Everything You Need to Know About Galvanized Steel Gutters Sourcing in 2025

Introduction: Navigating the Global Market for galvanized steel gutters

Navigating the global market for galvanized steel gutters presents unique challenges for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Sourcing high-quality galvanized steel gutters can be daunting, given the myriad of suppliers, varying standards, and fluctuating costs. This comprehensive guide is designed to demystify the process, covering essential aspects such as types of gutters, their applications across different climates, supplier vetting processes, and cost considerations.

Galvanized steel gutters are known for their durability and resistance to harsh weather conditions, making them an ideal choice for diverse environments. This guide not only outlines the specific benefits of galvanized steel compared to other materials but also provides actionable insights into how to assess suppliers effectively. With a focus on value-driven purchasing, international buyers will find practical tips for negotiating prices and understanding regional market dynamics.

By empowering decision-makers with in-depth knowledge and strategic advice, this guide aims to enhance the procurement process, ensuring that businesses secure reliable and cost-effective gutter solutions. Whether you are a contractor in Brazil seeking bulk orders or a distributor in Germany looking to expand your product range, this resource is tailored to meet your needs and facilitate informed purchasing decisions.

Understanding galvanized steel gutters Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| K-Style Gutters | Rectangular shape, flat bottom, and decorative front edge | Commercial buildings, residential properties | Pros: Efficient water flow, customizable sizes. Cons: May require more frequent maintenance. |

| Half-Round Gutters | Semi-circular shape, smooth design, and traditional aesthetic | Historic buildings, upscale residences | Pros: Attractive appearance, less prone to debris buildup. Cons: May have lower capacity than K-style. |

| Box Gutters | Square or rectangular profile, integrated into rooflines | Industrial facilities, flat-roofed structures | Pros: High capacity, suitable for heavy rainfall. Cons: More complex installation. |

| Seamless Gutters | Continuous lengths without seams, custom-fitted on-site | Large commercial projects, new constructions | Pros: Reduced leaks, low maintenance. Cons: Higher initial cost, requires specialized installation. |

| Gutter Accessories (Hangers, Brackets) | Essential components for installation and support | All gutter types, various applications | Pros: Enhances durability and functionality. Cons: Quality varies by manufacturer. |

What are K-Style Gutters and Their B2B Applications?

K-style gutters are characterized by their rectangular shape and flat bottom, featuring a decorative front edge that enhances aesthetic appeal. They are widely used in commercial buildings and residential properties due to their efficient water flow and customizable sizes. For B2B buyers, considerations include the gutter’s capacity to handle varying rainfall levels and the need for potential maintenance, particularly in regions with heavy precipitation.

How Do Half-Round Gutters Stand Out?

Half-round gutters offer a semi-circular shape that not only provides a classic look but also minimizes debris buildup due to their smooth design. They are particularly suitable for historic buildings and upscale residences where aesthetics are paramount. B2B buyers should weigh the attractive appearance against the potential for lower capacity compared to K-style gutters, making them ideal for moderate rainfall areas.

What are Box Gutters and Their Industrial Benefits?

Box gutters feature a square or rectangular profile and are often integrated into the roofline, making them suitable for industrial facilities and flat-roofed structures. They are designed to handle high water volumes, making them essential for regions with heavy rainfall. B2B buyers should consider the complexity of installation and the need for professional services, but the high capacity can significantly reduce overflow issues.

Why Choose Seamless Gutters for Large Projects?

Seamless gutters are manufactured in continuous lengths, minimizing seams and potential leak points. They are custom-fitted on-site, making them ideal for large commercial projects and new constructions. While they offer reduced maintenance and improved durability, the higher initial costs and specialized installation requirements are key considerations for B2B buyers looking for long-term solutions.

What Role Do Gutter Accessories Play in Gutter Systems?

Gutter accessories such as hangers and brackets are critical for the proper installation and support of all gutter types. They enhance the durability and functionality of the gutter system, ensuring it can withstand environmental stresses. For B2B buyers, the quality of these components is crucial, as it can vary significantly between manufacturers, impacting overall system performance.

Key Industrial Applications of galvanized steel gutters

| Industry/Sector | Specific Application of Galvanized Steel Gutters | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Roof drainage systems for commercial buildings | Enhances building longevity by preventing water damage | Compliance with local building codes and regulations |

| Agriculture | Water management in agricultural buildings and greenhouses | Protects crops from excess water accumulation and soil erosion | Resistance to corrosive substances and weather conditions |

| Industrial Facilities | Wastewater management systems | Reduces risk of flooding and improves site safety | Custom sizing and compatibility with existing systems |

| Infrastructure | Gutter systems for public infrastructure like bridges and highways | Ensures structural integrity and public safety | Durability against heavy rainfall and environmental factors |

| Residential Development | Residential gutter systems in urban developments | Increases property value and aesthetic appeal | Availability in various styles and finishes |

How Are Galvanized Steel Gutters Used in Construction Projects?

