Everything You Need to Know About Grit Blasting Machine Sourcing in 2025

Introduction: Navigating the Global Market for grit blasting machine

In the fast-paced world of industrial manufacturing and surface preparation, sourcing the right grit blasting machine can be a daunting challenge. With a plethora of options available, international B2B buyers face the critical task of identifying equipment that not only meets their operational needs but also aligns with their budgetary constraints. This comprehensive guide is designed to navigate the complexities of the grit blasting machine market, offering valuable insights into various types of machines, their applications, and the essential criteria for supplier vetting.

From portable units ideal for confined spaces to heavy-duty blast rooms engineered for large-scale operations, this guide explores the full spectrum of grit blasting solutions. We delve into key factors such as performance specifications, maintenance requirements, and compliance with international safety standards. Additionally, our guide provides a detailed breakdown of costs associated with different models and configurations, empowering buyers from regions like Africa, South America, the Middle East, and Europe—including prominent markets such as Saudi Arabia and Germany—to make informed purchasing decisions.

By equipping you with the knowledge and tools necessary to evaluate and select the right grit blasting machine, this guide aims to enhance your operational efficiency, reduce downtime, and ultimately drive your business success in the competitive global market.

Understanding grit blasting machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Dry Blast Machine | Utilizes dry abrasives, offering high efficiency and control | Metal surface preparation, coating removal | Pros: Versatile, high productivity. Cons: Dust generation can be an issue. |

| Wet Blast Machine | Combines water with abrasives to reduce dust and improve finish | Automotive refinishing, delicate surfaces | Pros: Dust suppression, suitable for sensitive jobs. Cons: More complex setup, higher maintenance. |

| Portable Blast Pot | Compact and mobile, designed for field applications | On-site blasting, maintenance work | Pros: Easy transport, quick setup. Cons: Limited capacity compared to stationary units. |

| Blast Room | Enclosed space with controlled environment for consistent blasting | Heavy industry, manufacturing facilities | Pros: Enhanced safety, optimized recovery systems. Cons: Higher initial investment. |

| Bulk Blaster | Large capacity for high-volume projects | Shipbuilding, large-scale industrial applications | Pros: Reduces downtime, efficient for massive projects. Cons: Requires significant space and logistics. |

What Are the Characteristics of Dry Blast Machines?

Dry blast machines are designed to utilize dry abrasive materials, which makes them highly efficient for various surface preparation tasks. They are commonly used in industries such as metal fabrication and coating removal. When considering a dry blast machine, B2B buyers should evaluate the machine’s capacity, pressure settings, and the type of abrasives compatible with the equipment. Although these machines offer high productivity, they can generate considerable dust, necessitating effective dust control measures.

How Do Wet Blast Machines Differ in Functionality?

Wet blast machines integrate water with abrasives to mitigate dust and provide a smoother finish. This makes them particularly suitable for automotive refinishing and projects requiring delicate handling of surfaces. Key purchasing considerations include water supply requirements, compatibility with various abrasives, and the overall maintenance needs of the system. While they offer advantages in terms of dust suppression, the complexity of setup and increased maintenance requirements can be drawbacks for some buyers.

Why Choose Portable Blast Pots for On-Site Applications?

Portable blast pots are compact and designed for mobility, making them ideal for on-site blasting operations such as maintenance work and smaller projects. Their key features include ease of transport and quick setup capabilities. B2B buyers should consider the capacity of the pot, the types of abrasives it can handle, and its pressure ratings. While these machines are advantageous for their portability, they typically have limited abrasive capacity compared to larger, stationary units.

What Advantages Do Blast Rooms Offer for Industrial Applications?

Blast rooms provide a controlled environment for abrasive blasting, enhancing safety and efficiency. They are particularly beneficial in heavy industry and manufacturing settings, where consistent operations are crucial. Buyers should evaluate the customization options available, the efficiency of the abrasive recovery systems, and the overall size of the room. Despite their high initial investment, blast rooms can significantly improve operational efficiency and worker safety.

When to Opt for Bulk Blasters in Large Projects?

Bulk blasters are designed for high-volume applications, capable of handling substantial amounts of abrasives. They are commonly used in industries such as shipbuilding and large-scale manufacturing. Key considerations for B2B buyers include the machine’s capacity, the logistics of abrasive handling, and the required space for operation. Although bulk blasters are efficient and reduce downtime, they require careful planning regarding space and logistics, which can be a challenge for some operations.

Key Industrial Applications of grit blasting machine

| Industry/Sector | Specific Application of grit blasting machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Surface preparation of pipelines and equipment | Enhances corrosion resistance and extends asset lifespan | Look for machines with high abrasive capacity and durability for harsh environments. |

| Construction & Infrastructure | Cleaning and preparing steel structures before coating | Ensures better adhesion of paints and coatings, reducing maintenance costs | Consider portability and ease of setup for on-site applications. |

| Automotive Manufacturing | Rust removal and surface finishing on vehicle components | Improves surface quality and reduces rework | Seek machines with adjustable pressure settings for different materials. |

| Shipbuilding | Hull cleaning and maintenance | Increases operational efficiency and prolongs vessel life | Evaluate the versatility of the machine for various blasting media. |

| Aerospace | Surface treatment of aircraft components | Enhances fatigue resistance and improves safety | Focus on precision and the ability to work with delicate materials without damage. |

How is Grit Blasting Used in the Oil & Gas Industry?

In the oil and gas sector, grit blasting machines are crucial for the surface preparation of pipelines and equipment. This process removes rust, scale, and other contaminants, ensuring that surfaces are clean and ready for coatings that enhance corrosion resistance. For international buyers, particularly in regions with extreme weather conditions, sourcing machines with robust construction and high abrasive capacities is vital. Additionally, these machines should be able to operate efficiently in remote locations, which is common in the oil and gas industry.

