Everything You Need to Know About Homogenizer Mixer Sourcing in 2025

Introduction: Navigating the Global Market for homogenizer mixer

In today’s dynamic global marketplace, sourcing a high-quality homogenizer mixer presents a significant challenge for international B2B buyers. With diverse applications ranging from pharmaceuticals to food production, selecting the right mixer can directly impact product quality and operational efficiency. This comprehensive guide addresses the complexities of navigating the homogenizer mixer market, offering valuable insights into various types, applications, and performance metrics.

Buyers will find detailed information on essential considerations such as supplier vetting processes, cost analysis, and the latest technological advancements in homogenization. Whether you are based in Africa, South America, the Middle East, or Europe—including countries like Saudi Arabia and Vietnam—this guide is designed to empower you with the knowledge needed to make informed purchasing decisions.

By understanding the unique attributes of different homogenizer mixers, including their capabilities for achieving fine emulsions and uniform particle sizes, you can enhance your production processes and meet stringent quality standards. Ultimately, this guide serves as a vital resource for international B2B buyers looking to optimize their sourcing strategies and improve their product offerings in an increasingly competitive landscape.

Understanding homogenizer mixer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High Shear Mixers | Intense mechanical shear, rotor-stator design, variable speed | Emulsions, creams, pharmaceuticals | Pros: Efficient, uniform mixing; Cons: May require specialized training for optimal use. |

| Benchtop Homogenizers | Compact design, lab-scale capabilities, easy to operate | R&D, small batch production | Pros: Space-efficient; Cons: Limited to smaller volumes. |

| In-Line Homogenizers | Continuous mixing, high throughput, scalable from lab to production | Food processing, cosmetics, chemicals | Pros: Seamless integration into production lines; Cons: Higher initial investment. |

| Batch Mixers | Suitable for larger batch sizes, in-tank mixing | Industrial manufacturing, pharmaceuticals | Pros: Good for large volumes; Cons: Slower than continuous options. |

| Drum Mixers | Rotating drum design for free-flowing materials | Bulk material handling, construction | Pros: Simple operation; Cons: Not suitable for viscous materials. |

What Are High Shear Mixers and Their B2B Suitability?

High shear mixers are designed to apply intense mechanical shear to mixtures, utilizing a rotor-stator configuration. This technology enables the efficient emulsification and homogenization of products, making it ideal for applications in food, pharmaceuticals, and cosmetics. B2B buyers should consider the specific viscosity and particle size requirements of their products, as these mixers excel in producing uniform emulsions and dispersions.

Why Choose Benchtop Homogenizers for Research and Development?

Benchtop homogenizers are compact, versatile tools ideal for R&D applications and small batch production. They offer precise control over mixing conditions, making them suitable for developing formulations in laboratories. Buyers should assess their space constraints and volume needs since these mixers are designed for smaller scale operations but can be pivotal in validating processes before scaling up.

How Do In-Line Homogenizers Enhance Production Efficiency?

In-line homogenizers facilitate continuous mixing and processing, making them suitable for high-volume production environments. Their ability to maintain consistent quality while integrating seamlessly into existing production lines is a significant advantage. Buyers should evaluate their production capacity and the need for scalability, as these systems often require a higher initial investment but can yield long-term operational efficiencies.

When to Use Batch Mixers in Industrial Applications?

Batch mixers are ideal for large-scale industrial applications where high volumes are processed in discrete batches. Their design allows for effective in-tank mixing, making them suitable for manufacturing pharmaceuticals and other bulk materials. However, buyers should consider that while batch mixers handle large quantities efficiently, they may have slower processing times compared to continuous systems.

What Are the Benefits of Drum Mixers for Bulk Material Handling?

Drum mixers utilize a rotating drum to mix free-flowing materials, making them suitable for bulk handling in industries like construction and agriculture. Their simple operation and low maintenance make them attractive for businesses dealing with large volumes of materials. However, B2B buyers should be aware that drum mixers are not designed for highly viscous substances, which limits their application scope.

Key Industrial Applications of homogenizer mixer

| Industry/Sector | Specific Application of homogenizer mixer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Emulsification of sauces and dressings | Improved product consistency and shelf life | Compatibility with food-grade materials, hygiene standards |

| Pharmaceuticals | Homogenization of creams and ointments | Enhanced bioavailability and stability of active ingredients | Regulatory compliance, precision in particle size reduction |

| Cosmetics and Personal Care | Blending of lotions and creams | Uniform texture and improved product performance | Customization options, scalability for production needs |

| Chemical Manufacturing | Mixing of coatings and adhesives | Increased efficiency and product quality | Equipment durability, ability to handle viscous materials |

| Biotechnology | Cell lysis for protein extraction | Higher yield of target proteins and compounds | Versatility in processing volumes, ease of cleaning |

How is the Homogenizer Mixer Used in the Food and Beverage Industry?

In the food and beverage sector, homogenizer mixers are vital for emulsifying sauces and dressings, ensuring a smooth and consistent texture. This process enhances the shelf life and stability of products, meeting consumer expectations for quality. Buyers in this industry must consider the compatibility of the mixer with food-grade materials and compliance with hygiene standards to prevent contamination and ensure safety.

What Role Does the Homogenizer Mixer Play in Pharmaceuticals?

In pharmaceuticals, homogenizer mixers are essential for creating creams and ointments with uniform consistency. They help enhance the bioavailability of active ingredients, ensuring effective delivery in topical applications. International buyers should prioritize sourcing equipment that meets stringent regulatory compliance and offers precise control over particle size reduction, which is crucial for product efficacy and safety.

How is the Homogenizer Mixer Beneficial in Cosmetics and Personal Care?

The cosmetics industry relies on homogenizer mixers for blending lotions and creams to achieve a uniform texture and consistent performance. This ensures that products meet consumer expectations for quality and efficacy. Buyers should look for customization options that allow for specific formulations and scalability to meet varying production demands, ensuring that their manufacturing processes remain efficient and flexible.

