Everything You Need to Know About Graphite Tube Sourcing in 2025

Introduction: Navigating the Global Market for graphite tube

Navigating the complex landscape of sourcing graphite tubes can be daunting for international B2B buyers, especially those operating in regions such as Africa, South America, the Middle East, and Europe. The challenge lies not only in identifying high-quality suppliers but also in understanding the diverse applications and specifications of graphite tubes that are essential for various industrial processes. This guide aims to demystify the global market for graphite tubes by providing insights into the different types available, their applications across industries, and critical considerations for supplier vetting.

From high-temperature furnace applications to specialized uses in electrical discharge machining, the versatility of graphite tubes makes them indispensable in many sectors. Buyers will benefit from a thorough exploration of the cost factors associated with these products, as well as tips for negotiating favorable terms with suppliers. Additionally, this guide emphasizes the importance of understanding the manufacturing processes and material properties that influence the performance of graphite tubes, ensuring that buyers can make informed purchasing decisions.

By equipping B2B buyers with comprehensive knowledge and actionable strategies, this guide empowers them to confidently navigate the graphite tube market, ultimately enhancing their operational efficiency and reducing total costs in the long run.

Understanding graphite tube Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Carbon-Bonded Graphite Tubes | Made from extruded graphite flour and resin | Electrical discharge machining (EDM) | Pros: Good thermal conductivity; Cons: Limited mechanical strength at high temperatures |

| Isostatically Pressed Graphite Tubes | Superior particle fineness and smooth finishes | High-precision machining and aerospace | Pros: Excellent dimensional accuracy; Cons: Higher cost due to advanced manufacturing |

| Extruded Graphite Tubes | Continuous lengths with uniform cross-sections | General industrial applications | Pros: Cost-effective; Cons: Limited customization options |

| Copper Graphite Tubes | Blends of copper and graphite for enhanced conductivity | Electrical components and EDM | Pros: High electrical and thermal conductivity; Cons: More expensive than pure graphite |

| Specialty Graphite Tubes | Custom formulations for specific applications | Chemical processing and high-temperature environments | Pros: Tailored properties; Cons: Longer lead times for custom orders |

What Are Carbon-Bonded Graphite Tubes and Their Applications?

Carbon-bonded graphite tubes are created by combining graphite flour with lubricants and resin, offering a balance of thermal conductivity and mechanical stability. These tubes are particularly suited for applications in electrical discharge machining (EDM), where precise thermal management is essential. Buyers should consider their specific temperature requirements and potential exposure to mechanical stress when choosing this type.

How Do Isostatically Pressed Graphite Tubes Stand Out?

Isostatically pressed graphite tubes are known for their fine grain structure and smooth surfaces, making them ideal for high-precision applications such as aerospace and advanced manufacturing. Their manufacturing process allows for superior dimensional accuracy, which is crucial in industries demanding tight tolerances. While they offer excellent performance, potential buyers should weigh the higher costs against the benefits of enhanced precision.

What Are the Advantages of Extruded Graphite Tubes?

Extruded graphite tubes are produced in continuous lengths, making them a versatile option for various industrial applications. They are cost-effective and widely available, suitable for less demanding environments. However, their limitations in customization may not meet the needs of specialized applications, so buyers should assess their specific requirements before selecting this type.

Why Choose Copper Graphite Tubes for Electrical Applications?

Copper graphite tubes combine the conductive properties of copper with the thermal resistance of graphite, making them ideal for electrical components and EDM processes. These tubes excel in applications requiring high electrical and thermal conductivity. Buyers should consider the higher cost associated with these tubes and evaluate whether the performance benefits justify the investment for their specific use cases.

What Are Specialty Graphite Tubes and Their Benefits?

Specialty graphite tubes are custom-formulated to meet specific industry needs, often used in chemical processing and high-temperature environments. Their tailored properties provide unique advantages, such as enhanced corrosion resistance or improved thermal stability. However, the longer lead times for custom orders can be a drawback, so businesses should plan accordingly when sourcing these specialized products.

Key Industrial Applications of graphite tube

| Industry/Sector | Specific Application of graphite tube | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Thermal protection in engine components | Enhances durability and performance in extreme conditions | High-temperature resistance, lightweight materials |

| Chemical Processing | Reaction vessels and piping systems | Corrosion resistance and thermal stability | Compatibility with chemicals, custom sizes |

| Electronics | EDM electrodes and components | Superior electrical conductivity | Precision machining capabilities, quality certifications |

| Metallurgy | Furnaces and heating elements | High thermal conductivity and structural integrity | Supplier reliability, material purity |

| Renewable Energy | Components for solar thermal systems | Improved efficiency and longevity | Customization options, environmental compliance |

How is Graphite Tube Used in Aerospace Applications?

In the aerospace sector, graphite tubes are utilized for thermal protection in engine components. They withstand extreme temperatures while maintaining structural integrity, reducing the risk of failure during operation. This is critical for ensuring safety and performance in high-stakes environments. International buyers should prioritize suppliers who can provide materials certified for aerospace applications, ensuring compliance with rigorous industry standards.

What Role Does Graphite Tube Play in Chemical Processing?

Graphite tubes serve as reaction vessels and piping systems in chemical processing due to their exceptional corrosion resistance and thermal stability. They can handle aggressive chemicals at high temperatures, minimizing the risk of leaks and failures. For international buyers, sourcing from manufacturers who offer customizable solutions that meet specific chemical compatibility requirements is essential to ensure the longevity and efficiency of their operations.

