Everything You Need to Know About Frosted Green Glass Dropper Bottle Sourcing in 2025

Introduction: Navigating the Global Market for frosted green glass dropper bottle

In the competitive landscape of packaging solutions, sourcing high-quality frosted green glass dropper bottles presents a unique challenge for international B2B buyers. These bottles not only offer an aesthetically pleasing option for product presentation but also provide functional benefits, such as UV protection and precise dispensing. As industries ranging from pharmaceuticals to cosmetics increasingly turn to glass packaging for its sustainability and preservation qualities, understanding the nuances of this market becomes essential.

This comprehensive guide is designed to equip buyers with the knowledge they need to navigate the complexities of sourcing frosted green glass dropper bottles. We will explore various types of bottles available, their applications across different sectors, and key factors to consider when vetting suppliers. Additionally, we will delve into pricing structures and bulk purchasing options, ensuring that you can make informed decisions that align with your business objectives.

Whether you are based in Africa, South America, the Middle East, or Europe—regions where the demand for premium packaging is rising—this guide aims to empower you to choose the right frosted green glass dropper bottles that meet your product requirements. By leveraging the insights provided, you can enhance your packaging strategy, improve your product’s marketability, and ultimately drive business growth.

Understanding frosted green glass dropper bottle Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Frosted Green Dropper | Classic design with a frosted finish; available in various sizes (0.5 oz to 4 oz) | Essential oils, tinctures, and herbal extracts | Pros: UV protection, aesthetic appeal. Cons: Limited to standard closures. |

| Euro Round Frosted Green Bottle | Euro round shape with an 18-DIN neck finish; compatible with various closures | Pharmaceuticals, cosmetics, and oils | Pros: Versatile closure options, high chemical resistance. Cons: Higher cost per unit. |

| Child-Resistant Frosted Green Dropper | Designed with safety features to prevent accidental opening; tamper-evident | Pharmaceuticals, child-safe products | Pros: Enhanced safety, ideal for sensitive markets. Cons: May be less convenient for adult users. |

| Graduated Frosted Green Dropper | Features graduated markings for precise dosing; includes a patented drip trap | Nutraceuticals and liquid medications | Pros: Accurate dosing, minimizes waste. Cons: More complex design may increase costs. |

| Customizable Frosted Green Bottle | Options for personalized branding and closures; available in bulk | Retail packaging for various products | Pros: Tailored branding, flexibility in order sizes. Cons: Longer lead times for customization. |

What are the Characteristics and Suitability of Standard Frosted Green Droppers?

Standard frosted green dropper bottles are characterized by their classic design and frosted finish, which not only provides aesthetic appeal but also offers UV protection for sensitive contents. Available in multiple sizes ranging from 0.5 oz to 4 oz, these bottles are widely used for packaging essential oils, tinctures, and herbal extracts. B2B buyers should consider their compatibility with standard closures and the potential for bulk ordering, which can offer cost savings for businesses looking to streamline packaging solutions.

How Does the Euro Round Frosted Green Bottle Stand Out in the Market?

The Euro round frosted green bottle features a unique shape and an 18-DIN neck finish, making it compatible with a variety of closures, including tamper-evident and child-resistant options. This versatility makes it suitable for pharmaceuticals, cosmetics, and oils. B2B buyers should evaluate the bottle’s high chemical resistance and the suitability of different closure types for their specific applications, as this can enhance product safety and integrity.

What Benefits Does the Child-Resistant Frosted Green Dropper Offer?

Designed with safety in mind, child-resistant frosted green droppers feature mechanisms that prevent accidental opening, making them ideal for pharmaceutical and child-safe products. These bottles often come with tamper-evident seals to enhance security. For B2B buyers, the added safety features can be a significant selling point, particularly in markets where product safety is paramount. However, the complexity of the design may pose usability challenges for adult consumers.

Why Choose Graduated Frosted Green Droppers for Nutraceuticals?

Graduated frosted green droppers are equipped with precise measurement markings, allowing for accurate dosing of liquids. This feature is particularly valuable in the nutraceutical and liquid medication sectors, where dosage precision is critical. B2B buyers should assess the potential for reduced waste and increased customer satisfaction that comes with accurate dosing. However, the complexity of these designs can lead to higher production costs.

What Are the Advantages of Customizable Frosted Green Bottles?

Customizable frosted green bottles allow businesses to incorporate their branding and select closures that best fit their products. This flexibility is especially advantageous for retail packaging, where brand identity plays a crucial role in consumer choice. B2B buyers should weigh the benefits of tailored branding against the longer lead times and potential costs associated with customization. The ability to order in bulk can also help mitigate expenses for businesses looking to enhance their market presence.

Key Industrial Applications of frosted green glass dropper bottle

| Industry/Sector | Specific Application of frosted green glass dropper bottle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pharmaceuticals | Packaging for liquid medications and serums | Provides precise dosing and protects sensitive contents | Compliance with health regulations and quality standards |

| Cosmetics and Skincare | Storage for essential oils and serums | Enhances product appeal while maintaining efficacy | Compatibility with various closures and dropper designs |

| Food and Beverage | Packaging for flavor extracts and oils | Preserves freshness and prevents contamination | Sourcing for food-grade materials and certifications |

| Herbal Remedies | Bottling for tinctures and herbal extracts | Ensures product integrity and accurate dispensing | Need for UV protection and airtight seals |

| Aromatherapy | Storage for aromatherapy oils and blends | Maintains aroma quality and offers user-friendly application | Availability of graduated droppers for precise dosing |

How is the Frosted Green Glass Dropper Bottle Used in Pharmaceuticals?