What Role Does Grit Blasting Play in Construction & Infrastructure?

Grit blasting is widely used in construction and infrastructure to clean and prepare steel structures before the application of protective coatings. This application is essential as it ensures better adhesion of paints, which ultimately reduces maintenance costs over time. Buyers should prioritize machines that are portable and easy to set up, allowing for quick mobilization to various job sites. Furthermore, the ability to adjust the blasting pressure is critical to accommodate different surface conditions and materials.

How is Grit Blasting Beneficial in Automotive Manufacturing?

In automotive manufacturing, grit blasting machines are employed for rust removal and surface finishing on vehicle components. This process not only improves the overall surface quality but also significantly reduces rework, saving time and costs in the production line. Buyers in this sector should seek machines that offer adjustable pressure settings, enabling them to adapt to various materials and component sizes. Additionally, the availability of specialized nozzles can enhance efficiency and precision in the blasting process.

Why is Grit Blasting Important in Shipbuilding?

In shipbuilding, grit blasting machines are utilized for hull cleaning and maintenance, which is crucial for ensuring operational efficiency and prolonging the life of vessels. The grit blasting process effectively removes marine growth, rust, and old coatings, preparing the surface for new protective layers. For international buyers, especially in maritime regions, evaluating the versatility of the blasting machine to accommodate different media types is essential. Machines should also be designed for ease of use in challenging environments, such as docks or shipyards.

How Does Grit Blasting Enhance Aerospace Component Treatment?

In the aerospace industry, grit blasting is used for the surface treatment of aircraft components, enhancing fatigue resistance and improving safety. This application is vital as it ensures that components meet stringent regulatory standards. Buyers should focus on precision machines capable of working with delicate materials without causing damage. The ability to control the blasting process meticulously is crucial, as it directly affects the performance and safety of aerospace components.

3 Common User Pain Points for ‘grit blasting machine’ & Their Solutions

Scenario 1: Difficulties in Equipment Portability and Setup

The Problem: Many B2B buyers of grit blasting machines, particularly those operating in remote or challenging environments such as construction sites or shipyards, face significant hurdles related to equipment portability and setup time. Traditional grit blasting machines can be heavy and cumbersome, requiring extensive time and labor to transport and assemble. This often leads to project delays and increased costs, especially when teams must wait for equipment to be set up before commencing work.

The Solution: To address these challenges, buyers should consider investing in portable grit blasting solutions, such as compact skid-mounted systems that integrate multiple functions into a single unit. For instance, options like the BlastOne Dry Combo Skid Blast Package allow users to transport and set up the machine with minimal effort—simply connect the compressor hose and blast hose to start blasting. Additionally, ensure that the chosen system includes features like plug-and-play design and built-in air dryers for streamlined operations. This will not only save time during setup but also enhance mobility across various job sites, effectively reducing downtime and operational costs.

Scenario 2: Inefficiencies in Abrasive Material Handling

The Problem: Buyers often struggle with the handling and loading of abrasive materials, which can be labor-intensive and prone to safety hazards. Manual loading of heavy bags or containers can lead to operator fatigue and potential injuries, while also increasing the risk of contamination or spillage, affecting the quality of blasting work. This inefficiency can escalate costs and negatively impact project timelines, especially in high-volume applications.

The Solution: Implementing advanced loading systems can significantly enhance efficiency and safety in abrasive material handling. Solutions like bulk loading racks designed for grit blasting machines can streamline the loading process. These racks facilitate the safe transfer of abrasive materials from bulk bags or containers directly into the blasting machine, minimizing manual handling. Buyers should prioritize purchasing grit blasting machines that are compatible with these loading systems. Furthermore, investing in automatic or semi-automatic loading systems can reduce operator strain and enhance throughput, ensuring that blasting operations remain consistent and effective.

Scenario 3: The Challenge of Dust and Environmental Compliance

The Problem: In many industries, especially those involving surface preparation and coating applications, the generation of dust during grit blasting can pose serious health risks to workers and environmental compliance challenges. Buyers are increasingly required to adhere to stringent regulations regarding air quality and worker safety, which can complicate the use of traditional grit blasting methods that produce high levels of airborne particles.

The Solution: To mitigate dust generation and comply with environmental regulations, B2B buyers should explore wet blasting technologies or advanced dust suppression systems. For example, the Clemco PowerGun H2O offers a portable solution that incorporates wet blasting techniques, effectively reducing dust while providing a high-quality finish. Additionally, investing in blast rooms with integrated dust collection systems can create a controlled environment for grit blasting operations, further minimizing airborne contaminants. Buyers should also engage with suppliers who can provide comprehensive training on safe blasting practices and recommend suitable equipment that aligns with local regulations, ensuring both compliance and worker safety.

Strategic Material Selection Guide for grit blasting machine

What Are the Key Materials Used in Grit Blasting Machines and Their Properties?

When selecting materials for grit blasting machines, several factors come into play, including performance properties, cost, and suitability for specific applications. Here, we analyze four common materials used in grit blasting machines: carbon steel, stainless steel, aluminum, and composite materials. Each material has unique properties that can significantly impact the machine’s performance and longevity.

How Does Carbon Steel Perform in Grit Blasting Machines?

Carbon steel is a widely used material in grit blasting machines due to its excellent strength and durability. It typically has a temperature rating of up to 400°F (204°C) and can withstand high pressures, making it suitable for various blasting applications.

Pros: Carbon steel is relatively inexpensive and easy to manufacture, making it a cost-effective choice for many manufacturers. Its high tensile strength ensures that it can endure the rigors of abrasive blasting.

Cons: However, carbon steel is prone to corrosion, especially in humid or saline environments, which can lead to rust and degradation over time. This necessitates regular maintenance and protective coatings.

Impact on Application: Carbon steel is compatible with a wide range of abrasive media, including steel grit and garnet, making it versatile for different blasting tasks.