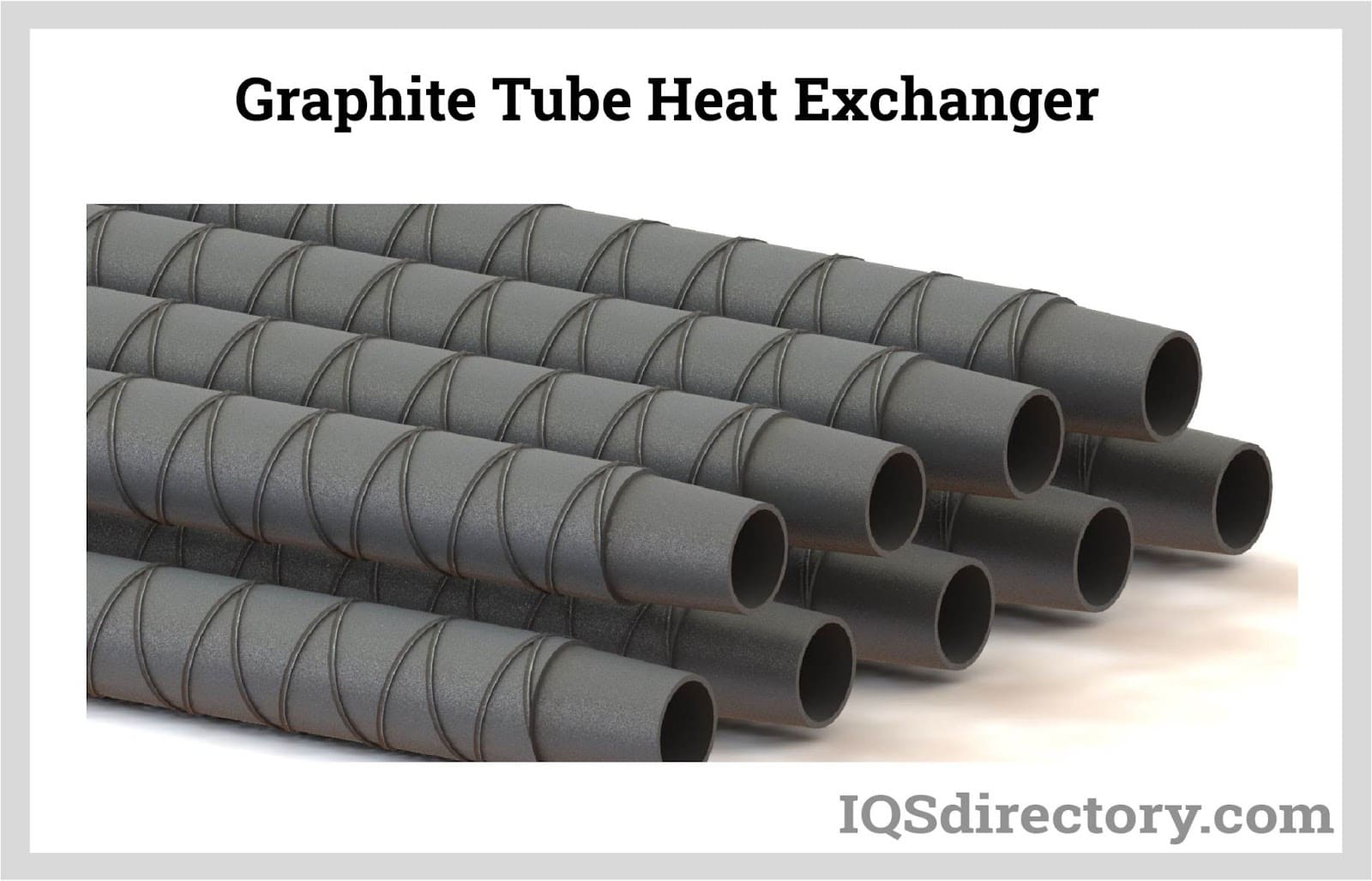

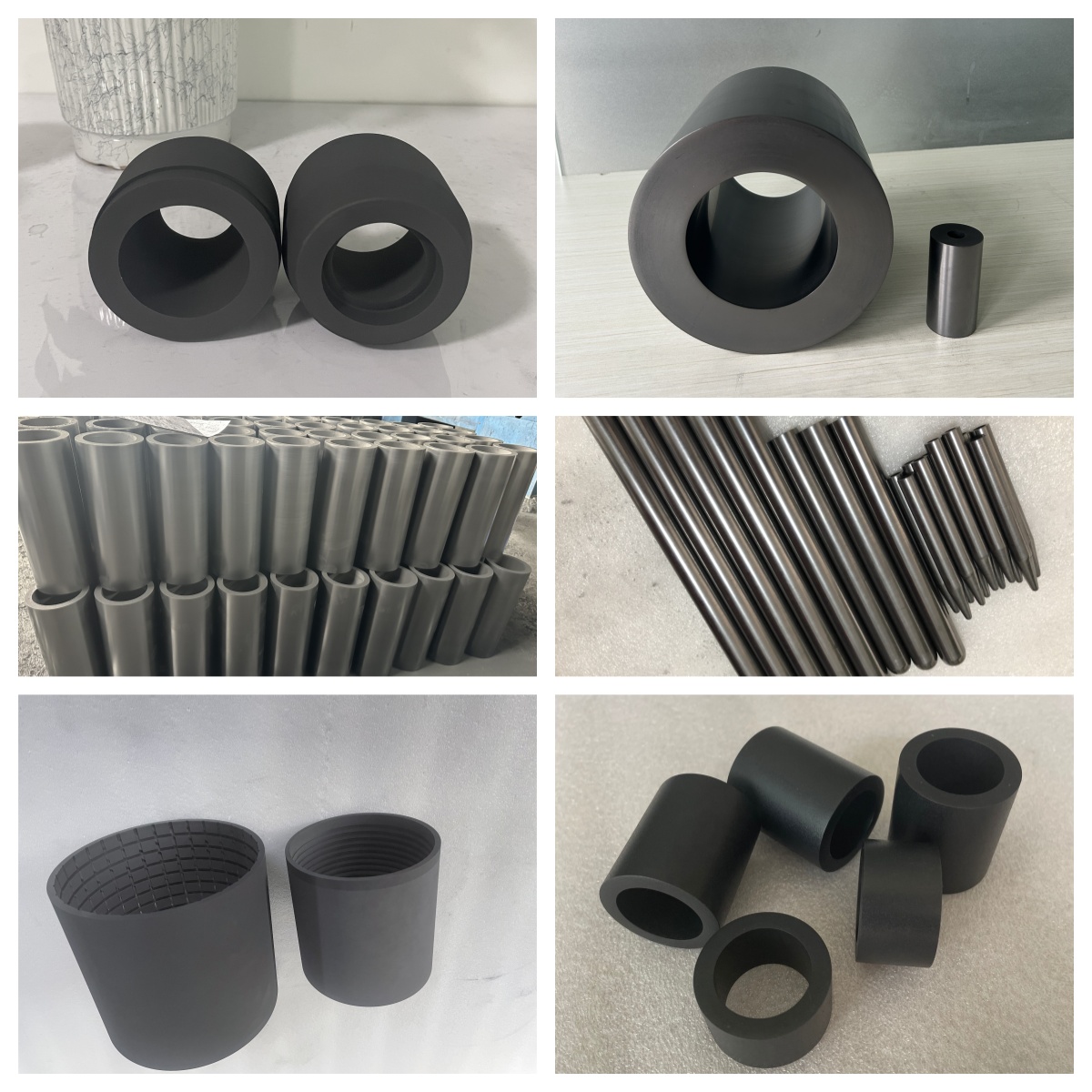

Illustrative image related to graphite tube

Why are Graphite Tubes Important in Electronics?

