systems is also a key consideration for maximizing efficiency.

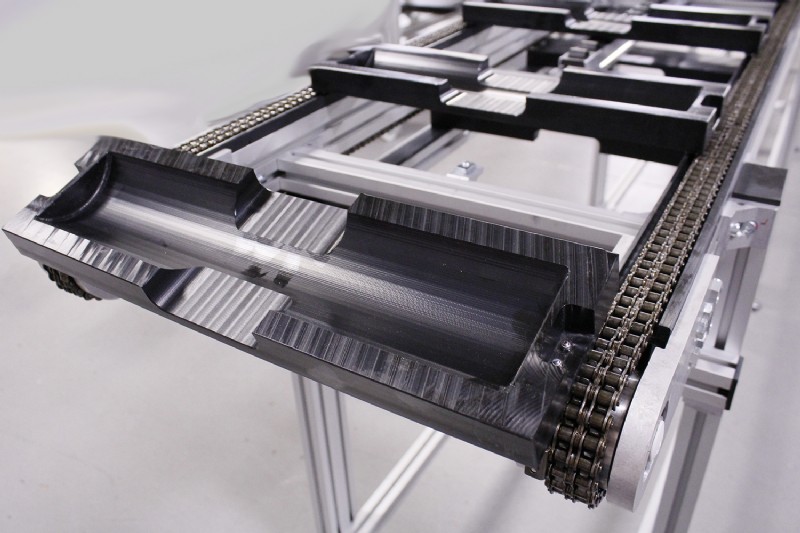

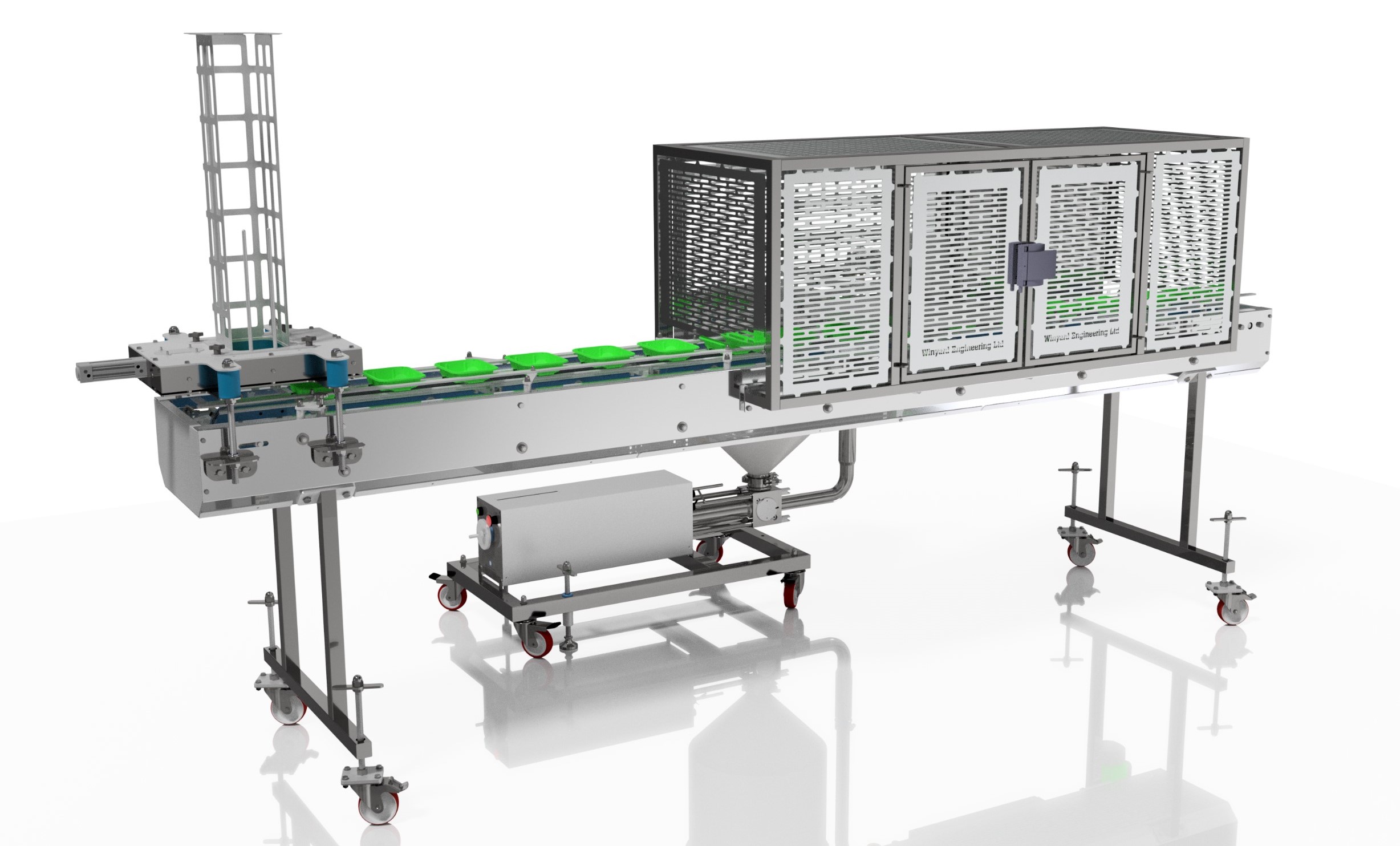

Illustrative image related to indexing conveyor

3 Common User Pain Points for ‘indexing conveyor’ & Their Solutions

Scenario 1: High Error Rates in Production Line

The Problem: In fast-paced manufacturing environments, maintaining accuracy is critical. A common pain point for B2B buyers is the high margin of error associated with traditional conveyor systems. This can lead to misplaced products, incorrect counts, and ultimately, costly production delays. For instance, a food processing plant may find that their indexing conveyor fails to position products accurately for packaging, resulting in inconsistent counts and subsequent rework. This not only disrupts workflow but also affects inventory management and customer satisfaction.

