Everything You Need to Know About Hamon Deltak Inc Hrsg Sourcing in 2025

Introduction: Navigating the Global Market for hamon deltak inc hrsg

In the competitive landscape of industrial solutions, sourcing reliable heat recovery steam generators (HRSG) from Hamon Deltak, Inc. presents a critical challenge for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe strive to enhance energy efficiency and reduce operational costs, understanding the intricacies of HRSG technology becomes paramount. This comprehensive guide delves into the various types of HRSGs offered by Hamon Deltak, their diverse applications across sectors such as power generation, petrochemicals, and manufacturing, and essential factors to consider during supplier vetting.

Navigating the complexities of HRSG procurement requires a strategic approach. This guide equips B2B buyers with actionable insights into the procurement process, including cost considerations, installation requirements, and long-term maintenance strategies. By understanding the unique features and benefits of Hamon Deltak’s offerings, buyers can make informed decisions that align with their operational goals. Additionally, the guide highlights case studies and testimonials from satisfied clients, providing a deeper understanding of the company’s commitment to quality and customer satisfaction.

Empowering your purchasing strategy with this guide will enable you to leverage Hamon Deltak’s innovative solutions, ensuring your organization remains competitive in a rapidly evolving global market.

Understanding hamon deltak inc hrsg Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Waste Heat Recovery Steam Generators | High efficiency in capturing and utilizing waste heat | Power generation, petrochemical, and food processing | Pros: Reduces energy costs, enhances sustainability. Cons: Initial investment can be high. |

| Modular Heat Recovery Boilers | Factory-assembled modules for easier on-site installation | Oil refineries, cement plants, glass manufacturing | Pros: Reduces field assembly time, custom designs. Cons: Requires precise logistics for transport. |

| High-Pressure Heat Recovery Boilers | Designed for high-temperature applications | Chemical processing, power generation | Pros: High efficiency, suitable for demanding processes. Cons: Maintenance may be complex and costly. |

| Firetube Heat Recovery Boilers | Compact design with efficient heat transfer capabilities | Heating, sterilization, and power generation | Pros: Space-efficient, easy to install. Cons: Lower efficiency compared to watertube designs. |

| Watertube Heat Recovery Boilers | Water-cooled membrane wall design for durability | Pulp and paper, food and beverage, power generation | Pros: High reliability, excellent heat transfer. Cons: Higher upfront cost compared to firetube options. |

What Are the Key Characteristics of Waste Heat Recovery Steam Generators?

Waste Heat Recovery Steam Generators (HRSG) are engineered to capture excess heat from industrial processes, converting it into steam for energy generation. They are particularly suited for industries with high thermal outputs, such as power generation and petrochemicals. When considering a purchase, buyers should assess the efficiency of heat recovery, potential cost savings on energy, and the environmental benefits of reduced emissions.

How Do Modular Heat Recovery Boilers Enhance Installation Efficiency?

Modular Heat Recovery Boilers are pre-assembled in a manufacturing facility, allowing for quicker installation on-site. This design is ideal for industries like oil refining and cement production, where downtime can be costly. Buyers should evaluate the logistics of transporting these modules, as well as the customization options available to meet specific operational needs. The reduction in field assembly time can significantly lower labor costs and expedite project timelines.

What Makes High-Pressure Heat Recovery Boilers Suitable for Demanding Applications?

High-Pressure Heat Recovery Boilers are designed to operate under extreme conditions, making them suitable for chemical processing and power generation applications. Their ability to handle high temperatures and pressures provides a robust solution for demanding industrial environments. Buyers must consider the complexity of maintenance and the associated costs, as well as the boiler’s efficiency ratings to ensure it meets their operational requirements.

Why Choose Firetube Heat Recovery Boilers for Compact Spaces?

Firetube Heat Recovery Boilers are characterized by their compact design, making them an excellent choice for facilities with limited space. They offer efficient heat transfer and are easy to install, making them suitable for heating and sterilization processes. However, buyers should weigh the lower efficiency against their specific energy needs, especially in comparison to watertube designs, which may provide better performance for larger applications.

What Are the Advantages of Watertube Heat Recovery Boilers?

Watertube Heat Recovery Boilers utilize a water-cooled membrane wall design, which enhances durability and heat transfer efficiency. They are particularly effective in industries like pulp and paper and food processing, where high reliability is essential. Buyers should consider the upfront investment and maintenance requirements, as these boilers tend to have a higher initial cost but offer long-term operational benefits due to their efficiency and lifespan.

Key Industrial Applications of hamon deltak inc hrsg

| Industry/Sector | Specific Application of hamon deltak inc hrsg | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Power Generation | Integration with gas turbines for combined cycle power plants | Increases energy efficiency and reduces fuel costs | Need for compliance with local regulations and standards |

| Oil and Gas | Waste heat recovery in refineries | Lowers operational costs and enhances sustainability | Availability of specialized engineering support |

| Chemical Processing | Steam generation for chemical reactions | Supports continuous production and improves process efficiency | Customization to meet specific chemical process requirements |

| Food and Beverage | Steam for sterilization and processing | Ensures product safety and quality, enhancing marketability | Compliance with food safety standards and certifications |

| Pulp and Paper | Steam and heat recovery for pulping processes | Increases production efficiency and reduces energy consumption | Robust design to handle corrosive environments |

How is Hamon Deltak Inc. HRSG Utilized in Power Generation?

In the power generation sector, Hamon Deltak’s heat recovery steam generators (HRSG) are critical in enhancing the efficiency of combined cycle power plants. By integrating HRSG with gas turbines, businesses can recover waste heat and convert it into additional electricity, significantly lowering fuel costs and improving overall energy efficiency. For international buyers, particularly in regions with stringent energy regulations, the ability to comply with local standards while maximizing output is paramount.

What Role Does Hamon Deltak HRSG Play in the Oil and Gas Industry?

