Everything You Need to Know About Gear Part Sourcing in 2025

Introduction: Navigating the Global Market for gear part

In an increasingly interconnected global market, sourcing the right gear parts can be a daunting challenge for B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe. The diversity of gear types—ranging from spur and helical gears to bevel and worm gears—along with their myriad applications in industries such as manufacturing, automotive, and robotics, necessitates a deep understanding of specifications and supplier capabilities. This guide serves as a comprehensive resource, equipping international buyers with the insights needed to navigate the complexities of gear part procurement.

Within this guide, you will find detailed analyses of various gear types, their specific applications, and the critical factors to consider when selecting suppliers. We delve into the nuances of vetting suppliers based on quality, reliability, and cost-effectiveness, ensuring that your purchasing decisions are backed by authoritative information. Additionally, we address the economic considerations relevant to different markets, including pricing trends and logistical challenges, empowering you to make informed choices that align with your business objectives.

By leveraging the insights presented in this guide, B2B buyers can confidently navigate the global gear part market, optimizing their sourcing strategies to meet their operational needs while fostering strong supplier relationships. Whether you are in Brazil or Nigeria, the knowledge contained herein is designed to enhance your purchasing power and streamline your procurement processes.

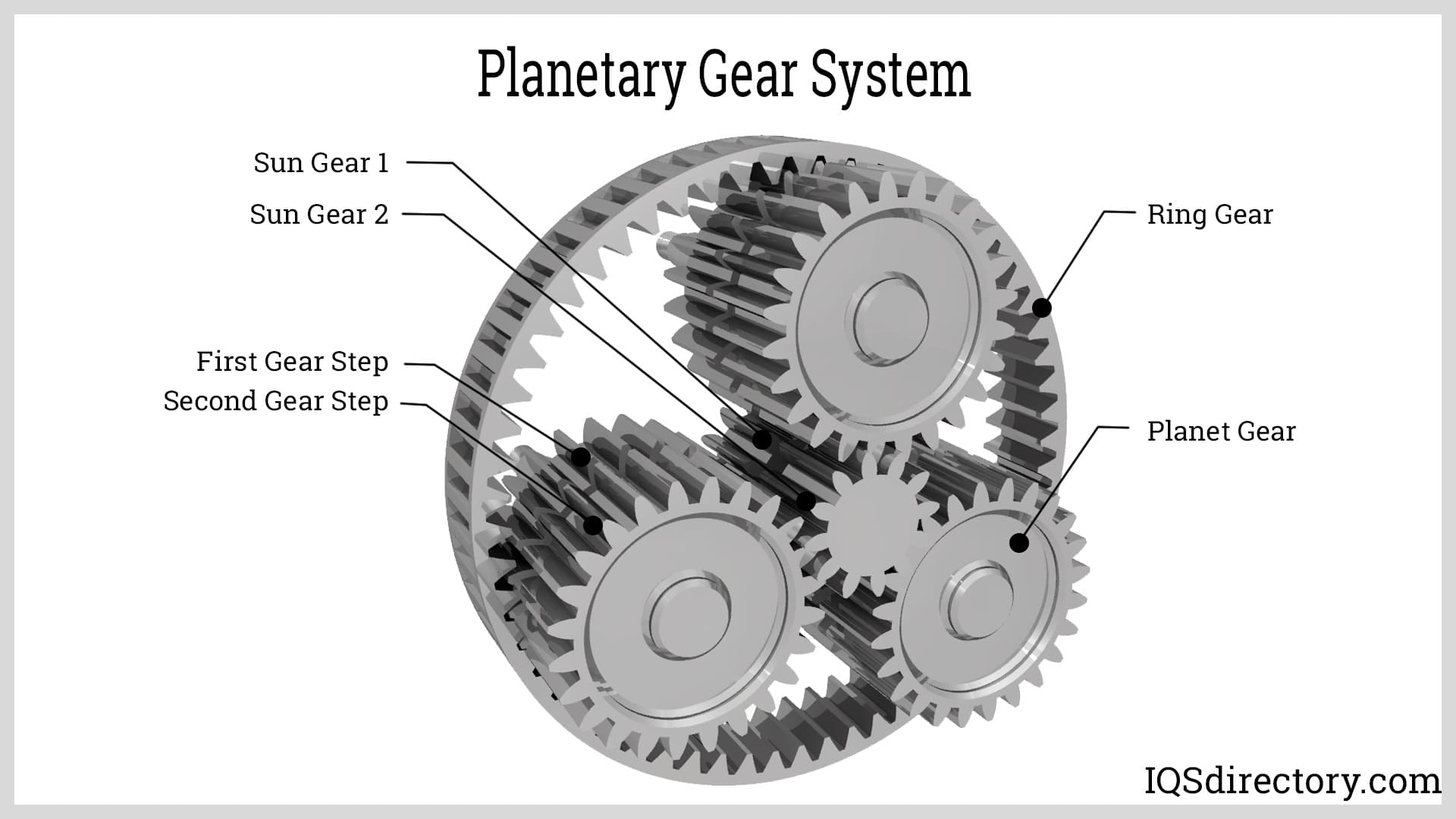

Understanding gear part Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Spur Gear | Straight teeth, parallel shafts, high efficiency | Automotive, industrial machinery | Pros: Simple design, cost-effective. Cons: Limited load capacity. |

| Helical Gear | Angled teeth, smoother operation, higher load capacity | Robotics, conveyor systems | Pros: Quieter operation, better load handling. Cons: More complex manufacturing. |

| Bevel Gear | Cone-shaped, used for intersecting shafts | Power transmission, automotive | Pros: Versatile in direction change. Cons: Can be more expensive due to complexity. |

| Worm Gear | Screw-like design, non-intersecting shafts, self-locking | Lifting equipment, conveyors | Pros: High torque transmission, compact. Cons: Lower efficiency, requires lubrication. |

| Gear Rack | Linear arrangement of teeth, converts rotational to linear motion | Linear actuators, machinery | Pros: Simple integration, effective for linear movement. Cons: Limited application range. |

What Are the Key Characteristics of Spur Gears for B2B Buyers?

Spur gears are the most common type of gear, characterized by their straight teeth and parallel shafts. They offer high efficiency and are relatively easy to manufacture, making them cost-effective for bulk purchasing. These gears are widely used in automotive and industrial machinery applications. However, buyers should consider their limited load capacity, which may not be suitable for high-torque applications.

How Do Helical Gears Stand Out in the Market?

Helical gears feature teeth that are cut at an angle, providing a smoother operation compared to spur gears. This design allows for better load capacity and reduces noise during operation, making them ideal for high-speed applications in robotics and conveyor systems. While they are generally more expensive and complex to manufacture, the benefits of reduced wear and tear can justify the investment for B2B buyers seeking durability and efficiency.

