Everything You Need to Know About Hidden Hinge Sourcing in 2025

Introduction: Navigating the Global Market for hidden hinge

In today’s competitive landscape, sourcing hidden hinges poses a unique challenge for international B2B buyers. As businesses strive for security and aesthetic appeal in their products, understanding the nuances of hidden hinge technology becomes crucial. This comprehensive guide delves into the various types of hidden hinges, their applications across different industries, and the importance of supplier vetting. It also provides valuable insights on cost considerations, ensuring you make informed purchasing decisions that align with your operational goals.

This guide is tailored for B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, such as Nigeria and Germany. By exploring the latest trends and innovations in hidden hinge solutions, you will gain a competitive edge in your market. The detailed sections will equip you with the knowledge needed to evaluate potential suppliers, assess product quality, and understand the intricacies of installation and maintenance.

Whether you’re looking to enhance product security, streamline installation processes, or optimize design aesthetics, this guide empowers you to navigate the global market for hidden hinges effectively. In an era where every detail counts, making the right hinge choice can significantly impact your business operations and customer satisfaction. Let’s embark on this journey to uncover the best hidden hinge solutions that meet your needs and elevate your offerings in the marketplace.

Understanding hidden hinge Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Concealed Door Hinges | Invisible when the door is closed; various finishes available | Commercial and residential doors | Pros: Aesthetic appeal, enhanced security. Cons: Installation complexity can vary. |

| Hidden Hinge Systems | Allows for hidden access panels behind furniture or artwork | Home safes, utilities access | Pros: Discreet storage solutions, easy access. Cons: Requires customization for specific applications. |

| Pivot Hinges | Rotates around a fixed point, allowing for flush mounting | High-end cabinetry, specialty doors | Pros: Smooth operation, space-saving design. Cons: Higher cost, requires precise installation. |

| European Concealed Hinges | Designed for frameless cabinets, fully adjustable | Kitchen and bathroom cabinetry | Pros: Easy adjustments, seamless look. Cons: Limited to specific cabinet designs. |

| Heavy-Duty Hidden Hinges | Built for high traffic, robust construction | Industrial applications, commercial use | Pros: Durability, supports heavy doors. Cons: Heavier weight may complicate installation. |

What Are the Key Characteristics of Concealed Door Hinges?

Concealed door hinges are designed to be invisible when the door is closed, providing a clean and modern aesthetic. They come in various finishes, making them suitable for diverse interior designs. In B2B applications, these hinges are commonly used in commercial and residential doors where aesthetics and security are paramount. Buyers should consider the installation complexity, as some models may require specialized fittings or adjustments.

How Do Hidden Hinge Systems Function?

Hidden hinge systems enable discreet access to concealed storage areas, such as safes or utility panels, behind furniture or artwork. These hinges are ideal for businesses looking to enhance security while maintaining an organized appearance. They can be customized to fit different sizes and styles, but this customization may require additional planning and investment. Buyers should assess their specific needs for access and security when choosing this type of hinge.

What Are the Benefits of Using Pivot Hinges?

Pivot hinges allow doors to rotate around a fixed point, enabling a flush mount that is both functional and visually appealing. They are often utilized in high-end cabinetry or specialty doors, making them a popular choice for luxury commercial projects. The smooth operation and space-saving design are significant advantages, although the cost and installation precision can be a drawback for some buyers. It is crucial to ensure compatibility with existing door frames.

What Makes European Concealed Hinges Unique?

European concealed hinges are specifically designed for frameless cabinets, offering full adjustability to ensure perfect alignment. These hinges are commonly used in kitchen and bathroom cabinetry, providing a seamless look that appeals to modern aesthetics. While they are easy to adjust, their design is limited to specific cabinet styles, which may restrict their application in some projects. B2B buyers should evaluate their cabinetry designs to determine suitability.

Why Choose Heavy-Duty Hidden Hinges?

Heavy-duty hidden hinges are constructed for high-traffic areas and demanding applications, making them ideal for industrial and commercial use. Their robust design supports heavier doors, ensuring durability and longevity. While they offer significant advantages in strength and reliability, the added weight may complicate installation and require more substantial mounting surfaces. Buyers should weigh the benefits of durability against potential installation challenges when selecting these hinges.

Key Industrial Applications of hidden hinge

| Industry/Sector | Specific Application of Hidden Hinge | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Architecture | Concealed access panels for utilities | Streamlined aesthetic, improved access for maintenance | Durability, load-bearing capacity, and finish options |

| Interior Design | Hidden storage solutions behind decorative elements | Maximizes space utilization while maintaining aesthetics | Customization options, installation ease, and security features |

| Security & Safe Storage | In-wall safes concealed behind artwork | Enhanced security for valuables while maintaining decor | Material strength, locking mechanisms, and size compatibility |

| Retail & Commercial | Concealed display cases for merchandise | Improved visual appeal and security for products | Visibility, ease of access, and integration with existing displays |

| Hospitality | Hidden doors for staff access in hotels | Maintains guest privacy while facilitating staff movement | Design compatibility, durability, and ease of installation |

How Are Hidden Hinges Used in Construction and Architecture?

In the construction and architecture sectors, hidden hinges are primarily utilized for creating concealed access panels that provide easy access to plumbing, electrical systems, and other utilities. These hinges allow for a seamless integration into walls or ceilings, preserving the aesthetic appeal of the space. For international buyers, particularly in regions like Africa and the Middle East, sourcing hinges that can withstand varying climate conditions and have a robust load-bearing capacity is crucial. Additionally, finishes that match local architectural styles can enhance overall design coherence.

What Role Do Hidden Hinges Play in Interior Design?

Interior designers often leverage hidden hinges to create hidden storage solutions behind decorative elements such as picture frames or mirrors. This application allows for maximum space utilization without compromising the room’s visual appeal. Buyers from South America and Europe should consider customization options that fit their specific design requirements. Moreover, the ease of installation is a significant factor, as designers often work within tight timelines to meet project deadlines.

How Do Hidden Hinges Enhance Security and Safe Storage?

In the security and safe storage sector, hidden hinges are used to conceal in-wall safes behind artwork or other decorative pieces. This application provides an added layer of security for valuables, making them less detectable to potential intruders. For B2B buyers, particularly in regions with high security concerns, sourcing hinges made from high-strength materials is essential. Additionally, understanding the locking mechanisms available can further enhance security measures.

In What Ways Are Hidden Hinges Beneficial for Retail and Commercial Spaces?

Retailers and commercial businesses utilize hidden hinges in display cases to create a clean and unobtrusive look while ensuring product security. This application not only enhances the visual appeal of merchandise but also allows for easy access for staff. Buyers in Europe and South America should focus on sourcing hinges that offer visibility and ease of access, ensuring that the display cases are both functional and attractive to customers.

How Are Hidden Hinges Used in the Hospitality Industry?

In the hospitality sector, hidden hinges are often employed to create concealed doors for staff access in hotels and restaurants. This design keeps guest areas private while allowing staff to move efficiently between back-of-house and front-of-house operations. For international buyers, considerations should include the hinges’ durability and compatibility with various design styles to ensure they blend seamlessly with the overall aesthetic of the establishment.