The Solution: To tackle the issue of accuracy, B2B buyers should consider investing in precision indexing conveyors specifically designed for high-accuracy applications. Look for conveyors that utilize positive drive-toothed belts, which lock the belt position to end rollers, ensuring precise movement. Additionally, integrating advanced sensors and automation technology can significantly reduce human error. When sourcing these conveyors, buyers should work closely with manufacturers to specify their unique requirements, such as product dimensions and required throughput. Custom solutions can be tailored to meet specific operational needs, ensuring that products are consistently positioned correctly and efficiently.

Scenario 2: Integration Challenges with Existing Systems

The Problem: Many manufacturers face significant hurdles when trying to integrate new indexing conveyor systems with their existing machinery and workflows. This challenge is particularly pronounced in facilities that utilize a mix of old and new technologies. For example, a packaging company may struggle to connect a new indexing conveyor with legacy systems that control the flow of materials, leading to inefficiencies and downtime during the transition period.

The Solution: To ensure seamless integration, B2B buyers should prioritize flexibility and compatibility when selecting indexing conveyors. It is essential to choose a system that offers customizable features and can easily interface with existing machinery. Engaging with suppliers who provide comprehensive engineering support and customization options is critical. Buyers should request detailed schematics and conduct compatibility tests before finalizing their purchase. Additionally, consider investing in modular conveyor systems that can be easily adjusted or expanded as production needs change. This approach not only minimizes integration challenges but also future-proofs the investment.

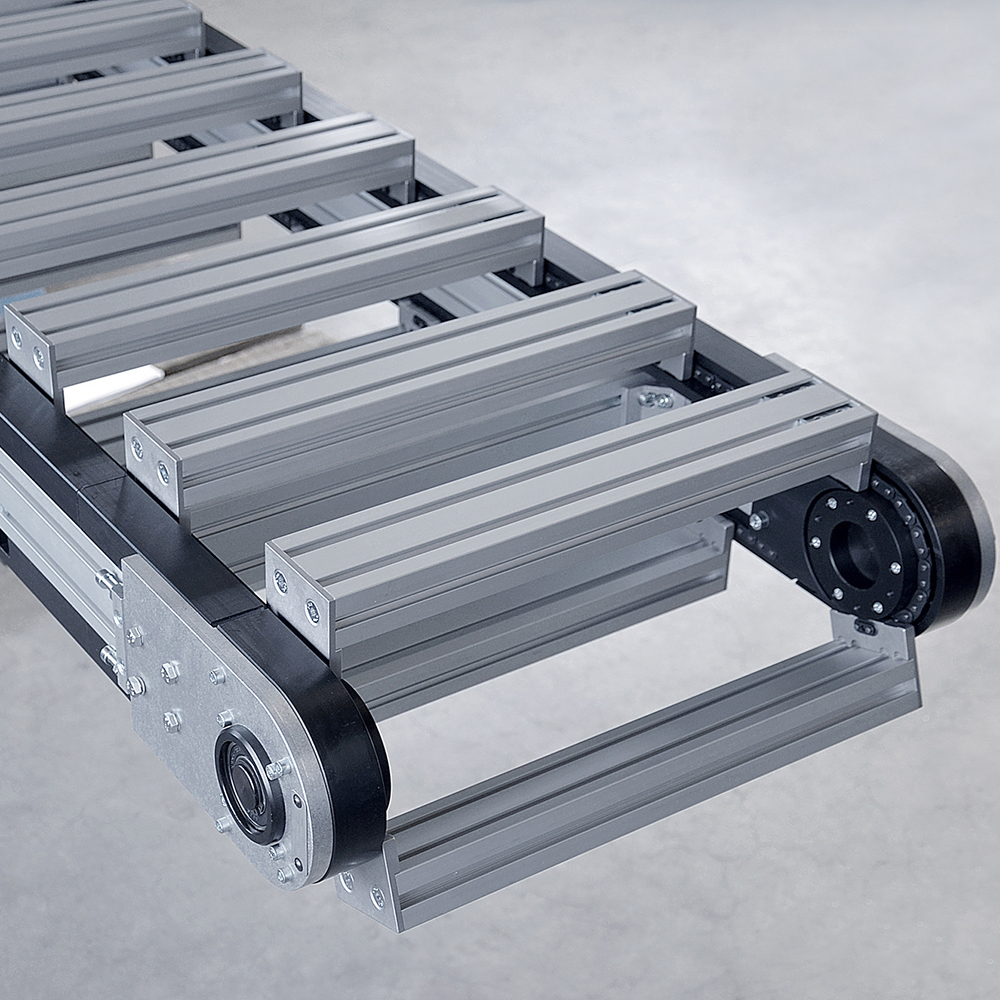

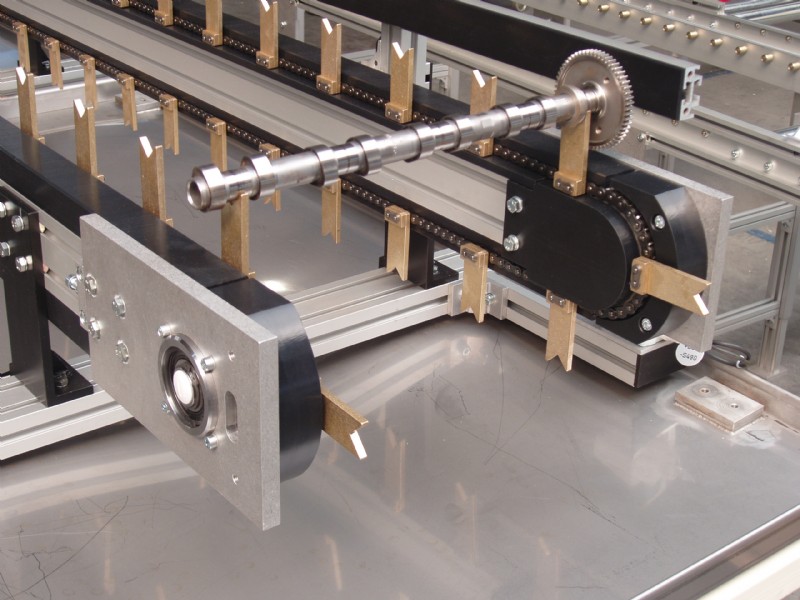

Illustrative image related to indexing conveyor

Scenario 3: Insufficient Space for New Equipment

The Problem: In many manufacturing facilities, floor space is at a premium. B2B buyers often encounter the dilemma of needing to implement an indexing conveyor system to enhance productivity, yet facing spatial constraints that prevent the installation of larger equipment. For instance, a small-scale automotive parts manufacturer may find that their available floor space limits their ability to introduce a conveyor system that could streamline their assembly process.