Considerations for International Buyers: Buyers from regions with high humidity, such as parts of Africa and South America, should consider corrosion-resistant coatings. Compliance with standards like ASTM A36 is essential for ensuring quality.

What Are the Advantages of Using Stainless Steel in Grit Blasting Machines?

Stainless steel is another popular choice for grit blasting machines, known for its superior corrosion resistance and durability. It can handle temperatures up to 1500°F (815°C) and high pressures, making it ideal for demanding applications.

Pros: The primary advantage of stainless steel is its resistance to rust and corrosion, which extends the lifespan of the equipment. This material also requires less maintenance compared to carbon steel.

Cons: The downside is its higher cost, which can be a significant factor for budget-conscious buyers. Additionally, stainless steel can be more challenging to machine, increasing manufacturing complexity.

Illustrative image related to grit blasting machine

Impact on Application: Stainless steel is particularly suited for applications involving moisture or chemicals, such as in the oil and gas industry. Its compatibility with various abrasive media ensures consistent performance.

Considerations for International Buyers: Buyers in Europe and the Middle East often prefer stainless steel due to stringent corrosion resistance standards, such as DIN 17440. Understanding local compliance requirements is crucial.

Why Choose Aluminum for Grit Blasting Machines?

Aluminum is gaining traction in the grit blasting industry due to its lightweight properties and resistance to corrosion. It typically has a temperature rating of around 600°F (316°C) and can handle moderate pressures.

Illustrative image related to grit blasting machine

Pros: The lightweight nature of aluminum makes it easier to transport and set up, reducing labor costs. Additionally, its natural corrosion resistance minimizes maintenance needs.

Cons: However, aluminum is less durable than steel and may not withstand heavy-duty applications as effectively. Its lower tensile strength can also limit its use in high-pressure environments.

Impact on Application: Aluminum is suitable for smaller, portable grit blasting machines used in less demanding environments. It works well with lighter abrasive materials.

Considerations for International Buyers: In regions like Africa and South America, where portability is essential, aluminum machines can be advantageous. Compliance with local standards is still necessary, though aluminum is less regulated than steel.

What Role Do Composite Materials Play in Grit Blasting Machines?

Composite materials are increasingly used in grit blasting machines due to their unique properties, including high strength-to-weight ratios and excellent corrosion resistance. These materials can handle temperatures up to 350°F (177°C) and moderate pressures.

Pros: Composites are lightweight, reducing transportation costs and improving maneuverability. They also offer excellent resistance to chemicals and moisture, enhancing durability.

Illustrative image related to grit blasting machine

Cons: The primary drawback is the higher manufacturing cost and complexity, which can deter some buyers. Additionally, composites may not be suitable for all abrasive media types.

Impact on Application: Composites are ideal for specialized applications where corrosion resistance is paramount, such as in marine environments.

Considerations for International Buyers: Buyers should be aware of the varying standards for composite materials in different regions, including compliance with ASTM and ISO standards.

Summary Table of Material Selection for Grit Blasting Machines

| Material | Typical Use Case for grit blasting machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General-purpose blasting applications | Cost-effective and durable | Prone to corrosion | Low |

| Stainless Steel | Heavy-duty and corrosive environments | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Portable and lightweight machines | Lightweight and easy to transport | Less durable under heavy use | Medium |

| Composite | Specialized applications in harsh environments | High strength-to-weight ratio | Higher manufacturing cost | High |

This strategic material selection guide provides essential insights for B2B buyers looking to optimize their grit blasting machine investments. Understanding the properties and implications of each material can help in making informed purchasing decisions tailored to specific operational needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for grit blasting machine

What Are the Key Stages in the Manufacturing Process of Grit Blasting Machines?

The manufacturing process for grit blasting machines involves several critical stages, each designed to ensure the durability, efficiency, and performance of the final product. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Grit Blasting Machines?

Material preparation is the foundational step in the production of grit blasting machines. Manufacturers typically source high-quality raw materials, such as carbon steel or stainless steel, which are known for their strength and resistance to corrosion. The selected materials undergo thorough inspections to verify their compliance with industry standards.

Once approved, the materials are cut to specified dimensions using advanced cutting technologies, such as laser cutting or water jet cutting. This precision ensures that the components fit together seamlessly during assembly, minimizing the potential for leaks or structural weaknesses.

What Forming Techniques Are Used in Grit Blasting Machine Manufacturing?

The forming stage involves shaping the cut materials into the necessary components of the grit blasting machine. Common techniques include welding, bending, and machining.

Welding is a critical process for joining metal parts, ensuring that the joints can withstand high pressures and abrasive conditions. Manufacturers often use MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding methods, known for their precision and strength.

Bending and machining are employed to create specific shapes and dimensions required for the machine’s functionality. CNC (Computer Numerical Control) machines are frequently used to achieve high levels of accuracy, allowing for complex geometries that enhance the machine’s performance.

How Is the Assembly Process Conducted for Grit Blasting Machines?

Assembly is the stage where all the prepared components come together to form the complete grit blasting machine. This process often involves both manual and automated techniques. Skilled technicians assemble various parts, including the blast pot, air compressor, hoses, and nozzles, ensuring that each component is securely connected and correctly aligned.

During assembly, manufacturers also integrate safety features and controls, such as pressure relief valves and deadman controls, which are crucial for safe operation. Quality checks are performed at this stage to verify that all components meet the design specifications and safety standards.

What Finishing Processes Are Applied to Grit Blasting Machines?

Finishing processes enhance the durability and aesthetic appeal of grit blasting machines. Common finishing techniques include surface treatment, painting, and coating.

Surface treatments like sandblasting or shot blasting are employed to prepare the metal surfaces for painting or coating, ensuring better adhesion and corrosion resistance.