In the pharmaceutical industry, frosted green glass dropper bottles are utilized for packaging liquid medications and serums. The frosted finish not only enhances the aesthetic appeal but also provides a barrier against UV light, which can degrade sensitive formulations. These bottles are designed for precise dosing, ensuring that healthcare providers can dispense the exact amount of medication needed. International buyers must ensure compliance with local health regulations and quality standards, which may vary across regions, particularly in Africa and the Middle East.

What Role Does the Frosted Green Glass Dropper Bottle Play in Cosmetics and Skincare?

Frosted green glass dropper bottles serve as an elegant and functional solution for storing essential oils, serums, and other cosmetic products. The frosted texture adds a premium look, appealing to consumers in the cosmetics market. These bottles not only protect the integrity of the products from light exposure but also facilitate easy dispensing, which is crucial for user experience. Buyers should consider compatibility with various closure types and droppers to ensure a seamless packaging solution for their brands in South America and Europe.

How is the Frosted Green Glass Dropper Bottle Applied in Food and Beverage?

In the food and beverage sector, frosted green glass dropper bottles are ideal for packaging flavor extracts and oils. The glass material preserves the freshness of sensitive contents, while the dropper mechanism allows for precise control over dispensing, minimizing waste and ensuring consistency in flavoring. Buyers in this sector must prioritize food-grade certifications and compliance with health regulations to meet consumer safety standards, particularly in emerging markets across Africa and Latin America.

What Benefits Does the Frosted Green Glass Dropper Bottle Offer for Herbal Remedies?

Frosted green glass dropper bottles are widely used for bottling tinctures and herbal extracts. Their design ensures product integrity by providing an airtight seal, which is essential for maintaining the potency of herbal formulations. Additionally, the dropper feature allows for accurate dosing, which is vital for both manufacturers and consumers. Buyers must consider the need for UV protection and the availability of airtight seals when sourcing these bottles, especially in regions with varying climate conditions.

How Does the Frosted Green Glass Dropper Bottle Enhance Aromatherapy Products?

In the aromatherapy industry, frosted green glass dropper bottles are perfect for storing essential oils and blends. The frosted finish not only provides a stylish look but also helps protect the oils from light, preserving their aromatic qualities. The dropper design allows users to easily dispense the oils, enhancing the overall user experience. Buyers should focus on sourcing options that include graduated droppers for precise dosing, ensuring that their products meet the needs of consumers in diverse markets, including those in Europe and the Middle East.

3 Common User Pain Points for ‘frosted green glass dropper bottle’ & Their Solutions

Scenario 1: Difficulty in Ensuring Product Integrity During Shipping

The Problem: For B2B buyers sourcing frosted green glass dropper bottles, one of the most pressing challenges is ensuring that the bottles arrive intact and free from damage. Fragility is inherent in glass products, and the risks of breakage during transportation are heightened, especially for international shipments where handling practices can vary significantly. This can lead to costly delays, increased shipping expenses, and potentially losing customer trust if the products cannot be delivered as expected.

The Solution: To mitigate these risks, buyers should prioritize suppliers that offer robust packaging solutions specifically designed for glass items. This includes using reinforced cartons, protective padding, and dividers to minimize movement during transit. Additionally, opting for suppliers that provide insurance for high-value shipments can safeguard against financial loss due to damage. Buyers should also consider ordering samples to evaluate the supplier’s packaging quality and ensure it meets their standards. Establishing strong relationships with logistics partners who understand the unique handling requirements of glass products can further enhance the reliability of shipments.

Scenario 2: Inconsistent Quality Across Different Suppliers

The Problem: A common issue faced by B2B buyers is the inconsistency in quality when sourcing frosted green glass dropper bottles from various suppliers. Differences in manufacturing processes, glass thickness, and dropper quality can lead to discrepancies that affect the end product’s performance and customer satisfaction. This inconsistency can pose significant challenges for businesses that rely on these bottles for high-end products, such as essential oils or pharmaceuticals, where quality is paramount.

The Solution: To address this, buyers should implement a stringent vetting process for suppliers. This includes requesting detailed product specifications and quality assurance certifications to ensure compliance with industry standards. Establishing clear communication channels to discuss quality expectations and conducting regular audits of the suppliers’ production facilities can help maintain consistent quality. Additionally, forming partnerships with a select few reliable suppliers rather than spreading orders across many can streamline quality control and ensure uniformity in product offerings.

Scenario 3: Navigating Regulatory Compliance for Different Markets

The Problem: B2B buyers often struggle with understanding and complying with various regulatory requirements when importing frosted green glass dropper bottles into different markets. Each region, such as Africa, Europe, and South America, has its own set of regulations concerning packaging materials, labeling, and safety standards. Navigating these complexities can lead to compliance issues, fines, or even product recalls, which can be detrimental to business operations.

The Solution: To effectively navigate regulatory compliance, buyers should invest in research and seek expert advice on the specific regulations governing their target markets. Collaborating with a compliance consultant who specializes in packaging regulations can provide valuable insights into the legal requirements for each region. Additionally, suppliers that offer documentation and certifications proving their products meet international standards can simplify the compliance process. Implementing an internal checklist to track compliance requirements during the sourcing process can also help ensure that all necessary regulations are met before importing the products. Regular training for procurement teams on regional regulations can further enhance the company’s ability to stay compliant and mitigate risks.