What Applications Exist in Chemical Manufacturing?

In chemical manufacturing, homogenizer mixers are used for mixing coatings and adhesives, which require a consistent blend for optimal performance. The efficient mixing process increases product quality and minimizes waste. Buyers in this sector should focus on the durability of the equipment, especially its ability to handle viscous materials, as well as its maintenance requirements to ensure long-term operational efficiency.

How Does the Homogenizer Mixer Support Biotechnology Applications?

In biotechnology, homogenizer mixers are employed for cell lysis, facilitating the extraction of proteins and other compounds. This process is critical for maximizing yields and ensuring the purity of target substances. Buyers should consider the versatility of the mixer in handling different processing volumes and the ease of cleaning, which is essential for maintaining sterile environments and preventing cross-contamination.

3 Common User Pain Points for ‘homogenizer mixer’ & Their Solutions

Scenario 1: Difficulty Achieving Consistent Product Quality

The Problem: Many B2B buyers encounter challenges in maintaining the consistency and quality of their products when using homogenizer mixers. Variability in particle size, droplet dispersion, and emulsification can lead to product inconsistency, affecting both performance and customer satisfaction. Buyers may find that despite following standard operating procedures, their homogenizer mixers deliver uneven results, causing waste and requiring additional processing time to rectify the issues. This inconsistency can be particularly detrimental for industries such as pharmaceuticals or food production, where precise formulations are critical.

The Solution: To overcome this challenge, buyers should invest in high-shear homogenizer mixers that offer precise control over speed and processing parameters. When sourcing a homogenizer, consider models with advanced features such as variable speed control, which allows operators to adjust the mixing intensity based on the specific formulation. It’s also crucial to conduct thorough equipment testing and validation, including pilot-scale trials, to ensure that the chosen mixer can replicate the desired outcomes before full-scale production. Regular maintenance and calibration of the equipment will also help maintain consistent performance over time. Partnering with manufacturers who provide comprehensive support and training can further enhance operational efficiency and product quality.

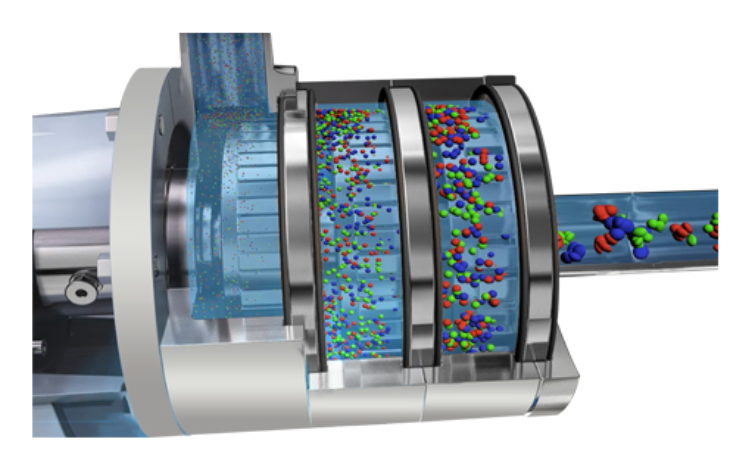

Illustrative image related to homogenizer mixer

Scenario 2: High Operational Costs and Inefficiency

The Problem: B2B buyers often grapple with high operational costs associated with running homogenizer mixers, particularly when using older or more complex systems. These mixers may consume excessive energy, require frequent maintenance, or necessitate additional equipment to achieve desired results. In regions with limited resources, such as parts of Africa or South America, these costs can be prohibitive, leading to reduced competitiveness and profitability.

The Solution: To mitigate operational costs, buyers should consider investing in modern, high-efficiency homogenizer mixers designed for lower energy consumption and reduced maintenance needs. For instance, high-shear mixers like those from Silverson utilize a rotor/stator design that minimizes clogging and downtime. Buyers can also explore options that integrate seamlessly into existing processes, allowing for easier scaling from lab to production without significant investment in additional machinery. It’s advisable to conduct a cost-benefit analysis that includes potential savings from reduced energy use and maintenance, as well as increased productivity from faster processing times. Additionally, implementing regular training for operators can enhance efficiency and reduce the likelihood of costly operational errors.

Scenario 3: Inability to Scale Formulations from Lab to Production

The Problem: A common issue faced by B2B buyers is the difficulty in scaling formulations developed in the laboratory to full-scale production. The transition often leads to unexpected changes in product quality and performance due to differences in mixing dynamics and equipment capabilities. This problem can be particularly frustrating for companies looking to introduce new products to the market quickly, as delays in scaling can hinder time-to-market and competitiveness.

The Solution: Buyers should seek homogenizer mixers that are designed for scalability, such as those that maintain the same core technology across lab and production models. For example, utilizing a lab-scale homogenizer that mirrors the design and operation of larger production units can ensure that formulations remain consistent when scaled up. It’s also essential to document all processes meticulously and run comparative tests at different scales to identify any discrepancies early in the transition. Collaborating with equipment manufacturers who provide guidance on scaling processes and offer custom solutions can further support successful product launches. By prioritizing equipment that facilitates easy scaling and thorough testing protocols, buyers can streamline the transition from lab to market while maintaining product integrity.

Strategic Material Selection Guide for homogenizer mixer

When selecting materials for homogenizer mixers, it is crucial to consider their properties and how they align with the specific needs of various applications. Here, we analyze four common materials used in homogenizer mixers: stainless steel, ceramic, plastic, and glass. Each material has distinct characteristics that can influence performance, durability, and compatibility with different media.

What Are the Key Properties of Stainless Steel for Homogenizer Mixers?

Stainless steel is renowned for its excellent corrosion resistance, high strength, and ability to withstand high temperatures and pressures. It typically has a temperature rating of up to 500°F (260°C) and can handle pressures exceeding 500 psi, depending on the grade. The most common grades used in homogenizer mixers are 304 and 316, with the latter providing superior corrosion resistance, particularly in saline or acidic environments.

