Everything You Need to Know About Filter Fluid Sourcing in 2025

Introduction: Navigating the Global Market for filter fluid

In the evolving landscape of industrial applications, sourcing the right filter fluid can pose significant challenges for international B2B buyers. Whether you’re in the oil and gas sector, manufacturing, or environmental management, the need for high-quality filter fluids to enhance operational efficiency is paramount. This comprehensive guide delves into the intricacies of the global market for filter fluids, equipping you with the knowledge to make informed purchasing decisions. From understanding the various types of filter fluids and their specific applications to effective supplier vetting and cost considerations, this resource is designed to address your unique needs.

As buyers from diverse regions—including Africa, South America, the Middle East, and Europe—navigate the complexities of sourcing filter fluids, it is crucial to have access to reliable information. This guide empowers you by providing actionable insights into market trends, regulatory considerations, and best practices for supplier selection. By leveraging the expertise contained within these pages, you can streamline your procurement process, mitigate risks, and ultimately enhance your operational capabilities. Prepare to navigate the global market with confidence, ensuring that your business remains competitive and compliant in an increasingly demanding environment.

Understanding filter fluid Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Water-based Fluids | Solvent-based, easy to clean, environmentally friendly | Automotive, manufacturing, food processing | Pros: Non-toxic, biodegradable. Cons: Less effective in high-temperature environments. |

| Oil-based Fluids | High viscosity, excellent lubrication properties | Industrial machinery, hydraulic systems | Pros: Superior lubrication, withstands high temperatures. Cons: Can be harmful to the environment, harder to clean. |

| Synthetic Fluids | Customizable formulations, enhanced performance | Aerospace, automotive, high-performance engines | Pros: Longer lifespan, better thermal stability. Cons: Higher initial cost, may require specialized disposal. |

| Biodegradable Fluids | Made from renewable resources, eco-friendly | Agriculture, food production | Pros: Environmentally safe, complies with regulations. Cons: May have limited availability and higher cost. |

| Specialty Fluids | Tailored for specific applications, unique properties | Electronics, pharmaceuticals | Pros: Optimized for performance, can enhance product life. Cons: Often more expensive, limited availability. |

What are the Key Characteristics of Water-based Fluids?

Water-based fluids are primarily solvent-based and known for their ease of cleaning and environmental friendliness. They are widely used in applications such as automotive, manufacturing, and food processing, where non-toxic solutions are essential. When considering water-based fluids, buyers should evaluate the specific operational conditions, as these fluids may not perform well in extreme temperatures or heavy-duty applications. Additionally, their biodegradable nature can enhance a company’s sustainability profile.

How Do Oil-based Fluids Compare in Performance?

Oil-based fluids are characterized by their high viscosity and exceptional lubrication properties, making them ideal for industrial machinery and hydraulic systems. They can withstand high temperatures and provide superior lubrication compared to their water-based counterparts. However, buyers should consider the environmental impact, as oil-based fluids can be harmful and are often more challenging to clean up. Cost considerations are also crucial, as the long-term benefits may justify the initial investment.

What Advantages Do Synthetic Fluids Offer?

Synthetic fluids are formulated for enhanced performance and can be customized to meet specific requirements in industries like aerospace and automotive. They boast a longer lifespan and superior thermal stability, making them a preferred choice for high-performance engines. However, the higher initial cost and the need for specialized disposal methods can be a deterrent for some buyers. When purchasing synthetic fluids, companies should assess their operational needs and the potential return on investment.

Why Are Biodegradable Fluids Important for Sustainability?

Biodegradable fluids are made from renewable resources and are designed to be environmentally friendly, making them suitable for agriculture and food production. Their compliance with environmental regulations is a significant advantage for companies aiming for sustainability. However, buyers should be aware of potential limitations in availability and higher costs compared to traditional fluids. Evaluating the long-term benefits and regulatory requirements can help companies make informed decisions.

What are Specialty Fluids and Their Unique Benefits?

Specialty fluids are tailored for specific applications and possess unique properties that enhance performance in fields like electronics and pharmaceuticals. These fluids can optimize product life and efficiency but often come at a higher price point. Buyers should consider the specific requirements of their applications and the availability of these fluids when making purchasing decisions. The investment in specialty fluids can lead to improved operational performance and product longevity, making them worthwhile for many businesses.

Key Industrial Applications of filter fluid

| Industry/Sector | Specific Application of filter fluid | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Lubrication and cooling in machining processes | Enhances machining efficiency and prolongs tool life | Quality certifications, compatibility with materials, and environmental compliance |

| Oil & Gas | Filtration in hydraulic systems | Improves equipment reliability and reduces maintenance costs | Supplier reliability, technical support, and regional availability |

| Food & Beverage | Clarification and filtration in processing | Ensures product purity and compliance with safety standards | Regulatory compliance, hygiene standards, and sustainability practices |

| Chemical Processing | Separation of contaminants in production | Increases yield and product quality, minimizing waste | Chemical compatibility, performance under varying conditions, and sourcing from certified manufacturers |

| Pharmaceuticals | Purification in drug formulation | Guarantees product safety and efficacy, meeting regulatory requirements | Proven track record, certifications, and technical expertise in filtration technologies |

How is Filter Fluid Used in Automotive Manufacturing?

In the automotive manufacturing sector, filter fluid is essential for lubrication and cooling during machining processes. It helps to maintain optimal temperatures and reduces friction between tools and materials, ultimately enhancing machining efficiency and prolonging tool life. For buyers, particularly in regions like Saudi Arabia or Nigeria, it’s crucial to source filter fluids that meet specific quality certifications and compatibility with various materials to ensure seamless integration into existing processes.

What Role Does Filter Fluid Play in the Oil & Gas Industry?

In the oil and gas industry, filter fluid is employed in hydraulic systems to separate contaminants and maintain equipment functionality. By ensuring clean hydraulic fluid, businesses can improve equipment reliability and significantly reduce maintenance costs. International B2B buyers must consider supplier reliability and technical support, especially in remote regions, to ensure consistent supply and support for their operations.

Why is Filter Fluid Important in Food & Beverage Processing?

Filter fluid is critical in the food and beverage industry for clarification and filtration processes. It guarantees product purity and compliance with stringent safety standards, which is paramount for consumer trust and regulatory compliance. Buyers in South America and Africa should prioritize sourcing from suppliers that adhere to hygiene standards and demonstrate sustainable practices to meet the growing demand for safe, high-quality food products.

How is Filter Fluid Used in Chemical Processing?

In chemical processing, filter fluid is utilized to separate contaminants during production, thereby increasing yield and enhancing product quality. This application minimizes waste and ensures that the final products meet industry standards. B2B buyers must ensure that the filter fluids are chemically compatible and perform effectively under varying operational conditions to maintain productivity and compliance.

