Everything You Need to Know About Flotex Foam Sourcing in 2025

Introduction: Navigating the Global Market for flotex foam

In today’s competitive landscape, sourcing high-quality flotex foam can pose significant challenges for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. The demand for this versatile closed-cell foam—widely recognized for its applications in yoga mats, outdoor cushions, and marine products—highlights the need for reliable suppliers and comprehensive market insights. As businesses seek to enhance their product offerings, understanding the nuances of flotex foam, including its properties, applications, and cost factors, is essential.

This guide delves into the diverse types of flotex foam available, examining their specific applications and advantages across various industries. We will also explore effective supplier vetting strategies, ensuring that buyers can confidently partner with reputable manufacturers. Cost considerations, including potential bulk purchasing discounts and shipping logistics, will be discussed to help businesses budget effectively.

By equipping B2B buyers with the knowledge and tools necessary to make informed purchasing decisions, this guide aims to streamline the sourcing process and foster successful collaborations. Whether you’re in Germany seeking durable materials for outdoor use or in Vietnam looking to enhance your wellness product line, understanding flotex foam is crucial for meeting market demands and driving business growth.

Understanding flotex foam Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Flotex | Medium-firm feel, lightweight, non-UV resistant | Boat cushions, exercise mats | Pros: Comfortable, versatile; Cons: Limited UV protection. |

| High-Density Flotex | Increased density for enhanced durability and support | Industrial seating, outdoor gear | Pros: Long-lasting, excellent support; Cons: Heavier, higher cost. |

| Custom-Cut Flotex | Tailored dimensions and shapes for specific needs | Specialized equipment padding | Pros: Perfect fit for unique applications; Cons: Non-returnable. |

| Flotex for Marine | Certified for flotation, specifically designed for marine use | Life jackets, boat interiors | Pros: Safety certified, water-resistant; Cons: Not UV resistant. |

| Eco-Friendly Flotex | Made from sustainable materials, biodegradable options | Green building projects, eco-friendly products | Pros: Environmentally friendly; Cons: May have a higher price point. |

What are the Key Characteristics of Standard Flotex Foam?

Standard Flotex foam is characterized by its medium-firm feel and lightweight nature, making it an ideal choice for various applications such as boat cushions and exercise mats. Its closed-cell structure provides comfort while ensuring water resistance, although it is not UV resistant. B2B buyers should consider this foam for projects where weight and comfort are priorities, but should also be aware of its limitations in outdoor applications.

How Does High-Density Flotex Foam Stand Out?

High-density Flotex foam offers increased durability and support compared to its standard counterpart. This variation is well-suited for industrial seating and outdoor gear, where greater resilience is required. While it tends to be heavier and more expensive, its longevity and ability to withstand rigorous use make it a valuable investment for businesses seeking reliable materials.

What Are the Advantages of Custom-Cut Flotex Foam?

Custom-cut Flotex foam allows B2B buyers to obtain foam in tailored dimensions and shapes, catering to specific needs such as specialized equipment padding. This flexibility enhances its usability across various sectors, including manufacturing and design. However, buyers should note that custom orders are non-returnable, necessitating careful planning before purchase.

Why Choose Flotex Foam for Marine Applications?

Flotex foam designed for marine use is certified for flotation, making it essential for safety equipment like life jackets and boat interiors. Its water-resistant properties ensure it performs well in aquatic environments. B2B buyers in the marine industry should prioritize this foam for safety-critical applications, although they should keep in mind that it lacks UV resistance.

What Makes Eco-Friendly Flotex Foam a Smart Choice?

Eco-friendly Flotex foam is made from sustainable materials and offers biodegradable options, appealing to businesses focused on green building projects. While this foam can come at a higher price point, its environmental benefits can enhance a company’s sustainability profile. B2B buyers should weigh the cost against the potential marketing advantages of using eco-friendly materials in their products.

Key Industrial Applications of flotex foam

| Industry/Sector | Specific Application of flotex foam | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine & Boating | Boat cushions and life preservers | Enhanced comfort and safety for users on the water | Look for ULC certification for flotation and durability |

| Sports & Fitness | Exercise and yoga mats | Provides a stable, cushioned surface for workouts | Ensure the foam is lightweight and easy to transport |

| Construction & Insulation | Insulation pads for buildings | Improves energy efficiency and reduces noise transmission | Consider thermal resistance properties and density |

| Automotive | Interior padding for vehicles | Increases passenger comfort and sound insulation | Assess fire safety ratings and compliance with regulations |

| Outdoor Recreation | Camping pads and outdoor seating | Offers lightweight, portable comfort for outdoor activities | Evaluate water resistance and durability in outdoor conditions |

How is Flotex Foam Used in Marine and Boating Applications?

Flotex foam is an ideal choice for marine applications, particularly for boat cushions and life preservers. Its closed-cell structure ensures that it remains buoyant and resistant to water absorption, which is critical for safety on the water. Buyers in this sector should prioritize ULC certification to guarantee compliance with flotation safety standards. Additionally, the lightweight nature of flotex foam makes it easy to handle and install, enhancing overall user comfort.