Pros: Stainless steel is durable, easy to clean, and resistant to rust and staining. It is also compliant with food safety standards, making it suitable for food and pharmaceutical applications.

Cons: The primary drawback is its higher cost compared to other materials. Additionally, while it is resistant to many chemicals, it can be susceptible to pitting in the presence of chlorides.

Impact on Application: Stainless steel is ideal for applications involving aggressive solvents or high-temperature processes, ensuring product integrity and safety.

Considerations for International Buyers: Buyers from regions such as the Middle East and Europe should ensure compliance with ASTM and DIN standards, as these are commonly accepted in the industry.

How Does Ceramic Material Perform in Homogenizer Mixers?

Ceramic materials are known for their exceptional hardness and wear resistance. They can withstand high temperatures and are chemically inert, making them suitable for applications involving corrosive substances. Typical ceramic materials used in homogenizers include alumina and zirconia, which can operate effectively at temperatures up to 2000°F (1093°C).

Pros: Ceramics offer excellent durability and low friction, which reduces wear on mixer components. They are also non-reactive, ensuring that the final product remains uncontaminated.

Cons: The brittleness of ceramic materials can lead to breakage if not handled properly. Additionally, they are more expensive to manufacture and may complicate the design process.

Impact on Application: Ceramics are particularly effective in applications requiring high purity, such as pharmaceuticals and specialty chemicals.

Considerations for International Buyers: Buyers should verify that ceramic components meet local regulations regarding safety and material specifications.

What Are the Advantages of Using Plastic in Homogenizer Mixers?

Plastic materials, such as polypropylene and polycarbonate, are lightweight and resistant to corrosion. They typically have a temperature rating of around 200°F (93°C) and are suitable for low-pressure applications.

Pros: Plastics are cost-effective and can be molded into complex shapes, allowing for versatile designs. They are also resistant to many chemicals, making them suitable for various applications.

Cons: However, plastics have lower strength and temperature resistance compared to metals and ceramics. They may also degrade over time when exposed to UV light or certain solvents.

Impact on Application: Plastic mixers are ideal for low-viscosity liquids and applications where contamination must be minimized, such as in cosmetic formulations.

Considerations for International Buyers: Compliance with food safety standards is critical for buyers in the food and beverage industry, particularly in regions like Africa and South America.

Why Is Glass a Viable Option for Homogenizer Mixers?

Glass is often used in laboratory settings due to its transparency and chemical inertness. It can withstand temperatures up to 400°F (204°C) and is resistant to many acids and bases.

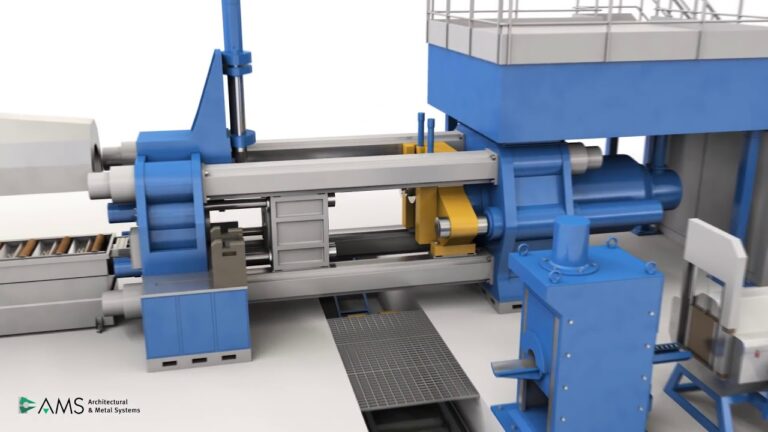

Illustrative image related to homogenizer mixer

Pros: Glass allows for easy monitoring of the mixing process and is non-reactive, ensuring that the product remains uncontaminated.

Cons: The fragility of glass makes it less suitable for high-volume industrial applications. It is also heavier than other materials, which can complicate handling and installation.

Impact on Application: Glass is ideal for small-scale laboratory applications where visual inspection is essential.

Considerations for International Buyers: Buyers should consider the shipping and handling costs associated with glass components, especially in regions with less developed logistics networks.

Illustrative image related to homogenizer mixer

Summary Table

| Material | Typical Use Case for homogenizer mixer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food and pharmaceutical applications | Excellent corrosion resistance | Higher cost, susceptible to pitting | High |

| Ceramic | High-purity applications | Exceptional hardness and wear resistance | Brittle, higher manufacturing complexity | High |

| Plastic | Cosmetic and low-viscosity liquids | Cost-effective and versatile design | Lower strength, UV degradation | Low |

| Glass | Laboratory settings | Non-reactive and transparent | Fragile, heavier than alternatives | Medium |

This strategic material selection guide aims to equip B2B buyers with the insights necessary to make informed decisions when sourcing homogenizer mixers, ensuring compatibility with their specific applications and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for homogenizer mixer

What Are the Main Stages of Manufacturing a Homogenizer Mixer?

The manufacturing process for a homogenizer mixer involves several critical stages, each designed to ensure the final product meets the high standards required for industrial applications. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage focuses on sourcing high-quality raw materials, such as stainless steel for the body and rotor/stator components. Suppliers should ensure that materials comply with international standards, such as ASTM or ISO specifications. Proper material handling and storage are crucial to prevent contamination or degradation before production begins.

-

Forming: In this stage, the prepared materials undergo various forming processes such as machining, casting, or forging. Precision machining is particularly important for components like rotor/stator assemblies, where exact tolerances are necessary to achieve the desired shear rates and homogenization efficiency. Advanced techniques such as CNC (Computer Numerical Control) machining are commonly used to ensure high precision and repeatability.