3 Common User Pain Points for ‘hidden hinge’ & Their Solutions

Scenario 1: Difficulty in Installation of Hidden Hinges for Wall Safes

The Problem: A common challenge faced by B2B buyers, particularly in the construction and home improvement sectors, is the complexity associated with installing hidden hinges for wall safes. Many buyers report that the installation process can be misleadingly simple in promotional materials, yet in practice, it often requires precise measurements and an understanding of wall structures. In regions where labor is costly or expertise is limited, this can lead to significant delays and increased project costs. Buyers may also encounter issues with aligning the hinges properly to ensure the picture frame operates smoothly.

The Solution: To streamline the installation process, B2B buyers should focus on sourcing high-quality hidden hinges that come with comprehensive installation guides or video tutorials. Additionally, partnering with suppliers that offer technical support can be invaluable. Before installation, conducting a thorough site assessment to understand wall composition (drywall, concrete, etc.) is crucial. Using tools like a stud finder can help ensure that the hinges are anchored properly. For complex installations, consider hiring skilled labor or providing training sessions for local contractors to ensure they are familiar with the unique requirements of hidden hinge systems.

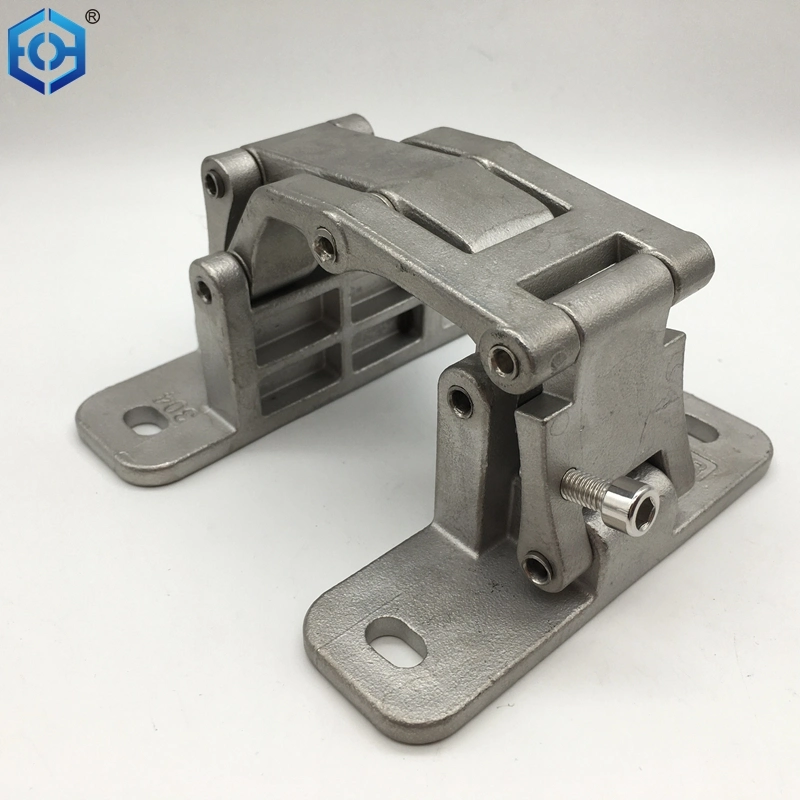

Illustrative image related to hidden hinge

Scenario 2: Ensuring Security with Hidden Hinges in Commercial Spaces

The Problem: Security is a paramount concern for businesses that use hidden hinges for concealing storage solutions, such as safes behind picture frames. B2B buyers often grapple with ensuring that these concealed spaces are not only functional but also secure against unauthorized access. In regions with higher crime rates, the inadequacy of security measures can lead to theft and loss of valuable assets, putting pressure on business owners to find reliable solutions.

The Solution: To address security concerns, B2B buyers should prioritize hidden hinges that are designed with enhanced security features. This includes hinges made from high-grade steel and designs that prevent tampering. Integrating the hidden hinge system with a robust locking mechanism, such as biometric locks or electronic keypads, can significantly elevate security levels. Additionally, buyers should conduct risk assessments to determine the level of security needed based on the type of valuables stored and the specific threats in their location. Regular training for staff on security protocols related to concealed storage can also enhance overall safety.

Scenario 3: Aesthetic Concerns When Using Hidden Hinges in Interior Design

The Problem: Aesthetic integration is often a pain point for B2B buyers in the interior design and renovation industries when utilizing hidden hinges. Buyers frequently find that standard picture frames do not align well with the design theme of a space, leading to a lack of cohesion and visual appeal. This can be particularly challenging in markets like Europe and the Middle East, where design standards are high and clients expect seamless integration of all elements.

The Solution: To overcome aesthetic issues, buyers should consider custom solutions that allow for tailored designs that fit the overall theme of a space. Collaborating with local artisans or designers who specialize in bespoke framing can yield better results. Furthermore, sourcing hidden hinges that offer a variety of finishes can help match the hinges with existing décor. Buyers can also encourage clients to choose frames that complement their interior design style, ensuring that the hidden hinge installations blend seamlessly into the environment. Providing samples or visual mock-ups can assist clients in visualizing the final product, thereby reducing the likelihood of dissatisfaction with the end result.

Strategic Material Selection Guide for hidden hinge

What Are the Key Materials Used in Hidden Hinges?

Hidden hinges are essential components in various applications, providing both functionality and aesthetic appeal. Selecting the right material is crucial for ensuring optimal performance, durability, and compliance with international standards. Below, we analyze four common materials used in hidden hinges, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

