Everything You Need to Know About Flex Connector Sourcing in 2025

Introduction: Navigating the Global Market for flex connector

In the dynamic landscape of international trade, sourcing flex connectors presents unique challenges for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. These essential components, used to link electrical conduits and systems, require careful consideration regarding material specifications, regulatory compliance, and environmental factors. This guide aims to serve as a comprehensive resource for navigating the complexities of the global market for flex connectors.

Throughout this guide, we will explore various types of flex connectors, their applications across different industries, and the criteria for effectively vetting suppliers. Additionally, we will address cost considerations and the impact of regional market trends on pricing and availability. By equipping international B2B buyers with in-depth insights and practical strategies, this guide empowers them to make informed purchasing decisions that align with their operational needs and compliance requirements.

Whether you are a buyer in Germany seeking high-quality materials or a procurement manager in Saudi Arabia looking for reliable suppliers, understanding the nuances of flex connectors is crucial for optimizing your supply chain. With our expert guidance, you can confidently navigate this market, ensuring that your sourcing strategy is both efficient and effective.

Understanding flex connector Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flexible Metallic Connectors | Made from metal, offering durability and flexibility; often liquid-tight. | Electrical installations, industrial machinery | Pros: High durability, excellent flexibility. Cons: Heavier than non-metallic options. |

| Non-Metallic Flex Connectors | Lightweight, often made from PVC or nylon; resistant to corrosion. | Residential wiring, low-voltage applications | Pros: Lightweight, corrosion-resistant. Cons: Less durable in harsh environments. |

| Insulated Flex Connectors | Feature an insulated throat to prevent electrical shorts; often used in wet locations. | Outdoor installations, wet environments | Pros: Enhanced safety, prevents shorts. Cons: May be more expensive than non-insulated types. |

| Strain Relief Connectors | Designed to absorb stress and prevent cable damage; often used in high-vibration areas. | Robotics, automotive applications | Pros: Protects cables from wear, enhances longevity. Cons: Can be bulkier than standard connectors. |

| Duplex Flex Connectors | Allow for multiple connections; usually feature a duplex opening for versatility. | Complex electrical systems, commercial buildings | Pros: Space-efficient, versatile. Cons: May require more planning for installation. |

What Are Flexible Metallic Connectors and Their Applications?

Flexible metallic connectors are constructed from durable metals, providing both flexibility and strength. These connectors are particularly suited for applications that require a robust solution, such as electrical installations in industrial machinery. Their ability to withstand harsh conditions makes them a preferred choice in environments where durability is crucial. When purchasing, buyers should consider the weight and installation requirements, as these connectors can be heavier compared to non-metallic options.

How Do Non-Metallic Flex Connectors Differ?

Non-metallic flex connectors, typically made from materials like PVC or nylon, are lightweight and resistant to corrosion. These connectors are ideal for residential wiring and low-voltage applications, where the risk of mechanical stress is lower. Their lightweight nature simplifies installation, making them appealing for projects where ease of handling is essential. However, buyers should evaluate the environmental conditions where these connectors will be used, as they may not perform well in extreme conditions compared to their metallic counterparts.

Why Choose Insulated Flex Connectors?

Insulated flex connectors feature a protective throat that prevents electrical shorts, making them highly suitable for outdoor installations and environments exposed to moisture. Their enhanced safety features are critical for projects that prioritize electrical safety. While these connectors may come at a higher price point, the investment can be justified by the added protection and compliance with safety standards, particularly in regions with strict electrical codes.

What Are the Benefits of Strain Relief Connectors?

Strain relief connectors are specifically designed to absorb stress from cable movement, making them essential in high-vibration applications like robotics and automotive systems. By preventing cable damage, these connectors enhance the longevity of electrical systems. Buyers should consider the space and installation requirements, as these connectors can be bulkier than standard options, potentially influencing the overall design of the installation.

How Do Duplex Flex Connectors Enhance Versatility?

Duplex flex connectors provide multiple connection points, making them highly versatile for complex electrical systems found in commercial buildings. Their duplex opening allows for efficient use of space and simplifies wiring configurations. While they can be more complex to install, the benefits in terms of efficiency and adaptability often outweigh the initial challenges. Buyers should assess their specific project needs to determine if the versatility of duplex connectors aligns with their objectives.

Key Industrial Applications of flex connector

| Industry/Sector | Specific Application of flex connector | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electrical & Electronics | Connecting flexible conduits in power distribution | Ensures reliable electrical connections, reducing downtime risk | Compliance with international standards and certifications |

| HVAC Systems | Integration of flexible ducting in air handling units | Enhances energy efficiency and reduces noise transmission | Material compatibility with local regulations and environmental factors |

| Industrial Automation | Linking sensors and actuators in manufacturing plants | Increases system flexibility and adaptability to changing needs | Durability against harsh environments and ease of installation |

| Oil & Gas | Connecting flexible piping in offshore platforms | Ensures safety and reliability in volatile environments | Resistance to corrosion and extreme temperatures |

| Telecommunications | Connecting cables in data centers | Supports high-speed data transmission with minimal interference | Compatibility with various cable types and ease of maintenance |

How Are Flex Connectors Used in Electrical & Electronics Applications?

In the electrical and electronics sector, flex connectors play a crucial role in connecting flexible conduits that carry electrical power. These connectors are designed to accommodate movement and vibrations, ensuring a stable and reliable connection. For international buyers, particularly those in regions with variable climates like Africa and the Middle East, sourcing connectors that comply with local and international electrical standards is essential to minimize operational risks and enhance safety.

What Role Do Flex Connectors Play in HVAC Systems?

In HVAC systems, flex connectors are integral to the integration of flexible ducting, which is essential for efficient air distribution. They help reduce noise transmission and allow for easy adjustments during installation. Buyers from Europe, such as Germany, should consider sourcing connectors that comply with energy efficiency regulations and local building codes, ensuring optimal performance and sustainability in their projects.

How Are Flex Connectors Utilized in Industrial Automation?

Flex connectors are vital in industrial automation, particularly for linking sensors and actuators in manufacturing environments. They provide the flexibility needed to adapt to dynamic production processes while maintaining reliable connections. For businesses in South America looking to enhance their automation systems, sourcing connectors that can withstand harsh industrial conditions, such as dust and moisture, is critical for long-term reliability.

Why Are Flex Connectors Important in the Oil & Gas Sector?

In the oil and gas industry, flex connectors are used to connect flexible piping systems on offshore platforms. These connectors are designed to withstand extreme environmental conditions, ensuring safety and reliability in volatile settings. Buyers in this sector must prioritize sourcing connectors that offer high corrosion resistance and can endure significant temperature fluctuations, which are common in regions like the Middle East.

