Everything You Need to Know About Fake Chains Sourcing in 2025

Introduction: Navigating the Global Market for fake chains

In today’s dynamic global marketplace, sourcing high-quality fake chains can be a daunting challenge for B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe. The proliferation of styles, materials, and suppliers can overwhelm even the most seasoned professionals. This guide aims to navigate the intricacies of the fake chains market, offering insights into various types such as Miami Cuban links, Franco chains, and herringbone designs. By exploring applications, supplier vetting processes, and cost considerations, we equip international buyers with the knowledge needed to make informed purchasing decisions.

Understanding the nuances of the fake chains market is essential for maximizing investment and ensuring product quality. As buyers from diverse regions like Saudi Arabia and Nigeria seek to enhance their offerings, this comprehensive guide serves as a vital resource. It empowers B2B purchasers to identify reliable suppliers, evaluate pricing structures, and select the most suitable chain styles that resonate with their target audiences. Whether you’re looking to make a bold statement with iced designs or prefer classic styles, this guide will help you navigate the market landscape effectively, ensuring that your sourcing strategy is both strategic and successful.

Understanding fake chains Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Miami Cuban Link | Thick, interlocking links with a flat surface | Fashion retailers, jewelry manufacturers | Pros: Stylish, durable; Cons: Heavier, may not appeal to all markets |

| Franco Chain | Smooth, rounded links with a unique twist | Wholesale jewelry, custom design shops | Pros: Elegant look, versatile; Cons: Limited size options, can be costly |

| Tennis Chain | Alternating links with small stones or embellishments | Event planners, luxury retailers | Pros: Eye-catching, great for promotions; Cons: Fragile, may require careful handling |

| Rope Chain | Twisted links resembling a rope | Casual fashion brands, costume jewelry | Pros: Unique design, lightweight; Cons: Less formal, may not suit luxury markets |

| Herringbone Chain | Zigzag pattern that lays flat against the skin | High-end fashion boutiques, online retailers | Pros: Sophisticated appearance, lays flat; Cons: Can be prone to kinks, higher maintenance |

What are the Characteristics of Miami Cuban Link Chains?

Miami Cuban Link chains are characterized by their thick, interlocking links that create a bold statement. These chains often feature a flat surface, enhancing their visual appeal. They are highly sought after in the fashion industry, especially among retailers looking to offer trendy, durable products. When considering B2B purchases, buyers should evaluate the weight and style preferences of their target market, as the Miami Cuban Link may not appeal to all consumer segments.

How Do Franco Chains Stand Out in the Market?

Franco chains are distinguished by their smooth, rounded links that twist together, providing an elegant and sophisticated look. These chains are popular among wholesale jewelry suppliers and custom design shops. Their versatility makes them suitable for various occasions, from casual wear to formal events. Buyers should consider the limited size options and potential costs associated with Franco chains when planning their inventory, ensuring they align with market demands.

Why Choose Tennis Chains for B2B Sales?

Tennis chains feature alternating links adorned with small stones or embellishments, creating a dazzling effect that attracts consumers. They are commonly used in luxury retail settings and by event planners looking to enhance their offerings. While tennis chains can serve as excellent promotional items, buyers must be cautious of their fragility, as they may require careful handling and maintenance. Evaluating the target audience’s preferences will be crucial for successful sales.

What Makes Rope Chains a Viable Option?

Rope chains are notable for their twisted links that resemble a rope, providing a unique and casual aesthetic. They are often favored by casual fashion brands and costume jewelry makers. While their lightweight design makes them appealing for everyday wear, buyers should be mindful of their less formal appearance, which may not fit high-end markets. Understanding the target demographic’s style will aid in effective inventory decisions.

