Everything You Need to Know About Huijin Aluminum Expanded Metal Grating Sourcing in 2025

Introduction: Navigating the Global Market for huijin aluminum expanded metal grating

In the rapidly evolving global market, sourcing huijin aluminum expanded metal grating presents unique challenges for B2B buyers, particularly in diverse regions such as Africa, South America, the Middle East, and Europe. With applications ranging from industrial walkways to architectural features, understanding the specifications, benefits, and supplier options is crucial for making informed purchasing decisions. This guide delves into the various types of aluminum expanded metal grating, exploring their applications across multiple industries—including construction, transportation, and safety solutions.

Buyers will learn how to effectively vet suppliers, assess cost structures, and leverage the unique advantages that huijin aluminum expanded metal grating offers, such as durability, skid resistance, and ease of installation. Additionally, insights into customization options and international shipping logistics will empower businesses to navigate procurement processes with confidence.

By equipping international buyers with comprehensive knowledge and actionable strategies, this guide ensures that every decision made regarding huijin aluminum expanded metal grating aligns with their project needs and budget considerations. Whether you are in Vietnam or Saudi Arabia, understanding these dynamics will enhance your purchasing strategy, fostering successful partnerships and long-term value in your projects.

Understanding huijin aluminum expanded metal grating Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Expanded Aluminum | Heavy gauge, large strand width, high open area (up to 50%) | Walkways, platforms, industrial applications | Pros: Durable, versatile; Cons: Heavier, may require more support |

| Lightweight Expanded Aluminum | Thinner gauge, reduced weight, good for non-load bearing uses | Decorative applications, partitions, light-duty walkways | Pros: Easy to handle, cost-effective; Cons: Less durable than standard |

| Heavy-Duty Expanded Aluminum | Extra-thick strands, designed for high traffic areas | Heavy machinery platforms, industrial flooring | Pros: Exceptional strength, long-lasting; Cons: Higher cost, heavier |

| Custom Expanded Aluminum | Tailored dimensions and strand configurations | Specialized industrial needs, architectural designs | Pros: Meets specific requirements; Cons: Longer lead times, potentially higher costs |

| Anti-Skid Expanded Aluminum | Textured surface for enhanced grip | Stairs, ramps, safety walkways | Pros: Increased safety, versatile; Cons: Surface texture may require cleaning |

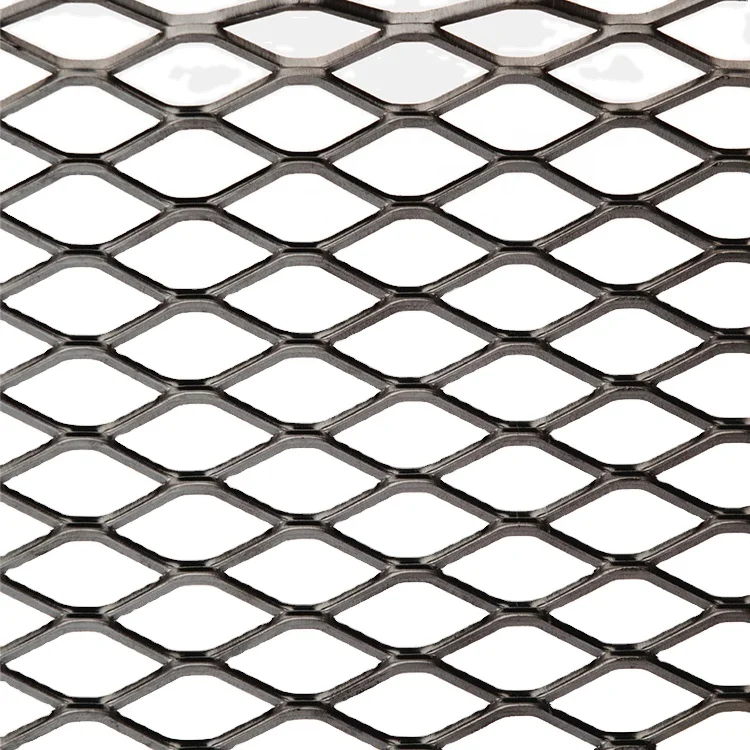

What Are the Characteristics of Standard Expanded Aluminum Grating?

Standard expanded aluminum grating features a heavy gauge with large strand widths, providing a high open area of up to 50%. This type is ideal for high-traffic areas such as walkways and platforms in various industrial applications. When purchasing, B2B buyers should consider load-bearing requirements and installation conditions, as the durability and versatility of this grating make it suitable for a wide range of uses.

How Does Lightweight Expanded Aluminum Differ from Other Types?

Lightweight expanded aluminum grating is characterized by a thinner gauge, making it easier to handle and install. This type is primarily used in decorative applications, partitions, and light-duty walkways. Buyers should evaluate the specific load requirements of their projects, as this option may not be suitable for high-stress environments but offers a cost-effective and aesthetically pleasing solution.

What Makes Heavy-Duty Expanded Aluminum Ideal for Industrial Use?

Heavy-duty expanded aluminum grating is designed with extra-thick strands, making it perfect for high-traffic areas and heavy machinery platforms. This type provides exceptional strength and longevity, which is critical for industrial flooring applications. B2B buyers should weigh the benefits of its robustness against the higher cost and weight, as these factors can influence shipping and installation logistics.

Why Choose Custom Expanded Aluminum Grating?

Custom expanded aluminum grating allows for tailored dimensions and strand configurations to meet specific project needs. This option is particularly useful for specialized industrial applications and unique architectural designs. Buyers should consider the longer lead times and potentially higher costs associated with custom orders, but the ability to meet exact specifications can justify the investment.

