Everything You Need to Know About Heat Seal Machine Spices Sourcing in 2025

Introduction: Navigating the Global Market for heat seal machine spices

The global market for heat seal machine spices is rapidly evolving, presenting a significant challenge for international B2B buyers seeking reliable and efficient packaging solutions. As the demand for spices continues to soar across regions like Africa, South America, the Middle East, and Europe, sourcing the right heat seal machines becomes crucial for businesses aiming to enhance productivity and maintain product integrity. This comprehensive guide addresses the complexities of selecting heat seal machines tailored for spice packaging, covering essential aspects such as types of machines, their specific applications, and the importance of supplier vetting.

In the following sections, we will explore the various types of heat seal machines available, highlighting their functionalities and advantages in the spice industry. Additionally, we will delve into the cost considerations that can impact your investment, ensuring that you are equipped to make informed decisions. With insights into the latest technological advancements and practical tips for optimizing your packaging processes, this guide empowers B2B buyers to navigate the global market confidently. Whether you are operating in Brazil, Germany, or any other region, understanding the nuances of heat seal machine spices will help you streamline operations, reduce waste, and ultimately achieve a speedy return on investment.

Understanding heat seal machine spices Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Continuous Heat Sealers | Automated sealing process, high-speed operation | High-volume spice packaging | Pros: Efficient for large batches; reduces labor costs. Cons: Higher upfront investment. |

| Semi-Automatic Sealers | Manual loading with automated sealing | Small to medium spice businesses | Pros: Lower cost; flexibility in operation. Cons: Slower than fully automated options. |

| Vertical Form Fill Seal | Combines forming, filling, and sealing in one machine | Diverse spice packaging (powders, granules) | Pros: Space-efficient; versatile for different products. Cons: May require more maintenance. |

| Pouch Sealers | Specifically designed for pre-made pouches | Retail spice packaging | Pros: Quick setup; attractive presentation. Cons: Limited to pre-made pouch sizes. |

| Multi-Head Weighers | Accurate weight measurement with multiple hoppers | Bulk spice distribution | Pros: High accuracy; reduces product waste. Cons: Complex setup and calibration. |

What are the Key Characteristics of Continuous Heat Sealers for Spices?

Continuous heat sealers are designed for high-speed operations, making them ideal for businesses with substantial production volumes. These machines automate the sealing process, allowing for seamless integration into existing production lines. They are particularly suitable for businesses looking to scale up their operations, as they significantly reduce labor costs and increase throughput. When considering a continuous heat sealer, buyers should evaluate the machine’s speed, compatibility with various packaging materials, and maintenance requirements to ensure it aligns with their production goals.

How Do Semi-Automatic Sealers Benefit Small to Medium Spice Businesses?

Semi-automatic sealers offer a balance between manual and fully automated systems, making them an excellent choice for small to medium-sized spice companies. These machines require manual loading but automate the sealing process, allowing for flexibility and lower initial investment compared to fully automated systems. They are particularly advantageous for businesses that need to adapt quickly to changes in demand or packaging sizes. Buyers should consider the machine’s ease of use, maintenance needs, and sealing speed when making a purchasing decision.

Why Choose Vertical Form Fill Seal Machines for Spice Packaging?

Vertical form fill seal (VFFS) machines are versatile solutions that can handle a wide range of spice packaging needs, from powders to granules. These machines create pouches from a roll of film, filling and sealing them in a single operation, which is both space-efficient and cost-effective. VFFS machines are well-suited for businesses that require quick changeovers between different products or sizes. Buyers should assess the machine’s adaptability to various spice types, production speed, and the quality of the seals produced.

What Are the Advantages of Using Pouch Sealers in Retail Spice Packaging?

Pouch sealers are specifically designed for sealing pre-made pouches, making them a popular choice for retail spice packaging. They allow for quick setup and can enhance the visual appeal of the product, which is crucial in retail environments. These machines are ideal for businesses that focus on small batch sizes or specialty products. When selecting a pouch sealer, buyers should consider the range of pouch sizes it can accommodate and the speed of operation to ensure it meets their packaging requirements.

How Do Multi-Head Weighers Enhance Bulk Spice Distribution?

Multi-head weighers are essential for businesses engaged in bulk spice distribution, as they provide accurate weight measurements while minimizing product waste. These machines utilize multiple hoppers to dispense the desired amount of spice quickly and accurately. They are particularly beneficial for companies that require high precision in their packaging processes, such as those dealing with premium spices. Buyers should evaluate the complexity of the setup, calibration requirements, and the machine’s speed to ensure it aligns with their operational needs.

Key Industrial Applications of heat seal machine spices

| Industry/Sector | Specific Application of heat seal machine spices | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Packaging of spice blends for retail distribution | Enhances shelf life and product integrity | Ensure compliance with local food safety regulations and standards. |

| E-commerce | Sealing individual spice packets for online sales | Reduces spoilage during transit, appealing packaging | Consider machine size and speed to meet order fulfillment demands. |

| Hospitality | Bulk packaging of spices for restaurants | Streamlines inventory management and reduces waste | Look for machines that can handle various spice types efficiently. |

| Agricultural Export | Sealing spices for export to international markets | Maintains quality during long-distance transport | Verify machine adaptability to different packaging materials. |

| Health and Wellness | Packaging of organic and specialty spices | Attracts health-conscious consumers with appealing design | Focus on machines that offer customization for branding and labeling. |

In the Food and Beverage industry, heat seal machines are critical for packaging spice blends destined for retail shelves. By providing airtight seals, these machines enhance the shelf life of spices, ensuring that flavor and freshness are preserved. Businesses must consider compliance with local food safety regulations, as well as the capability of the machine to handle various spice types and packaging formats.