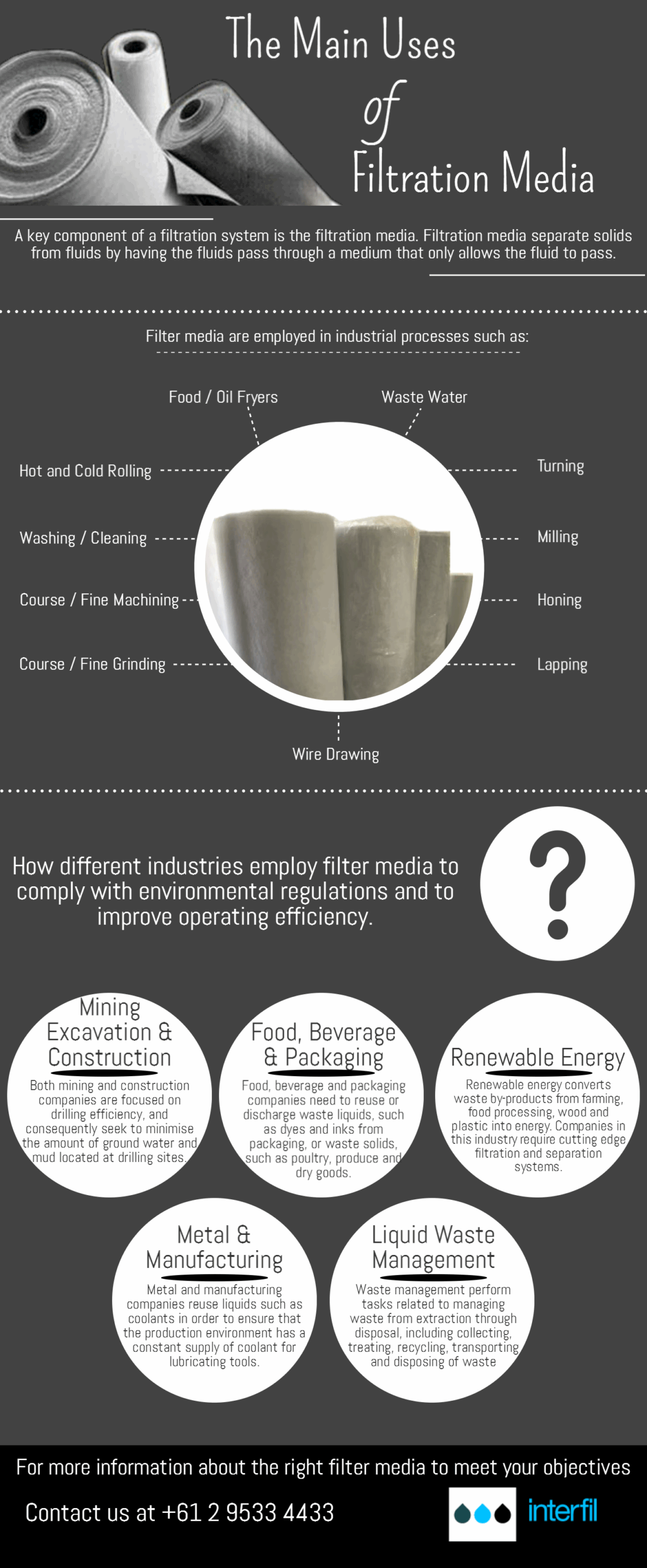

Illustrative image related to filter fluid

What is the Significance of Filter Fluid in Pharmaceutical Manufacturing?

In the pharmaceutical industry, filter fluid plays a vital role in the purification of drug formulations. It is essential for guaranteeing product safety and efficacy while meeting regulatory requirements. Buyers should seek suppliers with a proven track record and appropriate certifications, as well as technical expertise in filtration technologies, to ensure that their products are safe and effective for consumer use.

3 Common User Pain Points for ‘filter fluid’ & Their Solutions

Scenario 1: Difficulty in Identifying the Right Filter Fluid for Specific Applications

The Problem: B2B buyers often struggle to determine which filter fluid is best suited for their particular operational needs. This challenge is exacerbated by the wide variety of products available on the market, each formulated for specific applications such as oil separation, coolant filtration, or air filtration. Misidentifying the correct fluid can lead to equipment failure, increased maintenance costs, and ultimately, downtime that impacts productivity.

The Solution: To effectively source the right filter fluid, buyers should start by conducting a thorough assessment of their filtration requirements. This includes understanding the specific contaminants present in their systems and the operational conditions under which their equipment operates. Collaborating with filter fluid manufacturers can provide insight into product specifications and performance characteristics. Furthermore, it’s beneficial to request samples for testing in real-world applications, enabling buyers to evaluate compatibility and effectiveness before making a bulk purchase. Maintaining an open line of communication with suppliers can ensure ongoing support and advice as operational needs evolve.

Scenario 2: Concerns About Environmental Compliance and Safety

The Problem: Environmental regulations are becoming increasingly stringent, and B2B buyers are often anxious about ensuring their filter fluids comply with local and international environmental standards. Non-compliance can result in hefty fines and damage to a company’s reputation. Additionally, many filter fluids contain hazardous substances that require careful handling and disposal, adding to the complexity of their use.

The Solution: Buyers should prioritize sourcing filter fluids that are explicitly marked as compliant with relevant regulations, such as REACH or EPA standards. This can be accomplished by partnering with reputable suppliers who provide transparent documentation regarding the environmental impact and safety data of their products. Implementing a robust training program for employees on the handling and disposal of filter fluids can further mitigate risks. Additionally, exploring eco-friendly alternatives, such as biodegradable filter fluids, can help businesses not only comply with regulations but also enhance their sustainability profile. Regular audits and reviews of fluid usage and disposal practices will ensure ongoing compliance and safety.

Scenario 3: Managing Inventory and Cost Efficiency

The Problem: Many B2B buyers face challenges in managing their inventory of filter fluids, which can lead to stockouts or excess inventory. Both situations can be costly: stockouts can halt operations, while excess inventory ties up capital and may lead to obsolescence if products expire or become outdated.

The Solution: To optimize inventory management, buyers should implement a just-in-time (JIT) inventory system that aligns fluid purchases with actual consumption rates. This involves closely monitoring usage patterns and establishing reorder points based on historical data. Utilizing inventory management software can streamline this process by providing real-time insights into stock levels and automating reorder alerts. Additionally, negotiating long-term contracts with suppliers can provide cost savings and ensure a steady supply of filter fluids, reducing the risk of stockouts. Regularly reviewing and adjusting inventory levels based on changing operational needs will further enhance efficiency and cost management.

Strategic Material Selection Guide for filter fluid

What Are the Key Materials Used in Filter Fluids?

When selecting materials for filter fluids, it is crucial to consider their properties, advantages, and limitations, particularly from a B2B perspective. This section analyzes four common materials used in filter fluids: mineral oils, synthetic oils, biodegradable fluids, and water-based fluids. Each material has unique characteristics that can significantly impact performance and suitability for various applications.