Within the oil and gas industry, HRSG systems are employed to capture waste heat from refining processes. This technology not only helps in lowering operational costs but also enhances sustainability by reducing emissions. Buyers in this sector should consider the availability of specialized engineering support to ensure that the HRSG systems are tailored to their specific operational needs, particularly in remote or developing regions.

How is HRSG Applied in Chemical Processing?

In chemical processing, Hamon Deltak’s HRSG provides essential steam generation for various chemical reactions, facilitating continuous production. The efficiency of the steam system is crucial, as it directly impacts the overall process efficiency and product quality. Buyers must ensure that the HRSG solutions are customized to meet specific chemical requirements and that they comply with industry regulations, especially in international markets where standards may vary.

What Benefits Does HRSG Offer to the Food and Beverage Sector?

For the food and beverage industry, HRSG systems are vital for steam generation used in sterilization and processing. This ensures the safety and quality of food products, which is crucial for marketability and compliance with health regulations. International buyers should focus on sourcing HRSG solutions that meet food safety standards and certifications, ensuring that their production processes are both efficient and compliant.

How Does HRSG Improve Efficiency in the Pulp and Paper Industry?

In the pulp and paper sector, Hamon Deltak’s HRSG systems are used for steam and heat recovery, significantly enhancing production efficiency. By utilizing waste heat, companies can reduce energy consumption and operational costs. Buyers need to consider the robustness of the HRSG design to withstand the corrosive environments typical in pulp and paper operations, ensuring long-term reliability and performance.

3 Common User Pain Points for ‘hamon deltak inc hrsg’ & Their Solutions

Scenario 1: Navigating Complex Regulatory Compliance in Boiler Systems

The Problem: B2B buyers, particularly those in regions like Europe and the Middle East, often face stringent regulatory compliance requirements for industrial boilers. These regulations can vary significantly by country and industry, creating a daunting task for procurement teams. Buyers may find it challenging to ensure that their selected heat recovery steam generators (HRSG) from Hamon Deltak meet local codes and standards, leading to potential project delays, fines, or even operational shutdowns.

The Solution: To effectively navigate regulatory compliance, buyers should engage early with Hamon Deltak’s engineering team. Initiating discussions during the planning phase allows for tailored solutions that align with specific regulatory requirements. Buyers should request detailed documentation on the compliance certifications of the HRSG products and understand the engineering processes that ensure adherence to local codes. Furthermore, leveraging Hamon Deltak’s extensive international experience—having worked with over 22 foreign codes—can provide insights into best practices and streamline the compliance process. Establishing a clear communication channel with Hamon Deltak ensures that any regulatory changes can be promptly addressed, minimizing risk and ensuring smoother project execution.

Scenario 2: Managing High Installation and Maintenance Costs

The Problem: Many industries, especially those in developing regions like Africa and South America, grapple with high installation and maintenance costs associated with industrial boiler systems. The complexity of HRSG installations can lead to extended downtimes, increased labor costs, and unanticipated expenses during maintenance, which can strain budgets and affect overall profitability.

The Solution: Buyers should consider the modularization approach offered by Hamon Deltak. By utilizing larger, pre-fabricated components that can be shipped and assembled on-site, companies can significantly reduce installation time and associated labor costs. It’s advisable to conduct a constructability review with Hamon Deltak’s engineering and project management teams to identify potential efficiencies in the installation process. Additionally, investing in Hamon Deltak’s preventive maintenance programs can help mitigate long-term maintenance costs. Tailored maintenance schedules, regular inspections, and training for in-house staff ensure that the HRSG operates efficiently, preventing costly breakdowns and extending the lifespan of the equipment.

Scenario 3: Ensuring Optimal Performance in Diverse Operating Conditions

The Problem: B2B buyers often operate in varying environmental conditions, which can impact the performance of heat recovery systems. For instance, industrial facilities in regions with extreme temperatures or humidity levels may struggle to maintain efficiency and reliability in their boiler operations, leading to production inefficiencies and increased energy costs.

The Solution: To ensure optimal performance in diverse operating conditions, buyers should work closely with Hamon Deltak to customize their HRSG systems. This collaboration should include a thorough analysis of the facility’s operating environment and specific thermal requirements. Hamon Deltak’s capability to design tailored solutions means that buyers can receive equipment optimized for their unique conditions, whether it involves enhancing insulation for extreme temperatures or integrating advanced controls for varying load conditions. Additionally, regular performance assessments and adjustments, facilitated by Hamon Deltak’s technical support team, can help identify and rectify any efficiency issues promptly, ensuring sustained operational excellence. By proactively addressing these challenges, buyers can maximize the performance and reliability of their HRSG systems, ultimately leading to improved operational efficiency and reduced costs.

Strategic Material Selection Guide for hamon deltak inc hrsg

What Are the Key Materials Used in Hamon Deltak Inc. HRSG Products?

Hamon Deltak Inc. specializes in the design and manufacturing of Heat Recovery Steam Generators (HRSG), which are critical for optimizing energy efficiency in industrial applications. The selection of materials used in these systems is paramount, influencing performance, durability, and compliance with international standards. Below, we analyze four common materials used in Hamon Deltak HRSGs, focusing on their properties, advantages, limitations, and considerations for international buyers.

How Do Carbon Steel and Stainless Steel Compare for HRSG Applications?

Carbon Steel is a primary material used in HRSG construction due to its strength and cost-effectiveness. It typically has a high-temperature rating, making it suitable for various applications. However, carbon steel is prone to corrosion, especially in high-moisture environments, which can limit its lifespan.

Stainless Steel, on the other hand, offers superior corrosion resistance and can withstand higher temperatures and pressures. This makes it ideal for applications where the HRSG is exposed to flue gases and other corrosive media. The downside is that stainless steel can be significantly more expensive and may require more complex manufacturing processes.

For international buyers, understanding the specific grades of carbon and stainless steel is crucial, as compliance with standards such as ASTM for the U.S. or DIN for Germany may dictate material selection.

What Role Does Alloy Steel Play in HRSG Design?