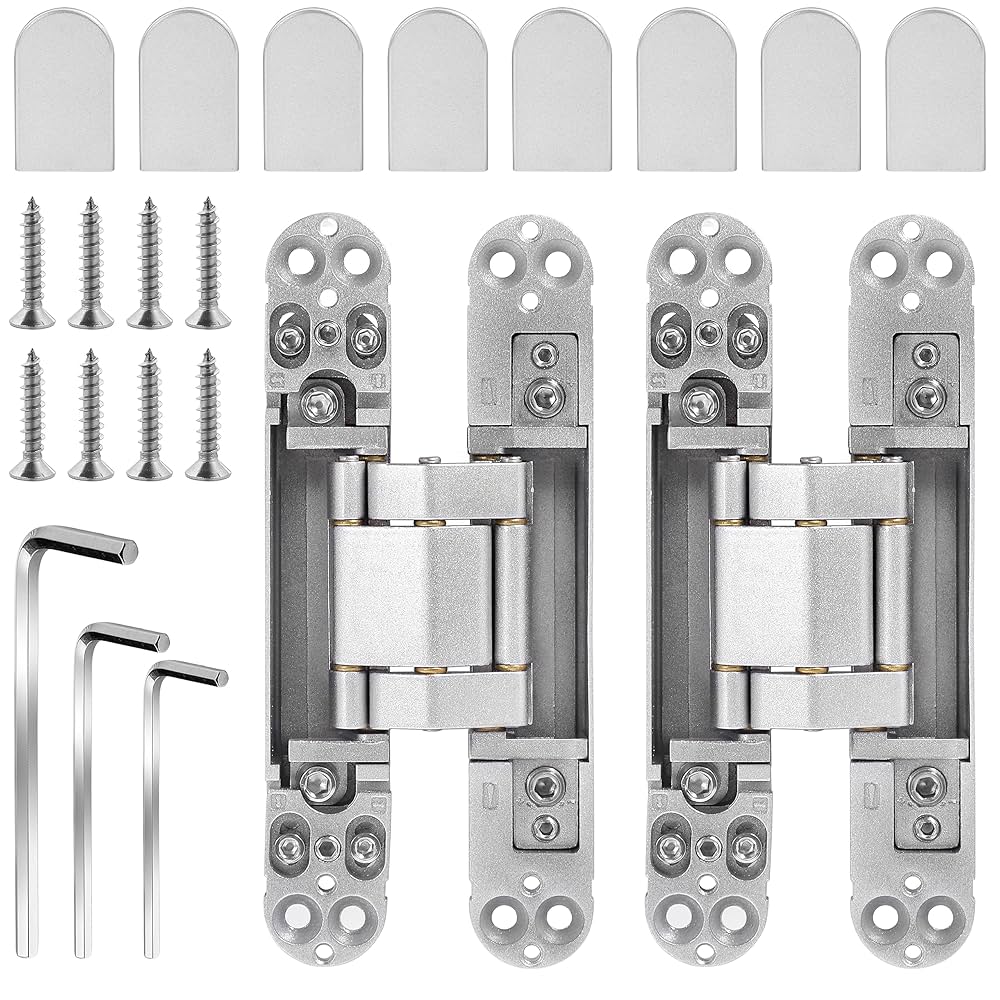

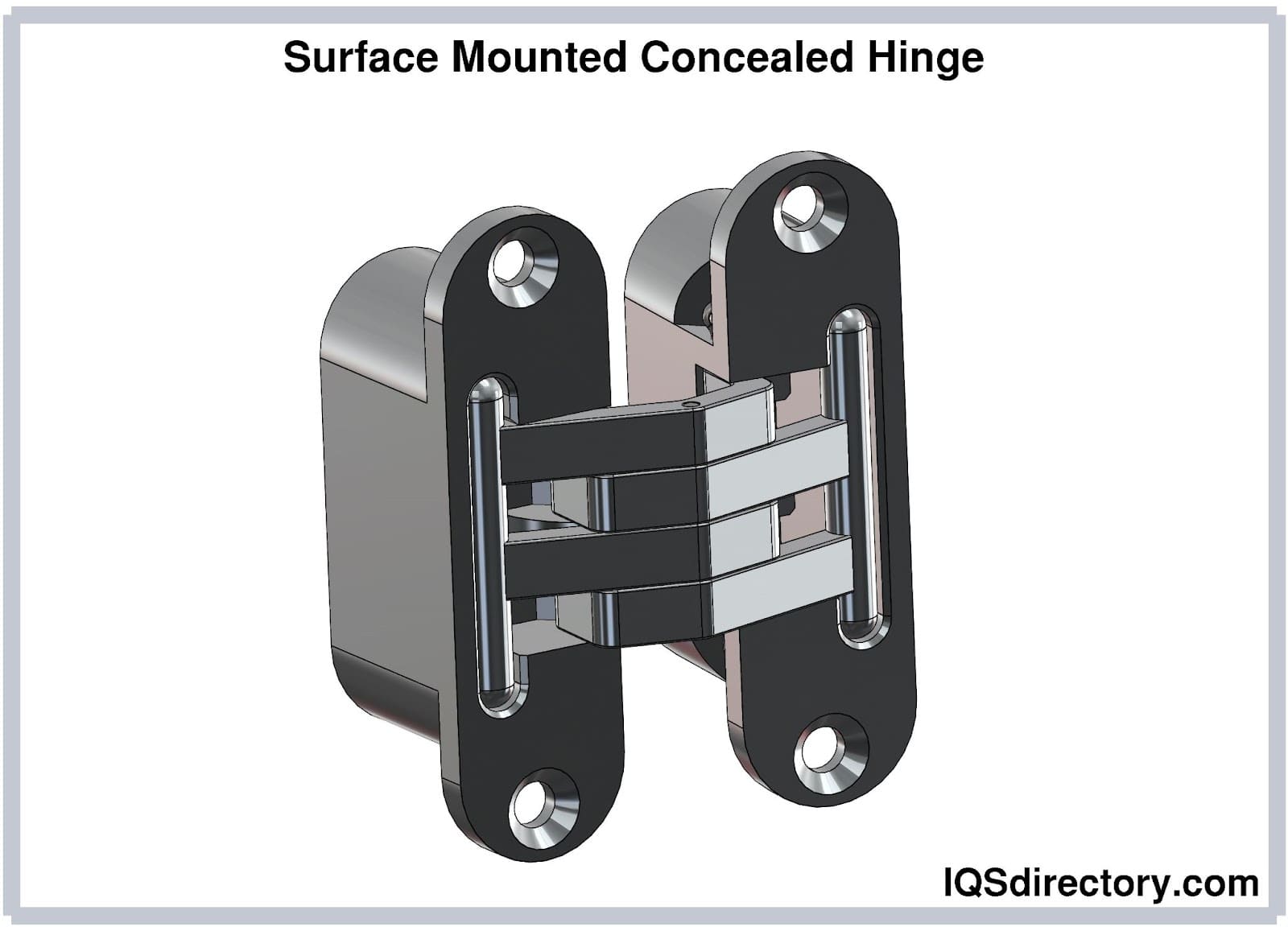

Illustrative image related to hidden hinge

How Does Steel Perform as a Material for Hidden Hinges?

Steel, particularly stainless steel, is widely used in hidden hinges due to its strength and durability. It offers excellent corrosion resistance, making it suitable for environments exposed to moisture or chemicals. Steel hinges can withstand high temperatures and pressures, which is beneficial in industrial applications.

Pros: Steel hinges are robust and long-lasting, providing reliable performance in demanding conditions. They are also relatively cost-effective compared to other materials.

Cons: While stainless steel is resistant to rust, it can still corrode if not properly maintained. Additionally, the manufacturing process can be complex, requiring specialized equipment.

Impact on Application: Steel hinges are ideal for heavy doors and high-traffic areas, but they may not be suitable for applications requiring lightweight solutions.

Illustrative image related to hidden hinge

Considerations for International Buyers: Buyers from regions like Nigeria and Germany should ensure compliance with ASTM or DIN standards for steel quality, especially in construction and industrial applications.

What Are the Benefits of Using Brass in Hidden Hinges?

Brass is another popular choice for hidden hinges, known for its aesthetic appeal and corrosion resistance. It is often used in decorative applications where appearance is as important as functionality.

Pros: Brass hinges are visually appealing and resist tarnishing, making them suitable for high-end residential and commercial applications. They also provide good mechanical strength.