In the construction industry, galvanized steel gutters are integral to roof drainage systems for commercial buildings. These gutters effectively channel rainwater away from the structure, preventing water damage that could compromise the integrity of the building. For international buyers, especially in regions like Africa and South America, it’s crucial to ensure compliance with local building codes and regulations to avoid costly penalties and project delays. Additionally, sourcing options that offer customized lengths and fittings can facilitate easier installation and maintenance.

What Role Do Galvanized Steel Gutters Play in Agriculture?

In agricultural settings, galvanized steel gutters are employed in water management systems, particularly in greenhouses and barns. They help manage excess water, preventing soil erosion and protecting crops from potential flooding. For buyers in the Middle East, where water scarcity is a concern, selecting gutters with high resistance to corrosive elements found in fertilizers and chemicals is essential. This durability ensures long-term functionality, reducing the need for frequent replacements.

How Are Galvanized Steel Gutters Essential for Industrial Facilities?

Industrial facilities often utilize galvanized steel gutters for effective wastewater management. These systems mitigate flooding risks and enhance site safety by directing water away from critical operational areas. Buyers should consider the specific requirements of their site, such as the capacity to handle heavy rainfall and the potential for industrial pollutants. Ensuring compatibility with existing drainage systems can also streamline the installation process, making it vital for international buyers to engage with suppliers who understand local environmental regulations.

Why Are Galvanized Steel Gutters Important for Infrastructure Projects?

In infrastructure projects, such as bridges and highways, galvanized steel gutters are crucial for maintaining structural integrity by managing water runoff. They help prevent erosion and deterioration of the infrastructure, which can be particularly important in regions with heavy rainfall. Buyers should focus on sourcing gutters that offer high durability and weather resistance to ensure longevity. Understanding the specific environmental challenges of the project location is key to selecting the right gutter systems.

How Do Galvanized Steel Gutters Enhance Residential Developments?

In residential development, galvanized steel gutters not only serve a functional purpose but also contribute to the aesthetic appeal of properties. They can be customized in various styles and finishes to match the architectural design of homes. For developers and contractors in Europe, where building aesthetics are highly valued, sourcing options that provide both durability and style is essential. This approach enhances property value while ensuring effective water management, making it a win-win for developers and homeowners alike.

3 Common User Pain Points for ‘galvanized steel gutters’ & Their Solutions

Scenario 1: Installation Challenges with Galvanized Steel Gutters

The Problem: B2B buyers often face difficulties during the installation of galvanized steel gutters. These challenges can arise from the weight of the material, which can complicate handling and alignment. Additionally, without proper training, teams may struggle with cutting and fitting the gutters accurately, leading to potential leaks or misalignment. This can result in project delays and increased labor costs, ultimately affecting the bottom line.

The Solution: To mitigate installation challenges, it’s essential to provide thorough training for installation teams on the specific techniques for handling and installing galvanized steel gutters. Partnering with suppliers who offer detailed installation guides or on-site training can greatly enhance the skill set of your workforce. Additionally, consider investing in specialized tools designed for cutting and fitting galvanized steel, which can streamline the process and ensure precision. Ensuring that teams are equipped with proper safety gear and handling techniques will also minimize risks associated with the weight and sharp edges of the material.

Scenario 2: Corrosion Resistance and Longevity of Galvanized Steel Gutters

The Problem: A common concern for B2B buyers is the long-term durability of galvanized steel gutters, especially in regions with extreme weather conditions. Buyers may worry about the potential for corrosion over time, which could lead to leaks and necessitate costly replacements. This is particularly significant in areas with high humidity or salt exposure, where the protective zinc coating can wear down more quickly.

The Solution: To enhance the longevity of galvanized steel gutters, buyers should prioritize sourcing high-quality products that feature a thicker zinc coating. It’s advisable to consult with manufacturers about the specifications of their galvanized steel, as variations in coating thickness can significantly impact corrosion resistance. Additionally, regular maintenance, including cleaning gutters to remove debris and inspecting for any signs of wear, can prevent corrosion. Implementing a proactive maintenance schedule will ensure that any issues are identified early, extending the lifespan of the gutters and reducing the likelihood of costly repairs or replacements.

Scenario 3: Aesthetic Concerns and Customization Options for Galvanized Steel Gutters

The Problem: B2B buyers may encounter aesthetic limitations with galvanized steel gutters, which typically have a raw, industrial appearance. This can be a significant drawback for projects that require a more polished or customized look, particularly in residential or high-end commercial applications. Buyers may feel constrained by the standard options available, leading to dissatisfaction with the final project outcome.

The Solution: To address aesthetic concerns, buyers can explore customization options available through various suppliers. Many manufacturers offer pre-painted or coated galvanized steel gutters that can match specific color schemes or design requirements. Additionally, consider collaborating with suppliers who can provide custom sizes and profiles that better fit the architectural style of the project. Painting galvanized steel gutters with high-quality exterior-grade paint can also enhance their appearance while providing an additional layer of protection against corrosion. By taking these steps, buyers can ensure that the gutters not only perform well but also complement the overall aesthetic of the building.

Strategic Material Selection Guide for galvanized steel gutters

What Are the Key Properties of Galvanized Steel Gutters?