Alloy Steel is often used in HRSG applications where enhanced mechanical properties are required. This material can withstand extreme temperatures and pressures, making it suitable for high-performance environments. The addition of elements like chromium and molybdenum improves its strength and resistance to oxidation.

While alloy steel provides excellent performance, it is generally more expensive than carbon steel and requires specialized fabrication techniques. Buyers from regions with stringent regulatory frameworks, such as the Middle East and Europe, should ensure that the alloy steel used complies with local standards and certifications.

Why Is Inconel a Preferred Material for Specific HRSG Components?

Inconel, a family of nickel-chromium-based superalloys, is favored for components exposed to extreme conditions, such as heat exchangers and turbine inlet sections. Its high-temperature strength and oxidation resistance make it ideal for applications where conventional materials would fail.

The primary disadvantage of Inconel is its high cost and the complexity of machining and welding, which can increase overall project timelines. International buyers should consider the total lifecycle cost and the specific application requirements when opting for Inconel, particularly in regions like Africa and South America, where budget constraints may be a concern.

What Are the Considerations for Selecting Composite Materials in HRSG?

Composite Materials are increasingly being explored for HRSG applications due to their lightweight and high-strength properties. These materials can offer excellent thermal insulation and resistance to corrosive environments, making them suitable for specific components.

However, composites can be more expensive and may not be as widely accepted in traditional industrial applications, leading to potential compatibility issues with existing systems. International buyers should evaluate the local acceptance of composite materials and their compliance with relevant standards before making a decision.

Summary of Material Properties for Hamon Deltak Inc. HRSG

Here’s a summary of the key materials analyzed, their typical use cases, advantages, disadvantages, and relative costs:

| Material | Typical Use Case for hamon deltak inc hrsg | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Structural components of HRSGs | Cost-effective and strong | Prone to corrosion in humid environments | Medium |

| Stainless Steel | Flue gas ducts and heat exchangers | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Alloy Steel | High-pressure and high-temperature areas | Superior mechanical properties | More expensive and requires specialized fabrication | High |

| Inconel | Extreme condition components | High-temperature strength and oxidation resistance | High cost and machining complexity | High |

| Composite | Thermal insulation and lightweight parts | Lightweight with good thermal properties | Higher cost and potential compatibility issues | Medium |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for HRSG applications, allowing for informed decisions that align with performance requirements and regulatory standards in their respective regions.

In-depth Look: Manufacturing Processes and Quality Assurance for hamon deltak inc hrsg

What Are the Main Stages in the Manufacturing Process of Hamon Deltak HRSG?

The manufacturing process of Hamon Deltak’s Heat Recovery Steam Generators (HRSG) is a meticulously structured operation that ensures high-quality output tailored to the specific needs of clients. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-grade materials, primarily steel, sourced from certified suppliers. Hamon Deltak emphasizes the importance of quality raw materials, as they form the backbone of durable and efficient HRSG systems. Rigorous inspections are conducted upon receipt of materials to ensure they meet the necessary specifications.

-

Forming: The forming stage employs advanced techniques such as cutting, bending, and welding. Hamon Deltak utilizes state-of-the-art machinery that adheres to the American Society of Mechanical Engineers (ASME) standards. This stage is critical as it shapes the components that will eventually come together to form the HRSG.

-

Assembly: In the assembly phase, individual components are meticulously put together. This is where modularization plays a significant role. By prefabricating larger sections, Hamon Deltak minimizes the time required for assembly on-site, reducing labor costs and enhancing quality control. The assembly is conducted in a controlled environment, ensuring optimal conditions for welding and fitting.

-

Finishing: The final stage involves surface treatments, insulation, and the application of protective coatings. This not only enhances the aesthetic appeal of the HRSG but also ensures durability and efficiency in operation. Finishing processes are performed in compliance with international standards, preparing the equipment for installation and operation.

How Does Hamon Deltak Ensure Quality Control in Their Manufacturing Process?

Quality control is paramount in the manufacturing of HRSG units at Hamon Deltak. The company adheres to both international standards such as ISO 9001 and industry-specific regulations like CE marking and API standards.

-

Quality Checkpoints: The quality control process is structured around several key checkpoints:

– Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure compliance with specifications.

– In-Process Quality Control (IPQC): Ongoing inspections are conducted throughout the manufacturing stages to identify and rectify issues in real-time.

– Final Quality Control (FQC): A comprehensive evaluation is performed on the completed HRSG units, focusing on functionality, safety, and compliance with customer specifications. -

Testing Methods: Common testing methods include non-destructive testing (NDT), hydrostatic testing, and performance evaluations. These tests are essential for verifying the integrity and operational efficiency of the HRSG units.

-

Verification of Supplier Quality Control: B2B buyers can verify the quality control processes of suppliers like Hamon Deltak through several means:

– Audits: Regular audits can be conducted to assess compliance with quality standards and operational efficiency.

– Reports: Requesting detailed quality reports and certifications can provide insights into the supplier’s commitment to quality.

– Third-party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of the manufacturing processes and quality measures in place.

What International Standards Should B2B Buyers Consider When Evaluating Hamon Deltak HRSG?

When sourcing HRSG systems, international B2B buyers should be aware of various quality standards and certifications that can impact their purchasing decisions.

-

ISO 9001: This globally recognized standard ensures that organizations maintain quality management systems, focusing on customer satisfaction and continuous improvement. Hamon Deltak’s adherence to ISO 9001 signifies its commitment to delivering high-quality products consistently.

-

CE Marking: For buyers in Europe, CE marking is crucial as it indicates compliance with European health, safety, and environmental protection standards. This certification is particularly relevant for equipment used in industrial applications.

-

API Standards: The American Petroleum Institute (API) standards are essential for buyers in the oil and gas sector. Compliance with these standards ensures that the equipment meets the necessary safety and performance criteria for critical applications.

How Can International B2B Buyers Navigate Quality Control Nuances?