How Do Flex Connectors Support Telecommunications Infrastructure?

Flex connectors are essential in telecommunications, particularly for connecting cables in data centers. They facilitate high-speed data transmission while minimizing signal interference. International B2B buyers, especially in Europe, should focus on sourcing connectors that are compatible with various cable types and ensure ease of maintenance, as this can significantly impact the overall efficiency of telecommunications networks.

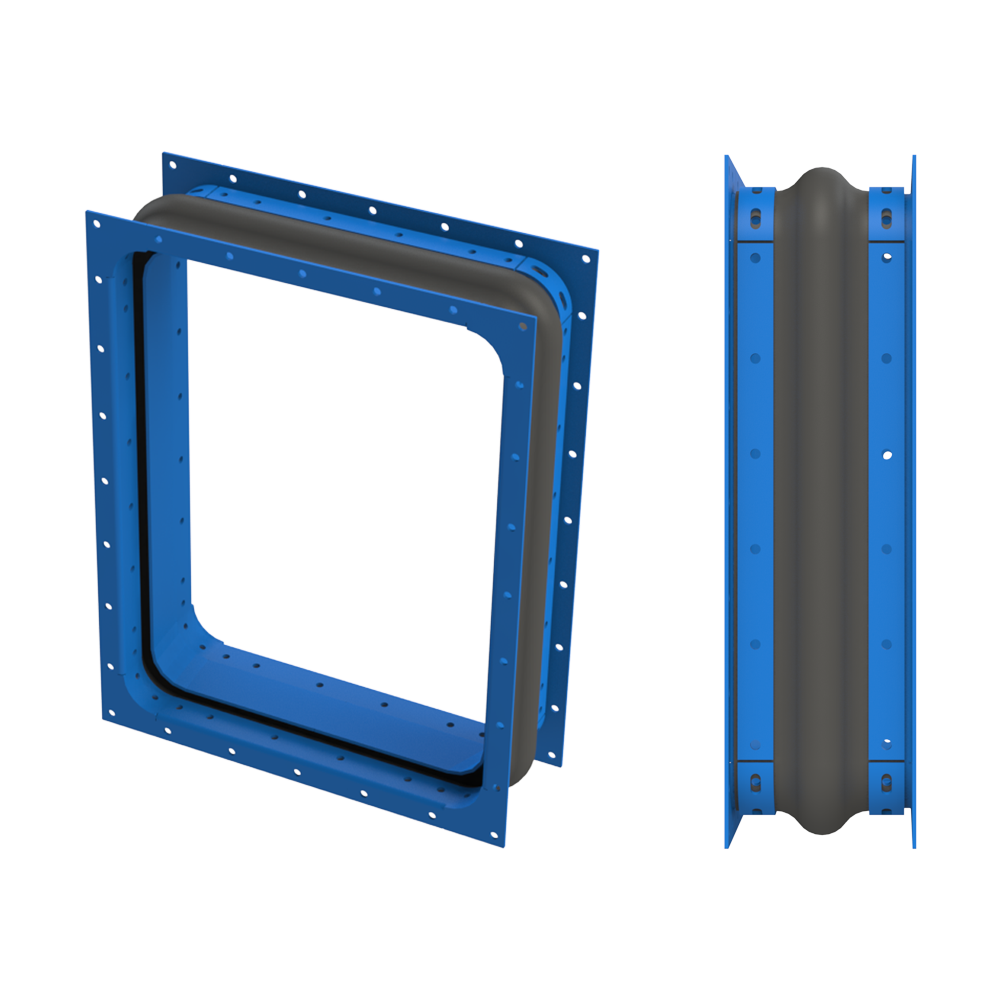

Illustrative image related to flex connector

3 Common User Pain Points for ‘flex connector’ & Their Solutions

Scenario 1: Difficulty in Sourcing the Right Flex Connectors for Diverse Applications

The Problem: B2B buyers often face the challenge of sourcing flex connectors that meet specific application requirements. With the diversity of projects ranging from industrial installations to commercial settings, the need for connectors that can handle different cable types, sizes, and environmental conditions becomes paramount. Buyers may struggle with limited supplier options, unclear specifications, or connectors that don’t align with the unique demands of their projects. This can lead to delays, increased costs, and ultimately, dissatisfaction with the installation’s performance.

The Solution: To mitigate sourcing difficulties, buyers should conduct thorough research to identify suppliers that specialize in a wide range of flex connectors. Prioritize suppliers with robust product catalogs that include detailed specifications, such as material composition, size compatibility, and environmental ratings. It’s advisable to engage with manufacturers that offer customization options, allowing for tailored solutions that match the specific requirements of your projects. Additionally, leveraging online platforms for product comparisons and reading user reviews can provide insights into performance and reliability, helping buyers make informed decisions.

Scenario 2: Ensuring Compatibility with Existing Electrical Systems

The Problem: Many buyers encounter compatibility issues when integrating new flex connectors into existing electrical systems. This often arises from variations in connector design, threading, or size, which can lead to improper fittings, potential safety hazards, and operational inefficiencies. Such incompatibility can delay project timelines and inflate costs due to the need for additional fittings or modifications.

The Solution: To ensure compatibility, buyers should begin by conducting a comprehensive audit of their existing systems, noting the specifications of current connectors and conduits. When sourcing new flex connectors, it is crucial to consult with suppliers who provide comprehensive technical support, including compatibility assessments. Buyers should also consider connectors that feature adjustable or universal fittings, which can accommodate a range of sizes and threading types. Providing installation teams with detailed installation guides or training sessions can further ensure that compatibility is maximized, reducing the risk of costly mistakes during integration.

Scenario 3: Managing Installation Challenges and Safety Standards

The Problem: The installation of flex connectors can present several challenges, particularly in terms of adhering to safety standards and ensuring proper installation techniques. Inadequate installation can lead to equipment failures, safety hazards, and non-compliance with regulatory standards, especially in industrial settings where the stakes are high. Buyers often find it difficult to ensure that their teams are adequately trained to handle specific installation requirements, leading to inconsistent results.

The Solution: To address installation challenges, buyers should prioritize suppliers that offer comprehensive training programs and installation support. Engaging in workshops or webinars can help installation teams understand best practices and safety standards related to flex connectors. Additionally, adopting a standardized installation process, complete with checklists and quality control measures, can streamline operations and ensure compliance with safety regulations. Investing in high-quality, user-friendly connectors that simplify installation can also reduce the potential for errors, ultimately leading to safer and more efficient operations. Regular feedback sessions with installation teams can provide insights into recurring issues, enabling ongoing improvements to the installation process.

