Everything You Need to Know About Full System For Suzuki 250 Gixxer Sourcing in 2025

Introduction: Navigating the Global Market for full system for suzuki 250 gixxer

In the dynamic landscape of the global motorcycle parts market, sourcing a high-performance full system for the Suzuki 250 Gixxer presents unique challenges for B2B buyers. With a growing demand for enhanced performance and compliance with regional regulations, businesses must navigate a plethora of options, each varying in quality, design, and compatibility. This guide aims to illuminate the intricacies of selecting the right full system for the Suzuki 250 Gixxer, addressing critical factors such as product specifications, applications, and supplier vetting processes.

Within these pages, you will find a comprehensive overview of available exhaust systems, including the popular Yoshimura R-77S and GP-MAGNUM105 models, their performance characteristics, and their suitability for various markets. The guide also delves into cost considerations, market trends, and tips for evaluating suppliers to ensure that you make informed purchasing decisions.

By equipping international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, with the knowledge to assess options effectively, this guide serves as a valuable resource. It empowers businesses to enhance their product offerings, meet customer demands, and ensure compliance with local regulations, all while maintaining competitive pricing and quality standards.

Understanding full system for suzuki 250 gixxer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| R-77S Full System | Stainless steel construction, lightweight (3.7kg), noise compliant (94dB) | Performance upgrades, racing applications | Pros: Enhanced power and torque, stylish design. Cons: Higher price point compared to OEM. |

| GP-MAGNUM 105 | Simple round design, lightweight (3.8kg), mid to high RPM power boost | Custom builds, sport riding | Pros: Significant weight reduction, improved acceleration. Cons: May require tuning for optimal performance. |

| OEM Replacement | Standard factory design, heavier (6.8kg), noise compliant | Replacement for damaged or worn systems | Pros: Cost-effective, direct fit. Cons: Limited performance enhancement, heavier. |

| Stainless Steel | Durable material, various finishes, good heat resistance | Long-term maintenance, fleet applications | Pros: Corrosion resistant, longevity. Cons: Heavier than titanium alternatives. |

| Titanium Variants | Ultra-lightweight options (as low as 3.7kg), high thermal efficiency | High-performance racing, professional use | Pros: Exceptional weight savings, enhanced performance. Cons: Higher cost, may require special care. |

What are the Characteristics of the R-77S Full System for Suzuki 250 Gixxer?

The R-77S full system is crafted from stainless steel, making it both durable and lightweight, weighing in at just 3.7kg. It is designed to comply with strict noise regulations, producing a sound level of 94dB at 4,650rpm. This system enhances the power and torque across a wide RPM range, making it ideal for both street and racing applications. Buyers should consider its stylish design and performance benefits, although it comes at a premium compared to OEM options.

How Does the GP-MAGNUM 105 Enhance Performance?

The GP-MAGNUM 105 features a simple round design that not only looks appealing but also significantly boosts mid to high RPM performance. Weighing 3.8kg, it offers a 44% weight reduction over the OEM system. This exhaust system is ideal for custom builds and sport riding, providing a noticeable improvement in acceleration. However, potential buyers should be aware that it may require tuning to maximize its performance benefits.

Why Choose an OEM Replacement Exhaust System?

For businesses looking to replace damaged or worn exhaust systems, the OEM replacement offers a cost-effective solution. While it maintains the original design and weight of 6.8kg, it does not enhance performance significantly. Its primary application is in fleet maintenance or for everyday riders who prefer reliability over performance enhancements. The advantage lies in its direct fit and lower cost, but buyers should be mindful of its limitations in terms of performance.

What are the Benefits of Stainless Steel Exhausts?

Stainless steel exhaust systems provide excellent durability and resistance to corrosion, making them suitable for long-term maintenance applications. They come in various finishes, catering to aesthetic preferences. However, they are generally heavier than titanium alternatives, which could be a consideration for performance-focused buyers. Businesses may find value in offering stainless steel options for their clients seeking reliable solutions without the need for frequent replacements.

What Makes Titanium Variants a Popular Choice for High-Performance Use?

Titanium exhaust systems are favored in high-performance settings due to their ultra-lightweight nature, with some variants weighing as little as 3.7kg. They offer superior thermal efficiency and enhance overall performance, making them ideal for professional racing applications. While they come at a higher cost, the benefits in terms of weight savings and performance enhancements can justify the investment for serious enthusiasts and competitive riders. Buyers should ensure they are prepared for the care required to maintain these premium systems.

Key Industrial Applications of full system for suzuki 250 gixxer

| Industry/Sector | Specific Application of Full System for Suzuki 250 Gixxer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Motorcycle Manufacturing | Integration into new motorcycle models | Enhances performance and compliance with noise regulations | Quality certification, material specifications, and weight reduction |

| Custom Motorcycle Retailers | Upgrades for performance motorcycles | Increases customer satisfaction and market competitiveness | Variety of options, compatibility with different models, pricing |

| Racing and Motorsports | Race bike modifications for competitive events | Improved speed and performance on the track | Durability under high stress, weight considerations, and performance metrics |

| Motorcycle Maintenance Shops | Replacement for worn-out exhaust systems | Ensures optimal performance and customer trust | Availability of parts, warranty options, and ease of installation |

| Export and Import Businesses | Distribution of high-performance parts | Access to growing markets and increased revenue potential | Compliance with international shipping regulations and local standards |

How is the Full System for Suzuki 250 Gixxer Used in Motorcycle Manufacturing?