How Do Mineral Oils Perform in Filter Fluids?

Mineral oils are derived from refining crude oil and are commonly used in filter fluids due to their excellent lubricating properties and cost-effectiveness. They typically exhibit good temperature stability and can handle moderate pressure ratings. However, they are susceptible to oxidation and can degrade over time, leading to increased maintenance costs.

Pros: Mineral oils are readily available and generally less expensive than synthetic alternatives. They provide good compatibility with a wide range of materials and are often used in industrial applications.

Cons: The main drawback is their environmental impact, as they are not biodegradable. Additionally, they can pose risks in regions with strict environmental regulations, making compliance a consideration for international buyers.

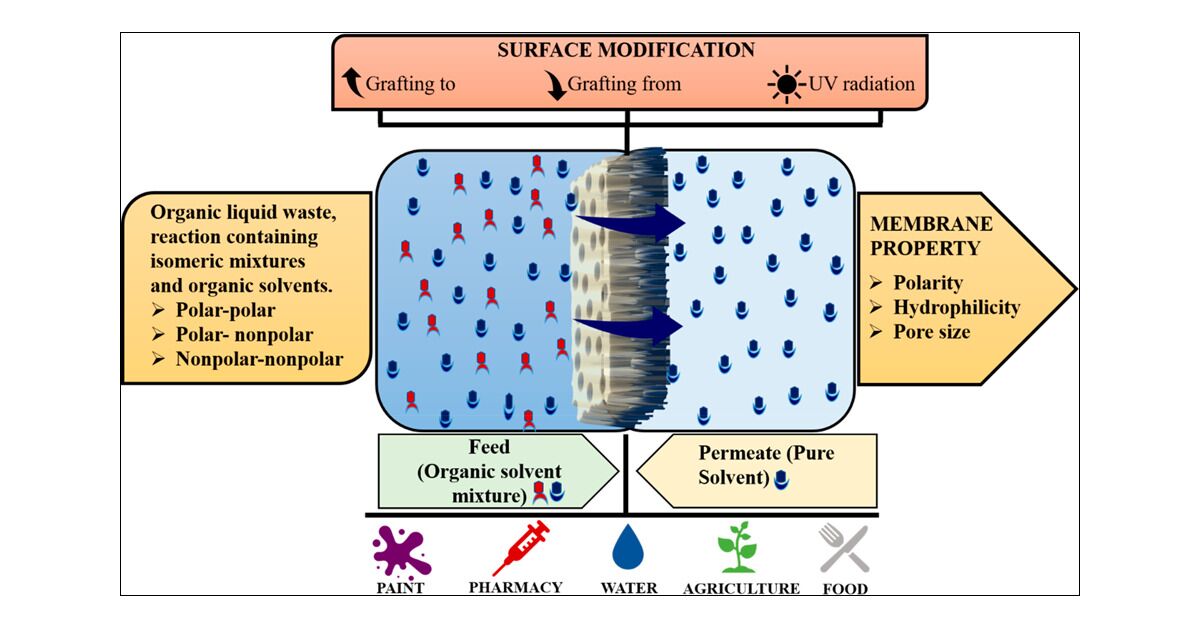

Illustrative image related to filter fluid

What Advantages Do Synthetic Oils Offer for Filter Fluids?

Synthetic oils are engineered fluids that provide superior performance compared to mineral oils. They exhibit excellent temperature stability, high viscosity index, and superior lubrication properties, making them suitable for high-performance applications. Synthetic oils are also more resistant to oxidation and thermal breakdown.

Pros: Their long service life and reduced maintenance requirements can lead to lower total costs over time. They also offer better performance in extreme temperatures and pressures.

Cons: The primary disadvantage is the higher initial cost, which can be a barrier for some businesses. Additionally, sourcing synthetic oils may require navigating more complex supply chains, particularly in developing regions.

Why Choose Biodegradable Fluids for Filter Applications?

Biodegradable fluids are increasingly popular due to their environmental benefits. These fluids are formulated from renewable resources and are designed to break down naturally, reducing the ecological footprint. They are suitable for applications where environmental considerations are paramount, such as in agriculture or near water bodies.

Pros: The main advantage is their environmental friendliness, which can enhance a company’s sustainability profile. They often meet stringent environmental regulations, making them appealing for international buyers in regions with strict compliance requirements.

Cons: However, biodegradable fluids may not perform as well as synthetic or mineral oils in extreme conditions. They can also be more expensive, which may deter some buyers.

What Are the Benefits and Limitations of Water-Based Fluids?

Water-based fluids are primarily used in applications where safety and environmental impact are critical. They are non-toxic and can be easily disposed of, making them suitable for industries focused on sustainability.

Pros: Their low cost and safety profile make them attractive for many applications. They are also compatible with various materials and can be formulated to meet specific performance requirements.

Cons: The limitations include lower lubrication properties compared to oil-based fluids and potential corrosion issues if not properly formulated. International buyers need to consider local regulations and standards regarding water-based fluids.

Summary Table of Material Selection for Filter Fluids

| Material | Typical Use Case for Filter Fluid | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Mineral Oils | General industrial applications | Cost-effective and widely available | Environmental impact and oxidation risk | Low |

| Synthetic Oils | High-performance machinery and automotive systems | Superior performance and longevity | Higher initial cost and complex sourcing | High |

| Biodegradable Fluids | Eco-sensitive applications like agriculture | Environmentally friendly | Potentially lower performance in extremes | Medium |

| Water-Based Fluids | Safety-critical applications | Non-toxic and easy disposal | Lower lubrication properties and corrosion risk | Low |

This guide provides a comprehensive overview of the materials used in filter fluids, emphasizing their properties and implications for international B2B buyers. Understanding these factors is crucial for making informed purchasing decisions that align with both performance requirements and regulatory compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for filter fluid

What Are the Key Stages in the Manufacturing Process of Filter Fluid?

The manufacturing process of filter fluid is intricate, involving several stages that ensure the final product meets quality and performance standards. The main stages include material preparation, forming, assembly, and finishing.

1. Material Preparation:

The process begins with the selection and sourcing of high-quality raw materials. For filter fluids, this typically includes specialized oils, emulsifiers, and additives designed to enhance filtration properties. The materials are then subjected to rigorous testing to ensure they meet the necessary specifications and are free from contaminants.

2. Forming:

Once the materials are prepared, they undergo a forming process, which may involve mixing or blending to create a homogeneous solution. Advanced mixing techniques, such as high-shear mixing or emulsification, are often employed to ensure uniform distribution of additives. This step is crucial as it directly affects the performance of the filter fluid.

3. Assembly:

In some cases, filter fluids may require additional components, such as packaging or labeling. This assembly stage involves integrating these components with the fluid itself. Automated systems are often utilized to streamline the assembly process, ensuring consistency and efficiency.