For international B2B buyers, understanding the nuances of quality control in different regions can be challenging. Here are some actionable insights to consider:

-

Cultural Differences: Different regions may have varying expectations regarding quality. Buyers should familiarize themselves with local standards and practices in regions such as Africa, South America, the Middle East, and Europe to ensure alignment.

-

Regulatory Compliance: Buyers should be aware of specific regulations that may affect the import and use of HRSG systems in their countries. This includes understanding any additional certifications required by local authorities.

-

Local Partnerships: Establishing partnerships with local agents or representatives can provide valuable insights into the supplier’s reputation and reliability. Local partners can also facilitate communication and help navigate regulatory landscapes.

-

Documentation and Transparency: Buyers should insist on clear documentation regarding the quality control processes and certifications. Transparency from suppliers will help build trust and ensure that the products meet the expected standards.

By understanding the manufacturing processes and quality assurance measures implemented by Hamon Deltak, international B2B buyers can make informed decisions, ensuring they invest in reliable and efficient HRSG systems tailored to their specific industrial needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hamon deltak inc hrsg’

The following guide serves as a practical checklist for B2B buyers looking to procure heat recovery steam generators (HRSG) from Hamon Deltak Inc. This step-by-step approach will ensure that you make informed decisions that align with your operational needs and sustainability goals.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it’s essential to clearly outline your technical requirements. This includes understanding the steam generation capacity, operating pressure, and the specific applications for which the HRSG will be used. Providing detailed specifications will help suppliers tailor their proposals to meet your precise needs.

- Considerations: Assess the type of fuel you will use, potential waste heat sources, and any industry-specific regulations that may apply.

Step 2: Research Supplier Reputation

Investigate the reputation of Hamon Deltak Inc. in the market by reviewing their project history and customer testimonials. A strong reputation often correlates with reliability and quality in product delivery and customer service.

- Action Items: Seek out case studies and references, particularly from industries similar to yours, to gauge the supplier’s experience and success rate.

Step 3: Evaluate Potential Suppliers

Thorough vetting of suppliers is crucial to ensure you are working with a reputable partner. Inquire about the company’s engineering capabilities, manufacturing processes, and adherence to international standards.

- Details to Look For: Request information on certifications, such as ASME compliance, and examples of past projects that demonstrate their ability to meet complex specifications.

Step 4: Assess Product Customization Options

Hamon Deltak Inc. emphasizes tailored solutions for each client. Evaluate how well the supplier can customize their HRSG products to fit your unique operational requirements.

- Key Questions: What customization options are available? Can they adapt designs based on specific environmental or operational constraints?

Step 5: Understand Service and Support Offerings

Robust after-sales service and support are critical for the longevity and efficiency of your HRSG. Inquire about the supplier’s maintenance programs, training services, and technical support availability.

- Important Aspects: Assess whether they provide ongoing maintenance, training for your staff, and 24/7 technical support to troubleshoot any issues that may arise post-installation.

Step 6: Review Pricing and Payment Terms

Once you have shortlisted potential suppliers, request detailed quotations that outline all costs involved. This should include not only the purchase price but also installation, maintenance, and any potential upgrades.

- Considerations: Compare payment terms and financing options. Ensure that the total cost aligns with your budget while still meeting your quality and performance expectations.

Step 7: Finalize Contracts and Terms

Before finalizing any agreements, carefully review all contract terms to ensure they reflect your negotiations and protect your interests. Pay special attention to warranty provisions, delivery timelines, and penalties for non-compliance.

- Final Checks: Ensure clarity on all deliverables and that there are provisions for modifications if project requirements change.

By following this structured checklist, B2B buyers can effectively navigate the procurement process for Hamon Deltak Inc.’s HRSG solutions, ensuring alignment with their operational goals and sustainability objectives.

Comprehensive Cost and Pricing Analysis for hamon deltak inc hrsg Sourcing

What Are the Key Cost Components in Hamon Deltak Inc. HRSG Sourcing?

When considering the procurement of Heat Recovery Steam Generators (HRSG) from Hamon Deltak Inc., it’s essential to understand the various cost components that contribute to the overall pricing structure. The major cost elements include:

-

Materials: The choice of materials directly influences the pricing. High-quality steel and specialized alloys used in manufacturing HRSGs contribute significantly to the material costs. These materials are often sourced based on specific project requirements, impacting both price and delivery timelines.

-

Labor: Labor costs are influenced by the complexity of the design and the level of customization required. Skilled labor is essential for the precision manufacturing of HRSGs, and costs can vary based on local wage rates and the availability of skilled workers.

-

Manufacturing Overhead: Overhead costs encompass utilities, facility maintenance, and indirect labor. These costs are often allocated per unit based on the production volume and play a crucial role in determining the final pricing.

-

Tooling: Specialized tooling may be required for the fabrication of HRSGs, especially for custom designs. This initial investment can be significant but is amortized over the production run, affecting the price per unit.

-

Quality Control (QC): Rigorous quality control processes are vital to ensure the safety and efficiency of HRSGs. Costs associated with testing, inspections, and compliance with industry standards (like ASME codes) are integral to the overall pricing.

-

Logistics: Transportation and handling of large, heavy components can incur substantial costs. The logistics strategy, including shipping methods and distances, significantly affects pricing, especially for international buyers.

-

Margin: The profit margin applied by Hamon Deltak Inc. also affects the overall pricing. This margin can vary based on market demand, competition, and the uniqueness of the offered solution.

How Do Price Influencers Affect HRSG Sourcing Costs?

Several factors can influence the pricing of HRSGs, particularly for B2B buyers in diverse regions. Understanding these price influencers can lead to more informed purchasing decisions.

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for volume discounts, making it essential for buyers to assess their needs carefully. Negotiating MOQs can also lead to cost efficiencies.

-

Specifications and Customization: Custom-designed HRSGs tailored to specific operational requirements tend to have higher costs due to the additional engineering and material specifications involved.

-

Materials and Quality Certifications: The quality of materials used, along with certifications (e.g., ISO, ASME), can affect pricing. Buyers should evaluate the trade-offs between cost and quality to ensure compliance with operational standards.