In What Scenarios Are Bevel Gears Most Effective?

Bevel gears are distinguished by their cone-shaped design, enabling power transmission between intersecting shafts. They are particularly useful in applications where direction changes are necessary, such as in automotive and power transmission systems. Although they offer versatility, buyers should be aware that bevel gears can be more costly due to their complex manufacturing processes.

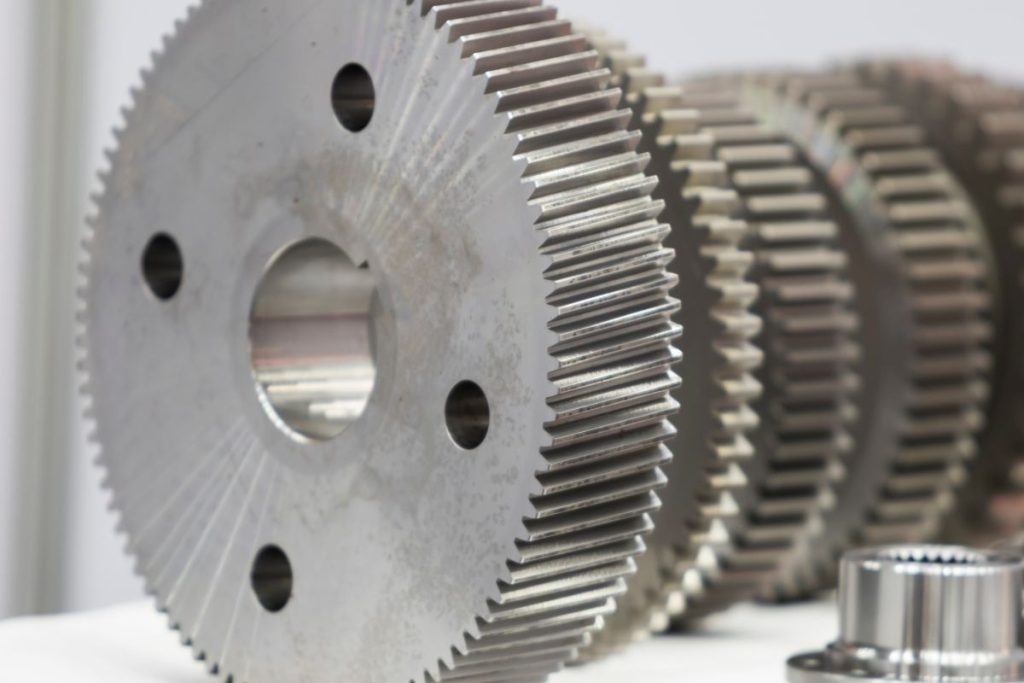

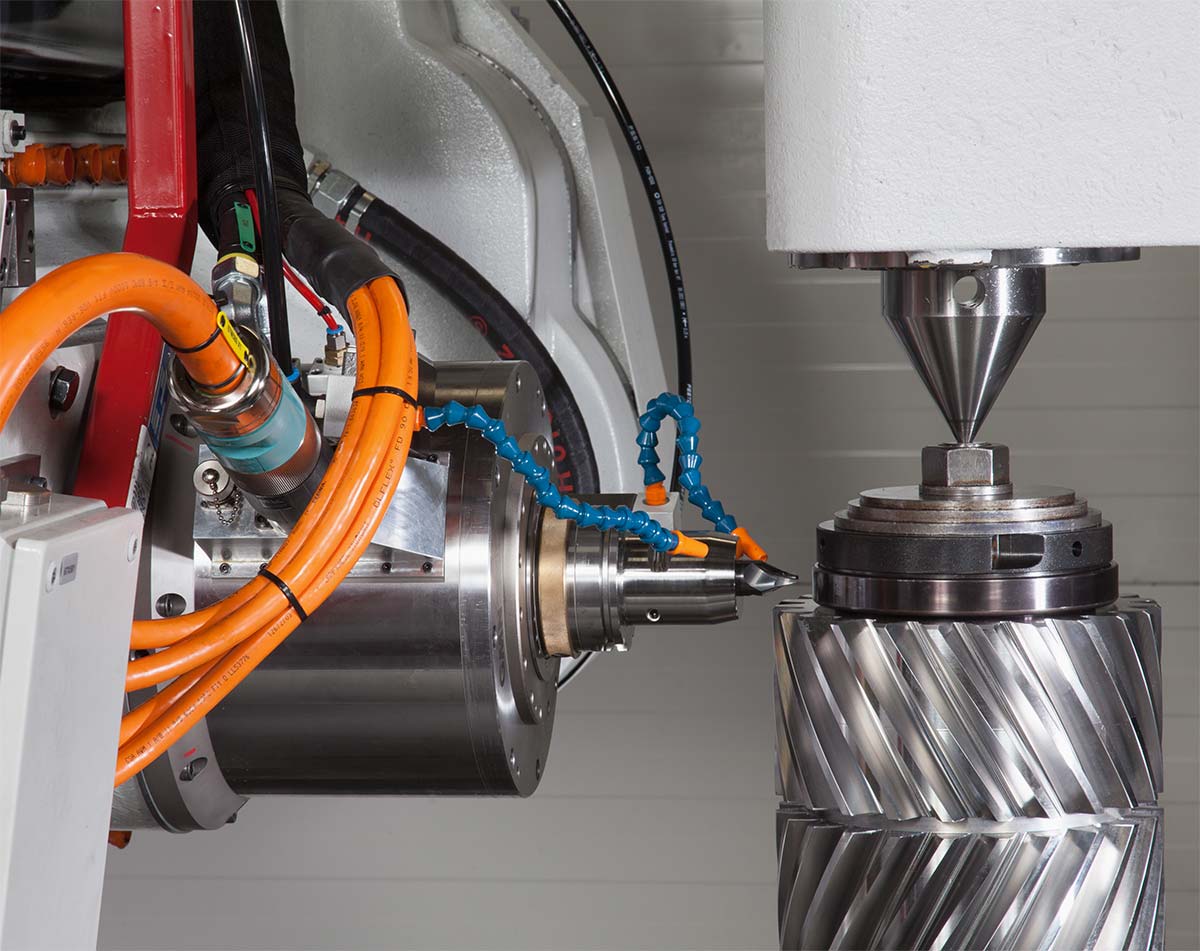

Illustrative image related to gear part

Why Choose Worm Gears for Specific Applications?

Worm gears consist of a screw-like worm and a mating worm wheel, ideal for applications requiring high torque transmission, such as lifting equipment and conveyors. Their compact design and self-locking feature make them attractive for B2B buyers looking for space-efficient solutions. However, the lower efficiency and need for lubrication should be considered when evaluating their suitability for specific applications.

What Are the Advantages of Using Gear Racks?