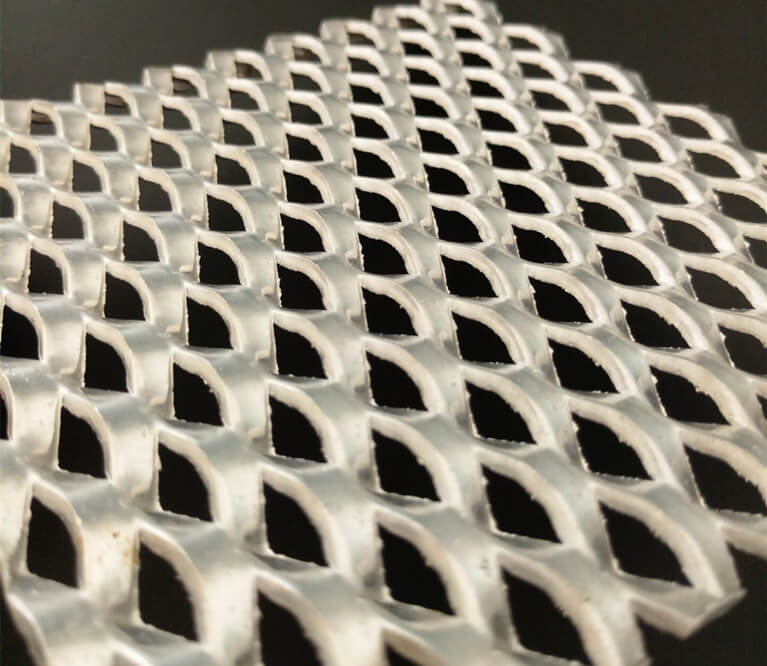

How Does Anti-Skid Expanded Aluminum Enhance Safety?

Anti-skid expanded aluminum grating features a textured surface that provides enhanced grip, making it an excellent choice for stairs, ramps, and safety walkways. This type is essential in environments where slip resistance is critical. Buyers should assess the maintenance requirements of the textured surface, as it may require more frequent cleaning to maintain its safety features, but the increased safety can significantly reduce liability risks in industrial settings.

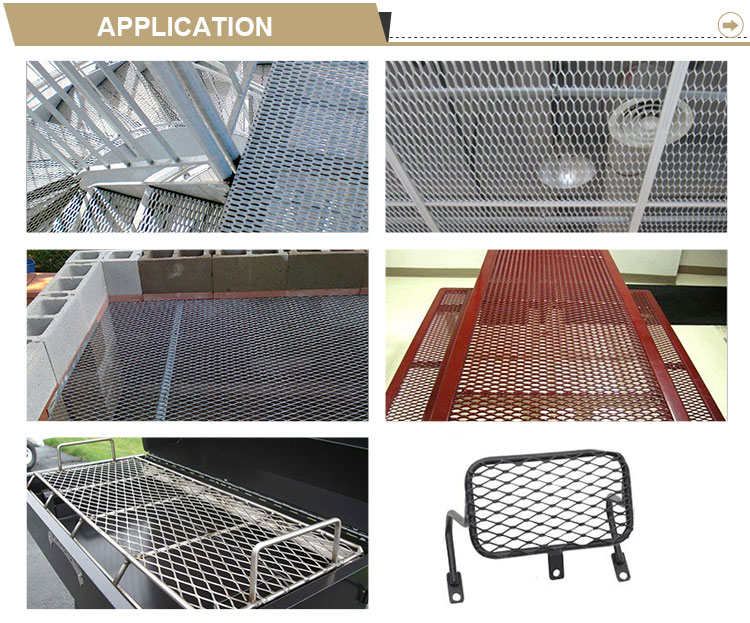

Key Industrial Applications of huijin aluminum expanded metal grating

| Industry/Sector | Specific Application of huijin aluminum expanded metal grating | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Architecture | Walkways and Mezzanines | Provides a durable, lightweight solution for safe access | Ensure compliance with local safety regulations and load specifications. |

| Oil & Gas | Platform Flooring and Stair Treads | Enhances safety and accessibility in hazardous environments | Require corrosion resistance and specific thickness for heavy loads. |

| Water Treatment | Grating for Filtration Systems | Allows efficient drainage and prevents clogging | Verify material compatibility with chemicals used in treatment processes. |

| Transportation | Trailer Flooring and Vehicle Safety Screens | Increases safety and reduces maintenance costs | Consider weight limits and ease of installation in logistics operations. |

| Security | Fencing and Window Protection | Provides visibility while ensuring high security | Assess the need for customization in size and mesh opening dimensions. |

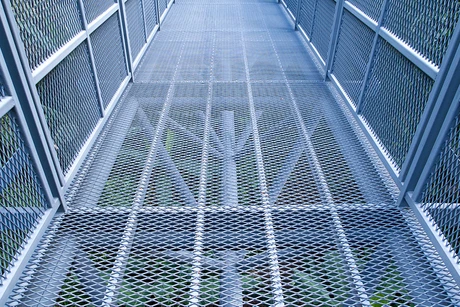

How is huijin aluminum expanded metal grating used in Construction & Architecture?

In the construction and architecture sectors, huijin aluminum expanded metal grating is commonly utilized for walkways and mezzanines. Its lightweight yet durable structure ensures safe access in various environments, from commercial buildings to industrial sites. This grating is designed to meet stringent safety regulations, making it a reliable choice for architects and builders. International buyers should consider local building codes and load-bearing requirements when sourcing, ensuring that the selected product aligns with project specifications.

What role does huijin aluminum expanded metal grating play in Oil & Gas applications?

In the oil and gas industry, huijin aluminum expanded metal grating is essential for platform flooring and stair treads, providing safe and stable footing in often hazardous conditions. Its slip-resistant surface and corrosion-resistant properties enhance safety and durability, crucial for operations in demanding environments. Buyers from regions like the Middle East and South America should prioritize grating that meets specific thickness and load requirements, ensuring it can withstand heavy machinery and environmental stressors.

How does huijin aluminum expanded metal grating benefit Water Treatment facilities?

Water treatment facilities use huijin aluminum expanded metal grating in filtration systems to facilitate efficient drainage while preventing clogging. Its open mesh design allows for optimal water flow while supporting the structural integrity of the filtration system. Buyers should ensure that the selected grating material is compatible with the chemicals used in their treatment processes, as this can significantly impact longevity and performance.

