Everything You Need to Know About Gravity Latch Sourcing in 2025

Introduction: Navigating the Global Market for gravity latch

In the fast-evolving global market for gravity latches, sourcing reliable and secure gate hardware can pose significant challenges for B2B buyers. Whether you are in Africa, South America, the Middle East, or Europe, understanding the nuances of gravity latch types, applications, and supplier qualifications is crucial to making informed purchasing decisions. This comprehensive guide aims to equip you with essential insights into the various gravity latch options available, including their material specifications, installation requirements, and suitability for different gate types.

We delve into the specific applications of gravity latches across multiple industries, from residential fencing to commercial security solutions. Additionally, we provide a framework for vetting suppliers, ensuring that you partner with reputable manufacturers who meet international quality standards. Cost considerations are also addressed, helping you balance budget constraints with the need for durability and performance.

By leveraging the information presented in this guide, international B2B buyers can navigate the complexities of the gravity latch market with confidence. Our goal is to empower you to make strategic purchasing decisions that enhance security and operational efficiency, ultimately driving success in your projects. With a focus on practicality and reliability, this resource serves as your roadmap to sourcing the best gravity latches for your specific needs.

Understanding gravity latch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Gravity Latch | Self-latching design, easy installation, padlock compatible | Residential and commercial gates | Pros: Cost-effective, versatile. Cons: Limited security features for high-risk areas. |

| Polymer Gravity Latch | Lightweight, corrosion-resistant, decorative options available | Vinyl, wood, and metal gates | Pros: Aesthetically pleasing, durable. Cons: May not be as robust as metal counterparts. |

| Heavy-Duty Gravity Latch | Made from steel or reinforced materials, designed for heavy gates | Industrial and agricultural gates | Pros: Extremely durable, high load capacity. Cons: Higher cost, heavier installation requirements. |

| Lockable Gravity Latch | One or two-side locking mechanisms, enhanced security options | Security-sensitive environments | Pros: Enhanced security, customizable locking options. Cons: More complex installation and potentially higher costs. |

| MagnaLatch Safety Latch | Magnetic technology, self-closing, child and pool safety approved | Child safety gates, pool enclosures | Pros: High safety standards, reliable. Cons: More expensive, requires specific installation guidelines. |

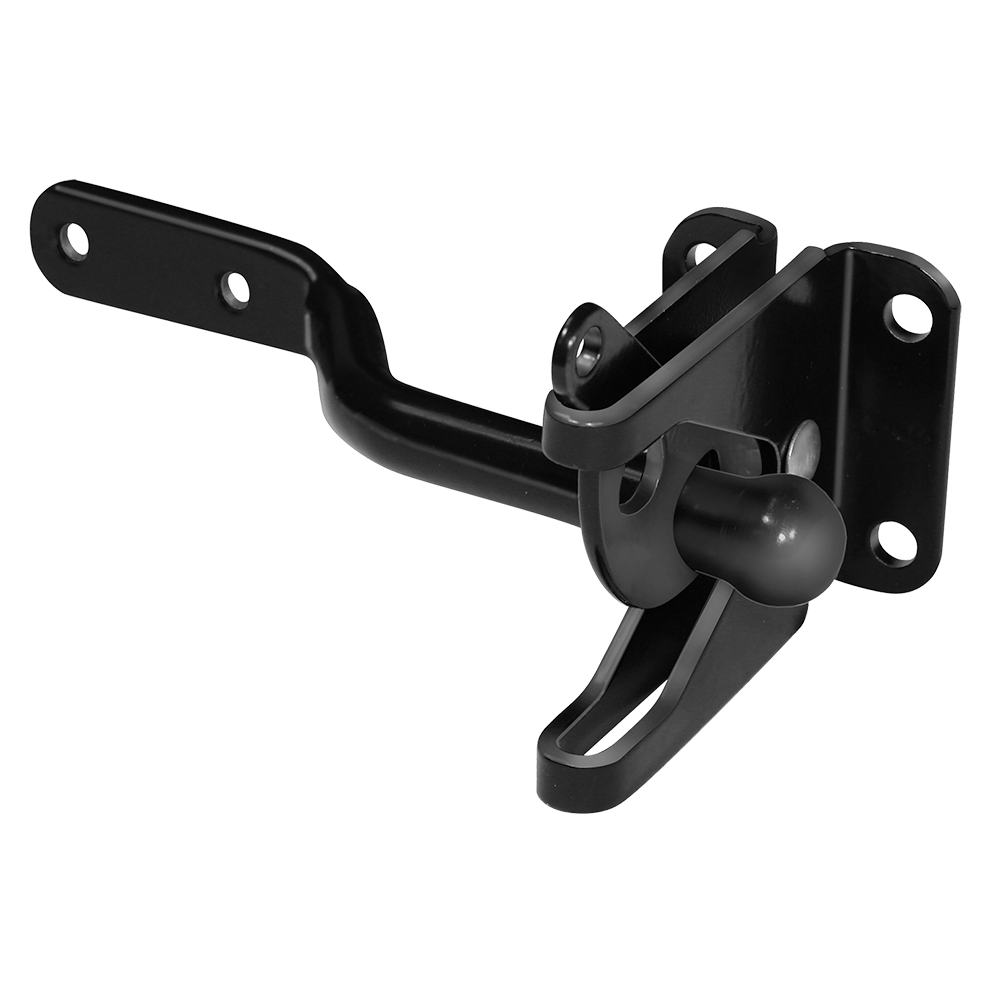

What are the Characteristics of Standard Gravity Latches?

Standard gravity latches are designed for ease of use and installation, making them a popular choice for residential and light commercial applications. They feature a self-latching mechanism that automatically secures the gate upon closing, and many models allow for the addition of a padlock for extra security. While they are versatile and cost-effective, buyers should be aware that they may not be suitable for high-security environments due to their basic locking features.

How Do Polymer Gravity Latches Differ from Metal Options?

Polymer gravity latches are ideal for buyers seeking a lightweight and corrosion-resistant solution. These latches are available in various decorative finishes, making them suitable for aesthetic applications in residential settings. They are compatible with vinyl, wood, and metal gates, offering flexibility in design. However, while they provide an attractive option, their durability may not match that of heavier metal latches, which could be a consideration for high-traffic areas.

Why Choose Heavy-Duty Gravity Latches for Industrial Applications?

Heavy-duty gravity latches are specifically engineered to withstand the rigors of industrial and agricultural settings. Made from steel or other reinforced materials, these latches are built to handle heavy gates and high usage. They provide exceptional durability and security, making them the preferred choice for environments where gate reliability is critical. However, buyers should consider the higher costs and more complex installation requirements associated with these robust options.

What Are the Benefits of Lockable Gravity Latches?

Lockable gravity latches offer enhanced security features, with options for one or two-side locking mechanisms. These latches are particularly suitable for environments where security is paramount, such as commercial properties or sensitive areas. While they provide peace of mind through customizable locking solutions, buyers must factor in the potential for more complex installation and higher costs compared to standard models.

How Does the MagnaLatch Safety Latch Enhance Safety?

The MagnaLatch safety latch employs innovative magnetic technology to provide a self-closing and self-latching mechanism, making it a top choice for child safety gates and pool enclosures. This type of latch meets rigorous safety standards, ensuring reliability in preventing unauthorized access. Although it may come at a premium price, the investment is justified for applications where safety is a critical concern. Buyers should also note that specific installation guidelines must be followed to ensure optimal performance.