In the motorcycle manufacturing sector, the full system for the Suzuki 250 Gixxer is essential for integrating into new models. By utilizing a high-performance exhaust system, manufacturers can enhance the motorcycle’s power output while ensuring compliance with strict noise regulations. This is particularly important in international markets where emission and noise standards are rigorously enforced. Buyers in this sector should prioritize sourcing systems that are certified and have proven performance metrics to guarantee reliability and customer satisfaction.

What Role Does the Full System Play for Custom Motorcycle Retailers?

Custom motorcycle retailers leverage the full system for the Suzuki 250 Gixxer as a popular upgrade option. These exhaust systems not only improve the motorcycle’s aesthetics but also enhance its performance, making them attractive to enthusiasts looking for personalized solutions. Retailers benefit from increased customer satisfaction and loyalty by offering high-quality, performance-enhancing products. It’s crucial for these businesses to consider the variety of options available, ensuring compatibility with different motorcycle models to meet diverse customer needs.

How is the Full System Beneficial in Racing and Motorsports?

In the racing and motorsports industry, the full system for the Suzuki 250 Gixxer is used for modifying race bikes to achieve superior speed and performance. The lightweight construction and improved exhaust flow can significantly enhance acceleration and overall handling, which is vital in competitive environments. Teams should focus on sourcing exhaust systems that can withstand the rigors of racing, offering durability and performance metrics that align with their racing goals.

Why is the Full System Important for Motorcycle Maintenance Shops?

Motorcycle maintenance shops frequently replace worn-out exhaust systems with full systems for the Suzuki 250 Gixxer to restore optimal performance. This application is crucial for maintaining customer trust, as a well-functioning exhaust system directly impacts ride quality and engine efficiency. Maintenance shops should ensure they have a reliable supply of certified parts, consider the warranty options available, and understand the ease of installation to streamline their service processes.

How Do Export and Import Businesses Utilize the Full System?

Export and import businesses capitalize on the demand for high-performance motorcycle parts, including the full system for the Suzuki 250 Gixxer. By distributing these products in emerging markets, they can tap into a growing customer base seeking quality upgrades for their motorcycles. Compliance with international shipping regulations and local standards is vital for these businesses to ensure smooth transactions and market entry. Sourcing strategies should focus on reliable suppliers who can meet quality and certification requirements to facilitate successful trade.

3 Common User Pain Points for ‘full system for suzuki 250 gixxer’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Exhaust Systems

The Problem: B2B buyers often struggle to find a reliable supplier for high-quality full exhaust systems for the Suzuki 250 Gixxer. Many aftermarket products are available, but not all meet international quality standards or regulations. Buyers may encounter discrepancies in product specifications, leading to frustration, especially when trying to ensure compliance with local regulations. This can result in delays in delivery and the risk of investing in subpar products that do not enhance performance or durability.

The Solution: To overcome this challenge, B2B buyers should prioritize sourcing from established manufacturers known for their commitment to quality, such as Yoshimura. Conduct thorough research on potential suppliers, looking for certifications like JMCA (Japanese Motorcycle Certification) which ensures compliance with noise and emission standards. Additionally, utilize online platforms that specialize in motorcycle parts to compare specifications, read reviews, and verify the credibility of suppliers. Establishing a strong relationship with a trusted supplier can also facilitate better communication regarding product specifications and availability, ensuring that buyers receive the right exhaust system tailored for the Suzuki 250 Gixxer.

Scenario 2: Incompatibility with Existing Motorcycle Parts

The Problem: Another common pain point for B2B buyers is the risk of purchasing exhaust systems that are incompatible with existing motorcycle parts. The Suzuki 250 Gixxer has specific design features and mounting points, and a mismatch can lead to installation challenges, additional costs for modifications, and potential safety risks. Buyers may also face difficulties in returning incompatible products, further complicating the purchasing process.

The Solution: To mitigate this issue, it is essential for buyers to conduct a compatibility assessment before making a purchase. This involves cross-referencing the specifications of the exhaust system with the Suzuki 250 Gixxer’s model year and configuration. Buyers should refer to detailed product descriptions that highlight compatibility information. Additionally, reaching out to the supplier’s customer service for clarification can prevent costly mistakes. For added assurance, consider opting for exhaust systems that come with comprehensive installation guides and support, ensuring a seamless integration with the motorcycle’s existing components.

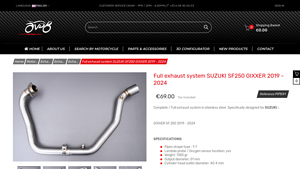

Illustrative image related to full system for suzuki 250 gixxer

Scenario 3: Uncertainty About Performance Enhancements

The Problem: B2B buyers often experience uncertainty regarding the performance enhancements that a full exhaust system will provide for the Suzuki 250 Gixxer. With various products claiming to increase horsepower and torque, it can be challenging to determine which systems will deliver tangible benefits. This ambiguity may lead to hesitation in making a purchase, impacting inventory decisions and customer satisfaction.