4. Finishing:

The final stage involves quality checks and packaging. The filter fluid is filled into containers, which are then sealed and labeled according to regulatory requirements. This stage may also include additional treatments, such as filtration or sterilization, to ensure the product is free from particulate contamination.

How Is Quality Assurance Implemented in Filter Fluid Production?

Quality assurance (QA) is paramount in the manufacturing of filter fluids, ensuring that products meet international standards and customer expectations. Various QA methodologies are employed throughout the production process.

Illustrative image related to filter fluid

International Standards Compliance:

To maintain high-quality standards, manufacturers often adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may be applicable depending on the region and the specific uses of the filter fluid.

Quality Control Checkpoints:

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to monitor and verify product quality. These include:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials before they enter the production process. Suppliers must provide certification and test reports to confirm material quality.

-

In-Process Quality Control (IPQC): Continuous monitoring during production ensures that processes remain within specified parameters. This may involve taking samples for testing at various stages of manufacturing.

-

Final Quality Control (FQC): After production, the finished product undergoes a series of tests to verify its performance and quality. This may include viscosity tests, filtration efficiency tests, and stability assessments.

What Common Testing Methods Are Used for Filter Fluids?

Testing methods for filter fluids are critical to validating product performance and safety. Common testing techniques include:

Illustrative image related to filter fluid

- Viscosity Testing: Measures the fluid’s resistance to flow, which is essential for filtration efficiency.

- Filtration Efficiency Tests: Evaluates the ability of the filter fluid to remove particulates from the fluid stream.

- Stability Testing: Assesses the product’s stability over time, ensuring it maintains its performance characteristics under various conditions.

- Compatibility Testing: Determines how well the filter fluid interacts with different materials, such as gaskets and seals, to prevent adverse reactions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are several ways to ensure suppliers maintain high-quality standards:

-

Supplier Audits: Conducting on-site audits allows buyers to review the manufacturing processes and quality control systems firsthand. This is an excellent way to assess compliance with international standards and identify any potential issues.

-

Requesting Quality Reports: Buyers should request detailed quality reports, including IQC, IPQC, and FQC results. This documentation provides insight into the supplier’s commitment to quality and transparency.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control measures. This can be particularly useful for buyers unfamiliar with local suppliers’ practices.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control nuances, especially when sourcing from different regions. Here are key considerations:

-

Regulatory Compliance: Different regions have varying regulatory requirements. Buyers should ensure that the filter fluid complies with local regulations in their market, which may differ from those in the supplier’s country.

-

Cultural Differences in Quality Standards: Understanding cultural attitudes toward quality assurance is essential. Some regions may prioritize cost over quality, which can impact the final product. Buyers should seek suppliers with a strong commitment to quality, regardless of regional norms.

-

Language and Communication Barriers: Effective communication is vital for ensuring quality standards are met. Buyers should establish clear lines of communication with suppliers and consider language barriers that may lead to misunderstandings regarding quality expectations.

Conclusion

In summary, the manufacturing processes and quality assurance measures for filter fluid are complex yet crucial for delivering high-quality products to B2B buyers. By understanding these processes, and utilizing effective verification methods, international buyers can ensure they partner with suppliers who prioritize quality and compliance, ultimately leading to successful business outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘filter fluid’

Introduction

In the dynamic landscape of B2B procurement, sourcing the right filter fluid requires careful consideration and strategic planning. This guide offers a practical checklist to assist international buyers, particularly those in Africa, South America, the Middle East, and Europe, in navigating the complexities of filter fluid procurement. By following these steps, you can ensure that you select a product that meets your technical requirements while also aligning with your business objectives.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in the procurement process. Identify the specific applications for the filter fluid, such as its viscosity, compatibility with existing systems, and required performance characteristics. This clarity will guide your search and ensure that potential suppliers can meet your needs effectively.

- Consider application requirements: Different industries may have unique demands; for example, automotive filter fluids may require specific properties compared to those used in industrial machinery.

- Determine regulatory standards: Ensure that your specifications comply with local and international regulations governing chemical products.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in filter fluids. Utilize industry directories, trade shows, and online platforms to compile a list of qualified manufacturers.

- Check supplier credentials: Look for certifications such as ISO 9001 or relevant industry-specific standards to ensure quality and reliability.

- Examine product range: A supplier with a diverse product range may be better equipped to meet your evolving needs.

Step 3: Evaluate Supplier Capabilities

Before committing to a supplier, assess their capabilities in terms of production capacity, technology, and quality control processes. This evaluation helps ensure that the supplier can meet your volume and consistency requirements.

- Request case studies: Ask for examples of past projects that demonstrate their ability to deliver on time and meet specifications.

- Visit production facilities: If possible, arrange site visits to observe their operations and quality assurance protocols firsthand.

Step 4: Request Samples for Testing

Once you’ve narrowed down potential suppliers, request samples of the filter fluid for testing. This step is critical in determining whether the product meets your performance criteria.

- Conduct thorough testing: Evaluate the samples in real-world conditions to assess their effectiveness and compatibility with your systems.

- Gather feedback from users: Involve your technical team to provide insights on the product’s performance during testing.

Step 5: Negotiate Terms and Pricing

After selecting a preferred supplier, enter negotiations to finalize terms and pricing. This step is vital for ensuring that you achieve a favorable deal that aligns with your budget.

- Discuss bulk pricing options: If you plan to order large quantities, inquire about discounts for bulk purchases or long-term contracts.

- Clarify payment terms: Establish clear payment terms and conditions to avoid misunderstandings later on.

Step 6: Verify Compliance and Certifications

Before finalizing your order, verify that the filter fluid complies with all relevant regulations and certifications. This verification is essential to avoid legal issues and ensure product safety.

- Request documentation: Ask for certificates of compliance and safety data sheets to ensure transparency and regulatory adherence.

- Evaluate environmental impact: Consider suppliers who prioritize sustainable practices and offer eco-friendly products.

Step 7: Establish a Communication Plan

Finally, develop a robust communication plan with your chosen supplier. Effective communication is key to maintaining a successful partnership and addressing any issues that may arise.

- Set regular check-ins: Schedule periodic meetings to discuss product performance, address concerns, and explore future needs.

- Utilize technology: Leverage digital tools for seamless communication, order tracking, and feedback sharing.

By following this structured checklist, you can streamline your sourcing process for filter fluid, ensuring that you select the right product from a reliable supplier that meets your business requirements.

Comprehensive Cost and Pricing Analysis for filter fluid Sourcing

What Are the Key Cost Components in Filter Fluid Sourcing?

Understanding the cost structure of filter fluid sourcing is crucial for B2B buyers aiming to optimize their procurement strategies. The primary cost components include:

-

Materials: The choice of base ingredients, such as squalane and various pigments, significantly affects the overall cost. High-quality materials can enhance product efficacy and marketability but come with a higher price tag.