Key Industrial Applications of gravity latch

| Industry/Sector | Specific Application of gravity latch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Securing construction site gates | Enhances site security and safety compliance | Durability, weather resistance, and ease of installation |

| Agriculture | Closing livestock enclosures | Prevents animal escape and protects crops | Material compatibility with fencing, corrosion resistance |

| Transportation | Locking cargo containers | Secures valuable goods during transit | Weight capacity, ease of use, and tamper-proof features |

| Manufacturing | Access control for machinery enclosures | Ensures safety and restricts unauthorized access | Compliance with industry safety standards and robust construction |

| Residential Security | Gates for residential properties | Provides peace of mind and enhances property value | Aesthetic appeal, ease of operation, and compatibility with existing gates |

How is a Gravity Latch Used in the Construction Industry?

In the construction sector, gravity latches are crucial for securing gates that control access to construction sites. They provide a reliable self-latching mechanism that enhances security, preventing unauthorized entry and ensuring compliance with safety regulations. Buyers should prioritize durability and weather resistance, as these latches will be exposed to harsh environmental conditions. Additionally, ease of installation is essential for construction teams to minimize downtime and maintain workflow efficiency.

What Role Does a Gravity Latch Play in Agriculture?

Agricultural applications often involve securing livestock enclosures or crop protection areas. Gravity latches are used to ensure that gates close securely, preventing animals from escaping and safeguarding crops from wildlife. For international buyers, especially in regions with diverse agricultural practices, selecting latches compatible with various fencing materials is crucial. Corrosion resistance is also a key consideration, as agricultural environments can be harsh and humid.