Strategic Material Selection Guide for flex connector

What Are the Key Properties of Common Materials Used in Flex Connectors?

When selecting materials for flex connectors, it is crucial to consider their properties, as these directly affect performance in various applications. Here, we analyze four common materials: aluminum, steel, zinc, and nylon. Each material has unique characteristics that influence its suitability for specific environments and applications.

How Does Aluminum Perform as a Material for Flex Connectors?

Aluminum is lightweight and offers excellent corrosion resistance, making it a popular choice for flex connectors, especially in environments where moisture and oxidation are concerns. It typically has a temperature rating of up to 150°C (302°F), which is suitable for many industrial applications. However, while aluminum is durable, it may not withstand extreme pressure as effectively as other materials.

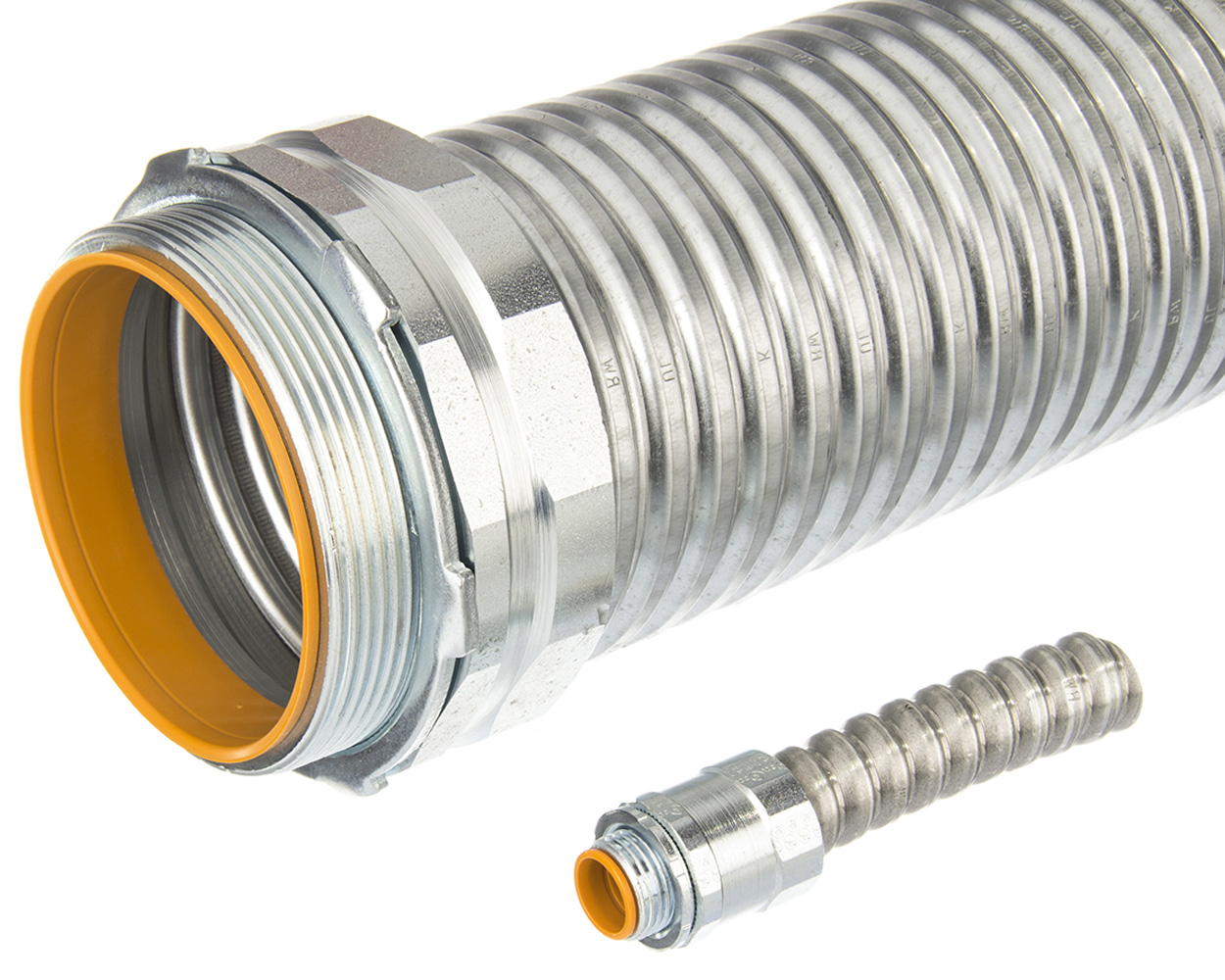

Illustrative image related to flex connector

Pros:

– Lightweight and easy to handle.

– Good corrosion resistance, ideal for humid environments.

– Cost-effective for mass production.

Cons:

– Lower pressure tolerance compared to steel.

– Can be prone to wear in high-friction applications.

For international buyers, especially in regions like Europe and the Middle East, compliance with standards such as DIN and IEC is essential. Aluminum connectors often meet these standards, making them a reliable choice.

What Benefits and Limitations Does Steel Offer in Flex Connectors?

Steel, particularly stainless steel, is known for its high strength and durability. It can handle higher pressures and temperatures, typically rated up to 250°C (482°F). This makes steel connectors suitable for heavy-duty applications, including those in industrial settings.

Pros:

– High strength and durability, suitable for demanding applications.

– Excellent pressure and temperature resistance.

– Long lifespan, reducing replacement frequency.

Cons:

– Heavier than aluminum, which can complicate installation.

– Higher cost compared to aluminum and zinc.

Steel connectors are often preferred in industries where mechanical stress is a concern. Buyers from regions like Africa and South America should consider the availability of stainless steel options that comply with ASTM standards.

How Does Zinc Compare as a Material for Flex Connectors?

Zinc is commonly used for its excellent corrosion resistance and cost-effectiveness. It is often found in die-cast connectors, which are easy to manufacture and provide a good seal against moisture. Zinc connectors typically have a temperature rating of around 120°C (248°F).

Pros:

– Cost-effective and easy to manufacture.

– Good corrosion resistance, especially when plated.

– Lightweight, facilitating easier installation.

Illustrative image related to flex connector

Cons:

– Lower temperature and pressure ratings than steel and aluminum.

– Prone to galvanic corrosion when in contact with other metals.

For international buyers, zinc connectors are often compliant with various standards, but it’s important to ensure compatibility with local regulations, especially in Europe where specific certifications may apply.

What Role Does Nylon Play in Flex Connector Applications?