Illustrative image related to huijin aluminum expanded metal grating

In what ways does huijin aluminum expanded metal grating enhance Transportation safety?

In the transportation sector, huijin aluminum expanded metal grating serves as flooring for trailers and safety screens for vehicles. This application enhances safety by providing a robust surface that can withstand heavy loads while minimizing maintenance costs. Buyers in logistics and transportation must consider weight limits and ease of installation when sourcing, as these factors can influence operational efficiency and safety.

How is huijin aluminum expanded metal grating utilized in Security applications?

For security applications, huijin aluminum expanded metal grating is often employed in fencing and window protection. Its design allows for visibility while ensuring high security, making it ideal for various settings, including commercial and residential properties. Buyers should evaluate the need for customization in size and mesh opening dimensions to fit specific security needs, ensuring the product provides adequate protection without compromising aesthetics.

3 Common User Pain Points for ‘huijin aluminum expanded metal grating’ & Their Solutions

Scenario 1: Challenges with Product Specifications and Customization

The Problem: One common challenge faced by B2B buyers is navigating the myriad of specifications and customization options available for Huijin aluminum expanded metal grating. Buyers often require specific dimensions, strand widths, and open areas that can significantly impact the performance and suitability of the product for their intended applications, such as walkways or industrial platforms. Miscommunication about these specifications can lead to costly delays, project failures, and safety concerns.

Illustrative image related to huijin aluminum expanded metal grating

The Solution: To overcome this challenge, buyers should conduct thorough research on their project requirements before engaging with suppliers. Clearly outline the necessary specifications, including SWD (Short Way of Diamond), LWD (Long Way of Diamond), strand thickness, and weight per sheet. When discussing customization, be explicit about the intended use of the grating, as this will guide the supplier in recommending the most suitable options. Huijin’s customer service team is equipped to assist with custom orders; therefore, leveraging their expertise can ensure that the final product meets all necessary criteria. Additionally, requesting samples can provide a tangible reference to confirm that the specifications align with your project needs.

Scenario 2: Concerns About Durability and Safety Standards

The Problem: B2B buyers often express concerns regarding the durability and safety of aluminum expanded metal grating, particularly in high-traffic or heavy-duty applications. Industries such as construction, oil and gas, and manufacturing require materials that can withstand significant wear and tear. Buyers worry that opting for lower-quality products may lead to premature failure, safety hazards, and increased maintenance costs.

The Solution: To address these concerns, buyers should prioritize sourcing from reputable manufacturers like Huijin, known for their commitment to quality and adherence to international safety standards, such as ISO9001. When evaluating products, pay close attention to the material specifications, including the thickness of the aluminum and the design of the grating (e.g., strand width and open area percentage). Additionally, request documentation that verifies compliance with safety regulations and industry standards. Engaging with suppliers who have a track record of successful projects, such as those involving major infrastructure developments, can provide further assurance of the product’s reliability and safety.

Scenario 3: Issues with Lead Times and Delivery Reliability

The Problem: Another frequent pain point for B2B buyers is the unpredictability of lead times and delivery schedules, which can disrupt project timelines and lead to financial losses. Buyers need to ensure that the aluminum expanded metal grating arrives on-site when required, particularly for projects with tight deadlines. Delays in procurement can result in project stalls, increased labor costs, and strained relationships with clients.

The Solution: To mitigate these risks, buyers should establish clear communication with suppliers regarding delivery timelines at the outset of the procurement process. Discuss lead times for standard products versus custom orders, and inquire about the supplier’s capacity to meet urgent requests. Huijin’s extensive experience in the industry positions them well to provide reliable delivery schedules, so it’s beneficial to leverage their insights into typical turnaround times. Additionally, consider building a buffer into your project timelines to accommodate any unforeseen delays. Regular follow-ups and updates from your supplier can also help ensure that you remain informed about the status of your order and can plan accordingly.

Strategic Material Selection Guide for huijin aluminum expanded metal grating

What Are the Key Materials Used in Huijin Aluminum Expanded Metal Grating?

When selecting materials for Huijin aluminum expanded metal grating, international B2B buyers must consider various options that align with their project requirements. The most common materials include aluminum, stainless steel, galvanized steel, and carbon steel. Each material possesses unique properties that can significantly impact performance, durability, and suitability for specific applications.

How Does Aluminum Perform in Expanded Metal Grating Applications?

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It performs well in moderate temperature and pressure environments, making it ideal for various applications.

Pros & Cons: The primary advantage of aluminum is its excellent corrosion resistance, which is essential for outdoor applications or environments with high humidity. However, it is less durable than steel, making it unsuitable for heavy-duty applications. Additionally, aluminum can be more expensive than carbon steel.

Impact on Application: Aluminum expanded metal grating is particularly effective in applications like walkways and platforms where weight savings are crucial. Its corrosion resistance makes it suitable for marine and chemical processing environments.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local standards such as ASTM or DIN to avoid issues with material quality. Additionally, understanding the local market’s preferences for aluminum’s aesthetic qualities can influence purchasing decisions.

What Are the Benefits of Using Stainless Steel for Expanded Metal Grating?

Key Properties: Stainless steel is known for its exceptional strength, corrosion resistance, and ability to withstand high temperatures. It is particularly effective in harsh environments.

Pros & Cons: The key advantage of stainless steel is its durability and resistance to corrosion, making it suitable for applications in food processing, pharmaceuticals, and marine environments. However, it is typically more expensive than other materials, which can be a drawback for budget-conscious projects.

Impact on Application: Stainless steel expanded metal grating is often used in industrial settings where hygiene and corrosion resistance are critical. It is also suitable for applications requiring high strength, such as stair treads and mezzanines.

Considerations for International Buyers: Buyers should be aware of the different grades of stainless steel (e.g., 304 vs. 316) and their specific applications. Compliance with international standards and certifications is crucial, especially in industries like food and pharmaceuticals.