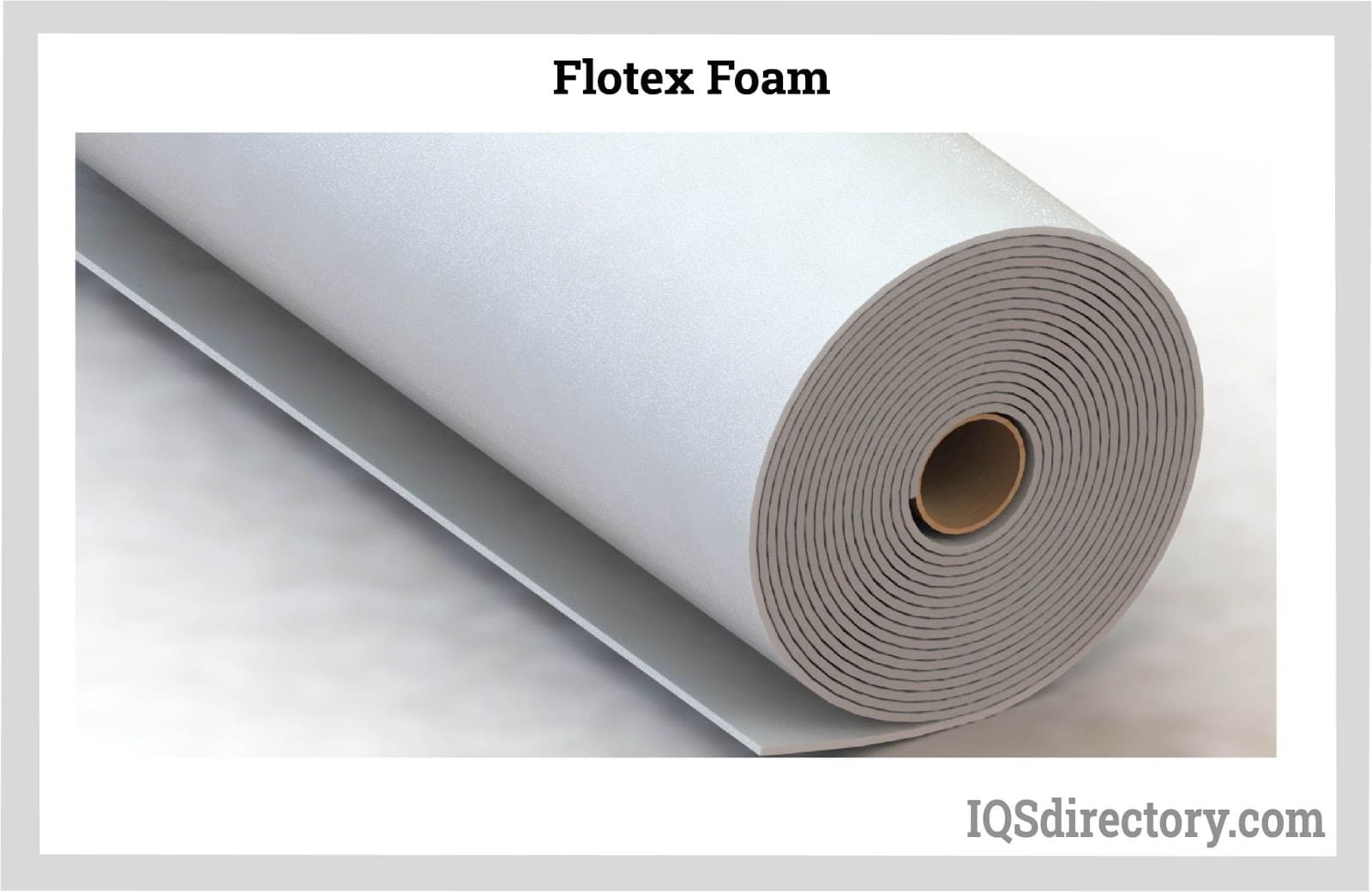

Illustrative image related to flotex foam

What Role Does Flotex Foam Play in Sports and Fitness?

In the sports and fitness industry, flotex foam is widely utilized for exercise and yoga mats. Its medium-firm feel provides a stable surface that enhances performance during workouts. For international buyers, sourcing lightweight and portable options is essential, especially for fitness studios and gyms that require easy transportation of equipment. Durability and ease of cleaning are also key factors to consider, ensuring long-lasting use in high-traffic environments.

How Can Flotex Foam Improve Energy Efficiency in Construction?

In construction, flotex foam serves as effective insulation pads, contributing to energy efficiency and sound dampening within buildings. Its closed-cell design helps in minimizing heat loss and noise transfer, making it a valuable material for both residential and commercial projects. Buyers should focus on the thermal resistance properties of the foam to meet specific building codes and regulations. Additionally, sourcing from reputable manufacturers ensures compliance with safety standards.

Why is Flotex Foam Essential for Automotive Comfort?

The automotive industry benefits significantly from flotex foam used in interior padding for vehicles. This foam enhances passenger comfort and provides sound insulation, which is crucial for a pleasant driving experience. When sourcing flotex foam for automotive applications, it is vital to assess fire safety ratings and compliance with industry regulations to ensure passenger safety. Additionally, durability under varying temperature conditions is a critical consideration for long-term performance.

What Advantages Does Flotex Foam Offer for Outdoor Recreation?

Flotex foam is increasingly popular in outdoor recreation, particularly for camping pads and seating solutions. Its lightweight and portable nature makes it an excellent choice for outdoor enthusiasts who require comfort without the bulk. Buyers should consider the foam’s water resistance and durability to withstand various weather conditions. Evaluating the thickness and density of the foam can also help in selecting the right option for specific outdoor activities, ensuring optimal comfort and support.

3 Common User Pain Points for ‘flotex foam’ & Their Solutions

Scenario 1: Sourcing Flotex Foam for Diverse Applications

The Problem: B2B buyers often struggle with sourcing Flotex foam that meets their specific application needs. Whether it’s for outdoor cushions, exercise mats, or marine applications, the variability in foam density, thickness, and finish can lead to confusion and potential mismatches. This can result in wasted resources, unsatisfied customers, and project delays, especially when buyers are not fully aware of the foam’s certifications and limitations.