-

Assembly: The assembly phase involves fitting together the various components, including the motor, rotor, stator, and mixing chambers. This stage requires meticulous attention to detail, as improper assembly can lead to operational inefficiencies or product failure. Quality control checks are often integrated into this stage to ensure that components are assembled correctly and function as intended.

-

Finishing: The final stage includes surface treatment, painting, or polishing, which not only enhances the aesthetic appeal but also protects against corrosion and wear. This stage may also involve the application of coatings that enhance the mixer’s performance, such as non-stick surfaces. Ensuring that the finishing process meets industry standards is vital for the longevity and reliability of the homogenizer mixer.

What Key Techniques Are Used in the Manufacturing of Homogenizer Mixers?

Several techniques and technologies enhance the manufacturing process of homogenizer mixers. These include:

-

High-Precision Machining: This is essential for producing components with tight tolerances, particularly for rotor/stator assemblies, which play a crucial role in creating the shear forces necessary for effective homogenization.

-

Welding and Joining Techniques: The assembly of different parts often involves advanced welding techniques, ensuring strong and reliable joints that can withstand operational stresses.

-

Quality Testing and Calibration: After assembly, mixers undergo rigorous testing to ensure they perform to specifications. This includes calibrating speed controls and checking for any vibrations or imbalances that could affect performance.

-

Automation and Robotics: The use of automated systems in manufacturing can enhance efficiency and precision, particularly in high-volume production environments. Robotics can assist in assembly and quality testing, reducing human error.

How Is Quality Assurance Implemented in Homogenizer Mixer Manufacturing?

Quality assurance (QA) is an integral part of the homogenizer mixer manufacturing process, ensuring that each unit produced meets industry standards and customer expectations. The QA process typically adheres to various international standards, such as ISO 9001, which focuses on quality management systems.

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival at the manufacturing facility. Suppliers must provide certification that materials meet specified standards, and any non-conformance can lead to rejection of materials.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are conducted to ensure that each stage adheres to quality specifications. This may include monitoring machining tolerances and ensuring proper assembly techniques are followed.

-

Final Quality Control (FQC): After assembly and finishing, a comprehensive inspection is carried out. This includes testing the operational efficiency of the homogenizer mixers under real-world conditions to validate performance claims. This stage often involves functional testing, visual inspections, and performance evaluations.

What International Standards and Certifications Should B2B Buyers Consider?

For international B2B buyers, understanding the relevant standards and certifications is crucial. Some key certifications include:

-

ISO 9001: This standard outlines quality management principles and is widely recognized. Manufacturers adhering to ISO 9001 demonstrate a commitment to quality and continuous improvement.

-

CE Marking: For products sold in Europe, CE marking indicates compliance with EU safety, health, and environmental protection standards. This is particularly important for buyers in the European market.

-

API Certification: For industries related to oil and gas, API certification can be a requirement, ensuring that equipment meets specific industry standards.

-

FDA Compliance: For manufacturers producing mixers intended for food or pharmaceutical applications, compliance with FDA regulations is essential to ensure safety and efficacy.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control processes of potential suppliers:

-

Supplier Audits: Conducting on-site audits can provide insights into a manufacturer’s quality management practices and production capabilities. This allows buyers to assess the adherence to international standards.

-

Quality Assurance Reports: Requesting detailed reports on the supplier’s QA processes, including IQC, IPQC, and FQC documentation, can help verify their commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing processes and product quality. This is particularly beneficial for buyers in regions like Africa and South America, where direct oversight may be challenging.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing homogenizer mixers from international suppliers, several nuances should be considered:

-

Cultural and Regulatory Differences: Understanding the regulatory environment and cultural practices in regions like the Middle East and Africa is vital. Buyers should be aware that standards may vary significantly between countries.

-

Communication Barriers: Clear communication regarding quality expectations is essential. Buyers should ensure that suppliers understand their requirements and can meet them consistently.

-

Lead Times and Logistics: Quality assurance can be impacted by lead times and logistics. Buyers should factor in potential delays that could affect the supply chain and the quality of the final product.

-

Post-Purchase Support: Assessing the supplier’s ability to provide ongoing support, including maintenance and troubleshooting, is critical for long-term satisfaction with the product.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing homogenizer mixers, ensuring they select suppliers that align with their quality and operational standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘homogenizer mixer’

Introduction

Sourcing a homogenizer mixer is a critical decision for businesses in various sectors, including food and beverage, pharmaceuticals, and cosmetics. This guide provides a structured checklist to help B2B buyers navigate the procurement process effectively, ensuring they select the right equipment that meets their operational needs and quality standards.

Step 1: Define Your Technical Specifications

Before starting the procurement process, clearly outline your technical requirements. Consider factors such as the type of materials you will be processing, the desired particle size reduction, and the volume of production.

– Key specifications to define include:

– Processing capacity: Understand the range of batch sizes you will be handling.

– Speed and power requirements: Determine the necessary RPM and wattage to achieve optimal results.

Step 2: Research Different Types of Homogenizer Mixers

Familiarize yourself with the various types of homogenizer mixers available in the market, such as high shear mixers, inline mixers, and batch mixers. Each type serves different purposes and is suitable for specific applications.

– Considerations include:

– High shear mixers are ideal for emulsification and particle size reduction.

– Inline mixers offer continuous processing, which can enhance efficiency.

Step 3: Evaluate Potential Suppliers

It’s essential to conduct thorough research on potential suppliers before making a commitment. Look for companies with a proven track record and expertise in manufacturing homogenizer mixers.

– What to assess:

– Supplier certifications: Verify industry certifications such as ISO to ensure compliance with quality standards.

– Client testimonials: Seek reviews or case studies from similar industries to gauge reliability.

Step 4: Request Quotes and Compare Pricing

Once you have identified potential suppliers, request detailed quotes that include pricing, delivery timelines, and warranty information. Comparing these quotes will help you understand market rates and identify the best deal.