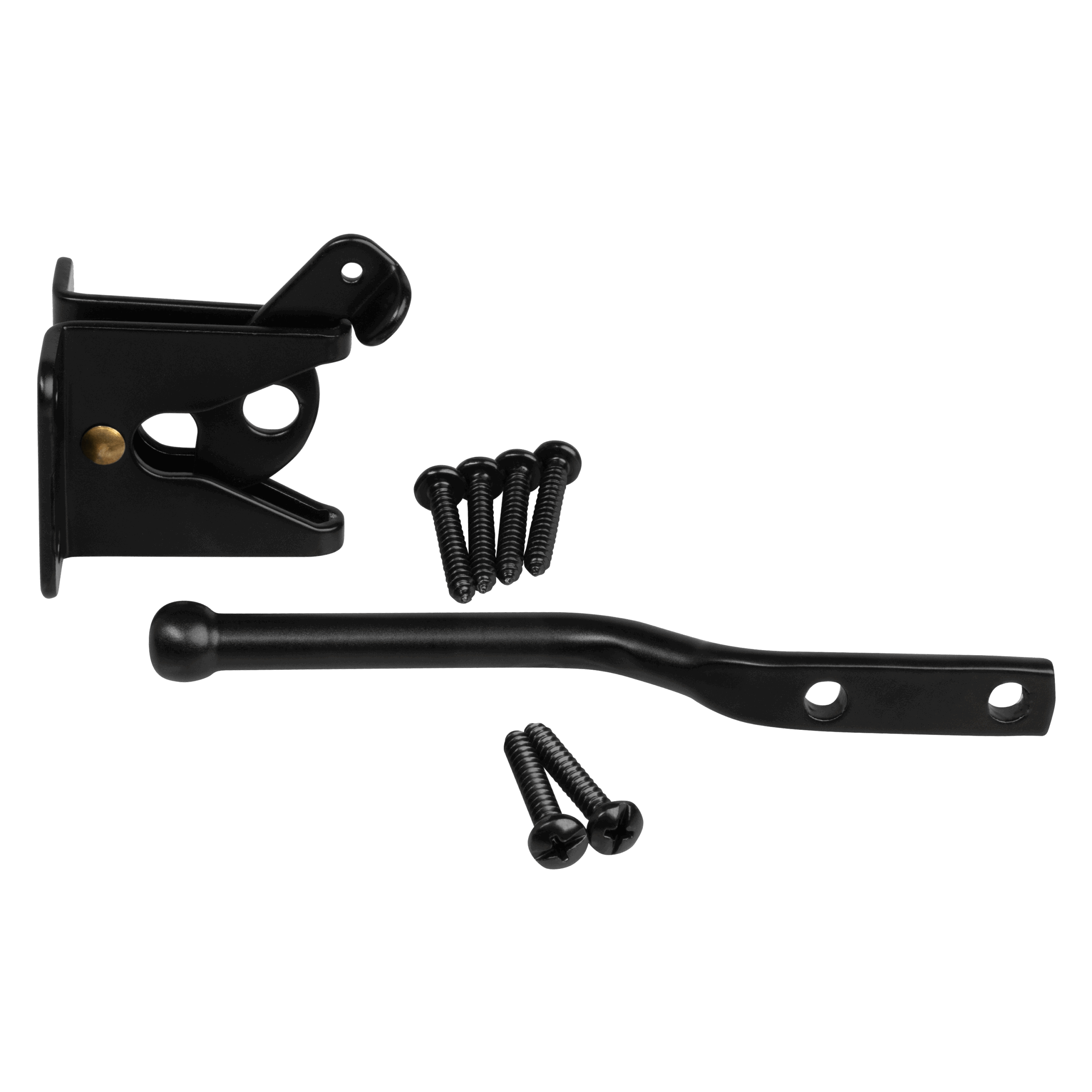

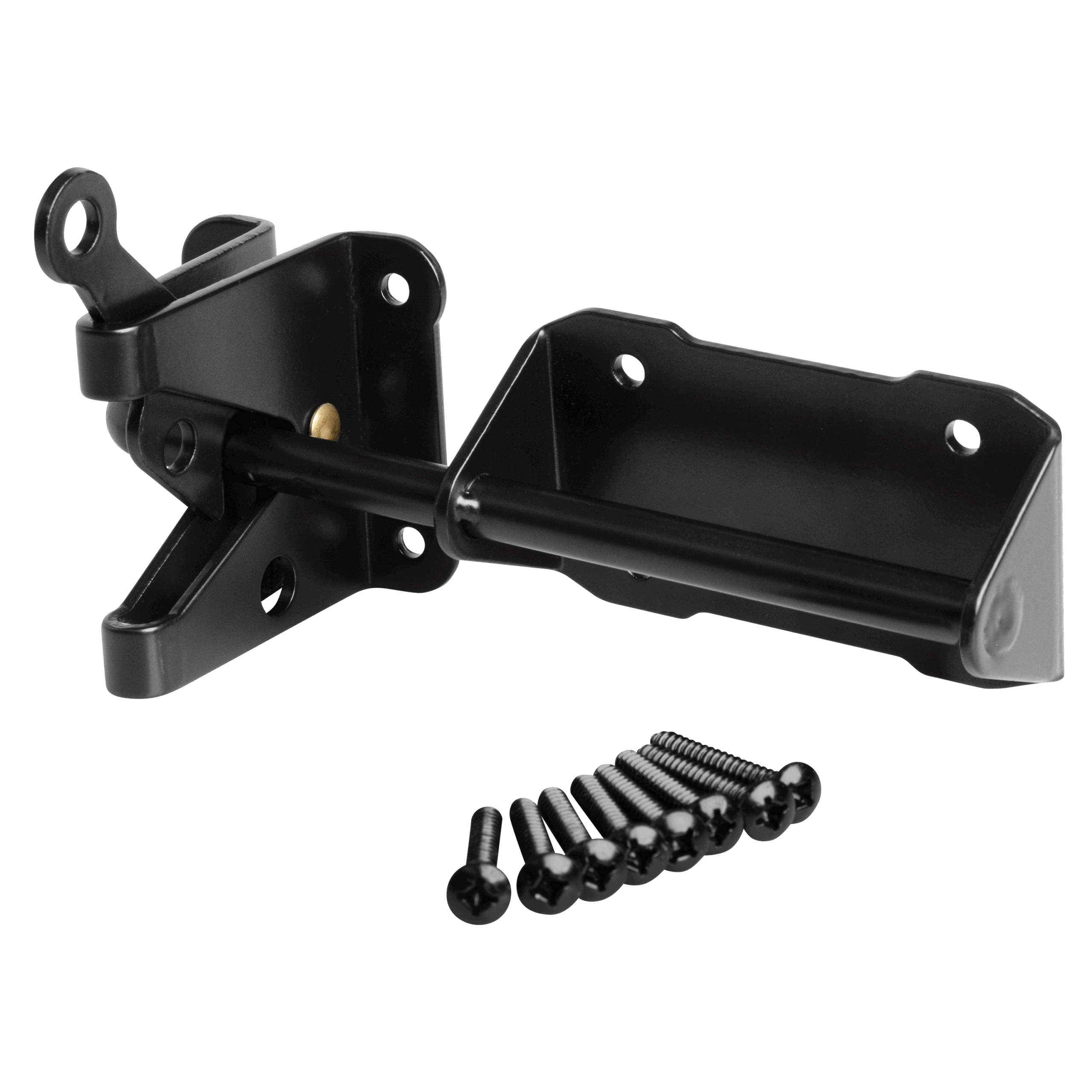

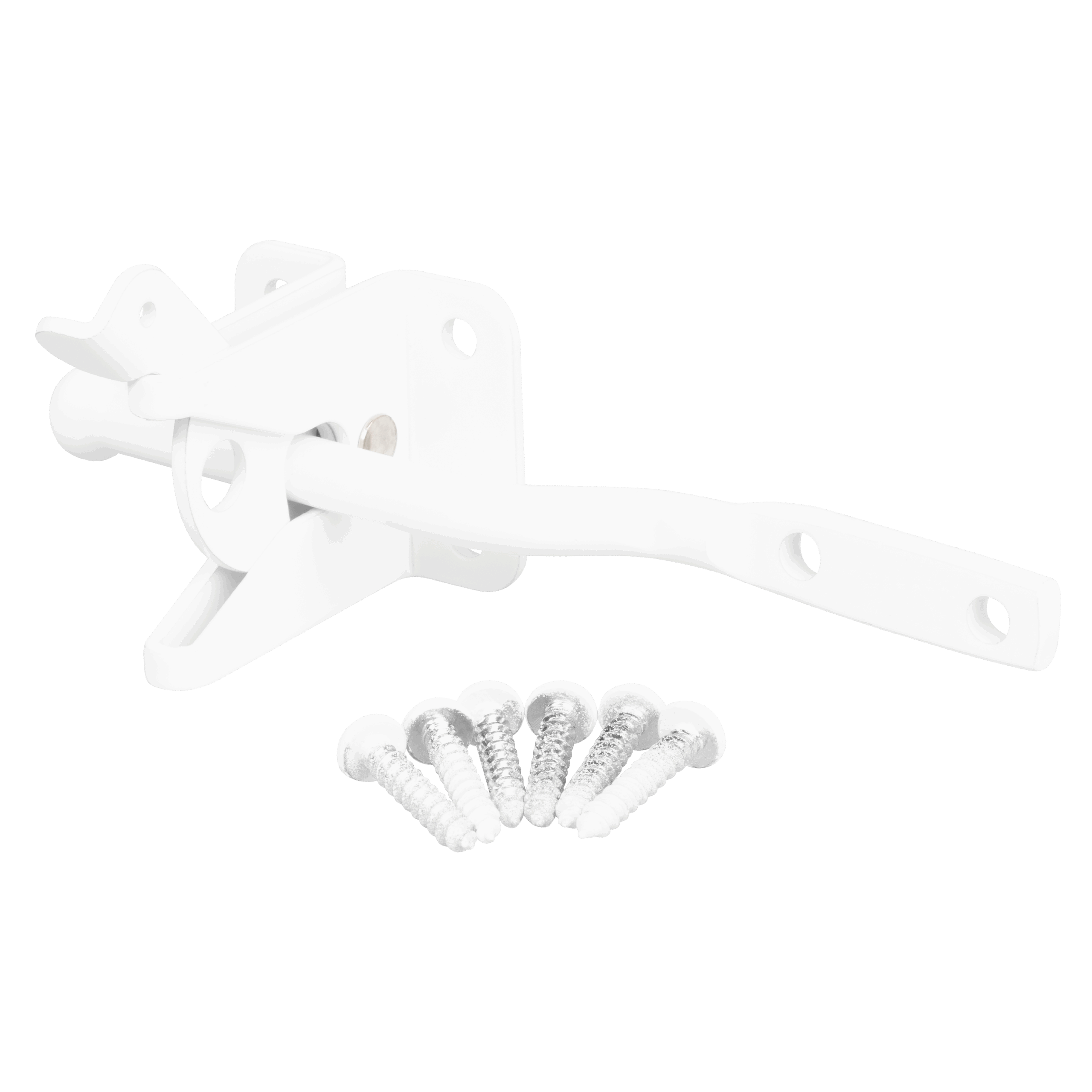

Illustrative image related to gravity latch

How Can Gravity Latches Enhance Security in Transportation?

In the transportation industry, gravity latches are widely utilized for locking cargo containers. These latches provide a simple yet effective means of securing valuable goods during transit, reducing the risk of theft or loss. For B2B buyers, it is essential to consider the weight capacity of the latch and its ease of use, especially in high-volume shipping scenarios. Additionally, tamper-proof features can further enhance the security of cargo.

Why Are Gravity Latches Important in Manufacturing?

Manufacturing facilities often require strict access control to protect machinery and sensitive areas. Gravity latches serve as effective solutions for securing access points, ensuring that only authorized personnel can enter hazardous zones. Buyers in this sector should focus on latches that comply with industry safety standards and offer robust construction to withstand frequent use. The ability to integrate with existing safety systems can also be a significant advantage.

How Do Gravity Latches Contribute to Residential Security?

For residential properties, gravity latches are commonly used on gates to enhance security and provide peace of mind for homeowners. They are designed to be user-friendly while offering reliable closure, which is vital for maintaining property safety. Buyers should consider the aesthetic appeal of the latch to match their home’s design, alongside ease of operation and compatibility with existing gate systems. Investing in high-quality materials can also improve the longevity and functionality of the latch.

3 Common User Pain Points for ‘gravity latch’ & Their Solutions

Scenario 1: Difficulty in Ensuring Security with Gravity Latches

The Problem: Many B2B buyers in the fencing and gate industry face challenges with ensuring the security of their properties when using gravity latches. The self-latching design, while convenient, can be a concern in high-security environments where unauthorized access must be strictly controlled. Buyers often worry that gravity latches may not provide adequate locking capabilities, leading to potential breaches and safety issues.

Illustrative image related to gravity latch

The Solution: To address security concerns, buyers should prioritize sourcing gravity latches that offer enhanced locking features. For instance, consider latches that include options for padlocks or keyed entries, providing an additional layer of security. When specifying gravity latches, look for products that adhere to specific security certifications and standards relevant to your industry. Additionally, it’s beneficial to consult with manufacturers who can provide insights into the best practices for installation and maintenance, ensuring that the latch functions optimally over time.

Scenario 2: Challenges with Installation and Compatibility

The Problem: Another common issue faced by B2B buyers is the complexity of installing gravity latches on various gate types. Many buyers find that the latches they purchase are not compatible with their existing gates due to differences in materials, sizes, or installation requirements. This mismatch can lead to increased labor costs and project delays, frustrating buyers who are working under tight timelines.