Gear racks consist of a linear arrangement of teeth that convert rotational motion into linear motion, making them essential in linear actuators and machinery. Their straightforward design allows for easy integration into various systems. However, B2B buyers should note that gear racks have a limited application range and may not be suitable for all mechanical designs.

Key Industrial Applications of gear part

| Industry/Sector | Specific Application of gear part | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Transmission Systems | Enhanced vehicle performance and fuel efficiency | Precision manufacturing standards, durability, and weight considerations |

| Manufacturing | CNC Machinery | Improved operational efficiency and precision | Material quality, customization options, and lead times |

| Renewable Energy | Wind Turbines | Increased energy output and reliability | Resistance to environmental factors, maintenance requirements, and certifications |

| Robotics | Actuation Systems | Enhanced precision in automated processes | Compatibility with existing systems, size constraints, and load capacity |

| Agriculture | Harvesting Equipment | Increased productivity and reduced labor costs | Adaptability to various terrains, durability against wear, and ease of maintenance |

How are gear parts utilized in the automotive industry?

In the automotive sector, gear parts are integral to transmission systems, which convert engine power to vehicle movement. These components enhance performance by allowing for smooth gear shifts and optimal power distribution, significantly improving fuel efficiency. International buyers should prioritize precision manufacturing standards and durability to ensure these parts withstand harsh driving conditions. Additionally, sourcing from suppliers with robust quality assurance processes is crucial to minimize operational risks.

What role do gear parts play in manufacturing machinery?

Gear parts are vital in CNC (Computer Numerical Control) machinery, where they facilitate precise movements required for cutting and shaping materials. By improving operational efficiency and accuracy, these gears contribute to higher production rates and reduced waste. Buyers in this sector must consider the material quality and customization options of gear parts to meet specific machine requirements. Furthermore, understanding lead times is essential for maintaining production schedules.

How do gear parts contribute to renewable energy systems?

In renewable energy, particularly in wind turbines, gear parts are essential for converting wind energy into electrical power. These gears help maximize energy output and ensure the reliability of turbine operations. For international buyers, sourcing gears that resist environmental factors such as corrosion and extreme temperatures is critical. Additionally, maintenance requirements and certifications can impact the long-term viability of these components in renewable energy projects.

Illustrative image related to gear part

What benefits do gear parts provide in robotics?

In robotics, gear parts are crucial for actuation systems, enabling precise movement and control in automated processes. They enhance the accuracy and responsiveness of robotic applications, which is essential for industries such as manufacturing and healthcare. Buyers should ensure compatibility with existing systems and consider size constraints when sourcing gear parts. Load capacity is also a key factor, as it directly impacts the performance and longevity of robotic systems.

How do gear parts enhance agricultural equipment?

Gear parts play a significant role in agricultural machinery, particularly in harvesting equipment, where they contribute to increased productivity and reduced labor costs. By facilitating efficient operation, these gears help farmers maximize yield and minimize downtime. When sourcing gear parts for agriculture, adaptability to various terrains and durability against wear are vital considerations. Additionally, ease of maintenance can enhance operational efficiency, making it a crucial factor for buyers in this sector.

3 Common User Pain Points for ‘gear part’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Gear Type for Applications

The Problem: Many B2B buyers face the challenge of selecting the appropriate type of gear for their specific applications. With a myriad of options available—such as spur, helical, bevel, and worm gears—making the right choice can be overwhelming. Each type has unique characteristics, load capacities, and operational efficiencies that can significantly impact the performance of machinery. For instance, using a spur gear in a high-speed application where noise reduction is critical may result in operational failure and additional costs. This confusion can lead to project delays and increased expenses as buyers may need to reorder or modify components after initial miscalculations.

Illustrative image related to gear part

The Solution: To effectively select the right gear type, buyers should begin by thoroughly assessing their application requirements. This includes understanding the load conditions, speed, and environmental factors such as temperature and humidity. Engaging with gear manufacturers early in the design process can provide invaluable insights. Manufacturers often offer detailed catalogs and technical support to help buyers navigate their options. Additionally, utilizing gear selection software or consulting with a gear specialist can aid in determining the most suitable gear type based on specific parameters. Lastly, conducting testing and prototyping can validate the selected gear’s performance before full-scale production, minimizing risks and ensuring compatibility with existing systems.

Scenario 2: Challenges with Gear Sizing and Specifications

The Problem: A common pain point for B2B buyers is accurately determining gear dimensions and specifications. Inaccurate sizing can lead to misalignment, excessive wear, and reduced efficiency, ultimately resulting in costly downtime. For example, if a gear is too large, it may not fit within the designated machinery space, while a gear that is too small may not handle the required torque. This issue is particularly prevalent in industries where precision engineering is critical, such as automotive or aerospace manufacturing, where tolerances are minimal.

The Solution: To address sizing challenges, buyers should leverage precise measurement techniques and tools during the design phase. Utilizing CAD software can facilitate accurate gear modeling and simulation, allowing for adjustments before manufacturing. Furthermore, collaborating with suppliers who offer customizable solutions can provide flexibility in meeting specific dimensional requirements. It’s also beneficial to establish a clear communication channel with gear manufacturers to discuss tolerances, surface finishes, and material choices. Creating a detailed specification document that outlines all necessary parameters can streamline the sourcing process and ensure that suppliers fully understand the buyer’s needs.

Scenario 3: Managing Quality and Performance Consistency

The Problem: Ensuring consistent quality and performance from gear parts is a significant concern for international B2B buyers, particularly when sourcing from diverse suppliers across different regions. Variability in manufacturing processes, materials, and quality control standards can lead to discrepancies in gear performance, affecting the overall reliability of machinery. Buyers may find themselves dealing with issues such as premature wear, failure under load, or operational noise, which can compromise their products’ integrity and customer satisfaction.

The Solution: To mitigate quality concerns, buyers should implement a rigorous supplier evaluation process that includes reviewing certifications, quality assurance protocols, and production capabilities. Establishing long-term relationships with reputable manufacturers known for their quality control standards can also enhance reliability. It’s advisable to request samples for testing before placing bulk orders to verify that the gear parts meet specified performance criteria. Moreover, implementing a quality management system that includes regular audits and performance reviews of suppliers can help maintain high standards throughout the supply chain. By prioritizing quality assurance at every stage of the procurement process, buyers can significantly reduce the risk of operational disruptions caused by subpar gear components.

Strategic Material Selection Guide for gear part

What Are the Key Properties of Common Materials Used for Gear Parts?

When selecting materials for gear parts, it’s essential to consider the specific performance requirements of the application. Different materials offer various properties that can significantly affect the durability, efficiency, and overall success of the gear system. Here, we analyze four common materials used in gear manufacturing: steel, aluminum, plastic, and bronze.

How Does Steel Perform as a Material for Gear Parts?