The Solution: To ensure effective sourcing, it is crucial to engage with reputable suppliers who offer detailed product specifications and application guidance. Start by requesting samples to evaluate the foam’s texture, firmness, and buoyancy, which are critical for applications like boat cushions. Additionally, leverage the expertise of the supplier’s customer service team to discuss specific requirements and certifications, such as flotation and UV resistance. Establishing a relationship with a supplier that understands your market can also lead to better pricing and customized options, ensuring you receive the right foam for your unique needs.

Scenario 2: Ensuring Durability and Longevity of Flotex Foam Products

The Problem: Buyers often face concerns about the durability and longevity of Flotex foam products, particularly in demanding environments such as outdoor settings or high-traffic areas. The susceptibility of foam to wear and tear, moisture, and UV exposure can lead to premature degradation, affecting customer satisfaction and brand reputation.

The Solution: To mitigate these concerns, it is essential to conduct a thorough evaluation of the foam’s characteristics. Buyers should prioritize sourcing high-density Flotex foam, which offers greater resistance to compression and wear. Implementing a proactive maintenance plan, including regular cleaning and protective treatments, can also extend the life of foam products. Additionally, consulting with manufacturers about the best finishes and coatings for specific environments—such as water-repellent or UV-resistant treatments—can enhance product longevity. Educating customers on proper usage and care will further ensure that the foam maintains its integrity over time.

Scenario 3: Navigating Customization Challenges in Flotex Foam Orders

The Problem: B2B buyers frequently encounter challenges when ordering custom-cut Flotex foam shapes and sizes. Miscommunication about dimensions or design specifications can lead to costly mistakes and delays, particularly when buyers are working on tight deadlines or specific project requirements.

The Solution: To streamline the customization process, buyers should utilize clear and detailed specifications when placing orders. Create a comprehensive design brief that includes exact dimensions, shapes, and intended applications. Engaging in a preliminary consultation with the foam supplier can help clarify these details and address any potential issues before production begins. Additionally, consider using CAD software to create visual representations of the desired product, which can significantly reduce the chances of misinterpretation. Establishing a feedback loop with the supplier—where both parties can review and confirm the specifications before production—will also enhance accuracy and satisfaction with the final product.

Strategic Material Selection Guide for flotex foam

What Are the Key Properties of Flotex Foam Materials?

Flotex foam is a specialized closed-cell foam known for its versatility and performance across various applications. Understanding the key properties of different materials used in flotex foam can help international B2B buyers make informed decisions. Here are four common materials associated with flotex foam:

1. Polyethylene Foam

Key Properties: Polyethylene foam is lightweight and features a closed-cell structure that provides excellent buoyancy and thermal insulation. It typically has a temperature rating of -40°F to 180°F and offers good resistance to moisture and chemicals.

Pros & Cons: The material is durable and resistant to impact, making it suitable for applications like boat cushions and protective packaging. However, it can be more expensive than other foams and may not be as flexible, limiting its use in certain designs.

Illustrative image related to flotex foam

Impact on Application: Polyethylene foam’s resistance to water makes it ideal for marine applications, while its insulation properties are beneficial in temperature-sensitive environments.

Considerations for International Buyers: Compliance with international standards such as ASTM and EN is crucial for buyers in Europe and other regions. Additionally, buyers should consider the availability of polyethylene foam in their local markets, as sourcing can vary significantly.

2. EVA Foam (Ethylene Vinyl Acetate)

Key Properties: EVA foam is known for its elasticity and softness, with a temperature resistance ranging from -40°F to 150°F. It is also UV resistant, which enhances its longevity in outdoor applications.

Pros & Cons: The material is cost-effective and easy to manufacture, making it suitable for a wide range of applications, including yoga mats and outdoor cushions. However, EVA foam may not provide the same level of buoyancy as polyethylene, which can be a drawback in flotation devices.

Impact on Application: EVA foam’s flexibility allows it to conform to various shapes, making it ideal for custom applications. Its UV resistance is particularly beneficial for outdoor use, especially in regions with high sun exposure.

Considerations for International Buyers: Buyers should verify compliance with local safety standards, particularly in Europe where regulations can be stringent. The availability of EVA foam in different densities can also influence purchasing decisions.

3. Polyurethane Foam

Key Properties: Polyurethane foam is a versatile material that can be formulated to achieve varying densities and firmness levels. It has a temperature rating of -20°F to 120°F and offers good resistance to wear and tear.

Pros & Cons: This foam is highly adaptable and can be used in a variety of applications, from cushioning to insulation. However, it is generally more expensive and may have a shorter lifespan compared to other closed-cell foams.

Illustrative image related to flotex foam

Impact on Application: Polyurethane foam’s adaptability allows it to be tailored for specific uses, such as custom cushioning solutions. Its wear resistance makes it suitable for high-traffic areas.

Considerations for International Buyers: Compliance with ASTM and ISO standards is essential, especially for applications in the automotive and aerospace industries. Buyers should also consider the environmental impact of polyurethane foam production.

4. Flotex Foam

Key Properties: Flotex foam is characterized by its medium-firm feel and squishy texture, offering excellent comfort and support. It has a density of approximately 3.6 lbs/ft³ and is certified for flotation applications.

Pros & Cons: This foam is ideal for outdoor cushions and exercise mats due to its comfort and buoyancy. However, it lacks UV resistance, which can limit its applications in direct sunlight.

Impact on Application: Flotex foam is particularly effective in environments where comfort and buoyancy are essential, such as in marine settings or fitness applications.