The Solution: To address this uncertainty, buyers should focus on detailed product analyses and performance reviews from trusted sources. Engaging with forums and communities of Suzuki Gixxer enthusiasts can provide firsthand insights into how specific exhaust systems perform under real-world conditions. Additionally, look for exhaust systems with documented performance metrics from the manufacturer, such as horsepower gains and weight reductions. Many reputable brands offer dyno charts and performance tests that clearly demonstrate the benefits of their products. By relying on empirical data and user experiences, buyers can make informed decisions that align with their performance goals for the Suzuki 250 Gixxer, ultimately enhancing customer satisfaction and loyalty.

Strategic Material Selection Guide for full system for suzuki 250 gixxer

When selecting materials for the full exhaust system of the Suzuki 250 Gixxer, it is crucial to consider various factors such as performance, durability, cost, and compliance with international standards. Below is a detailed analysis of four common materials used in manufacturing exhaust systems, along with their advantages and disadvantages, particularly from a B2B perspective.

Illustrative image related to full system for suzuki 250 gixxer

What Are the Key Properties of Stainless Steel for Exhaust Systems?

Stainless steel is a popular choice for exhaust systems due to its excellent corrosion resistance and ability to withstand high temperatures. It typically has a temperature rating of up to 1,000°C and can handle significant pressure without deforming. The alloy’s chromium content provides a protective layer that prevents rust and oxidation, making it suitable for various environmental conditions.

Pros: Stainless steel is durable and can last for many years, even under harsh conditions. It is also relatively easy to manufacture, allowing for complex shapes and designs.

Cons: The primary drawback is its cost, which is higher than other materials like mild steel. Additionally, it can be heavier than alternatives, potentially affecting the overall weight of the motorcycle.

Impact on Application: Stainless steel is compatible with various exhaust gases, making it an excellent choice for performance applications. However, buyers must ensure that the specific grade used meets the necessary emissions and noise regulations.

How Does Titanium Compare as a Material for Exhaust Systems?

Titanium is known for its lightweight and high strength-to-weight ratio, making it an attractive option for performance-oriented exhaust systems. It can withstand temperatures exceeding 1,200°C and offers exceptional corrosion resistance, particularly in high-heat environments.

Illustrative image related to full system for suzuki 250 gixxer

Pros: The significant weight savings can enhance the motorcycle’s performance by improving handling and acceleration. Titanium also has a distinctive aesthetic appeal, often preferred for high-end models.

Cons: The manufacturing process for titanium is more complex and costly than for stainless steel. This complexity can lead to higher prices, making it less accessible for budget-conscious buyers.

Impact on Application: Titanium’s lightweight nature makes it particularly suitable for racing applications. However, international buyers should be aware of the need for specialized welding and fabrication techniques, which may not be readily available in all regions.

What Role Does Mild Steel Play in Exhaust System Manufacturing?

Mild steel is often used in budget-friendly exhaust systems. It has a lower cost compared to stainless steel and titanium, making it a common choice for entry-level motorcycles.

Pros: The manufacturing process for mild steel is straightforward, resulting in lower production costs. It can also be easily welded and formed into various shapes.

Cons: Mild steel is prone to rust and corrosion, particularly in wet or humid environments. Its lifespan is significantly shorter than that of stainless steel or titanium, which can lead to increased maintenance costs over time.

Impact on Application: While mild steel can be suitable for less demanding applications, buyers in regions with high humidity or corrosive environments should consider the long-term implications of using this material.

How Does Carbon Fiber Enhance Exhaust System Performance?

Carbon fiber is increasingly being used in high-performance exhaust systems due to its lightweight and high strength. It can withstand high temperatures, though it is often used in conjunction with metal components to enhance durability.

Pros: The primary advantage of carbon fiber is its weight reduction, which can significantly improve the motorcycle’s performance. It also offers a unique aesthetic appeal and can be molded into complex shapes.

Cons: The cost of carbon fiber is considerably higher than traditional materials. Its manufacturing process is specialized and may not be available in all regions.

Impact on Application: Carbon fiber is ideal for high-performance applications, but international buyers should ensure they have access to the necessary fabrication techniques and compliance with local regulations.

Summary Table of Material Selection for Full System for Suzuki 250 Gixxer

| Material | Typical Use Case for full system for suzuki 250 gixxer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | General performance exhaust systems | Excellent corrosion resistance | Higher cost compared to mild steel | Medium |

| Titanium | High-performance racing exhaust systems | Lightweight with high strength | More expensive and complex to manufacture | High |

| Mild Steel | Budget-friendly exhaust systems | Low cost and easy to manufacture | Prone to rust and shorter lifespan | Low |

| Carbon Fiber | Premium high-performance exhaust systems | Significant weight reduction | Very high cost and specialized fabrication | High |

In conclusion, selecting the right material for the full exhaust system of the Suzuki 250 Gixxer requires careful consideration of the intended application, cost, and compliance with international standards. By understanding the properties and implications of each material, B2B buyers can make informed decisions that align with their market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for full system for suzuki 250 gixxer

What Are the Key Stages in the Manufacturing Process of Full Systems for Suzuki 250 Gixxer?