Cons: Brass can be more expensive than steel and may not withstand heavy loads as effectively. It is also softer, which can lead to wear over time.

Impact on Application: Brass is ideal for lightweight doors and decorative installations, but its softness limits its use in heavy-duty applications.

Illustrative image related to hidden hinge

Considerations for International Buyers: Buyers should be aware of the varying quality standards for brass in different regions, ensuring compliance with local regulations regarding metal content and manufacturing practices.

How Does Plastic Compare as a Material for Hidden Hinges?

Plastic hinges, often made from high-density polyethylene (HDPE) or polycarbonate, are increasingly popular due to their lightweight nature and resistance to corrosion.

Pros: Plastic hinges are lightweight, easy to install, and resistant to moisture and chemicals. They are also cost-effective and can be produced in various colors and finishes.

Cons: Plastic may not offer the same load-bearing capacity as metal hinges, making them less suitable for heavy applications. They can also be affected by extreme temperatures, leading to potential deformation.

Impact on Application: Plastic hinges are ideal for lightweight doors, cabinets, and applications where moisture resistance is critical.

Illustrative image related to hidden hinge

Considerations for International Buyers: Buyers should check for compliance with international standards such as JIS for plastic materials, particularly in regions with strict regulations regarding material safety and environmental impact.

What Role Does Aluminum Play in Hidden Hinges?

Aluminum is another viable option for hidden hinges, known for its lightweight and corrosion-resistant properties. It is often used in applications where weight reduction is a priority.

Pros: Aluminum hinges are lightweight, resistant to rust, and can be anodized for enhanced durability. They are also relatively easy to manufacture and customize.

Cons: While aluminum is strong for its weight, it may not be as durable as steel in high-stress applications. Additionally, the cost can be higher than that of plastic.

Impact on Application: Aluminum is suitable for lightweight doors and applications requiring a balance between strength and weight, such as in aviation or automotive industries.

Considerations for International Buyers: Buyers should ensure that aluminum hinges meet relevant standards, such as ASTM for aerospace applications, especially in regions with stringent safety regulations.

Summary Table of Material Selection for Hidden Hinges

| Material | Typical Use Case for hidden hinge | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy doors, industrial applications | High strength and durability | Corrosion potential without maintenance | Medium |

| Brass | Decorative applications | Aesthetic appeal and corrosion resistance | Softer, less load-bearing capacity | High |

| Plastic | Lightweight doors, cabinets | Moisture and chemical resistance | Limited load capacity, deformation risk | Low |

| Aluminum | Lightweight doors, automotive | Lightweight and corrosion-resistant | Not as durable under heavy stress | Medium |

This strategic material selection guide provides insights into the various materials used for hidden hinges, helping international B2B buyers make informed decisions based on their specific application needs and regional compliance requirements.

Illustrative image related to hidden hinge

In-depth Look: Manufacturing Processes and Quality Assurance for hidden hinge

What Are the Main Stages of Hidden Hinge Manufacturing?

The manufacturing process for hidden hinges involves several key stages that ensure quality and functionality. Understanding these stages is crucial for B2B buyers who prioritize durability and performance in their procurement decisions.

Material Preparation: What Materials Are Used in Hidden Hinges?

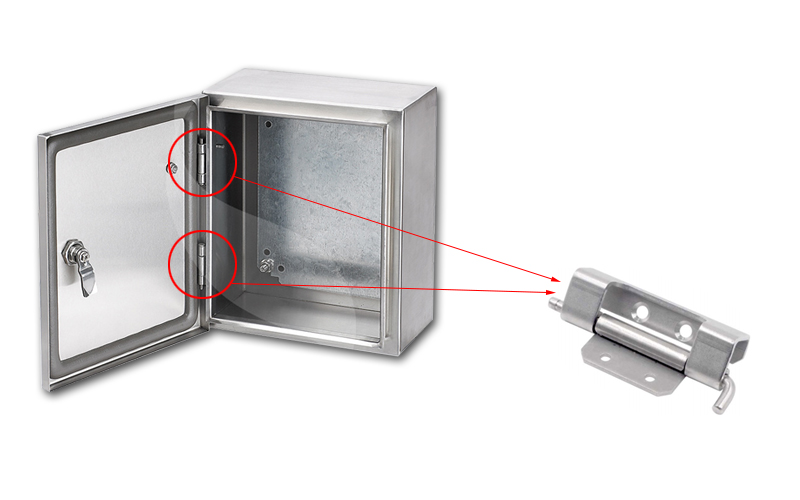

The first stage in the manufacturing of hidden hinges is material preparation. Typically, high-quality materials such as stainless steel or cold-rolled steel are used. Stainless steel is favored for its corrosion resistance, while cold-rolled steel offers strength and durability. The choice of material impacts the hinge’s lifespan and performance under various conditions, making it essential for buyers to inquire about material specifications.

How Are Hidden Hinges Formed?

Once the materials are prepared, the next step is forming. This involves cutting, stamping, or machining the metal to create the hinge components. Advanced techniques such as laser cutting and CNC machining are often employed to achieve precision. These methods ensure that each part fits together perfectly, which is critical for the hinge’s functionality. For buyers, understanding the forming techniques can provide insights into the hinge’s overall quality and performance.

What Is the Assembly Process for Hidden Hinges?

After forming, the hinge components undergo assembly. This stage involves joining the various parts, including the hinge plates, pins, and any additional mechanisms like springs or latches. Automated assembly lines may be used for efficiency, but manual assembly is also common to ensure quality control. Buyers should consider asking about the assembly process, as it can affect the hinge’s reliability and ease of installation.

What Finishing Techniques Are Applied to Hidden Hinges?

The final manufacturing stage is finishing, which enhances both aesthetics and corrosion resistance. Common finishing techniques include powder coating, electroplating, and polishing. These processes not only improve the hinge’s appearance but also contribute to its durability. Buyers should evaluate the finishing options available, as different finishes may be better suited for specific environments, especially in regions with high humidity or exposure to chemicals.

How Is Quality Assurance Implemented in Hidden Hinge Manufacturing?

Quality assurance (QA) is a critical aspect of the hidden hinge manufacturing process, ensuring that the final product meets industry standards and customer expectations. Understanding these QA practices can help B2B buyers make informed decisions when selecting suppliers.

What International Standards Should B2B Buyers Consider?

Manufacturers of hidden hinges often adhere to international standards such as ISO 9001, which focuses on quality management systems. Compliance with ISO standards indicates that a manufacturer has established processes to ensure consistent quality. Additionally, industry-specific certifications like CE (for European markets) and API (for applications in the oil and gas sector) may also apply. B2B buyers should verify that their suppliers hold relevant certifications to ensure product reliability.