The Solution: Buyers should explore compact indexing conveyor options specifically designed for operations with limited space. Many manufacturers offer small-footprint solutions that maintain high productivity levels without compromising efficiency. When evaluating potential systems, focus on conveyors that utilize vertical space, such as incline or z-frame designs. Additionally, consider conveyors that can be integrated into existing workflows without requiring significant layout changes. Collaborating with suppliers to create custom-sized solutions can also optimize space utilization. This approach not only enhances operational efficiency but also ensures that the new system fits seamlessly into the existing production environment.

Strategic Material Selection Guide for indexing conveyor

What Are the Common Materials Used in Indexing Conveyors?

When selecting materials for indexing conveyors, it’s essential to consider properties that affect performance, durability, and application compatibility. Below, we analyze four common materials used in the construction of indexing conveyors: stainless steel, aluminum, plastic, and carbon steel.

How Does Stainless Steel Benefit Indexing Conveyors?

Stainless steel is a popular choice for indexing conveyors, especially in industries that require high hygiene standards, such as food and pharmaceuticals. Key properties include excellent corrosion resistance, high-temperature tolerance, and robust structural integrity. These features make stainless steel suitable for environments where moisture and chemical exposure are prevalent.

Pros: Stainless steel offers exceptional durability and resistance to wear and tear. It is also easy to clean, which is crucial in maintaining sanitary conditions. However, it tends to be more expensive than other materials, which can impact initial project budgets.

Illustrative image related to indexing conveyor

Cons: The high cost can be a barrier for some businesses, particularly small manufacturers. Additionally, the weight of stainless steel may require more robust supporting structures, increasing manufacturing complexity.

Impact on Application: Stainless steel is ideal for indexing conveyors used in food processing, pharmaceuticals, and other applications where hygiene and durability are paramount.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is critical. Buyers from regions like Europe and the Middle East should ensure that the stainless steel grades meet local regulations for food safety.

What Advantages Does Aluminum Provide for Indexing Conveyors?

Aluminum is another commonly used material in indexing conveyors, known for its lightweight and strength. It has excellent corrosion resistance and is easy to machine, making it suitable for various applications.

Illustrative image related to indexing conveyor

Pros: The lightweight nature of aluminum allows for easier installation and less structural support. Its cost-effectiveness makes it an attractive option for budget-conscious buyers.

Cons: While aluminum is durable, it may not withstand extreme temperatures or heavy loads as well as stainless steel. Additionally, it can be more susceptible to scratches and dents.

Impact on Application: Aluminum is often used in applications that require moderate strength and where weight reduction is essential, such as in assembly lines and packaging.

Considerations for International Buyers: Buyers should verify that aluminum grades comply with local standards, such as JIS in Japan or EN in Europe, to ensure compatibility with their operational needs.

How Do Plastics Enhance Indexing Conveyor Performance?

Plastic materials, such as polypropylene and polyethylene, are increasingly used in indexing conveyors, particularly in low-load applications. They offer good chemical resistance and are lightweight.

Illustrative image related to indexing conveyor

Pros: Plastics are typically less expensive than metals and can be molded into complex shapes, allowing for customized designs. They are also resistant to corrosion and can handle a variety of chemicals.

Cons: Plastics may not be suitable for high-temperature applications and can wear out faster than metal counterparts. Their load-bearing capacity is generally lower, which can limit their use in heavy-duty environments.

Impact on Application: Plastic indexing conveyors are ideal for light-duty applications, such as packaging and assembly in industries where chemical exposure is a concern.

Considerations for International Buyers: Buyers should ensure that the plastics used meet relevant safety and environmental regulations, particularly in regions with strict compliance standards.

What Role Does Carbon Steel Play in Indexing Conveyors?