Galvanized steel gutters are primarily made from steel coated with a layer of zinc, which provides enhanced corrosion resistance and durability. This material can withstand various environmental conditions, making it suitable for diverse climates. The temperature and pressure ratings for galvanized steel are generally high, allowing it to handle significant rainfall and resist thermal expansion and contraction. Its ability to endure physical impacts, such as falling branches or debris, further enhances its performance in gutter systems.

What Are the Pros and Cons of Galvanized Steel Gutters?

Pros:

1. Durability: Galvanized steel is exceptionally durable, with a lifespan that can exceed 20 years when properly maintained. Its resistance to rust and corrosion due to the zinc coating makes it ideal for regions with high humidity or rainfall.

2. Cost-Effectiveness: Compared to stainless steel, galvanized steel is generally more affordable, providing a budget-friendly option without compromising on quality.

3. Ease of Installation: The material is relatively lightweight, making it easier to handle and install than heavier alternatives like copper or stainless steel.

Cons:

1. Maintenance Requirements: While galvanized steel is resistant to corrosion, it still requires regular maintenance to prevent rust, especially in harsh climates.

2. Limited Aesthetic Options: The default silver finish may not align with all architectural styles, although it can be painted to match specific preferences.

3. Environmental Concerns: The production process of galvanized steel can have environmental implications, which may be a consideration for eco-conscious buyers.

How Does Material Selection Impact Application in Various Regions?

When selecting galvanized steel gutters, international B2B buyers must consider specific regional factors. For instance, in Africa and South America, where heavy rainfall and fluctuating temperatures are common, the durability and corrosion resistance of galvanized steel make it a preferred choice. In Europe, compliance with standards such as DIN (Deutsches Institut für Normung) is crucial, as many countries have stringent regulations regarding building materials. Buyers in the Middle East may prioritize materials that can withstand extreme heat and sandstorms, making the thermal stability of galvanized steel an important consideration.

What Compliance and Standards Should International Buyers Consider?

International buyers should be aware of compliance with various standards like ASTM (American Society for Testing and Materials), DIN, and JIS (Japanese Industrial Standards). These standards ensure that the materials used meet safety, durability, and performance benchmarks. Additionally, understanding local preferences and regulations can help buyers make informed decisions that align with market demands.

Illustrative image related to galvanized steel gutters

Summary Table of Material Selection for Galvanized Steel Gutters

| Material | Typical Use Case for galvanized steel gutters | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvanized Steel | Residential and commercial gutter systems | High durability and corrosion resistance | Requires regular maintenance | Medium |

| Stainless Steel | High-end residential and architectural designs | Exceptional corrosion resistance | Higher cost and weight | High |

| Aluminum | Lightweight applications in low rainfall areas | Lightweight and easy to install | Less durable than steel | Low |

| Copper | Premium installations with aesthetic appeal | Long lifespan and attractive appearance | Very high cost and requires special care | High |

This analysis provides a comprehensive overview of galvanized steel gutters, highlighting the critical aspects of material selection for B2B buyers across different regions. Understanding these factors will help in making informed purchasing decisions that align with specific project requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for galvanized steel gutters

What Are the Key Stages in the Manufacturing Process of Galvanized Steel Gutters?

The manufacturing process for galvanized steel gutters involves several critical stages designed to ensure the durability and performance of the final product.

-

Material Preparation: The process begins with selecting high-quality steel sheets, often cold-rolled or hot-rolled, depending on the desired strength and finish. The steel is then subjected to a cleaning process to remove any oil, grease, or rust that could affect the galvanization process. This is typically achieved through chemical cleaning or abrasive blasting.

-

Forming: Once the steel sheets are prepared, they are formed into the desired gutter shapes using processes such as roll forming or die stamping. Roll forming is particularly popular because it allows for continuous production of long lengths of gutters with uniform thickness. The forming process is critical as it determines the gutter’s structural integrity and aesthetic finish.

-

Assembly: After forming, the gutter sections are cut to size and assembled. This may involve welding or using mechanical fasteners, depending on the design specifications. Proper assembly techniques are essential to ensure that the gutters can withstand environmental stresses, such as wind and rain.

-

Finishing: The final stage involves galvanization, where the formed gutters are coated with a layer of zinc to protect against corrosion. This is typically done through hot-dip galvanization, where the gutters are submerged in molten zinc. The process provides a robust barrier against rust and extends the lifespan of the gutters. After galvanization, additional finishes such as painting or coating may be applied for enhanced aesthetics and further protection.

What Quality Assurance Measures Are Typically Implemented in Galvanized Steel Gutter Manufacturing?

Quality assurance (QA) is vital in the manufacturing of galvanized steel gutters to meet both international standards and customer expectations.

-

Adherence to International Standards: Manufacturers often comply with ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific standards such as CE marking in Europe and API standards may be applicable, especially for gutters used in industrial settings.

-

Quality Control Checkpoints: Throughout the manufacturing process, several quality control checkpoints are established:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified criteria.

– In-Process Quality Control (IPQC): This occurs during the manufacturing process, where dimensions, weights, and coating thickness are regularly checked.