The manufacturing of full exhaust systems for the Suzuki 250 Gixxer involves several critical stages that ensure both performance and compliance with global standards. The process typically includes:

-

Material Preparation: The primary materials used in the construction of exhaust systems are high-grade stainless steel and, in some cases, titanium. These materials are selected for their durability, resistance to corrosion, and weight-to-strength ratio. During this stage, raw materials are sourced from certified suppliers, and samples are often tested for quality assurance before proceeding.

-

Forming: This stage involves the shaping of materials into the required components of the exhaust system. Techniques such as precision bending and welding are employed to create exhaust pipes, mufflers, and other components. Advanced machinery is used to ensure accuracy and consistency in dimensions, which is crucial for optimal fitment and performance.

-

Assembly: Once the individual parts are formed, they are assembled into a complete exhaust system. This may involve the use of fixtures to hold parts in place during welding or bolting. Quality checks are often integrated into this stage to ensure that components fit together perfectly, which is essential for performance and safety.

-

Finishing: The finishing process includes surface treatments such as polishing, coating, or painting to enhance aesthetic appeal and protect against environmental factors. This stage may also involve the installation of branding elements, such as logos, which contribute to the product’s marketability.

How is Quality Assurance Implemented in the Manufacturing of Exhaust Systems?

Quality assurance is a critical aspect of manufacturing full systems for the Suzuki 250 Gixxer, particularly for B2B buyers who demand high standards. The following international and industry-specific standards are commonly applied:

Illustrative image related to full system for suzuki 250 gixxer

-

International Standards: Compliance with ISO 9001 is a fundamental requirement for manufacturers. This standard ensures that organizations maintain a quality management system that consistently meets customer and regulatory requirements.

-

Industry-Specific Certifications: In addition to ISO standards, manufacturers may also seek certifications such as CE marking, which signifies compliance with European health, safety, and environmental protection standards. Other relevant certifications include those related to emissions and noise regulations, which are particularly important in the motorcycle industry.

What Are the Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are established throughout the manufacturing process to ensure that every component meets the required standards. The following checkpoints are typically employed:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon delivery. Suppliers are required to provide certificates of compliance, and materials are tested for quality before they are accepted into the production line.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are performed to monitor the production workflow. This includes checks on dimensions, weld quality, and assembly accuracy. Any deviations from set standards are addressed immediately to prevent defects in the final product.

-

Final Quality Control (FQC): Before the exhaust systems are packaged for shipment, a final inspection is conducted. This includes testing for fitment, functionality, and compliance with noise and emissions standards. Components may also undergo performance testing, such as dyno runs, to ensure they deliver the expected power and efficiency.

What Testing Methods Are Commonly Used for Quality Assurance?

Various testing methods are employed to verify the quality and performance of the exhaust systems:

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, magnetic particle inspection, or dye penetrant testing are used to detect internal and surface defects without damaging the components.

-

Performance Testing: Exhaust systems are often tested on dynamometers to measure power output, torque, and sound levels. This data helps in validating the system’s performance against manufacturer claims.

-

Environmental Testing: Compliance with emission regulations is verified through exhaust gas analysis. This testing ensures that the exhaust system meets the standards set by local and international regulations.

How Can B2B Buyers Verify the Quality Control of Their Suppliers?

For B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are several strategies:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should assess whether suppliers maintain necessary certifications and follow established QC procedures.

-

Quality Assurance Reports: Requesting documentation that details the quality assurance processes, including test results and compliance certificates, allows buyers to verify that suppliers adhere to international standards.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes and product quality. This is especially important for buyers in regions where regulatory compliance might vary.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate various nuances related to quality control and certification when sourcing exhaust systems. These may include:

-

Regulatory Variations: Different countries have varying regulations regarding emissions and noise levels. Buyers should ensure that the products comply with the regulations specific to their market.

-

Documentation Requirements: Importing products often requires extensive documentation, including compliance certificates and testing results. Buyers should be proactive in understanding what documents are necessary for their region to avoid delays and penalties.

-

Cultural Considerations: Understanding the business culture of suppliers can also impact the effectiveness of communication regarding quality expectations. Building strong relationships can facilitate better quality assurance practices.

In conclusion, B2B buyers seeking full exhaust systems for the Suzuki 250 Gixxer must consider the comprehensive manufacturing processes and rigorous quality assurance practices in place. By understanding these elements, buyers can make informed decisions that align with their quality expectations and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘full system for suzuki 250 gixxer’

In the competitive landscape of motorcycle accessories, sourcing a full exhaust system for the Suzuki 250 Gixxer requires a systematic approach. This guide provides a step-by-step checklist to help international B2B buyers navigate the procurement process effectively, ensuring that they select high-quality products that meet their business needs.