-

Supplier Factors: The reputation and reliability of Hamon Deltak Inc. as a supplier can influence pricing. Established suppliers may charge a premium for their proven track record and customer support.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) can impact costs related to shipping, insurance, and responsibilities during transit. Understanding these terms is crucial for avoiding unexpected expenses.

What Are the Best Buyer Tips for Negotiating HRSG Prices?

For international buyers, especially those from Africa, South America, the Middle East, and Europe, several strategies can help secure favorable pricing:

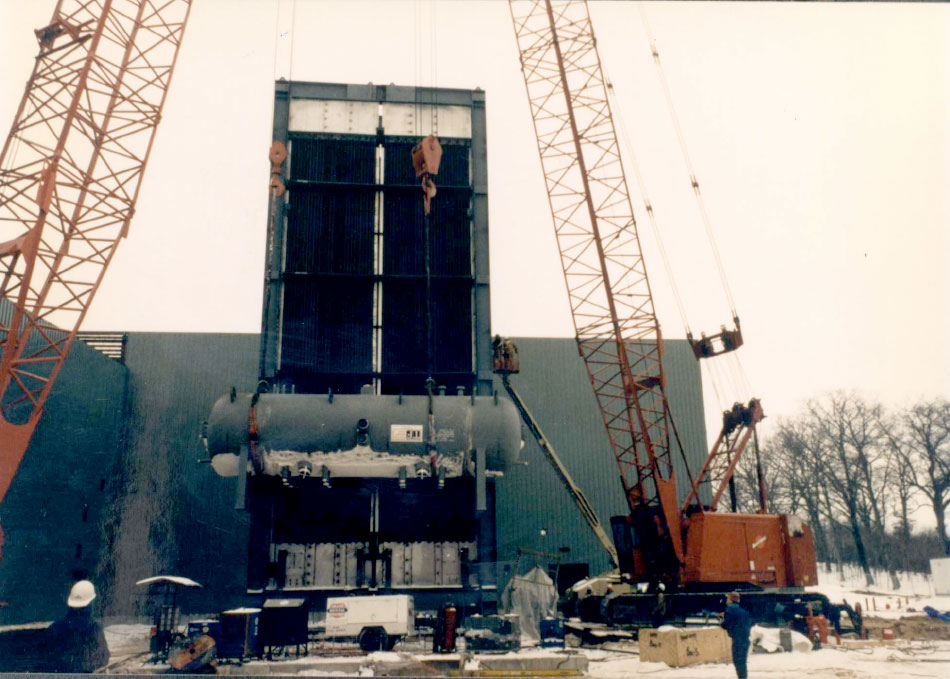

Illustrative image related to hamon deltak inc hrsg

-

Effective Negotiation: Engage in open discussions with Hamon Deltak’s sales team. Articulating your needs and exploring flexibility in specifications can lead to better pricing options.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes initial purchase price, installation, maintenance, and operational efficiency. This holistic view can highlight potential long-term savings.

-

Leverage International Relationships: If your business has experience with Hamon Deltak or similar suppliers, use those relationships to negotiate better terms or seek referrals for potential discounts.

-

Understand Pricing Nuances: Familiarize yourself with regional market conditions and currency fluctuations that could affect pricing. This knowledge can empower you during negotiations.

Disclaimer on Indicative Prices

Pricing for Hamon Deltak Inc. HRSGs can vary widely based on the specific requirements of each project, including customization levels and market conditions. It is advisable for buyers to request detailed quotes tailored to their unique needs for accurate financial planning.

Alternatives Analysis: Comparing hamon deltak inc hrsg With Other Solutions

Exploring Alternatives to Hamon Deltak Inc. HRSG

In the industrial boiler market, particularly regarding heat recovery steam generators (HRSG), understanding available alternatives is crucial for buyers seeking optimal solutions tailored to their specific needs. This analysis compares Hamon Deltak Inc.’s HRSG with two notable alternatives: Siemens’ HRSG and GE’s Heat Recovery Solutions. Each solution offers unique features, advantages, and challenges, making it imperative for B2B buyers to evaluate them based on critical aspects.

| Comparison Aspect | Hamon Deltak Inc HRSG | Siemens HRSG | GE Heat Recovery Solutions |

|---|---|---|---|

| Performance | High efficiency, modular design for rapid deployment | Advanced technology, highly efficient with low emissions | Proven reliability, good efficiency, and scalability |

| Cost | Competitive pricing; custom solutions may increase costs | Generally higher upfront costs due to advanced technology | Variable pricing; competitive for large-scale projects |

| Ease of Implementation | Modular design facilitates easier assembly | More complex installation requiring specialized teams | Straightforward, but may require significant site preparation |

| Maintenance | Comprehensive service offerings; preventive maintenance options | Strong service network but potentially higher maintenance costs | Good support; maintenance tailored to specific installations |

| Best Use Case | Ideal for diverse industrial applications needing flexibility | Best for large-scale power plants with stringent emissions regulations | Suitable for utilities and industries needing scalable solutions |

In-Depth Analysis of Alternatives

Siemens HRSG

Siemens offers a robust HRSG solution that incorporates advanced technology to optimize efficiency and reduce emissions. Its systems are particularly suited for large-scale power plants where performance and compliance with stringent regulations are paramount. However, the higher upfront costs and the complexity of installation may deter some buyers, especially those with limited technical resources. The investment, while significant, often pays off in terms of operational efficiency and long-term savings.

GE Heat Recovery Solutions

GE’s offerings in heat recovery are known for their reliability and scalability. These systems can adapt to a variety of applications, making them a versatile choice for both utilities and industrial facilities. While GE solutions are generally competitively priced for large projects, they may require substantial site preparation, which could lead to increased project timelines. Additionally, GE provides strong support, ensuring that maintenance is effectively managed, although the specific requirements can vary greatly between installations.