In the electronics industry, graphite tubes are commonly used as EDM (Electrical Discharge Machining) electrodes and components. Their superior electrical conductivity and thermal stability make them ideal for precision machining applications. Buyers should consider sourcing from manufacturers with advanced machining capabilities and quality certifications to ensure high performance and reliability in their electronic components.

How are Graphite Tubes Applied in Metallurgy?

Graphite tubes are extensively used in furnaces and heating elements within the metallurgy industry. Their high thermal conductivity allows for efficient heat transfer, while their structural integrity at elevated temperatures ensures durability. When sourcing graphite tubes for metallurgy, buyers should focus on suppliers known for their reliability and the purity of their materials, as these factors directly influence the performance and lifespan of the products.

What is the Use of Graphite Tubes in Renewable Energy?

In renewable energy, particularly solar thermal systems, graphite tubes are vital for enhancing efficiency and longevity. They can withstand high temperatures and provide excellent thermal conductivity, making them ideal for heat transfer applications. International buyers should seek suppliers who can offer customization options tailored to specific project requirements and ensure compliance with environmental standards, thereby maximizing the sustainability of their energy solutions.

3 Common User Pain Points for ‘graphite tube’ & Their Solutions

Scenario 1: Inconsistent Quality Leading to Production Delays

The Problem: Many B2B buyers face the challenge of inconsistent quality when sourcing graphite tubes. This inconsistency can lead to significant production delays, as inferior products may not meet the required specifications for high-temperature applications. For instance, if a manufacturer uses low-quality graphite tubes in their furnace, the tubes might degrade rapidly, causing unexpected shutdowns and costly repairs. This not only affects production schedules but also strains relationships with clients who rely on timely delivery.

The Solution: To mitigate this issue, buyers should prioritize sourcing from reputable manufacturers with a proven track record in producing high-quality graphite tubes. Conduct thorough research by reviewing certifications, customer testimonials, and product specifications. When placing an order, insist on detailed documentation that verifies the material’s properties, including thermal conductivity, tensile strength, and chemical resistance. Additionally, consider requesting sample tubes to assess their quality before committing to a larger purchase. Establishing a long-term relationship with a reliable supplier can lead to consistent quality and support in troubleshooting any issues that arise during production.

Scenario 2: Difficulty in Selecting the Right Type of Graphite Tube

The Problem: B2B buyers often struggle with selecting the appropriate type of graphite tube for their specific applications due to the variety of options available. For example, industries requiring tubes for high-temperature processes may be unsure whether to choose extruded, isostatically pressed, or carbon-bonded graphite tubes. This confusion can lead to using the wrong type, resulting in premature failure or inefficient performance, which can have severe financial implications.

The Solution: To overcome this challenge, buyers should invest time in understanding the unique properties of different graphite tube types. Engage with technical experts or suppliers who can provide insights based on application requirements. Create a detailed specification sheet that outlines the operational conditions—such as temperature, pressure, and chemical exposure—your tubes will face. This will facilitate informed discussions with suppliers, helping to narrow down the options to those best suited for your needs. Additionally, consider utilizing custom solutions if standard products do not meet your specifications, ensuring optimal performance in your applications.

Scenario 3: High Maintenance Costs Due to Rapid Wear

The Problem: A common pain point for buyers is the high maintenance costs associated with graphite tubes that wear out too quickly, particularly in corrosive or high-temperature environments. This not only leads to increased operational costs but also affects overall productivity. For instance, if graphite tubes in a furnace require frequent replacement, it can disrupt operations and necessitate additional labor costs for installation.

The Solution: To address this issue, buyers should focus on selecting graphite tubes with enhanced durability features. Look for products that offer protective coatings, such as siloxane, which can significantly increase resistance to oxidation and extend the service life of the tubes. Additionally, consider the manufacturing process used to create the tubes; for example, isostatically pressed graphite tubes typically offer superior mechanical strength and thermal stability. Work closely with suppliers to identify materials that have been specifically engineered for longevity in extreme conditions. Implementing a regular maintenance schedule that includes inspections and timely replacements will also help in managing costs and ensuring uninterrupted operations.

Illustrative image related to graphite tube

Strategic Material Selection Guide for graphite tube

What Are the Key Properties of Different Graphite Tube Materials?

When selecting graphite tubes for industrial applications, understanding the properties of various materials is crucial for ensuring optimal performance. Here, we analyze four common materials used in the manufacturing of graphite tubes: high-purity graphite, carbon-bonded graphite, copper graphite, and isostatically pressed graphite. Each material presents unique characteristics that can significantly impact their suitability for specific applications.

High-Purity Graphite: What Makes It Stand Out?

High-purity graphite is known for its exceptional thermal conductivity, high-temperature resistance (up to 5000°F or 2760°C), and excellent chemical stability. This material is ideal for applications involving extreme heat or corrosive environments, such as furnace components and heat exchangers.

Pros: High-purity graphite offers superior durability and thermal shock resistance, making it suitable for demanding industrial settings. Its low porosity enhances corrosion resistance, leading to a longer service life.

Cons: The primary drawback is its cost, which can be significantly higher than other graphite options. Additionally, the manufacturing process can be complex, requiring specialized techniques to maintain purity.

Impact on Application: High-purity graphite is compatible with various media, including molten metals and aggressive chemicals, making it a versatile choice for industries like metallurgy and chemical processing.

Considerations for International Buyers: Compliance with international standards (e.g., ASTM, DIN) is essential. Buyers in regions like Africa and the Middle East should ensure that suppliers can provide certifications confirming material purity and performance.

Carbon-Bonded Graphite: A Cost-Effective Alternative?

Carbon-bonded graphite tubes are created by combining graphite flour, lubricants, and resins, followed by a curing process. This material offers a balance between performance and cost, making it a popular choice for medium-duty applications.