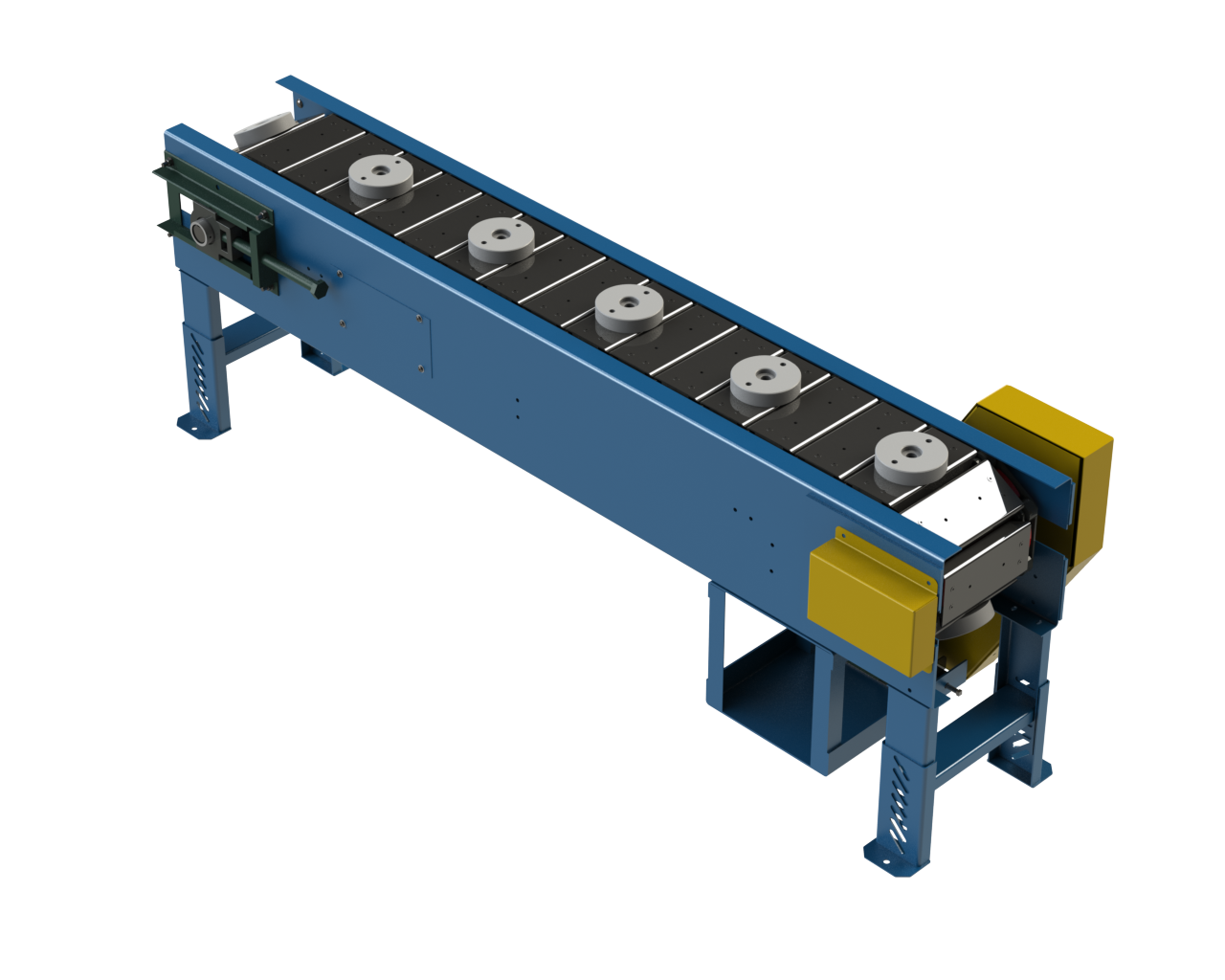

Carbon steel is often used in indexing conveyors for heavy-duty applications due to its high strength and durability. It is typically coated or treated to enhance corrosion resistance.

Pros: Carbon steel provides excellent strength and load-bearing capacity, making it suitable for heavy materials. It is generally less expensive than stainless steel.

Cons: Carbon steel is prone to corrosion, which can be a significant drawback in humid or corrosive environments. It also requires regular maintenance to prevent rust.

Impact on Application: Carbon steel is best suited for industrial applications where heavy loads and durability are critical, such as in automotive manufacturing.

Illustrative image related to indexing conveyor

Considerations for International Buyers: Buyers should be aware of the need for protective coatings and maintenance schedules to ensure longevity, especially in humid climates prevalent in regions like Africa and South America.

Summary Table of Material Selection for Indexing Conveyors

| Material | Typical Use Case for indexing conveyor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost, heavier weight | High |

| Aluminum | Assembly lines, packaging | Lightweight, cost-effective | Lower load capacity, less durable | Medium |

| Plastic | Light-duty applications | Customizable, chemical resistant | Not suitable for high temperatures | Low |

| Carbon Steel | Heavy-duty industrial applications | High strength, cost-effective | Prone to corrosion, requires maintenance | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for indexing conveyor

What Are the Main Stages of Manufacturing Indexing Conveyors?

The manufacturing process of indexing conveyors involves several critical stages, each ensuring the final product meets high standards of quality, precision, and reliability. Understanding these stages can help B2B buyers assess potential suppliers effectively.

How is Material Prepared for Indexing Conveyors?

Material preparation is the initial step in the manufacturing process. High-quality materials such as stainless steel, aluminum, and various polymers are selected based on the specific application of the indexing conveyor. For example, stainless steel is often preferred in food processing and pharmaceutical applications due to its corrosion resistance and ease of cleaning.

Once the materials are chosen, they undergo cutting and machining processes to achieve the desired dimensions and specifications. This stage is crucial as it directly impacts the accuracy and durability of the conveyor system. Advanced techniques like laser cutting and CNC machining are commonly used to ensure precision.

What Techniques are Used for Forming Indexing Conveyors?

The forming stage involves shaping the prepared materials into functional components of the conveyor system. Techniques such as bending, welding, and assembling are utilized here. For indexing conveyors, it is essential to create parts that can withstand repetitive motion and heavy loads.

Welding techniques, including MIG and TIG welding, are often employed to join metal components. For non-metal parts, adhesives or mechanical fasteners may be used to ensure a secure fit. The choice of technique is dictated by the materials used and the specific requirements of the indexing application.

How is the Assembly of Indexing Conveyors Conducted?

Assembly is a critical stage where individual components are integrated to form the complete indexing conveyor system. This stage often involves the installation of motors, sensors, and control systems that enable precise product movement.

Quality assurance is paramount during assembly. Components are checked for compatibility and alignment, and adjustments are made as necessary to ensure smooth operation. Skilled technicians typically handle this stage, using specialized tools and equipment to guarantee that every part functions correctly within the system.

Illustrative image related to indexing conveyor

What Finishing Processes Are Applied to Indexing Conveyors?

The finishing stage includes surface treatments, painting, or coating to enhance the conveyor’s durability and aesthetics. For indexing conveyors, protective coatings such as powder coating are often applied to prevent corrosion, especially in harsh environments.

Additionally, finishing may include polishing or buffing surfaces to reduce friction and improve performance. This stage not only impacts the conveyor’s functionality but also its longevity, making it a crucial step for B2B buyers to consider.

What Quality Assurance Measures Are Implemented for Indexing Conveyors?

Quality assurance (QA) is integral to the manufacturing of indexing conveyors. Various international standards, industry-specific certifications, and internal checkpoints ensure that the final product meets the required specifications.

Illustrative image related to indexing conveyor

Which International Standards Should B2B Buyers Consider?

International standards such as ISO 9001 are vital for ensuring consistent quality management systems in manufacturing. Compliance with ISO 9001 indicates that the manufacturer follows best practices in quality control and continuous improvement.

In addition to ISO certifications, industry-specific standards such as CE marking for European markets and API standards for the oil and gas sector are also essential. These certifications demonstrate that the indexing conveyor meets regulatory requirements and safety standards relevant to specific industries.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are implemented at various stages of the manufacturing process to ensure adherence to quality standards. Key checkpoints include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials and components upon arrival at the manufacturing facility. Suppliers must provide documentation to verify material quality.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, inspections are conducted to identify defects or deviations from specifications. This may involve measuring dimensions, testing for functionality, and ensuring proper assembly.