Step 1: Define Your Technical Specifications

Before initiating your search, clearly outline the technical specifications required for the full exhaust system. This includes understanding the specific model compatibility (e.g., Gixxer 250/SF250), material preferences (stainless steel, titanium), and performance metrics such as weight reduction and noise levels. Defining these parameters upfront helps in narrowing down your options and ensures that you only consider products that meet your operational standards.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in motorcycle exhaust systems. Utilize online platforms, trade directories, and industry networks to compile a list of manufacturers and distributors. Pay attention to their reputation in the market, product range, and geographic reach, especially in regions like Africa, South America, the Middle East, and Europe, where demand may vary.

Step 3: Verify Supplier Certifications

It’s essential to ensure that your chosen suppliers comply with relevant industry standards and certifications. Look for certifications such as JMCA (Japanese Motorcycle Certification Association) for exhaust systems, which indicates adherence to noise and emission regulations. Additionally, verify any international quality certifications, such as ISO 9001, to ensure the supplier’s commitment to quality management.

Step 4: Request Product Samples

Before making a bulk purchase, request samples of the exhaust systems. This allows you to assess the product’s build quality, fitment compatibility, and overall performance. Evaluate the samples against your defined specifications, paying close attention to weight, noise levels, and material quality. This step is crucial to avoid future discrepancies and ensure customer satisfaction.

Step 5: Assess Pricing and Payment Terms

Once you have shortlisted potential suppliers, compare their pricing structures and payment terms. Ensure that the pricing aligns with your budget while also reflecting the product’s quality and features. Negotiate payment terms that suit your cash flow needs, such as deferred payments or bulk purchase discounts, to optimize your procurement strategy.

Step 6: Review Warranty and Support Services

Evaluate the warranty and after-sales support offered by the suppliers. A robust warranty indicates the manufacturer’s confidence in their product, while reliable customer support can significantly ease any post-purchase issues. Ensure that the warranty covers key components and that the supplier provides accessible channels for technical assistance.

Step 7: Finalize Logistics and Shipping Arrangements

Once you have selected a supplier, finalize the logistics and shipping arrangements. Discuss lead times, shipping methods, and costs to ensure timely delivery. Also, consider potential import duties and regulations in your region to avoid unforeseen expenses. Establishing clear communication with the supplier regarding these aspects will facilitate a smoother procurement process.

Illustrative image related to full system for suzuki 250 gixxer

By following this checklist, B2B buyers can streamline their sourcing efforts for a full exhaust system for the Suzuki 250 Gixxer, ensuring they make informed decisions that align with their business objectives and customer expectations.

Comprehensive Cost and Pricing Analysis for full system for suzuki 250 gixxer Sourcing

What are the Key Cost Components for Sourcing a Full Exhaust System for the Suzuki 250 Gixxer?

When considering the sourcing of a full exhaust system for the Suzuki 250 Gixxer, it’s essential to break down the cost structure. The primary components include:

-

Materials: The choice of materials significantly impacts the cost. Stainless steel is commonly used for its durability and resistance to corrosion. Variants like titanium or carbon fiber can increase costs but also enhance performance and aesthetics.

-

Labor: Labor costs can vary depending on the manufacturing location. Regions with lower labor costs may provide a more economical solution, but this can sometimes compromise quality.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and equipment depreciation. A manufacturer with efficient processes may offer lower overhead, reflecting in their pricing.

-

Tooling: Initial tooling costs for custom parts can be substantial. If the exhaust system requires specialized molds or machinery, these costs should be factored into the overall price.

-

Quality Control (QC): Implementing rigorous QC processes ensures that products meet required standards, which can add to the costs. However, it is crucial for maintaining quality, especially for international markets.

-

Logistics: Shipping costs can vary widely based on the origin of the product, the destination, and the chosen shipping method. Understanding Incoterms can help buyers manage these costs effectively.

-

Margin: Suppliers typically add a markup to cover their costs and profit margins. This can vary based on market demand and competition.

How Do Price Influencers Affect the Cost of Full Exhaust Systems for the Suzuki 250 Gixxer?

Several factors influence the pricing of exhaust systems, particularly in international markets:

-

Volume/MOQ: Bulk purchasing often leads to discounts. Understanding the Minimum Order Quantity (MOQ) can help buyers negotiate better prices.

-

Specifications and Customization: Custom designs or specifications can increase costs. It’s essential to balance the need for customization with budget constraints.

-

Materials Quality and Certifications: Higher-quality materials and certifications can raise the price but may be necessary for compliance with local regulations, particularly in regions with stringent emission standards.

-

Supplier Reputation: Established suppliers may charge more due to their proven track record and reliability. However, they often provide better support and quality assurance.

-

Incoterms: These terms dictate the responsibilities of buyers and sellers in shipping arrangements. Understanding them can help avoid unexpected costs related to tariffs and customs.

What Are Essential Buyer Tips for Cost-Efficient Sourcing of Exhaust Systems?

International B2B buyers should consider the following strategies to ensure cost-effective sourcing:

-

Negotiate Effectively: Always approach negotiations with a clear understanding of the market prices and your budget. Being informed about competitor pricing can strengthen your position.

-

Focus on Total Cost of Ownership (TCO): Beyond the initial purchase price, consider long-term costs such as maintenance, durability, and performance. A slightly higher upfront cost may lead to savings in the long run.