Nylon is a non-metallic option that offers flexibility and resistance to chemical corrosion. It is ideal for applications where electrical insulation is paramount. Nylon connectors typically operate effectively within a temperature range of -40°C to 120°C (-40°F to 248°F).

Pros:

– Excellent electrical insulation properties.

– Resistant to many chemicals, making it suitable for various environments.

– Lightweight and flexible, allowing for easier installation.

Cons:

– Lower mechanical strength compared to metals.

– Limited temperature and pressure ratings.

For buyers in regions like Saudi Arabia and Germany, nylon connectors can meet specific safety and electrical standards, making them suitable for diverse applications.

Illustrative image related to flex connector

Summary Table of Material Selection for Flex Connectors

| Material | Typical Use Case for flex connector | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | General industrial applications | Lightweight and corrosion-resistant | Lower pressure tolerance | Medium |

| Steel | Heavy-duty industrial applications | High strength and durability | Heavier and more expensive | High |

| Zinc | Moisture-prone environments | Cost-effective and good corrosion resistance | Lower temperature/pressure ratings | Low |

| Nylon | Electrical insulation applications | Excellent insulation and chemical resistance | Lower mechanical strength | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various materials used in flex connectors, facilitating informed purchasing decisions tailored to specific application requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for flex connector

What Are the Key Stages in the Manufacturing Process of Flex Connectors?

Manufacturing flex connectors involves several critical stages that ensure the final product meets industry standards and customer requirements. The process typically encompasses material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used?

The manufacturing process begins with the selection of high-quality raw materials, commonly metals like aluminum, steel, or die-cast zinc. These materials are chosen for their strength, flexibility, and resistance to corrosion. Before fabrication, materials undergo rigorous testing for properties such as tensile strength and ductility. This ensures that only the best materials are used, providing durability and reliability in various applications.

Illustrative image related to flex connector

How Are Flex Connectors Formed?

Once the materials are prepared, they are subjected to forming techniques. Common methods include stamping, bending, and extrusion. Stamping involves using dies to cut and shape the metal into specific forms, while bending adjusts the material to create the desired angles and configurations. Extrusion, often used for creating hollow sections, allows for the efficient production of long components with uniform cross-sections. Advanced technologies such as CNC (Computer Numerical Control) machining may also be employed to enhance precision and repeatability.

What Assembly Techniques Are Commonly Used for Flex Connectors?

After forming, the next stage is assembly. This involves joining various components, such as connectors, strain reliefs, and seals. Techniques like welding, soldering, or using mechanical fasteners are common. Each method has its advantages; for instance, welding provides a strong, permanent bond, while mechanical fasteners allow for easier disassembly and maintenance.

Quality assurance is a vital aspect of the assembly process. Components are inspected for alignment, fit, and finish. This ensures that each connector functions as intended and meets the specified tolerances.

What Finishing Processes Are Involved in Flex Connector Manufacturing?

Finishing processes enhance the aesthetic and functional properties of flex connectors. Common techniques include electroplating, painting, or anodizing. These processes not only improve the appearance but also provide additional protection against environmental factors such as moisture and chemicals. This is particularly important for connectors used in outdoor or industrial settings where exposure to harsh conditions is common.

What International Standards Govern Flex Connector Quality Assurance?

Quality assurance for flex connectors is governed by various international standards, such as ISO 9001, which outlines requirements for a quality management system (QMS). Compliance with ISO standards ensures that manufacturers consistently produce high-quality products. Additionally, industry-specific standards like CE marking in Europe or API specifications in the oil and gas sector may also apply, depending on the application of the connectors.

How Is Quality Controlled Throughout the Manufacturing Process?

Quality control (QC) is integral to the manufacturing of flex connectors and typically involves several checkpoints:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials for compliance with specifications before they enter production. Suppliers must provide certification of material properties, which can be verified through lab tests.

-

In-Process Quality Control (IPQC): During the manufacturing process, routine checks are performed to monitor parameters such as dimensions, tolerances, and surface finishes. This helps identify any deviations early, reducing waste and rework.

-

Final Quality Control (FQC): After assembly and finishing, connectors undergo comprehensive testing to ensure they meet all specifications. Common tests include electrical conductivity, tensile strength, and environmental resistance. Certificates of compliance are often issued at this stage.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must ensure their suppliers maintain rigorous quality control practices. One effective way to do this is through audits. Buyers can request to conduct on-site audits of the manufacturing facilities, assessing the quality management systems, processes, and compliance with international standards.

Illustrative image related to flex connector

Additionally, suppliers should provide detailed quality control reports, including test results and compliance certifications. Third-party inspections by accredited organizations can also add an extra layer of assurance. These inspections verify that the products meet both industry standards and the buyer’s specifications.

What Are the QC and Certification Nuances for International Buyers?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of QC and certifications is crucial. Different regions may have specific requirements that must be met, and compliance with local regulations can vary significantly.

For instance, European buyers may prioritize CE marking, which signifies conformity with health, safety, and environmental protection standards. In contrast, buyers in the Middle East may focus on certifications that comply with local standards like Saudi Standards, Metrology and Quality Organization (SASO).

Buyers should engage with suppliers who have experience exporting to their region, as they will be more familiar with the necessary documentation and certification processes. Ensuring that suppliers can navigate these complexities will help mitigate risks associated with non-compliance.

Conclusion: Why Quality Assurance Is Essential in Flex Connector Manufacturing

In summary, the manufacturing processes and quality assurance practices for flex connectors are vital for ensuring that the final products meet the high standards required in various applications. By understanding these processes and actively engaging with suppliers regarding their QC practices, international B2B buyers can make informed decisions that lead to successful partnerships and high-quality product outcomes. Quality assurance is not just a checklist; it’s a commitment to excellence that can significantly impact operational efficiency and product reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘flex connector’

In the competitive landscape of international B2B sourcing, procuring flex connectors requires a methodical approach. This guide provides a structured checklist to help buyers navigate the complexities of selecting the right flex connectors that meet their operational needs.

Illustrative image related to flex connector

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the flex connectors you select will suit your application. Consider the type of conduit you will be using, the required bend radius, and the environmental conditions they will face. This includes factors like moisture, temperature fluctuations, and potential exposure to chemicals.

- Material Choices: Determine whether aluminum, steel, or non-metallic options are best for your application.

- Size and Trade Specifications: Identify the appropriate sizes and trade dimensions necessary for your project.

Step 2: Identify Compliance and Standards

Flex connectors must comply with local and international standards to ensure safety and reliability. Research applicable regulations in your region, such as UL, IEC, or ISO certifications, depending on your target market.

- Certification Verification: Ensure that the products have the necessary certifications by reputable organizations.

- Regional Compliance: Understand any specific compliance requirements that may apply in regions such as Europe or the Middle East.