– Key elements to compare:

– Total cost of ownership: Consider not just the initial purchase price but also maintenance, energy consumption, and potential downtime costs.

– Warranty terms: Ensure the warranty covers critical components and includes post-purchase support.

Step 5: Analyze After-Sales Support and Service

Assess the level of after-sales support provided by the supplier. Good after-sales service can significantly impact your operational efficiency and equipment longevity.

– Look for:

– Technical support availability: Ensure that the supplier offers timely support for troubleshooting and maintenance.

– Training programs: Check if the supplier provides training for your staff on equipment operation and maintenance.

Step 6: Conduct a Risk Assessment

Before finalizing your purchase, perform a risk assessment to identify any potential challenges associated with the supplier or equipment. This step is vital to mitigate risks that could affect your production process.

– Considerations include:

– Supply chain stability: Evaluate the supplier’s ability to deliver on time and maintain stock levels.

– Compliance risks: Ensure that the equipment meets local regulations and industry standards.

Step 7: Finalize the Purchase Agreement

Once you have completed all previous steps, finalize the purchase agreement with your chosen supplier. Ensure that all terms and conditions are clearly outlined, including payment terms, delivery schedules, and service agreements.

– Important aspects to include:

– Clear specifications: Ensure the agreement reflects all technical specifications discussed.

– Contingency plans: Discuss and document what happens in case of delays or equipment failure.

By following this checklist, B2B buyers can make informed decisions when sourcing homogenizer mixers, ultimately enhancing their production capabilities and ensuring product quality.

Comprehensive Cost and Pricing Analysis for homogenizer mixer Sourcing

What Are the Key Cost Components in Sourcing a Homogenizer Mixer?

When sourcing homogenizer mixers, understanding the cost structure is vital for making informed purchasing decisions. The primary cost components include:

-

Materials: The quality of materials, such as stainless steel for the mixer body and high-grade components for the motor and rotor/stator assemblies, directly affects the price. Higher-quality materials typically yield better performance and durability.

-

Labor: Manufacturing labor costs can vary significantly by region. Countries with lower labor costs can offer more competitive pricing, but this may come at the expense of quality control and manufacturing standards.

-

Manufacturing Overhead: This includes expenses related to facility operations, utilities, and equipment maintenance. Efficient production processes can help minimize these costs, impacting the final price of the homogenizer mixer.

-

Tooling: Investment in specialized tools for production can be a significant upfront cost. However, manufacturers that spread these costs over large production runs can offer more competitive prices.

-

Quality Control (QC): Robust QC processes ensure that the homogenizers meet performance standards and regulatory compliance. While this adds to the cost, it is essential for minimizing defects and ensuring reliability.

-

Logistics: Shipping costs, including freight and handling, can vary based on the destination. International buyers should factor in tariffs and taxes, which can significantly affect the total cost.

-

Margin: Manufacturer margins can vary widely based on brand reputation, market demand, and competition. Established brands may command higher prices due to perceived reliability and support.

How Do Price Influencers Affect Homogenizer Mixer Costs?

Several factors can influence the pricing of homogenizer mixers, including:

-

Volume/MOQ: Bulk purchasing often leads to lower per-unit costs. Buyers should negotiate Minimum Order Quantities (MOQs) to optimize their investment.

-

Specifications and Customization: Custom features, such as specific rotor designs or enhanced motor capabilities, can increase costs. Buyers should clearly define their requirements to avoid unnecessary expenses.

-

Materials and Quality Certifications: Higher quality and certified materials can drive up costs. Buyers should assess whether the added expense aligns with their operational needs.

-

Supplier Factors: The reputation and reliability of suppliers play a crucial role. Trusted suppliers may offer better support and warranty services, which can justify higher prices.

-

Incoterms: The choice of Incoterms (International Commercial Terms) affects shipping responsibilities and costs. Buyers should understand how these terms impact overall pricing and liability.

What Are the Best Buyer Tips for Cost-Efficiency in Purchasing Homogenizer Mixers?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, navigating the complexities of homogenizer mixer pricing requires strategic approaches:

-

Negotiate Effectively: Leverage your purchasing volume and long-term partnership potential to negotiate better terms. Suppliers may offer discounts for larger orders or repeat business.

-

Consider Total Cost of Ownership (TCO): Evaluate not only the purchase price but also operating costs, maintenance, and potential downtime. A higher initial investment in a reliable mixer may result in lower TCO over its lifecycle.

-

Understand Pricing Nuances: Be aware of local market conditions, currency fluctuations, and economic factors that may influence pricing. This knowledge can aid in making well-timed purchasing decisions.

-

Research Suppliers Thoroughly: Engage with multiple suppliers to compare offerings, prices, and service levels. Look for customer reviews and case studies to gauge reliability and support.

-

Plan for Long-Term Needs: Anticipate future production requirements and consider scalability in your purchasing decisions. Investing in a mixer that can grow with your operations may save costs in the long run.

Conclusion

While the cost of sourcing homogenizer mixers can vary significantly, understanding the key components and influencing factors enables B2B buyers to make informed, strategic decisions. By considering all aspects of cost and engaging in thorough research and negotiation, buyers can optimize their investments in homogenization technology.

Alternatives Analysis: Comparing homogenizer mixer With Other Solutions

When evaluating equipment for mixing and homogenization, it’s crucial to consider various alternatives to homogenizer mixers. Each option presents unique advantages and challenges, influencing their suitability for specific applications. This analysis explores how homogenizer mixers compare against alternative solutions such as high-pressure homogenizers and emulsifiers.

| Comparison Aspect | Homogenizer Mixer | High-Pressure Homogenizer | Emulsifier |

|---|---|---|---|

| Performance | Delivers uniform particle sizes (2-5 microns) | Achieves finer emulsions (sub-micron range) | Effective for creating stable emulsions |

| Cost | Moderate initial investment | High initial investment and operational costs | Lower cost, but may require additional equipment |

| Ease of Implementation | User-friendly with varied applications | Complex setup and operation | Simple operation, but effectiveness depends on formulation |

| Maintenance | Low maintenance requirements | High maintenance needs due to pressure systems | Minimal maintenance, but sensitive to contamination |

| Best Use Case | Ideal for creams, lotions, and sauces | Suitable for pharmaceuticals and high-end emulsions | Excellent for food and cosmetic applications |

What are the Advantages and Disadvantages of High-Pressure Homogenizers?