Why Choose Galvanized Steel for Expanded Metal Grating?

Key Properties: Galvanized steel is carbon steel that has been coated with zinc to enhance its corrosion resistance. It is strong and can handle moderate to high loads.

Pros & Cons: The primary advantage of galvanized steel is its cost-effectiveness and durability, making it a popular choice for construction and industrial applications. However, it may not perform as well as stainless steel in extremely corrosive environments.

Impact on Application: Galvanized steel expanded metal grating is commonly used in outdoor applications, such as walkways and platforms, where it can withstand the elements. Its strength makes it suitable for heavy-duty applications.

Considerations for International Buyers: Buyers should check for compliance with local galvanization standards to ensure product longevity. In regions with high humidity, understanding the limitations of galvanized steel in corrosive environments is essential.

What Are the Advantages of Carbon Steel in Expanded Metal Grating?

Key Properties: Carbon steel is known for its high strength and durability. It is suitable for a wide range of applications but is prone to corrosion without protective coatings.

Pros & Cons: The main advantage of carbon steel is its cost-effectiveness and strength, making it ideal for heavy-duty applications. However, its susceptibility to rust makes it less desirable for outdoor or wet environments unless properly treated.

Impact on Application: Carbon steel expanded metal grating is often used in construction and industrial settings where strength is paramount. It is not recommended for applications exposed to moisture unless adequately protected.

Considerations for International Buyers: Buyers should consider the need for protective coatings or treatments to enhance corrosion resistance. Understanding local regulations regarding steel quality and safety standards is also crucial for compliance.

Summary Table of Material Selection for Huijin Aluminum Expanded Metal Grating

| Material | Typical Use Case for huijin aluminum expanded metal grating | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Walkways, platforms, marine applications | Excellent corrosion resistance | Less durable than steel | Medium |

| Stainless Steel | Food processing, pharmaceuticals, industrial applications | High strength and corrosion resistance | Higher cost compared to other materials | High |

| Galvanized Steel | Outdoor walkways, construction sites | Cost-effective and durable | Limited performance in highly corrosive areas | Low |

| Carbon Steel | Heavy-duty industrial applications | High strength and cost-effective | Prone to corrosion without treatment | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for huijin aluminum expanded metal grating

What Are the Key Stages in the Manufacturing Process of Huijin Aluminum Expanded Metal Grating?

The manufacturing of Huijin aluminum expanded metal grating involves several meticulous stages that ensure the final product meets high standards of quality and functionality. Understanding these processes is essential for B2B buyers, particularly those in international markets such as Africa, South America, the Middle East, and Europe.

Material Preparation: How Are Raw Materials Chosen and Processed?

The first step in manufacturing aluminum expanded metal grating is the selection of high-quality raw materials. Huijin primarily uses 5052 H-32 aluminum alloy due to its excellent corrosion resistance, durability, and lightweight properties. The materials undergo rigorous quality checks before being processed.

Once the materials are approved, they are cut into specified dimensions to prepare for the forming process. This stage is crucial as the quality of the raw material significantly influences the strength and longevity of the final product.

Forming: What Techniques Are Used to Create the Expanded Metal Structure?

The forming process employs advanced machinery to transform flat aluminum sheets into expanded metal grating. This is achieved through a process known as “expanding,” where the metal sheets are slit and stretched, creating a diamond-shaped mesh pattern.

The machines used in this process are designed to ensure precise cuts and uniform expansion, which are critical for maintaining the structural integrity of the grating. Huijin leverages cutting-edge technology and automated systems to enhance efficiency and minimize production errors.

Assembly: How Are the Grating Components Joined?

Once the expanded metal sheets are formed, the next step is assembly, where different components may be joined to create custom solutions for clients. This could include integrating additional features like anti-slip surfaces or custom sizes tailored to specific applications.

Skilled technicians oversee the assembly process to ensure that all components fit seamlessly and meet the required specifications. This attention to detail is particularly important for applications in demanding environments, such as industrial plants and construction sites.

Finishing: What Treatments Are Applied to Enhance Durability?

The finishing stage involves applying protective coatings and treatments to enhance the durability and aesthetics of the aluminum expanded metal grating. Options include anodizing, which increases corrosion resistance, and powder coating, which adds color and additional protection against wear and tear.

Finishing processes are crucial for applications exposed to harsh conditions, ensuring that the grating remains functional and visually appealing over time. Buyers should inquire about the specific finishing options available to meet their project’s needs.

How Is Quality Assurance Integrated Throughout the Manufacturing Process?

Quality assurance is a cornerstone of Huijin’s manufacturing philosophy. The company adheres to international standards such as ISO 9001, ensuring that their processes are consistently evaluated and improved.

What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process to ensure that the final product meets the highest standards.

-

Incoming Quality Control (IQC): Raw materials undergo inspection upon arrival. This includes verifying material certifications and conducting tests to check for defects or inconsistencies.

-

In-Process Quality Control (IPQC): During the manufacturing stages, random samples are tested to ensure they meet specified tolerances and performance standards. This includes checking the dimensions of the expanded metal and the quality of the cuts.

-

Final Quality Control (FQC): Before shipment, finished products are subjected to rigorous testing, including load testing and visual inspections. This final checkpoint ensures that all products meet the required specifications and are ready for use in various applications.

What Testing Methods Are Commonly Used in Quality Assurance?

Several testing methods are employed to ensure the integrity and durability of Huijin’s aluminum expanded metal grating. Common methods include:

- Load Testing: To assess the weight-bearing capacity of the grating, ensuring it meets the requirements for its intended application.

- Corrosion Resistance Testing: Evaluating the material’s ability to withstand environmental factors, particularly for products intended for coastal or industrial environments.

- Dimensional Accuracy Testing: Ensuring that the finished product adheres to specified measurements and tolerances.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, verifying the quality control processes of suppliers like Huijin is crucial to ensure product reliability. Here are several ways to conduct this verification:

-

Audits: Conducting on-site audits of the manufacturing facility can provide insights into the production processes and quality control measures in place. This also allows buyers to assess the working conditions and adherence to safety standards.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the performance of the products over time and any issues that may have arisen during production.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the manufacturing process and product quality. This is particularly important for buyers in regions with stringent regulatory requirements.