Step 3: Evaluate Potential Suppliers

Before finalizing a supplier, conduct thorough evaluations to gauge their reliability and quality. Request documentation such as company profiles, case studies, and references from clients in similar industries.

- Supplier Background Check: Investigate the supplier’s history, experience, and market reputation.

- Quality Assurance Processes: Assess the supplier’s quality control measures and product testing protocols.

Step 4: Request Samples for Testing

Obtaining samples allows you to assess the quality and functionality of the flex connectors firsthand. This is essential for ensuring that they meet your technical specifications and can withstand operational demands.

- Testing for Fit and Function: Evaluate how well the connectors fit with your existing systems and whether they perform under expected conditions.

- Feedback from Technical Teams: Involve your engineering or technical teams in the evaluation process to gather insights on usability.

Step 5: Negotiate Terms and Pricing

Negotiating favorable terms is vital for optimizing your procurement process. Discuss pricing, minimum order quantities, and delivery timelines to ensure they align with your project budget and schedule.

- Volume Discounts: Inquire about bulk purchase discounts to maximize cost savings.

- Lead Times: Confirm production and shipping timelines to avoid project delays.

Step 6: Finalize Your Order and Monitor Delivery

Once you’ve settled on a supplier and agreed on terms, finalize your order. However, it’s important to maintain open lines of communication regarding the status of your delivery.

- Tracking Shipments: Utilize tracking systems provided by suppliers to monitor delivery progress.

- Quality Control Upon Arrival: Inspect the connectors upon delivery to ensure they meet your specifications and standards.

Step 7: Establish Long-term Relationships

Building a lasting relationship with your suppliers can lead to better pricing, improved service, and access to new products. Consider regular evaluations and feedback sessions to foster collaboration.

- Feedback Loop: Create a system for providing feedback on product performance and service levels.

- Supplier Development Programs: Engage in programs that enhance supplier capabilities and foster innovation.

By following this checklist, B2B buyers can streamline the procurement process for flex connectors, ensuring that they make informed decisions that align with their operational needs.

Comprehensive Cost and Pricing Analysis for flex connector Sourcing

Understanding the cost structure and pricing dynamics of flex connectors is crucial for international B2B buyers. This analysis will cover the essential cost components, price influencers, and provide actionable tips for negotiating favorable terms, particularly for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components for Flex Connectors?

The cost of flex connectors is influenced by several components:

-

Materials: The choice of materials, such as aluminum, zinc, or non-metallic options, significantly impacts pricing. High-quality materials may result in higher initial costs but can lead to improved durability and performance.

-

Labor Costs: Labor expenses vary by region and can affect the overall price of manufacturing flex connectors. In regions with higher labor costs, manufacturers may pass these expenses onto buyers.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize overhead, thus reducing the final price.

-

Tooling: Tooling costs depend on the complexity of the connector design and the need for specialized machinery. Custom tooling can lead to higher initial costs, which might be amortized over larger production runs.

-

Quality Control (QC): Implementing stringent QC measures ensures that the products meet required standards. While this adds to the cost, it can prevent costly returns and replacements down the line.

-

Logistics: Transportation and shipping costs can vary significantly depending on the origin of the product and the destination. Incoterms play a crucial role in determining who bears these costs.

-

Profit Margin: Suppliers typically add a margin to cover their costs and profit. Understanding the market can help buyers negotiate better terms.

How Do Price Influencers Affect Flex Connector Costs?

Several factors influence the pricing of flex connectors:

-

Volume/MOQ: Purchasing in larger volumes can lead to significant discounts. Manufacturers often have Minimum Order Quantities (MOQs) that can affect pricing; hence, consolidating orders can be beneficial.

-

Specifications and Customization: Custom-designed connectors may incur additional costs. Buyers should weigh the benefits of customization against potential price increases.

-

Material Quality and Certifications: Higher quality materials and certifications (such as UL or CE) typically command higher prices. Buyers should consider whether these certifications are necessary for their applications.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium for their reliability and service quality, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the terms of shipment (e.g., FOB, CIF) can help buyers evaluate total landed costs and avoid unexpected charges.

What Tips Can Help Buyers Negotiate Better Prices?

To optimize sourcing strategies and achieve cost-efficiency, buyers should consider the following:

-

Negotiate Terms: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Building a relationship can often lead to better deals.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, replacement, and operational costs to assess the overall value.

-

Understand Pricing Nuances: Different regions may have varying pricing structures due to local economic conditions, tariffs, or shipping costs. Familiarize yourself with these factors to make informed decisions.

-

Stay Informed on Market Trends: Keeping abreast of market trends and material costs can provide leverage in negotiations. For instance, if metal prices are rising, suppliers might be more open to discussions about fixed pricing agreements.

-

Consider Long-Term Contracts: If a supplier offers favorable pricing for long-term commitments, it can provide cost stability and secure supply chains.

Conclusion

Navigating the cost and pricing landscape of flex connectors requires a thorough understanding of the various components and influencers at play. By leveraging this knowledge, international B2B buyers can make informed decisions that align with their operational needs and budgetary constraints. As always, it is advisable to request indicative prices from multiple suppliers to ensure competitive sourcing.

Alternatives Analysis: Comparing flex connector With Other Solutions

Exploring Alternative Solutions to Flex Connectors

In the world of electrical and mechanical engineering, selecting the right connector is crucial for ensuring optimal performance and reliability. While flex connectors offer unique benefits, various alternative solutions can also meet similar needs. This analysis will compare flex connectors with two prominent alternatives: rigid conduit systems and flexible piping connectors. Each option has its strengths and weaknesses, making it essential for B2B buyers to consider their specific requirements when making a choice.

| Comparison Aspect | Flex Connector | Rigid Conduit System | Flexible Piping Connectors |

|---|---|---|---|

| Performance | Excellent flexibility and adaptability; reduces stress on joints | High strength and durability; ideal for static applications | Effective noise and vibration isolation; compensates for movement |

| Cost | Moderate upfront cost; cost-effective for dynamic applications | Generally higher initial investment; lower long-term maintenance costs | Competitive pricing; may require additional fittings |

| Ease of Implementation | Easy to install; requires minimal tools and training | More complex installation; often requires professional assistance | Simple installation; flexible design allows for quick adaptations |

| Maintenance | Low maintenance; designed for longevity | Low maintenance; but can be challenging to access for repairs | Moderate maintenance; regular checks needed to ensure integrity |

| Best Use Case | Ideal for applications with frequent movement or changes | Best for permanent installations in stable environments | Suitable for systems requiring noise reduction and flexibility |

What Are the Pros and Cons of Rigid Conduit Systems?