-

Final Quality Control (FQC): Before shipment, the completed indexing conveyor undergoes a final inspection to ensure it meets all quality and performance standards. This may include functional tests, load tests, and visual inspections.

What Common Testing Methods Are Used in Indexing Conveyor Manufacturing?

Testing methods play a crucial role in verifying the quality and functionality of indexing conveyors. Common methods include:

- Load Testing: Ensures the conveyor can handle the specified weight and stress during operation.

- Functional Testing: Verifies that all components, including motors and sensors, operate correctly under various conditions.

- Environmental Testing: Assesses the conveyor’s performance under different environmental conditions, such as temperature variations and humidity levels.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control measures of potential suppliers. Here are some effective strategies:

Illustrative image related to indexing conveyor

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturer’s quality control processes firsthand. This includes reviewing documentation, inspecting facilities, and interviewing key personnel.

-

Quality Assurance Reports: Requesting detailed QA reports can provide insights into the manufacturer’s performance, including defect rates and corrective actions taken.

-

Third-Party Inspections: Engaging independent inspection agencies can help ensure that the indexing conveyors meet specified standards before delivery.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers must be aware of specific QC and certification nuances when sourcing indexing conveyors. Regulatory requirements can vary significantly by region. For instance, compliance with CE marking is essential for products sold in Europe, while UL certifications may be necessary for North American markets.

Understanding these regional differences is crucial for avoiding compliance issues that could lead to delays or additional costs. Additionally, buyers should ensure that suppliers can provide documentation proving compliance with these standards.

In conclusion, understanding the manufacturing processes and quality assurance measures for indexing conveyors is essential for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with robust quality control practices, buyers can make informed decisions when selecting suppliers for their conveyor needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘indexing conveyor’

To effectively procure an indexing conveyor, it is essential to follow a structured approach that ensures you meet your operational needs while minimizing risks. This checklist provides a comprehensive guide for B2B buyers, particularly in international markets, to navigate the complexities of sourcing indexing conveyors.

Step 1: Define Your Technical Specifications

Start by clearly outlining your operational requirements, including the type of products to be conveyed, the required precision, and the production volume. Understanding these specifications is crucial for selecting a conveyor that can accommodate your needs without compromising efficiency. Consider factors such as load capacity, speed, and the type of materials being handled.

Step 2: Assess Your Manufacturing Environment

Evaluate the conditions in which the indexing conveyor will operate. Factors such as temperature, humidity, and exposure to chemicals or dust can significantly influence your choice of conveyor. For instance, if you’re in a food processing facility, opt for conveyors designed with sanitary materials and easy-to-clean features to comply with health regulations.

Step 3: Evaluate Potential Suppliers

Conduct thorough research to identify reputable suppliers. Look for companies with a proven track record in delivering indexing conveyors tailored to your industry. Request references and case studies from similar businesses to gauge their reliability and customer satisfaction. This step ensures that you partner with a supplier who understands your specific needs.

Step 4: Consider Customization Options

Not all indexing conveyors are one-size-fits-all; many applications require customization. Discuss with potential suppliers about the ability to modify conveyor dimensions, belt types, and integration with existing systems. Custom solutions can enhance productivity by ensuring that the conveyor aligns perfectly with your production processes.

Step 5: Review Technology and Automation Features

Assess the technological capabilities of the indexing conveyors you are considering. Features such as servo motors, indexing controls, and product sensors can enhance precision and productivity. Ensure that the technology aligns with your automation goals, as this can lead to reduced labor costs and improved operational efficiency.

Step 6: Verify Compliance with Industry Standards

Ensure that the indexing conveyor complies with relevant industry standards and regulations, especially if operating in sectors like food processing or pharmaceuticals. Compliance guarantees that the equipment meets safety and operational benchmarks, reducing the risk of costly downtimes or legal issues.

Step 7: Request a Comprehensive Proposal

Once you have narrowed down your options, request detailed proposals from your shortlisted suppliers. These should include specifications, pricing, delivery timelines, and warranty information. A comprehensive proposal allows for easy comparison and ensures that you make an informed decision based on all critical factors.

Illustrative image related to indexing conveyor

By following this step-by-step checklist, B2B buyers can effectively source indexing conveyors that enhance their production capabilities while ensuring compliance and reliability.

Comprehensive Cost and Pricing Analysis for indexing conveyor Sourcing

What Are the Key Cost Components in Indexing Conveyor Manufacturing?

When sourcing indexing conveyors, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials significantly influences costs. Stainless steel, for example, is more expensive but essential for food and pharmaceutical applications due to its durability and resistance to corrosion. The use of high-quality belts and motors also adds to material costs but impacts performance and longevity.

-

Labor: Labor costs encompass both direct assembly labor and indirect costs associated with engineering, design, and installation. Skilled labor may command higher wages, especially for custom solutions, which can further elevate the overall cost.

-

Manufacturing Overhead: This includes expenses related to facility operations, utilities, and indirect labor. Efficient manufacturing processes can reduce overhead, impacting the final price of the conveyors.

-

Tooling: Custom tooling is often necessary for specific conveyor designs, adding a significant upfront cost. However, this investment can lead to better efficiency and lower long-term costs.

-

Quality Control (QC): Rigorous QC processes are essential to ensure reliability and performance. The cost of QC can vary based on the complexity of the conveyors and the industry standards that need to be met.

-

Logistics: Transportation costs can vary widely based on the location of the supplier and the buyer. International shipping, tariffs, and customs duties can significantly add to the cost of sourcing indexing conveyors.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on the supplier’s market position, brand reputation, and the level of service they provide.

What Factors Influence the Pricing of Indexing Conveyors?

Several factors can influence the pricing of indexing conveyors, and understanding these can help buyers negotiate better deals.

-

Volume/MOQ: The minimum order quantity (MOQ) can impact pricing significantly. Bulk orders often come with discounts, making it economically viable for larger operations. Conversely, smaller orders may incur higher per-unit costs.

-

Specifications and Customization: Custom solutions tailored to specific operational needs will generally be more expensive than standard models. Buyers should clearly define their specifications to avoid unexpected costs.