Painting typically involves the application of industrial-grade coatings that provide protection against environmental factors, such as humidity and salt. Manufacturers often opt for powder coating, which offers a durable finish and is environmentally friendly compared to traditional paint.

What Quality Assurance Practices Are Essential for Grit Blasting Machines?

Quality assurance (QA) is a critical aspect of the manufacturing process for grit blasting machines, ensuring that products meet stringent international and industry-specific standards.

Which International Standards Should B2B Buyers Be Aware Of?

One of the primary international standards relevant to grit blasting machines is ISO 9001, which outlines requirements for a quality management system. Compliance with ISO 9001 indicates that a manufacturer has established processes to ensure consistent quality in its products and services.

Additionally, industry-specific certifications such as CE marking for products sold in the European Economic Area and API (American Petroleum Institute) standards for oil and gas applications are vital. These certifications demonstrate compliance with safety, health, and environmental regulations.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are integrated throughout the manufacturing process. These typically include:

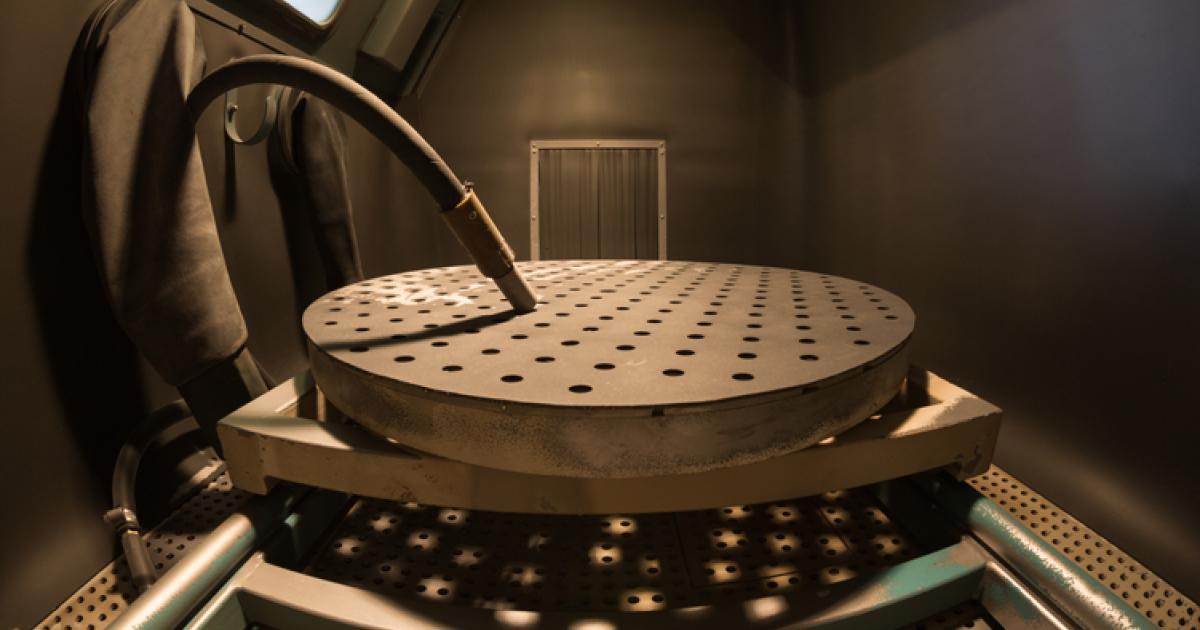

Illustrative image related to grit blasting machine

- Incoming Quality Control (IQC): Inspecting raw materials upon receipt to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitoring critical stages of production to catch defects early.

- Final Quality Control (FQC): Conducting thorough inspections of the finished product before shipping to verify compliance with quality standards.

Common testing methods used in QC include pressure testing, dimensional checks, and operational tests to ensure that the machines perform as expected under various conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those sourcing from international markets, verifying a supplier’s quality control processes is essential. Here are some actionable steps:

-

Supplier Audits: Conducting on-site audits can provide insights into a manufacturer’s production processes and quality management systems. This helps assess compliance with international standards and industry-specific regulations.

-

Requesting Quality Reports: Buyers should request documentation detailing the supplier’s quality control procedures, including inspection reports and certification copies. This documentation serves as evidence of adherence to quality standards.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the manufacturing process and product quality. These agencies can conduct inspections at various stages of production, ensuring that the final product meets the buyer’s requirements.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from Africa, South America, the Middle East, and Europe must be aware of certain nuances in quality control. Different regions may have varying regulatory requirements, and understanding these can facilitate smoother transactions.

Illustrative image related to grit blasting machine

For example, buyers in Europe may prioritize CE marking for compliance, while those in the Middle East may focus on local standards and certifications. Additionally, logistical considerations such as shipping regulations and import duties can affect the overall cost and compliance of grit blasting machines.

By being informed about these nuances, international buyers can make more educated decisions when selecting suppliers, ultimately leading to successful procurement of high-quality grit blasting machines.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘grit blasting machine’

Introduction

Acquiring a grit blasting machine is a significant investment for any industrial operation. This guide provides a structured checklist to help B2B buyers navigate the procurement process effectively. By following these steps, you can ensure that you select the right equipment for your specific needs while minimizing risks associated with supplier selection and equipment performance.

Step 1: Define Your Technical Specifications

Before beginning your search, clearly outline the technical requirements of the grit blasting machine you need. Consider factors such as the size of the machine, the type of abrasive material to be used, and the specific applications it will serve.

– Capacity and Output: Determine the volume of abrasive material the machine should handle and the expected output rate.

– Operational Environment: Assess whether the machine will be used indoors or outdoors, as this will influence your choice of features, such as dust collection systems.

Step 2: Set Your Budget Parameters

Establish a budget that includes not just the purchase price, but also installation, maintenance, and operational costs.

– Total Cost of Ownership: Evaluate long-term costs, including energy consumption and replacement parts, to avoid unexpected expenses.