-

Understand Pricing Nuances: Different regions may have varying pricing structures based on local market dynamics. For example, buyers in Africa or South America may face different tariffs or shipping costs compared to those in Europe.

-

Evaluate Supplier Options: Don’t settle for the first supplier. Explore multiple options to compare pricing, quality, and service levels. Request samples when possible to assess quality before making bulk purchases.

Conclusion

Sourcing a full exhaust system for the Suzuki 250 Gixxer involves navigating a complex landscape of costs and pricing influences. By understanding the key cost components, recognizing price influencers, and applying effective buyer strategies, international B2B buyers can make informed decisions that align with their budgetary and operational needs. Always remember to conduct thorough research and maintain open lines of communication with suppliers to achieve the best possible outcomes.

Illustrative image related to full system for suzuki 250 gixxer

Alternatives Analysis: Comparing full system for suzuki 250 gixxer With Other Solutions

Introduction to Alternatives for Full System Exhaust Solutions

When considering exhaust systems for the Suzuki 250 Gixxer, buyers often explore various alternatives that can deliver comparable performance, sound, and compliance with local regulations. These alternatives can include different exhaust designs or systems specifically engineered for similar models. Understanding the strengths and weaknesses of these alternatives is crucial for making informed purchasing decisions that align with specific operational needs.

Comparison Table

| Comparison Aspect | Full System For Suzuki 250 Gixxer | Alternative 1: Slip-On Exhaust | Alternative 2: OEM Replacement |

|---|---|---|---|

| Performance | Increased power and torque across RPM range; noise levels around 94dB | Moderate power increase; generally quieter than full systems | Standard performance; compliant with original specs |

| Cost | Higher initial investment (approx. $500-$700) | Lower cost (approx. $200-$400) | Cost-effective (approx. $150-$300) |

| Ease of Implementation | Requires professional installation; may need tuning | Easier to install; often a direct fit | Direct replacement; minimal installation effort |

| Maintenance | Low maintenance; durable materials | Moderate maintenance; may require more frequent checks | Low maintenance; OEM reliability |

| Best Use Case | Optimal for performance enthusiasts and competitive riders | Ideal for casual riders seeking improved sound | Suitable for budget-conscious buyers needing OEM compliance |

Detailed Breakdown of Alternatives

Alternative 1: Slip-On Exhaust

Slip-on exhaust systems are a popular choice for riders looking to enhance sound and performance without the complexity of a full system installation. While they provide a moderate power increase, they generally do not match the performance gains of a full system. The cost is significantly lower, making it an attractive option for casual riders. However, slip-ons may require more maintenance over time to ensure optimal performance and sound quality.

Alternative 2: OEM Replacement

OEM replacement exhausts are designed to restore the original performance and sound levels of the Suzuki 250 Gixxer. This option is cost-effective and easy to install, making it ideal for budget-conscious buyers. However, while they offer reliability and compliance with local regulations, they do not enhance performance compared to aftermarket solutions. Therefore, this alternative is best for riders prioritizing warranty and reliability over performance upgrades.

Conclusion: Choosing the Right Exhaust Solution

For B2B buyers in the market for an exhaust system for the Suzuki 250 Gixxer, the decision ultimately hinges on specific performance needs, budget constraints, and installation capabilities. If performance enhancement and sound are top priorities, investing in a full system like the Yoshimura offerings may be the best choice. On the other hand, slip-on systems offer a balance of performance and cost, while OEM replacements provide peace of mind and compliance for those who prioritize reliability. By assessing these factors, buyers can select the solution that best fits their operational requirements and market expectations.

Essential Technical Properties and Trade Terminology for full system for suzuki 250 gixxer

What Are the Key Technical Properties of Full Exhaust Systems for the Suzuki 250 Gixxer?

When evaluating full exhaust systems for the Suzuki 250 Gixxer, understanding key technical properties is essential for making informed B2B purchasing decisions. Here are some critical specifications to consider:

-

Material Composition

The most common materials used in full exhaust systems include stainless steel and titanium. Stainless steel offers durability and corrosion resistance, while titanium is lighter and enhances performance by reducing overall weight. A full system made from high-grade materials ensures longevity and better performance, which is crucial for B2B buyers looking to minimize replacement costs and maximize customer satisfaction. -

Weight Reduction

A significant advantage of aftermarket exhaust systems is their reduced weight compared to OEM systems. For example, the Yoshimura R-77S weighs approximately 3.7 kg, compared to the OEM weight of 6.8 kg. This reduction not only improves handling and performance but also appeals to customers seeking enhanced riding experiences. Understanding weight specifications helps businesses market these products effectively. -

Noise Levels (Decibel Ratings)

Exhaust systems are often rated for noise output, measured in decibels (dB). For instance, the R-77S system has a noise level of 94 dB at 4,650 rpm. B2B buyers must be aware of local regulations regarding noise emissions to ensure compliance, especially in markets with strict noise control laws. Providing clear noise level specifications can also help in building trust with end consumers. -

Power and Torque Enhancements

Aftermarket systems are designed to optimize engine performance, particularly in the mid to high RPM range. Products like the Yoshimura GP-MAGNUM105 significantly boost horsepower and torque, which is a key selling point for performance-focused customers. Buyers should evaluate the performance gains to align product offerings with market demands. -

Certification and Compliance

Many exhaust systems, such as those from Yoshimura, are JMCA certified, indicating compliance with Japanese vehicle regulations for emissions and noise. This certification can add value to the product by assuring customers of its quality and legality in various markets. Understanding the importance of compliance can help B2B buyers navigate regulatory landscapes more effectively.