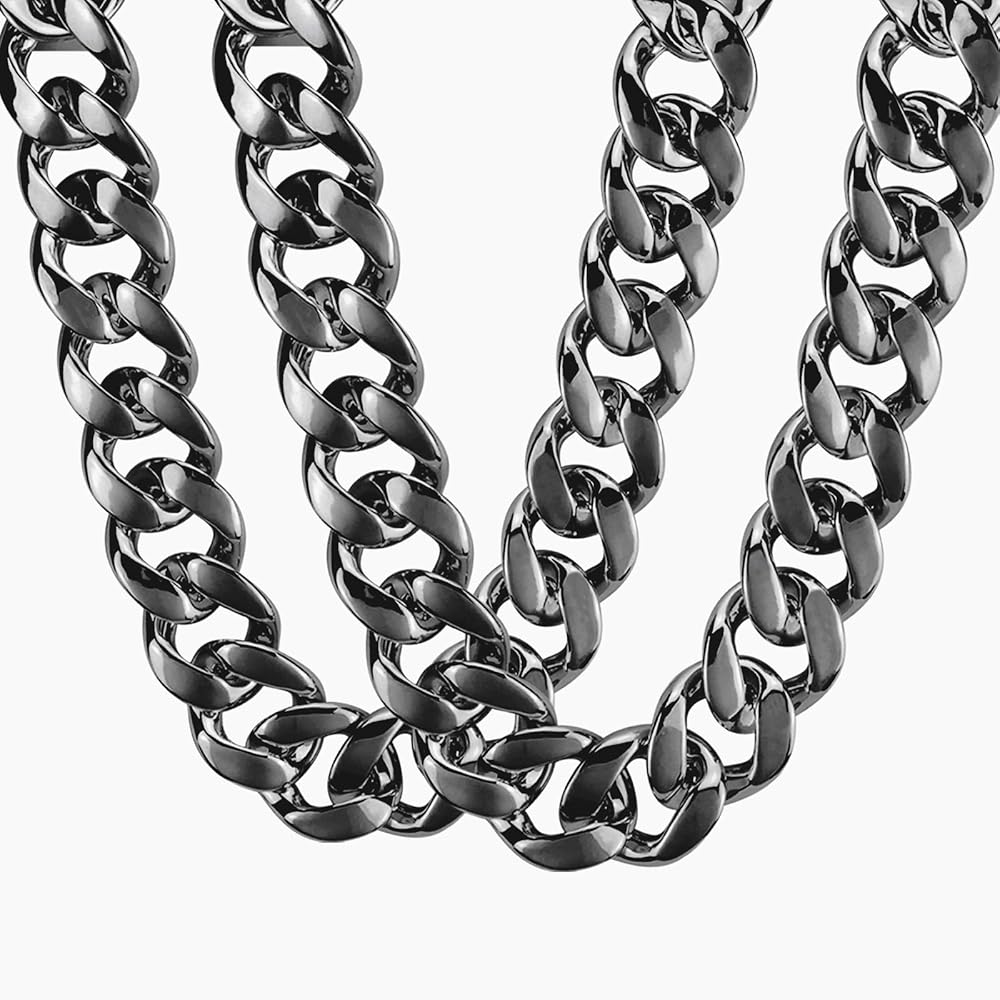

Illustrative image related to fake chains

How Do Herringbone Chains Appeal to High-End Retailers?

Herringbone chains are recognized for their distinctive zigzag pattern, which lays flat against the skin, exuding sophistication. These chains are ideal for high-end fashion boutiques and online retailers targeting luxury consumers. While they offer a refined look, buyers should be aware of the potential for kinks and the higher maintenance required. Assessing the market’s demand for such products will be essential for successful B2B transactions.

Key Industrial Applications of fake chains

| Industry/Sector | Specific Application of fake chains | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Jewelry | Trendy Accessories for Retail | High profit margins due to low production costs | Quality of materials, design authenticity, and market trends |

| Entertainment & Media | Costuming for Performances and Events | Budget-friendly options for large productions | Durability, customization options, and quick turnaround time |

| Event Management | Decorations and Thematic Displays | Enhances visual appeal without high costs | Availability in bulk, color variety, and shipping logistics |

| Sports Merchandise | Team Spirit Items and Fan Gear | Engages fans with affordable accessories | Licensing agreements, quality assurance, and market demand |

| Promotional Products | Branded Giveaways for Marketing Campaigns | Increases brand visibility and customer engagement | Customization capabilities, lead times, and pricing strategies |

How Are Fake Chains Used in the Fashion & Jewelry Industry?