-

Labor: Labor costs encompass wages for skilled workers involved in the production, formulation, and packaging of filter fluids. Efficient labor management can help keep these costs under control.

-

Manufacturing Overhead: This includes costs related to utilities, maintenance, and facility management. Reducing waste and improving operational efficiency can lower these overheads.

-

Tooling: The initial investment in machinery and tools for production can be substantial. Buyers should consider suppliers with modern equipment to ensure high-quality outputs and lower long-term costs.

-

Quality Control (QC): Implementing robust QC processes is essential to maintain product standards. While this incurs additional costs, it can prevent costly recalls and reputational damage.

-

Logistics: Shipping and handling can dramatically affect the total cost, especially for international buyers. Understanding Incoterms is vital for managing logistics costs effectively.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Buyers should be aware of the typical margins in the industry to negotiate better prices.

How Do Price Influencers Impact Filter Fluid Costs?

Several factors can influence the pricing of filter fluids:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for bulk discounts. Buyers should assess their needs carefully to strike a balance between inventory costs and price advantages.

-

Specifications/Customization: Customized products generally come at a premium. Buyers should clarify their requirements upfront to avoid unexpected costs.

-

Materials: The choice of materials can significantly impact price. Specialty ingredients may drive up costs, so it’s essential to weigh the benefits against the added expense.

-

Quality and Certifications: Products with certifications (e.g., organic, cruelty-free) may command higher prices. Buyers should evaluate the necessity of these certifications based on their target market.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer competitive rates to gain market share.

-

Incoterms: Understanding the implications of different Incoterms can help buyers manage logistics costs and risks. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly alter the total landed cost.

What Are Effective Negotiation Strategies for B2B Buyers?

To achieve cost-efficiency in filter fluid sourcing, buyers should consider the following tips:

-

Leverage Volume Discounts: When possible, consolidate purchases to reach higher volumes that can unlock better pricing.

-

Focus on Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the product, including maintenance, disposal, and potential returns, rather than just the upfront price.

-

Build Relationships with Suppliers: Developing a strong rapport with suppliers can lead to more favorable terms, including flexible payment options and priority service.

-

Negotiate Terms: Don’t hesitate to negotiate payment terms, delivery schedules, and service agreements. This can improve cash flow and reduce risks.

-

Research Market Trends: Stay informed about market fluctuations and trends in the filter fluid industry. This knowledge can empower buyers during negotiations and help them make informed decisions.

What Should International Buyers Consider When Sourcing Filter Fluids?

For B2B buyers from regions like Africa, South America, the Middle East, and Europe, several nuances come into play:

-

Cultural Differences: Understanding cultural norms in negotiation can facilitate smoother interactions with suppliers from different regions.

-

Regulatory Compliance: Ensure that the sourced products meet local regulations and standards, as non-compliance can lead to costly penalties.

-

Currency Fluctuations: Be mindful of exchange rate fluctuations when sourcing internationally, as this can impact the final cost.

-

Shipping and Customs: Factor in shipping times and customs duties, which can vary significantly by region and affect the total cost and delivery timeline.

Conclusion

While the indicative prices for filter fluids can vary widely based on several factors, understanding the cost components, price influencers, and negotiation strategies can empower B2B buyers to make informed decisions. By taking a strategic approach to sourcing, companies can optimize their procurement processes and enhance their overall competitiveness in the market.

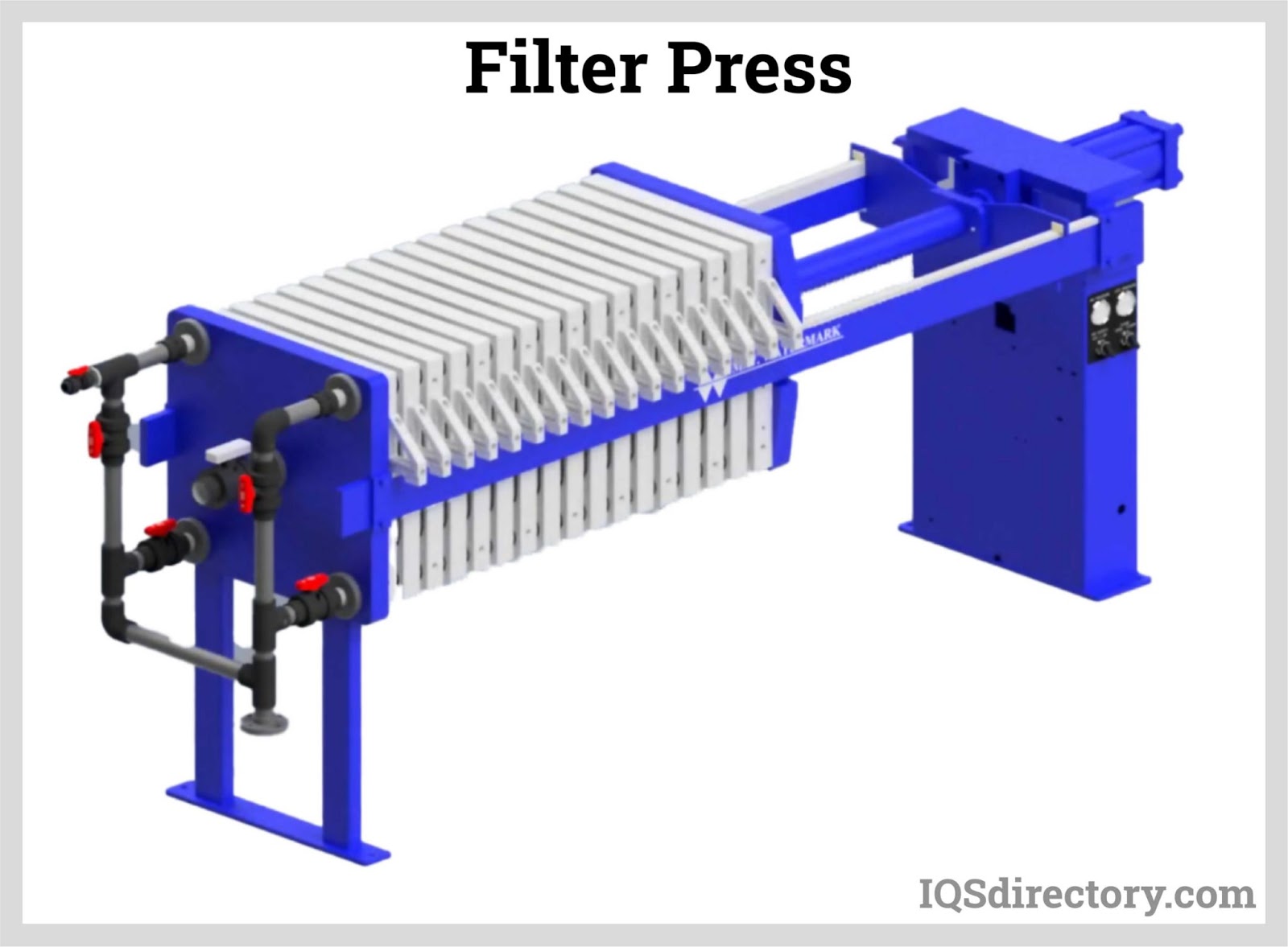

Illustrative image related to filter fluid

Alternatives Analysis: Comparing filter fluid With Other Solutions

Exploring Alternative Solutions to Filter Fluid

In the quest for optimal fluid solutions, businesses often explore various alternatives to filter fluid, each offering distinct advantages and drawbacks. Understanding these options is crucial for B2B buyers who seek to maximize efficiency, reduce costs, and ensure compatibility with their operations. This analysis delves into two viable alternatives: Oil-Based Solutions and Water-Based Solutions.