Strategic Material Selection Guide for frosted green glass dropper bottle

When selecting materials for frosted green glass dropper bottles, it’s essential to consider various factors that affect performance, durability, and compliance with international standards. Below is an analysis of common materials used in the manufacturing of these bottles, focusing on their properties, advantages, disadvantages, and implications for international buyers.

What are the Key Properties of Frosted Green Glass?

Frosted Green Glass

Frosted green glass is the primary material for these dropper bottles. It offers a unique aesthetic while providing essential functionality. The key properties include:

- Temperature Resistance: Frosted glass can withstand high temperatures, making it suitable for various applications, including essential oils and tinctures that may require heat during processing.

- Chemical Resistance: This glass type is highly resistant to a wide range of chemicals, ensuring that the contents remain uncontaminated.

- UV Protection: The green tint provides some level of UV protection, which is crucial for preserving sensitive formulations.

Pros and Cons

– Advantages: The frosted finish not only enhances the visual appeal but also provides a non-slip surface, making it user-friendly. Additionally, its chemical resistance ensures longevity and product integrity.

– Disadvantages: The manufacturing process can be complex and more costly than plastic alternatives. Frosted glass is also heavier, which may increase shipping costs.

Impact on Application

Frosted green glass is particularly suitable for storing essential oils, herbal extracts, and pharmaceuticals. Its chemical resistance ensures that it can safely house various media without risk of leaching or degradation.

Considerations for International Buyers

International buyers should be aware of compliance with standards such as ASTM and DIN, which may vary by region. In markets like Africa and South America, where regulations may differ, ensuring that the glass meets local safety and quality standards is crucial.

How Does Plastic Compare for Dropper Bottles?

Plastic (PET or HDPE)

Plastic options like PET (Polyethylene Terephthalate) or HDPE (High-Density Polyethylene) are often considered alternatives for dropper bottles.

- Temperature Resistance: While PET can handle moderate temperatures, HDPE is more versatile but may not withstand high heat as well as glass.

- Chemical Resistance: PET offers good chemical resistance, but it may not be suitable for all essential oils or solvents.

Pros and Cons

– Advantages: Plastic is lightweight, cost-effective, and less prone to breakage, making it ideal for high-volume shipping and handling.

– Disadvantages: Plastics can leach chemicals over time, especially when exposed to heat or sunlight, and they lack the premium feel of glass.

Impact on Application

Plastic dropper bottles are suitable for less sensitive products but may not be ideal for high-value essential oils or pharmaceuticals.

Considerations for International Buyers

Buyers should ensure that the plastic materials comply with food safety and chemical standards in their respective countries. In regions with stringent regulations, such as Europe, adherence to EU directives is mandatory.

What Role Does Closure Material Play in Dropper Bottle Functionality?

Rubber or Silicone for Droppers

The material used for droppers, typically rubber or silicone, is critical for functionality.

- Temperature Resistance: Both materials can handle a range of temperatures, but rubber may degrade faster under extreme conditions.

- Chemical Resistance: Silicone generally offers superior chemical resistance compared to rubber.

Pros and Cons

– Advantages: Silicone droppers provide a better seal and are less prone to leaking, ensuring accurate dispensing.

– Disadvantages: Silicone can be more expensive than rubber and may not be as readily available in all markets.

Impact on Application

The choice of dropper material can significantly affect the dispensing of sensitive liquids, making it crucial for pharmaceuticals and essential oils.

Considerations for International Buyers

Buyers should verify that the closure materials meet relevant safety standards, particularly in regions where consumer safety is a priority.

Summary Table of Material Selection for Frosted Green Glass Dropper Bottles

| Material | Typical Use Case for frosted green glass dropper bottle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Frosted Green Glass | Essential oils, tinctures, pharmaceuticals | High chemical resistance and UV protection | Higher manufacturing complexity and cost | High |

| Plastic (PET/HDPE) | Non-sensitive liquids, bulk products | Lightweight and cost-effective | Potential chemical leaching | Medium |

| Rubber/Silicone Droppers | Pharmaceuticals, essential oils | Superior sealing and leak prevention | Higher cost and availability issues | Medium |

This strategic material selection guide provides a comprehensive overview for B2B buyers, helping them make informed decisions tailored to their specific needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for frosted green glass dropper bottle

What Are the Main Stages in the Manufacturing Process of Frosted Green Glass Dropper Bottles?

The manufacturing of frosted green glass dropper bottles involves several key stages, ensuring that the final product meets industry standards and customer expectations.

Material Preparation: Selecting Quality Raw Materials

The process begins with the selection of high-quality raw materials, primarily silica sand, soda ash, and limestone. For frosted glass, additional materials like fluorides may be included to achieve the desired texture and appearance. The raw materials are carefully weighed and mixed to ensure uniformity in composition, which is crucial for the strength and clarity of the glass.

Forming: Shaping the Glass Bottles

Once the materials are prepared, they are melted in a furnace at temperatures exceeding 1,400 degrees Celsius. The molten glass is then shaped into bottles using various forming techniques, such as blow molding or press molding. In blow molding, air is introduced into the molten glass to expand it into the desired bottle shape. This stage is critical as it determines the bottle’s design, including its neck finish, which is essential for compatibility with droppers and closures.

Assembly: Integrating Functional Components

After forming, the bottles undergo assembly, which includes fitting them with dropper closures. The closures are designed to ensure precise dispensing of liquids, making them ideal for pharmaceuticals and essential oils. During this stage, manufacturers may also incorporate features such as tamper-evident seals or child-resistant caps, depending on the intended use of the bottles.