Steel is a popular choice for gear parts due to its excellent strength and durability. Key properties include high tensile strength, good wear resistance, and the ability to withstand high temperatures and pressures. Steel gears can be heat-treated to enhance their hardness and performance under load.

Pros: Steel gears are known for their longevity and ability to handle high torque applications. They are also relatively cost-effective when produced in large quantities.

Cons: However, steel is susceptible to corrosion if not properly treated, which can be a concern in certain environments. Additionally, manufacturing steel gears can be complex and may require significant machining, increasing production time.

Impact on Application: Steel gears are suitable for heavy-duty applications, including automotive and industrial machinery. Buyers should ensure compliance with international standards such as ASTM and DIN to guarantee quality and reliability.

What Advantages Does Aluminum Offer for Gear Parts?

Aluminum is another common material for gear parts, especially in lightweight applications. Its key properties include a favorable strength-to-weight ratio, corrosion resistance, and good machinability.

Pros: Aluminum gears are lightweight, making them ideal for applications where weight reduction is crucial, such as in aerospace and automotive industries. They also exhibit good thermal conductivity.

Cons: The primary limitation of aluminum is its lower strength compared to steel, which may not be suitable for high-load applications. Additionally, aluminum gears may have a shorter lifespan under heavy use.

Impact on Application: Aluminum gears are often used in applications requiring reduced weight and good corrosion resistance. Buyers should consider the specific environmental conditions and ensure compliance with relevant standards.

How Do Plastics Compare as a Material for Gear Parts?

Plastic gears are increasingly being used in various applications due to their unique properties. They offer low friction, good wear resistance, and are generally lightweight.

Pros: Plastic gears are resistant to corrosion and can operate quietly, making them suitable for applications such as consumer electronics and appliances. They are also cost-effective for mass production.

Cons: However, plastic gears may not withstand high temperatures or heavy loads as effectively as metal gears. Their durability can be a concern in demanding environments.

Impact on Application: Plastic gears are ideal for low-load applications and environments where moisture or chemicals are present. International buyers should ensure that the selected plastic materials comply with relevant standards for safety and performance.

What Role Does Bronze Play in Gear Part Manufacturing?

Bronze is often used for gears in applications requiring high wear resistance and low friction. Its key properties include excellent corrosion resistance and good machinability.

Pros: Bronze gears are durable and can operate smoothly under high load conditions. They are particularly effective in marine and chemical environments due to their corrosion resistance.

Cons: The primary drawback of bronze is its higher cost compared to other materials like steel and plastic. Additionally, the manufacturing process can be more complex.

Impact on Application: Bronze gears are commonly used in applications such as marine equipment and high-performance machinery. Buyers should verify compliance with standards such as ASTM B584 to ensure quality.

Summary Table of Material Selection for Gear Parts

| Material | Typical Use Case for gear part | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty machinery | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Aerospace and automotive | Lightweight and corrosion-resistant | Lower strength than steel | Medium |

| Plastic | Consumer electronics | Low friction and quiet operation | Limited high-load capacity | Low |

| Bronze | Marine equipment | Excellent wear resistance | Higher cost and complex manufacturing | High |

This guide provides a comprehensive overview of material selection for gear parts, helping international B2B buyers make informed decisions tailored to their specific applications and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for gear part

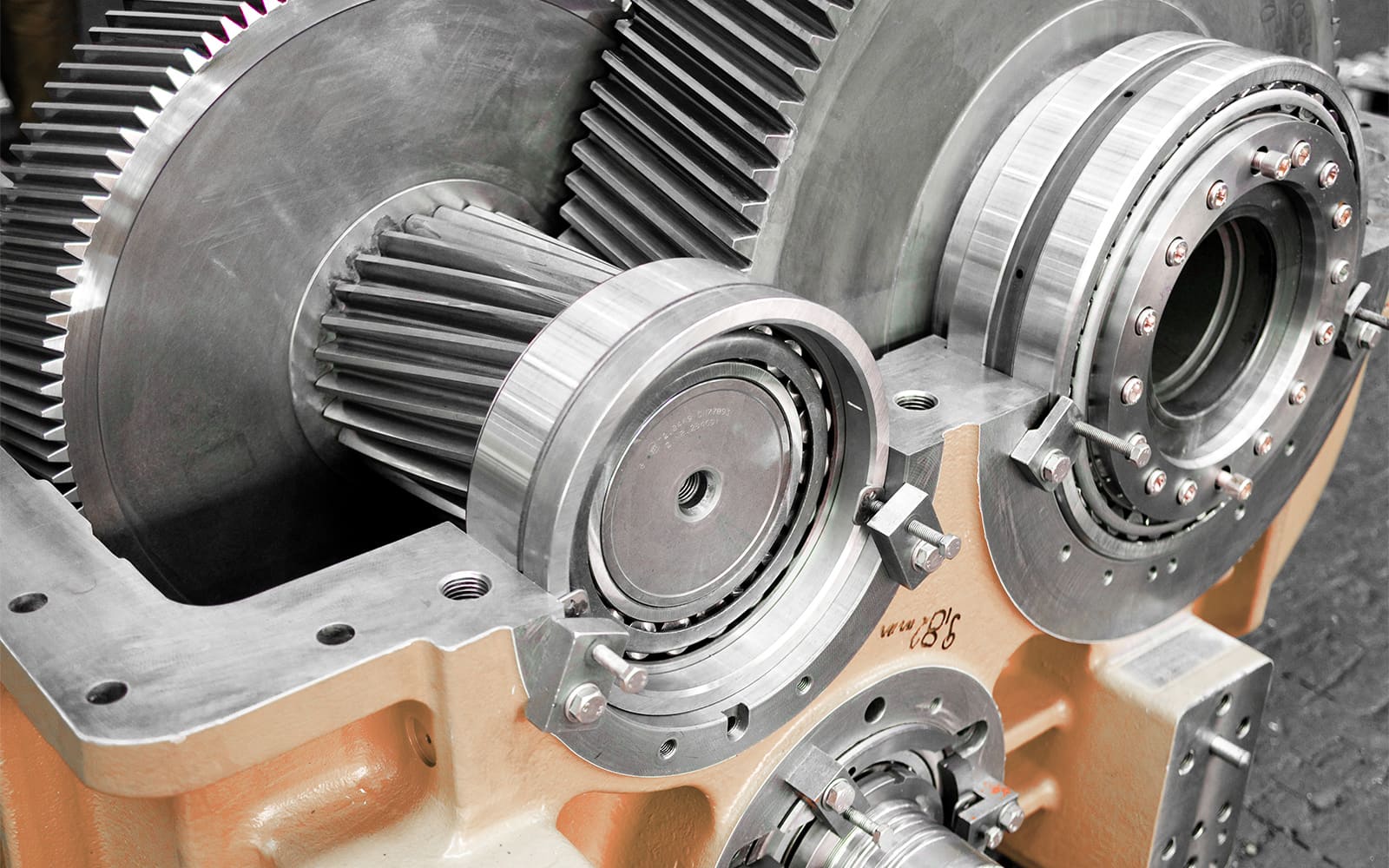

What Are the Key Stages in the Manufacturing Process of Gear Parts?