What Are the Quality Certification Nuances for International B2B Buyers?

For B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality certifications is essential. Certifications such as CE mark for European markets and API specifications for oil and gas applications can significantly influence purchasing decisions.

Huijin’s commitment to international standards not only enhances product credibility but also facilitates smoother transactions across borders. Buyers should ensure that the products they procure comply with local regulations and standards, which may vary significantly depending on the region.

Conclusion

In summary, Huijin’s aluminum expanded metal grating is produced through a comprehensive manufacturing process that emphasizes quality at every stage. By understanding the intricacies of manufacturing and quality assurance, B2B buyers can make informed purchasing decisions that align with their operational needs and industry standards. Engaging with suppliers who prioritize quality assurance and adhere to international standards can lead to successful and sustainable business partnerships.

Illustrative image related to huijin aluminum expanded metal grating

Practical Sourcing Guide: A Step-by-Step Checklist for ‘huijin aluminum expanded metal grating’

This guide is designed to assist international B2B buyers in sourcing Huijin aluminum expanded metal grating effectively. By following these structured steps, you can ensure a smooth procurement process, tailored to your specific requirements and regional considerations.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential to ensure that the aluminum expanded metal grating meets your project’s needs. Consider factors such as strand width, thickness, and load-bearing capacity. Specify the dimensions you require, such as 48”x96” or customized sizes, to avoid misunderstandings during production.

Step 2: Research and Identify Reliable Suppliers

Finding a trustworthy supplier is crucial for a successful procurement process. Look for manufacturers with a proven track record in producing aluminum expanded metal grating, such as Huijin, which has decades of experience. Check their certifications, such as ISO9001, to ensure quality standards are met.

Step 3: Evaluate Potential Suppliers

Before making a commitment, conduct thorough evaluations of potential suppliers. Request company profiles, case studies, and references from similar industries or regions. Assess their production capabilities and quality control processes to ensure they can meet your demands reliably.

Illustrative image related to huijin aluminum expanded metal grating

- Tip: Engage with suppliers who have a robust export team familiar with international logistics, especially if you’re sourcing from regions like Africa or South America.

Step 4: Request Samples for Quality Assessment

Always request samples of the aluminum expanded metal grating before placing a bulk order. This allows you to verify the quality, durability, and suitability of the product for your specific application. Pay attention to the finish and any potential defects that could affect performance.

Step 5: Understand Pricing and Payment Terms

Transparent pricing and favorable payment terms are vital for budgeting your procurement. Inquire about the unit cost based on your specifications and volume, and understand any additional costs, such as shipping and customs duties. Discuss payment options to find a mutually agreeable arrangement.

- Tip: Consider negotiating for bulk order discounts or exploring financing options if you plan to make large purchases.

Step 6: Confirm Lead Times and Delivery Logistics

Understanding lead times is critical for project planning. Confirm the production and shipping timelines with your supplier to ensure timely delivery. Discuss logistics, including shipping methods and any potential delays related to customs clearance, especially for international shipments.

Step 7: Establish After-Sales Support and Warranty Terms

Finally, ensure that the supplier offers robust after-sales support and clear warranty terms for the aluminum expanded metal grating. This includes understanding their policies on returns, replacements, and customer service availability. A reliable support system can help resolve any issues that arise post-purchase.

By following this checklist, B2B buyers can navigate the complexities of sourcing Huijin aluminum expanded metal grating with confidence, ensuring that they receive quality products that meet their operational needs.

Illustrative image related to huijin aluminum expanded metal grating

Comprehensive Cost and Pricing Analysis for huijin aluminum expanded metal grating Sourcing

What Are the Key Cost Components for Huijin Aluminum Expanded Metal Grating?

When analyzing the cost structure for sourcing Huijin aluminum expanded metal grating, several critical components come into play. The primary cost factors include:

-

Materials: The choice of aluminum, known for its lightweight and corrosion-resistant properties, significantly influences cost. Additional considerations include the type of aluminum alloy used, thickness, and surface finish. Prices can fluctuate based on global aluminum market rates.

-

Labor: Labor costs encompass not only the wages of the workforce involved in production but also any specialized training required for handling advanced machinery and quality control processes.

-

Manufacturing Overhead: This includes expenses related to the facility, utilities, equipment maintenance, and administrative costs. Efficient manufacturing practices can mitigate these costs.

-

Tooling: Initial investments in tooling and molds can be substantial, especially for customized specifications. However, these costs are amortized over larger production runs, making them less impactful per unit for bulk orders.

-

Quality Control (QC): Implementing rigorous QC measures ensures that products meet international standards, which may involve additional testing and certification costs.

-

Logistics: Transportation and shipping costs can vary significantly based on the destination, particularly for international buyers. Factors such as shipping mode (air vs. sea), freight rates, and customs duties must be considered.

-

Margin: Supplier profit margins typically range from 10% to 30% depending on market dynamics, competition, and perceived value of the product.

How Do Pricing Influencers Affect the Cost of Huijin Aluminum Expanded Metal Grating?

Several factors can influence the pricing of Huijin aluminum expanded metal grating:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes generally lead to lower per-unit costs due to economies of scale. Buyers should negotiate for better pricing based on their projected needs.

-

Specifications and Customization: Custom sizes, thicknesses, or finishes may incur additional costs. Clear communication of requirements can help avoid unexpected price increases.

-

Material Quality and Certifications: Products that meet specific industry standards (such as ISO or EMMA) may command higher prices. Certifications can also assure buyers of product reliability.

-

Supplier Factors: Established suppliers like Huijin, with a long track record and reputation for quality, may offer pricing that reflects their brand value and customer service levels.

-

Incoterms: Understanding the chosen Incoterm is crucial for budgeting logistics costs. Terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) can impact total landed costs.