Making an Informed Choice for Your HRSG Needs

When selecting the right heat recovery steam generator, B2B buyers should consider several factors, including operational efficiency, total cost of ownership, and specific application requirements. Hamon Deltak Inc. HRSG stands out for its adaptability and service offerings, making it a strong contender for diverse industrial needs. Siemens and GE provide advanced technology and reliability, ideal for large-scale operations but may come with higher initial investments and installation complexities.

Ultimately, the choice will depend on the buyer’s specific operational goals, budget constraints, and the technical capabilities of their teams. A thorough assessment of these alternatives, along with a clear understanding of one’s unique needs, will facilitate a more informed decision that aligns with long-term business objectives.

Essential Technical Properties and Trade Terminology for hamon deltak inc hrsg

What Are the Essential Technical Properties of Hamon Deltak Inc. HRSG?

When evaluating Heat Recovery Steam Generators (HRSG) from Hamon Deltak Inc., several technical properties are vital for B2B buyers. Understanding these specifications can enhance decision-making and ensure alignment with operational requirements.

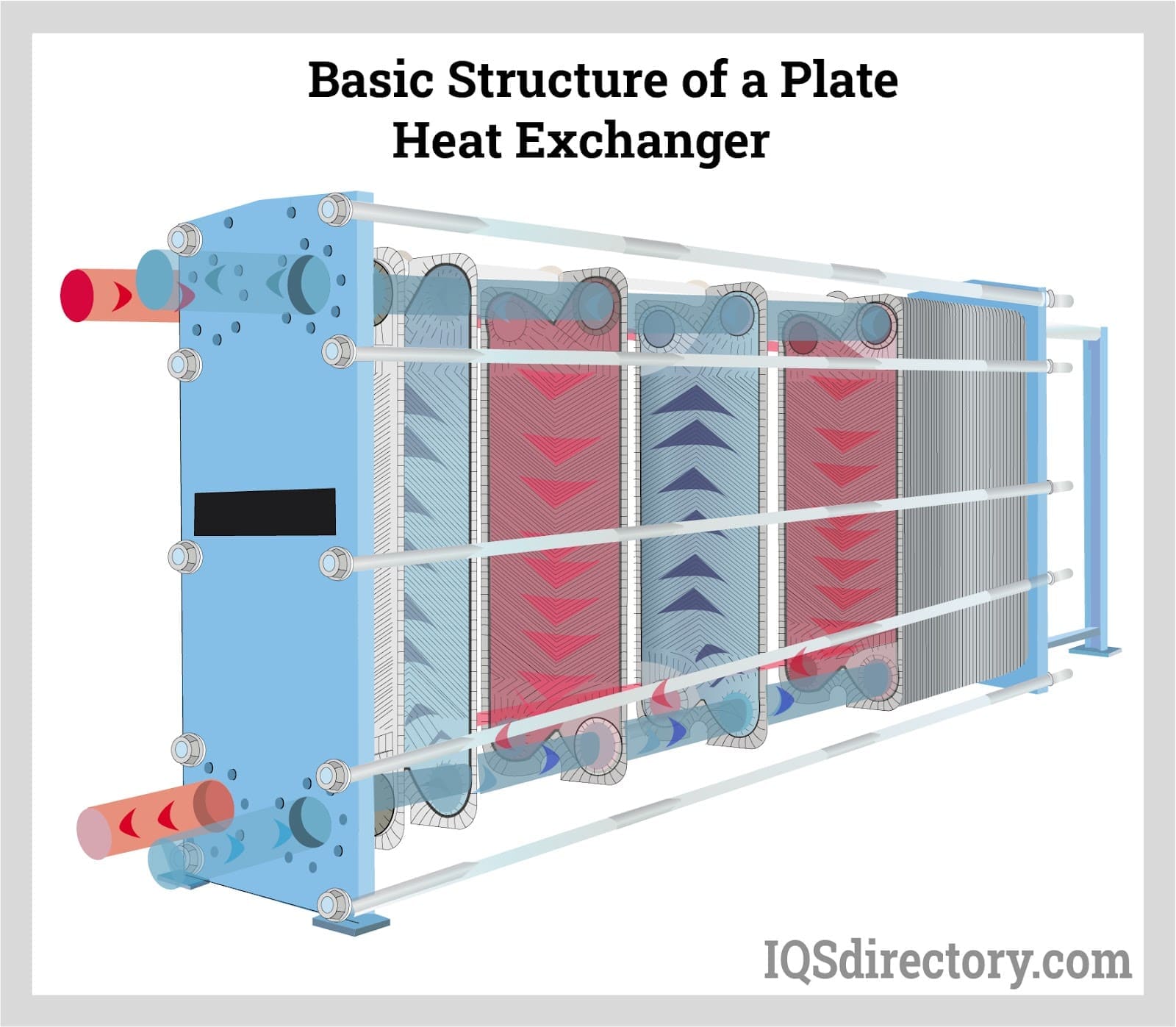

Illustrative image related to hamon deltak inc hrsg

1. Material Grade

Hamon Deltak HRSGs are constructed using high-grade materials such as carbon steel and stainless steel. The choice of material is crucial as it affects the boiler’s durability, corrosion resistance, and overall performance. High-quality materials ensure longevity, which is essential for reducing maintenance costs and downtime in industrial operations.

2. Design Pressure

Design pressure is a critical specification that defines the maximum pressure the HRSG can withstand during operation. This specification is vital for safety and compliance with industry standards. Understanding the design pressure helps buyers ensure that the HRSG will meet the operational needs of their specific applications without risking equipment failure.

3. Efficiency Rating

Efficiency ratings measure how effectively an HRSG converts waste heat into usable energy. Hamon Deltak emphasizes high efficiency in its designs, which can significantly reduce fuel consumption and operational costs. For B2B buyers, a high-efficiency rating translates to a more sustainable and cost-effective solution in the long run.