Pros: The primary advantage of carbon-bonded graphite is its lower cost compared to high-purity graphite. It also provides good thermal conductivity and mechanical strength, suitable for many industrial applications.

Cons: However, it may not withstand extreme temperatures or corrosive environments as effectively as high-purity graphite. Additionally, the presence of resins can affect its thermal stability at high temperatures.

Impact on Application: These tubes are often used in applications where cost is a significant factor, such as in heating elements and various manufacturing processes.

Considerations for International Buyers: Buyers should be aware of the specific performance standards required in their regions, particularly in Europe, where regulations may dictate material properties.

Copper Graphite: When Is It the Right Choice?

Copper graphite tubes integrate copper into the graphite matrix, enhancing electrical and thermal conductivity. This material is commonly used in electrical discharge machining (EDM) and other applications requiring high conductivity.

Pros: The key advantage of copper graphite is its excellent electrical and thermal conductivity, making it suitable for high-performance applications. Its mechanical strength also improves at elevated temperatures.

Cons: The main limitation is the higher cost associated with copper graphite, as well as its susceptibility to oxidation, which may require additional protective coatings.

Impact on Application: This material is particularly effective in environments where electrical performance is critical, such as in electrical connectors and electrodes.

Considerations for International Buyers: Compliance with electrical standards (such as JIS in Japan or IEC in Europe) is crucial for ensuring product reliability. Buyers should verify that suppliers can meet these specifications.

Isostatically Pressed Graphite: Why Choose This Manufacturing Method?

Isostatically pressed graphite is produced through a specialized process that applies equal pressure from all directions, resulting in a high-density, fine-grained material. This method enhances the mechanical properties and surface finish of the graphite tubes.

Pros: The primary advantage is the superior dimensional accuracy and surface quality, making it ideal for precision applications. It also offers excellent thermal stability and mechanical strength.

Cons: The manufacturing process is more complex and costly than traditional methods, which can lead to higher prices for the final product.

Illustrative image related to graphite tube

Impact on Application: Isostatically pressed graphite tubes are often used in high-precision applications, such as aerospace and advanced manufacturing.

Considerations for International Buyers: Buyers should ensure that the manufacturing processes comply with relevant international standards, as the quality of isostatically pressed graphite can vary significantly between suppliers.

Summary Table of Graphite Tube Materials

| Material | Typical Use Case for graphite tube | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Purity Graphite | Furnace components | Exceptional thermal conductivity | High cost and complex manufacturing | High |

| Carbon-Bonded Graphite | Medium-duty industrial applications | Cost-effective and good thermal conductivity | Limited high-temperature performance | Medium |

| Copper Graphite | Electrical discharge machining | Excellent electrical and thermal conductivity | Higher cost and oxidation susceptibility | High |

| Isostatically Pressed Graphite | Precision aerospace applications | Superior dimensional accuracy and strength | Higher manufacturing complexity | High |

In-depth Look: Manufacturing Processes and Quality Assurance for graphite tube

What Are the Main Stages in the Manufacturing Process of Graphite Tubes?

The manufacturing of graphite tubes involves several critical stages, each designed to ensure that the final product meets the demanding specifications required by various industries. The main stages include material preparation, forming, assembly, and finishing.

Illustrative image related to graphite tube

-

Material Preparation: The first step in the manufacturing process is the selection and preparation of raw materials. High-purity graphite is often chosen for its superior thermal and electrical properties. The graphite is typically ground into a fine powder, which may then be mixed with binders and additives to enhance specific characteristics like strength and thermal stability. This mixture is crucial as it determines the final properties of the graphite tube.

-

Forming Techniques: The forming of graphite tubes can be accomplished through various methods, each suited for different applications:

– Extrusion: This technique involves forcing the graphite mixture through a die to create a continuous tube shape. Extruded tubes are commonly used in medium-duty applications due to their cost-effectiveness and adequate performance.

– Compression Molding: In this method, the graphite powder is placed in a mold and subjected to high pressure to form a tube. This technique is often employed for producing thicker-walled tubes that require higher structural integrity.

– Isostatic Pressing: For applications demanding higher precision and finer grain structures, isostatic pressing is utilized. This method involves enclosing the graphite in a flexible mold and applying uniform pressure from all directions, resulting in tubes with enhanced mechanical properties and surface finishes. -

Assembly and Machining: After forming, the tubes may undergo additional machining processes to achieve specific dimensions and tolerances. This step may include cutting, grinding, or drilling to meet the precise requirements of the application.

-

Finishing Processes: The final stage involves applying coatings if necessary, such as siloxane, to enhance the tube’s resistance to oxidation and wear. Additionally, any surface defects are rectified, and the tubes are polished to achieve the desired finish.

What Quality Assurance Measures Are Commonly Used in Graphite Tube Production?

Quality assurance (QA) is paramount in the manufacturing of graphite tubes, especially for B2B buyers who require high reliability and performance. Various international and industry-specific standards guide the QA processes.

-

International Standards: Compliance with ISO 9001 is a fundamental requirement for manufacturers aiming to establish a quality management system. This certification ensures that companies consistently meet customer requirements and enhance satisfaction through effective processes. Additionally, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant, depending on the application of the graphite tubes.

-

Quality Control Checkpoints: Effective quality control (QC) includes several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial stage involves inspecting raw materials for conformity to specifications before they are used in production. Ensuring high-quality inputs is critical for achieving superior outputs.

– In-Process Quality Control (IPQC): During the manufacturing phases, ongoing inspections are conducted to monitor the production process. This step helps identify any deviations from established standards early, allowing for corrective measures to be implemented promptly.

– Final Quality Control (FQC): Once the tubes are manufactured, they undergo a final inspection and testing phase to ensure they meet all specifications and performance criteria before shipment. -

Common Testing Methods: Various testing methods are employed to validate the quality and performance of graphite tubes, including:

– Dimensional Inspection: Using calipers and gauges to ensure that the tubes meet specified dimensions.

– Thermal Conductivity Testing: Assessing the thermal performance of the tubes under specific conditions.

– Mechanical Testing: Evaluating the strength and durability of the tubes through tensile and compression tests.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential for maintaining product integrity.

-

Supplier Audits: Conducting regular audits of potential suppliers can provide insight into their manufacturing processes and quality control measures. These audits can assess compliance with international standards and the effectiveness of their QA systems.