What Are the Best Buyer Tips for Negotiating Pricing on Huijin Aluminum Expanded Metal Grating?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, here are several actionable tips:

-

Negotiate Volume Discounts: Leverage potential bulk purchases to negotiate better pricing. Many suppliers offer tiered pricing based on order size.

-

Focus on Total Cost of Ownership (TCO): Consider not only the initial purchase price but also factors like maintenance, longevity, and potential downtime costs. High-quality grating may have a higher upfront cost but can lead to savings over time.

-

Understand Pricing Nuances: Be aware of seasonal fluctuations in material prices, currency exchange rates, and any geopolitical factors that may affect shipping costs or availability.

-

Request Samples: Before placing large orders, request samples to assess quality. This can also serve as a bargaining chip during negotiations.

-

Build Relationships: Establishing a good rapport with suppliers can lead to better pricing, priority service, and insights into upcoming sales or product launches.

Conclusion

Navigating the cost and pricing landscape of Huijin aluminum expanded metal grating requires a thorough understanding of various cost components and influencing factors. By employing strategic negotiation tactics and focusing on total cost considerations, international buyers can optimize their sourcing strategy and ensure they receive quality products at competitive prices. Remember, while indicative prices can provide a starting point, the actual costs may vary based on specific requirements and market conditions.

Alternatives Analysis: Comparing huijin aluminum expanded metal grating With Other Solutions

Introduction: Understanding Alternative Solutions for Expanded Metal Grating

When selecting the right grating solution for industrial applications, buyers often encounter a variety of options that can meet their specific needs. Huijin Aluminum Expanded Metal Grating stands out due to its durability, versatility, and ease of installation. However, it is essential to consider alternative products to ensure that you choose the best fit for your projects. This analysis will compare Huijin Aluminum Expanded Metal Grating with two viable alternatives: Perforated Metal Grating and Steel Grating.

Comparison Table

| Comparison Aspect | Huijin Aluminum Expanded Metal Grating | Perforated Metal Grating | Steel Grating |

|---|---|---|---|

| Performance | High durability; excellent load-bearing | Moderate durability; varies by thickness | Very high durability; heavy load-bearing |

| Cost | Moderate pricing; competitive for aluminum | Generally lower cost; depends on material | Higher initial cost; long-term value |

| Ease of Implementation | Easy to install; lightweight | Moderate; requires precise cutting | More complex; heavier and requires more support |

| Maintenance | Low maintenance; resistant to corrosion | Moderate; depends on coating | High; may require regular maintenance to prevent rust |

| Best Use Case | Walkways, industrial applications, ramps | Decorative applications, ventilation | Heavy-duty industrial flooring, platforms |

Detailed Breakdown of Alternatives

Perforated Metal Grating

Perforated Metal Grating offers a unique solution for applications requiring air circulation and light passage. Its design features holes punched into a sheet of metal, allowing for both aesthetic appeal and functionality. While this type of grating is generally more affordable than aluminum expanded metal, its durability can be compromised based on the thickness of the material selected. Perforated grating is best suited for environments where visual appeal and ventilation are prioritized, such as in architectural designs or decorative applications. However, it may not withstand heavy loads as effectively as aluminum expanded grating.

Steel Grating

Steel Grating is renowned for its strength and resilience, making it ideal for heavy-duty applications such as industrial flooring and platforms. Its robust construction can handle significant weight and impact, often outperforming aluminum alternatives in terms of load-bearing capacity. However, this strength comes at a higher cost and often requires more complex installation processes due to its weight. Additionally, steel grating is susceptible to rust and corrosion, necessitating regular maintenance or protective coatings, which may increase the overall long-term costs. This makes it less ideal for environments where maintenance is challenging.

Conclusion: Choosing the Right Grating Solution for Your Needs

When evaluating grating options, B2B buyers must consider the specific requirements of their projects, including load capacity, environmental conditions, and budget constraints. Huijin Aluminum Expanded Metal Grating offers a balanced solution with its combination of durability, lightweight properties, and low maintenance needs, making it suitable for a wide range of applications. In contrast, Perforated Metal Grating may be the right choice for those prioritizing aesthetics and ventilation, while Steel Grating excels in heavy-duty contexts but requires careful consideration of maintenance and costs. Ultimately, the decision should align with the project’s specific goals and operational requirements to ensure optimal performance and value.

Essential Technical Properties and Trade Terminology for huijin aluminum expanded metal grating

What Are the Key Technical Properties of Huijin Aluminum Expanded Metal Grating?

When evaluating Huijin aluminum expanded metal grating, several critical specifications come into play. Understanding these properties is vital for B2B buyers to make informed purchasing decisions that align with their specific applications.

Illustrative image related to huijin aluminum expanded metal grating

1. Material Grade

The primary material used in Huijin’s expanded metal grating is high-quality aluminum. Aluminum offers a favorable strength-to-weight ratio, corrosion resistance, and durability. This is particularly important for applications in various industries, including construction and manufacturing, where longevity and reliability are essential. The choice of material directly impacts the grating’s performance and lifespan, making it a key consideration for buyers.

2. Strand Width

Strand width refers to the thickness of the strands in the expanded metal grating. For Huijin products, this typically ranges from 0.35 inches to more substantial widths depending on the design and application. A wider strand width enhances load-bearing capacity, making it suitable for heavy-duty applications such as walkways and platforms. Buyers should consider the strand width in relation to the expected load to ensure safety and functionality.

3. Overall Thickness

Overall thickness indicates the depth of the expanded metal sheet, which can affect its strength and rigidity. Huijin’s aluminum grating features thicknesses of approximately 0.312 inches, providing a robust structure suitable for various applications, including industrial environments. Buyers must assess the thickness based on the anticipated stress and environmental factors to ensure optimal performance.

4. Open Area Percentage

The open area percentage is a critical metric that describes the proportion of the grating that is open space versus solid material. Huijin’s aluminum grating typically has an open area of around 50%. This feature allows for effective drainage, ventilation, and visibility, making it ideal for outdoor applications like walkways and catwalks. Understanding the open area percentage helps buyers determine the suitability of the grating for specific environments.