The manufacturing process for gear parts involves several critical stages that ensure the final product meets the required specifications for performance and quality. Understanding these stages is essential for B2B buyers looking to source high-quality gear components.

Material Preparation: How Is the Right Material Chosen for Gear Parts?

The first step in manufacturing gear parts is selecting the appropriate material. Common materials include carbon steel, stainless steel, aluminum, and plastic, each chosen based on the specific application requirements. The selection process takes into account factors such as load capacity, environmental conditions, and required durability.

Once the material is selected, it undergoes processes such as cutting and shaping to prepare it for forming. This may involve machining or heat treatment to enhance its mechanical properties. For example, heat treatment can increase hardness and wear resistance, which is crucial for gears that will endure significant stress.

What Forming Techniques Are Commonly Used in Gear Manufacturing?

Forming techniques play a vital role in shaping gear components accurately. Common methods include:

- Hobbing: A widely used method for creating spur and helical gears, hobbing involves rotating a cutting tool (hob) against the workpiece, allowing for efficient mass production.

- Shaping: This technique is often employed for internal gears or complex shapes where a hob cannot reach. It uses a reciprocating cutting tool to shape the teeth.

- Casting: In some cases, gears can be produced through casting methods, especially for larger or intricate designs. This involves pouring molten metal into a mold, allowing it to solidify into the desired form.

Each of these techniques has its advantages and is chosen based on the gear’s design, size, and required precision.

How Is the Assembly Process Managed in Gear Manufacturing?

After the individual components are formed, they are assembled into complete gear systems. This may involve:

- Fitting: Ensuring that each component fits together correctly, which is critical for maintaining the gear’s functionality and performance.

- Alignment: Proper alignment of gears is essential to prevent premature wear or failure. This is often achieved using specialized jigs and fixtures during assembly.

- Lubrication: Applying the appropriate lubrication during assembly helps reduce friction and wear between moving parts, enhancing the gear’s lifespan.

What Finishing Processes Are Important for Gear Parts?

Finishing processes add the final touches to gear parts, ensuring they meet quality and aesthetic standards. Key finishing techniques include:

- Grinding: This process removes any surface imperfections and sharp edges, improving the gear’s precision and performance.

- Polishing: Polishing enhances the surface finish, which can be critical for gears operating in high-speed environments.

- Coating: Applying protective coatings can enhance corrosion resistance and reduce friction, especially in gears exposed to harsh environmental conditions.

What Quality Assurance Measures Are Essential for Gear Parts?

Quality assurance (QA) is crucial in gear manufacturing to ensure products meet international standards and customer specifications. B2B buyers should be aware of the QA processes in place when selecting suppliers.

Illustrative image related to gear part

Which International Standards Should Gear Part Manufacturers Adhere To?

Gear part manufacturers often adhere to several international quality standards, including:

- ISO 9001: This standard focuses on quality management systems and is widely recognized across various industries. Compliance indicates that the manufacturer has robust processes to ensure consistent quality.

- CE Marking: For products sold in Europe, CE marking demonstrates compliance with health, safety, and environmental protection standards.

- API Standards: For gears used in the oil and gas industry, manufacturers may need to comply with American Petroleum Institute (API) standards, which ensure that products can withstand demanding operational conditions.

What Are the Key Quality Control Checkpoints in Gear Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process to ensure that each stage meets established standards:

- Incoming Quality Control (IQC): This initial checkpoint examines raw materials upon arrival to ensure they meet specifications before production begins.

- In-Process Quality Control (IPQC): During the manufacturing process, IPQC checks are conducted to monitor production quality, ensuring that any deviations from specifications are identified and corrected promptly.

- Final Quality Control (FQC): At the end of the production line, FQC involves comprehensive testing of the finished gears to verify they meet performance standards and customer requirements.

What Testing Methods Are Commonly Used to Ensure Gear Quality?

Various testing methods are employed to validate the quality and performance of gear parts, including:

- Dimensional Inspection: Using precision measuring tools to verify that gear dimensions align with specifications.

- Load Testing: Subjecting gear parts to operational loads to assess their performance under stress.

- Non-destructive Testing (NDT): Techniques like ultrasonic testing or magnetic particle inspection are used to identify internal defects without damaging the components.

How Can B2B Buyers Verify Supplier Quality Assurance Processes?

B2B buyers must conduct due diligence to verify the quality assurance processes of potential suppliers. Key methods include:

- Supplier Audits: Conducting on-site audits to assess manufacturing processes, quality control measures, and compliance with relevant standards.

- Reviewing Quality Reports: Requesting and reviewing quality control reports and certifications can provide insight into a supplier’s commitment to quality.

- Third-Party Inspections: Engaging independent inspection agencies can offer an unbiased assessment of a supplier’s quality assurance practices.

What Nuances Should International Buyers Consider Regarding Quality Control?

For international buyers, particularly from regions like Africa, South America, and the Middle East, understanding the nuances of quality control is essential. These may include:

Illustrative image related to gear part

- Cultural Differences: Different regions may have varying approaches to quality assurance. Buyers should be aware of these differences and how they might impact supplier relationships.

- Logistical Challenges: Transporting gear parts across international borders can introduce risks. Ensuring that the supplier has robust logistics and quality tracking systems can mitigate these risks.

- Regulatory Compliance: Buyers should be familiar with local regulations and standards that may affect the importation and use of gear parts in their markets.

By understanding the manufacturing processes and quality assurance measures associated with gear parts, B2B buyers can make informed decisions when sourcing components from international suppliers. This knowledge not only enhances the likelihood of acquiring high-quality products but also fosters long-term partnerships built on trust and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gear part’

Introduction

Sourcing gear parts can be a complex process that requires careful consideration of technical specifications, supplier capabilities, and market dynamics. This practical checklist is designed to guide international B2B buyers—particularly from regions like Africa, South America, the Middle East, and Europe—through the essential steps of procuring gear parts efficiently and effectively.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the gear parts you need. This includes dimensions, material types, load capacities, and compatibility with existing systems. A well-defined specification reduces the risk of miscommunication and ensures that suppliers can meet your precise needs.

- Considerations:

- Specify gear types (e.g., spur, helical, bevel) based on your application.

- Include tolerance levels and any necessary surface treatments or coatings.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in gear parts. Look for manufacturers with a strong reputation, extensive experience, and a track record of quality.