What Are Common Trade Terms Relevant to Full Exhaust Systems for the Suzuki 250 Gixxer?

In the B2B landscape, familiarity with industry jargon can facilitate smoother transactions and better negotiations. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

This term refers to the original manufacturer of the vehicle’s components, such as the exhaust system. B2B buyers often compare OEM parts with aftermarket options to assess quality and performance differences. Understanding OEM relevance helps buyers make informed decisions regarding product sourcing. -

MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell. This term is crucial for B2B transactions, as it impacts inventory management and purchasing strategies. Buyers should negotiate MOQs that align with their market demands to optimize cash flow. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products. B2B buyers use RFQs to compare offers and negotiate better deals. Familiarity with this term allows buyers to streamline procurement processes. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in shipping goods. Understanding these terms is vital for B2B transactions, as they clarify shipping costs, risk, and insurance responsibilities. This knowledge can prevent misunderstandings and enhance supply chain efficiency. -

Lead Time

Lead time is the amount of time it takes from placing an order to receiving the goods. For B2B buyers, understanding lead times is essential for inventory planning and customer satisfaction. Longer lead times may necessitate adjustments in purchasing strategies to ensure product availability. -

Warranty

Warranties are assurances provided by manufacturers regarding the product’s performance and longevity. A two-year warranty on an exhaust system, for example, can significantly enhance its appeal to buyers. Familiarity with warranty terms helps buyers assess risk and product reliability.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing full exhaust systems for the Suzuki 250 Gixxer, ultimately leading to better product offerings and improved customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the full system for suzuki 250 gixxer Sector

Market Overview & Key Trends

The global market for performance exhaust systems, particularly for models like the Suzuki 250 Gixxer, is witnessing significant growth driven by several factors. First, increasing consumer demand for enhanced motorcycle performance and aesthetics is pushing manufacturers to innovate with lightweight and high-efficiency exhaust systems. In regions such as Africa and South America, where the motorcycle market is booming due to urbanization and rising disposable incomes, the demand for aftermarket performance parts is particularly strong.

Emerging trends in B2B sourcing include the adoption of advanced manufacturing technologies, such as 3D printing and CNC machining, which allow for more precise and customizable exhaust solutions. Additionally, the rise of e-commerce platforms has made it easier for international buyers to source products directly from manufacturers, reducing lead times and costs.

Another key dynamic is the emphasis on compliance with environmental regulations. Many countries are tightening emission standards, prompting manufacturers to develop exhaust systems that not only enhance performance but also meet stringent noise and emission requirements. For instance, products like the Yoshimura R-77S and GP-MAGNUM105 are JMCA certified, ensuring they meet these necessary standards, which is a significant selling point for B2B buyers focused on compliance.

Illustrative image related to full system for suzuki 250 gixxer

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming an essential consideration in the procurement of motorcycle parts, including exhaust systems for the Suzuki 250 Gixxer. The environmental impact of manufacturing processes, such as the carbon footprint associated with metal extraction and processing, is under scrutiny. Ethical sourcing practices are gaining traction among international buyers who prioritize suppliers committed to reducing their environmental impact.

Key aspects of sustainable sourcing include the use of recyclable materials, such as stainless steel and titanium, which are prevalent in high-performance exhaust systems. Additionally, certifications such as ISO 14001 for environmental management systems can serve as indicators of a manufacturer’s commitment to sustainability.

Moreover, transparency in supply chains is crucial. Buyers should seek suppliers who can provide clear documentation of their sourcing practices, ensuring that materials are obtained responsibly and ethically. As global awareness of environmental issues grows, B2B buyers who prioritize sustainability will likely gain a competitive advantage in their markets.

Illustrative image related to full system for suzuki 250 gixxer

Brief Evolution/History

The evolution of motorcycle exhaust systems has been closely tied to advancements in engineering and technology. Early exhaust systems were primarily designed for functionality, focusing on noise reduction and basic emission control. However, as motorcycle culture evolved and performance became a key selling point, manufacturers began to innovate with designs that not only improved performance but also enhanced the visual appeal of motorcycles.

The introduction of performance brands like Yoshimura has marked a significant shift in the market, emphasizing the integration of high-quality materials and cutting-edge designs. Products specifically engineered for models like the Suzuki 250 Gixxer now combine aesthetics with functionality, offering lighter weights and better exhaust flow. This evolution reflects a broader trend in the motorcycle industry towards personalization and performance enhancement, catering to a new generation of riders seeking both style and substance in their machines.

Frequently Asked Questions (FAQs) for B2B Buyers of full system for suzuki 250 gixxer

-

How do I choose the right full exhaust system for my Suzuki Gixxer 250?