In the fashion and jewelry sector, fake chains are utilized as trendy accessories that cater to diverse consumer tastes. Retailers can offer these stylish chains at competitive prices, capitalizing on high-profit margins. Buyers in this sector should focus on sourcing high-quality materials that mimic luxury items while ensuring they align with current fashion trends. Additionally, understanding regional preferences, especially in markets like Africa and Europe, is crucial for successful product placement.

What Role Do Fake Chains Play in Entertainment & Media?

Fake chains serve a significant role in the entertainment and media industry, particularly for costuming in performances and events. They provide budget-friendly alternatives for productions, allowing costume designers to create visually striking outfits without overspending. For international buyers, sourcing durable chains that can withstand the rigors of performances is essential. Customization options may also be necessary to align with specific character designs or themes.

How Are Fake Chains Applied in Event Management?

In event management, fake chains are often used for decorations and thematic displays, enhancing the overall visual appeal of events without incurring high costs. They can be used to create stunning backdrops or as part of centerpieces, making events memorable. Buyers should consider the availability of these chains in bulk and their color variety to match specific event themes. Efficient shipping logistics are also vital to ensure timely delivery before events.

Illustrative image related to fake chains

How Do Fake Chains Enhance Sports Merchandise?

In the sports merchandise industry, fake chains are popular for creating team spirit items and fan gear. They provide an affordable way for fans to showcase their support, fostering community engagement. For buyers, ensuring that the chains are of good quality and align with licensing agreements is crucial. Understanding the market demand in different regions, such as South America and the Middle East, can also inform inventory decisions.

What Benefits Do Fake Chains Offer in Promotional Products?

Fake chains are increasingly used as branded giveaways in marketing campaigns, enhancing brand visibility and customer engagement. They serve as cost-effective promotional items that can be customized to feature company logos or slogans. Businesses should focus on sourcing chains that offer customization capabilities, competitive lead times, and favorable pricing strategies to maximize their marketing efforts.

3 Common User Pain Points for ‘fake chains’ & Their Solutions

Scenario 1: Quality Assurance in Sourcing Fake Chains

The Problem: International B2B buyers often face the challenge of ensuring the quality and authenticity of ‘fake chains’ they source. Due to the proliferation of counterfeit products, buyers may receive chains that are poorly made, tarnish easily, or lack the aesthetic appeal needed for their market. This not only affects customer satisfaction but can also damage the buyer’s reputation and result in financial losses.

The Solution: To mitigate quality concerns, buyers should establish a robust supplier vetting process. This includes requesting samples before placing large orders and evaluating the supplier’s production processes. Additionally, buyers can look for certifications or quality assurance programs that suppliers may offer. Engaging in direct communication with manufacturers to discuss materials used, production methods, and post-purchase support can further ensure that the chains meet desired standards. Utilizing platforms that provide supplier ratings and reviews can also help buyers make informed decisions about whom to partner with.

Scenario 2: Understanding Market Preferences for Fake Chains

The Problem: B2B buyers may struggle to understand regional market preferences for fake chains, which can vary significantly across different cultures and demographics. For example, a design that sells well in Europe might not resonate with customers in Africa or South America. This misalignment can lead to unsold inventory and wasted resources, adversely affecting the bottom line.

Illustrative image related to fake chains

The Solution: Conducting thorough market research is essential to grasp local tastes and preferences. Buyers can leverage analytics tools to analyze purchasing patterns and trends within their target markets. Additionally, connecting with local influencers or fashion experts can provide insights into current styles and cultural significance. Participating in trade shows and networking events can also help buyers gauge market sentiments firsthand. By tailoring their offerings based on these insights, buyers can better align their inventory with what consumers truly desire, thereby increasing sales and customer loyalty.