4. Heat Transfer Surface Area

The heat transfer surface area is a key factor in determining the performance of an HRSG. A larger surface area allows for better heat exchange, which can enhance steam generation and overall efficiency. Buyers should consider the heat transfer surface area to ensure the unit meets their specific energy requirements.

Illustrative image related to hamon deltak inc hrsg

5. Tolerance Levels

Tolerance levels indicate the acceptable limits of deviation in measurements during the manufacturing process. High precision in tolerances is essential for ensuring the reliability and functionality of the HRSG. For B2B buyers, understanding tolerance levels can help in assessing the quality of the product and its suitability for complex industrial applications.

What Are Common Trade Terms Related to Hamon Deltak Inc. HRSG?

Familiarity with industry terminology is crucial for effective communication and negotiation in the procurement process. Below are common trade terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of Hamon Deltak, this term applies to the relationship between the company and its clients, such as utilities and EPC contractors, who rely on their HRSGs as integral components in their systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for buyers to avoid overcommitting resources. It allows companies to plan their purchases strategically, ensuring they meet their operational needs without incurring unnecessary costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products or services. For B2B buyers, issuing an RFQ to Hamon Deltak can streamline the procurement process, ensuring that they receive competitive quotes tailored to their specifications.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international trade terms that define the responsibilities of buyers and sellers in shipping goods. Understanding Incoterms is crucial for B2B buyers as they dictate who bears the risk and costs associated with shipping, delivery, and insurance.

5. EPC (Engineering, Procurement, and Construction)

EPC refers to a project delivery system where the contractor is responsible for all aspects of project execution. For buyers, engaging with EPC firms that utilize Hamon Deltak HRSGs ensures that they receive integrated solutions tailored to complex industrial needs.

By grasping these technical properties and industry terms, international B2B buyers can make informed decisions, ultimately leading to successful procurement and operational efficiency in their energy systems.

Illustrative image related to hamon deltak inc hrsg

Navigating Market Dynamics and Sourcing Trends in the hamon deltak inc hrsg Sector

What Are the Key Trends Shaping the Hamon Deltak Inc. HRSG Market?

The global market for Heat Recovery Steam Generators (HRSG) is witnessing transformative changes driven by the increasing demand for energy efficiency and sustainability. As industries worldwide face mounting pressure to reduce emissions and enhance operational efficiency, HRSG systems have become vital in optimizing power generation processes. Key trends include the rise of modularization in manufacturing, which allows for quicker assembly and reduced labor costs on-site. This trend is particularly beneficial for international B2B buyers in emerging markets such as Africa and South America, where rapid deployment of energy solutions is critical.

Additionally, the integration of advanced technologies such as IoT and AI into HRSG systems is revolutionizing maintenance practices. Predictive maintenance capabilities enable clients to anticipate issues before they arise, minimizing downtime and operational costs. Furthermore, the global push towards renewable energy sources is driving investments in HRSG systems, as these technologies can efficiently utilize waste heat from renewable sources, making them an attractive option for buyers in Europe and the Middle East.

How Is Sustainability and Ethical Sourcing Impacting the Hamon Deltak Inc. HRSG Sector?

Sustainability has emerged as a core consideration for international B2B buyers, especially in sectors like power generation and manufacturing. The environmental impact of industrial processes is under scrutiny, making it imperative for companies to adopt sustainable practices. Hamon Deltak Inc. recognizes this shift and is committed to enhancing the sustainability of its HRSG products. This includes sourcing materials from suppliers who adhere to ethical practices and hold certifications that reflect their commitment to environmental stewardship.

The use of ‘green’ materials and technologies not only reduces the carbon footprint of HRSG systems but also aligns with regulatory requirements and market expectations. Buyers are increasingly looking for suppliers who can demonstrate compliance with international sustainability standards, such as ISO 14001. By prioritizing ethical sourcing and sustainability, Hamon Deltak Inc. positions itself as a preferred partner for B2B buyers who are serious about their environmental responsibilities.

What Is the Evolution of Hamon Deltak Inc. in the HRSG Market?

Founded in 1972, Hamon Deltak Inc. has evolved from a regional manufacturer into a global leader in the HRSG sector. Initially focusing on heat recovery steam generators, the company has expanded its offerings to include a wide range of industrial boiler solutions tailored to the specific needs of various industries. The company’s commitment to innovation has been pivotal in its growth, allowing it to adapt to changing market demands and technological advancements.

Over the decades, Hamon Deltak has established a strong reputation for quality and customer satisfaction, with approximately 80% of its business coming from repeat customers and referrals. This history of excellence and adaptability positions Hamon Deltak as a reliable partner for international B2B buyers seeking advanced, customized solutions in the HRSG sector.

Frequently Asked Questions (FAQs) for B2B Buyers of hamon deltak inc hrsg

-

How can I ensure the quality of Hamon Deltak HRSG products?

To ensure the quality of Hamon Deltak’s Heat Recovery Steam Generators (HRSG), it is essential to review their compliance with industry standards, such as the American Society of Mechanical Engineers (ASME) certifications. Additionally, inquire about their quality assurance processes, including testing and inspections carried out during manufacturing. Engaging with past clients and reviewing case studies can provide insights into product performance and customer satisfaction. Lastly, Hamon Deltak offers a comprehensive service program that includes ongoing maintenance and support, further ensuring the longevity and reliability of their products. -

What customization options are available for Hamon Deltak HRSG?

Hamon Deltak specializes in tailor-made solutions, offering customization based on specific project requirements. Each HRSG is engineered and designed to meet the unique needs of the client’s operational environment. Buyers can specify various parameters, including size, capacity, and efficiency levels, ensuring the product aligns with their project goals. It’s advisable to engage in detailed discussions with their engineering team to explore the full range of customization possibilities and how they can integrate with existing systems. -

What are the minimum order quantities (MOQ) for Hamon Deltak HRSG?