– Financial Flexibility: Factor in potential financing options that may be available to spread out the cost over time.

Step 3: Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers who specialize in grit blasting machines.

– Industry Reputation: Look for suppliers with a proven track record in your region or industry, as local support and knowledge can be invaluable.

– Product Range: Ensure that the suppliers offer a variety of machines to meet your specific needs, including both standard and custom options.

Step 4: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Certifications and Compliance: Verify that suppliers adhere to relevant safety and quality standards, which can affect both performance and liability.

– Customer Reviews: Look for feedback from existing clients to gauge reliability and support responsiveness.

Step 5: Request Quotes and Compare Offerings

Once you have shortlisted potential suppliers, request detailed quotes for the machines that meet your specifications.

– Inclusions in Quotes: Ensure that quotes include all necessary components such as hoses, nozzles, and safety equipment.

– Warranty and Service Terms: Compare warranty periods and service agreements to understand the level of post-purchase support provided.

Illustrative image related to grit blasting machine

Step 6: Conduct Site Visits or Demos

If possible, arrange site visits or demonstrations of the grit blasting machines you are considering.

– Hands-On Evaluation: Observing the equipment in action can provide insights into its performance and ease of use.

– Operator Feedback: Involve your team in the evaluation process to gather feedback on usability and ergonomics.

Step 7: Finalize Purchase and Plan for Implementation

After selecting a supplier and machine, finalize your purchase agreement and plan for implementation.

– Training Requirements: Ensure that the supplier provides adequate training for your operators to maximize safety and efficiency.

– Installation Support: Confirm that the supplier will assist with installation and initial setup to ensure the machine operates optimally from day one.

By following this checklist, B2B buyers can streamline the sourcing process for grit blasting machines and make informed decisions that align with their operational goals.

Comprehensive Cost and Pricing Analysis for grit blasting machine Sourcing

Analyzing the cost structure and pricing for grit blasting machines is essential for international B2B buyers aiming to optimize their sourcing strategies. Understanding the components of cost and the various price influencers can significantly impact purchasing decisions, especially when considering the diverse markets in Africa, South America, the Middle East, and Europe.

What are the Key Components of Cost in Grit Blasting Machine Manufacturing?

The cost structure for grit blasting machines typically comprises several critical components:

-

Materials: The primary cost driver includes high-quality metals, components for abrasive delivery systems, and safety features. The choice of materials directly affects durability and performance, which can lead to varying price points across suppliers.

-

Labor: Skilled labor is essential for manufacturing, assembly, and quality control. Labor costs can fluctuate based on the region of production. For instance, manufacturers in Europe may face higher labor costs compared to those in South America or Africa.

-

Manufacturing Overhead: This encompasses utilities, facility costs, and indirect labor. Efficient manufacturing processes can help reduce overhead costs, which can influence the final price of the machine.

-

Tooling: Investment in specialized tooling for production can add to initial costs but is necessary for ensuring precision and quality in grit blasting machines.

-

Quality Control (QC): Rigorous QC processes are vital for ensuring safety and performance standards. This can involve additional testing and certification, which may increase upfront costs.

-

Logistics: Shipping and handling costs vary widely based on destination and the selected Incoterms. These costs must be factored into the overall purchase price, particularly for international buyers.

-

Margin: Suppliers typically build a profit margin into their pricing, which can vary based on market competition and their business strategy.

How Do Price Influencers Affect Grit Blasting Machine Costs?

Several factors influence the pricing of grit blasting machines, making it essential for buyers to be aware of these variables:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for volume discounts, reducing the per-unit cost significantly. Buyers should negotiate based on their anticipated usage.

-

Specifications and Customization: Customized machines tailored to specific applications or operational environments can lead to higher prices. However, these machines may provide better efficiency and longevity.

-

Material Quality and Certifications: Machines built with premium materials and certified to international standards can command higher prices. Buyers should consider the long-term benefits of investing in quality.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established manufacturers may offer warranties and support, justifying higher prices.

-

Incoterms: Understanding shipping terms is crucial. Ex-works (EXW) pricing may seem lower, but it could lead to higher overall costs due to logistics challenges. Buyers should consider CIF (Cost, Insurance, and Freight) for better predictability in total costs.

What Are the Best Tips for B2B Buyers in Grit Blasting Machine Sourcing?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation and strategic purchasing can lead to significant savings:

-

Negotiate Wisely: Engage suppliers in discussions about pricing, especially for larger orders. Leverage competitive quotes to negotiate better terms and pricing.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, operational costs, and potential downtime. A slightly higher initial investment might result in lower long-term costs.

-

Understand Pricing Nuances: Be aware of regional differences in pricing due to factors like import duties, taxes, and currency fluctuations. This understanding can help in making more informed purchasing decisions.

-

Request Indicative Pricing: Given the variability in costs due to customization and specifications, always ask for indicative pricing to establish a baseline for your budget.

In conclusion, comprehensively analyzing the cost components and pricing influencers of grit blasting machines equips international B2B buyers with the insights needed to make informed purchasing decisions, ultimately leading to more efficient and cost-effective operations.

Illustrative image related to grit blasting machine

Alternatives Analysis: Comparing grit blasting machine With Other Solutions

Understanding Alternatives to Grit Blasting Machines

In the industrial sector, various surface preparation methods are available, each offering unique advantages and disadvantages. Grit blasting machines are widely used for their efficiency in removing contaminants and preparing surfaces for coatings. However, businesses must consider alternative solutions that may better fit their operational needs, budget constraints, or specific project requirements. This section explores viable alternatives to grit blasting machines, focusing on wet blasting systems and abrasive blasting rooms.

| Comparison Aspect | Grit Blasting Machine | Wet Blasting System | Abrasive Blasting Room |

|---|---|---|---|

| Performance | High efficiency; effective for large areas | Reduces dust; suitable for delicate surfaces | Consistent results; ideal for high-volume operations |

| Cost | Moderate initial investment; ongoing media costs | Higher initial cost; lower media usage | High setup costs; long-term savings on media and labor |

| Ease of Implementation | Quick setup; requires adequate space | Requires water source; may need specialized training | Complex installation; requires significant space |

| Maintenance | Moderate; periodic checks needed | Higher maintenance due to water systems | Low maintenance; designed for continuous use |

| Best Use Case | Heavy-duty applications; large projects | Sensitive tasks; dust-sensitive environments | High-volume production; controlled environments |

What Are the Advantages and Disadvantages of Wet Blasting Systems?