– Final Quality Control (FQC): The completed gutters undergo final inspections to verify that they meet all specifications and quality standards before shipping. -

Common Testing Methods: Various testing methods are employed to ensure quality, including:

– Visual Inspection: Checking for surface defects and ensuring proper finish.

– Dimensional Testing: Verifying that the dimensions conform to design specifications using calipers and gauges.

– Coating Thickness Measurement: Using non-destructive testing methods to ensure adequate zinc coating.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is critical. Here are several methods:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality assurance measures. Audits can help identify areas for improvement and ensure compliance with international standards.

-

Reviewing Quality Control Reports: Requesting detailed QC reports can help buyers understand the frequency and results of quality inspections throughout the manufacturing process. These reports should include data from IQC, IPQC, and FQC stages.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s operations. These inspections often include thorough evaluations of materials, processes, and finished products against industry standards.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

International buyers must navigate several nuances related to quality control when sourcing galvanized steel gutters.

Illustrative image related to galvanized steel gutters

-

Regional Standards and Certifications: Different regions may have specific standards and certifications that suppliers must adhere to. For example, the European Union has strict regulations regarding product quality and safety, which may require additional certifications such as CE marking.

-

Cultural and Legal Differences: Understanding cultural differences in business practices and legal requirements is vital. For instance, some regions may have less stringent enforcement of quality standards, which could impact the reliability of suppliers.

-

Logistics and Supply Chain Considerations: Quality control does not end at the factory; it extends to the entire supply chain. International buyers should consider how logistics, storage conditions, and transportation may affect product quality upon delivery.

Conclusion: Ensuring Quality in Galvanized Steel Gutters

The manufacturing processes and quality assurance measures for galvanized steel gutters are crucial in delivering durable, high-performance products. B2B buyers must be diligent in verifying supplier practices and understanding international standards to ensure they receive products that meet their quality expectations. By focusing on robust manufacturing processes and comprehensive quality control measures, businesses can secure reliable sources of galvanized steel gutters that will perform well in a variety of environmental conditions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘galvanized steel gutters’

Introduction

This practical sourcing guide is designed to assist B2B buyers in effectively procuring galvanized steel gutters. With a focus on durability, weather resistance, and ease of maintenance, galvanized steel gutters are an optimal choice for various applications. This checklist outlines critical steps to ensure a successful procurement process, emphasizing the importance of thorough evaluation and strategic decision-making.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it is essential to clearly outline your technical requirements. This includes dimensions, weight capacity, and the specific coating or finish needed for your gutters.

– Consider factors such as regional weather conditions and installation environments.

– Determine whether you need additional features, such as rust resistance or compatibility with existing systems.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify reputable suppliers specializing in galvanized steel gutters. Look for suppliers with a strong market presence and positive reviews from other B2B buyers.

– Utilize online platforms and industry networks to gather information on potential suppliers.

– Create a shortlist of suppliers who meet your basic criteria before proceeding to the next step.

Step 3: Evaluate Supplier Certifications

Ensuring that your suppliers have the necessary certifications is crucial for quality assurance. Check for industry standards, such as ISO certifications or compliance with local regulations.

– This step helps mitigate risks associated with product quality and safety.

– Verify that the suppliers adhere to environmentally friendly practices, particularly if sustainability is a priority for your business.

Step 4: Request Samples and Technical Data Sheets

Before making a bulk purchase, request samples and detailed technical data sheets from your shortlisted suppliers. This will allow you to assess the quality and suitability of the products firsthand.

– Evaluate the samples for durability, weight, and finish.

– Review the technical data sheets to confirm that the products meet your defined specifications.

Step 5: Compare Pricing and Terms of Sale

Once you have evaluated the products, compare pricing and terms of sale among your shortlisted suppliers. Look beyond the initial cost and consider factors like bulk discounts, shipping costs, and payment terms.

– Engage in negotiations to secure the best possible deal without compromising on quality.

– Understand the warranty and return policies to protect your investment.

Step 6: Check References and Past Projects

To gain insights into a supplier’s reliability, request references and case studies from their previous clients. This can provide valuable information about the supplier’s performance and customer satisfaction levels.

– Focus on references from businesses in similar industries or regions.

– Inquire about the supplier’s responsiveness and support during and after the procurement process.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, draft a comprehensive purchase agreement that outlines all terms, including delivery schedules, payment terms, and warranty information. Ensure all parties are clear on their responsibilities to avoid misunderstandings.

– This step is crucial for establishing a professional relationship and ensuring accountability.

– Review the agreement carefully before signing, and consider legal advice if necessary.

By following this step-by-step checklist, B2B buyers can streamline their procurement process for galvanized steel gutters, ensuring they make informed decisions that align with their business needs.

Comprehensive Cost and Pricing Analysis for galvanized steel gutters Sourcing

What Are the Key Cost Components in Sourcing Galvanized Steel Gutters?

When sourcing galvanized steel gutters, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The raw material for galvanized steel gutters is steel, which is coated with zinc to enhance durability and corrosion resistance. Fluctuations in steel prices can significantly impact overall costs. It’s advisable to monitor market trends and consider sourcing from regions with lower steel prices.