The minimum order quantity for Hamon Deltak HRSG typically varies based on the specific project requirements and complexity of the design. For large-scale industrial applications, it is common for orders to involve complete systems rather than individual units. Buyers are encouraged to consult directly with Hamon Deltak’s sales team to discuss their project needs and determine the most suitable order size that aligns with their operational plans and budget. -

What payment terms does Hamon Deltak offer for international buyers?

Hamon Deltak provides flexible payment terms tailored to the needs of international buyers. Common arrangements include upfront deposits, milestone payments based on project phases, and final payments upon delivery and installation. It is recommended to discuss specific terms with their sales team early in the negotiation process to ensure clarity and alignment with your financial practices. Additionally, consider the implications of currency exchange rates and international transaction fees. -

How does Hamon Deltak handle logistics and shipping for international orders?

Hamon Deltak has experience in managing logistics for international orders, ensuring that products are delivered efficiently and safely. They work closely with reputable shipping companies to handle transportation, customs clearance, and delivery to your site. Buyers should communicate their preferred delivery timelines and any specific logistical requirements during the procurement process. Understanding local regulations and potential tariffs in your country is also crucial to avoid delays. -

What after-sales support does Hamon Deltak provide for HRSG products?

Hamon Deltak offers robust after-sales support, which includes installation assistance, training for operational staff, and ongoing maintenance services. Their technical support team is available 24/7 to address any operational issues or inquiries. Regular preventive maintenance programs can be established to ensure optimal performance and longevity of the HRSG systems. Engaging with their support team post-purchase can enhance operational efficiency and reduce downtime. -

How can I vet Hamon Deltak as a supplier for my project needs?

To vet Hamon Deltak as a supplier, start by researching their industry reputation and history, focusing on client testimonials and case studies. Evaluate their experience in your specific sector and the countries in which they operate. Request references from previous clients, especially those in similar industries or geographic regions. Additionally, assess their compliance with international safety and quality standards, which can provide further confidence in their capabilities. -

What industries typically utilize Hamon Deltak HRSG products?

Hamon Deltak HRSG products are widely utilized across various industries, including power generation, oil and gas, petrochemical, food and beverage, and pulp and paper. These systems are essential for enhancing energy efficiency and sustainability by recovering waste heat from industrial processes. Understanding the specific applications within your industry can help determine how Hamon Deltak’s offerings can be integrated into your operational framework for improved performance and reduced environmental impact.

Top 8 Hamon Deltak Inc Hrsg Manufacturers & Suppliers List

1. Hamon Deltak – Industrial Boilers

Domain: industrial-boilers.com

Registered: 2001 (24 years)

Introduction: Hamon Deltak, Inc. specializes in the design, manufacturing, and servicing of a wide range of industrial boilers, including:

1. Watertube Boilers: High efficiency, reliability, robust construction, water-cooled membrane wall design for optimum heat transfer, capable of generating steam and hot water for various industrial processes, power generation, and cogeneration applications.

2. Firetube Boi…

2. LinkedIn – Dedicated API

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: To scrape Linkedin use our dedicated Linkedin API.

3. Hamon Deltak – HRSG & Boiler Design

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Hamon Deltak – HRSG & Boiler Design, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Hamon Deltak – HRSGs & WHBs

Domain: rocketreach.co

Registered: 2015 (10 years)

Introduction: Hamon Deltak, Inc. specializes in engineering and manufacturing combustion turbine heat recovery steam generators (HRSGs) and waste heat boilers (WHBs) for various applications. They are a leader in HRSGs for combined cycle and cogeneration applications, and WHBs for refining, petrochemical, incineration, oil production, industrial, and marine applications. The company offers solutions of any size…

5. Indeed – HRSG Solutions

Domain: indeed.com

Registered: 1998 (27 years)

Introduction: This company, Indeed – HRSG Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Frank Lill & Son – HRSG Installation Services

Domain: franklillandson.com

Registered: 2001 (24 years)

Introduction: Frank Lill & Son, Inc. offers turnkey installation, erection, modification, and repair services for large shop-assembled HRSGs and modular field erected heat recovery units. They have experience installing HRSGs on turbines ranging from under 7MW to over 200MW in utility and cogeneration sectors. The company has extensive firsthand experience servicing and installing HRSGs from OEMs such as Vogt P…

7. Deltak Inc. – Heat Recovery Solutions

Domain: leadiq.com

Registered: 2009 (16 years)

Introduction: Deltak Inc. specializes in waste heat recovery solutions, including Heat Recovery Steam Generators (HRSGs) and Waste Heat Boilers (WHBs). The company has over 2,500 units installed in 50 countries, indicating a strong international presence. Deltak is known for innovations such as the first ultra-low emission G-class HRSGs, replaceable water tube designs, and the world’s largest enhanced oil recov…

8. Hamon Deltak, Inc. – Custom-Designed Boilers

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Hamon Deltak, Inc. is a supplier of custom-designed boilers for waste heat recovery applications. They offer installation, start-up, operation training, and after-market services for the boiler industry. The company provides a wide range of spare parts and has an on-site manufacturing shop.

Strategic Sourcing Conclusion and Outlook for hamon deltak inc hrsg

In conclusion, Hamon Deltak Inc. stands out as a premier provider of heat recovery steam generators (HRSG) and industrial boilers, driven by a commitment to quality and innovation. The company’s tailored solutions cater to diverse sectors, including power generation, petrochemicals, and food processing, ensuring clients receive equipment that meets their specific operational requirements. Strategic sourcing from Hamon Deltak not only enhances energy efficiency but also supports sustainability initiatives by maximizing the use of waste heat.

For international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe, partnering with Hamon Deltak offers significant advantages. Their extensive engineering expertise and modular manufacturing approach minimize installation time and costs, providing a competitive edge in project execution.

As industries increasingly focus on sustainable practices and energy efficiency, now is the opportune moment to engage with Hamon Deltak. By leveraging their advanced technologies and customer-centric service, businesses can position themselves for future growth and success. Explore how Hamon Deltak can meet your industrial energy needs and contribute to a more sustainable operational framework.

Illustrative image related to hamon deltak inc hrsg

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.