-

Material Quality and Certifications: Higher-quality materials and certifications (like ISO or food safety standards) often lead to increased costs but can provide long-term savings through reduced maintenance and higher reliability.

-

Supplier Factors: The supplier’s reputation, experience, and geographic location can impact pricing. Established suppliers may charge a premium for their brand assurance, while newer entrants may offer competitive pricing to gain market share.

-

Incoterms: The chosen Incoterms can affect the total cost of ownership. Options like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) will determine who bears the risk and costs associated with transportation, insurance, and customs duties.

How Can Buyers Optimize Costs When Sourcing Indexing Conveyors?

To ensure cost-efficiency in sourcing indexing conveyors, buyers should consider the following tips:

-

Negotiate Pricing: Always engage in negotiations, especially if you have multiple suppliers. Leverage quotes from different suppliers to secure the best price.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, operational efficiency, and potential downtime costs to get a comprehensive view of what the conveyor will cost over its lifespan.

-

Be Aware of International Pricing Nuances: When sourcing from different regions, understand local economic conditions, currency fluctuations, and trade policies. This knowledge can help in negotiating better terms and anticipating price changes.

-

Assess Supplier Relationships: Building long-term relationships with suppliers can lead to better pricing, priority service, and access to new technologies.

-

Conduct a Market Analysis: Regularly review the market for changes in material costs, labor rates, and technological advancements that could impact pricing.

Disclaimer on Indicative Prices

Prices for indexing conveyors can vary widely based on the aforementioned factors. Buyers should seek quotes from multiple suppliers and conduct thorough due diligence to ensure they receive the best value for their investment.

Alternatives Analysis: Comparing indexing conveyor With Other Solutions

Understanding Alternative Solutions to Indexing Conveyors

When evaluating production line solutions, it’s crucial to consider alternatives to indexing conveyors that can achieve similar goals of efficiency and precision. This analysis will compare indexing conveyors with two viable alternatives: Automated Guided Vehicles (AGVs) and Traditional Belt Conveyors. Each solution has unique attributes that cater to different operational needs, which can significantly impact productivity and cost-effectiveness in various manufacturing environments.

Comparison Table

| Comparison Aspect | Indexing Conveyor | Automated Guided Vehicles (AGVs) | Traditional Belt Conveyors |

|---|---|---|---|

| Performance | High precision and accuracy in part placement | Flexible routing with moderate precision | Continuous flow, less precise than indexing |

| Cost | Moderate to high initial investment | High initial cost, potential for savings long-term | Low initial cost, but may require more maintenance |

| Ease of Implementation | Requires specific setup and calibration | Generally easy to implement with existing infrastructure | Simple installation and integration |

| Maintenance | Moderate maintenance needs due to moving parts | Low maintenance, but battery management required | High maintenance needs due to wear and tear |

| Best Use Case | High-precision tasks in assembly and packaging | Material transport in large facilities | Continuous transport of bulk materials |

Detailed Breakdown of Alternatives

Automated Guided Vehicles (AGVs)

AGVs are mobile robots that transport materials within a facility. They can navigate autonomously, adapting to changing layouts and workflows. The primary advantage of AGVs is their flexibility; they can be programmed to follow various routes, making them suitable for environments with fluctuating production needs. However, AGVs typically come with a high initial investment and require a sophisticated management system to monitor and control their movements effectively. While they reduce the need for manual labor and can optimize transport routes, their reliance on battery power can pose challenges in terms of uptime and maintenance.

Traditional Belt Conveyors

Traditional belt conveyors are designed for continuous material handling and are often utilized in environments where high throughput is required. They are generally more affordable than indexing conveyors and AGVs, making them attractive for companies with budget constraints. However, they lack the precision offered by indexing systems and may lead to bottlenecks if not appropriately managed. Traditional conveyors excel in transporting bulk materials but may require more frequent maintenance due to wear on the belts and mechanical components. Their simplicity in design allows for easy installation and integration into existing operations.

Conclusion: Choosing the Right Solution for Your Manufacturing Needs

When selecting between indexing conveyors and their alternatives, B2B buyers should assess their specific operational requirements, budget constraints, and desired levels of precision. Indexing conveyors are ideal for applications requiring high accuracy and organization, particularly in assembly and packaging processes. In contrast, AGVs offer flexibility and adaptability for dynamic production environments, while traditional belt conveyors provide a cost-effective solution for high-volume material transport. By evaluating these aspects, buyers can make informed decisions that align with their production goals and enhance overall efficiency.

Essential Technical Properties and Trade Terminology for indexing conveyor

What Are the Essential Technical Properties of Indexing Conveyors?

Understanding the technical properties of indexing conveyors is crucial for B2B buyers aiming to enhance their manufacturing processes. Here are some key specifications that play a significant role in decision-making:

1. Material Grade

Indexing conveyors can be constructed from various materials, including stainless steel, aluminum, and plastic. The choice of material affects durability, resistance to corrosion, and suitability for specific industries such as food processing or pharmaceuticals. Selecting the right material grade ensures longevity and compliance with industry regulations, which is vital for maintaining operational efficiency.

2. Load Capacity

This specification refers to the maximum weight an indexing conveyor can handle. Understanding load capacity is essential for ensuring that the conveyor can support the products being moved without compromising performance. Proper assessment of load capacity helps prevent breakdowns, reduces maintenance costs, and ensures a seamless production flow.

Illustrative image related to indexing conveyor

3. Speed and Indexing Distance

Speed indicates how quickly the conveyor can move products, while indexing distance refers to the specific distance each product moves in a single step. These metrics are critical for optimizing production cycles. A well-calibrated speed and distance can significantly enhance throughput and minimize delays in manufacturing processes.

4. Precision and Tolerance

Precision refers to the accuracy with which the conveyor positions products, while tolerance denotes the acceptable deviation from specified measurements. High precision and low tolerance are especially important in industries like automotive and electronics, where exact placements are necessary for assembly. This specification directly impacts the quality of the final product and reduces the likelihood of defects.

5. Drive System Type

Indexing conveyors can utilize various drive systems, including servo motors, stepper motors, or belt drives. The choice of drive system affects both the performance and the operational costs. Servo motors, for example, offer high precision and speed control, making them ideal for complex applications. Understanding the implications of each drive type can guide buyers in selecting the most effective solution for their specific needs.