High-pressure homogenizers are renowned for their ability to produce ultra-fine emulsions and dispersions. They operate by forcing liquids through a narrow gap at high pressure, achieving particle sizes in the sub-micron range. However, this technology comes with significant drawbacks. The initial investment and ongoing operational costs are considerably higher than those associated with homogenizer mixers. Additionally, the complexity of operation and maintenance can pose challenges, especially in environments with limited technical expertise. While they are excellent for applications requiring precision and uniformity, such as in the pharmaceutical industry, the cost and maintenance burden may be prohibitive for many B2B buyers.

How Do Emulsifiers Compare to Homogenizer Mixers?

Emulsifiers are devices designed specifically for creating stable emulsions by combining immiscible liquids. They are generally lower in cost and simpler to operate than homogenizer mixers, making them an attractive option for businesses looking to optimize their budgets. However, the effectiveness of emulsifiers can be heavily dependent on the formulation and the presence of emulsifying agents. While they excel in food and cosmetic applications, emulsifiers may not provide the same level of versatility and performance across a broader range of products as homogenizer mixers do. For companies focused on specific emulsification tasks, they can be a viable solution, but they may fall short for more complex mixing requirements.

How Should B2B Buyers Choose the Right Mixing Solution?

In selecting the appropriate mixing solution, B2B buyers should assess their specific application needs, budget constraints, and operational capabilities. Homogenizer mixers offer a balance of performance, cost-effectiveness, and ease of use, making them suitable for a wide range of products. For those requiring ultra-fine emulsions, high-pressure homogenizers may be worth the investment despite their higher costs. Conversely, businesses focusing on simple emulsification tasks might find emulsifiers to be a more economical choice. Ultimately, understanding the unique strengths and limitations of each solution will empower buyers to make informed decisions that align with their operational goals and financial parameters.

Essential Technical Properties and Trade Terminology for homogenizer mixer

What Are the Key Technical Properties of a Homogenizer Mixer?

Understanding the essential technical properties of homogenizer mixers is crucial for B2B buyers to make informed purchasing decisions. Here are some of the most critical specifications:

1. Power Rating

The power rating, typically measured in watts, indicates the energy output of the homogenizer mixer. A higher wattage usually translates to greater efficiency and the ability to handle more challenging mixing tasks. For instance, a 600-watt mixer can efficiently process samples ranging from 0.25 mL to 10 L, making it suitable for both laboratory and small-scale production.

2. Speed Control

Speed control is a vital feature that allows users to adjust the rotation speed of the mixer, typically measured in revolutions per minute (rpm). Variable speed capabilities can range from 500 to 18,000 rpm. This flexibility is important for different applications, as specific formulations may require distinct shear rates to achieve optimal emulsification or homogenization.

3. Processing Capacity

The processing capacity defines the volume of material that can be effectively homogenized in a single batch. It is crucial for scalability and efficiency in production. For example, a homogenizer that accommodates volumes from 2 mL to 10 L can serve both research and large-scale production needs, making it a versatile choice for manufacturers.

Illustrative image related to homogenizer mixer

4. Material Grade

The material grade of the homogenizer’s components—such as stainless steel or food-grade plastics—affects durability and compliance with industry regulations. High-grade materials are essential for maintaining hygiene standards, especially in food and pharmaceutical applications. Selecting a mixer made from appropriate materials ensures longevity and minimizes contamination risks.

5. Noise Level

The operational noise level, measured in decibels (dB), is an often-overlooked specification. A lower noise level, ideally below 68 dB, is preferred in laboratory settings to maintain a conducive working environment. Buyers should consider this factor, especially when the equipment will be used in close quarters or in research facilities.

6. Warranty and Support

A robust warranty, such as a three-year motor warranty, is indicative of the manufacturer’s confidence in their product’s reliability. Additionally, ongoing technical support and user training can enhance the operational efficiency of the homogenizer, ensuring that businesses get the most out of their investment.

What Are Common Trade Terms in the Homogenizer Mixer Market?

Navigating the homogenizer mixer market involves familiarizing oneself with specific industry terminology. Here are several key terms that every B2B buyer should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces components or products that are marketed by another company under its own brand name. Understanding OEM relationships can be crucial for buyers seeking custom solutions or specific technical requirements in homogenizer mixers.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest number of units a supplier is willing to sell. This term is significant for buyers as it can impact initial costs and inventory management. Knowing the MOQ can help businesses plan their purchases effectively, especially when budgeting for equipment.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products or services. Submitting an RFQ for homogenizer mixers allows buyers to compare costs and features from multiple vendors, enabling better decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), is essential for understanding shipping logistics and cost allocation when purchasing equipment internationally.

5. Lead Time

Lead time refers to the time taken from placing an order to delivery. This is a critical factor for businesses planning production schedules. Buyers should inquire about lead times when negotiating contracts to ensure that equipment arrives when needed.

6. Technical Support

Technical support encompasses the assistance provided by manufacturers regarding equipment operation, maintenance, and troubleshooting. Reliable technical support is crucial for minimizing downtime and maximizing the efficiency of homogenizer mixers in production processes.

Illustrative image related to homogenizer mixer

Understanding these technical properties and trade terms equips B2B buyers with the knowledge to make informed decisions, ensuring that they select the right homogenizer mixer to meet their specific operational needs.

Navigating Market Dynamics and Sourcing Trends in the homogenizer mixer Sector

What Are the Key Market Dynamics and Trends Influencing the Homogenizer Mixer Sector?