For the E-commerce sector, heat seal machines play a vital role in sealing individual spice packets intended for online sales. This application reduces spoilage during transit and offers an attractive presentation to consumers. B2B buyers should evaluate the machine’s speed and size, ensuring it can meet the demands of order fulfillment while maintaining packaging quality.

In the Hospitality sector, bulk packaging of spices for restaurants is streamlined with heat seal machines, which facilitate efficient inventory management and minimize waste. The ability to package different spice types efficiently is crucial, so buyers should prioritize machines that offer versatility in handling diverse products.

For Agricultural Export, sealing spices for international markets is essential to maintain quality during long-distance transport. Heat seal machines help prevent contamination and spoilage, which is vital for preserving the product’s integrity. Buyers should verify that the machines can adapt to various packaging materials, ensuring they meet specific export requirements.

In the Health and Wellness industry, heat seal machines are used to package organic and specialty spices that cater to health-conscious consumers. The appeal of visually attractive packaging can significantly influence purchasing decisions. Buyers should focus on machines that provide customization options for branding and labeling, enabling them to stand out in a competitive market.

3 Common User Pain Points for ‘heat seal machine spices’ & Their Solutions

Scenario 1: Inconsistent Sealing Quality Leading to Product Loss

The Problem: A common challenge faced by B2B buyers in the spice industry is the inconsistency in sealing quality when using heat seal machines. This inconsistency can lead to product spoilage, contamination, and ultimately, financial loss. For instance, if the heat sealing temperature is not correctly calibrated, it may result in either weak seals that fail during handling or excessive heat that degrades the spice quality. This issue is particularly pressing for businesses looking to maintain high standards of quality and hygiene in their packaging.

The Solution: To address this issue, buyers should invest in heat seal machines with advanced temperature control features. When sourcing these machines, look for models that offer precise temperature settings and feedback mechanisms, such as digital displays that allow for real-time monitoring. Additionally, conducting regular maintenance checks to ensure that heating elements are functioning optimally can mitigate sealing inconsistencies. Training staff on the correct operational procedures, including adjusting settings based on the type of spice being packaged, can further enhance seal quality. Implementing these practices not only reduces waste but also ensures that the spices reach customers in pristine condition.

Scenario 2: Operational Inefficiencies and Downtime

The Problem: Many businesses experience operational inefficiencies due to frequent machine downtimes. This can stem from a lack of understanding of machine capabilities or improper setup for specific spice types, which can lead to delays in production schedules. For example, a spice manufacturer may use a heat seal machine that is not suited for the viscosity or flow characteristics of their products, causing blockages or malfunctions that halt production.

The Solution: To overcome this challenge, buyers should conduct a thorough analysis of their production needs before purchasing a heat seal machine. Understanding the specific characteristics of the spices being packaged—such as particle size and moisture content—can guide the selection of a machine that is well-suited for those materials. Buyers should also consider machines that offer versatility in adjusting settings for different spice types. Regular training sessions for operators can ensure they are familiar with the machine’s functions and can troubleshoot common issues quickly. Establishing a preventive maintenance schedule will help identify potential problems before they lead to significant downtime, thus maintaining a steady production flow.

Scenario 3: High Initial Investment Costs and ROI Concerns

The Problem: One of the most significant barriers to acquiring heat seal machines for spice packaging is the high initial investment cost. Many B2B buyers, particularly small and medium enterprises, may hesitate to invest in advanced machinery due to concerns about return on investment (ROI) and the fear that their production volume may not justify the expense. This hesitation can lead to continued reliance on manual packaging methods, which are less efficient and scalable.

The Solution: To address ROI concerns, buyers should evaluate the long-term benefits of heat seal machines against their initial costs. Conducting a cost-benefit analysis can provide insights into potential savings from reduced labor costs, decreased product waste, and increased packaging speed. Additionally, considering leasing options or purchasing used machines can lower upfront costs while still providing access to modern technology. It is also beneficial to research manufacturers that offer comprehensive training and support, ensuring that operators can maximize the machine’s capabilities from day one. By strategically planning the investment and focusing on the long-term efficiencies gained, buyers can achieve a favorable ROI and position their business for growth.

Strategic Material Selection Guide for heat seal machine spices

When selecting materials for heat seal machine spices, it is essential to consider the properties, advantages, and limitations of the materials used in packaging. This section will analyze four common materials: polyethylene (PE), polypropylene (PP), polyester (PET), and aluminum foil. Each material has unique characteristics that influence its suitability for different spice packaging applications.

What Are the Key Properties of Polyethylene (PE) for Heat Seal Applications?

Polyethylene is a widely used thermoplastic known for its excellent moisture barrier properties and flexibility. It can withstand temperatures up to 80°C (176°F) and offers good chemical resistance, making it suitable for packaging various spices. Its low-density form (LDPE) is particularly favored for creating flexible pouches, while high-density polyethylene (HDPE) is used for more rigid packaging.

Pros & Cons:

The advantages of PE include its low cost, ease of manufacturing, and recyclability. However, it has limited heat resistance compared to other materials, which can affect its performance under high-temperature conditions. Additionally, its lower barrier properties against oxygen and light may not be ideal for spices that require long shelf life.

How Does Polypropylene (PP) Compare for Spice Packaging?

Polypropylene is another common thermoplastic used in heat sealing applications. It has a higher temperature resistance (up to 120°C or 248°F) than PE and offers excellent clarity and gloss, enhancing the visual appeal of spice packaging. PP also exhibits good resistance to moisture and chemicals, making it suitable for a variety of spice products.