Wet blasting systems, such as the Clemco PowerGun H2O, offer a portable solution that combines abrasive materials with water to mitigate dust during operation. This method is particularly advantageous for sensitive tasks, as it reduces the risk of damaging delicate surfaces. However, the requirement for a water source and potential complexities in setup may pose challenges for some operations. Additionally, while the initial cost can be higher than traditional grit blasting, lower media consumption may offset this over time.

How Do Abrasive Blasting Rooms Compare?

Abrasive blasting rooms are designed to provide a controlled environment for surface preparation, making them ideal for high-volume operations. These rooms allow for consistent results and can accommodate multiple operators simultaneously, significantly increasing productivity. However, the initial investment for building or leasing a blasting room is substantial, and businesses need to consider the space requirements. Over time, these facilities can lead to savings in media costs and labor, making them a long-term solution for industrial operations.

Conclusion: Choosing the Right Surface Preparation Solution

When selecting a surface preparation solution, B2B buyers must carefully evaluate their specific operational needs, budget, and project requirements. Grit blasting machines offer robust performance for heavy-duty applications, while wet blasting systems and abrasive blasting rooms provide alternative advantages in terms of dust control and operational efficiency. By analyzing the performance, cost implications, ease of implementation, and maintenance needs of each option, businesses can make informed decisions that align with their strategic goals and enhance their operational effectiveness.

Essential Technical Properties and Trade Terminology for grit blasting machine

What Are the Essential Technical Properties of Grit Blasting Machines?

When considering grit blasting machines, understanding their technical properties is crucial for making informed purchasing decisions. Here are some of the key specifications that B2B buyers should focus on:

-

Abrasive Capacity

– This refers to the amount of abrasive material the machine can hold, typically measured in cubic feet (cf). For example, machines can vary from 6.5 cf to over 160 cf. A larger capacity allows for longer operational periods between refills, which is essential for maximizing productivity on large projects. B2B buyers should assess their project sizes to choose a machine that meets their needs without frequent interruptions. -

Pressure Rating

– The maximum pressure at which the machine operates, commonly expressed in pounds per square inch (psi). For instance, many machines operate at 100 to 150 psi. A higher pressure rating enhances the blasting effectiveness, enabling faster surface preparation and better finish quality. Understanding the pressure requirements is vital for selecting compatible compressors and ensuring optimal performance. -

Material Grade

– Grit blasting machines are often constructed from high-grade steel or other durable materials to withstand the abrasive nature of blasting operations. The material grade impacts the machine’s longevity, resistance to wear, and overall reliability. Buyers should inquire about the material specifications to ensure that they are investing in a machine that can handle their specific operational demands. -

Hose Length and Configuration

– The length and type of blast hoses can significantly affect operational efficiency. Hoses are available in various lengths, typically ranging from 50 to 100 feet. Longer hoses provide greater flexibility on job sites, while specific configurations (single or dual outlet) allow for multiple operators to work simultaneously. Understanding hose specifications helps buyers optimize their workflow and minimize downtime. -

Safety Features

– Modern grit blasting machines often include advanced safety features such as pressure relief valves, deadman controls, and ergonomic designs. These features are critical for protecting operators and ensuring compliance with safety regulations. Buyers should prioritize machines that offer robust safety mechanisms to reduce workplace accidents and enhance operator confidence.

What Are Common Trade Terms Used in Grit Blasting Equipment?

Familiarity with industry terminology is essential for effective communication and negotiation in the grit blasting sector. Here are some common trade terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

– This term refers to the company that produces the original equipment or components. When purchasing grit blasting machines, knowing the OEM can provide insights into the quality and reliability of the equipment. Buyers often prefer established OEMs with a proven track record in the industry. -

MOQ (Minimum Order Quantity)

– MOQ represents the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for buyers, especially when budgeting for large projects. It helps in negotiating terms with suppliers to ensure that they can meet project requirements without incurring excess costs. -

RFQ (Request for Quotation)

– An RFQ is a formal request sent by buyers to suppliers, asking for a price quote on specific products or services. This process allows buyers to gather competitive pricing and terms before making purchasing decisions. Crafting a detailed RFQ can lead to better pricing and more favorable terms from suppliers. -

Incoterms (International Commercial Terms)

– These are standardized terms used in international trade to clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is crucial for buyers engaged in cross-border transactions, as they dictate who bears the costs and risks associated with the shipping process. -

Blasting Media

– This term refers to the materials used in the blasting process, such as steel grit, garnet, or glass beads. The choice of blasting media impacts the efficiency and finish quality of the blasting operation. Buyers should evaluate the compatibility of different media types with their specific grit blasting applications.

By grasping these technical properties and trade terms, B2B buyers can enhance their purchasing strategies, ensuring they select the right grit blasting machines that align with their operational needs and budget constraints.

Navigating Market Dynamics and Sourcing Trends in the grit blasting machine Sector

What Are the Key Market Trends in the Grit Blasting Machine Sector?

The global grit blasting machine market is witnessing significant growth driven by various factors, including increased industrial activity, a rise in infrastructure projects, and advancements in technology. Emerging markets in Africa and South America are particularly notable, as they invest in modernization and expansion of manufacturing capabilities. In the Middle East, particularly in Saudi Arabia, initiatives like Vision 2030 are stimulating demand for abrasive blasting solutions across construction and oil & gas sectors.