Finishing: Achieving the Frosted Effect

The finishing stage involves the application of the frosted texture, which not only enhances the aesthetic appeal but also provides a level of UV protection. This is achieved through sandblasting or acid etching processes, which create a matte finish on the glass surface. Quality checks are performed to ensure uniformity and adherence to specifications.

How Is Quality Assurance Implemented in the Production of Frosted Green Glass Dropper Bottles?

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that products meet both international and industry-specific standards.

What International Standards Are Relevant for Frosted Green Glass Dropper Bottles?

Manufacturers typically adhere to international standards such as ISO 9001, which outlines criteria for a quality management system. This standard ensures that organizations consistently provide products that meet customer and regulatory requirements. Additionally, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant for glass bottles used in pharmaceutical applications, ensuring they are safe and effective for their intended use.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials for quality and consistency before production begins. This step is crucial as it sets the foundation for the entire manufacturing process.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC is employed to monitor and verify that processes are being followed correctly. This includes checking the temperature of the furnace, monitoring the forming process, and ensuring that assembly operations meet specifications.

-

Final Quality Control (FQC): After the bottles are finished, they undergo FQC, where they are inspected for defects such as cracks, uneven frosted surfaces, and closure compatibility. This step is essential to ensure that only high-quality products are shipped to customers.

What Common Testing Methods Are Used in Quality Assurance?

Manufacturers employ various testing methods to verify the quality of frosted green glass dropper bottles, including:

- Visual Inspection: A thorough visual check to identify any surface defects or inconsistencies.

- Dimensional Testing: Ensuring that the bottles meet specified dimensions for compatibility with droppers and closures.

- Strength Testing: Assessing the mechanical strength of the glass to withstand handling and transportation.

- Chemical Resistance Testing: Verifying that the glass can safely store various liquids without degradation.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must ensure that their suppliers maintain rigorous quality control practices. Here are several strategies to verify supplier QC:

What Are the Best Practices for Supplier Audits?

Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing and quality assurance processes. During an audit, buyers can assess:

- Production Facilities: Inspecting the cleanliness and organization of the manufacturing environment.

- Quality Control Procedures: Reviewing documentation related to IQC, IPQC, and FQC processes.

- Employee Training: Ensuring that staff are well-trained in quality management practices.

How Can Buyers Request Quality Control Reports?

Buyers should not hesitate to request documentation that outlines the supplier’s quality control measures. This can include:

- Quality Assurance Manuals: Detailed descriptions of QA processes.

- Testing Certificates: Documentation of completed tests and their results.

- Compliance Certifications: Proof of adherence to international standards and industry-specific regulations.

What Role Do Third-Party Inspections Play in Ensuring Quality?

Engaging third-party inspection services can provide an additional layer of confidence in a supplier’s quality control processes. These independent organizations can conduct inspections at various stages of production and provide unbiased reports on compliance with quality standards.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must consider specific nuances in quality control:

-

Regulatory Compliance: Different countries may have unique regulations concerning packaging materials, especially for products intended for the pharmaceutical or cosmetic industries. Understanding these regulations is vital for ensuring compliance and avoiding costly penalties.

-

Cultural Considerations: Communication styles and business practices may vary significantly across regions. Establishing clear expectations regarding quality standards and QC processes can help bridge these cultural gaps.

-

Logistical Challenges: International shipping can introduce risks such as breakage or contamination. Buyers should discuss packaging and handling procedures with suppliers to ensure that products arrive safely.

By understanding the intricacies of the manufacturing processes and quality assurance protocols for frosted green glass dropper bottles, B2B buyers can make informed decisions, ensuring they select reliable suppliers that meet their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘frosted green glass dropper bottle’

Introduction

Sourcing frosted green glass dropper bottles requires a systematic approach to ensure that the product meets your specific needs while also aligning with quality standards and supplier reliability. This guide provides a step-by-step checklist to help B2B buyers navigate the procurement process efficiently, focusing on critical aspects such as specifications, supplier evaluation, and compliance.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is fundamental before engaging with suppliers. Consider the size (e.g., 30ml, 50ml), type of closure (e.g., tamper-evident, child-resistant), and design features (e.g., graduated pipette) that best suit your product line. This clarity will streamline communication and ensure that suppliers can meet your requirements accurately.

Step 2: Research and Shortlist Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in frosted green glass dropper bottles. Utilize industry directories, trade shows, and online marketplaces to gather a list of candidates. Focus on suppliers with a proven track record in your target regions, such as Africa or South America, as this can influence shipping times and costs.

Step 3: Evaluate Supplier Certifications

Before finalizing any agreements, verify that your selected suppliers hold relevant certifications. Look for ISO certifications, quality management systems, and compliance with international safety standards. These certifications not only reflect a commitment to quality but also mitigate risks associated with product recalls or safety issues.

Step 4: Request Samples for Quality Assessment

Obtaining samples is crucial for assessing the quality and suitability of the frosted green glass dropper bottles. Evaluate the samples for aspects such as glass thickness, clarity, and the functionality of the dropper mechanism. This hands-on evaluation allows you to verify that the product aligns with your brand’s standards and customer expectations.

Step 5: Discuss Pricing and Minimum Order Quantities

Engage suppliers in discussions regarding pricing structures and minimum order quantities (MOQs). It is essential to understand how volume discounts may apply and whether the MOQ fits your initial purchasing capacity. A transparent conversation about costs can help you budget effectively and identify potential savings.