The homogenizer mixer market is witnessing significant growth driven by various global factors. Key among these is the increasing demand for processed food and beverages, pharmaceuticals, and cosmetics, which require consistent and high-quality emulsions and dispersions. As emerging economies in Africa, South America, and the Middle East expand their manufacturing capabilities, there is a notable uptick in the investment in advanced mixing technologies. This trend is particularly evident in countries like Saudi Arabia and Vietnam, where industries are increasingly focusing on high-shear mixers for their ability to deliver uniform particle sizes and improve product stability.

Technological advancements are also reshaping the market landscape. The rise of Industry 4.0 and smart manufacturing solutions is leading to the integration of automation in homogenizer mixers, enhancing operational efficiency and reducing labor costs. Furthermore, the growing trend of sustainability is prompting manufacturers to adopt energy-efficient and low-waste technologies. The shift towards in-line homogenization processes over traditional batch methods reflects a broader market movement toward continuous production, which not only improves efficiency but also aligns with sustainability goals.

How Is Sustainability Shaping the Sourcing of Homogenizer Mixers in B2B?

Sustainability and ethical sourcing are increasingly becoming central to the purchasing decisions of B2B buyers in the homogenizer mixer sector. The environmental impact of manufacturing processes has raised awareness among companies about their supply chain practices. Buyers are now looking for suppliers that prioritize sustainable manufacturing methods and materials, as well as those that adhere to international environmental standards.

Moreover, certifications such as ISO 14001 (Environmental Management) and adherence to RoHS (Restriction of Hazardous Substances) are becoming critical for suppliers to demonstrate their commitment to reducing their ecological footprint. Buyers are also favoring suppliers that utilize recycled or eco-friendly materials in their equipment designs. This shift not only enhances brand reputation but also meets the growing consumer demand for environmentally responsible products.

Illustrative image related to homogenizer mixer

In regions like Europe, where regulatory frameworks are stricter, companies are under increasing pressure to align their sourcing strategies with sustainability goals. Consequently, B2B buyers are encouraged to engage with suppliers who can provide transparency in their sourcing practices and demonstrate a commitment to ethical supply chains.

How Has the Homogenizer Mixer Market Evolved Over Time?

The evolution of the homogenizer mixer market is marked by significant technological advancements and changing consumer demands. Initially, the focus was primarily on mechanical mixers that provided basic homogenization capabilities. However, as industries evolved, so did the requirements for more sophisticated mixing solutions.

The introduction of high-shear mixers revolutionized the sector, allowing for finer emulsions and improved product stability. Over the years, innovations such as rotor-stator designs and in-line homogenization systems have transformed the landscape, enabling seamless scaling from laboratory to production settings. Today, the market is characterized by a diverse range of mixers that cater to specific applications across food and beverage, pharmaceuticals, and personal care industries, reflecting the dynamic nature of global manufacturing demands.

This historical context underscores the importance of understanding technological advancements and their implications for modern B2B buyers seeking reliable, efficient, and sustainable homogenization solutions.

Illustrative image related to homogenizer mixer

Frequently Asked Questions (FAQs) for B2B Buyers of homogenizer mixer

-

How do I choose the right homogenizer mixer for my application?

Selecting the appropriate homogenizer mixer involves assessing your specific application requirements. Consider factors such as the type of materials you will be mixing, desired particle size, and batch volume. Evaluate the homogenizer’s speed range, power rating, and compatibility with various containers and probes. It’s beneficial to consult with manufacturers or suppliers who can provide tailored recommendations based on your unique needs, ensuring optimal performance and efficiency in your processes. -

What are the advantages of high shear mixers over traditional mixing methods?

High shear mixers are designed for efficient and uniform homogenization, offering several advantages over traditional methods. They provide faster processing times and achieve finer particle sizes, often down to 0.5 microns, which is essential for creating stable emulsions and dispersions. Additionally, high shear mixers minimize aeration and the risk of contamination, ensuring product integrity. Their ability to seamlessly scale from lab to production also enhances consistency and simplifies process validation, making them a smart investment for manufacturers. -

What is the typical lead time for ordering a homogenizer mixer from international suppliers?

Lead times for ordering homogenizer mixers can vary widely based on factors such as the supplier’s location, production capacity, and customization requirements. Generally, standard models may have a lead time of 4 to 8 weeks, while customized solutions could take longer. It is advisable to communicate directly with suppliers to get a precise estimate and to account for any potential shipping delays, especially when importing equipment from overseas. -

What are the key factors to consider when vetting a supplier for homogenizer mixers?

When vetting suppliers, focus on their industry experience, reputation, and customer service. Check for certifications such as ISO standards, which indicate quality management practices. Request references or case studies from previous clients to assess their reliability. Additionally, inquire about the warranty, technical support, and after-sales service they offer, as these factors are crucial for long-term satisfaction and operational continuity. -

What customization options are available for homogenizer mixers?

Many manufacturers offer customization options to meet specific operational needs. Customizations can include varying motor power, speed controls, and different types of mixing heads or probes suited for particular materials. Additionally, you can request modifications for size, materials used in construction, and specialized features like enhanced sealing for sterile applications. Engaging with suppliers early in the procurement process can help ensure that the final product aligns with your operational requirements. -

What is the minimum order quantity (MOQ) for homogenizer mixers?

The MOQ for homogenizer mixers typically varies by manufacturer and product type. Some suppliers may offer single units for lab-scale applications, while others might require bulk orders for industrial-scale mixers. It is important to clarify MOQs before placing an order, as this can impact your budget and inventory planning. Discussing your needs with suppliers can sometimes lead to flexible arrangements, especially for first-time buyers. -

What payment terms should I expect when purchasing a homogenizer mixer internationally?