-

Requesting Quality Reports: Buyers should request documentation that details the quality control processes implemented by suppliers. This includes reports on IQC, IPQC, and FQC, as well as certifications that demonstrate adherence to international standards.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control measures. These inspections can validate that the supplier meets the necessary specifications and industry standards before shipping.

What Are the QC and Certification Nuances for International B2B Buyers?

B2B buyers operating in diverse international markets must navigate various certification requirements and quality assurance practices.

-

Understanding Regional Standards: Each region may have different quality assurance standards that suppliers must meet. For example, European buyers may prioritize CE marking, while buyers in the Middle East might require compliance with local regulations. It’s crucial to be informed about these differences when selecting suppliers.

-

Language and Documentation: Ensure that all quality control documentation is available in a language that is understandable to the buyers. This facilitates better communication and comprehension of the quality standards being upheld.

-

Cultural Considerations: Cultural factors can influence manufacturing practices and quality perceptions. Buyers should be aware of these nuances to establish effective communication and expectations with suppliers from different regions.

In conclusion, understanding the manufacturing processes and quality assurance measures for graphite tubes is essential for B2B buyers looking to source these products effectively. By focusing on the stages of production and the rigor of quality control, buyers can ensure they select suppliers that meet their specific needs and uphold high standards of performance and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘graphite tube’

Introduction

Sourcing graphite tubes for industrial applications requires careful consideration and strategic planning. This guide provides a step-by-step checklist to help B2B buyers navigate the procurement process effectively. By following these steps, you can ensure that you select the right product and supplier to meet your operational needs.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical specifications required for your graphite tubes. This includes dimensions, wall thickness, thermal conductivity, and any specific chemical resistance needed for your application.

– Why It’s Important: Precise specifications help avoid costly mistakes and ensure that the tubes will perform effectively in your specific environment.

– What to Look For: Consider the operating temperature range and any industry standards relevant to your sector.

Step 2: Identify Suitable Applications

Understand the applications where graphite tubes will be utilized, such as in furnaces, heat exchangers, or as components in electronic devices.

– Why It’s Important: Knowing the intended use will guide you in selecting the appropriate type of graphite tube, whether it’s extruded, molded, or isostatically pressed.

– What to Look For: Evaluate the specific performance requirements based on the application, including mechanical strength and thermal stability.

Step 3: Research and Compare Suppliers

Conduct thorough research to identify potential suppliers of graphite tubes. Look for manufacturers with a proven track record in your industry.

– Why It’s Important: A reliable supplier can significantly impact the quality and performance of the products you procure.

– What to Look For: Check for customer reviews, industry certifications, and case studies that demonstrate their capability in delivering high-quality products.

Step 4: Request Samples and Specifications

Before making a bulk order, request samples of the graphite tubes to evaluate their quality and suitability for your needs.

– Why It’s Important: Testing samples allows you to verify that the product meets your specifications and performs as expected under real-world conditions.

– What to Look For: Inspect the physical characteristics, such as density and surface finish, and assess how well they align with your requirements.

Step 5: Verify Supplier Certifications and Compliance

Ensure that your chosen suppliers hold relevant certifications and comply with industry standards for quality and safety.

– Why It’s Important: Certifications are often indicators of a supplier’s commitment to quality management and adherence to regulatory requirements.

– What to Look For: Look for ISO certifications or specific industry-related standards that might apply to your purchase.

Illustrative image related to graphite tube

Step 6: Evaluate Pricing and Payment Terms

Gather quotes from multiple suppliers and compare pricing structures, including volume discounts and payment terms.

– Why It’s Important: Understanding the pricing landscape helps ensure that you are getting competitive rates while also considering the overall value of the product.

– What to Look For: Pay attention to hidden costs such as shipping, customs duties, and potential tariffs that may affect total expenditure.

Step 7: Establish a Clear Communication Channel

Maintain open communication with your supplier throughout the sourcing process. This includes discussing timelines, order updates, and any potential issues.

– Why It’s Important: Clear communication helps prevent misunderstandings and ensures that both parties are aligned on expectations.

– What to Look For: Choose suppliers who are responsive and willing to engage in discussions about product specifications and service delivery.

By following this checklist, B2B buyers can streamline the sourcing process for graphite tubes, ensuring they make informed decisions that align with their operational needs and strategic goals.

Comprehensive Cost and Pricing Analysis for graphite tube Sourcing

What Are the Key Cost Components in Graphite Tube Manufacturing?

When sourcing graphite tubes, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The quality of graphite used significantly impacts pricing. High-purity graphite, essential for high-temperature applications, tends to be more expensive. Additionally, any custom materials or coatings will increase costs.

-

Labor: Labor costs vary by region and manufacturing method. Automated processes may reduce labor costs, but specialized machining often requires skilled labor, especially for high-precision applications.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, including utilities, maintenance, and facility costs. Overhead can fluctuate based on the production scale and efficiency of the manufacturing facility.

-

Tooling: Initial tooling costs can be substantial, particularly for custom designs. However, these costs can be amortized over large production runs, lowering the per-unit cost.

-

Quality Control (QC): Ensuring that graphite tubes meet industry standards and specifications is vital. QC processes add to the overall cost but are essential for maintaining product integrity, especially for high-stakes applications.

-

Logistics: Shipping costs can vary significantly based on the destination, volume, and chosen logistics partner. International buyers should consider import duties and taxes that may apply.

-

Margin: Supplier profit margins can vary based on their market positioning, product quality, and service levels. Understanding this can help buyers gauge the overall pricing landscape.

How Do Price Influencers Affect Graphite Tube Costs?

Several factors can influence the price of graphite tubes:

-

Volume/MOQ: Suppliers often provide better pricing for larger orders due to economies of scale. Understanding minimum order quantities (MOQs) can help buyers negotiate more favorable terms.

-

Specifications/Customization: Custom sizes, grades, or features (like coatings) can increase the price. Buyers should clearly define their needs to avoid unexpected costs later.

-

Materials Quality/Certifications: Tubes made from higher quality materials or those that come with certifications (like ISO) typically command higher prices due to their reliability and performance in demanding applications.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established suppliers may charge a premium for their expertise and reliability.

-

Incoterms: Understanding the Incoterms agreed upon in the contract can significantly affect the total cost, as they define responsibilities for shipping, insurance, and tariffs.