Rigid conduit systems are known for their strength and durability, making them suitable for environments where protection from physical damage is paramount. They are often used in industrial settings, providing a secure pathway for electrical wiring. However, their installation can be more labor-intensive and often requires skilled labor, leading to higher upfront costs. Once installed, they typically require less maintenance, but accessing the conduits for repairs can be cumbersome.

How Do Flexible Piping Connectors Compare?

Flexible piping connectors, such as KINFLEX™ connectors, offer a unique solution by isolating noise and vibration while accommodating movement and misalignment. These connectors are ideal for HVAC and plumbing applications where flexibility and sound dampening are required. While they are generally easy to install and competitively priced, users must consider that they may need additional fittings, which can add to the overall cost. Regular maintenance checks are also recommended to ensure the connectors remain effective over time.

How Can B2B Buyers Choose the Right Solution?

Choosing the right connector solution hinges on the specific needs of the application. Buyers should evaluate the performance requirements, cost constraints, and installation capabilities of their teams. For dynamic environments where flexibility is essential, flex connectors may be the best option. In contrast, rigid conduits excel in static settings, while flexible piping connectors are optimal for systems needing noise reduction. By carefully considering these factors, businesses can select the most appropriate solution to enhance operational efficiency and reliability.

Essential Technical Properties and Trade Terminology for flex connector

What Are the Key Technical Properties of Flex Connectors for B2B Buyers?

When sourcing flex connectors, understanding their technical properties is crucial for ensuring compatibility and performance in various applications. Here are some essential specifications to consider:

-

Material Grade: Flex connectors are typically made from materials such as aluminum, zinc, or steel. The choice of material affects durability, weight, and resistance to corrosion. For example, aluminum connectors are lightweight and resistant to rust, making them suitable for outdoor applications, while zinc-plated options provide enhanced corrosion resistance. Selecting the right material can significantly impact the longevity and reliability of your installation.

-

Trade Size: This dimension indicates the connector’s compatibility with specific conduit sizes. Common trade sizes include 3/8″, 1/2″, and 3/4″. It is essential to match the trade size with the conduit to ensure a secure and safe installation. Incorrect sizing can lead to leaks or failures in electrical systems, which can be costly in terms of repairs and downtime.

-

Connection Type: Flex connectors can come with various connection types, such as clamp screw, male threaded, or snap-in. The connection type determines how the connector interfaces with other components. For instance, snap-in connectors allow for quick and easy installation, which can save time during assembly, while screw-type connections offer a more secure fit for heavy-duty applications.

-

Liquid Tight Rating: This specification indicates whether a connector can prevent the ingress of liquids. Liquid-tight connectors are essential in environments where exposure to moisture is a concern, such as outdoor installations or in damp locations. Ensuring the connector has the appropriate liquid-tight rating can protect your electrical systems from water damage and ensure compliance with safety standards.

-

Strain Relief Features: Strain relief is crucial in preventing damage to cables and connectors from bending or pulling forces. Connectors with built-in strain relief help maintain the integrity of the electrical system, reducing the risk of failure due to mechanical stress. This feature is especially important in applications where flexibility and movement are common.

-

Temperature Rating: Flex connectors are designed to operate within specific temperature ranges. Understanding the temperature rating is vital for applications in extreme environments, as it ensures that the connector will perform reliably without degrading over time. Selecting connectors with suitable temperature ratings can prevent failures that may arise from overheating or freezing.

What Are Common Trade Terms Related to Flex Connectors?

Familiarizing yourself with industry terminology can facilitate smoother transactions and better communication with suppliers. Here are several key terms relevant to flex connectors:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce components that are used in another company’s end products. In the context of flex connectors, OEMs may supply connectors that are integrated into larger systems, requiring precise specifications and quality assurance.

-

MOQ (Minimum Order Quantity): MOQ represents the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management, particularly for businesses that may not need large volumes of flex connectors but still require reliable supplies.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to obtain pricing and other details for specific products. When sourcing flex connectors, sending out RFQs can help businesses compare options and negotiate better terms, ensuring they receive competitive pricing and suitable specifications.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for managing shipping, costs, and liability when importing flex connectors from overseas suppliers.

-

Lead Time: This term refers to the amount of time it takes for an order to be fulfilled after it is placed. Knowing the lead time for flex connectors can help businesses plan their projects more effectively and avoid delays in production or installation.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when selecting flex connectors, ensuring compatibility, reliability, and cost-effectiveness in their applications.

Navigating Market Dynamics and Sourcing Trends in the flex connector Sector

Market Overview & Key Trends in the Flex Connector Sector

The flex connector market is experiencing dynamic growth, primarily driven by the rising demand for flexible electrical systems across various industries, including construction, telecommunications, and automotive. Global drivers such as urbanization, technological advancements, and the increasing need for efficient electrical installations are propelling the market forward. Key trends include the growing adoption of smart technologies and automation in industrial applications, which require reliable and adaptable connectivity solutions.

International B2B buyers from regions like Africa, South America, the Middle East, and Europe should pay close attention to emerging technologies that enhance the performance and safety of flex connectors. This includes innovations such as liquid-tight connectors and insulated throat designs that provide enhanced protection against environmental factors. Additionally, the market is witnessing a shift towards modular systems, allowing for easier installation and maintenance, which is particularly beneficial for large-scale projects.

Furthermore, the increasing focus on energy efficiency and sustainability is shaping sourcing trends. Buyers are encouraged to prioritize suppliers who offer products that meet international standards for quality and safety, particularly those aligned with IEC and UL certifications. A proactive approach to understanding local regulations and standards will also help mitigate compliance risks and ensure the successful implementation of projects.

How Does Sustainability & Ethical Sourcing Impact the Flex Connector Market?

Sustainability is becoming a central theme in the flex connector sector as businesses increasingly recognize their environmental impact. The production of electrical connectors can involve significant resource use and waste generation, making it essential for companies to adopt sustainable practices. Ethical sourcing is paramount, as buyers seek suppliers who prioritize responsible manufacturing processes, including the use of recyclable materials and the reduction of carbon footprints.

Buyers should look for products that carry ‘green’ certifications, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals). These certifications ensure that products are free from harmful substances and comply with environmental regulations. Additionally, sourcing from manufacturers that invest in renewable energy sources or adopt waste reduction strategies can enhance a company’s corporate responsibility profile.

In regions like Africa and South America, where economic development is closely tied to environmental sustainability, ethical sourcing can also serve as a competitive advantage. By aligning sourcing strategies with sustainable practices, businesses can not only meet regulatory demands but also appeal to a growing segment of environmentally conscious consumers and clients.