-

Labor: Labor costs can vary based on the manufacturing location. In countries with lower labor costs, such as some in Africa and South America, buyers may find competitive pricing. However, quality and expertise in manufacturing processes should not be compromised.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce these costs, which in turn can affect pricing for buyers.

-

Tooling: Specialized tools and machinery required for producing customized gutter designs can add to the initial investment. Buyers should consider whether they need standard or custom solutions, as this can significantly influence tooling costs.

-

Quality Control (QC): Ensuring that the gutters meet specific quality standards is essential. Implementing rigorous QC processes may add to the cost but can save money in the long run by reducing defects and returns.

-

Logistics: Transportation costs are particularly relevant for international buyers. Factors such as shipping methods, distance, and local tariffs can impact the final price. Utilizing Incoterms effectively can help clarify responsibilities and costs associated with shipping.

-

Margin: Suppliers typically build a profit margin into their pricing. Understanding the competitive landscape can empower buyers to negotiate better deals.

How Do Price Influencers Affect Sourcing Decisions?

Several factors can influence the pricing of galvanized steel gutters, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract discounts. Buyers should assess their needs to negotiate better terms based on projected usage.

-

Specifications and Customization: Customized solutions can lead to higher costs. Buyers should weigh the benefits of tailored products against the potential for increased expenses.

-

Materials and Quality Certifications: Higher-grade materials or additional certifications (e.g., ISO, ASTM) can increase costs. Buyers should evaluate whether the benefits of enhanced quality align with their project requirements.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their perceived value and trustworthiness.

-

Incoterms: Understanding the implications of different Incoterms (e.g., FOB, CIF) is essential for managing logistics costs and responsibilities. This can impact the overall pricing structure.

What Negotiation Tips Can Help Achieve Cost Efficiency?

To maximize cost efficiency in sourcing galvanized steel gutters, buyers should consider the following tips:

-

Negotiate Terms: Engage in discussions about pricing based on volume, payment terms, and delivery schedules. Suppliers may offer concessions for larger orders or upfront payments.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also installation, maintenance, and potential replacement costs over the product’s lifespan. A higher initial investment in quality materials can yield savings in the long run.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations, local tariffs, and import/export regulations can affect overall costs. Buyers should account for these factors when negotiating prices with suppliers from different regions.

-

Build Long-Term Relationships: Establishing a strong relationship with suppliers can lead to better pricing, priority service, and access to exclusive offers. Regular communication and collaboration can foster trust and reliability.

Disclaimer on Indicative Prices

Prices for galvanized steel gutters can vary widely based on numerous factors, including market conditions, supplier strategies, and geographic considerations. It is essential for buyers to conduct thorough market research and obtain multiple quotes to ensure they receive competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing galvanized steel gutters With Other Solutions

Exploring Alternatives to Galvanized Steel Gutters

When evaluating gutter systems for commercial or industrial applications, it is crucial to consider various material options. Each alternative presents distinct benefits and drawbacks that can significantly impact overall performance, cost, and maintenance requirements. This analysis compares galvanized steel gutters with aluminum gutters and PVC (polyvinyl chloride) gutters, providing insights for B2B buyers to make informed decisions.

| Comparison Aspect | Galvanized Steel Gutters | Aluminum Gutters | PVC Gutters |

|---|---|---|---|

| Performance | Highly durable; resistant to rust due to zinc coating; withstands heavy debris. | Lightweight; resistant to rust; good for low- to moderate rainfall areas. | Not as durable; can warp or crack under extreme temperatures; less effective in heavy rain. |

| Cost | Moderate initial cost; long lifespan can offset expenses. | Generally higher initial cost; lightweight can reduce installation costs. | Lower initial cost; however, may require more frequent replacement. |

| Ease of Implementation | Relatively easy to install; requires specific tools for cutting. | Easy to handle; pre-formed pieces simplify installation. | Very lightweight; can be installed without heavy equipment. |

| Maintenance | Requires periodic cleaning; can be painted for aesthetics and protection. | Low maintenance; not prone to rust but may require painting over time. | Minimal maintenance; however, more susceptible to damage from UV rays. |

| Best Use Case | Ideal for areas with heavy rainfall and debris; commercial buildings. | Suitable for residential and light commercial applications; good in moderate climates. | Best for budget-sensitive projects; suitable for low-traffic areas. |

In-Depth Analysis of Alternatives

Aluminum Gutters

Aluminum gutters are known for their lightweight nature and resistance to rust, making them a popular choice for residential and light commercial applications. They are easy to install and often come in various colors, reducing the need for painting. However, aluminum gutters may not handle heavy debris as effectively as galvanized steel. Their performance is best suited for regions with moderate rainfall, and while they have a longer lifespan than plastic options, they can be more expensive initially.

PVC Gutters

PVC gutters offer a cost-effective alternative with their lower upfront pricing and minimal maintenance requirements. They are lightweight and easy to install, which can significantly reduce labor costs. However, PVC gutters are less durable than both galvanized steel and aluminum. They can warp or crack under extreme temperatures and are not ideal for areas with heavy rainfall or debris. Despite their affordability, their shorter lifespan may lead to higher long-term costs due to more frequent replacements.