The Solution: To mitigate installation challenges, buyers should conduct thorough compatibility assessments before purchasing gravity latches. This involves measuring gate dimensions and understanding the material specifications of both the gate and the latch. It is advisable to select latches that come with comprehensive installation instructions and mounting hardware included. Additionally, working with suppliers who offer technical support or professional installation services can significantly reduce the risk of errors during setup. Investing in adjustable latches that can accommodate various gate sizes and types will also help streamline the installation process.

Scenario 3: Weather-Related Performance Issues

The Problem: B2B buyers in regions with extreme weather conditions often experience performance issues with gravity latches. Factors such as humidity, heat, or cold can cause latches to malfunction, leading to gates not closing properly or becoming stuck. This can result in operational inefficiencies and potential security risks, especially in industries that require regular access control.

The Solution: To combat weather-related issues, it is crucial for buyers to select gravity latches that are specifically designed for durability in harsh environments. Look for latches made from corrosion-resistant materials such as stainless steel or high-grade polymers that withstand various weather conditions. Additionally, consider latches with weather seals or protective coatings that prevent moisture ingress. Regular maintenance checks should be scheduled to ensure that latches are functioning correctly and to address any wear caused by environmental factors. Providing training for staff on how to care for and monitor latch performance can further enhance reliability and longevity.

Strategic Material Selection Guide for gravity latch

When selecting materials for gravity latches, it is essential to consider the specific properties, advantages, and limitations of each option. This analysis will focus on four common materials: stainless steel, polymer, aluminum, and powder-coated steel. Each material has unique characteristics that can significantly influence performance, durability, and suitability for various applications.

What Are the Key Properties of Stainless Steel for Gravity Latches?

Stainless steel is renowned for its exceptional corrosion resistance and strength. It can withstand high temperatures and pressures, making it suitable for a variety of environments, including coastal areas where salt exposure is a concern. The material’s inherent durability ensures that it maintains structural integrity over time, even under heavy use.

Pros: Stainless steel gravity latches offer high durability and resistance to rust and corrosion, making them ideal for outdoor applications. They are also relatively easy to manufacture and can be produced in various designs.

Cons: The primary drawback of stainless steel is its cost, which is generally higher than other materials. Additionally, while it is resistant to corrosion, it can still be susceptible to scratching and denting.

Impact on Application: Stainless steel is compatible with a wide range of media, including water and chemicals, making it versatile for various industrial applications. However, buyers should ensure compliance with international standards such as ASTM and DIN, particularly for projects in Europe and the Middle East.

How Does Polymer Compare as a Material for Gravity Latches?

Polymer materials, often used in the production of gravity latches, provide a lightweight alternative to metals. They are resistant to corrosion and can withstand a range of environmental conditions without degrading.

Pros: The primary advantage of polymer gravity latches is their resistance to rust and chemical exposure. They are also lightweight, which can simplify installation and reduce shipping costs. Additionally, polymers can be manufactured in various colors and styles, enhancing aesthetic appeal.