Step 6: Review Delivery and Payment Terms

Ensure that you are clear on delivery timelines and payment terms before making any commitments. Discuss lead times for production and shipping, as delays can disrupt your supply chain. Additionally, inquire about payment options, including credit terms and any advance payment requirements to manage cash flow effectively.

Step 7: Establish a Long-Term Relationship

Consider the potential for a long-term partnership with your supplier. Building a solid relationship can lead to better pricing, priority service, and tailored support for your specific needs. Regular communication and feedback can enhance collaboration, making it easier to adapt to market changes or product updates in the future.

By following this checklist, B2B buyers can streamline their sourcing process for frosted green glass dropper bottles, ensuring that they select the right suppliers while maintaining quality and efficiency.

Comprehensive Cost and Pricing Analysis for frosted green glass dropper bottle Sourcing

When sourcing frosted green glass dropper bottles, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. This analysis will help you navigate the complexities of procurement and optimize your purchasing strategy.

What Are the Key Cost Components in Sourcing Frosted Green Glass Dropper Bottles?

-

Materials: The primary cost driver in the production of frosted green glass dropper bottles is the raw materials used, including high-quality glass and the components of the dropper assembly. The price of glass can fluctuate based on global supply and demand, impacting your overall costs.

-

Labor: Labor costs vary significantly by region. In countries with lower labor costs, such as Vietnam or Brazil, you may find more competitive pricing. However, skilled labor is required for quality assurance and ensuring precise manufacturing standards, which can elevate costs.

-

Manufacturing Overhead: This includes costs associated with utilities, maintenance, and facility management. Efficient manufacturing processes can help minimize these overheads, which is particularly relevant when considering suppliers in regions with varying operational efficiencies.

-

Tooling: If you’re opting for customized bottle designs or sizes, tooling costs can be substantial. These are one-time expenses associated with creating molds and machinery adjustments specific to your design needs.

-

Quality Control (QC): Ensuring that the bottles meet industry standards is crucial, especially for products intended for pharmaceuticals or cosmetics. QC costs should be factored into your total sourcing budget, as rigorous testing can prevent costly returns and reputation damage.

-

Logistics: Shipping costs can significantly affect the total cost of ownership. Factors such as distance, mode of transport, and customs duties need to be considered. Incoterms will determine who bears the cost and risk at different stages of the shipping process.

-

Margin: Suppliers will typically add a margin to cover their costs and profit. Understanding the competitive landscape can help you assess whether the margin is justified based on the quality and service offered.

What Factors Influence the Pricing of Frosted Green Glass Dropper Bottles?

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to discounts. Suppliers may have different pricing tiers based on MOQs, so negotiating for larger orders can yield significant savings.

-

Specifications and Customization: Custom features such as unique designs, colors, or closure types can increase costs. Determine which specifications are essential for your product to avoid unnecessary expenses.

-

Material Quality and Certifications: Higher-quality glass and certifications (e.g., ISO, FDA) can drive up costs but may be necessary for compliance in specific markets. Assess the certifications required for your target market before finalizing suppliers.

-

Supplier Factors: The reputation and reliability of suppliers play a crucial role in pricing. Established suppliers may charge a premium but can offer better quality assurance and customer service.

-

Incoterms: Understanding Incoterms is vital for pricing negotiations. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) determine who is responsible for shipping costs and risks, influencing your final pricing.

What Are Effective Buyer Tips for Negotiating Prices?

-

Negotiate Bulk Discounts: Always inquire about discounts for larger orders. Building a long-term relationship with suppliers can also lead to better pricing over time.

-

Evaluate Total Cost of Ownership (TCO): Beyond the unit price, consider all associated costs, including logistics, customs, and potential tariffs. This holistic view can reveal the true cost of sourcing.

-

Understand Pricing Nuances for International Markets: Be aware of the economic conditions and currency fluctuations in your target markets. This knowledge can be leveraged during negotiations to secure favorable terms.

-

Stay Informed About Market Trends: Regularly monitor market trends, such as changes in raw material prices or shifts in demand. This information can provide leverage in negotiations and help you make informed purchasing decisions.

Disclaimer

Prices and cost structures mentioned in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough market research and supplier evaluations to obtain the most accurate and current pricing information.

Alternatives Analysis: Comparing frosted green glass dropper bottle With Other Solutions

Exploring Alternatives to Frosted Green Glass Dropper Bottles

In the competitive world of packaging solutions, businesses often seek alternatives that provide similar functionality to frosted green glass dropper bottles. The right choice can significantly impact product integrity, aesthetics, and customer satisfaction. This section evaluates two viable alternatives: plastic dropper bottles and amber glass dropper bottles, focusing on their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Frosted Green Glass Dropper Bottle | Plastic Dropper Bottle | Amber Glass Dropper Bottle |

|---|---|---|---|

| Performance | Excellent chemical resistance; UV protection | Good for non-sensitive products; less durable | High UV protection; ideal for sensitive formulations |

| Cost | Moderate to high | Low to moderate | Moderate |

| Ease of Implementation | Requires careful handling | Easy to mold and produce | Requires careful handling |

| Maintenance | Requires careful cleaning; recyclable | Minimal maintenance; recyclable | Requires careful cleaning; recyclable |

| Best Use Case | Essential oils, serums, and tinctures | General liquid products | Pharmaceuticals and light-sensitive products |

Detailed Breakdown of Alternatives

Plastic Dropper Bottles

Plastic dropper bottles are a cost-effective alternative to frosted green glass. They are lightweight and shatterproof, making them ideal for shipping and handling. However, they typically lack the same level of chemical resistance and UV protection, which can affect the quality of sensitive products. While they are easy to produce and come in various sizes and colors, businesses must consider the environmental impact of plastic. For general liquid products that do not require stringent protection from light or air, plastic dropper bottles can be a practical choice.