What is the Brief Evolution and History of Flex Connectors?

The evolution of flex connectors has been shaped by advancements in electrical engineering and the growing need for flexibility in electrical installations. Initially developed to provide basic connectivity, early flex connectors were primarily rigid and limited in their application. As industries began to embrace more complex electrical systems, the demand for more adaptable solutions led to the development of flexible metallic conduits and connectors.

Over the years, innovations such as improved materials, enhanced insulation techniques, and the introduction of liquid-tight designs have transformed the flex connector landscape. These advancements have not only improved the performance and longevity of connectors but have also made them essential components in modern electrical systems. Today, flex connectors are integral to a variety of applications, from residential wiring to large-scale industrial installations, reflecting the ongoing trend towards greater versatility and efficiency in electrical design.

In conclusion, the flex connector sector is poised for continued growth, driven by technological advancements and an increasing focus on sustainability. International buyers must navigate these market dynamics thoughtfully, ensuring they partner with suppliers who align with their business values and operational needs.

Frequently Asked Questions (FAQs) for B2B Buyers of flex connector

-

How do I select the right flex connector for my application?

Choosing the right flex connector involves understanding the specific requirements of your application. Consider factors such as the type of conduit (e.g., flexible metallic or non-metallic), the diameter of the cable, and the environmental conditions (like moisture or temperature). Ensure the connector’s material (such as zinc or nylon) is compatible with the conduit and can withstand the stresses of expansion, contraction, and vibration. Consulting with suppliers about the specifications can help ensure you select the most appropriate connector for your needs. -

What are the key features to look for in a flex connector?

Key features to consider include the connector’s material, which affects durability and suitability for specific environments, such as liquid-tight or insulated options. The connection type (e.g., clamp screw, snap-in) should also match your installation requirements. Additionally, look for features like strain relief and compatibility with various cable types. Understanding these features can help ensure the connector performs reliably over time, reducing the need for replacements and maintenance. -

What is the minimum order quantity (MOQ) for flex connectors?

Minimum order quantities for flex connectors vary by supplier and manufacturer. Typically, MOQs can range from as low as 10 units to several hundred, depending on the type and customization of the connectors. When sourcing, it’s essential to discuss your needs with potential suppliers to negotiate MOQs that align with your purchasing strategy, especially if you’re testing different products or are a smaller buyer. -

How can I verify the quality of flex connectors from suppliers?

To ensure quality, request certifications and compliance documentation from suppliers, such as ISO certifications or industry-specific standards. Additionally, consider asking for samples to assess the connectors’ construction and performance. Reading reviews and seeking recommendations from other businesses can also provide insights into a supplier’s reliability. Establishing a quality assurance protocol, including inspection upon receipt, can further mitigate risks. -

What payment terms are commonly offered for flex connector purchases?

Payment terms can vary widely depending on the supplier and the relationship established. Common terms include net 30 or net 60 days, requiring payment within that timeframe after invoicing. Some suppliers may offer discounts for early payments or require a deposit for larger orders. It’s advisable to clarify payment options and negotiate terms that suit your cash flow while ensuring security in your transactions. -

How do I handle logistics and shipping for international orders of flex connectors?

When ordering flex connectors internationally, consider logistics factors such as shipping methods, costs, and delivery timelines. Work with suppliers who have experience in international shipping to ensure compliance with customs regulations. It may also be beneficial to partner with a freight forwarder to streamline the process. Additionally, discuss packaging options that protect the connectors during transit to avoid damage. -

Can flex connectors be customized to fit specific applications?

Yes, many manufacturers offer customization options for flex connectors, including size, material, and features tailored to specific applications. Discuss your requirements with potential suppliers, as they may provide solutions that meet your unique needs. Customization can enhance performance and compatibility, but be mindful of potential impacts on lead times and costs associated with bespoke products. -

What are the common applications for flex connectors in various industries?

Flex connectors are widely used across multiple industries, including construction, manufacturing, and telecommunications. They are essential in environments where flexibility and movement are required, such as in machinery, HVAC systems, and electrical installations. Understanding the specific applications in your industry can help you choose the right type of connector, ensuring reliability and efficiency in your operations.

Top 7 Flex Connector Manufacturers & Suppliers List

1. Maine Electric Supply – Flex Connectors

Domain: mainelectricsupply.com

Registered: 2001 (24 years)

Introduction: Flex Connectors – Various sizes and materials available including Zinc, Aluminum, and Steel. Features include Non-Insulated, Liquid Tight, and Strain Relief options. Suitable for use with Aluminum/Steel AC/MC/Flexible Metal Conduit. Connection types include Clamp Screw, Snap-In, and Threaded. Available sizes range from 3/8″ to 4″. Brands include Arlington, AFC Cable Systems, and others.

2. Galesburg Electric – Flex Connectors

Domain: galesburgelectric.com

Registered: 1997 (28 years)

Introduction: Flex Connectors are part of the Conduit & Fittings category offered by Galesburg Electric/Industrial Supply, Inc. They include Flexible Greenfield – Steel, Flexible to EMT Couplings, and Flexible to Rigid Couplings.

3. Graybar – Flexible Metallic Conduit Connectors

Domain: graybar.com

Registered: 1995 (30 years)

Introduction: Flexible Metallic Conduit Connectors available in various trade sizes including 3/8 in., 1/2 in., 3/4 in., 1-1/4 in., 1-1/2 in., 2 in., 2-1/2 in., 3 in., and 4 in. Conduit types include FMC and AC/MC. Lengths range from 1.437 in. to 24 in. Finishes include Electro Plated Zinc, Zinc Plated, Ball Burnished, and Nickel Plated. Temperature ratings vary from -40° to +350°C. Products are sourced from ma…

4. Kinetics Noise – KINFLEX Flexible Connectors

Domain: kineticsnoise.com

Registered: 1996 (29 years)

Introduction: KINFLEX flexible connectors prevent stresses due to expansion and contraction, isolate against the transfer of noise and vibration, and compensate for misalignment. They absorb movement in piping systems caused by varying ambient temperatures and material differences, eliminating the danger of buckling or pulling apart. KINFLEX connectors reduce noise and vibration in systems connected to pumps an…