Comparison Table

| Comparison Aspect | Filter Fluid | Oil-Based Solutions | Water-Based Solutions |

|---|---|---|---|

| Performance | High optical clarity; even skin tone | Excellent durability; good for high-performance applications | Good for hydration; less intensive care |

| Cost | Moderate ($10 per unit) | Higher initial investment but longer-lasting | Lower initial cost; may require frequent reapplication |

| Ease of Implementation | Simple application process | Requires specialized handling | Easy to apply; user-friendly |

| Maintenance | Low maintenance | Moderate; needs regular checks | Low; easy to clean up |

| Best Use Case | Everyday makeup; special occasions | Long-lasting wear for events | Lightweight use; hydration-focused |

Analyzing Oil-Based Solutions: What Are the Key Benefits and Drawbacks?

Oil-based solutions are often favored in professional settings, particularly in cosmetics and personal care. Their main advantage lies in their durability and resistance to environmental factors, making them ideal for long-lasting applications. However, they typically come with a higher upfront cost and require careful handling during application. Additionally, oil-based products can be challenging to remove and may not suit all skin types, particularly for those prone to acne.

Understanding Water-Based Solutions: What Makes Them a Popular Choice?

Water-based solutions are gaining traction due to their affordability and ease of use. They are often lighter and provide a refreshing feel, making them suitable for everyday applications. However, they may require more frequent reapplication, which can lead to higher long-term costs. While water-based products are less likely to clog pores, they may not offer the same level of coverage or performance in terms of durability compared to filter fluid or oil-based alternatives.

Illustrative image related to filter fluid

How Can B2B Buyers Make the Right Choice for Their Needs?

When selecting between filter fluid and its alternatives, B2B buyers should evaluate their specific use cases, budget constraints, and desired outcomes. For businesses focused on everyday applications with a need for hydration, water-based solutions may be the most economical choice. In contrast, companies seeking long-lasting performance for special events might find oil-based solutions more suitable, despite the higher cost. Ultimately, understanding the unique properties and trade-offs of each option will enable buyers to make informed decisions that align with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for filter fluid

What Are the Key Technical Properties of Filter Fluid?

When selecting filter fluid, understanding its technical properties is crucial for ensuring optimal performance in various applications. Here are some essential specifications to consider:

-

Viscosity

Viscosity measures a fluid’s resistance to flow, which is critical in filtration systems. A lower viscosity allows for easier movement through filters, while higher viscosity may indicate better filtration properties. B2B buyers should assess viscosity to ensure compatibility with their equipment and desired filtration rates. -

Chemical Composition

The chemical makeup of filter fluid can significantly impact its effectiveness and safety. Key components often include organic and inorganic compounds that can affect filtration efficiency and the potential for chemical reactions. Buyers must evaluate chemical composition to ensure it meets industry standards and regulations, especially in sensitive applications. -

Filtration Efficiency

This property indicates how well the fluid can remove contaminants from a solution. Measured in terms of particle retention rate, filtration efficiency is paramount for maintaining product quality and system integrity. B2B purchasers need to inquire about filtration efficiency ratings to align with their operational requirements. -

Temperature Stability

Filter fluids must maintain their properties across a range of temperatures. Temperature stability refers to the fluid’s ability to perform effectively without degradation when subjected to heat or cold. This is especially important for industries that operate in extreme conditions, as temperature fluctuations can affect both fluid performance and equipment longevity. -

Compatibility with Materials

Compatibility assesses how filter fluid interacts with different materials used in filtration systems, such as seals and gaskets. Incompatibility can lead to system failures or reduced efficiency. Buyers should confirm that the chosen filter fluid is compatible with their specific system materials to avoid costly repairs or replacements.

What Common Trade Terms Should B2B Buyers Know When Purchasing Filter Fluid?

Understanding industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some key terms relevant to filter fluid transactions:

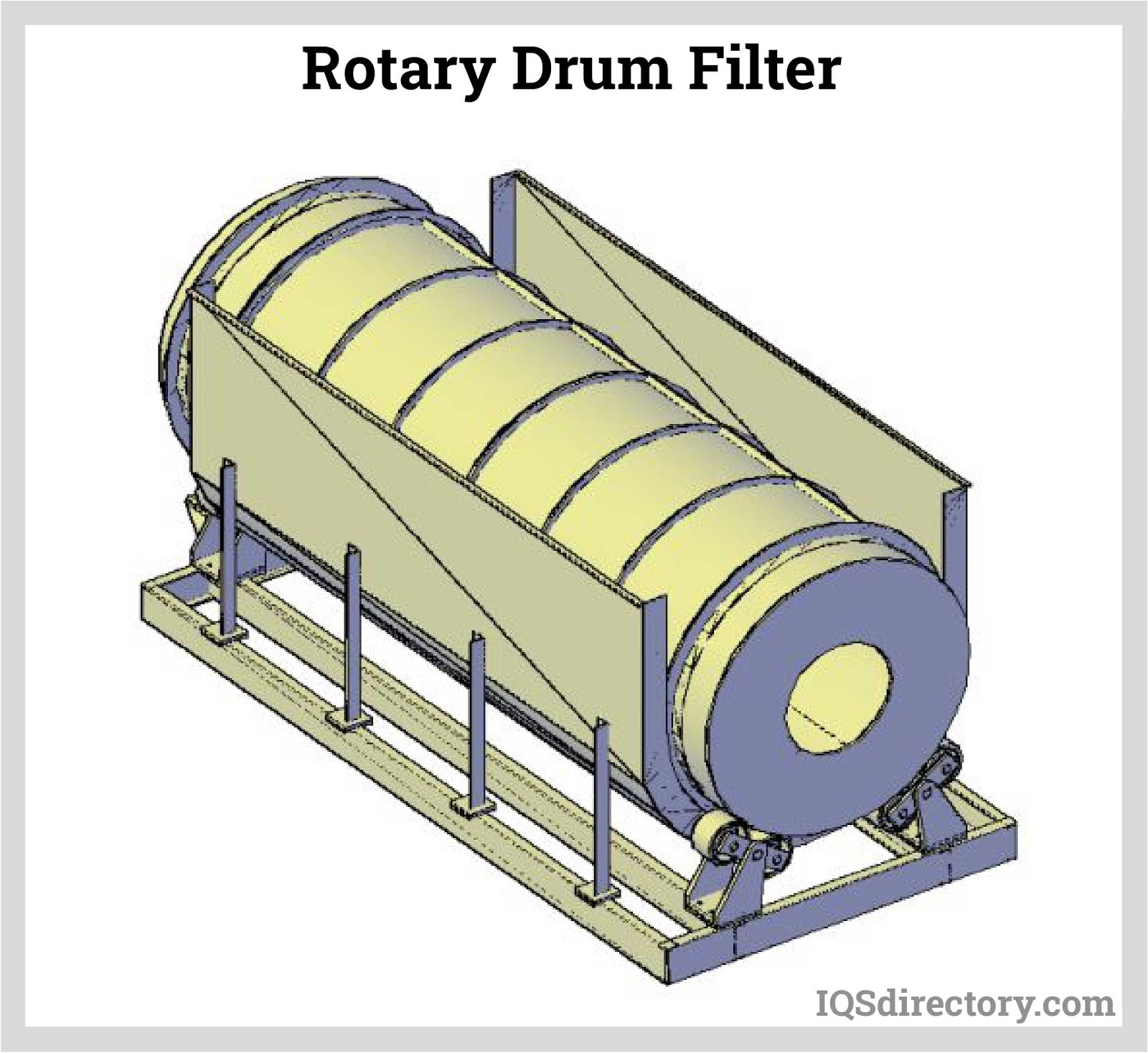

Illustrative image related to filter fluid

-

OEM (Original Equipment Manufacturer)

An OEM produces components or products that are used in another company’s end product. In the context of filter fluid, knowing if a supplier is an OEM can assure buyers of the quality and reliability of the product, as OEMs often adhere to strict manufacturing standards. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest amount of product a supplier is willing to sell. This term is significant for B2B buyers as it affects inventory management and cash flow. Understanding the MOQ can help businesses plan their purchasing strategy effectively. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. Utilizing RFQs allows B2B buyers to compare options and negotiate better deals, ensuring they receive the best value for their filter fluid requirements. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms used in international trade. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms can help B2B buyers understand shipping costs and risks associated with their filter fluid purchases. -

Lead Time

Lead time refers to the period from placing an order to its delivery. Understanding lead times is crucial for B2B buyers to manage their inventory and production schedules efficiently. It helps in planning and mitigating potential disruptions in the supply chain. -

Bulk Pricing

This term indicates the cost savings available when purchasing filter fluids in larger quantities. Many suppliers offer bulk pricing to encourage larger orders, which can significantly reduce per-unit costs for B2B buyers. Understanding bulk pricing strategies can enhance cost efficiency for businesses looking to stock up on filter fluids.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and product quality in their industries.

Navigating Market Dynamics and Sourcing Trends in the filter fluid Sector

What are the Current Market Dynamics and Key Trends in the Filter Fluid Sector?

The global filter fluid market is currently experiencing significant growth, driven by increasing industrial applications and rising demand for high-performance filtration solutions. Key trends shaping the market include the adoption of advanced filtration technologies, such as nanofiltration and microfiltration, which offer improved efficiency and effectiveness. Additionally, the shift towards automation and smart manufacturing processes is enhancing the precision and reliability of filter fluid systems. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of the increasing importance of digital platforms for sourcing filter fluids. These platforms provide comprehensive product information and allow for easier comparisons between suppliers, leading to more informed purchasing decisions.

Another critical factor influencing market dynamics is the growing emphasis on customization. Businesses are seeking tailored filter fluid solutions that meet specific operational needs, which can lead to improved performance and reduced downtime. Furthermore, the ongoing global focus on sustainability is prompting companies to invest in eco-friendly filter fluid products. The demand for sustainable solutions is particularly pronounced in regions with stringent environmental regulations, such as Europe. As a result, suppliers that can offer innovative, high-quality products while maintaining a commitment to sustainability will likely have a competitive edge in the market.

Illustrative image related to filter fluid

How is Sustainability and Ethical Sourcing Reshaping the Filter Fluid Sector?

The environmental impact of manufacturing and using filter fluids has become a crucial concern for businesses. B2B buyers are increasingly prioritizing sustainability in their sourcing strategies, pushing suppliers to adopt greener practices. This shift is leading to the development of filter fluids that utilize biodegradable materials and processes that minimize waste. Furthermore, companies are seeking products that are free from harmful substances, aligning with global initiatives to reduce environmental footprints.

Ethical sourcing is another vital aspect of this trend. Buyers are demanding transparency in supply chains, focusing on suppliers that adhere to ethical labor practices and environmental standards. Certifications such as ISO 14001 for environmental management and certifications for sustainable materials are becoming essential for suppliers looking to establish credibility in the market. For B2B buyers, partnering with ethically responsible suppliers not only enhances brand reputation but also contributes to long-term sustainability goals.

What is the Brief Evolution of the Filter Fluid Market?

The filter fluid sector has evolved significantly over the past few decades. Initially focused on basic filtration applications, the market has transitioned toward more sophisticated solutions that cater to diverse industrial needs. Early developments in filter fluids were primarily driven by the automotive and manufacturing industries, but today, the market spans various sectors, including food and beverage, pharmaceuticals, and chemicals.

Advancements in technology have played a pivotal role in this evolution, with the introduction of synthetic filter fluids and innovative filtration techniques. As environmental awareness has grown, the sector has increasingly embraced sustainability, leading to the creation of eco-friendly products and practices. This evolution reflects the broader trends in global manufacturing and supply chain management, positioning the filter fluid market for continued growth and innovation in the coming years.

Frequently Asked Questions (FAQs) for B2B Buyers of filter fluid

-

How do I ensure the quality of filter fluid from international suppliers?

To ensure quality, it is essential to conduct thorough due diligence on potential suppliers. Start by requesting product samples and specifications to evaluate their compliance with industry standards. Additionally, consider visiting the supplier’s facility if possible or using third-party inspection services. Look for certifications such as ISO or other relevant quality assurance standards that verify their manufacturing processes. Establishing clear communication channels for ongoing quality checks and feedback is also crucial. -

What is the best type of filter fluid for various applications?

The best filter fluid depends on the specific application and the type of filtration system in use. For example, hydraulic systems often require fluids with high viscosity indices, while air filtration systems may benefit from lighter, less viscous options. When sourcing, consider the fluid’s chemical compatibility with the system materials, temperature stability, and environmental regulations. Consulting with a filtration expert or the supplier can help you identify the most suitable fluid for your needs. -

What are the typical minimum order quantities (MOQ) for filter fluid?