Furthermore, digital transformation is reshaping the grit blasting industry. Innovations such as remote monitoring and predictive maintenance technologies are becoming integral to operations, allowing companies to enhance efficiency and reduce downtime. The adoption of automation in grit blasting processes is also on the rise, with businesses seeking to optimize labor costs and ensure consistent quality.

Additionally, the trend towards integrated solutions, such as the combination of blast machines with air dryers and breathing air systems, is gaining traction. This bundling not only streamlines operations but also provides enhanced safety and convenience for field contractors. As international B2B buyers evaluate suppliers, they are increasingly looking for companies that offer comprehensive, ready-to-use solutions that meet their specific needs.

How Are Sustainability and Ethical Sourcing Influencing the Grit Blasting Machine Market?

Sustainability is becoming a critical focus in the grit blasting machine sector, driven by heightened environmental awareness and regulatory pressures. The industry is under scrutiny for its environmental impact, particularly concerning the use of hazardous materials and waste generation. As such, many manufacturers are transitioning towards ‘green’ practices by utilizing biodegradable abrasives and developing machines that minimize dust and emissions.

Ethical sourcing is equally important, with buyers increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices throughout their supply chains. This includes ensuring that raw materials are sourced responsibly and that manufacturing processes comply with environmental standards. Certifications such as ISO 14001 for environmental management and adherence to REACH regulations are becoming vital for companies aiming to position themselves favorably in the market.

Moreover, companies that adopt sustainable practices often gain a competitive edge, attracting environmentally conscious clients and fostering loyalty among existing customers. As international buyers evaluate suppliers, they will likely favor those who can provide assurances of sustainability and ethical sourcing in their grit blasting solutions.

How Has the Grit Blasting Machine Market Evolved Over Time?

The grit blasting machine market has evolved significantly since its inception, transitioning from manual processes to highly automated systems. Early grit blasting techniques relied heavily on human labor and less efficient equipment, which posed safety risks and limited operational capabilities.

The introduction of mechanized blasting systems in the mid-20th century marked a pivotal shift, enhancing efficiency and safety. Over the decades, technological advancements have led to the development of sophisticated machines that offer improved performance, versatility, and precision. The integration of digital technologies, such as IoT and data analytics, is now shaping the future of grit blasting operations, allowing for real-time monitoring and optimization.

As industries continue to prioritize efficiency and sustainability, the grit blasting sector is poised for further innovation, making it essential for international B2B buyers to stay informed about evolving trends and technologies.

Frequently Asked Questions (FAQs) for B2B Buyers of grit blasting machine

-

How do I select the right grit blasting machine for my project needs?

Choosing the right grit blasting machine depends on several factors, including the size of the project, the type of surface being blasted, and the required finish. Assess the abrasive material you will use, as different machines are compatible with various media types. For larger projects, consider machines with higher capacities and dual outlets for increased efficiency. Additionally, evaluate features like portability, setup time, and whether you need a wet or dry blasting system based on environmental considerations. -

What are the key features to look for in a grit blasting machine?

When sourcing a grit blasting machine, prioritize features such as capacity (measured in cubic feet), pressure rating, and nozzle technology. Look for machines with efficient abrasive recovery systems to minimize waste and maximize productivity. Safety features like pressure-hold valves and ergonomic designs can enhance operator safety and comfort. Additionally, consider whether the machine offers customization options to suit specific project requirements, such as integrated air dryers or portable setups. -

What are the typical payment terms for purchasing grit blasting machines internationally?

Payment terms for international purchases can vary significantly based on the supplier and the buyer’s location. Common terms include advance payment, letters of credit, or payment upon delivery. It is essential to discuss and negotiate payment terms before finalizing the contract to ensure mutual agreement. Be aware of any additional costs associated with shipping, customs duties, and taxes, which can affect the overall budget for your grit blasting machine acquisition. -

How do I vet suppliers of grit blasting machines?

To vet suppliers, start by checking their industry reputation through reviews and testimonials from previous clients. Request references and case studies that demonstrate their experience with similar projects. Ensure that the supplier adheres to international quality standards, such as ISO certifications. Additionally, assess their customer support services, warranty policies, and the availability of spare parts to ensure reliability and assistance throughout the machine’s lifecycle. -

What is the minimum order quantity (MOQ) for grit blasting machines?

The MOQ for grit blasting machines can vary widely depending on the manufacturer or supplier. Some may offer single units, while others may have an MOQ that requires bulk orders to ensure cost-effectiveness. When negotiating with suppliers, inquire about flexibility in order quantities, especially if you are a small or first-time buyer. Establishing a relationship with the supplier can sometimes lead to more favorable terms regarding MOQs. -

What logistics considerations should I keep in mind when importing grit blasting machines?

Logistics is critical when importing grit blasting machines, especially regarding shipping methods and timelines. Assess the transportation options available, such as sea freight or air freight, and choose based on urgency and budget constraints. Ensure that the supplier provides clear shipping terms, including incoterms that define responsibilities for shipping costs and risks. Additionally, consider the import regulations and customs procedures in your country to avoid delays and additional charges upon arrival. -

How can I ensure quality assurance (QA) for grit blasting machines?

To ensure quality assurance, request detailed specifications and compliance certifications from the manufacturer before purchase. Conduct inspections during the production process if possible, or arrange for third-party inspections to verify quality standards. After delivery, perform thorough testing of the machine to confirm it operates as expected and meets your project requirements. Establishing a clear communication line with the supplier for post-purchase support and maintenance can also enhance quality assurance. -

What are the benefits of customizing a grit blasting machine for my specific needs?