Illustrative image related to flotex foam

Considerations for International Buyers: Buyers should ensure that flotex foam meets local safety certifications, especially for flotation devices. Understanding regional preferences for foam density and firmness can also influence purchasing decisions.

Summary Table of Flotex Foam Materials

| Material | Typical Use Case for flotex foam | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene Foam | Boat cushions, protective packaging | Excellent buoyancy and insulation | Higher cost, less flexibility | Medium |

| EVA Foam | Yoga mats, outdoor cushions | Cost-effective and UV resistant | Lower buoyancy compared to others | Low |

| Polyurethane Foam | Custom cushioning, insulation | Highly adaptable | More expensive, shorter lifespan | High |

| Flotex Foam | Outdoor cushions, exercise mats | Comfort and buoyancy | Lacks UV resistance | Medium |

This strategic material selection guide provides essential insights for B2B buyers looking to source flotex foam materials, ensuring they can make informed decisions that align with their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for flotex foam

What Are the Key Stages in the Manufacturing Process of Flotex Foam?

The manufacturing process of Flotex foam involves several critical stages, each designed to ensure the material meets the necessary quality and performance standards for various applications, such as yoga mats, boat cushions, and life preservers. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Flotex Foam Production?

Material preparation begins with sourcing high-quality raw materials, typically closed-cell foam formulations that provide the desired buoyancy and density. The foam is usually made from polyethylene or polyurethane, which are selected based on their specific properties, such as water resistance and durability. During this stage, manufacturers often conduct an initial quality check to ensure that the raw materials meet industry specifications.

Once the materials are confirmed to be of high quality, they undergo processes such as mixing, where additives are introduced to enhance properties like UV resistance and durability. This step is crucial as it sets the foundation for the foam’s performance characteristics.

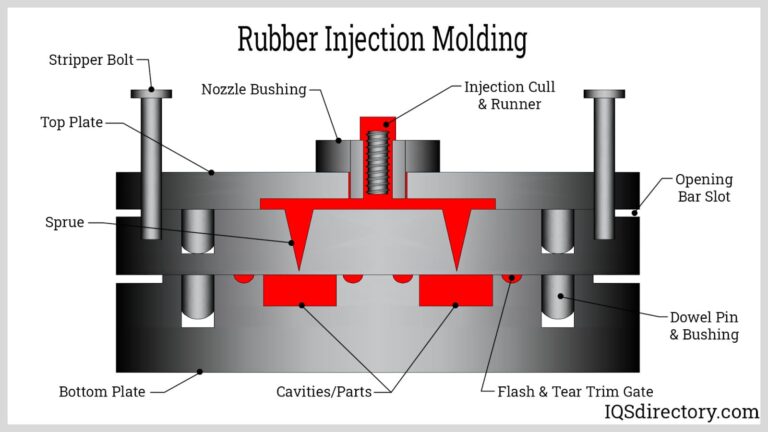

What Techniques Are Used in Forming Flotex Foam?

After material preparation, the forming stage involves shaping the foam into the desired configuration. Techniques such as extrusion and molding are commonly employed. In the extrusion process, the prepared foam mixture is forced through a die to create continuous sheets of foam, which can then be cut to specific sizes.

Alternatively, molding allows for the production of custom shapes, catering to specific customer requirements. For instance, specialized molds can be created for unique applications, ensuring that the final product meets precise specifications. This flexibility is particularly beneficial for B2B buyers looking for tailored solutions.

How Is Flotex Foam Assembled and Finished?

The assembly stage may involve cutting the foam sheets or shapes to final dimensions and preparing them for packaging. This often includes adding features such as adhesive backing for mats or coatings for enhanced durability. The finishing touches are vital for ensuring that the foam not only meets functional requirements but also appeals to end-users in terms of aesthetics and usability.

During this stage, manufacturers may also conduct secondary processes, such as lamination or surface treatment, to enhance properties like grip and comfort. Each step is meticulously monitored to ensure consistency and quality.

What Quality Assurance Practices Are Critical for Flotex Foam?

Quality assurance is integral to the manufacturing of Flotex foam, ensuring that the products meet international standards and customer expectations. Various international standards, such as ISO 9001, provide a framework for quality management systems, emphasizing continuous improvement and customer satisfaction.

Which International Standards Should B2B Buyers Be Aware Of?

B2B buyers should familiarize themselves with relevant international and industry-specific standards. For instance, CE marking is essential for products sold within the European Economic Area, indicating compliance with safety, health, and environmental protection standards. Additionally, certifications from organizations such as Underwriters Laboratories (UL) can provide assurance regarding the flotation and fire-resistance properties of the foam.

In specific industries, buyers may also encounter standards like the American Petroleum Institute (API) for marine applications, which ensures that materials used in these environments meet stringent safety and performance criteria.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are established at various stages of the manufacturing process to ensure product integrity. Incoming Quality Control (IQC) checks the quality of raw materials upon arrival. In-Process Quality Control (IPQC) monitors the production processes, ensuring adherence to specifications throughout manufacturing. Finally, Final Quality Control (FQC) evaluates the finished products before they are shipped to customers.

Common testing methods include density tests, tensile strength assessments, and water absorption tests. These evaluations ensure that the foam meets the required specifications and performs as expected in real-world applications.

How Can B2B Buyers Verify Supplier Quality Assurance?

B2B buyers can take proactive steps to verify the quality assurance processes of potential suppliers. Conducting audits is one effective method, allowing buyers to assess the manufacturer’s quality management systems firsthand. During an audit, buyers can review documentation, observe manufacturing processes, and evaluate the facility’s adherence to relevant standards.