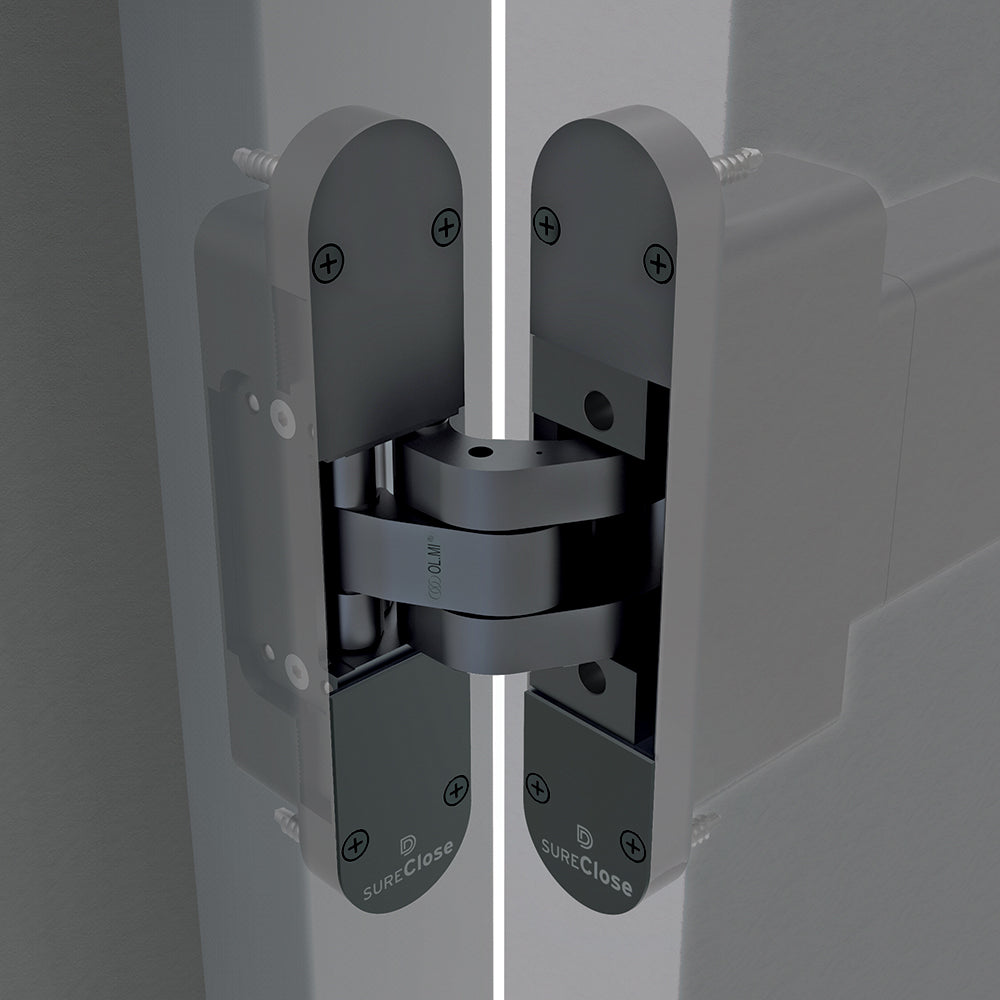

Illustrative image related to hidden hinge

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are essential throughout the manufacturing process. These typically include:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified requirements.

-

In-Process Quality Control (IPQC): During manufacturing, periodic checks are performed to monitor the production process and detect any deviations from quality standards.

-

Final Quality Control (FQC): Once assembly is complete, the final product undergoes thorough testing to ensure it meets all specifications and performance criteria.

B2B buyers should inquire about the specific quality control procedures implemented by manufacturers to ensure that their products will perform reliably in the field.

What Common Testing Methods Are Used for Hidden Hinges?

Testing methods play a crucial role in quality assurance. Common testing methods for hidden hinges include:

-

Load Testing: This assesses the strength and durability of the hinge under specified load conditions. It helps determine if the hinge can withstand the weight of the door or panel it will support.

-

Corrosion Resistance Testing: This evaluates how well the hinge withstands exposure to moisture and corrosive environments. This is especially important for buyers in humid regions.

-

Cycle Testing: This simulates the life cycle of the hinge by repeatedly opening and closing it to assess wear and tear over time.

Understanding these testing methods can provide B2B buyers with confidence in the longevity and reliability of the hinges they are considering.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must have a strategy for verifying the quality control practices of potential suppliers. Here are some actionable steps:

What Should Buyers Look for in Supplier Audits and Reports?

Requesting audit reports from suppliers can provide insights into their quality management systems. These reports typically detail compliance with ISO standards and highlight any areas for improvement. Buyers should look for recent audits to ensure the supplier’s practices are up to date.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can add an extra layer of assurance. These independent entities can perform quality checks at various stages of the manufacturing process, providing unbiased evaluations of the product’s quality. Buyers should consider incorporating third-party inspections as part of their procurement strategy.

What Are the Quality Control Nuances for International Buyers?

For international B2B buyers, especially from diverse markets like Africa, South America, the Middle East, and Europe, understanding local regulations and standards is crucial. Buyers should ensure that their suppliers comply with both international and local quality standards, as this can affect the product’s acceptance in their respective markets. Additionally, considering logistical factors, such as shipping and handling practices, can further impact product integrity upon arrival.

Conclusion: How to Make Informed Decisions When Sourcing Hidden Hinges

In summary, understanding the manufacturing processes and quality assurance practices for hidden hinges is vital for B2B buyers. By focusing on the key stages of manufacturing, relevant quality standards, testing methods, and supplier verification processes, buyers can make informed decisions that enhance their procurement strategies. Prioritizing quality will not only ensure product reliability but also contribute to long-term operational success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hidden hinge’

This guide provides a practical checklist for B2B buyers looking to procure hidden hinges, which are essential for creating concealed storage solutions in various applications, from residential to commercial. By following these steps, you can ensure you choose the right product and supplier, enhancing security and aesthetics in your projects.

Illustrative image related to hidden hinge

Step 1: Define Your Technical Specifications

Before starting your search, clearly outline the technical specifications required for your hidden hinges. Consider factors such as size, weight capacity, material (e.g., stainless steel for durability), and specific applications (e.g., wall safes or concealed doors). This clarity will help you communicate effectively with suppliers and ensure compatibility with your intended use.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in hidden hinges. Look for manufacturers with a proven track record and positive reviews in your industry. Utilize online marketplaces, industry forums, and trade shows to gather a list of potential suppliers and their offerings.

Step 3: Evaluate Supplier Certifications

Verify that your potential suppliers have the necessary certifications, such as ISO or CE, which indicate adherence to international quality and safety standards. Certifications can also reflect a supplier’s commitment to sustainability and ethical practices, which are increasingly important in global sourcing.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples of the hidden hinges to assess their quality and performance. Testing samples can provide insights into ease of installation, functionality, and durability. Ensure the samples align with your technical specifications and application needs.

Step 5: Analyze Pricing and Terms

Compare pricing across different suppliers while considering the overall value. Look for transparent pricing structures that include shipping and handling costs. Additionally, review payment terms, minimum order quantities, and potential discounts for bulk purchases to optimize your budget.

Step 6: Check Customer Support and Warranty Policies

Investigate the customer support services offered by potential suppliers. Reliable customer support can be crucial for resolving any issues that arise post-purchase. Additionally, review warranty policies to ensure that you have coverage in case of defects or performance issues with the hinges.