Making the Right Choice for Your Gutter System

When selecting the appropriate gutter system, B2B buyers must consider specific project requirements, including climate conditions, budget constraints, and long-term maintenance plans. Galvanized steel gutters provide superior durability and performance, especially in areas prone to heavy rainfall and debris. Alternatively, aluminum and PVC gutters can be suitable for projects with lighter demands and tighter budgets. Evaluating these factors will help buyers make informed decisions that align with their operational needs and financial objectives.

Essential Technical Properties and Trade Terminology for galvanized steel gutters

What Are the Key Technical Properties of Galvanized Steel Gutters?

When considering galvanized steel gutters, understanding their essential technical properties is crucial for making informed purchasing decisions. Here are some critical specifications:

Material Grade

Galvanized steel typically comes in various grades, with G90 being a common standard. This grade indicates the thickness of the zinc coating, which directly affects corrosion resistance. In B2B contexts, selecting the appropriate material grade is vital for ensuring long-term durability, particularly in regions with harsh weather conditions.

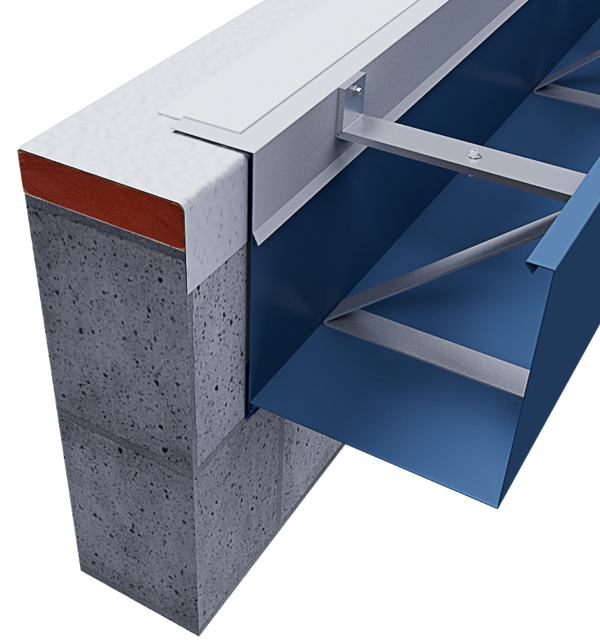

Illustrative image related to galvanized steel gutters

Tolerance

Tolerance refers to the permissible variation in dimensions during the manufacturing process. For gutters, this can affect how well components fit together. Accurate tolerances ensure that gutters can effectively channel water without leaks. In B2B transactions, tolerances are critical for contractors who need precise measurements for installation.

Coating Thickness

The thickness of the zinc coating on galvanized steel gutters is a key property that influences their lifespan. A thicker coating provides better corrosion resistance. Buyers should prioritize products with adequate coating thickness for their climate to avoid premature rusting, which can lead to costly repairs.

Weight

The weight of galvanized steel gutters can impact shipping costs and installation ease. Heavier materials might require more robust support structures, while lighter options can reduce installation labor. Understanding weight specifications helps buyers assess logistics and installation requirements.

Load Capacity

Load capacity refers to the amount of water and debris a gutter can handle before failure. This property is influenced by the gutter’s design and material strength. For B2B buyers, especially in regions prone to heavy rainfall, selecting gutters with adequate load capacity is crucial to prevent overflow and structural damage.

What Are Common Trade Terms Related to Galvanized Steel Gutters?

Understanding industry terminology can streamline communication and negotiations in B2B transactions. Here are some common terms:

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that are sold under another company’s brand. In the context of galvanized steel gutters, buyers may source products from OEMs that specialize in gutter systems, ensuring quality and consistency.

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding MOQ is essential for budgeting and inventory management. It can also affect pricing; larger orders often lead to better per-unit costs.

RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit price quotes from suppliers. In the galvanized steel gutter market, an RFQ can help buyers compare prices and terms from multiple suppliers, ensuring they make cost-effective purchasing decisions.

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. Familiarity with these terms helps buyers understand shipping costs, risk management, and delivery obligations when importing galvanized steel gutters from different regions.

Illustrative image related to galvanized steel gutters

Lead Time

Lead time refers to the amount of time between placing an order and receiving the goods. In the construction industry, knowing lead times for galvanized steel gutters is crucial for project planning and avoiding delays.

ASTM Standards

ASTM (American Society for Testing and Materials) standards set benchmarks for the quality and performance of materials, including galvanized steel. Buyers should ensure that the products meet relevant ASTM standards to guarantee reliability and compliance.

By familiarizing themselves with these technical properties and trade terminologies, B2B buyers can make informed decisions, optimize their purchasing strategies, and ultimately enhance their project outcomes.

Navigating Market Dynamics and Sourcing Trends in the galvanized steel gutters Sector

What Are the Key Trends Shaping the Global Galvanized Steel Gutters Market?

The global galvanized steel gutters market is witnessing significant growth driven by several factors. Increasing urbanization and infrastructure development in regions such as Africa, South America, and the Middle East are propelling demand for durable and efficient building materials. Additionally, galvanized steel’s resistance to corrosion and weather extremes makes it an attractive choice for diverse climatic conditions. B2B buyers are increasingly focusing on high-quality products that offer longevity and minimal maintenance, reflecting a shift towards value-driven purchasing decisions.