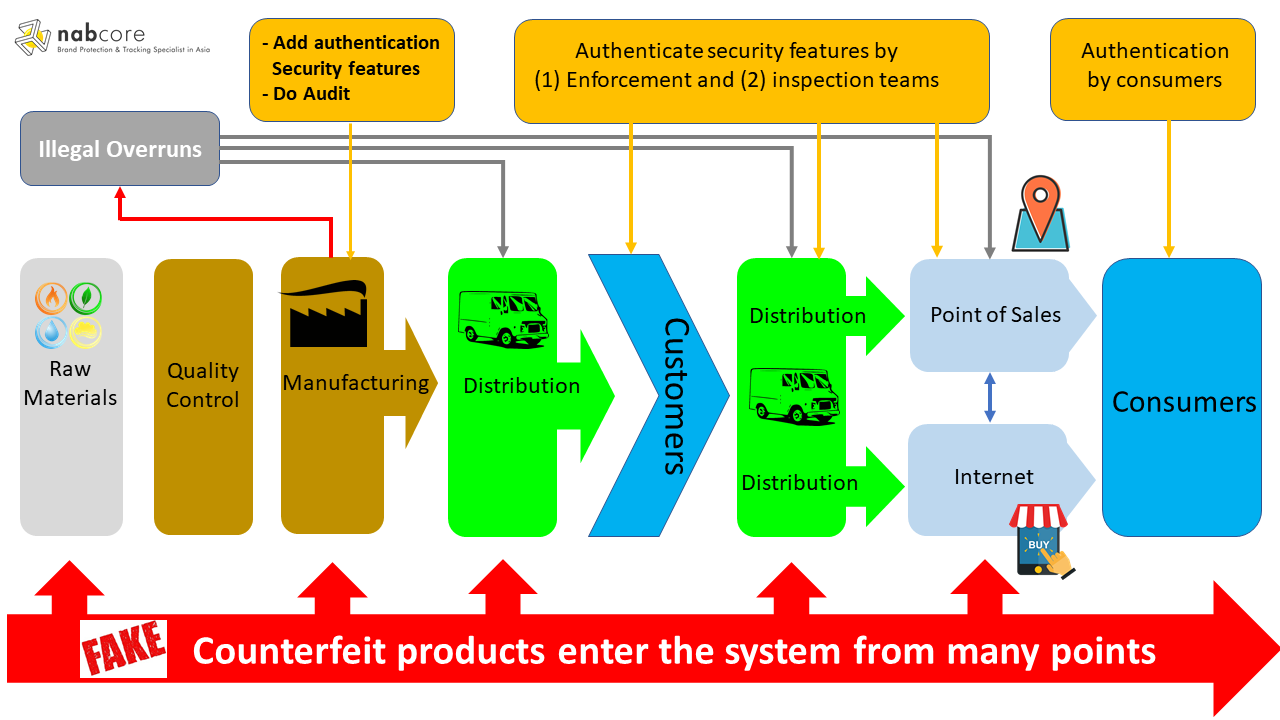

Scenario 3: Navigating Import Regulations and Compliance for Fake Chains

The Problem: Importing fake chains can be fraught with regulatory challenges, including customs duties, import taxes, and compliance with local laws regarding material safety and authenticity. For B2B buyers operating in regions with stringent regulations, failure to comply can result in fines, shipment delays, or even confiscation of goods, severely impacting business operations.

The Solution: To navigate these complexities, buyers should familiarize themselves with the specific import regulations of their target markets. Consulting with a customs broker or a legal expert in international trade can provide valuable guidance on necessary documentation and compliance requirements. Additionally, buyers should ensure that their suppliers are aware of and adhere to these regulations, as this can streamline the import process. Implementing a robust logistics plan that includes contingency measures for potential delays can also safeguard against disruptions. By staying informed and proactive, buyers can successfully import fake chains while minimizing risks and ensuring smooth operations.

Strategic Material Selection Guide for fake chains

What Are the Key Materials Used in Fake Chains for B2B Buyers?

When selecting materials for fake chains, it is essential to consider various factors that influence performance, durability, and cost. Below, we analyze four common materials used in the production of fake chains, highlighting their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Stainless Steel Perform in Fake Chains?

Stainless steel is a popular choice for fake chains due to its excellent corrosion resistance and durability. It can withstand a range of temperatures and pressures, making it suitable for various environments. The key properties of stainless steel include a high tensile strength and resistance to tarnishing, which enhances the longevity of the product.

Pros: Stainless steel chains are durable and can withstand harsh conditions, making them ideal for outdoor use. They are also relatively cost-effective, providing a good balance between quality and price.