Minimum order quantities can vary significantly by supplier and region. Typically, MOQs for filter fluids range from 100 liters to several thousand liters, depending on the manufacturer’s production capacity and market demand. To negotiate favorable terms, communicate your projected needs and be open to discussing flexible options. Suppliers may offer tiered pricing based on order size, allowing you to scale your purchase according to your business growth. -

What payment terms are common for international filter fluid purchases?

Common payment terms in international trade include advance payment, letters of credit, and open account terms. Many suppliers prefer partial upfront payments (e.g., 30% deposit) with the balance due upon delivery. Letters of credit provide security for both parties, ensuring payment is made only when agreed conditions are met. Discussing payment terms upfront can help establish trust and transparency, reducing the risk of disputes later in the transaction process. -

How can I customize filter fluid to meet specific requirements?

Customization of filter fluid can often be achieved by working closely with your supplier. Many manufacturers offer tailored solutions, such as adjusting viscosity, adding specific additives, or formulating fluids for particular environmental conditions. Clearly outline your requirements, including performance specifications and regulatory compliance needs. A collaborative approach will enable the supplier to develop a product that aligns perfectly with your operational demands. -

What logistics considerations should I keep in mind when sourcing filter fluid internationally?

When sourcing filter fluid, logistics play a critical role in ensuring timely delivery and maintaining product integrity. Consider factors such as shipping methods (air vs. sea), customs regulations, and the availability of local distribution channels. It’s essential to work with logistics partners experienced in handling hazardous materials if applicable. Additionally, plan for potential delays by establishing buffer times in your supply chain to mitigate risks associated with international shipping. -

How do I vet suppliers to ensure reliability and compliance?

Vetting suppliers involves several steps to ensure they are reliable and compliant with industry standards. Start by researching their business history, client testimonials, and industry certifications. Request references from previous clients and check their performance track record. Consider conducting background checks or using third-party verification services. Establishing a trial order can also help assess their reliability in terms of product quality and delivery timelines. -

What regulatory considerations should I be aware of when sourcing filter fluid?

Different regions have varying regulations regarding the import and use of filter fluids, particularly concerning environmental and safety standards. Familiarize yourself with regulations in your target markets, such as REACH in Europe or local environmental laws in Africa and South America. Ensure that the products comply with any relevant safety data sheets (SDS) and labeling requirements. Collaborating with a knowledgeable supplier can help navigate these regulations effectively.

Top 7 Filter Fluid Manufacturers & Suppliers List

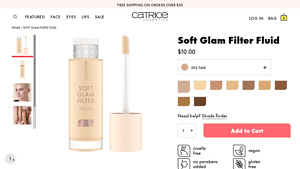

1. Catrice Cosmetics – Soft Glam Filter Fluid

Domain: catricecosmetics.com

Registered: 2016 (9 years)

Introduction: {“product_name”: “Soft Glam Filter Fluid”, “brand”: “Catrice Cosmetics”, “product_type”: “Makeup”, “features”: [“Lightweight”, “Buildable coverage”, “Natural finish”, “Hydrating formula”], “available_shades”: [“Fair”, “Light”, “Medium”, “Tan”, “Deep”], “size”: “30ml”, “application”: “Apply with fingers or a brush for a seamless blend.”, “benefits”: [“Enhances skin’s natural glow”, “Blurs imperfect…

2. Fernox – Protector+ Filter Fluid F9

Domain: fernox.us

Registered: 2011 (14 years)

Introduction: {“Product Name”: “Protector+ Filter Fluid F9”, “Volume”: “2.6 gal (10 liters)”, “Code”: “62710”, “Description”: “Enhanced inhibitor incorporating dispersant technology for corrosion protection, limescale inhibition, and pH control in HVAC and light commercial heating and cooling systems.”, “Compatibility”: “Compatible with all Fernox commercial products and suitable for all materials and metals co…

3. Soft Glam – Filter Fluid

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: The Soft Glam Filter Fluid is designed for natural daytime make-up. It can be applied evenly on the face using a brush, fingers, or a beauty blender. The product is available for purchase on Takealot. It is vegan and cruelty-free.

4. Filter Elements – Fluid Filtration Solutions

Domain: filter-elements.com

Registered: 2006 (19 years)

Introduction: Fluid Filter Elements for Air and Liquid (Oil and Water) Control. Types include Polymer Melt Filter Elements, Candle Filters, Filter Housing, Cartridges, and Filter Fittings. Forms include Pleated Filter Elements, Pipe Filter Elements, Extruded Screen Packs, Filter Discs, Leafs, Baskets, and Bags. Applications include filtering of air, gas, oil, grease, liquid, and fuel. Key specifications: Temper…

5. Catrice – Soft Glam Filter Fluid Glow Booster

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Catrice Soft Glam Filter Fluid Glow Booster in shades 010 Fair-Light and 002 Fair. Shade 002 Fair is available online only, while shade 010 Fair-Light can be found in drugstores. Both shades blend out to be very sheer, making them suitable for a variety of pale skin tones. The product is noted for its glow filter effect, ideal for pale complexions.

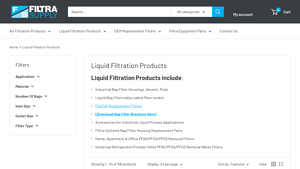

6. Liquid Filters – Essential Filtration Solutions

Domain: liquid-filters.net

Registered: 2002 (23 years)

Introduction: Liquid filters are porous mechanisms that enable filtration systems to remove solid particles from a fluid stream. They are essential in industrial processes where various fluids can become contaminated by unwanted solids. Key types of liquid filters include:

1. **Bag Filters** – Used for filtering hot liquids, available in advanced versions for demanding applications.

2. **Cartridge Filters** -…

7. Filtra Supply – Free 90-Day Returns

Domain: filtrasupply.com

Registered: 2018 (7 years)

Introduction: This company, Filtra Supply – Free 90-Day Returns, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for filter fluid

How Can Strategic Sourcing Enhance Your Filter Fluid Procurement?

In today’s competitive landscape, effective strategic sourcing is crucial for international B2B buyers seeking filter fluids. By prioritizing quality, sustainability, and supplier reliability, organizations can ensure they are not only meeting immediate needs but also positioning themselves for long-term success. The growing demand for eco-friendly products and innovative solutions underscores the importance of aligning sourcing strategies with market trends and customer preferences.

Furthermore, leveraging diverse supplier networks across Africa, South America, the Middle East, and Europe can lead to significant cost savings and improved product availability. Collaborating with suppliers who share your commitment to sustainability and quality can enhance your brand reputation and customer satisfaction.

As we move forward, it is essential to remain proactive in evaluating sourcing strategies. Monitor market dynamics, invest in technology for better supplier management, and foster relationships that encourage innovation. By doing so, you can not only streamline your procurement process but also stay ahead of the competition.

Take action now—reassess your sourcing strategies for filter fluids and explore new partnerships that can drive efficiency and sustainability in your supply chain. The future of your business depends on the strategic decisions you make today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.