Pros & Cons:

The key advantages of PP include its durability and ability to maintain structural integrity under heat. However, it can be more expensive than PE and may require specific sealing conditions to achieve optimal results. Additionally, while it has good barrier properties, it may not provide sufficient protection against oxygen for certain spice types.

What Role Does Polyester (PET) Play in Heat Seal Applications?

Polyester, particularly in its biaxially oriented form (BOPET), is known for its exceptional strength and barrier properties. It can withstand temperatures up to 150°C (302°F) and offers excellent resistance to moisture, oxygen, and UV light, making it ideal for preserving the freshness of spices.

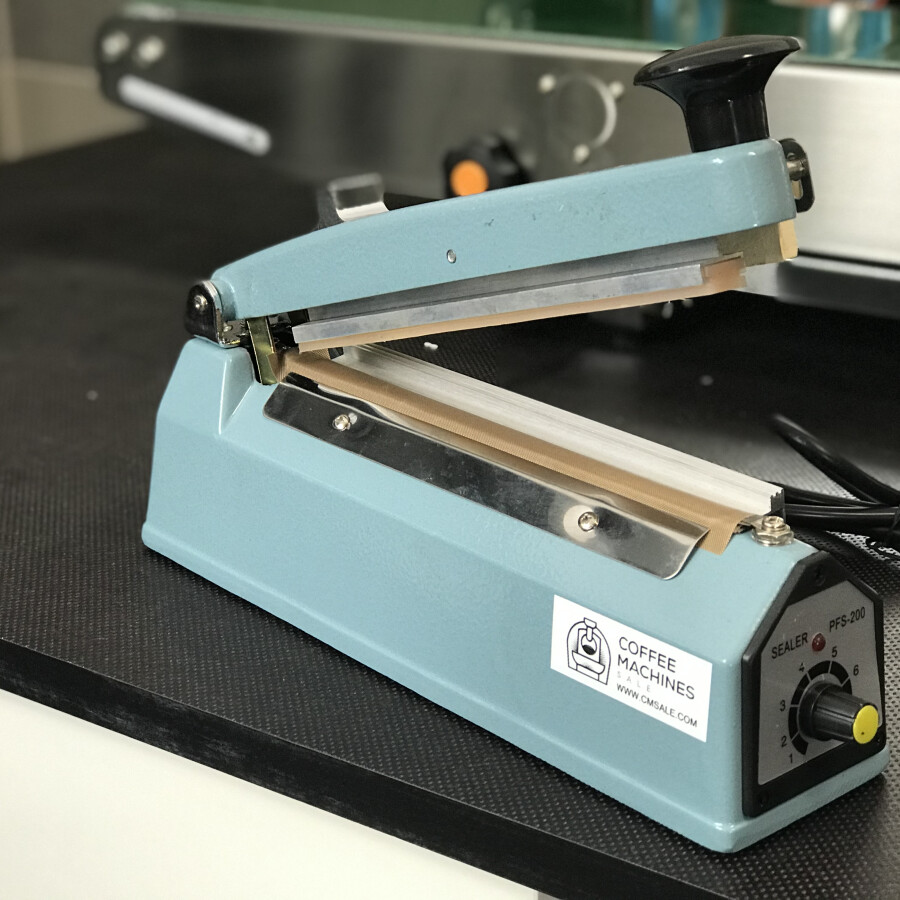

Illustrative image related to heat seal machine spices

Pros & Cons:

The primary advantage of PET is its superior barrier properties, which help extend the shelf life of spices. However, it is generally more expensive than PE and PP, and its manufacturing process can be more complex. Additionally, PET is not as flexible as PE, which may limit its use in certain pouch designs.

Why Is Aluminum Foil a Preferred Material for Spice Packaging?

Aluminum foil is renowned for its exceptional barrier properties against moisture, oxygen, and light. It can withstand high temperatures and is often used in combination with other materials to create multi-layer packaging. Its ability to form a hermetic seal makes it ideal for preserving the quality of spices.

Pros & Cons:

The key advantage of aluminum foil is its unmatched barrier performance, ensuring the longevity of spice products. However, it is more expensive than plastic alternatives and can be less environmentally friendly unless recycled properly. Additionally, its rigidity may limit its application in flexible packaging formats.

Considerations for International B2B Buyers

When sourcing materials for heat seal machine spices, international buyers, especially from Africa, South America, the Middle East, and Europe, must consider compliance with local regulations and standards such as ASTM, DIN, and JIS. Understanding the preferences for packaging materials in these regions can help ensure product acceptance and marketability. Additionally, factors such as shipping costs, currency fluctuations, and local sourcing capabilities should be evaluated to optimize procurement strategies.

| Material | Typical Use Case for heat seal machine spices | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene (PE) | Flexible pouches for spices | Low cost and recyclability | Limited heat resistance | Low |

| Polypropylene (PP) | Rigid containers and flexible pouches | Higher temperature resistance | Higher cost and specific sealing needs | Med |

| Polyester (PET) | High-performance spice packaging | Superior barrier properties | Higher cost and complex manufacturing | High |

| Aluminum Foil | Multi-layer packaging for long shelf life | Unmatched barrier performance | Higher cost and environmental concerns | High |

In-depth Look: Manufacturing Processes and Quality Assurance for heat seal machine spices

What Are the Main Stages of Manufacturing Heat Seal Machines for Spices?

Manufacturing heat seal machines for spices involves a systematic approach, ensuring both functionality and quality. The process can be broken down into several main stages:

Material Preparation: What Is Involved in the Initial Stage?