Amber Glass Dropper Bottles

Amber glass dropper bottles are well-regarded for their ability to protect light-sensitive formulations, making them suitable for pharmaceuticals and essential oils. Like frosted green glass, they offer excellent chemical resistance and are recyclable. However, they are generally more fragile and require careful handling. The cost of amber glass is comparable to frosted green glass, making them a viable option for businesses looking to ensure product integrity while maintaining a professional appearance. Their distinct color adds a touch of sophistication, appealing to premium product lines.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a packaging solution, B2B buyers should carefully assess their product requirements and target market. Frosted green glass dropper bottles excel in protecting sensitive formulations and offering a premium look, making them ideal for high-end products. On the other hand, plastic dropper bottles present a budget-friendly option for less sensitive liquids, while amber glass bottles strike a balance between protection and aesthetics for pharmaceutical applications. By weighing the pros and cons of each alternative, businesses can make informed decisions that align with their operational needs and market expectations.

Essential Technical Properties and Trade Terminology for frosted green glass dropper bottle

What Are the Essential Technical Properties of Frosted Green Glass Dropper Bottles?

1. Material Composition

Frosted green glass dropper bottles are typically made from high-quality borosilicate glass, which offers superior chemical resistance and thermal stability. This material is essential for protecting sensitive contents like essential oils, tinctures, and pharmaceuticals from degradation. The frosted finish not only enhances aesthetic appeal but also provides additional UV protection, making it suitable for light-sensitive formulations.

2. Capacity and Size Options

These bottles come in various capacities, commonly ranging from 15ml to 120ml (0.5 oz to 4 oz). Selecting the appropriate size is critical for businesses targeting specific market segments, whether for retail or wholesale. Smaller sizes are ideal for high-end products or samples, while larger sizes cater to bulk users and commercial applications.

3. Neck Finish and Compatibility

The neck finish of frosted green glass dropper bottles typically conforms to standardized dimensions, such as 18-DIN or 20-DIN necks. This standardization ensures compatibility with various closures, including tamper-evident and child-resistant options. Understanding neck specifications is crucial for ensuring a secure seal that prevents leaks and contamination, which is vital in maintaining product integrity.

4. Dropper Assembly and Functionality

Most frosted green glass dropper bottles come with fitted dropper assemblies designed for precise dispensing. Features like the DripTrap patented bulb help eliminate leakage and ensure accurate dosing. This functionality is particularly important in sectors like pharmaceuticals and cosmetics, where dosage precision directly impacts efficacy and safety.

5. Tolerance Levels

Manufacturers maintain specific tolerance levels for glass thickness and overall dimensions. Typical tolerances might range from ±0.5mm to ±1mm. These specifications are vital for ensuring that bottles fit correctly with closures and maintain structural integrity during shipping and handling.

6. Surface Finish

The frosted surface not only provides a unique aesthetic but also enhances grip, reducing the likelihood of accidental drops. Additionally, the texture can serve as a branding opportunity, allowing for silk-screen printing or labeling, which is particularly appealing for B2B buyers looking to differentiate their products in the marketplace.

What Are Common Trade Terms Associated with Frosted Green Glass Dropper Bottles?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on the designs and specifications provided by another company. For B2B buyers, partnering with an OEM can facilitate custom designs for frosted green glass dropper bottles, enabling unique branding opportunities.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers, especially when budgeting for initial inventory. Smaller MOQs can reduce upfront costs but may lead to higher per-unit prices.

3. RFQ (Request for Quotation)

An RFQ is a formal document that buyers send to suppliers requesting pricing information for specific quantities and specifications of products. For businesses sourcing frosted green glass dropper bottles, issuing an RFQ can help compare costs and negotiate better deals.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. Familiarity with these terms, such as FOB (Free On Board) and CIF (Cost, Insurance, and Freight), helps B2B buyers understand shipping costs, risks, and responsibilities, ensuring smoother transactions.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until delivery. In the context of frosted green glass dropper bottles, understanding lead times helps businesses plan inventory and manage customer expectations effectively.

6. Customization Options

This term encompasses various modifications available for frosted green glass dropper bottles, including size, color, and closure types. Knowing available customization options allows buyers to tailor products to specific market needs, enhancing brand visibility and customer satisfaction.

By understanding these essential properties and trade terms, B2B buyers can make informed purchasing decisions, streamline their procurement processes, and effectively position their products in competitive markets.

Navigating Market Dynamics and Sourcing Trends in the frosted green glass dropper bottle Sector

What Are the Current Market Dynamics and Key Trends in the Frosted Green Glass Dropper Bottle Sector?

The global market for frosted green glass dropper bottles is experiencing notable growth, driven by increased demand in sectors such as pharmaceuticals, cosmetics, and essential oils. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, seek high-quality packaging solutions, the frosted green glass dropper bottle stands out due to its combination of aesthetic appeal and functional benefits. The shift towards eco-friendly packaging options is also propelling the market, as consumers increasingly prioritize sustainability in their purchasing decisions.

Emerging technologies are reshaping sourcing trends in this sector. The integration of e-commerce platforms and digital supply chain solutions enhances accessibility for international buyers, allowing them to source products from manufacturers worldwide with greater ease. Additionally, innovations in dropper technology, such as leak-proof designs and graduated pipettes, cater to the precise dosing needs of various applications, making these bottles suitable for both retail and bulk sales. The rise of customization options, where buyers can select colors, sizes, and closures, is also gaining traction, offering businesses a competitive edge in branding.