What Negotiation Strategies Can Help Buyers Achieve Cost Efficiency?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, implementing effective negotiation strategies can enhance cost efficiency:

-

Leverage Volume Discounts: By consolidating orders or collaborating with other companies, buyers can achieve lower prices through bulk purchasing.

-

Assess Total Cost of Ownership (TCO): Consider not only the purchase price but also maintenance, operational efficiency, and longevity of the graphite tubes. Sometimes a higher upfront cost can lead to lower long-term expenses.

-

Be Aware of Pricing Nuances: Understand local market conditions and currency fluctuations that may impact pricing. This awareness can help in negotiating better terms.

-

Establish Relationships with Suppliers: Building long-term partnerships can lead to better pricing and service. Suppliers may offer better deals to loyal customers.

-

Request Transparency: Ask suppliers for a breakdown of costs to understand where savings can be made. Transparency can lead to more effective negotiations.

What Should Buyers Keep in Mind Regarding Indicative Prices?

While it is essential to have a ballpark figure for budgeting, indicative prices for graphite tubes can fluctuate based on the aforementioned factors. Buyers should approach price quotes as starting points for negotiation rather than fixed amounts. Always request updated quotes and consider market trends to ensure that the pricing aligns with current conditions.

In summary, understanding the intricate cost structure, influencing factors, and effective negotiation strategies can empower B2B buyers to make informed decisions when sourcing graphite tubes.

Illustrative image related to graphite tube

Alternatives Analysis: Comparing graphite tube With Other Solutions

Understanding Alternatives to Graphite Tubes

When evaluating materials for high-temperature or corrosive applications, it’s crucial to consider viable alternatives to graphite tubes. Each material comes with its own set of advantages and drawbacks, making it essential for B2B buyers to understand these differences to select the most suitable option for their specific needs.

Comparison Table

| Comparison Aspect | Graphite Tube | Ceramic Tube | Metal Tube (e.g., Stainless Steel) |

|---|---|---|---|

| Performance | Excellent thermal conductivity; stable at high temperatures | Good thermal resistance; brittle under stress | Strong and durable; moderate thermal conductivity |

| Cost | Moderate to high depending on purity and customization | Generally lower, but varies by type | Usually lower; cost-effective for bulk applications |

| Ease of Implementation | Requires specialized machining for custom sizes | Can be easily molded but may need special handling | Readily available and easy to fabricate |

| Maintenance | Low maintenance; resistant to wear | Moderate; can crack under thermal shock | Moderate; corrosion can require treatment |

| Best Use Case | High-temperature applications, chemical processing | High-temperature insulation applications | General-purpose applications, structural components |

In-Depth Analysis of Alternatives

Ceramic Tubes: Pros and Cons

Ceramic tubes are a viable alternative to graphite tubes, especially for applications requiring thermal insulation. They offer good resistance to high temperatures and are generally less expensive than graphite. However, ceramics are more brittle, making them susceptible to cracking under mechanical stress or sudden temperature changes. This limitation may reduce their effectiveness in dynamic environments where flexibility and durability are crucial.

Metal Tubes (e.g., Stainless Steel): Pros and Cons

Metal tubes, particularly those made from stainless steel, are widely used across various industries due to their strength and durability. They are cost-effective and easy to implement, making them suitable for a range of applications. However, their thermal conductivity is typically lower than that of graphite, and they may require additional coatings or treatments to enhance corrosion resistance, especially in high-temperature environments. Additionally, metals can degrade under extreme heat, impacting their longevity compared to graphite tubes.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right material for high-temperature or corrosive applications involves careful consideration of performance, cost, and maintenance requirements. Graphite tubes excel in high-temperature applications due to their superior thermal conductivity and resistance to wear, making them ideal for specialized environments. However, alternatives like ceramic and metal tubes can offer cost savings and ease of implementation for less demanding applications. Ultimately, B2B buyers should assess their specific operational needs, budget constraints, and long-term maintenance plans to make an informed decision that aligns with their business objectives.

Essential Technical Properties and Trade Terminology for graphite tube

What Are the Key Technical Properties of Graphite Tubes Important for B2B Buyers?

1. Material Grade

Graphite tubes are categorized based on material grades, which indicate their purity and performance characteristics. Common grades include high-purity graphite, which boasts exceptional thermal and electrical conductivity, and isostatically pressed graphite, known for its fine grain structure. Understanding material grades is crucial for B2B buyers as it directly impacts performance in high-temperature and corrosive environments, ensuring the selected tube meets the demands of specific applications.

2. Tolerance

Tolerance refers to the allowable deviation in dimensions such as diameter, length, and wall thickness. Precision is essential in applications where dimensional accuracy is critical, such as in aerospace or medical devices. Tight tolerances ensure that components fit together seamlessly, reducing the risk of failure and enhancing overall system reliability. For B2B buyers, specifying the right tolerance can lead to cost savings and improved operational efficiency.

3. Thermal Conductivity

The ability of graphite tubes to conduct heat efficiently is one of their most valued properties. High thermal conductivity allows for effective heat transfer in applications such as furnaces and heat exchangers. For B2B buyers, selecting tubes with the appropriate thermal conductivity is vital for optimizing performance and reducing energy costs in industrial processes.

4. Mechanical Strength

Graphite exhibits unique mechanical properties, including increased strength at elevated temperatures. This characteristic makes graphite tubes suitable for high-temperature applications where metals may fail. B2B buyers should consider mechanical strength to ensure longevity and reliability in demanding environments, ultimately minimizing maintenance needs and downtime.

5. Chemical Resistance

Graphite tubes are highly resistant to many chemicals, making them suitable for use in aggressive environments. This property is crucial for industries such as petrochemicals and pharmaceuticals, where exposure to corrosive substances is common. For B2B buyers, choosing tubes with excellent chemical resistance can lead to longer service life and reduced replacement costs.

Illustrative image related to graphite tube

What Are Common Trade Terms Related to Graphite Tubes?

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of graphite tubes, OEMs often require specific grades and custom specifications to meet their production needs. Understanding OEM relationships can help B2B buyers identify reliable suppliers who can provide the necessary components for their products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. For graphite tubes, MOQs can vary significantly based on the manufacturer and the complexity of the product. Knowing the MOQ is essential for B2B buyers to ensure they can meet their inventory needs without overcommitting to large quantities that may not be necessary.