The first step in the manufacturing process is material preparation. This involves sourcing high-quality raw materials such as stainless steel, which is favored for its durability and resistance to corrosion. Components like motors, sensors, and control systems are also procured from reliable suppliers. The choice of materials is crucial, as they must withstand the demands of heat sealing and maintain hygiene standards, especially when dealing with food products like spices.

Forming: How Are Components Shaped and Assembled?

Once materials are prepared, the forming stage begins. This involves cutting, bending, and machining components to precise specifications. Techniques such as laser cutting and CNC machining are commonly used to ensure accuracy. The forming process also includes the creation of the heat sealing area, where precise temperature control is vital. After individual components are formed, they are assembled into sub-units, such as the filling and sealing mechanisms.

Assembly: What Does the Assembly Process Entail?

The assembly process is critical as it combines various sub-units into a complete machine. This stage often employs automated systems to enhance efficiency and accuracy. Each machine is assembled according to specific configurations based on the intended application—whether for free-flowing spices like chili powder or non-free-flowing spices like brown sugar. Assembly also includes integrating control systems, which allow operators to monitor and adjust settings like sealing temperature and bag size.

Finishing: How Is Quality Enhanced During the Final Stages?

The finishing stage focuses on enhancing the machine’s aesthetic and functional qualities. This includes polishing surfaces, applying protective coatings, and conducting initial tests to ensure all components function correctly. Additionally, this stage often involves the installation of safety features and user-friendly interfaces, such as LCD touch screens, that improve operational efficiency.

What Quality Assurance Measures Are Essential for Heat Seal Machines?

Quality assurance is paramount in the manufacturing of heat seal machines, ensuring that the final product meets international standards and industry-specific regulations.

Which International Standards Should Buyers Be Aware Of?

B2B buyers should familiarize themselves with international quality standards such as ISO 9001, which focuses on quality management systems, and CE certification, indicating compliance with European safety and health regulations. These certifications assure buyers that the machines are manufactured to high standards, ensuring safety and reliability.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are integrated into the manufacturing process to maintain high standards. Key checkpoints include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials and components upon arrival to verify they meet specified standards.

- In-Process Quality Control (IPQC): Throughout the assembly process, inspections are conducted to ensure that components are assembled correctly and function as intended.

- Final Quality Control (FQC): After assembly, the machine undergoes a comprehensive evaluation to ensure it meets all operational standards before shipping. This includes testing heat sealing capabilities, speed, and overall performance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying the quality control practices of suppliers is crucial to ensure that the machines meet their operational needs. Here are several effective methods:

What Are the Best Practices for Conducting Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess quality control processes. Buyers should request access to the supplier’s quality management documentation, including their ISO certifications and QC protocols. On-site audits can provide further insights into manufacturing practices and adherence to safety standards.

How Can Buyers Utilize Reports and Third-Party Inspections?

Buyers can request quality assurance reports detailing the results of previous inspections and tests. Engaging third-party inspection services can also add an extra layer of assurance. These independent entities can conduct thorough inspections of the manufacturing process and the final product, providing an unbiased assessment of quality.

What Are the Specific QC Considerations for International Buyers?

International B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, should be mindful of specific quality control nuances.

How Do Regional Regulations Impact Quality Assurance?

Different regions may have varying regulations that affect the quality assurance processes. For instance, European buyers must ensure compliance with CE marking, while buyers in Africa may need to adhere to local health and safety standards. Understanding these regional requirements is essential to avoid compliance issues.

What Are the Challenges and Solutions in Quality Assurance for Export?

Exporting heat seal machines can introduce challenges such as differing standards and regulations. Buyers should ensure that their suppliers are well-versed in the compliance requirements of the target market. Establishing clear communication channels and documentation can help mitigate these challenges, ensuring that all parties are aligned on quality expectations.

Illustrative image related to heat seal machine spices

Conclusion: Why Quality Assurance Is Key in the Heat Seal Machine Market

In summary, the manufacturing processes and quality assurance measures for heat seal machines are vital for ensuring that these machines meet the rigorous demands of the spice industry. By understanding the stages of manufacturing and the importance of quality control, B2B buyers can make informed decisions, ensuring they invest in reliable, high-quality machinery that meets both operational and regulatory standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘heat seal machine spices’

When sourcing heat seal machines for spices, it’s essential to follow a structured approach to ensure you select the best equipment for your business needs. This guide outlines a practical checklist to facilitate informed decision-making.

Step 1: Define Your Technical Specifications

Before initiating your search, clearly outline the technical specifications required for your heat seal machine. Consider factors such as the types of spices you will package, the desired packaging weight, and the expected production volume. Identifying these parameters will help you narrow down your options and select machines that meet your operational requirements.

Step 2: Research Supplier Credentials

Thoroughly vet potential suppliers to ensure they have a solid reputation in the industry. Look for certifications that validate their compliance with international standards, such as ISO or CE certifications. This step is crucial as it ensures you are investing in high-quality machinery that adheres to safety and operational standards.

Illustrative image related to heat seal machine spices

- Check reviews and testimonials: Seek feedback from previous clients, especially those in similar markets or industries.

- Request case studies: This can provide insight into the supplier’s experience and the effectiveness of their machines.

Step 3: Evaluate Machine Features

When assessing different heat seal machines, focus on key features that enhance usability and efficiency. Look for automatic functions such as bag forming, filling, and sealing, which can significantly reduce labor costs and increase productivity.

- Consider flexibility: Machines that can handle both free-flowing and non-free-flowing powders will give you more versatility.

- Check for ease of maintenance: Machines with user-friendly designs will minimize downtime and maintenance costs.