- Where to Look:

- Industry directories, trade shows, and online marketplaces can be valuable resources.

- Pay attention to customer reviews and testimonials to gauge reliability.

Step 3: Evaluate Supplier Certifications

Before proceeding, verify that potential suppliers hold relevant industry certifications, such as ISO 9001 or other quality management standards. Certifications indicate a commitment to quality and adherence to international standards.

- Why It Matters:

- Certified suppliers are more likely to maintain consistent quality control processes.

- It can facilitate smoother customs processes, especially for international shipments.

Step 4: Request Samples for Testing

Once you have shortlisted suppliers, request samples of the gear parts you are considering. Testing samples allows you to evaluate quality, performance, and compatibility with your equipment before making a bulk purchase.

- What to Assess:

- Check for dimensional accuracy and material quality.

- Evaluate the operational performance under real-world conditions.

Step 5: Negotiate Terms and Pricing

Engage in discussions with suppliers to negotiate pricing, payment terms, and delivery schedules. Understanding the full cost of procurement—including shipping, tariffs, and taxes—is crucial for budgeting.

- Key Points:

- Inquire about bulk order discounts or loyalty programs.

- Clarify payment terms to ensure favorable cash flow management.

Step 6: Confirm Delivery and Logistics Arrangements

Coordinate with the supplier to confirm logistics arrangements, including shipping methods, timelines, and packaging. Effective logistics planning is essential to ensure timely delivery and minimize disruptions in your operations.

- Considerations:

- Discuss who will handle customs clearance and any associated fees.

- Ensure that the supplier has a reliable shipping partner.

Step 7: Establish a Quality Assurance Process

Once you have received the gear parts, implement a quality assurance process to verify that they meet your specifications. Regular inspections and testing can help maintain quality standards over time.

- Why It’s Important:

- Continuous quality checks can prevent costly downtimes and production issues.

- Establishing a feedback loop with suppliers can improve future transactions.

By following these steps, B2B buyers can streamline their sourcing process for gear parts, ensuring they make informed decisions that align with their operational needs and business objectives.

Comprehensive Cost and Pricing Analysis for gear part Sourcing

What Are the Key Cost Components in Gear Part Sourcing?

When sourcing gear parts, understanding the comprehensive cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The type of material used significantly impacts the cost. Common materials for gear parts include steel, aluminum, and plastic. High-grade materials or those with specific certifications can lead to higher costs but may offer better performance and longevity.

-

Labor: Labor costs can vary based on geographic location, skill level required, and the complexity of the gear part being produced. Skilled labor in regions with high living costs will generally increase the overall price.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce these overhead costs.

-

Tooling: The initial setup for producing gear parts often requires specialized tools and machinery. Tooling costs can be significant, especially for custom designs, and should be factored into the overall pricing.

-

Quality Control (QC): Implementing rigorous quality control measures is crucial, especially for industries where precision is paramount. The costs associated with QC can vary based on the standards required (ISO, AGMA, etc.).

-

Logistics: Transportation and shipping costs must be considered, particularly for international buyers. Factors such as distance, mode of transport, and customs duties can all influence logistics expenses.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding average margins in the gear industry can provide leverage during negotiations.

How Do Price Influencers Impact Gear Part Sourcing?

Several factors can influence the pricing of gear parts, which international B2B buyers should be aware of:

-

Volume/MOQ: Suppliers often have minimum order quantities (MOQs) that can affect pricing. Larger orders may lead to bulk discounts, making it crucial to align purchasing strategies with production needs.

-

Specifications and Customization: Custom gear parts tailored to specific applications will generally come at a higher price due to the additional design and manufacturing complexities involved.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications can significantly affect pricing. Buyers should balance cost with the need for quality to ensure long-term performance.

-

Supplier Factors: The supplier’s reputation, experience, and location can impact pricing. Established suppliers with a track record of reliability may charge more but can offer better assurances regarding quality and delivery timelines.

-

Incoterms: The chosen Incoterms dictate the responsibilities of buyers and sellers in the shipping process. Understanding these terms can help avoid unexpected costs related to shipping and customs.

What Are Effective Buyer Tips for Cost-Efficiency?

To optimize cost-efficiency in gear part sourcing, consider the following strategies:

-

Negotiation: Always engage in negotiations with potential suppliers. Discussing price, payment terms, and delivery conditions can lead to better deals. Building a good relationship with suppliers can also facilitate more favorable terms.

-

Total Cost of Ownership (TCO): Look beyond the initial purchase price to assess the total cost of ownership. This includes maintenance, operational costs, and potential downtime. Selecting high-quality gear parts might result in higher upfront costs but can lead to savings in the long run.

-

Understanding Pricing Nuances for International Markets: Different regions have varying pricing structures due to labor costs, material availability, and market demand. For instance, sourcing from countries with lower labor costs might be advantageous, but consider potential trade tariffs and shipping costs that could negate those savings.

-

Research and Benchmarking: Conduct thorough market research to understand pricing trends and benchmarks within the gear industry. This knowledge will empower buyers to make informed decisions and negotiate effectively.

Conclusion

Gear part sourcing involves a complex interplay of various cost components and price influencers. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, it is essential to analyze these factors comprehensively. By employing strategic negotiation and focusing on total cost of ownership, buyers can achieve significant cost savings while ensuring the quality and reliability of their gear parts. Always remember that the prices discussed are indicative and can vary based on specific requirements and market conditions.

Alternatives Analysis: Comparing gear part With Other Solutions

When evaluating gear parts, it’s essential to consider alternative solutions that can achieve similar performance outcomes. Various technologies and methods exist that may meet specific operational requirements or budget constraints more effectively. This analysis aims to compare gear parts with alternative solutions, providing insights into their respective advantages and disadvantages.

| Comparison Aspect | Gear Part | Alternative 1: Chain Drive | Alternative 2: Belt Drive |

|---|---|---|---|

| Performance | High precision and torque transfer | Moderate precision, lower torque transfer | Moderate precision, good torque transfer |

| Cost | Generally higher due to manufacturing complexity | Lower initial cost, but varying maintenance costs | Lower initial cost, but may require frequent replacement |

| Ease of Implementation | Requires precise alignment and installation | Easier to install and adjust | Simple installation and adjustment |

| Maintenance | Lower frequency, but complex repairs | Higher frequency due to wear and lubrication needs | Moderate frequency; requires tension adjustments |

| Best Use Case | Heavy machinery, automotive applications | Light to medium-duty applications | Light to medium-duty applications, especially where noise reduction is desired |

What are the Pros and Cons of Using Chain Drives as an Alternative to Gear Parts?