5. Load Capacity

Load capacity defines the maximum weight that the grating can safely support. This specification is crucial for applications in heavy-duty settings, such as industrial plants or construction sites. Huijin’s expanded metal grating is designed to meet various load requirements, ensuring safety and compliance with industry standards. Buyers should consult load capacity data to select the appropriate product for their needs.

What Are Common Trade Terminology and Jargon in the Expanded Metal Grating Industry?

Familiarity with industry-specific terminology can greatly enhance communication and negotiation processes for B2B buyers. Here are some essential terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that manufactures products that are sold by another company under its brand name. For buyers, understanding OEM relationships can aid in identifying quality standards and sourcing reliable products, such as Huijin’s expanded metal grating.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This is a critical factor for buyers as it influences purchasing decisions and inventory management. Knowing the MOQ for Huijin products helps buyers plan their orders effectively, especially for large projects.

Illustrative image related to huijin aluminum expanded metal grating

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request pricing and terms from suppliers. For international buyers, submitting an RFQ to Huijin ensures that they receive detailed pricing and product specifications tailored to their specific needs, facilitating better decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for understanding shipping costs, delivery responsibilities, and risk management, which can significantly impact the overall cost of acquiring Huijin aluminum expanded metal grating.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. Understanding lead times is essential for project planning and scheduling, particularly in industries where timely delivery is critical. Buyers should inquire about Huijin’s lead times to ensure they align with their project timelines.

By grasping these technical properties and industry terms, international B2B buyers can navigate the procurement process more efficiently, ensuring they choose the right products for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the huijin aluminum expanded metal grating Sector

What Are the Current Market Dynamics and Key Trends in the Huijin Aluminum Expanded Metal Grating Sector?

The global demand for Huijin aluminum expanded metal grating is experiencing significant growth, driven by several key factors. Urbanization, infrastructural development, and a surge in construction activities across emerging markets in Africa, South America, the Middle East, and Europe are major contributors to this trend. As countries like Vietnam and Saudi Arabia invest heavily in infrastructure, the need for versatile and durable materials such as aluminum grating for walkways, mezzanines, and safety applications is rising.

In addition, advancements in B2B technology are reshaping sourcing dynamics. The integration of digital platforms and e-commerce solutions has enhanced transparency and accessibility for international buyers, allowing them to easily compare products, prices, and suppliers. Data analytics tools are also becoming essential for buyers to make informed decisions based on market trends, supplier performance, and pricing fluctuations.

Another emerging trend is the customization of aluminum grating products to meet specific project requirements. Suppliers like Huijin offer tailored solutions, which is increasingly appealing to buyers looking for unique applications in various industries, from construction to transportation. Furthermore, there is a growing emphasis on quick turnaround times and reliable logistics, as businesses strive to meet tight project deadlines.

How Important Is Sustainability and Ethical Sourcing for Huijin Aluminum Expanded Metal Grating Buyers?

Sustainability and ethical sourcing are paramount considerations for today’s B2B buyers, particularly in the aluminum expanded metal grating sector. The environmental impact of production processes and the materials used significantly influences purchasing decisions. Buyers are increasingly seeking suppliers who prioritize sustainable practices, such as using recycled materials and minimizing waste during manufacturing. Huijin’s commitment to these principles aligns with the expectations of conscientious buyers looking to reduce their carbon footprint.

Moreover, certifications for green materials play a crucial role in establishing credibility. Certifications such as ISO 14001 (Environmental Management) and other industry-specific green certifications can enhance a supplier’s reputation and marketability. Buyers from regions like Europe, where environmental regulations are stringent, are especially inclined to partner with suppliers who can demonstrate compliance with these standards.

Ethical supply chains are also gaining traction, with buyers wanting assurance that their sourcing practices do not contribute to labor exploitation or environmental degradation. Huijin’s transparent supply chain and dedication to ethical manufacturing practices not only fulfill buyer requirements but also foster long-term partnerships based on trust and shared values.

Illustrative image related to huijin aluminum expanded metal grating

What Is the Brief Evolution of the Huijin Aluminum Expanded Metal Grating Sector?

The Huijin aluminum expanded metal grating sector has its roots in the broader wire mesh industry, with Huijin Wire Mesh Co., Ltd. being a pioneer since its establishment in 1986. Over the years, Huijin has evolved from a local manufacturer to a globally recognized supplier, thanks to its strategic focus on innovation and quality. The company has invested heavily in research and development, resulting in a diverse product range that includes not only aluminum grating but also perforated and safety grating solutions.

With a commitment to maintaining high standards, Huijin became ISO 9001 certified, which bolstered its credibility in international markets. This evolution has enabled Huijin to participate in significant projects worldwide, including major infrastructure developments in China and beyond, further solidifying its reputation as a leader in the expanded metal grating sector. As global market dynamics continue to shift, Huijin’s adaptability and forward-thinking approach position it well for future growth and collaboration in the international B2B landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of huijin aluminum expanded metal grating

-

How do I choose the right aluminum expanded metal grating for my project?

Selecting the appropriate aluminum expanded metal grating involves assessing the specific requirements of your application. Consider factors such as load-bearing capacity, strand width, thickness, and open area percentage. For example, grating with larger strand widths and thicker materials is suitable for heavy-duty applications like walkways in industrial settings. It’s also crucial to evaluate the environmental conditions, such as exposure to moisture or chemicals, to choose a material that offers durability and resistance. -

What are the advantages of using aluminum expanded metal grating over other materials?

Aluminum expanded metal grating offers numerous advantages, including lightweight construction, corrosion resistance, and ease of installation. Its skid-resistant surface enhances safety, making it ideal for walkways and stairs. Additionally, aluminum’s inherent strength allows it to withstand heavy loads while maintaining structural integrity. Compared to steel or stainless steel, aluminum is often more cost-effective and requires less maintenance, making it an attractive option for various industrial applications. -

What customization options are available for aluminum expanded metal grating?