Which Trade Terminology Should B2B Buyers Understand When Purchasing Indexing Conveyors?

Familiarity with industry jargon can streamline the procurement process and enhance communication with suppliers. Here are some essential trade terms to know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of indexing conveyors, buyers may engage with OEMs for custom solutions tailored to their specific production needs. Understanding this term helps buyers identify potential partners for their manufacturing solutions.

Illustrative image related to indexing conveyor

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This is crucial for budgeting and inventory management, as purchasing below the MOQ can lead to increased costs or the inability to procure necessary equipment. Knowing the MOQ helps buyers plan their orders effectively.

3. RFQ (Request for Quotation)

An RFQ is a formal document that solicits price proposals from suppliers. It typically includes specific requirements for the indexing conveyor, such as specifications and quantities. Submitting an RFQ enables buyers to compare offers and select the most cost-effective solution that meets their needs.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms that outline the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for navigating shipping, insurance, and customs duties related to purchasing indexing conveyors from global suppliers.

5. Lead Time

Lead time is the period between placing an order and receiving the product. For indexing conveyors, this can vary significantly based on customization and supplier capabilities. Buyers should consider lead time when planning their production schedules to avoid disruptions.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their manufacturing efficiency and productivity.

Navigating Market Dynamics and Sourcing Trends in the indexing conveyor Sector

What Are the Key Market Dynamics and Trends Impacting Indexing Conveyors?

The global indexing conveyor market is experiencing robust growth driven by the increasing demand for automation across various industries, including food processing, pharmaceuticals, and automotive manufacturing. As manufacturers strive for efficiency, indexing conveyors have become essential for optimizing production lines by enhancing speed, precision, and reducing error margins. In regions like Africa and South America, the emphasis on local manufacturing capabilities is prompting businesses to adopt advanced conveyor systems that can improve operational efficiencies and product handling.

Emerging technologies such as Industry 4.0, IoT, and smart manufacturing are reshaping the landscape for indexing conveyors. These technologies enable real-time monitoring and predictive maintenance, which significantly enhance production capabilities and reduce downtime. Furthermore, the demand for customized solutions is on the rise, as companies seek conveyor systems tailored to their specific needs, such as varying product shapes and sizes. This trend is particularly evident in Europe, where manufacturers are increasingly investing in bespoke automation solutions to remain competitive.

Additionally, sustainability is becoming a pivotal consideration in sourcing decisions. Buyers are increasingly evaluating suppliers based on their environmental impact, leading to a growing trend towards sourcing from manufacturers who prioritize eco-friendly practices and materials. This shift is influencing procurement strategies, with companies looking for indexing conveyor solutions that not only enhance productivity but also align with their sustainability goals.

How Is Sustainability and Ethical Sourcing Influencing the Indexing Conveyor Market?

Sustainability in the indexing conveyor sector has emerged as a critical factor for international buyers, particularly as environmental regulations tighten globally. The production and operation of indexing conveyors can have significant environmental impacts, including energy consumption and waste generation. Consequently, manufacturers are now prioritizing the development of energy-efficient systems that minimize these impacts.

Ethical sourcing has also gained traction, with buyers increasingly favoring suppliers who demonstrate a commitment to responsible practices. This includes sourcing raw materials from suppliers who adhere to ethical labor practices and environmental standards. Furthermore, the use of ‘green’ certifications and materials is becoming a key differentiator in the marketplace. Certifications such as ISO 14001 for environmental management systems can provide assurance to buyers that their suppliers are committed to reducing their environmental footprint.

Moreover, the integration of sustainable materials, such as recyclable components in conveyor systems, is becoming more prevalent. Buyers are encouraged to inquire about the sustainability credentials of their suppliers, including the sourcing of materials and the overall lifecycle impact of the conveyors. This focus on sustainability not only helps companies meet regulatory requirements but also enhances their brand reputation in an increasingly eco-conscious market.

What Is the Historical Context of Indexing Conveyors in B2B Applications?

The evolution of indexing conveyors dates back to the early 20th century when manufacturers began to recognize the need for more efficient material handling solutions. Initially, these systems were rudimentary, focusing primarily on moving products from one point to another. However, as industries evolved, so did the technology behind indexing conveyors. The introduction of automation in the late 20th century marked a significant turning point, allowing for greater precision and speed in production lines.

Illustrative image related to indexing conveyor

By the 2000s, advancements in technology, such as the integration of servo motors and smart controls, revolutionized indexing conveyors, enabling them to handle complex tasks like automated assembly and precise product placement. Today, indexing conveyors are indispensable in high-paced production environments, where efficiency, accuracy, and adaptability are paramount. This historical context underscores the ongoing innovation within the sector and highlights the importance of selecting suppliers who are at the forefront of these technological advancements.

Overall, understanding these market dynamics, sustainability considerations, and the historical evolution of indexing conveyors can help international B2B buyers make informed sourcing decisions that align with their operational needs and corporate values.

Frequently Asked Questions (FAQs) for B2B Buyers of indexing conveyor

-

How do I solve production bottlenecks in my facility using indexing conveyors?

To solve production bottlenecks, implementing indexing conveyors can help streamline your manufacturing process. These conveyors enable precise control over the movement of products, allowing for consistent pacing and spacing between items. This enhances workflow efficiency and minimizes delays, particularly in high-volume operations. Consider customizing your indexing conveyor system to match your specific production needs, including speed and load capacity. Collaborating with an experienced supplier can also provide insights into optimal configurations that address your unique bottleneck challenges. -

What is the best indexing conveyor for high-precision applications?

For high-precision applications, the best choice would be a precision indexing conveyor equipped with a positive drive-toothed belt. These conveyors offer enhanced accuracy by locking the belt position, reducing the margin of error significantly. Models such as mk’s ZRF-P 3000 or Dorner’s precision conveyors are specifically designed for tasks requiring exact product placement. Ensure that the conveyor system you choose also integrates well with your existing machinery and automation processes to maintain overall efficiency. -

What customization options are available for indexing conveyors?