Step 4: Assess Cost and ROI

Analyze the total cost of ownership for each machine, including initial purchase price, installation, and operational costs. A higher upfront investment may be justified if the machine offers greater efficiency and lower operating costs.

- Calculate potential ROI: Estimate how quickly you can expect to recoup your investment based on your production needs and market demand.

- Inquire about financing options: Some suppliers may offer leasing or payment plans that can ease the financial burden.

Step 5: Request Demonstrations or Trials

Whenever possible, arrange for a demonstration of the machines you are considering. Observing the machine in action allows you to assess its performance and ensure it meets your expectations.

- Test with actual spices: If feasible, use your own spice materials during the demonstration to evaluate how well the machine handles your products.

- Evaluate the user interface: Ensure that the machine’s controls are intuitive and easy for your operators to use.

Step 6: Understand After-Sales Support

Reliable after-sales support is essential for the long-term success of your equipment. Ensure that the supplier offers comprehensive service options, including installation, training, and ongoing maintenance.

- Check warranty terms: A solid warranty can provide peace of mind and protect your investment.

- Inquire about spare parts availability: Ensure that the supplier can provide spare parts quickly to minimize potential downtime.

Step 7: Finalize Your Purchase Decision

After thorough evaluation and consideration of all factors, make your final decision based on the machine that best meets your needs and offers the best value for your investment. Ensure all terms are clearly outlined in the purchase agreement.

By following this structured checklist, you can confidently source the right heat seal machines for your spice packaging needs, ultimately enhancing your operational efficiency and product quality.

Comprehensive Cost and Pricing Analysis for heat seal machine spices Sourcing

What Are the Key Cost Components for Heat Seal Machine Spices?

Understanding the cost structure of heat seal machines for spices is critical for B2B buyers. The primary cost components include:

-

Materials: The quality of materials used in manufacturing the heat seal machine significantly impacts the overall cost. High-grade stainless steel is often preferred for its durability and resistance to corrosion, especially important in food applications.

-

Labor: Labor costs can vary widely based on the manufacturing location. Countries with lower labor costs may offer competitive pricing but may also compromise on quality. Consider the skill level of the workforce as it directly influences production efficiency and machine reliability.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Efficient factories with lower overhead can offer more competitive pricing, making it essential to understand a supplier’s operational efficiency.

-

Tooling: The initial investment in tooling for production can be substantial. Custom tooling for specialized machines may increase upfront costs but can enhance production efficiency and reduce long-term expenses.

-

Quality Control (QC): Robust QC processes ensure that machines meet international safety and performance standards, which is crucial for food-related machinery. The costs associated with these processes can affect the final pricing.

-

Logistics: Shipping costs, including freight, insurance, and customs duties, can significantly impact the total cost, especially for international buyers. Understanding Incoterms can help clarify who bears these costs and risks.

-

Margin: Suppliers typically add a profit margin to their costs. This margin can vary based on market demand, competition, and the supplier’s business strategy.

How Do Price Influencers Affect Heat Seal Machine Costs?

Several factors influence the pricing of heat seal machines for spices:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to discounts, making it economically viable for larger operations. However, smaller businesses may need to negotiate MOQs or look for suppliers willing to accommodate lower volumes.

-

Specifications and Customization: Custom features or specifications can lead to higher costs. Buyers should be clear about their needs to avoid unnecessary expenses related to customizations that may not add significant value.

-

Material Quality and Certifications: Machines built with certified materials (e.g., food-grade certifications) may come at a premium. Buyers should prioritize quality to ensure compliance with health regulations in their respective markets.

-

Supplier Reputation and Reliability: Established suppliers with a proven track record may charge higher prices but offer better after-sales support, warranties, and reliability. Assessing supplier history can mitigate risks associated with purchasing.

-

Incoterms: The choice of Incoterms affects the pricing structure. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who pays for shipping and insurance, influencing overall costs.

What Negotiation Tips Should Buyers Consider?

When sourcing heat seal machines for spices, international B2B buyers can employ several strategies for effective negotiation:

-

Research and Benchmarking: Understand market prices and benchmark against multiple suppliers. This knowledge empowers buyers to negotiate better deals.

-

Total Cost of Ownership (TCO): Evaluate the TCO, including maintenance, operational costs, and efficiency. A lower purchase price may lead to higher operational costs, so consider long-term implications.

-

Volume Flexibility: If possible, express willingness to increase order volumes in exchange for discounts. Suppliers may offer better rates for commitments to larger orders.

-

Payment Terms: Negotiating favorable payment terms can improve cash flow. Consider options such as deferred payment or installment plans.

-

Quality Assurance Clauses: Include clauses that protect against defects and ensure compliance with industry standards. This can safeguard against future costs related to faulty machinery.

In conclusion, understanding the comprehensive cost structure and price influencers of heat seal machines for spices is vital for B2B buyers. By leveraging negotiation tactics and focusing on total cost efficiency, buyers can make informed decisions that align with their operational goals while ensuring quality and compliance in their spice packaging processes.