Additionally, requesting quality reports and certifications can provide insight into the supplier’s commitment to quality. Third-party inspections by independent organizations can further validate the supplier’s claims and ensure that the foam meets international standards.

Illustrative image related to flotex foam

What Nuances Should International B2B Buyers Consider Regarding Quality Assurance?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality assurance is essential. Different markets may have varying regulatory requirements, and it is crucial to ensure that products comply with local laws and standards.

Additionally, language barriers and cultural differences can impact communication regarding quality expectations. Establishing clear channels of communication and ensuring that all specifications are documented can help mitigate misunderstandings.

In conclusion, the manufacturing processes and quality assurance practices for Flotex foam are vital for ensuring that the final product meets the high standards expected by B2B buyers. By understanding these processes and engaging in due diligence, international buyers can make informed decisions and select suppliers that align with their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘flotex foam’

This guide serves as a practical checklist for B2B buyers looking to source Flotex foam, a versatile material often used in applications such as outdoor cushions, yoga mats, and various marine uses. Understanding the nuances of Flotex foam and the procurement process will enable you to make informed decisions and establish successful supplier relationships.

1. Define Your Technical Specifications

Establishing clear technical specifications is the first step in sourcing Flotex foam. Consider the intended application, such as whether it will be used for cushioning, flotation devices, or exercise mats.

– Key attributes to specify: density, thickness, and dimensions.

– Application requirements: For instance, if the foam is intended for marine use, ensure it meets flotation standards.

2. Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of Flotex foam. Look for companies that specialize in closed-cell foam products and have a proven track record in your target market.

– Supplier reputation: Check online reviews and testimonials from previous clients.

– Industry experience: Ensure that the supplier has experience with similar applications relevant to your needs.

3. Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications to ensure product quality and safety. Certifications such as ULC (Underwriters Laboratories Canada) indicate compliance with safety standards.

– Importance of certifications: These certifications can be crucial for applications where safety is paramount, such as in flotation devices.

– Inquire about testing: Ask suppliers about their quality control processes and any third-party testing conducted on their products.

4. Request Samples for Testing

Always request samples before making a bulk purchase. Testing the material firsthand allows you to evaluate its properties and suitability for your specific applications.

– Assess comfort and durability: For products like yoga mats or outdoor cushions, check for comfort and wear resistance.

– Verify dimensions and cut: Ensure that the samples match your specified dimensions and evaluate the cutting precision if you require custom shapes.

5. Compare Pricing and Terms

Once you have shortlisted suppliers, compare their pricing structures and terms of sale. Look beyond the initial cost to understand the overall value.

– Consider volume discounts: Many suppliers offer discounts for bulk orders, which can significantly reduce costs.

– Review payment terms: Ensure that the payment terms align with your cash flow needs and project timelines.

6. Negotiate Delivery and Logistics

Discuss delivery timelines and logistics with your chosen supplier to ensure that your order will arrive on time and within budget.

– Lead times: Understand how long it will take to process and ship your order.

– Shipping options: Explore available shipping methods and costs, especially if you are importing from international suppliers.

7. Establish a Relationship for Future Orders

After successfully sourcing Flotex foam, consider establishing a long-term relationship with your supplier. This can lead to better pricing, priority service, and tailored solutions for future projects.

– Open communication: Maintain regular contact to discuss product developments and any new offerings.

– Feedback loop: Provide feedback on the products and service, which can help enhance the supplier’s offerings in the future.

By following this checklist, B2B buyers can streamline their sourcing process for Flotex foam, ensuring that they procure the right materials to meet their specific needs effectively.

Comprehensive Cost and Pricing Analysis for flotex foam Sourcing

What Are the Key Cost Components in Flotex Foam Sourcing?

When sourcing flotex foam, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The raw materials for flotex foam often include closed-cell polyethylene or EVA, which are known for their buoyancy and durability. The price can fluctuate based on market demand and availability.

-

Labor: Labor costs depend on the region and the complexity of the foam production process. Skilled labor may be required for custom cutting and shaping, impacting overall costs.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize overhead expenses.

-

Tooling: The initial investment in tooling for custom shapes can be substantial but is essential for high-quality production.

-

Quality Control (QC): Ensuring that the flotex foam meets industry standards involves costs related to testing and certification, particularly for applications requiring flotation certifications.

-

Logistics: Shipping costs vary significantly depending on the destination and the chosen Incoterms. For international buyers, understanding these costs is critical to avoid unexpected expenses.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary widely based on competition and market conditions.

How Do Price Influencers Affect Flotex Foam Costs?

Several factors can influence the price of flotex foam, making it crucial for buyers to understand them for effective negotiation and budgeting.

-

Volume/MOQ: Suppliers often offer discounts for bulk orders. Minimum order quantities (MOQs) can affect pricing; larger orders typically reduce per-unit costs.

-

Specifications and Customization: Custom shapes or sizes can significantly increase costs due to additional labor and tooling. Standard sizes generally offer better pricing.

-

Materials and Quality/Certifications: The choice of material can impact pricing. High-quality, certified flotex foam will command a premium, but it may provide better performance and longevity.

-

Supplier Factors: Supplier reputation, reliability, and geographic location can influence pricing. Buyers should evaluate multiple suppliers to find the best fit for their needs.

-

Incoterms: Understanding the terms of sale is vital. Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect overall costs and responsibilities for shipping.

What Are the Best Buyer Tips for Cost-Efficiency?

To achieve cost-efficiency when sourcing flotex foam, B2B buyers should consider the following strategies:

-

Negotiation Tactics: Engage in negotiations with suppliers to explore volume discounts or flexible payment terms. Building a long-term relationship can also lead to better pricing.