Payment terms for international purchases can differ among suppliers, but common practices include advance payment, letters of credit, or payment upon delivery. Some suppliers may offer net terms, allowing payment within a specified period post-delivery. It’s important to discuss and agree on payment terms upfront to avoid potential issues later. Ensure you understand any additional costs such as shipping fees, tariffs, and taxes that may apply to international transactions. -

How do I ensure quality assurance for my homogenizer mixer?

Ensuring quality assurance for your homogenizer mixer involves several steps. First, request detailed product specifications and certifications from the supplier, such as CE or ISO compliance. Establish a clear quality control process that includes pre-shipment inspections and acceptance testing upon arrival. If possible, visit the manufacturing facility or request a demo unit to evaluate performance. Finally, maintain communication with the supplier for ongoing support and troubleshooting to ensure consistent quality in your operations.

Top 4 Homogenizer Mixer Manufacturers & Suppliers List

1. Arde Barinco – Homogenizer Mixers

Domain: arde-barinco.com

Registered: 1999 (26 years)

Introduction: Homogenizer Mixers for Uniform Blending and Quality Control. High shear dispersion of solids and emulsification of immiscible liquids at extremely high shear rates. Effective dual mode mixing process that disperses, emulsifies, and re-suspends settled solids. Proprietary feature to control shear rate by adjusting the gap between rotor and stator. Specifications include various models with differen…

2. IndustrialMixers – Homogenizers

Domain: industrialmixers.com

Registered: 2000 (25 years)

Introduction: Homogenizers are industrial equipment used to homogenize various materials such as soil, tissue, plants, and food. They are typically made from metal, with stainless steel used for food products. Homogenizers consist of a holding tank, a motor, and rotating impellers or high-speed rotors that blend materials. Types of homogenizers include rotor-stator, ultrasonic, bead mill, and high-pressure homo…

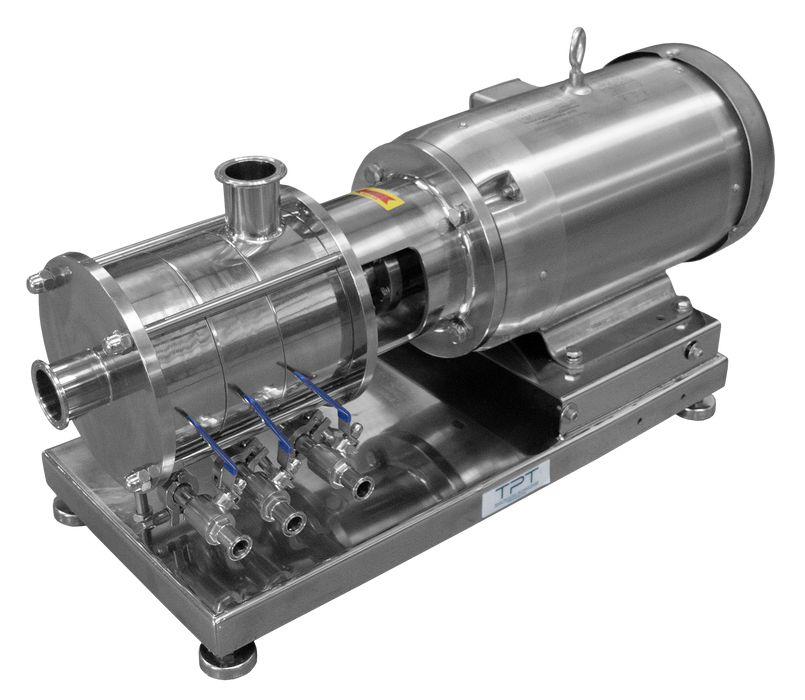

3. Texas Process Technologies – High Shear Mixer Homogenizer

Domain: texasprocesstechnologies.com

Registered: 2011 (14 years)

Introduction: High Shear Mixer Homogenizer 3 Stages (In Stock)

– Original Price: $20,419.75

– Current Price: $19,837.80 (10HP WEG TEFC General Purpose Motor)

– Availability: Low stock

– Shipping Limitation: Mixers do not qualify for free shipping; ships in 1-2 weeks if in stock.

– Features:

– 10HP Motor, 3 phase 460V (Baldor Stainless Steel Motor)

– 316 SS product contact parts

– Tri-clamp Connections

-…

4. Humblebee & Me – High Shear Homogenizer

Domain: humblebeeandme.com

Registered: 2011 (14 years)

Introduction: A homogenizer is a high shear mixer used in professional cosmetic manufacturing, typically more powerful than immersion blenders. It creates smaller particles for more stable emulsions but can over-homogenize, resulting in a thinner product. Cleaning is more complex than with immersion blenders. Recommended for those making many emulsions, if budget allows. Two types mentioned: 1) Dynamic MiniPro …

Strategic Sourcing Conclusion and Outlook for homogenizer mixer

How Can Strategic Sourcing Elevate Your Business in the Homogenizer Mixer Market?

In today’s competitive landscape, strategic sourcing for homogenizer mixers offers significant advantages for B2B buyers across Africa, South America, the Middle East, and Europe. By prioritizing quality, efficiency, and scalability, organizations can ensure that they select mixers that not only meet their immediate production needs but also adapt to future demands. The versatility of models, such as the Omni Mixer and Silverson Homogenizers, highlights the importance of investing in equipment that provides reliable performance across various applications, from laboratory research to large-scale manufacturing.

Furthermore, engaging with suppliers who emphasize robust support and tailored solutions will enhance your operational efficiency and product consistency. As you navigate the complexities of sourcing, consider the total cost of ownership, including maintenance and energy consumption, to make informed purchasing decisions that align with your budget and sustainability goals.

Looking ahead, the homogenizer mixer market is poised for growth, driven by advancements in technology and increasing demand for high-quality emulsions and dispersions. Now is the time to leverage strategic sourcing practices that not only fulfill your current requirements but also position your business for long-term success in an evolving marketplace. Connect with reputable suppliers today to explore the best options for your organization.

Illustrative image related to homogenizer mixer

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.