Alternatives Analysis: Comparing heat seal machine spices With Other Solutions

Understanding Alternative Solutions for Spice Packaging

When considering the packaging of spices, businesses often explore various methods to enhance efficiency, reduce costs, and meet market demands. This section compares heat seal machine spices with alternative packaging solutions, providing insights into their performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Heat Seal Machine Spices | Manual Packing Solutions | Vacuum Packaging Machines |

|---|---|---|---|

| Performance | High-speed, automated | Low-speed, labor-intensive | Preserves freshness longer |

| Cost | Moderate investment | Low initial costs | Higher initial investment |

| Ease of Implementation | Requires training | Simple, no special training | Requires setup and training |

| Maintenance | Moderate, requires regular checks | Minimal, but labor-intensive | Moderate, requires vacuum maintenance |

| Best Use Case | Large-scale production | Small-scale or artisanal | Long-term storage or export |

Detailed Breakdown of Alternatives

Manual Packing Solutions

Manual packing is the traditional method where workers fill and seal spice containers by hand. This approach is characterized by its low initial costs, making it accessible for startups or small businesses. However, the performance is limited due to its labor-intensive nature, resulting in slower production rates. Additionally, as demand increases, this method becomes unsustainable, leading to potential bottlenecks. While it allows for flexibility and customization, the reliance on human labor can introduce inconsistencies in packaging accuracy and quality.

Illustrative image related to heat seal machine spices

Vacuum Packaging Machines

Vacuum packaging machines are designed to extend the shelf life of spices by removing air from the packaging. This method significantly preserves flavor and freshness, making it an excellent choice for long-term storage or export. Although the initial investment in vacuum technology is higher compared to heat seal machines, the long-term savings on spoilage and waste can offset this cost. Implementation may require more setup time and specialized training for staff, but once operational, these machines can enhance the quality of the end product. Maintenance can be moderate, as vacuum systems require regular checks to ensure seal integrity and vacuum levels.

Conclusion: Choosing the Right Spice Packaging Solution

When selecting the appropriate packaging solution for spices, B2B buyers must carefully assess their specific needs, including production volume, budget, and product shelf life. Heat seal machines offer a robust solution for high-speed production, making them ideal for businesses aiming to scale. In contrast, manual packing may serve smaller operations or those emphasizing artisanal qualities. Vacuum packaging machines stand out for their ability to prolong freshness, suitable for businesses focused on export or long-term storage. Ultimately, aligning the chosen method with operational goals will lead to more efficient processes and better product quality.

Essential Technical Properties and Trade Terminology for heat seal machine spices

What Are the Key Technical Properties of Heat Seal Machines for Spices?

When considering heat seal machines for spice packaging, several technical properties are essential for ensuring efficiency, quality, and compliance with industry standards. Here are some critical specifications:

-

Material Grade

Heat seal machines are typically constructed from stainless steel or food-grade plastics. Stainless steel offers durability, resistance to corrosion, and ease of cleaning, which are vital for maintaining hygiene in food applications. For B2B buyers, selecting machines made from high-grade materials ensures longevity and compliance with food safety regulations. -

Sealing Temperature Range

The sealing temperature range is crucial for achieving optimal seal integrity, especially when working with various spice packaging materials. Machines that allow for adjustable temperature settings enable businesses to adapt to different pouch materials, ensuring that the seal is strong enough to prevent contamination while maintaining the freshness of spices. -

Production Speed

Measured in pouches per minute, production speed is a key performance indicator for heat seal machines. A higher production speed can significantly enhance operational efficiency, allowing businesses to meet market demand and reduce labor costs. For buyers, understanding production speed is critical for aligning machinery capabilities with their production goals. -

Weighing Accuracy

Precision in weighing is essential, particularly in the spice industry where product consistency impacts customer satisfaction. Machines equipped with advanced weighing systems (like screw or load cell technology) ensure accurate filling, reducing waste and minimizing the risk of customer complaints due to incorrect weights. -

Machine Dimensions and Footprint

The size and layout of the machine are important considerations for facilities with limited space. A compact design can facilitate easier integration into existing production lines without requiring extensive modifications. B2B buyers should assess their facility’s layout to ensure the chosen machine fits without compromising workflow. -

User Interface and Controls

A user-friendly interface with PLC control systems simplifies operation and reduces training time for staff. Machines that feature intuitive controls can minimize operational errors and enhance productivity, making them more appealing to businesses looking to streamline their processes.

What Are the Common Trade Terms Related to Heat Seal Machines for Spices?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are several common terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products or components that are sold under another company’s brand name. In the context of heat seal machines, buyers may source machines from OEMs that specialize in spice packaging technology to ensure quality and reliability. -

MOQ (Minimum Order Quantity)

This term specifies the smallest quantity of products that a supplier is willing to sell. For heat seal machines, MOQs can vary based on the manufacturer and can affect pricing. Buyers should be aware of MOQs to align their purchasing strategy with production needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. When looking to purchase heat seal machines, B2B buyers often use RFQs to compare prices and features from multiple manufacturers, ensuring they secure the best value. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. They clarify aspects such as shipping, insurance, and customs clearance. Understanding Incoterms is essential for B2B buyers, as they can significantly impact the overall cost and logistics of importing heat seal machines. -

Lead Time

This term refers to the time taken from placing an order to receiving the goods. For heat seal machines, lead times can vary based on manufacturing capacity and shipping logistics. Buyers should consider lead times when planning their production schedules to avoid disruptions. -

Warranty and After-Sales Support

Warranty refers to the guarantee provided by the manufacturer regarding the quality and performance of the machine over a specified period. After-sales support encompasses the assistance provided post-purchase, including maintenance and repairs. Understanding these terms is vital for buyers to ensure they receive adequate support for their investment in heat seal machines.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when investing in heat seal machines for spice packaging, ensuring they choose the right equipment to meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the heat seal machine spices Sector

What Are the Current Market Dynamics in the Heat Seal Machine Spices Sector?

The heat seal machine spices sector is experiencing significant growth driven by the rising demand for packaged spice products across international markets. Key trends include the increased adoption of automation and smart technology in packaging processes, which enhances efficiency and reduces labor costs. For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, particularly Brazil and Germany, this means a shift towards sourcing advanced heat seal machines that offer precision, scalability, and versatility in packaging various spice products.