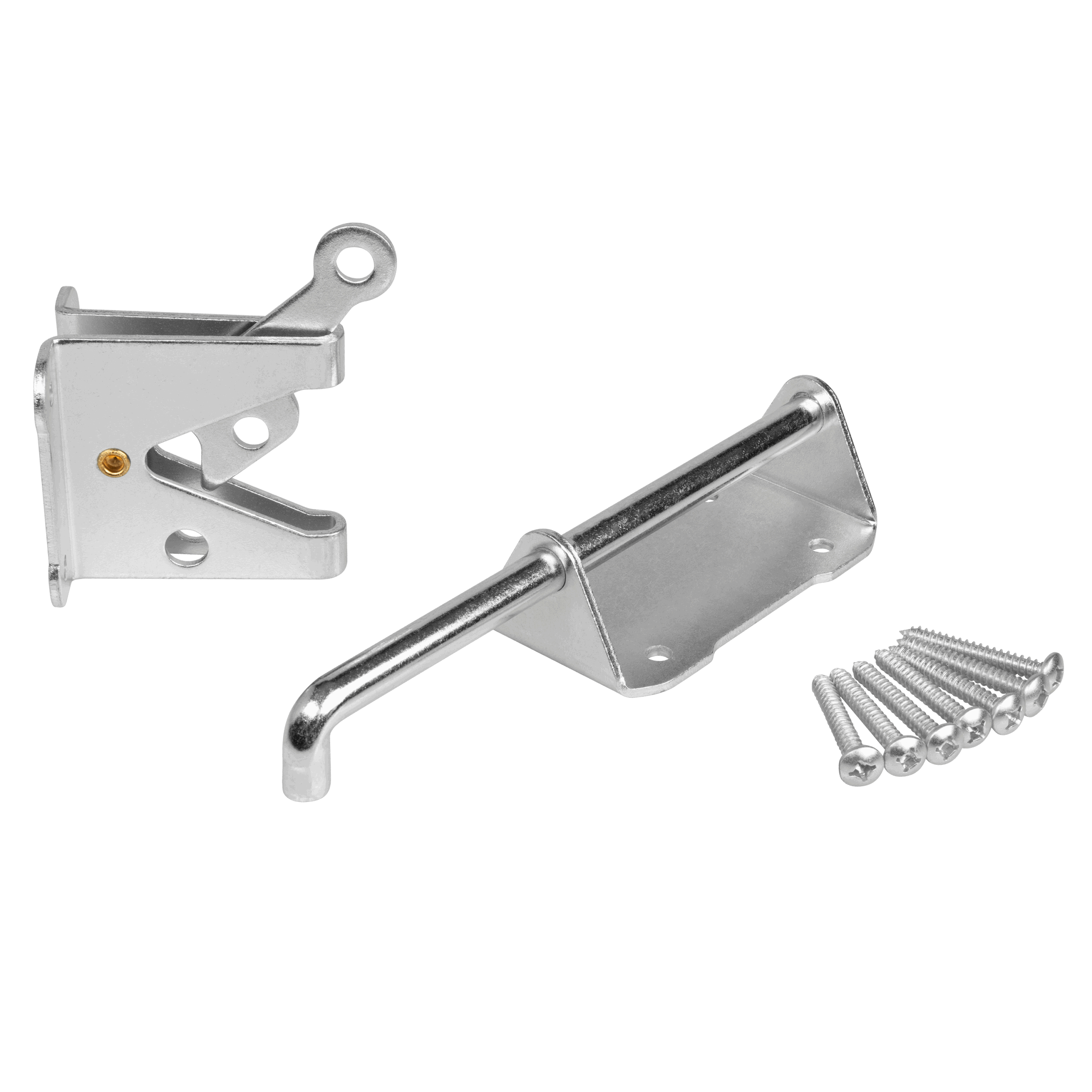

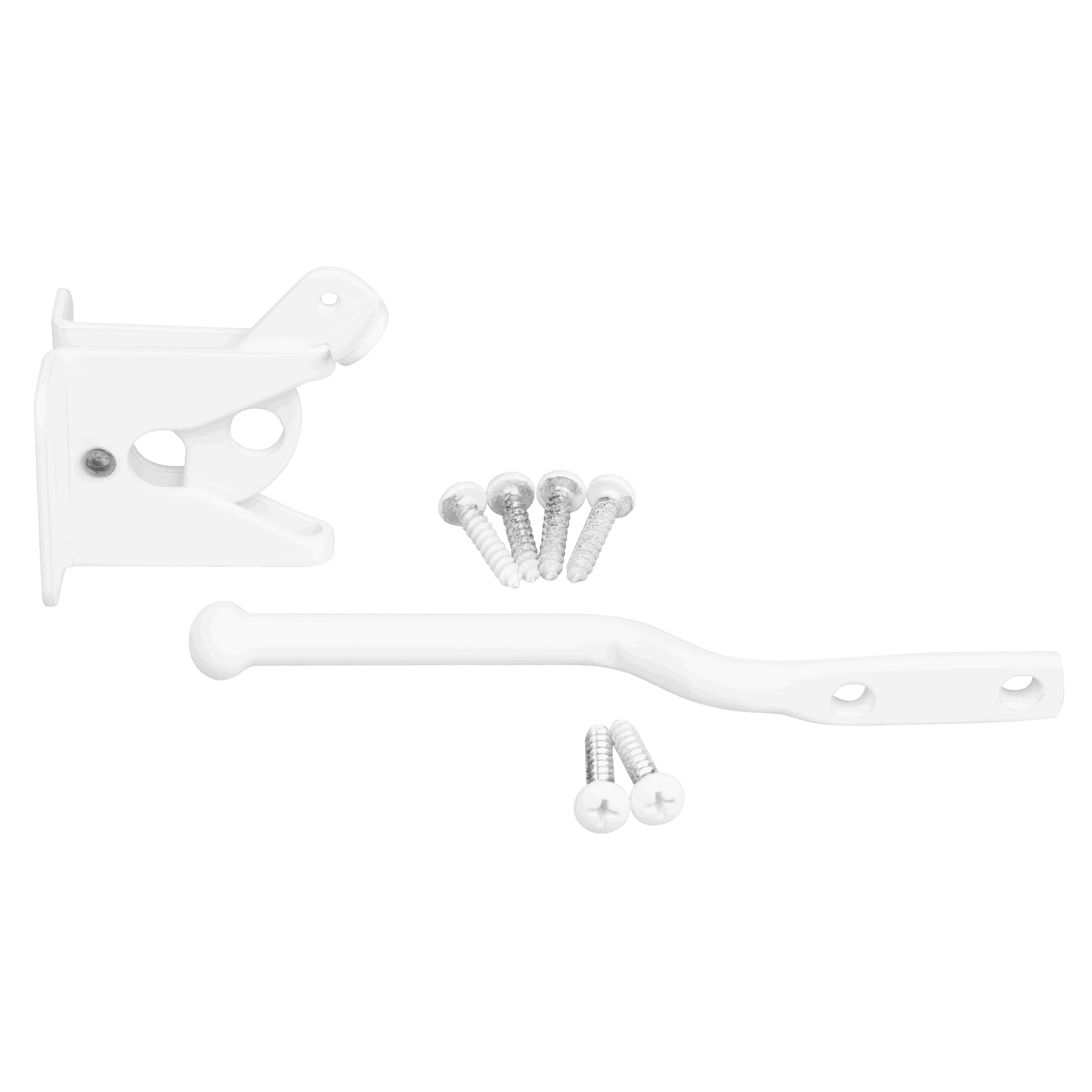

Illustrative image related to gravity latch

Cons: On the downside, polymers may not offer the same level of strength as metals, which could limit their use in high-stress applications. They can also be more susceptible to UV degradation over time, particularly in regions with intense sunlight.

Impact on Application: Polymer latches are suitable for residential and light commercial applications, particularly in environments where aesthetics are a priority. Buyers should consider local climate conditions and UV exposure when selecting polymer latches.

What Are the Benefits of Using Aluminum for Gravity Latches?

Aluminum is another popular choice for gravity latches due to its lightweight and corrosion-resistant properties. It is an excellent option for applications requiring a balance between strength and weight.

Illustrative image related to gravity latch

Pros: Aluminum latches are easy to handle and install, making them ideal for DIY projects. They also resist corrosion, particularly when anodized or powder-coated, enhancing their longevity.

Cons: While aluminum is lightweight and resistant to rust, it may not be as strong as stainless steel, making it less suitable for heavy-duty applications. Additionally, aluminum can be more expensive than other materials like plastic or steel.

Impact on Application: Aluminum latches are versatile and can be used in various applications, including residential gates and commercial fencing. International buyers should ensure that the aluminum used meets relevant standards for strength and durability.

Why Choose Powder-Coated Steel for Gravity Latches?

Powder-coated steel combines the strength of steel with a protective coating that enhances corrosion resistance. This material is particularly popular in industrial applications.

Pros: The powder coating provides an additional layer of protection against rust and scratches, making it suitable for outdoor use. Powder-coated steel latches are also available in various colors, allowing for customization.

Cons: One limitation is that if the coating is scratched, the underlying steel can become exposed and susceptible to rust. Additionally, the manufacturing process can be more complex, potentially leading to higher costs.

Impact on Application: Powder-coated steel latches are ideal for industrial and commercial settings where durability and aesthetics are important. Buyers should check for compliance with safety standards, especially in regions with stringent regulations.

Illustrative image related to gravity latch

Summary of Material Properties for Gravity Latches

| Material | Typical Use Case for gravity latch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty gates and industrial use | High durability and corrosion resistance | Higher cost and susceptibility to scratches | High |

| Polymer | Residential and light commercial | Lightweight and rust-resistant | Less strength, UV degradation potential | Medium |

| Aluminum | Residential gates and fencing | Easy to install and handle | Lower strength compared to stainless steel | Medium |

| Powder-Coated Steel | Industrial applications | Enhanced corrosion resistance | Risk of rust if coating is damaged | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers considering gravity latches. By understanding the key properties, advantages, and limitations of each material, buyers can make informed decisions that align with their specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for gravity latch

The manufacturing process and quality assurance (QA) for gravity latches are essential components that ensure the final product meets the high standards required by B2B buyers. Understanding these processes helps buyers make informed decisions, particularly in international markets where standards and practices may vary. Below is an in-depth exploration of the typical manufacturing stages, quality control measures, and relevant international standards associated with gravity latches.

What Are the Main Stages in the Manufacturing Process of Gravity Latches?

Material Preparation: What Materials Are Used?

The manufacturing of gravity latches typically begins with material selection, which is critical for durability and functionality. Common materials include stainless steel, polymer, and aluminum. Each material offers unique benefits:

- Stainless Steel: Known for its corrosion resistance and strength, making it suitable for outdoor applications.

- Polymer: Lightweight and resistant to rust, ideal for environments where moisture is a concern.

- Aluminum: Offers a good balance of weight and strength, often used in residential applications.

Once the materials are selected, they undergo a series of preparatory processes such as cutting and shaping to ensure they meet the specifications required for forming.

How Are Gravity Latches Formed?

The next step in the manufacturing process involves forming the components of the gravity latch. This is typically done through techniques such as:

- Stamping: For metal components, stamping machines shape the material into specific designs based on die specifications.

- Injection Molding: Used primarily for polymer latches, this technique allows for precise shaping of complex designs.

- Machining: This process can involve CNC (Computer Numerical Control) machines that provide high precision in shaping and finishing metal components.

The forming stage is crucial as it directly affects the performance and aesthetic of the latch.

What Happens During Assembly?

After the components are formed, they move to the assembly stage. This stage may involve:

- Manual Assembly: Skilled workers assemble the components, ensuring that each part fits together correctly.

- Automated Assembly: In high-volume manufacturing environments, automation may be used to increase efficiency and reduce human error.

During assembly, components such as locking mechanisms, latching arms, and mounting fixtures are integrated to create a complete latch.

What Are the Finishing Processes for Gravity Latches?

The finishing process enhances the latch’s appearance and durability. Common finishing techniques include:

- Powder Coating: This provides a protective layer that enhances corrosion resistance and is available in various colors.