Cons: While stainless steel is strong, it can be heavier than other materials, which may affect the comfort of the wearer. Additionally, manufacturing complexities can arise when creating intricate designs.

For international buyers, compliance with standards such as ASTM A240 for stainless steel is crucial. Buyers from regions like Europe and the Middle East often prefer stainless steel for its reliability and aesthetic appeal.

What Role Does Brass Play in Fake Chains?

Brass, an alloy of copper and zinc, is another common material used in fake chains. Its key properties include excellent machinability and resistance to corrosion, particularly in marine environments. Brass chains can be finished in various ways, enhancing their visual appeal.

Illustrative image related to fake chains

Pros: Brass chains are lightweight and can be produced at a lower cost than precious metals. They are also easy to work with, allowing for intricate designs and customization.

Cons: Brass is more prone to tarnishing and may require regular maintenance to retain its shine. Its strength is lower compared to stainless steel, which may limit its application in high-stress environments.

International buyers should be aware of the specific standards for brass alloys, such as ASTM B36. In regions like Africa and South America, where cost-effectiveness is a priority, brass can be an attractive option.

Illustrative image related to fake chains

Why Choose Gold-Plated Materials for Fake Chains?

Gold-plated materials are often used in fake chains to provide a luxurious appearance at a fraction of the cost of solid gold. The key properties of gold plating include a visually appealing finish and resistance to tarnishing, depending on the quality of the underlying material.

Pros: Gold-plated chains offer an elegant look and are lightweight, making them comfortable to wear. They are significantly less expensive than solid gold, appealing to budget-conscious buyers.

Cons: The durability of gold plating is a concern, as it can wear off over time, especially with frequent use. This can lead to a less appealing appearance and may require replacement.

For B2B buyers, understanding the quality of the gold plating is essential. Compliance with international standards, such as the ISO 8653 for gold plating, can help ensure quality. Buyers in regions like Saudi Arabia and Nigeria may prefer gold-plated options for their aesthetic value.

Illustrative image related to fake chains

What Are the Benefits of Using Acrylic in Fake Chains?

Acrylic is a synthetic polymer that is increasingly being used in the production of fake chains. Its key properties include lightweight, shatter-resistant qualities, and a wide range of colors and finishes.

Pros: Acrylic chains are highly customizable and can be produced in various colors and designs. They are also very lightweight, making them comfortable for everyday wear.

Cons: Acrylic is less durable than metals and can be prone to scratches. It may not be suitable for heavy-duty applications or environments with extreme temperatures.

Illustrative image related to fake chains

For international buyers, compliance with safety standards such as ASTM D638 for plastics is important. Buyers from South America and Africa may find acrylic chains appealing due to their affordability and versatility.

Summary of Material Selection for Fake Chains

| Material | Typical Use Case for fake chains | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Outdoor and heavy-duty applications | Excellent durability | Heavier than other materials | Medium |

| Brass | Fashion jewelry and decorative chains | Cost-effective and lightweight | Prone to tarnishing | Low |

| Gold-Plated | Fashion jewelry for luxury appeal | Elegant appearance | Durability concerns | Medium |

| Acrylic | Trendy and colorful fashion chains | Highly customizable | Less durable than metals | Low |

This guide provides valuable insights for B2B buyers in selecting the appropriate materials for fake chains, considering factors such as performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for fake chains

What Are the Key Stages in the Manufacturing Process of Fake Chains?

The manufacturing of fake chains, often used in fashion and costume jewelry, involves several critical stages that ensure both quality and aesthetic appeal. Understanding these stages can help B2B buyers make informed decisions when sourcing these products.

Illustrative image related to fake chains

Material Preparation: What Materials Are Used and How Are They Prepared?

The first step in the manufacturing process is material preparation, which typically involves selecting the appropriate base metals. Common materials include stainless steel, brass, or even lower-quality metals that can be coated or plated to achieve the desired look. The preparation phase also includes cleaning the raw materials to remove any impurities that could affect the final product’s finish.

Once the materials are selected, they may undergo treatments such as annealing to enhance malleability, ensuring that they can be formed into intricate designs. Manufacturers often use high-grade alloys to improve durability and minimize tarnishing, which is a crucial aspect for chains marketed as “fake” but aiming to provide a more premium look.