Customizing a grit blasting machine allows you to tailor features to meet your unique project requirements, enhancing efficiency and effectiveness. Custom options may include specialized nozzle designs, pressure settings, and integrated systems for dust control or moisture removal. This can lead to better surface preparation and finish quality, ultimately saving time and costs in the long run. Working closely with the supplier during the customization process ensures that the final product aligns perfectly with your operational needs.

Top 8 Grit Blasting Machine Manufacturers & Suppliers List

1. Progressive Surface – Robotic Grit Blast Equipment

Domain: progressivesurface.com

Registered: 2009 (16 years)

Introduction: Abrasive grit blasting (sandblasting) cabinets & equipment; remove paint/rust. Key products include: Small Robotic Grit Blast with Manual Station, Fine Mesh Robotic Grit Blast with Drying Station, Large Robotic Grit Blast with Manual Station, Robotic Turbine Blade Grit Blast with Conveyor, Large Composite Case Robotic Wet Blast, Dual Spindle Pressure Grit Blast Turbine Blades, Continuous Rotary Gr…

2. BlastOne – Industrial Blast Equipment and Abrasives

Domain: blastone.com

Registered: 2002 (23 years)

Introduction: Industrial Blast Equipment, Pots, and Machines for Professional Surface Preparation. Categories include: Abrasives (Aluminum Oxide, Garnet, Glass, Slag, Sponge, Soft, Corn Cob, Armex Soda, Walnut Shell, Staurolite, Steel), Blast Equipment (Air Dryers, Aftercoolers, Deliquescent Dryers, Moisture Separators, Suction Guns, Small Blast Pots, Contractor Blast Pots, Specialty Blast Pots, MistBlaster Wet…

3. Norton Sandblasting – Portable Blasters

Domain: nortonsandblasting.com

Registered: 1998 (27 years)

Introduction: JH Norton Company Inc. offers a wide range of sandblasting and abrasive blasting equipment, including:

1. **Portable Blasters**:

– Clemco Blast Machines

– Schmidt® Portable Abrasive Blasters

– Empire’s Vacuum Recovery System (VRS)

– Schmidt Blast Pots

– Blast Pot Restoration

2. **Abrasives/Media/Grit**:

– Various Abrasives, Media, and Grit

– Anchor Blasting Pattern

3. **B…

4. Empire – Abrasive Blast Equipment

Domain: empire-airblast.com

Registered: 1997 (28 years)

Introduction: Empire offers a comprehensive line of abrasive blast equipment including: 1. Robotic Abrasive Blast Systems – Efficient, quiet, and clean solutions for surface preparation and peening applications. 2. Automated Abrasive Blast Systems – Ranging from standard automation to advanced robotic nozzles, designed for various applications. 3. Blast Rooms – Balanced systems with field-proven components engi…

5. Kramer Industries – Blasting Systems

Domain: kramerindustriesonline.com

Registered: 2001 (24 years)

Introduction: Kramer Industries offers a range of Blasting Systems, including Portable and Cabinet systems in both Siphon/Suction and Direct Pressure styles. These systems are designed for various applications such as surface preparation, cleaning, and rust removal. Key features include:

– Wide variety of sizes for large and small parts processing

– Economical and heavy-duty options available

– Manual, semi-…

6. Guyson – Model SP-10 Grit Blasting Machine

Domain: guyson.com

Registered: 1996 (29 years)

Introduction: The Model SP-10 Grit Blasting Machine is designed for automated abrasive blasting of circular components up to 40 inches in diameter. It features a 60 x 60 x 60-inch blast chamber with an automatic sliding door, rails, and a transfer cart with a 36-inch diameter motor-driven turntable. The machine includes eight suction-feed blast guns on a swing-arm actuator for synchronized horizontal motion wit…

7. Rapid Prep – Grit Blasting Equipment

Domain: rapidprep.com

Registered: 2006 (19 years)

Introduction: Grit Blasting Equipment Overview: Rapid Prep offers a range of grit blasting equipment including the Schmidt Blast Recovery System, VB 2400 Blast & Recovery System, VB 1200 Blast & Recovery System, and Modular Abrasive Classification System. These systems are designed for contained open or vacuum blasting, featuring high-powered vacuum units that recover spent abrasives and minimize dust and waste…

8. Blast-It-All® – Automated Blasting Systems

Domain: blast-it-all.com

Registered: 1997 (28 years)

Introduction: Automated Blasting Systems by Blast-It-All® offer custom-built solutions for abrasive blast needs, including semi-automated, fully automated, and robotic systems. Each system is tailored to specific requirements such as part geometry, production quantity, quality control, maintenance ease, and system longevity. The company emphasizes consistent quality control and increased product output to addre…

Strategic Sourcing Conclusion and Outlook for grit blasting machine

What Are the Key Takeaways for Sourcing Grit Blasting Machines?

In conclusion, strategic sourcing of grit blasting machines is pivotal for enhancing operational efficiency and cost-effectiveness in various industries. By evaluating suppliers that offer advanced features such as integrated air dryers, portable designs, and high-capacity options, buyers can significantly reduce setup times and enhance productivity. Understanding the unique needs of your specific market—whether in Africa, South America, the Middle East, or Europe—will enable you to make informed decisions that align with both local regulations and industry standards.

How Can International Buyers Prepare for Future Trends in Grit Blasting?

Looking ahead, the demand for environmentally friendly and efficient blasting solutions is on the rise. Buyers are encouraged to consider suppliers that prioritize innovation, such as those offering wet blasting technologies that mitigate dust and enhance safety. As the industry evolves, staying abreast of technological advancements will be crucial for maintaining a competitive edge.

What Should B2B Buyers Do Next?

To maximize your investment, engage with reputable manufacturers and explore comprehensive sourcing strategies tailored to your operational needs. This proactive approach will not only secure high-quality grit blasting machines but also position your business for sustainable growth in a rapidly changing market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.