- Plating: Techniques such as zinc or chrome plating are used to improve aesthetics and add a layer of protection against wear and corrosion.

- Quality Polishing: For stainless steel latches, polishing improves the visual appeal and can enhance resistance to corrosion.

How Is Quality Assurance Implemented in Gravity Latch Manufacturing?

What International Standards Should Buyers Be Aware Of?

Quality assurance in gravity latch manufacturing is governed by several international standards. Key among these is ISO 9001, which outlines the requirements for a quality management system (QMS). Compliance with ISO 9001 demonstrates that a manufacturer is committed to consistent quality in their products.

In addition to ISO standards, specific industry certifications such as CE marking in Europe indicate that the product meets health, safety, and environmental protection standards. For buyers in regions like the Middle East or Africa, understanding local regulatory requirements and certifications can be equally important.

Illustrative image related to gravity latch

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are integrated into the manufacturing process to ensure each latch meets specified standards. These checkpoints include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet required specifications.

- In-Process Quality Control (IPQC): This involves continuous monitoring during the manufacturing process to detect defects early.

- Final Quality Control (FQC): After assembly, each latch undergoes rigorous testing to ensure it functions correctly and meets quality standards.

Common testing methods include functional testing, corrosion resistance tests, and dimensional checks to ensure that the latch operates as intended.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is crucial. Here are some actionable steps:

- Supplier Audits: Conducting on-site audits allows buyers to directly observe manufacturing practices and quality control measures.

- Requesting Quality Reports: Suppliers should provide detailed reports on their quality assurance processes, including results from testing and inspections.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality practices.

Buyers should also look for suppliers who are transparent about their quality assurance processes and willing to share documentation.

What Are the Quality Control Nuances for International Buyers?

When purchasing gravity latches from international suppliers, buyers must be aware of various nuances that can impact quality assurance:

Illustrative image related to gravity latch

- Regional Standards: Different regions may have unique requirements for materials and testing. For example, European buyers must comply with CE marking, while buyers in the Middle East may have specific safety standards to consider.

- Logistics and Supply Chain: Understanding the supplier’s logistics can help anticipate potential delays or quality issues that may arise during shipping.

- Cultural Considerations: Establishing a strong relationship with suppliers can facilitate better communication regarding quality expectations and standards.

By being informed about these factors, B2B buyers can make better decisions and ensure they receive high-quality gravity latches that meet their specific needs.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices for gravity latches is essential for B2B buyers. By focusing on material selection, manufacturing techniques, quality checkpoints, and verification methods, buyers can confidently source products that meet their expectations in terms of durability, functionality, and compliance with international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gravity latch’

Introduction

This guide serves as a comprehensive checklist for B2B buyers seeking to procure gravity latches. Gravity latches are essential components for securing gates and doors across various applications, from residential to industrial settings. Understanding the key factors in sourcing these products will ensure you make informed decisions that align with your operational needs and security standards.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. This includes understanding the specific application of the gravity latch—whether for residential gates, commercial facilities, or industrial applications. Consider factors such as:

– Material: Stainless steel, polymer, or powder-coated options for durability and corrosion resistance.

– Weight Capacity: Ensure the latch can support the weight of your gate.

– Locking Mechanism: Decide if you need a simple latch or one with a locking feature for added security.

Step 2: Research Market Trends and Standards

Stay informed about industry trends and regulatory standards that affect gravity latch procurement. This knowledge not only enhances your negotiating power but also ensures compliance with local regulations, especially in regions like Europe and the Middle East where safety standards can be stringent. Pay attention to:

– Safety Standards: Familiarize yourself with relevant codes, such as the BOCA Pool Code for pool gates.

– Market Innovations: Explore advancements in latch technology, such as self-latching mechanisms and materials that offer enhanced longevity.

Step 3: Evaluate Potential Suppliers

Conduct a thorough evaluation of potential suppliers to ensure reliability and quality. Look for suppliers that can provide comprehensive company profiles, customer testimonials, and case studies relevant to your industry. Key considerations include:

– Experience: Suppliers with a proven track record in your specific application area.

– Certifications: Verify compliance with international standards and local regulations.

Step 4: Request Samples for Testing

Once you have shortlisted suppliers, request samples of their gravity latches. Testing samples allows you to assess the quality, functionality, and compatibility of the latches with your existing systems. During testing, consider:

– Ease of Installation: Ensure that the latch can be installed without specialized tools.

– Performance Under Load: Check for smooth operation and durability under expected conditions.

Step 5: Negotiate Pricing and Terms

Engage in discussions to negotiate favorable pricing and terms. Understanding the cost structures involved can lead to better deals. Be prepared to discuss:

– Bulk Discounts: Inquire about pricing tiers based on order volume.

– Payment Terms: Clarify payment methods and terms to align with your cash flow.

Step 6: Confirm Delivery and Support Services

Before finalizing your order, confirm the delivery timelines and post-purchase support services. Reliable delivery is crucial for maintaining project schedules. Ensure you understand:

– Shipping Options: Explore available delivery methods and associated costs.

– Customer Support: Check if the supplier offers ongoing support for installation or troubleshooting.

Step 7: Finalize the Purchase Agreement

Once all conditions are met, finalize the purchase agreement. This document should clearly outline the specifications, pricing, delivery schedule, and warranty details. Ensure it protects your interests by including:

– Return Policies: Understand the conditions under which you can return defective products.

– Warranty Coverage: Review the warranty terms to ensure they meet your expectations for product longevity.

By following this structured approach, B2B buyers can effectively source gravity latches that meet their operational needs and maintain security standards, fostering successful procurement outcomes.

Comprehensive Cost and Pricing Analysis for gravity latch Sourcing

What Are the Key Cost Components in Gravity Latch Production?

When assessing the cost structure for gravity latches, various components come into play. The primary costs include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Illustrative image related to gravity latch

Materials: The choice of materials significantly impacts cost. Common materials include stainless steel, aluminum, and polymer. Each has its own pricing based on market fluctuations and supplier contracts. For instance, stainless steel tends to be more expensive due to its durability and resistance to corrosion, making it suitable for outdoor applications.

Labor: Labor costs vary based on the geographical location of the manufacturing facility. Regions with lower labor costs may offer more competitive pricing but may also raise concerns about quality and consistency.

Manufacturing Overhead: This includes expenses related to factory operations such as utilities, maintenance, and indirect labor. Effective management of overhead can enhance overall profitability.

Tooling: Depending on the complexity of the latch design, tooling costs can vary significantly. Custom designs may require specialized molds, increasing initial investment but potentially leading to better margins on unique products.

Quality Control: Ensuring product quality through rigorous testing and inspection processes adds to the cost but is essential for maintaining customer satisfaction and compliance with international standards.

Logistics: Transportation costs can fluctuate based on distance, mode of transport, and fuel prices. For international buyers, understanding Incoterms (International Commercial Terms) is crucial as they dictate who is responsible for shipping costs, insurance, and tariffs.

Margin: The profit margin is influenced by all the aforementioned factors and can vary based on market competition and demand. Suppliers may offer different pricing strategies, from cost-plus to value-based pricing, depending on their positioning in the market.

How Do Pricing Influencers Affect Gravity Latch Costs?

Several factors influence the final pricing of gravity latches, particularly for international B2B transactions.

Volume and Minimum Order Quantity (MOQ): Larger orders typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to optimize pricing.

Specifications and Customization: Custom designs or specific features (like locking mechanisms or color finishes) can increase costs. Buyers should weigh the benefits of customization against additional expenses.

Material Quality and Certifications: High-quality materials and certifications (such as ISO standards) can lead to higher prices but often result in greater durability and reliability, impacting the total cost of ownership.