Chain drives are a popular alternative to gear parts, particularly in applications requiring a compact design. They are characterized by their ability to transmit power over longer distances and can handle moderate loads effectively. The primary advantage of chain drives is their lower initial cost compared to gears. However, they require regular lubrication and maintenance to prevent wear, which can lead to increased operational costs over time. Chain drives are best suited for applications such as bicycles, motorcycles, and some industrial machinery where high torque is not a critical requirement.

How Do Belt Drives Compare to Gear Parts in Terms of Functionality?

Belt drives offer another viable alternative, especially in scenarios where noise reduction is a priority. They are generally simpler to install and adjust compared to gear parts, making them an attractive option for many manufacturers. The lower initial cost of belt drives is appealing; however, they may necessitate more frequent replacements and tension adjustments to maintain optimal performance. Belt drives are typically used in light to medium-duty applications, such as in conveyor systems and fans, where precise torque transmission is less critical.

Illustrative image related to gear part

How Should B2B Buyers Choose Between Gear Parts and Alternative Solutions?

When selecting between gear parts and alternative solutions, B2B buyers should assess their specific operational needs and constraints. Factors such as the required precision, torque transmission, budget, and maintenance capabilities play a crucial role in the decision-making process. For heavy machinery and applications requiring high precision, gear parts may be the best choice despite higher costs. Conversely, for lighter applications where cost and ease of maintenance are paramount, chain or belt drives may offer sufficient performance at a lower overall cost. By carefully evaluating these aspects, buyers can make informed decisions that align with their operational goals and budget considerations.

Essential Technical Properties and Trade Terminology for gear part

What Are the Key Technical Properties of Gear Parts That B2B Buyers Should Know?

Understanding the essential technical properties of gear parts is crucial for B2B buyers, especially when selecting components that meet specific application requirements. Here are some critical specifications to consider:

-

Material Grade

– The material used in gear manufacturing significantly impacts durability, strength, and performance. Common materials include carbon steel, alloy steel, and plastics. High-grade materials are essential for high-load applications, while lighter materials may be suitable for less demanding environments. Selecting the right material ensures longevity and reliability, reducing maintenance costs over time. -

Tolerance

– Tolerance refers to the permissible limit or limits of variation in a physical dimension. For gears, this is critical in ensuring proper meshing and function. Tight tolerances can lead to increased performance and efficiency, while loose tolerances may result in wear, noise, and failure. Understanding tolerance requirements helps buyers specify gears that will operate smoothly and efficiently in their applications. -

Gear Ratio

– The gear ratio defines the relationship between the number of teeth on two meshing gears. This ratio determines how torque and speed are transmitted through the system. A higher gear ratio can increase torque but may reduce speed, and vice versa. Selecting the appropriate gear ratio is essential for achieving the desired performance in machinery. -

Pitch Diameter

– The pitch diameter is the diameter of the pitch circle, an imaginary circle where the teeth of two gears effectively mesh. This measurement is critical in determining how gears will fit together in a system. Proper pitch diameter ensures optimal power transmission and minimizes wear and tear on the components. -

Face Width

– Face width is the width of the gear tooth. It influences the load-carrying capacity of the gear. A wider face can handle more load, making it suitable for high-torque applications. Buyers need to consider face width based on the expected load and performance requirements of their equipment. -

Heat Treatment

– Heat treatment processes, such as hardening and tempering, enhance the mechanical properties of gear materials. This treatment increases the strength and wear resistance of gears, making them suitable for high-stress applications. Understanding the benefits of heat treatment can guide buyers in selecting gears that offer superior performance under demanding conditions.

What Are Common Trade Terms That B2B Buyers Should Be Familiar With?

Familiarity with trade terminology can streamline communication and negotiations in the gear parts market. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers seeking reliable components that meet specific design and performance standards. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest number of units a supplier is willing to sell. Knowing the MOQ helps buyers plan their inventory and budget, ensuring they meet supplier requirements while minimizing excess stock. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to request pricing and availability for specific products. Submitting an RFQ helps buyers gather competitive pricing and evaluate suppliers based on their offerings. -

Incoterms (International Commercial Terms)

– Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and costs associated with the purchase of gear parts. -

Lead Time

– Lead time is the time between placing an order and receiving the goods. Understanding lead times helps buyers manage their production schedules and inventory levels effectively. -

Customization

– Customization refers to the process of modifying standard gear parts to meet specific requirements. Buyers should know the extent to which suppliers can accommodate custom designs, as this can significantly impact performance in specialized applications.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they procure the right gear parts for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the gear part Sector

What Are the Current Market Dynamics and Key Trends in the Gear Part Sector?

The global gear part market is experiencing a significant transformation driven by advancements in technology, increasing automation, and the growing demand for precision-engineered components across various industries. Key drivers include the rise of electric vehicles (EVs), which require specialized gears for efficient power transmission, and the ongoing expansion of robotics and automation in manufacturing. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly looking for suppliers who can provide innovative gear solutions that enhance performance while reducing operational costs.

Illustrative image related to gear part

Emerging trends indicate a shift towards digitalization in sourcing processes. B2B buyers are leveraging advanced technologies such as artificial intelligence (AI) and machine learning to optimize their supply chains. This includes predictive analytics for demand forecasting and automated inventory management, enabling companies to respond swiftly to market fluctuations. Additionally, there is a noticeable increase in the adoption of 3D printing technology for producing custom gear parts, allowing for rapid prototyping and reduced lead times.

As the market becomes more competitive, international buyers are also prioritizing suppliers with robust quality assurance processes. With stricter regulations and standards, especially in the automotive and aerospace sectors, companies must ensure that their gear parts meet international compliance norms. This demand for quality, coupled with the need for cost-effective solutions, is reshaping sourcing strategies globally.

How Is Sustainability and Ethical Sourcing Influencing Gear Part Procurement?

The gear part sector is increasingly recognizing the importance of sustainability and ethical sourcing practices. Environmental concerns are prompting buyers to seek suppliers who prioritize eco-friendly manufacturing processes and materials. This includes the use of recycled metals and sustainable materials, which not only reduce the environmental impact but also resonate with consumers’ growing preference for green products.

Ethical supply chains are becoming a critical factor in procurement decisions. Buyers are looking for transparency in sourcing practices, ensuring that suppliers adhere to fair labor standards and responsible sourcing of raw materials. Certifications such as ISO 14001 for environmental management and the Responsible Steel certification are gaining traction among B2B buyers as indicators of a supplier’s commitment to sustainability.

Moreover, the demand for ‘green’ certifications is driving manufacturers to invest in cleaner technologies and processes. This trend not only enhances brand reputation but also opens up new market opportunities, particularly in regions like Europe, where regulatory frameworks are becoming increasingly stringent regarding sustainability.

How Has the Gear Part Sector Evolved Over Time?

The evolution of the gear part sector is a testament to the interplay between innovation and industrial demand. Historically, gears have been essential mechanical components since ancient civilizations, with their use recorded in early Greek technology. The industrial revolution marked a significant turning point, introducing mass production techniques and the standardization of gear manufacturing.