Step 7: Finalize Your Order and Monitor Delivery

Once you have selected a supplier, finalize your order with clear specifications and expectations. Monitor the delivery process to ensure timely arrival and check for any discrepancies upon receipt. Establishing good communication with your supplier can help address any issues quickly and maintain a positive business relationship.

By following this checklist, B2B buyers can make informed decisions when sourcing hidden hinges, ensuring they select high-quality products that meet their specific needs while fostering strong supplier relationships.

Illustrative image related to hidden hinge

Comprehensive Cost and Pricing Analysis for hidden hinge Sourcing

What Are the Key Cost Components in Hidden Hinge Sourcing?

When analyzing the costs associated with sourcing hidden hinges, several key components must be considered. Materials typically account for a significant portion of the total cost. High-quality materials, such as 18-gauge steel or specialized finishes, enhance durability and functionality but also increase costs.

Labor costs encompass the wages paid to workers involved in production, which can vary widely based on geographical location. Regions with higher labor costs, such as Germany, may yield a higher price point compared to more cost-effective markets in Africa or South America.

Manufacturing overhead includes utilities, rent, and administrative expenses. This can vary significantly between suppliers, impacting overall pricing.

Tooling costs refer to the initial investment in machinery and equipment necessary for production. Custom tooling for specialized hinges can lead to higher costs but may be necessary for specific applications.

Illustrative image related to hidden hinge

Quality Control (QC) processes are essential to ensure product reliability and safety. The costs associated with QC can influence pricing, particularly if certification is required for specific markets.

Logistics costs, including shipping and handling, must also be factored in. International shipping can add complexity and costs, especially for buyers in regions like Nigeria or the Middle East, where transportation infrastructure may vary.

Margins are the final component, reflecting the supplier’s profit. Understanding the margin expectations can aid in negotiations.

How Do Price Influencers Impact Hidden Hinge Sourcing?

Several factors influence the pricing of hidden hinges, starting with volume or Minimum Order Quantity (MOQ). Higher volumes typically yield lower per-unit costs due to economies of scale. Buyers should evaluate their needs carefully to determine optimal order sizes.

Specifications and customization also play a critical role. Custom designs or finishes often lead to increased costs, as they require more time and resources to produce. Buyers should assess whether standard options meet their needs before committing to custom solutions.

The quality and certifications of the hinges can significantly impact pricing. Products that meet international standards or specific certifications may command higher prices but can also reduce liability and increase buyer confidence.

Illustrative image related to hidden hinge

Supplier factors such as reputation, reliability, and production capacity can influence prices. Engaging with well-established suppliers may come at a premium but often provides greater assurance of quality and service.

Incoterms, or international commercial terms, can affect the total landed cost of goods. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) determine who bears the cost and risk at various stages of transport, influencing the final price.

What Buyer Tips Can Enhance Cost-Efficiency in Hidden Hinge Sourcing?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency. Negotiation is key; understanding market pricing and establishing relationships with suppliers can lead to better terms and discounts.

It is essential to calculate the Total Cost of Ownership (TCO), which includes not just the initial purchase price but also long-term costs such as maintenance, replacement, and potential downtime. Buyers should consider these factors when evaluating different suppliers.

Illustrative image related to hidden hinge

Understanding pricing nuances specific to regions is crucial. For instance, logistics costs may be higher in remote areas, impacting overall pricing. Buyers should seek suppliers with efficient distribution networks to mitigate these costs.

Lastly, it is important to note that prices are subject to fluctuation based on market conditions, material availability, and geopolitical factors. Therefore, buyers should approach pricing discussions with flexibility and be prepared for potential adjustments.

Disclaimer on Indicative Prices

Pricing for hidden hinges can vary widely based on the factors discussed above. The information provided here is indicative and may not reflect actual market conditions at the time of purchase. Buyers are encouraged to conduct thorough market research and obtain quotes from multiple suppliers to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing hidden hinge With Other Solutions

Exploring Alternatives to Hidden Hinges for Concealed Storage Solutions

In the quest for innovative storage solutions, hidden hinges provide a unique method for concealing access points behind standard picture frames. However, several alternatives exist that can achieve similar objectives. This analysis compares hidden hinges with concealed door hinges and traditional cabinet hinges, assessing their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Hidden Hinge | Concealed Door Hinges | Traditional Cabinet Hinges |

|---|---|---|---|

| Performance | Excellent for quick access and concealment | High durability and stability | Good for standard cabinet doors |

| Cost | Moderate price range | Higher initial investment | Generally lower cost |

| Ease of Implementation | Relatively easy to install with basic tools | May require professional installation | Simple DIY installation |

| Maintenance | Low maintenance, durable materials | Requires occasional checks for wear | Varies; can be prone to rust if not treated |

| Best Use Case | Concealing wall safes and utilities | High-end residential or commercial doors | Standard cabinetry in kitchens/bathrooms |

What Are the Pros and Cons of Concealed Door Hinges?

Concealed door hinges are designed to be installed within the door and frame, offering a sleek appearance without visible hardware. Their performance is exceptional for heavy doors, providing stability and durability. However, they often require a higher initial investment and may necessitate professional installation, which can increase overall project costs. Maintenance is generally low, but it’s advisable to periodically inspect them for wear. They are best suited for high-end residential or commercial environments where aesthetics and functionality are paramount.

How Do Traditional Cabinet Hinges Compare?

Traditional cabinet hinges are a common choice for kitchen and bathroom cabinetry. They are typically more affordable than both hidden and concealed hinges, making them a budget-friendly option for many projects. Installation is straightforward, often achievable as a DIY task, which can save costs on labor. However, their visibility can detract from a clean, modern aesthetic, and they may not provide the same level of concealment as hidden hinges. Maintenance can vary; while many are designed to last, untreated metal hinges can rust, requiring periodic replacement or upkeep.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the appropriate hinge solution, B2B buyers should consider the specific requirements of their projects. Hidden hinges are ideal for applications where concealment and quick access are essential, such as in security or utility scenarios. Conversely, concealed door hinges may be the best choice for high-end projects that demand aesthetics and durability, while traditional cabinet hinges work well for standard cabinetry where budget constraints are a priority. Ultimately, understanding the unique benefits and limitations of each option will enable buyers to make informed decisions that align with their operational needs and financial considerations.

Essential Technical Properties and Trade Terminology for hidden hinge

What Are the Key Technical Properties of Hidden Hinges?

Hidden hinges, often referred to as concealed hinges, are characterized by several critical specifications that enhance their functionality and application. Understanding these properties is essential for B2B buyers looking to make informed purchasing decisions.