Supplier Factors: Supplier reputation, experience, and production capabilities play a crucial role in determining price. Established suppliers may command higher prices due to their reliability and quality assurance practices.

What Are the Best Practices for Negotiating Gravity Latch Prices?

For international buyers, especially those from Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to cost savings and better terms.

Illustrative image related to gravity latch

Understand Total Cost of Ownership: Consider not just the purchase price but also long-term costs associated with maintenance, replacement, and potential liability. Investing in higher-quality latches may reduce future costs.

Leverage Competitive Bidding: Soliciting quotes from multiple suppliers can provide leverage during negotiations. It’s essential to communicate your requirements clearly and ensure that all proposals are comparable.

Build Relationships: Establishing a strong relationship with suppliers can lead to better pricing and terms. Long-term partnerships often result in more favorable negotiations and potential discounts.

Be Aware of Pricing Nuances: Understand regional pricing variations, currency fluctuations, and tariff implications. For instance, importing goods into Europe might involve additional VAT or customs duties that can affect overall costs.

Illustrative image related to gravity latch

Conclusion

While gravity latch pricing is influenced by a myriad of factors, understanding the cost components and market dynamics allows international B2B buyers to make informed decisions. By leveraging negotiation strategies and being aware of pricing nuances, buyers can optimize their sourcing strategies and ensure they receive the best value for their investments. Always remember that the prices indicated in the market can vary based on specific requirements and supplier negotiations.

Alternatives Analysis: Comparing gravity latch With Other Solutions

Exploring Alternatives to Gravity Latches in Gate Security Solutions

When selecting a gate latch, B2B buyers often consider multiple solutions that cater to various security needs, installation environments, and budget constraints. Gravity latches are a popular choice for their simplicity and reliability. However, several alternative latch technologies also offer distinct advantages that may better align with specific applications and preferences. This analysis compares gravity latches against two viable alternatives: magnetic latches and slide bolts.

| Comparison Aspect | Gravity Latch | Magnetic Latch | Slide Bolt |

|---|---|---|---|

| Performance | Reliable self-latching mechanism; ideal for light to moderate use | High-performance closure; suited for high-traffic areas | Simple locking mechanism; effective but requires manual operation |

| Cost | Generally low-cost (approx. $8-12) | Moderate cost (approx. $20-50) | Low-cost (approx. $5-15) |

| Ease of Implementation | Easy installation; minimal tools required | Requires proper alignment for optimal performance | Simple installation; may require additional hardware for mounting |

| Maintenance | Low maintenance; durable materials available | Moderate maintenance; may need adjustments | Low maintenance; easy to replace if damaged |

| Best Use Case | Residential and light commercial gates | High-traffic gates, security-sensitive areas | Temporary or infrequently used gates |

What are the Pros and Cons of Magnetic Latches Compared to Gravity Latches?

Magnetic latches offer a unique approach to gate security, utilizing magnetic forces to ensure a tight closure. They are particularly effective in high-traffic areas where frequent use is expected, as they can automatically engage upon closure without manual operation. However, the installation requires precise alignment, which may complicate setup in less controlled environments. Additionally, the cost is typically higher than gravity latches, which can be a consideration for budget-conscious buyers.

How Do Slide Bolts Compare to Gravity Latches in Terms of Functionality?

Slide bolts provide a straightforward locking mechanism that can be very effective for securing gates. They are generally less expensive than both gravity latches and magnetic latches, making them an attractive option for temporary or rarely used gates. However, slide bolts require manual operation to lock and unlock, which may not be suitable for all users, particularly in high-security or high-traffic settings. While they are easy to install, they may not provide the same level of security as a self-latching mechanism.

Making the Right Choice: How Should B2B Buyers Select the Best Gate Latch Solution?

Choosing the right gate latch solution depends on several factors, including the intended use of the gate, the frequency of use, and specific security requirements. Gravity latches are ideal for residential applications where ease of use and low cost are priorities. For high-traffic commercial environments, magnetic latches may provide the necessary performance and reliability, albeit at a higher cost. Slide bolts can serve well in less frequently accessed areas, offering a budget-friendly solution, but may not meet the security needs of all applications.

Illustrative image related to gravity latch

In conclusion, B2B buyers should assess their unique requirements and weigh the pros and cons of each latch type. By carefully considering the performance, cost, and maintenance of each option, businesses can ensure they choose a solution that best fits their operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for gravity latch

What Are the Key Technical Properties of a Gravity Latch?

Understanding the technical properties of a gravity latch is crucial for B2B buyers, especially when selecting hardware for gates and fences. Here are several critical specifications that should be considered:

Material Grade

Gravity latches are typically made from materials such as stainless steel, polymer, or coated steel. The choice of material directly influences durability, corrosion resistance, and overall lifespan. For instance, stainless steel latches are ideal for outdoor applications where weather resistance is essential, while polymer latches may be suitable for environments where weight and aesthetics are a priority. Selecting the right material ensures that the latch can withstand environmental stresses and operational demands.

Load Capacity

The load capacity of a gravity latch refers to the maximum weight it can support without failing. This specification is critical when dealing with heavy gates or those subjected to frequent use. A latch with a higher load capacity not only enhances security but also reduces the likelihood of maintenance issues, making it a vital consideration for B2B buyers focusing on long-term reliability.

Tolerance

Tolerance indicates the permissible limit of variation in the latch’s dimensions. Accurate tolerances ensure that the latch fits properly with the corresponding gate or post, facilitating seamless operation. In a B2B context, precise tolerances are essential for ensuring compatibility and ease of installation, which can significantly reduce labor costs and time.

Locking Mechanism

Gravity latches can feature various locking mechanisms, such as single-side or double-side locking. Understanding these options allows buyers to choose latches that meet specific security requirements. For instance, double-side locking provides enhanced security for commercial applications, while single-side may suffice for residential use. This knowledge enables buyers to align their hardware choices with the necessary security protocols.

Finish

The finish on a gravity latch can affect both aesthetics and durability. Options may include powder-coated finishes for enhanced weather resistance or decorative finishes that match architectural styles. For B2B buyers, the finish is not merely a design choice; it can influence maintenance requirements and the overall lifespan of the product.

What Are Common Trade Terms Related to Gravity Latches?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are some common terms related to gravity latches:

OEM (Original Equipment Manufacturer)

An OEM is a company that produces components that are used in another company’s end products. In the context of gravity latches, understanding whether a product is OEM can help buyers gauge quality and compatibility with existing hardware.

Illustrative image related to gravity latch

MOQ (Minimum Order Quantity)

MOQ refers to the smallest amount of a product that a supplier is willing to sell. This term is crucial for buyers as it affects inventory management and purchasing strategies. Knowing the MOQ helps businesses plan their orders effectively, ensuring they meet both operational needs and budget constraints.

RFQ (Request for Quotation)

An RFQ is a standard business process where a buyer requests a quote from suppliers for specific products or services. For gravity latches, issuing an RFQ allows buyers to gather pricing information and terms from multiple suppliers, enabling informed purchasing decisions.

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers, as they dictate shipping responsibilities, risk transfer, and cost allocation, thereby influencing overall procurement strategies.

SKU (Stock Keeping Unit)

SKU is a unique identifier assigned to each product to track inventory. For businesses dealing with multiple types of gravity latches, understanding SKU systems helps streamline inventory management and simplifies order processing.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their specific needs and operational goals.

Navigating Market Dynamics and Sourcing Trends in the gravity latch Sector

What Are the Current Market Dynamics and Key Trends in the Gravity Latch Sector?