-

Total Cost of Ownership (TCO): Evaluate the TCO, including purchase price, maintenance, and disposal costs. A lower upfront cost may not always be the best value if the product has a shorter lifespan.

-

Pricing Nuances for International Buyers: For buyers from Africa, South America, the Middle East, and Europe, consider local tariffs, taxes, and currency fluctuations. These can significantly affect the final cost.

-

Supplier Diversification: Don’t rely on a single supplier. Having multiple sources can provide leverage in negotiations and reduce risk.

Disclaimer on Indicative Prices

While prices for flotex foam can vary widely based on the factors discussed, it is essential to note that the figures provided here are indicative. Actual costs may differ based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and obtain quotes from multiple suppliers to ensure the best pricing for your needs.

Alternatives Analysis: Comparing flotex foam With Other Solutions

In the competitive landscape of foam products, it’s essential for businesses to evaluate various options that meet their specific needs. Flotex foam is a versatile choice, but understanding how it compares to other alternatives can aid in making informed decisions. Below, we explore Flotex foam alongside two viable alternatives: EVA foam and polyethylene foam.

| Comparison Aspect | Flotex Foam | EVA Foam | Polyethylene Foam |

|---|---|---|---|

| Performance | Medium-firm, buoyant, good for cushioning | Lightweight, resilient, good shock absorption | High density, excellent water resistance |

| Cost | Moderate | Generally low | Varies based on density, can be higher for specialized types |

| Ease of Implementation | Easy to cut and shape, available in custom sizes | Simple to handle and cut | Requires specialized tools for cutting |

| Maintenance | Low maintenance, easy to clean | Low maintenance, can be wiped down | Very low maintenance, resistant to moisture |

| Best Use Case | Yoga mats, boat cushions, camping | Exercise mats, protective gear | Packaging, insulation, marine applications |

What are the Pros and Cons of EVA Foam Compared to Flotex Foam?

EVA (Ethylene Vinyl Acetate) foam is known for its lightweight and resilient properties, making it an excellent choice for applications requiring shock absorption, such as exercise mats and protective gear. The cost of EVA foam is generally lower than Flotex, which can be an attractive factor for budget-conscious buyers. However, it may not provide the same level of buoyancy as Flotex foam, which is essential for applications like boat cushions. Additionally, while EVA foam is easy to cut and handle, it lacks the medium-firm feel that some users prefer for specific uses like yoga.

How Does Polyethylene Foam Stack Up Against Flotex Foam?

Polyethylene foam offers high density and exceptional water resistance, making it ideal for packaging, insulation, and marine applications. Its durability and moisture resistance are significant advantages, especially in harsh environments. However, the cost can vary widely based on the density and specific type chosen, potentially making it a more expensive option than Flotex for certain applications. Additionally, polyethylene foam can require specialized tools for cutting and shaping, which may complicate its implementation compared to the user-friendly nature of Flotex.

How Can B2B Buyers Choose the Right Foam Solution?

When selecting a foam solution, B2B buyers should consider their specific application requirements, such as performance characteristics, budget constraints, and ease of implementation. Flotex foam excels in applications requiring buoyancy and comfort, while EVA foam is better suited for lightweight, shock-absorbing needs. Polyethylene foam stands out for its water resistance and durability, but may require more investment. Understanding these nuances will empower buyers to select the most appropriate foam solution tailored to their operational needs.

Essential Technical Properties and Trade Terminology for flotex foam

What Are the Key Technical Properties of Flotex Foam?

Understanding the essential technical properties of Flotex foam is crucial for B2B buyers aiming to make informed purchasing decisions. Here are some critical specifications that define the quality and application of this material:

-

Material Composition

Flotex foam is predominantly made from closed-cell polyethylene, which provides a lightweight yet durable product. The closed-cell structure ensures that water does not permeate the foam, making it ideal for applications in marine environments, such as boat cushions and life preservers. For buyers, this means selecting a product that meets specific performance standards for waterproofing and buoyancy. -

Density

The density of Flotex foam typically measures around 3.6 lbs/ft³. Density is a key indicator of the foam’s durability and firmness, impacting its suitability for various applications. Higher density foams are often more resilient and provide better support, which is especially important for products like yoga mats and exercise pads. Buyers should consider the density that aligns with their application’s specific comfort and durability needs. -

Thickness and Tolerance

Flotex foam is available in various thicknesses, commonly ranging from 1 inch to 2 inches. Tolerance levels refer to the permissible variations in thickness and dimensions during manufacturing. For B2B buyers, understanding these specifications helps ensure that the foam will fit within intended designs, especially in custom applications. -

Certification Standards

Flotex foam is certified by Underwriters Laboratory Canada (ULC) for flotation, which is critical for safety compliance in marine applications. Buyers in regulated markets must ensure that the products they purchase meet necessary certification standards to avoid liability and ensure user safety. -

UV Resistance

While Flotex foam is not UV resistant, this characteristic is essential for buyers to consider, especially for outdoor applications. Understanding the limitations regarding UV exposure can help businesses avoid premature material degradation, ensuring longevity and reliability in their products.

What Common Trade Terms Should B2B Buyers Know About Flotex Foam?