Emerging technologies, such as IoT-enabled machines, allow for real-time monitoring and control of packaging processes, improving production efficiency. Additionally, buyers are increasingly looking for machines that can handle both free-flowing and non-free-flowing spice powders, accommodating a diverse product range. The global trend towards e-commerce and online retailing is also influencing the packaging landscape, with businesses seeking compact, visually appealing packaging solutions to enhance shelf appeal and customer experience.

Moreover, sustainability is becoming a central theme in market dynamics. Buyers are prioritizing suppliers who offer energy-efficient machines and sustainable packaging materials, reflecting a broader shift towards environmentally responsible business practices. Understanding these trends is crucial for B2B buyers to make informed sourcing decisions and to align with consumer preferences in their respective markets.

How Is Sustainability Influencing Sourcing Decisions in the Heat Seal Machine Spices Sector?

Sustainability has emerged as a pivotal factor influencing sourcing decisions in the heat seal machine spices sector. As environmental concerns rise globally, B2B buyers are increasingly scrutinizing the environmental impact of their supply chains. This includes evaluating the sustainability of the machinery they invest in, such as heat seal machines that utilize energy-efficient technologies and materials that minimize waste.

Ethical sourcing is also gaining traction, with buyers favoring suppliers that adhere to fair labor practices and provide transparency in their supply chains. This shift is not only about compliance but also about building brand reputation and consumer trust. Certifications related to sustainability, such as ISO 14001 or FSC (Forest Stewardship Council), are becoming essential for suppliers to demonstrate their commitment to environmentally friendly practices.

Furthermore, the demand for ‘green’ packaging materials, such as biodegradable films and recyclable materials, is on the rise. B2B buyers are looking for heat seal machines compatible with these materials, ensuring that their packaging solutions align with sustainability goals. By prioritizing ethical sourcing and sustainability, businesses can not only reduce their environmental footprint but also meet the growing consumer demand for responsible products.

Illustrative image related to heat seal machine spices

What Is the Historical Context of Heat Seal Machines in Spice Packaging?

The evolution of heat seal machines in spice packaging can be traced back to the mid-20th century when advancements in packaging technology began to revolutionize the food industry. Initially, spice packaging was predominantly manual, which limited production capabilities and scalability. However, as global trade expanded and consumer demand for packaged goods increased, the need for efficient, automated packaging solutions became apparent.

The introduction of heat sealing technology marked a significant turning point. This method provided a reliable way to create airtight seals, enhancing product shelf life and maintaining flavor integrity. Over the decades, continuous improvements in technology have led to the development of sophisticated heat seal machines that can handle various spice powders with precision and speed.

Today, the landscape has transformed further with the integration of digital technologies and automation, allowing for greater flexibility and efficiency in spice packaging operations. B2B buyers now benefit from a wide array of machine options tailored to different spice types and market demands, making it easier to scale operations and respond to consumer trends effectively. This historical context underscores the importance of investing in modern packaging solutions to remain competitive in the evolving spice market.

Frequently Asked Questions (FAQs) for B2B Buyers of heat seal machine spices

-

How do I select the right heat seal machine for my spice packaging needs?

Selecting the right heat seal machine involves assessing your specific packaging requirements, including the type of spices you are dealing with and the desired packaging format. Consider factors such as the machine’s capacity, speed, and compatibility with different pouch sizes. It’s also important to evaluate features like ease of operation, maintenance needs, and the technology used for sealing. Consulting with suppliers about their machines’ specifications and seeking demonstrations can help ensure you choose a machine that aligns with your production goals. -

What are the advantages of using a heat seal machine for spice packaging?

Heat seal machines offer several advantages for spice packaging, including enhanced sealing integrity, which helps maintain product freshness and extends shelf life. They also improve efficiency by automating the sealing process, reducing labor costs, and minimizing human error. Additionally, these machines can accommodate various pouch materials and sizes, allowing for greater flexibility in packaging options. The result is a streamlined process that enhances productivity while ensuring high-quality packaging standards. -

What factors affect the cost of heat seal machines for spices?

The cost of heat seal machines can vary significantly based on several factors, including machine type (automatic vs. semi-automatic), production capacity, and the specific features offered (such as advanced controls or additional attachments). External factors like shipping costs and tariffs may also influence the final price, especially for international buyers. It’s advisable to request quotes from multiple suppliers and consider the total cost of ownership, which includes maintenance and operational costs over time. -

What is the minimum order quantity (MOQ) for heat seal machines?

The minimum order quantity for heat seal machines can vary by supplier. Some manufacturers may allow orders for a single unit, particularly for smaller or semi-automatic machines, while others may have higher MOQs for fully automatic systems. It’s essential to discuss your needs with suppliers and inquire about potential discounts for larger orders. This will help you balance your budget with your production requirements, especially if you plan to scale up operations. -

How can I verify the reliability of a heat seal machine supplier?

To verify a supplier’s reliability, start by checking their reputation through customer reviews and testimonials. Look for certifications that indicate compliance with industry standards, such as ISO certifications. Engaging in direct communication with the supplier can provide insights into their customer service and responsiveness. Additionally, consider visiting their manufacturing facility if possible, or request references from other international clients to gauge their experience and satisfaction with the supplier’s products and services. -

What payment terms should I expect when sourcing heat seal machines?

Payment terms for heat seal machines can vary widely among suppliers, but common practices include a deposit upfront (often 30-50%) with the balance paid before shipping. Some suppliers may offer flexible payment options, including financing or payment upon delivery. It’s crucial to clarify the terms before finalizing any order and to ensure that they align with your cash flow and budget constraints. Always obtain a written agreement to safeguard your interests. -

What quality assurance measures should I consider when purchasing heat seal machines?