3. RFQ (Request for Quotation)

An RFQ is a standard business process used to invite suppliers to submit price quotes for specific products or services. In the graphite tube industry, submitting an RFQ allows buyers to compare pricing, material specifications, and lead times from multiple vendors, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms that clarify the responsibilities of buyers and sellers in international transactions. They dictate aspects such as shipping, insurance, and delivery responsibilities. For B2B buyers sourcing graphite tubes globally, understanding Incoterms is critical to avoid unexpected costs and ensure smooth logistics.

5. Customization

Customization refers to the ability to modify products to meet specific requirements, such as size, shape, or material properties. In the graphite tube market, many manufacturers offer customization options, allowing B2B buyers to tailor products to their unique applications. This flexibility can enhance performance and ensure compatibility with existing systems.

Understanding these technical properties and trade terms equips B2B buyers with the knowledge necessary to make informed decisions when sourcing graphite tubes, ultimately leading to improved operational efficiency and cost savings.

Navigating Market Dynamics and Sourcing Trends in the graphite tube Sector

What Are the Current Market Dynamics and Key Trends Affecting Graphite Tube Sourcing?

The global graphite tube market is witnessing significant growth driven by various factors, including the increasing demand for high-performance materials in sectors such as aerospace, automotive, and electronics. The rapid industrialization in regions like Africa, South America, and the Middle East is fueling the demand for graphite tubes, especially in applications requiring thermal resistance and electrical conductivity. Emerging technologies in manufacturing, such as additive manufacturing and precision machining, are revolutionizing the way graphite tubes are produced, offering customization options that meet specific client needs.

Moreover, the rise of Industry 4.0 and the Internet of Things (IoT) are influencing sourcing trends by enabling real-time tracking and data analysis, which enhances supply chain efficiency. Buyers are increasingly seeking suppliers who can provide transparent information about their production processes and material sourcing. This trend is particularly relevant for international B2B buyers from Europe and regions like Vietnam and Saudi Arabia, where regulatory standards are becoming stricter, emphasizing the need for compliance with international quality benchmarks.

The competition among suppliers is intensifying, leading to price fluctuations and the introduction of innovative products that offer better performance at competitive prices. Buyers must stay informed about market conditions and supplier capabilities to make strategic sourcing decisions that align with their operational requirements.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in Graphite Tube Procurement?

Sustainability has emerged as a critical consideration in the procurement of graphite tubes, given the environmental impact associated with graphite mining and processing. International B2B buyers are increasingly prioritizing suppliers who adhere to sustainable practices, such as reducing carbon footprints and implementing eco-friendly production methods. The importance of ethical supply chains cannot be overstated; companies are now more than ever held accountable for the environmental and social impacts of their sourcing decisions.

Buyers should look for suppliers that offer ‘green’ certifications, such as ISO 14001 for environmental management systems or certifications for responsible sourcing of raw materials. These certifications not only demonstrate a commitment to sustainability but also enhance the credibility of suppliers in the eyes of environmentally conscious consumers and regulatory bodies.

Illustrative image related to graphite tube

In addition to certifications, the use of recycled materials in the production of graphite tubes is gaining traction. This approach not only minimizes waste but also reduces the reliance on virgin materials, contributing to a circular economy. B2B buyers should actively seek partnerships with manufacturers that prioritize sustainable practices, ensuring that their procurement strategies align with global sustainability goals.

What Is the Brief Evolution of Graphite Tube Manufacturing?

The evolution of graphite tube manufacturing has been marked by technological advancements and increased applications across various industries. Initially, graphite tubes were primarily used in traditional sectors such as metallurgy and ceramics. However, as the demand for high-performance materials grew, the manufacturing processes evolved to incorporate advanced techniques like extrusion, compression molding, and isostatic pressing. These methods have enabled the production of tubes with superior thermal and electrical properties, catering to more demanding applications.

In recent years, the focus has shifted towards customization and precision engineering, allowing manufacturers to produce graphite tubes tailored to specific requirements. This evolution has opened new markets and applications, from aerospace components to renewable energy technologies, illustrating the versatility and growing importance of graphite tubes in modern industry. B2B buyers can leverage this evolution to source innovative products that enhance their operational efficiency and meet emerging market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of graphite tube

-

How do I select the right graphite tube for my application?

When choosing a graphite tube, consider factors such as the operating temperature, chemical exposure, and required mechanical properties. Graphite tubes come in various grades, each tailored for specific applications like high-temperature furnaces or corrosive environments. Assess your application’s unique demands, such as thermal conductivity and strength, to ensure the selected graphite tube can maintain performance over time. Consulting with suppliers about their product specifications and previous applications can provide additional insights for making an informed decision. -

What are the advantages of using graphite tubes in industrial applications?

Graphite tubes offer several advantages, including excellent thermal conductivity, high-temperature stability, and resistance to corrosion. They can maintain dimensional integrity even at extreme temperatures, making them ideal for applications in furnaces or heat exchangers. Additionally, their lightweight nature and strength contribute to reduced operational costs and longer service life. These properties make graphite tubes a preferred choice in industries such as aerospace, automotive, and chemical processing. -

What customization options are available for graphite tubes?

Customization options for graphite tubes include variations in length, diameter, wall thickness, and flexibility, allowing them to meet specific project requirements. Manufacturers can also provide tailored grades based on the application, such as isostatically pressed graphite for precision applications or carbon-bonded options for added durability. Discussing your requirements with suppliers can help identify the best customization options to enhance performance and fit within your operational parameters. -

What is the minimum order quantity (MOQ) for graphite tubes?

Minimum order quantities for graphite tubes can vary significantly based on the manufacturer and specific product type. Some suppliers may offer low MOQ options for standard sizes, while custom orders typically require higher quantities to justify production costs. It is advisable to communicate your needs directly with potential suppliers to negotiate favorable terms and ensure they can accommodate your project’s scale without compromising on quality. -

What payment terms should I expect when sourcing graphite tubes internationally?

Payment terms for international orders of graphite tubes can range from upfront payment to net 30 or net 60 days, depending on the supplier’s policies and your business relationship. Common methods include bank transfers, letters of credit, and payment platforms. Always clarify terms before finalizing an order to avoid misunderstandings, and consider establishing a payment schedule that aligns with your cash flow to manage costs effectively. -

How can I ensure quality assurance when purchasing graphite tubes?