How Does Sustainability and Ethical Sourcing Impact the Frosted Green Glass Dropper Bottle Market?

Sustainability has become a paramount concern in the frosted green glass dropper bottle market. The environmental impact of packaging materials is under scrutiny, and glass is increasingly favored for its recyclability and lower carbon footprint compared to plastic alternatives. International buyers are now more inclined to partner with suppliers who demonstrate a commitment to sustainable practices, including the use of recycled materials in their manufacturing processes.

Ethical sourcing is equally vital, as businesses recognize the importance of maintaining transparent and responsible supply chains. Buyers are encouraged to seek out suppliers that adhere to ‘green’ certifications and standards, ensuring that their products are not only environmentally friendly but also produced under fair labor conditions. The demand for eco-conscious packaging solutions is expected to shape future sourcing strategies, driving manufacturers to innovate and align their operations with sustainable practices.

What Is the Brief Evolution of the Frosted Green Glass Dropper Bottle?

The frosted green glass dropper bottle has evolved significantly over the years, initially gaining popularity in the pharmaceutical industry for its ability to protect light-sensitive substances. The introduction of modern manufacturing techniques has allowed for greater customization and design flexibility, appealing to a broader range of industries. The trend towards sustainability in packaging has further propelled its popularity, as businesses look for eco-friendly options that do not compromise on quality or functionality. Today, frosted green glass dropper bottles are recognized not only for their practical applications but also for their aesthetic value, making them a preferred choice for premium product lines across various sectors.

Frequently Asked Questions (FAQs) for B2B Buyers of frosted green glass dropper bottle

-

How do I choose the right frosted green glass dropper bottle for my product?

Selecting the right frosted green glass dropper bottle involves considering several factors such as the type of liquid you plan to store, the required volume, and the desired closure type. Evaluate the chemical compatibility of the glass with your product to ensure no reactions occur. For essential oils or tinctures, consider bottles with UV protection to preserve product integrity. Additionally, assess the aesthetics; frosted glass provides a premium look that can enhance branding. Always request samples to test for compatibility and usability before placing a bulk order. -

What is the typical minimum order quantity (MOQ) for frosted green glass dropper bottles?

MOQs for frosted green glass dropper bottles can vary significantly based on the supplier and bottle specifications. Generally, you can expect an MOQ ranging from 100 to 1,000 units. It’s essential to discuss your specific needs with suppliers as many are flexible, especially for long-term partnerships or larger orders. Be sure to clarify whether the MOQ applies to a single size and style or across a range of products to better tailor your order to your business requirements. -

What are the payment terms I should expect when sourcing frosted green glass dropper bottles internationally?

Payment terms can differ widely among suppliers, but common practices include a deposit of 30% upfront with the remaining balance due before shipping. Some suppliers may offer net terms, allowing payment after delivery, but this is often reserved for established customers. It’s crucial to discuss payment methods accepted, such as wire transfers, credit cards, or trade finance options. Always ensure that you have a clear agreement in writing to avoid misunderstandings during the transaction. -

How can I ensure quality assurance when purchasing frosted green glass dropper bottles?

To ensure quality assurance, request detailed product specifications and certifications from your supplier, including information on material quality, manufacturing processes, and compliance with relevant industry standards. Conduct factory audits if possible, or consider third-party quality control services to inspect products before shipment. Establishing a solid communication channel with your supplier can also help in addressing any quality concerns promptly. Lastly, consider starting with a smaller order to evaluate quality before committing to larger purchases. -

What are the best practices for vetting suppliers of frosted green glass dropper bottles?

When vetting suppliers, start by researching their business history, customer reviews, and any certifications they hold. Request samples of their products to assess quality firsthand. Additionally, inquire about their manufacturing processes, lead times, and ability to meet your specific requirements. Establish communication with past clients to gain insights into their reliability and service. Lastly, consider visiting the supplier’s facility if feasible, as this can provide a clearer picture of their operations and capabilities. -

What are the logistics considerations when importing frosted green glass dropper bottles?

Logistics is a critical component when importing frosted green glass dropper bottles. Consider shipping methods (air vs. sea), as they can significantly impact delivery times and costs. Ensure your supplier can provide appropriate packaging to prevent breakage during transit. Familiarize yourself with customs regulations and duties applicable in your country to avoid unexpected costs. Additionally, working with a reputable freight forwarder can help streamline the shipping process, ensuring compliance and timely delivery. -

Can I customize frosted green glass dropper bottles with my branding?

Yes, many suppliers offer customization options for frosted green glass dropper bottles, including printing your logo or brand colors on the bottles. Customization can enhance brand visibility and create a cohesive product line. Discuss your design ideas with the supplier to understand the available techniques, such as screen printing or labeling, and any associated costs. Keep in mind that customized orders may have higher MOQs and longer lead times, so plan accordingly. -

What types of closures are available for frosted green glass dropper bottles?