Selecting the right exhaust system involves considering factors such as compatibility with your specific model year, desired sound level, and performance enhancements. Look for systems that offer emissions compliance, such as JMCA certification, to meet local regulations. Evaluate weight reduction benefits, as lighter systems can improve handling and performance. Brands like Yoshimura provide various options, including different finishes and materials, allowing you to align aesthetics with functionality. -

What are the advantages of upgrading to a full exhaust system?

Upgrading to a full exhaust system, such as those offered for the Suzuki Gixxer 250, can significantly enhance your motorcycle’s performance. Benefits include increased horsepower and torque, improved throttle response, and a more aggressive sound profile. Additionally, a lighter exhaust system reduces overall bike weight, contributing to better handling. Ensure that the system is designed specifically for your model to maximize these advantages. -

What are the typical lead times for full exhaust system orders?

Lead times can vary based on supplier location, manufacturing capacity, and shipping logistics. Generally, expect 2-4 weeks for standard orders, while custom requests may take longer. It’s advisable to confirm timelines with your supplier, especially if you have specific deadlines or events. Understanding potential delays in international shipping can also help in planning your procurement strategy effectively. -

What is the minimum order quantity (MOQ) for full exhaust systems?

MOQs vary by manufacturer and distributor, typically ranging from 5 to 50 units for B2B transactions. Some suppliers may offer flexibility on MOQs for established relationships or bulk orders. Always discuss your requirements upfront to ensure they can accommodate your needs. Consider negotiating terms if you anticipate future orders, which may provide leverage for lower MOQs. -

How can I ensure the quality of the exhaust systems I am sourcing?

To ensure quality, request certifications such as ISO or specific product standards like JMCA for exhaust systems. Conduct background checks on suppliers to assess their production capabilities and reputation. Sample orders can also be a prudent way to evaluate product quality before committing to larger purchases. Additionally, consider suppliers that offer warranties or guarantees, as these can be indicators of confidence in their product quality. -

What payment terms should I expect when sourcing exhaust systems internationally?

Payment terms can vary widely among suppliers. Common arrangements include upfront payments, partial payments upon order confirmation, or net terms (e.g., 30 or 60 days) after delivery. Always clarify payment methods accepted (e.g., wire transfer, credit card) and any associated fees. Discussing payment terms early in the negotiation process can help establish a mutually beneficial agreement. -

What logistics considerations should I keep in mind when importing exhaust systems?

When importing, consider shipping methods, customs duties, and any import restrictions specific to your country. Ensure that your supplier provides accurate shipping documentation to avoid delays at customs. Partnering with a reliable freight forwarder can facilitate smoother logistics and help navigate the complexities of international shipping. Also, factor in lead times for customs clearance when planning your inventory. -

Can I customize the exhaust system to fit specific performance needs?

Many manufacturers offer customization options for their exhaust systems, allowing you to tailor aspects such as sound level, material, and finish. Discuss your specific performance goals with the supplier, as they may provide recommendations based on their expertise. Customization could involve adjusting pipe diameters or incorporating specific tuning features to enhance power delivery according to your preferences.

Top 2 Full System For Suzuki 250 Gixxer Manufacturers & Suppliers List

1. AVDB – Full Exhaust System for Suzuki SF250 Gixxer

Domain: avdb-moto.fr

Registered: 2013 (12 years)

Introduction: Full exhaust system for Suzuki SF250 Gixxer (2019-2024)

2. Suzuki – 3P System Gixxer SF 250

Domain: shad.es

Introduction: {“product_name”: “3P SYSTEM SUZUKI GIXXER SF 250”, “price”: “899.000 Rp”, “sku”: “S0GX22IIF”, “description”: “Fitting to mount SHAD side cases on the motorcycle.”, “compatibility”: {“not_compatible_with”: [“TR40”, “TR30”, “TR36”, “TR47”]}, “compatible_motorcycle_models”: [{“brand”: “SUZUKI”, “model”: “GIXXER SF 250”, “years”: [2021, 2022, 2023, 2024, 2025]}], “features”: [“Integrated design: bette…

Strategic Sourcing Conclusion and Outlook for full system for suzuki 250 gixxer

In the competitive landscape of motorcycle performance upgrades, strategic sourcing for full systems specifically tailored for the Suzuki 250 Gixxer presents a significant opportunity for international B2B buyers. Notably, products like the Yoshimura R-77S and GP-MAGNUM105 exhaust systems exemplify the kind of high-quality, lightweight solutions that enhance both performance and compliance with regulatory standards. The reduction in weight, coupled with increased power output, not only improves rider experience but also aligns with growing consumer demands for efficiency and performance.

For buyers in regions such as Africa, South America, the Middle East, and Europe, the ability to source these innovative exhaust systems can provide a competitive edge in the market. Establishing partnerships with reputable manufacturers ensures access to premium products that meet both local and international standards.

As the demand for performance enhancements continues to rise, now is the time to capitalize on these trends. Engage with suppliers, explore the latest offerings, and integrate these cutting-edge exhaust systems into your product line to meet the evolving needs of your customers. The future of motorcycle performance is bright—embrace it and drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.