Huijin provides extensive customization options for aluminum expanded metal grating, including varying sizes, strand widths, and thicknesses. Buyers can request specific dimensions to suit their project needs, such as different lengths and widths beyond standard offerings. Additionally, surface treatments or finishes can be applied to enhance aesthetic appeal or improve resistance to environmental factors. Engaging directly with Huijin’s sales team can help you explore all available customization possibilities. -

What are the minimum order quantities (MOQs) for purchasing aluminum expanded metal grating?

The minimum order quantity for aluminum expanded metal grating can vary based on product specifications and customization requests. Generally, Huijin aims to accommodate both small and large-scale orders, making it easier for businesses of all sizes to source the materials they need. It’s advisable to discuss your specific requirements with the sales team to understand any MOQ constraints and how they can accommodate your project needs. -

What payment terms do you offer for international buyers?

Huijin offers flexible payment terms tailored to the needs of international buyers. Common options include telegraphic transfer (T/T) and letter of credit (L/C), depending on the order size and buyer’s location. For first-time customers, a partial advance payment may be required, with the balance due upon shipment. It’s essential to clarify payment terms during the initial negotiations to ensure a smooth transaction process. -

How does Huijin ensure quality assurance for its aluminum expanded metal grating?

Quality assurance at Huijin is maintained through rigorous testing and adherence to international standards such as ISO9001. Each batch of aluminum expanded metal grating undergoes inspections for material integrity, dimensional accuracy, and surface quality. Additionally, Huijin invests in advanced manufacturing technology to ensure consistency and reliability in production. Buyers can request certifications and test reports to verify compliance with their specific quality requirements. -

What logistics solutions do you provide for shipping aluminum expanded metal grating internationally?

Huijin collaborates with trusted logistics partners to provide efficient shipping solutions for international orders. Depending on the destination, various shipping methods, including sea freight and air freight, can be arranged to meet delivery timelines. The company ensures that all products are securely packaged to prevent damage during transit. Buyers will receive tracking information and updates on their shipment status to facilitate planning and coordination upon arrival. -

How can I vet Huijin as a reliable supplier for aluminum expanded metal grating?

To vet Huijin as a reliable supplier, consider reviewing their certifications, customer testimonials, and project history. Huijin has extensive experience in the industry, having participated in notable projects globally. Engaging in direct communication with their sales and support teams can provide insights into their responsiveness and willingness to address your concerns. Additionally, requesting samples of their products can help assess quality before making a larger commitment.

Top 3 Huijin Aluminum Expanded Metal Grating Manufacturers & Suppliers List

1. Huijin – Expanded Metal Gratings and Mesh Panels

Domain: huijinmaterials.com

Registered: 2023 (2 years)

Introduction: Expanded Metal Gratings and Mesh Panels in Stainless Steel and Aluminum from Huijin Mesh. Model No: HJGB-03. Specification: SWD X LWD: 1.41’’x5.33’’, Strand: 0.35’’, Thickness: 0.312’’, Size: 48’’x96’’ or others, Open: 50%. Material options include carbon, galvanized, aluminum, and stainless steel. Features: Durable, skid resistant, easy installation, extremely versatile, suitable for various meta…

2. HJ Metal Mesh – Expanded Metal Grating

Domain: hjmetalmesh.com

Registered: 2023 (2 years)

Introduction: Product: Expanded Metal Grating, Expanded Metal Walkway, Expanded Steel Grating, Heavy Duty Expanded Metal. Materials: Steel, Stainless Steel, Aluminum. Types: 2.0lb, 3lb, 3.14lb, 3.3lb, 4.0lb, 4.5lb, 4.27lb, 5.0lb, 6.25lb, 7.0lb. Common Size: 4ft LWD x 8ft SWD or 4ft SWD x 8ft LWD. Customization available. Standards: EMMA and ISO certified. Uses: Catwalks, ramps, stairs, platforms, maintenance pl…

3. Huijin Wire Mesh – Expanded Metal & Aluminum Solar Panel Mesh

Domain: huijinwiremesh.com

Registered: 2011 (14 years)

Introduction: 1/2#16 Expanded Metal: SWD×LWD: 0.5’’×1.20’’, Strand width: 0.087”, Thickness: 0.06”, Open rate: 65%

1/2.050 Aluminum Solar Panel Mesh: SWD x LWD: 0.5’’x1.20’’, Strand width: 0.087”, Thickness: 0.06”, Open rate: 65%

1/2.081 Expanded Metal: SWD×LWD: 01.33”×3.15”, Strand width: 0.143”, Thickness: 0.006”, Weight: 18lb/100sqft, Open rate: 59%

1/4#18 Expanded Metal: SWD×LWD: 0.25”×1.00”, Strand w…

Strategic Sourcing Conclusion and Outlook for huijin aluminum expanded metal grating

As international markets continue to evolve, the demand for durable, versatile, and cost-effective solutions like Huijin aluminum expanded metal grating is on the rise. This innovative product is not only suitable for various applications, including industrial flooring, walkways, and safety barriers, but it also offers significant advantages such as easy installation and excellent skid resistance. By leveraging Huijin’s extensive range of materials, specifications, and customization options, businesses can enhance operational efficiency while ensuring compliance with global standards.

Illustrative image related to huijin aluminum expanded metal grating

Strategic sourcing of Huijin aluminum expanded metal grating allows B2B buyers to benefit from competitive pricing, high-quality manufacturing, and reliable delivery. Establishing a partnership with Huijin means gaining access to a trusted supplier with a proven track record in major projects and a commitment to customer satisfaction.

Looking ahead, international buyers, especially from Africa, South America, the Middle East, and Europe, are encouraged to explore the potential of Huijin’s offerings. Engage with Huijin today to discover how their aluminum expanded metal grating can elevate your projects, ensuring safety, functionality, and aesthetic appeal. Together, let’s build a future defined by quality and innovation.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.