Navigating the B2B landscape requires familiarity with specific trade terminology. Here are some common terms relevant to Flotex foam:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For Flotex foam, OEM partnerships can be crucial for companies looking to integrate the foam into their product lines, ensuring that the materials meet specific quality standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest order quantity that a supplier is willing to accept. Understanding MOQ is vital for B2B buyers as it affects inventory management and cash flow. Suppliers of Flotex foam may have specific MOQs that influence purchasing decisions, especially for smaller businesses. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products. B2B buyers interested in Flotex foam should prepare RFQs to gather competitive pricing and ensure they are making cost-effective purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. Familiarity with these terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is essential for B2B transactions involving Flotex foam, especially when shipping across borders. -

Lead Time

This term refers to the time taken from placing an order to its delivery. Understanding lead times is crucial for B2B buyers to manage their inventory effectively and meet production schedules, especially when working with custom or bulk orders of Flotex foam.

By grasping these technical properties and trade terminologies, B2B buyers can enhance their procurement strategies, ensuring they select the right products that meet their business needs effectively.

Navigating Market Dynamics and Sourcing Trends in the flotex foam Sector

What Are the Current Market Dynamics and Key Trends Affecting Flotex Foam?

The flotex foam market is witnessing significant growth driven by increasing demand in various sectors, including marine, fitness, and outdoor industries. With its versatile applications—ranging from yoga mats to boat cushions—this closed-cell foam material is favored for its durability, comfort, and flotation properties. Emerging trends in B2B sourcing indicate a shift towards customization, as buyers seek tailor-made solutions that meet specific application needs. The rise of e-commerce platforms and digital marketplaces has also transformed how international buyers, particularly from Africa, South America, the Middle East, and Europe (including Germany and Vietnam), engage with suppliers. They can now source flotex foam products efficiently, compare prices, and access a broader range of options.

Furthermore, technological advancements in foam manufacturing, such as improved cutting techniques and material formulations, are enhancing product offerings. For instance, innovations in die cutting and kiss cutting allow for precise custom shapes, meeting the diverse needs of businesses. Additionally, there is a growing focus on lightweight materials that maintain structural integrity, which is crucial for applications in industries like aerospace and automotive. As global supply chains become more interconnected, B2B buyers must stay informed about fluctuating material costs and supply chain disruptions, which could impact pricing and availability.

How Does Sustainability and Ethical Sourcing Impact the Flotex Foam Industry?

Sustainability has become a pivotal consideration in the flotex foam sector, with increasing scrutiny on environmental impacts and ethical sourcing practices. The production of closed-cell foams, including flotex, can have significant ecological footprints due to the raw materials and energy consumption involved. Thus, buyers are encouraged to prioritize suppliers that adhere to green certifications and sustainable practices. Certifications such as ISO 14001 and products made from recycled materials signal a commitment to reducing environmental impact.

Moreover, ethical supply chains are gaining importance as companies aim to enhance their corporate social responsibility (CSR) profiles. B2B buyers are increasingly looking for suppliers who can demonstrate transparency in their sourcing processes, fair labor practices, and community engagement. The demand for eco-friendly materials is also on the rise, with businesses actively seeking flotex foam that is produced with lower emissions and sustainable manufacturing methods. Buyers who align with these values not only contribute to environmental conservation but also strengthen their brand reputation in increasingly eco-conscious markets.

What Is the Brief Evolution and History of Flotex Foam in the B2B Sector?

Flotex foam has evolved significantly since its inception, initially gaining popularity in the 1970s as a versatile material for various applications, particularly in the fitness and marine sectors. Its closed-cell structure offers unique benefits such as buoyancy, water resistance, and durability, making it suitable for outdoor and recreational uses. As the fitness industry expanded, so did the applications of flotex foam, becoming a staple in yoga mats and exercise equipment.

In recent years, the focus has shifted towards customization and innovation, driven by advances in manufacturing technology. This evolution has opened up new markets and applications, allowing flotex foam to penetrate industries such as automotive and aerospace, where weight reduction and material performance are critical. As businesses continue to seek high-performance materials, the flotex foam market is poised for further growth, shaped by consumer preferences and technological advancements.

Frequently Asked Questions (FAQs) for B2B Buyers of flotex foam

-

How do I ensure the quality of Flotex foam before purchasing?

To ensure the quality of Flotex foam, request samples from potential suppliers before placing a bulk order. Evaluate the foam’s density, firmness, and durability by testing it in real-world applications relevant to your needs, such as for boat cushions or exercise mats. Additionally, check for certifications from reputable organizations (e.g., ULC for flotation) to confirm compliance with safety and performance standards. Lastly, look for customer reviews and testimonials to gauge the supplier’s reliability and product satisfaction. -

What are the ideal applications for Flotex foam in my business?

Flotex foam is versatile and suited for various applications, including yoga mats, outdoor cushions, and marine products like boat cushions and life preservers. Its closed-cell structure provides excellent buoyancy and insulation, making it ideal for camping pads and other outdoor gear. When considering its use, evaluate your target market’s needs and preferences, as well as the specific environmental conditions the foam will encounter, such as moisture exposure or temperature variations. -

What customization options are available for Flotex foam products?

Many suppliers offer customization options for Flotex foam, including different thicknesses, dimensions, and shapes. Some can provide custom-cut pieces tailored to your specifications, while others may offer a range of colors or surface finishes. Before ordering, communicate your requirements clearly and confirm whether the supplier can accommodate your needs, as custom orders may have minimum quantity requirements and longer lead times. -

What are the minimum order quantities (MOQs) for Flotex foam?

Minimum order quantities for Flotex foam can vary significantly between suppliers. Typically, MOQs can range from a few sheets for standard sizes to larger quantities for custom orders. When sourcing foam, inquire about the specific MOQs for the products you need and whether discounts are available for bulk purchases. Understanding these terms upfront can help you budget and plan your inventory effectively. -

What payment terms should I expect when sourcing Flotex foam internationally?