The gravity latch sector is experiencing significant growth driven by increasing demand across various industries, including residential, commercial, and industrial applications. Key trends include the rising adoption of automation in security systems, which has led to the development of advanced gravity latch designs that integrate with smart home technologies. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly looking for versatile solutions that can accommodate both aesthetic and functional requirements.

In Africa and South America, the expansion of urban development and infrastructure projects is propelling demand for reliable and durable gate hardware. Meanwhile, in the Middle East, stringent safety regulations and a focus on luxury residential projects are influencing purchasing decisions. In Europe, especially in countries like Germany, buyers are leaning towards high-quality materials that offer longevity and low maintenance, further pushing manufacturers towards innovation in design and materials.

Illustrative image related to gravity latch

Emerging technologies, such as 3D printing and advanced polymer materials, are also reshaping the sourcing landscape. These technologies enable manufacturers to produce customized solutions that meet specific buyer needs, thereby enhancing competitiveness in the global market. Moreover, as e-commerce continues to thrive, international buyers are increasingly utilizing online platforms for sourcing, making it essential for suppliers to optimize their digital presence and offer seamless purchasing experiences.

How Can Sustainability and Ethical Sourcing Influence B2B Decisions in the Gravity Latch Market?

Sustainability is becoming a pivotal factor in the purchasing decisions of B2B buyers in the gravity latch sector. Environmental concerns are prompting companies to prioritize products that minimize ecological impact. The use of materials such as recycled metals and eco-friendly polymers not only reduces waste but also appeals to environmentally conscious customers. Manufacturers are increasingly focusing on obtaining ‘green’ certifications, which can enhance their reputation and marketability, particularly in regions with stringent environmental regulations.

Ethical sourcing is another critical consideration for international buyers. Companies are expected to demonstrate transparency in their supply chains, ensuring that materials are sourced responsibly and labor practices are ethical. This focus on ethical sourcing can influence partnerships and supplier selection, as buyers seek to align with manufacturers that share their values. Additionally, engaging in sustainable practices can lead to cost savings in the long run, as energy-efficient production methods and waste reduction strategies contribute to lower operational costs.

What Is the Brief Evolution of Gravity Latch Technology in the B2B Landscape?

The evolution of gravity latch technology reflects broader trends in security and convenience. Initially, gravity latches were simple mechanical devices primarily used in residential settings. However, as security needs evolved, so did the technology. The introduction of materials such as stainless steel and advanced polymers has significantly enhanced durability and resistance to corrosion, making them suitable for a wider range of applications, including industrial environments.

In recent years, the integration of smart technology has transformed gravity latches into sophisticated security solutions. Features such as remote locking mechanisms and compatibility with smart home systems have made gravity latches not only functional but also an integral part of modern security systems. This evolution signifies a shift towards more versatile products that cater to the diverse needs of international B2B buyers, emphasizing the importance of innovation in maintaining competitive advantage in the market.

Frequently Asked Questions (FAQs) for B2B Buyers of gravity latch

-

How do I choose the right gravity latch for my application?

When selecting a gravity latch, consider the material compatibility, gate type, and security needs. For instance, stainless steel latches are ideal for outdoor applications due to their corrosion resistance, while polymer options may be better suited for residential gates. Assess the weight and width of your gates to ensure the latch can handle the load and movement. Additionally, think about whether you require features like self-latching or locking mechanisms, especially for security-sensitive areas. -

What are the key features to look for in a high-quality gravity latch?

Look for features such as corrosion-resistant materials (like stainless steel or high-grade polymers), ease of installation, and robust locking options. A good gravity latch should offer a self-latching mechanism for convenience and security. Additionally, consider the aesthetic appeal if the latch will be visible, as options come in various colors and finishes. Warranty and compliance with international safety standards are also crucial factors to ensure reliability and longevity. -

What customization options are available for gravity latches?

Many suppliers offer customization options for gravity latches, including color finishes, locking mechanisms, and sizes to fit specific gate dimensions. If you have unique requirements, discuss them with your supplier to explore possibilities like branding or specific design alterations. Customization can enhance both functionality and visual appeal, making your product stand out in the market. -

What are the minimum order quantities (MOQ) for gravity latches?

MOQs can vary significantly between suppliers and regions. Typically, manufacturers may set MOQs based on production costs and logistics. For international buyers, it’s advisable to inquire directly with potential suppliers to negotiate MOQs that suit your purchasing needs. Some suppliers may offer flexibility for first-time orders or bulk purchases, which can help optimize your inventory management. -

What payment terms should I expect when sourcing gravity latches internationally?

Payment terms can differ widely based on the supplier’s policies, your relationship with them, and your purchasing volume. Common terms include a percentage upfront (usually 30-50%) with the balance due upon delivery or before shipping. Ensure you clarify payment methods accepted (e.g., bank transfer, credit card, or letters of credit) and any currency considerations, particularly when dealing with international transactions. -

How can I ensure the quality of gravity latches from suppliers?

To guarantee quality, vet suppliers by checking their certifications, customer reviews, and previous project references. Request samples before placing a bulk order to inspect the latch’s material and functionality. Additionally, inquire about their quality assurance processes and any warranties they offer. Establishing a quality control protocol upon receipt can also help ensure that the products meet your specifications. -

What logistics considerations should I take into account when importing gravity latches?

Consider factors such as shipping costs, delivery times, and customs regulations when planning your logistics. Partner with a reliable freight forwarder experienced in handling hardware products to navigate potential challenges. Be aware of import duties and taxes that may apply to your shipment. It is also prudent to have a clear understanding of the supplier’s shipping policies, including tracking options and liability during transit. -

What are the common applications for gravity latches in different industries?

Gravity latches are versatile and can be utilized across various sectors, including residential fencing, commercial gates, and industrial applications. They are commonly used in security gates, pool enclosures, and agricultural settings. Understanding the specific needs of your industry—like safety regulations in pool areas or durability requirements in industrial settings—can help you select the most appropriate latch for your application.

Top 1 Gravity Latch Manufacturers & Suppliers List

1. Nationwide Industries – Standard Gravity Latch

Domain: nationwideindustries.com

Registered: 2000 (25 years)

Introduction: {“name”:”Standard Gravity Latch”,”model”:”NW38204″,”color”:”Black”,”material”:”Zinc-plated steel”,”features”:”Dependable one-sided security, self-latching mechanism, pad-lockable, includes 13-inch pull cable, clip, and o-ring for access from opposite side of fence, corrosion resistant”,”strike_bar”:”0.38-inch with rounded ball tip for smooth engagement”,”available_finishes”:[“Bronze (NW38204BZ)”,”…

Strategic Sourcing Conclusion and Outlook for gravity latch

The strategic sourcing of gravity latches is pivotal for businesses across various sectors, especially in regions like Africa, South America, the Middle East, and Europe. By selecting high-quality materials—such as stainless steel and durable polymers—buyers can ensure their products withstand environmental stresses while maintaining security and functionality. The ease of installation and versatility of gravity latches make them an attractive option for both residential and industrial applications, enhancing operational efficiency and customer satisfaction.

Investing in strategic sourcing not only strengthens supply chains but also fosters long-term partnerships with manufacturers who prioritize quality and compliance with international standards. This is particularly crucial for businesses looking to expand their reach and improve their market competitiveness.

As the demand for reliable gate hardware continues to grow, international buyers are encouraged to explore innovative solutions that meet their specific needs. Engaging with reputable suppliers and keeping abreast of emerging trends in gate hardware technology can significantly enhance your business’s product offerings. Now is the time to act—prioritize strategic sourcing to secure a competitive edge in the dynamic marketplace for gravity latches.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.