Indexing conveyors can be highly customized to meet the specific requirements of your production line. Customization options include the type of belt (fabric, modular, or stainless steel), frame configuration (horizontal, incline, or z-frame), and additional features like sensors for product detection. Additionally, you can specify dimensions, load capacities, and integration capabilities with other equipment. Engaging with suppliers who offer tailored solutions can ensure that your indexing conveyor fits perfectly within your operational framework. -

What are the minimum order quantities (MOQ) for indexing conveyors?

Minimum order quantities for indexing conveyors can vary significantly based on the manufacturer and the complexity of the system. Typically, standard models may have lower MOQs, while custom solutions could require higher minimums due to their tailored nature. It’s essential to discuss your needs directly with suppliers to understand their MOQ policies and explore options that align with your production scale. Many suppliers may offer flexibility for first-time buyers or smaller operations. -

What payment terms should I expect when purchasing indexing conveyors internationally?

Payment terms for international purchases of indexing conveyors often include options such as upfront payments, net terms (e.g., net 30 or net 60), or letters of credit. Common practices involve a deposit upon order confirmation, followed by the balance before shipping or upon delivery. It’s crucial to negotiate terms that provide security for both parties, especially considering the complexities of international transactions. Discussing payment options with your supplier upfront can help establish clear expectations and facilitate a smoother transaction process. -

How can I vet suppliers of indexing conveyors for reliability?

To vet suppliers, start by researching their industry reputation and customer reviews. Look for suppliers with extensive experience in indexing conveyor systems and proven track records in your industry. Request case studies or references from past clients to assess their performance. Additionally, inquire about their warranty policies, quality assurance processes, and after-sales support. Attending industry trade shows or connecting with other businesses can also provide insights into reputable suppliers. -

What logistics considerations should I keep in mind when sourcing indexing conveyors internationally?

When sourcing indexing conveyors internationally, consider shipping methods, lead times, and customs regulations. Work with suppliers who have experience with international shipping to ensure that your conveyors arrive on time and in good condition. Factor in potential delays at customs and ensure compliance with local regulations in your country. Additionally, consider the costs associated with shipping, insurance, and any duties or tariffs that may apply, as these can impact your overall budget. -

What quality assurance measures should I expect with indexing conveyors?

Reputable suppliers of indexing conveyors should have stringent quality assurance measures in place. This typically includes thorough testing of the conveyors before shipment to ensure they meet specified standards. Ask about their quality control processes, including inspections and certifications. Many suppliers also provide documentation on compliance with industry standards, which can be crucial for industries like food processing or pharmaceuticals. Engaging with suppliers who prioritize quality assurance can significantly reduce the risk of operational issues post-installation.

Top 5 Indexing Conveyor Manufacturers & Suppliers List

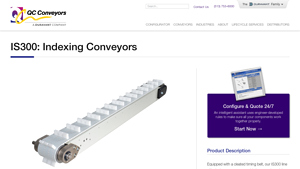

1. QC Conveyors – IS300 Precision Indexing Conveyors

Domain: qcconveyors.com

Registered: 2013 (12 years)

Introduction: IS300 Precision Indexing Conveyors are equipped with a cleated timing belt, providing increased precision with an accuracy of ±0.015. They are part of the heavy-duty Industrial Series, designed to withstand heavy load capacities and operate seamlessly within various processes. Key specifications include widths up to 18 inches, lengths up to 24 feet, and speeds up to 2,000 FPM. The conveyors featur…

2. Destaco – CAMCO Precision Link Conveyors

Domain: destaco.com

Registered: 1996 (29 years)

Introduction: CAMCO Precision Link Conveyors for specialty automation, designed for high positioning accuracy and fast station-to-station index times. Suitable for markets including automotive, food and packaging, aerospace, and consumer goods. Product series include 75RL Series, 115RL Series, 150RL Series, Heavy Duty Conveyors, and Modular Table Top Conveyors. Available finishes include industrial and medical….

3. nVenia – Ohlson Brand Indexing Conveyors

Domain: nvenia.com

Registered: 2020 (5 years)

Introduction: Ohlson Brand Indexing Conveyors produced by nVenia are designed for the precision movement of various containers such as bottles, jars, clamshell containers, trays, or boxes. Key features include: stainless steel belt, food grade plastic belting, automatic PLC controls for container handling, Stop-Fill-Release functionality, tool-less quick adjustment rails, and a user-friendly touchscreen interfa…

4. VBS Systems – Box Indexing Conveyor

Domain: vbssys.com

Registered: 1998 (27 years)

Introduction: Box Indexing Conveyor designed to evenly space boxes for downstream equipment. Key features include:

– Dual indexing and lane merging system with checkweigher and divert capabilities.

– Eliminates manual spacing of boxes for in-motion weighing scales, automatic labeling stations, scanning stations, palletizing stations, and sorting systems.

– Creates consistent start-to-start box spacing.

– St…

5. Visual Components – Carrier Indexing Conveyor

Domain: forum.visualcomponents.com

Registered: 1999 (26 years)

Introduction: Indexing Conveyors, Carrier Indexing Conveyor from PM Flow Components folder in Visual Components 4.4, cycle time of 9 seconds, distance between boxes of 24 inches, compatibility issues with versions 4.6 and 4.7, requires an additional Index Process for flow, suitable for robot integration at the end of the conveyor.

Strategic Sourcing Conclusion and Outlook for indexing conveyor

In the competitive landscape of manufacturing, indexing conveyors emerge as a pivotal asset for enhancing productivity and precision across various industries. Their ability to streamline operations, whether in high-volume or low-volume scenarios, underscores their versatility and effectiveness. B2B buyers should recognize that investing in custom indexing solutions not only mitigates errors but also optimizes labor costs, allowing for a more agile and responsive production environment.

Strategic sourcing plays a critical role in this equation. By collaborating with suppliers who offer tailored solutions—such as precision automation and flexible configurations—buyers can ensure that their specific operational needs are met. This approach not only fosters innovation but also enhances the overall efficiency of production lines.

Illustrative image related to indexing conveyor

As you look ahead, consider the transformative potential of indexing conveyors in your manufacturing processes. Engage with trusted suppliers to explore how these systems can be customized to fit your unique requirements. Embrace the opportunity to elevate your operational capabilities and position your business for future growth in the evolving global marketplace. Your commitment to leveraging advanced technology will be instrumental in achieving sustainable success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.