Frosted green glass dropper bottles can be fitted with various closures, including child-resistant caps, tamper-evident seals, and standard dropper tops. The choice of closure should be aligned with the product’s safety requirements and intended use. For instance, if your product is an essential oil or tincture, opt for a closure that provides accurate dispensing and prevents leakage. Discuss closure options with your supplier to find the best fit for your product’s needs and regulatory compliance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Frosted Green Glass Dropper Bottle Manufacturers & Suppliers List

1. The Bottle Depot – Glass Dropper Bottles

Domain: thebottledepot.co

Registered: 2019 (6 years)

Introduction: The glass dropper bottles collection at The Bottle Depot offers premium-quality packaging solutions in six colors: amber, clear, black, blue, green, and frosted. Available sizes include 0.5 oz, 1 oz, 2 oz, and 4 oz. Each bottle features a fitted dropper closure for precise dispensing. Ideal for pharmaceuticals, healthcare applications, tinctures, herbal extracts, and aromatherapy oils. Amber and g…

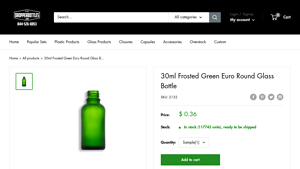

2. Dropper Bottles – 30ml Frosted Green Euro Round Glass Bottle

Domain: dropperbottles.com

Registered: 2004 (21 years)

Introduction: {“name”: “30ml Frosted Green Euro Round Glass Bottle”, “sku”: “2132”, “price”: “$0.36”, “stock”: “117743 units”, “volume”: “30ml”, “color”: “Frosted Green”, “type”: “Euro Round Glass Bottle”, “neck_finish”: “18-DIN”, “features”: [“Rounded shoulders”, “Rounded base”, “Tamper-evident closures”, “Child-resistant closures”, “Standard closures”, “Inverted pipettes”], “material”: “Glass”, “properties”: …

3. Green Frosted Glass Dropper Bottles – 30pcs Essential Oil Storage

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“title”:”NEW 30pcs 30ml Green Frosted Glass Dropper Bottle To store Essential Oil”,”condition”:”New”,”quantity_available”:2,”price”:”US $49.99 or Best Offer”,”shipping_cost”:”US $1.99 Economy Shipping from Greater China to worldwide”,”estimated_delivery”:”Estimated between Fri, Oct 3 and Tue, Nov 4 to 34000″,”returns”:”Seller does not accept returns”,”brand”:”Unbranded”,”MPN”:”Does not apply”,”UP…

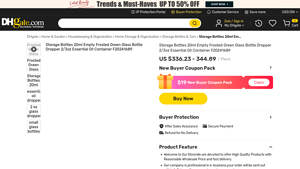

4. Frosted Green Glass – Storage Bottles 20ml

Domain: dhgate.com

Registered: 2004 (21 years)

Introduction: {“Product Name”: “Storage Bottles 20ml Empty Frosted Green Glass Bottle Dropper 2/3oz Essential Oil Container F20241689”, “Price”: “US $344.89 / Lot”, “Minimum Order Quantity (MOQ)”: “1 Lot (100 Pieces / Lot)”, “Material”: “Frosted Green Glass”, “Capacity”: “20ml (2/3oz)”, “Features”: [“High Quality Products”, “Fast Delivery”, “Eco Friendly”], “Shipping Information”: {“Processing Time”: “1-3 busin…

5. Pinterest – Frosted Green Glass Dropper Bottle Mockup

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Frosted Green Glass Dropper Bottle Mockup. Present your design on this mockup. Includes special layers and smart objects for your creative works. Tags: aroma, bottle, dropper, e-liquid, golden layer, green, label, liquid, mockup, oil, opened, pack, package, e-juice, vape, vaping.

6. Baolin – 30ml Frosted Green Glass Dropper Bottle

Domain: baolinglass.com

Registered: 2015 (10 years)

Introduction: {“name”: “1 oz 30ml Frosted Green Glass Dropper Bottle”, “capacity”: “30ml”, “material”: “Frosted green glass + Elec-Aluminum lid”, “cap_type”: “Dropper”, “features”: [“Durable with thick glass”, “Preserves formulas from sunlight to prevent oxidization”, “Safe, secure, and convenient packaging”, “Perfect for essential oils, perfume oils, or other liquids for travel”], “customization_options”: [“De…

7. YIXIN – Frosted Green Glass Bottles

Domain: yixin-glass.com

Registered: 2025 (0 years)

Introduction: Frosted Green Glass Bottles

– Capacity: 40ml, 100ml, 120ml, 30g, 50g

– Material: Glass

– Brand: YIXIN

– Origin: Guangdong, China

– Logo: Accept customized logos

– MOQ (Minimum Order Quantity): 3000 pieces

– Features: High-end appearance with dark green glass and golden caps, good sealing to prevent leakage and oxidation, convenient access with wide mouth design, various surface treatments availabl…

Strategic Sourcing Conclusion and Outlook for frosted green glass dropper bottle

In conclusion, strategic sourcing of frosted green glass dropper bottles offers significant advantages for international B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. The unique properties of frosted green glass, such as UV protection and chemical resistance, make these bottles ideal for a variety of applications, including pharmaceuticals, essential oils, and herbal extracts. By selecting high-quality packaging solutions tailored to specific needs, businesses can enhance product integrity and consumer trust.

Moreover, understanding market dynamics and supplier capabilities is crucial. Engaging with reliable manufacturers can ensure consistent quality, timely delivery, and competitive pricing, which are essential for maintaining operational efficiency and customer satisfaction.

As the demand for sustainable and effective packaging solutions continues to rise, now is the time for international buyers to explore partnerships that align with their strategic goals. Investing in frosted green glass dropper bottles not only supports product excellence but also positions companies to thrive in an increasingly eco-conscious marketplace. Take the next step in your sourcing strategy and connect with trusted suppliers to secure your packaging needs today.