Emerging technologies are reshaping sourcing practices within the sector. Digital platforms are enhancing the procurement process, enabling international buyers to access a wider range of suppliers and products. E-commerce solutions and supply chain management software streamline ordering and logistics, reducing lead times and improving inventory management. Moreover, trends like bulk purchasing and contractor-specific pricing models are gaining traction as businesses seek to optimize costs while ensuring product availability.

Illustrative image related to galvanized steel gutters

In the European market, particularly in Germany, stringent building regulations and sustainability initiatives are driving innovation in product offerings, including energy-efficient and environmentally friendly gutter solutions. In contrast, markets in Brazil and other South American countries are characterized by rapid construction activities, which are accelerating the demand for galvanized steel gutters.

How Is Sustainability and Ethical Sourcing Influencing Galvanized Steel Gutters?

Sustainability has become a critical consideration for B2B buyers in the galvanized steel gutters sector. The environmental impact of manufacturing processes is under scrutiny, and businesses are increasingly prioritizing suppliers that adopt eco-friendly practices. Ethical sourcing is essential, as buyers seek assurance that materials are obtained responsibly, minimizing harm to the environment and communities.

Certification schemes, such as LEED (Leadership in Energy and Environmental Design) and other green building certifications, are becoming vital for suppliers looking to differentiate their products. Buyers are encouraged to seek out galvanized steel gutters that are manufactured using recycled materials or processes that reduce carbon footprints. Additionally, the potential for painting or coating galvanized steel allows for customization while enhancing its durability, further supporting sustainable practices.

The importance of transparency in supply chains cannot be overstated. Buyers should engage with suppliers that provide clear documentation of their sourcing methods and material origins. This not only helps in ensuring compliance with international regulations but also builds trust and fosters long-term partnerships.

What Is the Historical Context of Galvanized Steel Gutters in the B2B Landscape?

The use of galvanized steel for gutters dates back to the early 19th century, with significant advancements made in the mid-20th century as manufacturing processes improved. Initially, galvanized steel was prized for its ability to resist rust and corrosion, offering a cost-effective solution for gutter systems.

As the construction industry evolved, so did the design and functionality of galvanized gutters. Today, they are not only recognized for their durability but also for their aesthetic versatility, allowing builders and contractors to meet both functional and design needs. The evolution of galvanized steel gutters reflects broader trends in construction, emphasizing quality, sustainability, and efficiency—key considerations for international B2B buyers navigating the modern market.

This historical context underscores the importance of galvanized steel gutters as a reliable choice in the ever-evolving landscape of construction materials, providing a solid foundation for current and future sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of galvanized steel gutters

-

How do I choose the right galvanized steel gutters for my project?

When selecting galvanized steel gutters, consider the specific needs of your project, including the climate, building design, and water drainage requirements. Evaluate the gauge of the steel, as thicker materials offer better durability. Additionally, consider the gutter profile, such as K-style or half-round, and the available colors or finishes. It’s advisable to consult with a supplier about local regulations and standards to ensure compliance. Ultimately, engaging with a contractor or an expert can help you make an informed decision tailored to your project’s unique demands. -

What factors influence the pricing of galvanized steel gutters?

The pricing of galvanized steel gutters is influenced by several factors, including the gauge of the steel, length and size of the gutters, and the complexity of the installation. Additional costs may arise from customization options, such as color and accessories. International shipping and tariffs can also affect the final price for buyers in different regions. It is beneficial to request quotes from multiple suppliers and consider bulk purchasing discounts to optimize costs. -

What is the minimum order quantity (MOQ) for galvanized steel gutters?

Minimum order quantities for galvanized steel gutters can vary significantly by supplier. Some manufacturers may have an MOQ as low as 100 units, while others may require orders of several thousand units. When sourcing, inquire about the MOQ during initial discussions with suppliers to ensure it aligns with your project needs. Additionally, consider the potential for reduced pricing on larger orders, which can be advantageous for ongoing projects. -

What payment terms should I expect when purchasing galvanized steel gutters internationally?

Payment terms for international purchases of galvanized steel gutters typically vary by supplier but often include options such as advance payment, letter of credit, or payment upon delivery. It’s crucial to clarify these terms upfront to avoid any misunderstandings. Ensure to discuss any potential financing options or installment payments if large orders are needed. Additionally, be aware of currency exchange rates and transaction fees that may impact the total cost. -

How can I ensure quality when sourcing galvanized steel gutters?

To ensure quality when sourcing galvanized steel gutters, request certifications from suppliers that demonstrate compliance with international standards. Look for suppliers that provide detailed product specifications, including material thickness and zinc coating weight. It’s advisable to ask for samples or visit the manufacturing facility if possible. Consider conducting third-party inspections before shipment to verify quality and adherence to specifications, especially for large orders. -

What logistical considerations should I keep in mind when importing galvanized steel gutters?