In the 20th century, advancements in materials science led to the development of high-strength alloys and composites, expanding the applications of gears across various sectors, including automotive, aerospace, and manufacturing. The late 20th and early 21st centuries have seen a shift towards precision engineering, with computer-aided design (CAD) and computer numerical control (CNC) machining enabling manufacturers to produce highly accurate and complex gear shapes.

Illustrative image related to gear part

Today, the sector is poised for further transformation as digital technologies and sustainable practices redefine the landscape. The focus on automation, customization, and ethical sourcing is set to drive the next phase of innovation, positioning the gear part sector as a critical player in the global manufacturing ecosystem.

Frequently Asked Questions (FAQs) for B2B Buyers of gear part

-

How do I choose the right type of gear part for my application?

Selecting the appropriate gear part involves understanding the specific requirements of your application, such as load capacity, speed, and efficiency. Begin by identifying the type of gear you need—such as spur, helical, or bevel—based on the orientation of the shafts in your design. Additionally, consider factors like the material, dimensions (module, number of teeth), and necessary precision standards (ISO, AGMA). Collaborate with your supplier to ensure that the gear specifications meet your performance expectations and operational conditions. -

What are the common applications for different types of gear parts?

Gear parts are utilized across various industries, including automotive, aerospace, robotics, and manufacturing. For instance, spur gears are prevalent in simple machinery due to their efficiency and ease of production, while helical gears are favored in applications requiring quieter operation and higher load capacities. Bevel gears are often used in systems requiring a change in the direction of power transmission. Understanding the specific application will help in selecting the most suitable gear part for your needs. -

What should I consider when vetting international gear part suppliers?

When evaluating potential suppliers, focus on their industry experience, product quality, and compliance with international standards. Check for certifications such as ISO, which indicates adherence to quality management principles. Look for customer reviews or testimonials to assess reliability and service quality. Additionally, inquire about their manufacturing capabilities, lead times, and after-sales support to ensure they can meet your specific requirements and maintain open communication throughout the process. -

What are the typical minimum order quantities (MOQs) for gear parts?

Minimum order quantities for gear parts can vary significantly based on the supplier, type of gear, and customization involved. Generally, MOQs can range from a few units for standard parts to hundreds or thousands for specialized or custom designs. It is advisable to discuss your needs directly with potential suppliers to negotiate MOQs that align with your project requirements while also ensuring cost-effectiveness. -

What payment terms are commonly offered by gear part suppliers?

Payment terms can differ among suppliers, but common arrangements include upfront payments, net 30, or net 60 days after delivery. Some suppliers may require a deposit before production, especially for custom orders. It’s essential to clarify payment options during negotiations and consider factors such as currency exchange rates and transaction fees, particularly when dealing with international suppliers. Establishing clear payment terms can help avoid misunderstandings and ensure a smooth purchasing process. -

How can I ensure quality assurance (QA) for gear parts sourced internationally?

To ensure quality assurance, request detailed documentation from suppliers, including product specifications, inspection reports, and certifications. Implement a quality control plan that includes pre-shipment inspections and testing of gear parts to verify they meet your standards. Additionally, consider partnering with third-party inspection services that specialize in industrial components, providing an unbiased assessment of product quality before shipment. -

What logistics considerations should I keep in mind when importing gear parts?

When importing gear parts, consider factors such as shipping methods, lead times, and customs regulations in your country. Choose a reliable logistics partner experienced in handling industrial components to streamline the shipping process. Additionally, be aware of potential tariffs or duties that may apply to your imports, and factor these costs into your overall budget. Clear communication with your supplier about shipping timelines and documentation will help avoid delays at customs. -

What customization options are available for gear parts?

Many suppliers offer customization options for gear parts, including alterations in size, material, tooth design, and surface treatment. Customization can enhance performance for specific applications or optimize the parts for unique environmental conditions. Engage with your supplier early in the design process to discuss your specific requirements and explore available options. Providing detailed specifications and performance expectations will help ensure the final product aligns with your operational needs.

Top 3 Gear Part Manufacturers & Suppliers List

1. KHK Gears – Types of Gears

Domain: khkgears.net

Registered: 2015 (10 years)

Introduction: Types of Gears: Spur Gears, Helical Gears, Gear Rack, Worm Gears, Bevel Gears, Miter Gears, Internal Gears, Screw Gears. Key characteristics include:

– Spur Gears: Cylindrical gears with straight teeth, no axial load, high accuracy.

– Helical Gears: Winding teeth, better meshing, suitable for high speed applications, creates axial thrust.

– Gear Rack: Converts rotational motion to linear motion…

2. Humbel Gears – Precision Gear Parts

Domain: humbel-gears.com

Registered: 2008 (17 years)

Introduction: Precision gear parts made from metal (steel, bronze, brass, titanium, aluminium) or plastic (thermoplastic, thermosetting polymers) with varying hardness levels. Key products include:

– Polygon connections

– Soft and hard machining of shafts and hub polygon

– Spiral toothing (Diameter up to 600mm, module 2-12 in ground quality)

– Clutch and Hirth coupling (Diameter up to 200mm in milled or gro…

3. Motive Gear – Ring and Pinions

Domain: motivegear.com

Registered: 1996 (29 years)

Introduction: Ring and Pinions from Motive Gear

– Manufactured by: Motive Gear

– Warranty Period: 1 Year or 50,000 Miles (for most products), 2 Years or 100,000 Miles (for performance products)

– Ring Gear Material: 8620 Steel

– Various Part Numbers: C8-456, AM20-410, G885411IFS, G885273, G875373X, D35-373, D35-411, D35-488, D30-513RJK, D35-456, D30-410TJ, GM10-430, GM10-456, T411, T411L, D30-373, T571, D44-456…

Strategic Sourcing Conclusion and Outlook for gear part

How Can Strategic Sourcing Enhance Your Gear Part Procurement?

In conclusion, strategic sourcing stands as a critical pillar for international B2B buyers seeking gear parts. Understanding the diverse types of gears—such as spur, helical, and bevel—and their specific applications can significantly influence procurement decisions. By prioritizing quality, precision, and compatibility, businesses can enhance operational efficiency and reduce long-term costs. Engaging with reputable suppliers who offer tailored solutions not only fosters stronger partnerships but also mitigates risks associated with supply chain disruptions.

As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for high-quality gear parts is set to rise. Buyers are encouraged to leverage local insights and global networks to identify reliable manufacturers that align with their unique needs. By investing in strategic sourcing practices now, companies can position themselves for future growth and innovation.

Take the next step in optimizing your procurement strategy. Connect with trusted suppliers today to explore how effective sourcing can enhance your operations and drive competitive advantage in the dynamic gear parts market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.