To ensure quality assurance, request detailed product specifications and certifications from your suppliers, including material composition and testing standards. Look for suppliers who implement rigorous quality control processes and can provide documentation for their products. Engaging in third-party inspections or requiring samples before full-scale orders can further safeguard against quality issues, ensuring that the graphite tubes meet your performance expectations. -

What logistics considerations should I be aware of when importing graphite tubes?

When importing graphite tubes, consider shipping methods, customs regulations, and potential tariffs based on your destination country. Assess the lead times for production and delivery to plan your inventory accordingly. Collaborating with logistics partners experienced in handling industrial materials can streamline the process and mitigate delays. Additionally, ensure that your supplier is familiar with international shipping practices to facilitate smooth transactions. -

How do I vet suppliers for graphite tubes in the international market?

Vetting suppliers involves researching their reputation, production capabilities, and customer reviews. Look for suppliers with industry certifications and a track record of reliability in delivering quality products. Engaging in direct communication to assess their responsiveness and understanding of your needs is crucial. Additionally, requesting case studies or references from other clients can provide insights into their performance, helping you make an informed decision before entering a contractual agreement.

Top 9 Graphite Tube Manufacturers & Suppliers List

1. Graphite Store – Graphite Plates, Rods, and Tubes

Domain: graphitestore.com

Registered: 2002 (23 years)

Introduction: This company, Graphite Store – Graphite Plates, Rods, and Tubes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Belmont – Graphite Tubing Solutions

Domain: belmont4edm.com

Registered: 1997 (28 years)

Introduction: Graphite Tubing products include various specifications such as: 0.062″ Outside Diameter, 0.032″ Inside Diameter, 3″ Length (Item Code: 03-062X3); 0.0984″ Diameter x 4″ Length (Item Code: 03-0984X4-RT); 0.118″ Diameter, 6″ Length (Item Code: 03-118-RT); 0.125″ Outside Diameter, 0.062″ Inside Diameter, 6″ Length (Item Code: 03-1250); 0.153″ Outside Diameter, 0.093″ Inside Diameter, 6″ Length (Item …

3. Goodfellow – High-Purity Graphite Tube

Domain: goodfellow.com

Registered: 1993 (32 years)

Introduction: Product Name: High-Purity Graphite Tube

Grade: Graphite

Formula: C

Form: Tube

Material: Carbon

CAS Number: 7440-44-0

Commodity: Metals

Purity: 99.95%

Description: Graphite Carbon Tube is a high-performance structural form of graphite that combines excellent thermal conductivity, high strength, and resistance to extreme environments. It is widely used in high-temperature furnaces, heat exchangers, …

4. Machined Graphite – Graphite Tubes

Domain: machinedgraphite.com

Registered: 2000 (25 years)

Introduction: Graphite tubes are lengths of cylinder or tubing formed from machined graphite or graphite mixtures, used in furnace and heat applications due to their physical properties. They offer exceptional performance in high-temperature, corrosive, and demanding industrial environments. Key features include superior thermal stability, electrical conductivity, and chemical resistance, making them suitable f…

5. Analytics-Shop – Graphite Tubes & Accessories

Domain: analytics-shop.com

Registered: 2010 (15 years)

Introduction: Graphite Tubes and Accessories | Analytics-Shop

– 2% online discount

– Fast delivery

– Reduced costs from $250

– More than 250,000 products available

– Contact: +1 470 777 2649, [email protected]

6. Kindle Tech – Graphite Tubes

Domain: kindle-tech.com

Registered: 2017 (8 years)

Introduction: Graphite tubes are essential components in high-temperature processes, commonly used in graphite tube furnaces for applications such as annealing, brazing, ceramic firing, degassing, graphitizing, carbonization, melting, and sintering. They maintain the integrity of the furnace interior and prevent unwanted chemical reactions that could damage the furnace or contaminate samples. Graphite tubes are…

7. Mersen – Graphite Shell and Tube Heat Exchanger

Domain: us.mersen.com

Registered: 2006 (19 years)

Introduction: Polytube – Graphite Shell and Tube Heat Exchanger

– Manufacturer: Mersen

– Type: Graphite shell and tube heat exchanger

– Key Features:

– Exceptional corrosion resistance

– High thermal conductivity (≥ 50 W/m.K)

– Mechanical strength certified by TÜV SÜD (G30-00-220)

– Longest monolithic graphite tubes available, up to 6 meters without joints

– Modular design with adjustable number of t…

8. Agilent – Graphite AAS Tubes

Domain: agilent.com

Registered: 1995 (30 years)

Introduction: Agilent graphite AAS tubes are machined from spectroscopically pure graphite coated with a dense, hard layer of pyrolytic graphite to improve sensitivity and lifetime. These tubes are individually batch tested for contamination, sensitivity, precision, electrical resistance, and lifetime. Key features include: 1. High-purity graphite reduces spurious absorption from trace contaminants and improves…

9. CFCCARBON – Graphite Pipes and Tubes

Domain: cfccarbon.com

Registered: 2012 (13 years)

Introduction: Product: Graphite Pipes and Tubes

Manufacturer: CFCCARBON LTD

Contact: [email protected], +86-18910941489

Types of Graphite Pipes:

1. Machined Graphite Pipes:

– Made from raw block graphite material.

– Characteristics: High strength, acid resistance, corrosion resistance, high temperature (up to 3000°C), low temperature (-204°C).

– Size Range: Diameter: 2-280 mm, Length: 30-2000 mm.

…

Strategic Sourcing Conclusion and Outlook for graphite tube

In navigating the complexities of sourcing graphite tubes, international B2B buyers must prioritize strategic partnerships and comprehensive market understanding. The unique properties of graphite, such as its exceptional thermal stability, chemical resistance, and mechanical strength, position it as a crucial material across various high-demand applications, from industrial furnaces to consumer products. By leveraging the diverse manufacturing techniques—such as extrusion and isostatic pressing—buyers can tailor solutions that meet specific operational requirements, ultimately enhancing performance and reducing total cost of ownership.

Furthermore, as industries evolve and sustainability becomes a focal point, investing in high-quality graphite tubes manufactured by reputable suppliers ensures longevity and reliability. Buyers should not overlook the importance of customization and potential coating options that can extend the lifespan of products in challenging environments.

Illustrative image related to graphite tube

Looking ahead, the demand for graphite tubes is expected to grow, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By establishing robust sourcing strategies now, businesses can secure a competitive edge in this dynamic landscape. Engage with trusted suppliers today to explore innovative solutions that drive efficiency and meet future market needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.