When importing galvanized steel gutters, consider shipping options, lead times, and customs clearance processes. Ensure you have a reliable logistics partner who understands the complexities of international shipping, including freight forwarding and handling duties. Be prepared for potential delays due to customs inspections or documentation issues. It’s also wise to have contingency plans in place for unexpected costs related to shipping or tariffs. -

Can I customize galvanized steel gutters to fit my specific needs?

Yes, many suppliers offer customization options for galvanized steel gutters, including size, color, and additional features like downspouts and brackets. Discuss your specific requirements with potential suppliers to understand the extent of customization they can provide. Customization may influence pricing and lead times, so it’s essential to communicate your needs early in the sourcing process to ensure timely delivery. -

What are the benefits of using galvanized steel gutters over other materials?

Galvanized steel gutters offer several advantages compared to other materials, such as aluminum or vinyl. They are highly durable, resistant to corrosion, and can withstand extreme weather conditions, making them ideal for various climates. Additionally, galvanized steel is less prone to cracking and warping, ensuring a longer lifespan. These gutters can also be painted, allowing for aesthetic flexibility to match building designs. Overall, they provide a robust solution for effective water management.

Top 5 Galvanized Steel Gutters Manufacturers & Suppliers List

1. Gutter Supply – Galvanized Steel Gutters & Accessories

Domain: guttersupply.com

Registered: 2000 (25 years)

Introduction: Galvanized Steel Rain Gutters, Galvanized Steel K-Style Gutters, Galvanized Steel Half Round Single Bead Gutters, Galvanized Steel Downspouts, Galvanized Steel Hangers, Steel Gutter Leaf Guards, Galvanized Steel Elbows, Galvanized Steel Miters, Galvanized Steel End Caps, Galvanized Steel Outlets, Galvanized Steel Downspout Brackets, Galvanized Steel Rack & Drives, Galvanized Steel Flashing, Galvan…

2. Sunrise – 20 FT Galvanized Steel Half Round Gutter

Domain: sunrisehalfround.com

Registered: 2020 (5 years)

Introduction: {“product_name”:”20 FT Galvanized Steel Half Round Gutter”,”dimensions”:”6 inches wide x 20 feet long”,”price”:”$140.00″,”price_per_foot”:”$7.00″,”material”:”DX51 Galvanized Steel G90″,”thickness”:”0.45mm”,”weight”:”18.5 lb”,”brand”:”Sunrise”,”lead_time”:”In stock and ready to ship”,”discount”:”Buy 10+ and get 10% off automatically”,”shipping_info”:”Local delivery available within a 150-mile radiu…

3. Zambelli – Galvanized Steel Half-Round Gutters

Domain: rapidmaterials.com

Registered: 2009 (16 years)

Introduction: Galvanized Steel Half-Round Gutters by Zambelli, available in stock. Product categories include 5″ and 6″ Galvanized Steel Gutter Systems, with various downspout options (3″ and 4″ systems). The color family primarily includes gray and metallic silver. The collection features 48 products, including downspout brackets, cleanouts, connectors, elbows, offsets, pipes, drop outlets, end caps, ground pi…

4. Reddit – Steel Gutters vs. Aluminum Durability

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Steel gutters, specifically galvanized steel, were used in homes built in the 1960s and have a lifespan of around 57 years. The user expresses concern about the durability of aluminum gutters, citing their tendency to be flimsy and easily damaged, especially when subjected to heavy snow loads and frequent ladder use. The user has experienced leaks in their old steel gutters but notes that they hav…

5. eGutter – 5 Half-Round Galvanized Steel Gutters

Domain: egutter.com

Registered: 1999 (26 years)

Introduction: Product: 5″ Half-Round Galvanized Steel Gutters

Material: 26 Gauge Galvanized Steel

Available Lengths: 10 Feet, 20 Feet

Features:

– Classic design suitable for small residential and commercial structures

– Available in unpainted galvanized steel and Paint Grip finish

– Related components include hangers, end caps, miters, outlets, downspouts, elbows, pipe fasteners, solder, sealant, and gutter gu…

Strategic Sourcing Conclusion and Outlook for galvanized steel gutters

As the demand for durable and cost-effective construction materials continues to rise globally, galvanized steel gutters stand out as a reliable choice for B2B buyers. Their robust construction, enhanced resistance to environmental elements, and ease of maintenance position them as a superior option compared to alternatives. Strategic sourcing not only ensures competitive pricing but also fosters long-term partnerships with suppliers who understand local market dynamics, especially in regions like Africa, South America, the Middle East, and Europe.

Investing in galvanized steel gutters can yield significant returns, reducing repair costs and enhancing the longevity of roofing systems. Furthermore, the ability to customize these gutters through painting or additional protective coatings allows businesses to meet specific aesthetic requirements while maintaining functionality.

Looking ahead, international B2B buyers should prioritize establishing relationships with trusted suppliers who can provide high-quality galvanized steel gutters tailored to regional needs. By leveraging strategic sourcing practices, companies can secure favorable terms and ensure timely delivery, ultimately driving project success. Embrace the opportunity to enhance your offerings with galvanized steel gutters and position your business for growth in an increasingly competitive market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to galvanized steel gutters