Illustrative image related to hidden hinge

-

Material Grade

– Hidden hinges are typically made from high-grade materials such as 18-gauge steel or stainless steel. The choice of material directly impacts durability, corrosion resistance, and the overall lifespan of the hinge. For commercial applications, selecting a hinge with a higher material grade ensures it can withstand frequent use without failure. -

Load Capacity

– This specification indicates the maximum weight the hinge can support. It is vital for B2B buyers to consider load capacity, particularly when the hinge is used in heavy doors or panels. An inadequate load capacity can lead to hinge malfunction, compromising both safety and functionality. -

Finish Options

– Hidden hinges come in various finishes, such as polished nickel, black, or brushed stainless steel. The finish not only influences aesthetic appeal but also affects corrosion resistance and maintenance requirements. Buyers should select finishes that align with their design preferences and environmental conditions. -

Installation Tolerance

– This refers to the permissible variation in the hinge’s dimensions during installation. A hinge with tight tolerances ensures a snug fit, reducing gaps and enhancing the overall appearance of the installation. It is crucial for B2B buyers to understand tolerances to ensure compatibility with their existing structures. -

Operational Mechanism

– Hidden hinges may feature different operational mechanisms, including self-closing or friction-based designs. The choice of mechanism affects ease of use and the level of security provided. Buyers should evaluate the operational needs of their application to select the most suitable hinge type. -

Magnetic Latching System

– Many hidden hinges incorporate a magnetic latch that keeps the door or panel securely closed when not in use. This feature is essential for applications requiring both concealment and quick access. Understanding the latching mechanism can help buyers ensure they choose a hinge that meets their security requirements.

What Are Common Trade Terminology and Jargon in the Hidden Hinge Industry?

Familiarity with industry terminology is crucial for effective communication and negotiation in B2B transactions. Here are some key terms relevant to hidden hinges:

-

OEM (Original Equipment Manufacturer)

– This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of hidden hinges, OEMs can provide custom solutions tailored to specific project requirements, which is essential for large-scale buyers. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is critical for businesses looking to maintain inventory levels while avoiding excess stock. Buyers should assess their needs to negotiate favorable terms with suppliers. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For hidden hinges, an RFQ allows buyers to compare offers from multiple suppliers, ensuring they receive the best value for their investment. -

Incoterms (International Commercial Terms)

– These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers dealing with suppliers across borders, as it clarifies who bears the risk and costs associated with shipping and delivery. -

Lead Time

– Lead time refers to the duration from placing an order to receiving the product. This is a critical consideration for businesses that need to synchronize hinge deliveries with project timelines. Buyers should inquire about lead times to ensure timely procurement. -

Warranty Terms

– Warranty terms outline the conditions under which a supplier will repair or replace defective products. Understanding warranty terms is vital for B2B buyers, as it provides insight into the product’s reliability and the manufacturer’s confidence in their offering.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing hidden hinges for their projects, enhancing both security and aesthetic appeal in their applications.

Navigating Market Dynamics and Sourcing Trends in the hidden hinge Sector

What Are the Current Market Dynamics and Key Trends in the Hidden Hinge Sector?

The hidden hinge market is witnessing significant growth, driven by a surge in demand for innovative, space-saving solutions in both residential and commercial applications. As urbanization continues, particularly in regions like Africa and South America, the need for effective storage solutions that maximize space is becoming paramount. Additionally, the rising trend of home automation and smart technology is influencing the design and functionality of hidden hinges, making them more desirable among tech-savvy consumers.

International buyers are increasingly looking for suppliers that offer custom solutions tailored to specific market needs. The emergence of B2B tech platforms is facilitating this trend, allowing businesses to connect with manufacturers worldwide. In Europe, for example, there is a growing preference for high-quality, durable materials that ensure longevity and safety, particularly in applications such as concealed doors and security systems.

Furthermore, the hidden hinge market is becoming more competitive, with manufacturers focusing on innovative designs and enhanced functionalities. This includes the development of magnetic latches and easy-install systems that simplify the installation process, making it more accessible for end-users. As a result, international B2B buyers should prioritize suppliers who stay ahead of these trends, ensuring they can meet evolving customer demands effectively.

How Are Sustainability and Ethical Sourcing Impacting the Hidden Hinge Industry?

Sustainability and ethical sourcing are increasingly vital considerations for businesses operating in the hidden hinge sector. As environmental concerns rise, consumers and businesses alike are seeking products that minimize ecological impact. Manufacturers are now focusing on sourcing materials that are not only durable but also environmentally friendly. This includes the use of recycled metals and sustainable manufacturing processes that reduce waste and energy consumption.

For B2B buyers, understanding the supply chain is crucial. Partnering with suppliers who prioritize ethical practices can enhance brand reputation and customer loyalty. Certifications such as ISO 14001 for environmental management and FSC certification for sustainable sourcing can serve as indicators of a supplier’s commitment to sustainability.

Illustrative image related to hidden hinge

Moreover, buyers should also consider the lifecycle of hidden hinges. Products that can be easily disassembled and recycled at the end of their life cycle contribute to a circular economy, further minimizing environmental impact. Therefore, when sourcing hidden hinges, it is essential for businesses to evaluate potential suppliers based on their environmental practices and certifications.

What Is the Brief Evolution and History of Hidden Hinges?

The concept of hidden hinges has evolved significantly over the years, originating from traditional hinge designs that were often bulky and visible. With the advent of modern design principles, the demand for seamless aesthetics in architecture and interior design catalyzed the development of concealed hinges. Initially used primarily in high-end residential projects, hidden hinges have now found applications in commercial spaces, including hotels, offices, and retail environments.

Technological advancements have also played a critical role in the evolution of hidden hinges. The introduction of materials like stainless steel and specialized coatings has enhanced durability and resistance to wear, making them suitable for a variety of environments. Today, hidden hinges not only serve functional purposes but also contribute to the overall design ethos of spaces, aligning with contemporary trends towards minimalism and clean lines.

As the market continues to grow, the focus on innovation and sustainability will likely shape the future of hidden hinge designs, making them an essential component for modern construction and renovation projects.

Frequently Asked Questions (FAQs) for B2B Buyers of hidden hinge

-

How do I solve installation challenges with hidden hinges?

Installing hidden hinges can be tricky, especially if you’re unfamiliar with the process. To ensure a smooth installation, first, review the manufacturer’s guidelines thoroughly. Use appropriate tools and ensure that the picture frame or door is properly supported while you work. It may also be beneficial to engage a local technician with experience in installing similar products. For large projects, consider purchasing a sample to test the installation process before committing to a bulk order. -

What is the best type of hidden hinge for concealed storage solutions?

The best type of hidden hinge for concealed storage largely depends on the application. For wall safes or access panels, look for heavy-duty options made from durable materials like steel, which can withstand frequent use. Additionally, ensure the hinge allows for easy opening and closing without compromising the aesthetics of the frame. Brands that offer customizable options can also provide tailored solutions for specific needs, enhancing functionality and security. -

What are the minimum order quantities (MOQ) for hidden hinges from international suppliers?

Minimum order quantities for hidden hinges can vary significantly between suppliers. Typically, MOQs may range from 50 to 500 units depending on the manufacturer and product type. It’s crucial to discuss these terms upfront with potential suppliers to understand their production capabilities and whether they can accommodate smaller orders for testing purposes. Some suppliers may also offer flexible MOQs for first-time buyers or larger projects. -

What payment terms are common in international B2B transactions for hidden hinges?