Payment terms for international orders of Flotex foam can vary by supplier and country. Common terms include upfront payment, partial payment upon order confirmation, and remaining balance prior to shipping. Some suppliers may offer credit terms based on your business history. It’s crucial to discuss payment options clearly and ensure that both parties agree to the terms in writing to avoid any misunderstandings. -

How can I vet suppliers of Flotex foam for reliability?

To vet suppliers, conduct thorough research by reviewing their business history, customer reviews, and product certifications. Request references from other businesses that have sourced from them. Verify their manufacturing processes and quality assurance measures, and ask about their experience with international shipping and customs regulations. Consider visiting their facility if possible or engaging a third-party inspection service to ensure they meet your standards. -

What logistics considerations should I keep in mind when importing Flotex foam?

When importing Flotex foam, consider shipping methods, lead times, and customs regulations in your country. Choose a reliable freight forwarder familiar with foam products to ensure proper handling and compliance with import regulations. Be aware of potential tariffs and duties that may apply, and factor these into your total cost. Timely communication with your supplier regarding shipping schedules and tracking can help mitigate delays. -

What are the warranty and return policies for Flotex foam products?

Warranty and return policies for Flotex foam can differ by supplier. Generally, full sheets in new condition may be returnable, often subject to a restocking fee. Custom-cut pieces typically cannot be returned. Before finalizing your order, review the supplier’s warranty policy for defects and performance issues. Understanding these policies can help you manage risks and ensure you have recourse if the products do not meet your expectations.

Top 6 Flotex Foam Manufacturers & Suppliers List

1. FoamOrder – Flotex Foam

Domain: foamorder.com

Registered: 1999 (26 years)

Introduction: Flotex Foam is a closed-cell foam primarily used for yoga mats, camping pads, and boat cushions. It has a squishy texture and medium-firm feel, weighing 3.6 lbs/ft³. It is certified by ULC for flotation but is not UV resistant. Available thicknesses include 1/4″, 1/2″, 3/4″, 1″, 2″, 3″, and 4″. The standard sheet dimensions are 56″ × 84″ × 0.25″ (142.2 × 213.4 × 0.6 cm) with a price of $78.24. Cus…

2. Gossamer Gear – Hammock Pad

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Gossamer Gear hammock pad dimensions: 40″x60″, price: around $45. EVA foam from foamorder.com dimensions: 40″x80″, price: $25. Both products have a density of 2 lb/cu ft. Shipping cost for foamorder.com: $25, making total cost $50. Gossamer Gear shipping cost: $10, total cost around $55. Foamorder also offers Flotex foam, marketed as a camping pad, with higher density than EVA foam.

3. Foam Mart – Closed Cell Foam Products

Domain: foammart.com

Registered: 1996 (29 years)

Introduction: Closed Cell Foam products available at Foam Mart include various types such as ENSOLITE, VOLARA FOAM, L200 XLPE FOAM SHEETS, and NEOPRENE CORD. Prices range from $0.85 for NEOPRENE CORD to $198.00 for L200 XLPE FOAM SHEETS (2″ thick). Products are sold by the linear foot or by the sheet, with dimensions like 48″ x 60″ for VOLARA FOAM and thickness options from 1/8″ to 2″ for L200 XLPE FOAM. Other …

4. IQS Directory – Closed Cell Foam Solutions

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Closed cell foam is characterized by tightly packed and enclosed “cells,” making it durable and resistant to water and moisture. It is available in various forms, including: 1. Polyethylene Foam – Resists water absorption and stains, suitable for packaging, arts and crafts. 2. Polyethylene Rolls – Used in automotive, healthcare, and sports applications. 3. Cross-Linked Polyethylene – Available in …

5. Foam By Mail – Closed-Cell Foams

Domain: foambymail.com

Registered: 2000 (25 years)

Introduction: Closed-Cell Foams include various types such as Polyethylene Foam, Cross Linked Polyethylene, Polystyrene Foam, Neoprene Rubber, Gym Rubber, Volara, and Polypropylene Foam. These foams are known for their sturdiness and stiffness compared to open-cell foams. They are suitable for a range of applications including packaging, arts and crafts, healthcare, automotive, sports, recreational uses, insula…

6. MakersRow – Closed Cell Foam

Domain: app.makersrow.com

Registered: 2012 (13 years)

Introduction: Closed Cell Foam; Price: $15.00; Minimum Order: No Minimum; Categories: EVA, Cross-poly, Flotex, Volara; Thicknesses: 1/8 inch to 4 inches thick; Available by sheet or custom cut; Characteristics: Enclosed cells, water-resistant, higher density, greater pressure resistance, versatile material, tight seal, enhanced stability.

Strategic Sourcing Conclusion and Outlook for flotex foam

In summary, flotex foam stands out as a versatile and essential material for various applications, ranging from yoga mats to boat cushions. Its closed-cell structure provides water resistance and durability, making it ideal for outdoor and marine environments. For international B2B buyers in regions like Africa, South America, the Middle East, and Europe, understanding the unique properties and applications of flotex foam can lead to more informed purchasing decisions.

Strategic sourcing is vital in maximizing value and minimizing costs. By partnering with reliable suppliers and leveraging bulk purchasing options, businesses can enhance their product offerings while ensuring quality and performance. Moreover, maintaining an awareness of market trends and supplier capabilities will empower buyers to adapt to changing demands.

As we look forward, the potential for flotex foam in emerging markets is promising. Now is the time for B2B buyers to explore innovative uses and applications, solidifying their competitive edge. Engage with suppliers, request samples, and consider collaborative opportunities to fully leverage the advantages of flotex foam in your product line.

Illustrative image related to flotex foam

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to flotex foam