When purchasing heat seal machines, inquire about the supplier’s quality assurance (QA) measures, including their testing protocols and certifications. Ensure that the machines undergo rigorous quality checks during manufacturing, and request documentation proving compliance with relevant industry standards. Additionally, consider asking about warranty terms and after-sales support, as these can provide added assurance of the machine’s reliability and the supplier’s commitment to customer satisfaction. -

What logistics considerations should I keep in mind for shipping heat seal machines internationally?

When shipping heat seal machines internationally, consider logistics factors such as shipping methods, customs regulations, and delivery times. Ensure that the supplier has experience with international shipping and can provide necessary documentation for customs clearance. It’s also vital to account for potential duties and taxes that may apply upon arrival. Collaborating with a logistics provider familiar with importing machinery can streamline the process and help mitigate any unforeseen delays or costs.

Top 6 Heat Seal Machine Spices Manufacturers & Suppliers List

1. Makwell – Automatic Spice Powder Packing Machine

Domain: makwell.com

Registered: 2009 (16 years)

Introduction: Automatic Spice Powder Packing Machine

– Type: Automatic Spice Powder Packing Machine

– Bag Length: 80-300mm

– Bag Width: 50-200mm

– Packaging Speed: 5-80 bags/min

– Max Width of Roll: 420mm

– Voltage: 220V

– Power: 2.2KW

– Machine Size (L*W*H): 1320*950*1360mm

– Weight: 540kg

– Features:

– Suitable for free-flow and non-free-flow powders, liquids, solids, and granules

– Automatic tasks: feed…

2. Taizy Packaging – Spice Packing Machine

Domain: taizypackaging.com

Registered: 2020 (5 years)

Introduction: Spice Packing Machine for Filling and Sealing Spice Pouch

Brand: Taizy Packaging

Packaging Range: 0~200g

Material: 304 stainless steel

Warranty: 12 months

Applications: Suitable for packing various spice powders such as chili powder, turmeric powder, black pepper, ginger powder, masala, curry powder, etc.

Type: Automatic vertical form fill seal machine

Functions: Weighing, filling, bag making, sea…

3. Restaurantware – Heat Seal Bags

Domain: restaurantware.com

Registered: 2003 (22 years)

Introduction: Heat Seal Equipment & Supplies include a variety of bags such as disposable bags, bakery bags, bread bags, concession food bags, cooking bags, drink bags, foil bags, gift basket bags, gusset bags, heat seal bags, lunch bags, take out bags, tape bags, vacuum seal bags, and zip bags. The collection is designed for various applications in food service and packaging.

4. Container and Packaging – Manual Heat Induction Sealing Machine

Domain: containerandpackaging.com

Registered: 2001 (24 years)

Introduction: {“item_number”:”M190HIS”,”type”:”Manual heat induction sealing machine”,”cap_diameter_range”:”20 mm to 100 mm”,”color”:”White/Natural”,”weight”:”11 lbs (5 kg)”,”dimensions”:{“height”:”6.00 in”,”width”:”12.00 in”,”weight”:”464.00 oz”},”material”:”Metal”,”recyclable”:”Yes”,”sealing_speed”:”up to 12 containers per minute”,”applications”:”suitable for glass and plastic containers with flat threaded ca…

5. Scayl – Spice Filling Machines

Domain: scayl.co.uk

Registered: 2018 (7 years)

Introduction: Packing and Sealing Machines for Spices include:

1. **Spice Filling Machines**:

– **Scayl Phil™ 300**: Regular price $1,384.00, In stock.

– **Scayl Phil™ 2500**: Regular price $4,565.00, Very low stock (4 units).

– **Scayl Phil™ 5000**: Regular price $5,257.00, Low stock (5 units).

– **Scayl Phil™ 5000 Duo**: Regular price $8,715.00.

– Features: Easy to use, maintenance-free, dispe…

6. Heat Seal – Granule Packing Machine

Domain: dhgate.com

Registered: 2004 (21 years)

Introduction: Product Name: Heat Seal Tea Bags Granule Packing Machine for Tea, Spices, and Seasonings

Price: $1,338.6

Material: Metal

Power Source: Electric

Voltage: 110V/220V

Power: 500W

Machine Weight: 65kg

Machine Size: 42*50*145cm

Packing Speed: 10-25 bags/min (depending on the material)

Error Range: ±0.2g (depending on the material)

Package Weight: 1-100g (various weight ranges can be customized)

Bag Maki…

Strategic Sourcing Conclusion and Outlook for heat seal machine spices

In the rapidly evolving spice industry, the adoption of heat seal machines is pivotal for enhancing efficiency and maintaining product quality. Strategic sourcing of these machines offers international buyers the opportunity to streamline their operations, reduce waste, and significantly boost productivity. By investing in advanced spice packing technology, businesses can ensure consistent quality and quick turnaround times, catering to the increasing global demand for spices.

Moreover, understanding the nuances of machine selection—whether for free-flowing or non-free-flowing spices—can lead to better operational decisions. As many businesses transition from manual packing to automated solutions, the return on investment can be realized in less than three months, making it a financially sound choice.

Looking ahead, international buyers from Africa, South America, the Middle East, and Europe should consider partnering with reputable suppliers who offer tailored solutions to meet their specific needs. Embrace this opportunity to modernize your operations and stay competitive in the global spice market. Take the next step in your sourcing strategy today and unlock the potential of heat seal machines for your spice business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to heat seal machine spices

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.