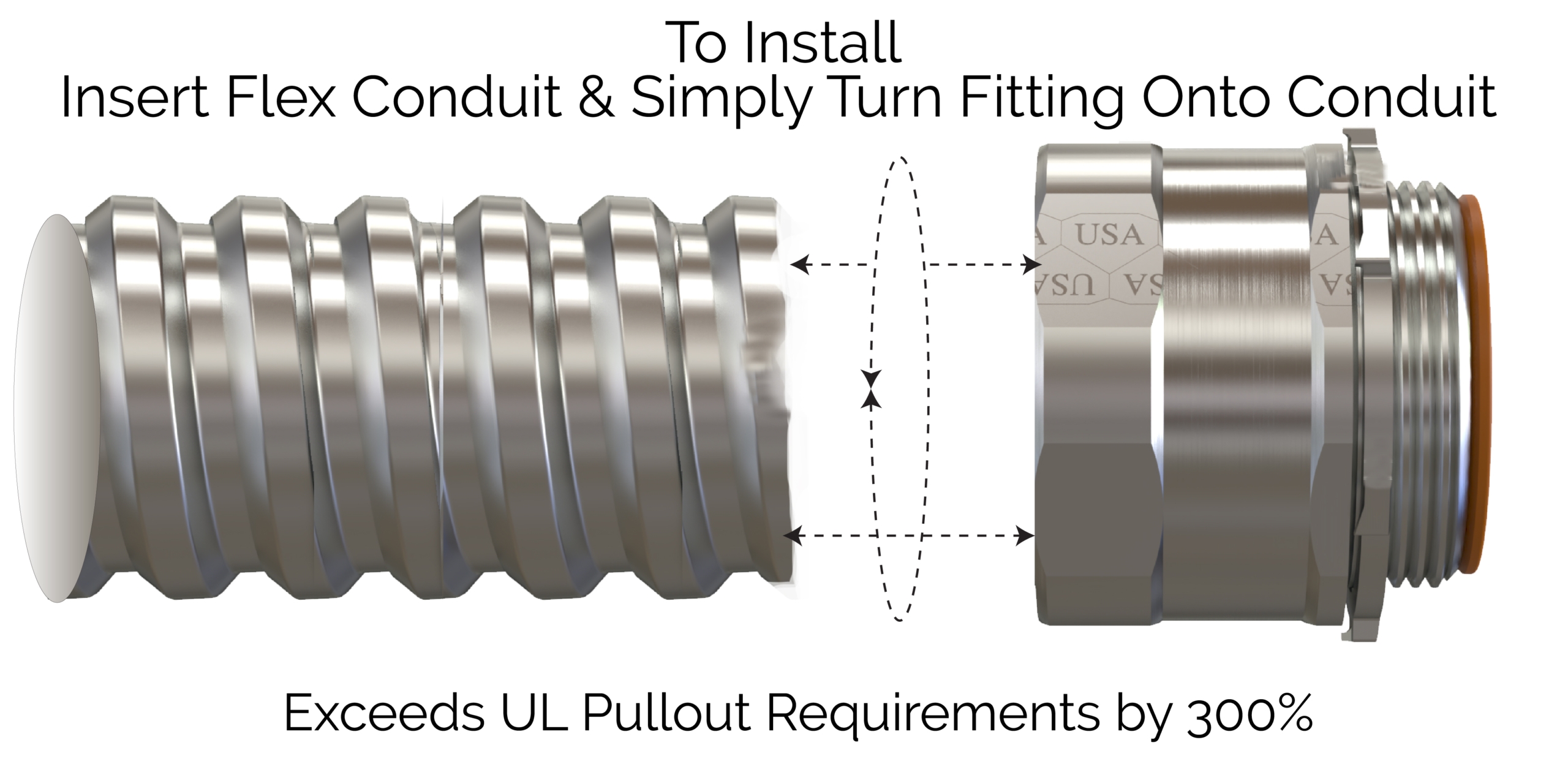

5. SPECflex – FMC FLEX Connectors

Domain: amftgs.com

Registered: 2012 (13 years)

Introduction: SPECflex FMC FLEX Connectors for Greenfield 3/8″ to 4″. Available in straight connectors, 90° connectors, and 45° connectors. Made in the USA with certifications including RoHS compliance, LEEDS certification, and REACH compliance. Suitable for various markets including petrochem facilities, food & beverage, infrastructure & construction, government projects, solar energy, wastewater treatment, in…

6. Emerson – Armored Cable Connectors

Domain: appleton.emerson.com

Registered: 1995 (30 years)

Introduction: This company, Emerson – Armored Cable Connectors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

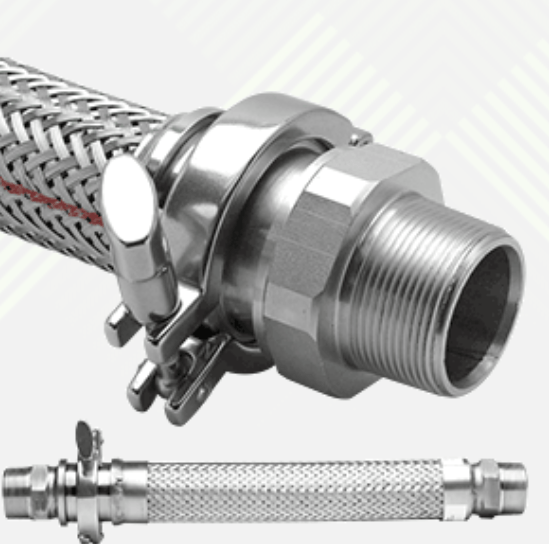

7. Hose Master – Petroleum Flex Connectors

Domain: hosemaster.com

Registered: 1995 (30 years)

Introduction: Hose Master is the leading manufacturer of petroleum flex connectors, offering unique designs and production capabilities. Their FireShield and QuickClamp products are easy to install and safe to use, with a commitment to quality that includes 100% testing of each connector. FireShield connectors are designed to minimize residual stress points, resist aromatic vapor permeation, and provide strong …

Strategic Sourcing Conclusion and Outlook for flex connector

In the rapidly evolving landscape of flex connectors, strategic sourcing emerges as a critical component for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The diverse applications of flex connectors, from electrical installations to mechanical systems, underscore their importance in ensuring operational efficiency and reliability. By prioritizing quality and compatibility, businesses can mitigate risks associated with poor performance and enhance overall project outcomes.

Investing in flexible connectors that meet international standards not only enhances product reliability but also fosters long-term supplier relationships. Buyers are encouraged to evaluate potential suppliers based on their ability to provide not just products, but comprehensive support and solutions tailored to specific industry needs. This approach will lead to better cost management and increased agility in responding to market demands.

Looking ahead, the demand for innovative flex connector solutions will continue to rise, driven by advancements in technology and the need for sustainable practices. B2B buyers should seize the opportunity to collaborate with reputable suppliers who can offer cutting-edge products and insights. Embrace strategic sourcing as a pathway to elevate your business and position yourself at the forefront of the flex connector market.

Illustrative image related to flex connector

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to flex connector