Common payment terms in international transactions can include options like 30% deposit upon order confirmation and 70% balance before shipment. Some suppliers may also accept letters of credit or escrow services to provide additional security for both parties. It’s essential to clarify payment terms during negotiations to ensure they align with your cash flow and budgeting requirements. -

How can I vet suppliers for hidden hinges effectively?

Vetting suppliers is crucial for ensuring quality and reliability. Start by checking their certifications and industry experience, such as ISO certifications or previous client testimonials. Request samples to evaluate product quality before placing a larger order. Additionally, consider utilizing platforms that offer supplier ratings and reviews, and engage in direct communication to assess their responsiveness and willingness to meet your requirements. -

What quality assurance measures should I expect from suppliers of hidden hinges?

Reputable suppliers should have established quality assurance processes, including product testing and inspection protocols. Look for suppliers that provide detailed reports on material specifications, load-bearing capabilities, and durability tests. Additionally, inquire about their return policy and warranty offerings, as these can provide insight into their commitment to quality and customer satisfaction. -

What are the logistics considerations when importing hidden hinges?

When importing hidden hinges, consider factors such as shipping costs, customs duties, and lead times. It’s advisable to work with a logistics partner who understands the regulations and requirements specific to your region, especially in Africa, South America, or the Middle East. Ensure that you factor in potential delays due to customs clearance and choose a shipping method that balances cost with delivery speed. -

How can I customize hidden hinges for my specific applications?

Many suppliers offer customization options for hidden hinges, allowing you to specify dimensions, finishes, and functionalities that meet your unique application needs. When contacting suppliers, provide detailed specifications and any design considerations. Discussing your requirements upfront will enable suppliers to propose suitable solutions and timelines for production, ensuring that the final product aligns with your project goals.

Top 9 Hidden Hinge Manufacturers & Suppliers List

1. The Hidden Hinge – Invisible Gun Storage Solution

Domain: thehiddenhinge.com

Registered: 2019 (6 years)

Introduction: Gun Storage Hidden Hinge | Invisible Hinge for Wall Safe Gun Storage – Made in the U.S.A. Features: invisible hardware, creates instant access, works with most picture frames, installs easily in under 30 minutes, no alterations to wall or picture frame. Allows homeowners to conceal access panels, wall safes, or storage areas behind a standard picture frame. Patent No. 11,814,887 unique design keep…

2. HingeOutlet – Concealed Hinges

Domain: hingeoutlet.com

Registered: 2004 (21 years)

Introduction: Concealed Hinges available at HingeOutlet. Free shipping on orders over $160. Wide variety of hinges for both commercial and residential applications. Includes guides for installation and selection of hinges. Various types of concealed hinges offered, including concealed cabinet hinges, soft close cabinet hinges, and more. Expert support available at 888-250-8133.

3. Swinging Cafe Doors – Stainless Steel Hidden Cabinet Door Pivot Hinge

Domain: swingingcafedoors.com

Registered: 2008 (17 years)

Introduction: Product Name: Stainless Steel Hidden Cabinet Door Pivot Hinge | Invisible Door Hinge

MSRP: $44.99 – $50.99

SKU: SSHDPIVOT-S-O

UPC: Not specified

Availability: Ships Same Day or Next Day | 30 Day Return Policy

Bulk Pricing: 5% off for 3-10 units, 10% off for 11 or more units

Door Weight Capacity: Small holds up to 50 lbs, Large holds up to 100 lbs

Finish: Stainless Steel

Dimensions: Small – 2.87″L …

4. Woodworker Express – Invisible Cabinet Hinges

Domain: woodworkerexpress.com

Registered: 2013 (12 years)

Introduction: This company, Woodworker Express – Invisible Cabinet Hinges, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Sugatsune – Invisible Door Hinges

Domain: sugatsune.com

Registered: 1996 (29 years)

Introduction: Invisible door hinges, also known as concealed or hidden hinges, provide a clean, minimal look for architectural doors, suitable for upscale residential and commercial environments. They come in conventional and 3-way adjustable options, allowing for adjustments in any direction for a perfect fit. Available finishes include black, white, brass, gold, silver, dull chrome, polished nickel, and dull …

6. Hardware Hut – Concealed Door Hinges

Domain: hardwarehut.com

Registered: 1998 (27 years)

Introduction: This company, Hardware Hut – Concealed Door Hinges, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Reddit – Hidden Hinge for Interior Doors

Domain: reddit.com

Introduction: Hidden hinge for interior door installation, designed for flush mounting on the jamb while allowing the door to outswing.

8. Hardwaresource – Specialty Concealed Hinges

Domain: hardwaresource.com

Registered: 1996 (29 years)

Introduction: Specialty Concealed Hinges include various models such as FritsJurgens System One Pivot Set (1100 lbs), Tectus TE 240 (for 1-3/8″ Thick Doors), Tectus TE 340 (for 1-3/4″ Thick Doors), Tectus TE 540 (for 1-3/4″ Thick Doors), Tectus TE 640 (A8 Cladding Hinge), Anselmi AN 170 (3D Adjustable Concealed Hinge), Weider Free Swinging 3D Adjustable Concealed Hinges, Weider Hold Open 3D Adjustable Concealed…

9. Sugatsune – Concealed Hinges

Domain: global.sugatsune.com

Registered: 1996 (29 years)

Introduction: Concealed hinges (hidden hinges) are designed to be invisible when a door or lid is closed, providing a seamless and aesthetically pleasing appearance. They come in various types, including those that integrate with thin door frames (8 mm), surface mount types, and options with features like ‘separable’ and ‘temporary holding’ for easier assembly. The HES Series includes several models such as: 1….

Strategic Sourcing Conclusion and Outlook for hidden hinge

What Are the Key Benefits of Strategic Sourcing for Hidden Hinges?

In conclusion, strategic sourcing of hidden hinges presents a significant opportunity for international B2B buyers to enhance product offerings while meeting the growing demand for security and aesthetic solutions. The unique design of hidden hinges allows for easy installation, quick access, and discreet storage, making them ideal for various applications—from concealed gun storage to hidden access panels. As buyers from regions such as Africa, South America, the Middle East, and Europe explore these innovations, they can benefit from the competitive pricing and diverse options available.

How Can Buyers Leverage the Market Trends for Hidden Hinges?

The increasing focus on home security and design aesthetics globally is driving demand for hidden hinges. Buyers are encouraged to capitalize on this trend by sourcing high-quality products that meet international standards. Engaging with reputable suppliers who prioritize durability and innovative designs can significantly enhance your product portfolio and customer satisfaction.

What’s Next for International Buyers in the Hidden Hinge Market?

As we look to the future, the hidden hinge market is poised for growth. By strategically sourcing these products, businesses can tap into a burgeoning market that values discretion and functionality. We encourage buyers to explore partnerships with manufacturers that offer robust support and innovative designs. Embrace this opportunity to enhance your offerings and meet the evolving needs of your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.