How Are Fake Chains Formed and Assembled?

The forming stage involves several techniques, including casting, stamping, and die-cutting. For example, the Miami Cuban link chains are often stamped from flat sheets of metal into the desired link shape, while rope chains may be created through a twisting process that intertwines strands of metal.

Illustrative image related to fake chains

After the initial forming, the assembly process begins. This stage may involve soldering or welding individual links together to create the final chain. Quality manufacturers ensure that joints are meticulously finished to prevent breakage or wear over time. Advanced robotic technology is increasingly used in this phase to ensure precision and reduce human error, which is particularly important when producing large volumes of chains.

What Finishing Techniques Enhance the Aesthetic Appeal of Fake Chains?

Finishing techniques are vital in determining the chain’s final appearance and quality. Common methods include polishing, plating, and applying protective coatings. Polishing enhances the shine and smoothness of the chain, while electroplating is often used to give the appearance of gold or silver without the associated costs.

Additionally, some manufacturers apply tarnish-resistant coatings to prolong the life of the chain, making it more appealing to buyers who are concerned about maintenance. These finishing touches are what often set apart high-quality fake chains from lower-quality alternatives.

What Quality Assurance Measures Are Essential for Fake Chain Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that the final product meets both international standards and buyer expectations.

Which International Standards Should Buyers Look For?

International standards, such as ISO 9001, provide a framework for quality management systems. Compliance with these standards indicates that the manufacturer has established processes for consistent product quality and continual improvement. For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, selecting suppliers that adhere to these standards can significantly reduce the risk of receiving subpar products.

Illustrative image related to fake chains

In addition to ISO certifications, industry-specific standards such as CE marking in Europe or API specifications can further assure quality. Understanding these standards can help buyers assess potential suppliers effectively.

What Are the Key Quality Control Checkpoints in Fake Chain Production?

Quality control (QC) checkpoints are essential to maintaining high standards throughout the manufacturing process. These checkpoints typically include:

-

Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Monitoring processes during manufacturing to catch defects early, which may involve regular inspections and testing of components at different stages of production.

-

Final Quality Control (FQC): Conducting thorough checks on the finished products to ensure they meet the required specifications before shipping.

Common testing methods include dimensional checks, visual inspections for surface defects, and material tests to ensure adherence to specified properties.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is crucial. Here are some actionable strategies:

-

Supplier Audits: Conducting audits, either independently or through third-party services, allows buyers to assess the manufacturing environment, processes, and compliance with quality standards.

-

Requesting Quality Reports: Buyers should ask for detailed quality reports that document the results of IQC, IPQC, and FQC processes. These reports provide insights into the supplier’s quality management practices.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturer’s processes and products. This can be particularly beneficial for buyers in regions where on-site visits may not be feasible.

What Are the Nuances of Quality Control for International Buyers?

B2B buyers, particularly from diverse regions, must navigate various regulatory and cultural expectations related to quality control. For example, buyers in Saudi Arabia may prioritize specific certifications that align with local regulations, while those in Europe may focus on compliance with CE marking.

Additionally, understanding the local manufacturing landscape can help buyers identify reliable suppliers who are accustomed to international standards. This knowledge enables more effective negotiations and fosters trust in the supplier relationship.

Conclusion: How Can Buyers Ensure Quality in Fake Chains?

In summary, the manufacturing processes and quality assurance measures for fake chains are intricate and vital for ensuring product quality. By understanding the key stages of manufacturing, the importance of international standards, and effective verification methods, B2B buyers can make informed decisions that lead to successful partnerships and high-quality products. Being diligent in these areas not only enhances the buyer’s reputation but also ensures customer satisfaction in their respective markets.

Illustrative image related to fake chains

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fake chains’

Introduction

Sourcing fake chains for your business can be a complex process, especially in a competitive B2B landscape. This guide provides a clear, actionable checklist to help international buyers, particularly those from Africa, South America, the Middle East, and Europe, navigate the procurement of high-quality fake chains. By following these steps, you can ensure that you select reliable suppliers and products that meet your specific needs.

Step 1: Define Your Technical Specifications

Understanding your technical requirements is the first step in the sourcing process. Specify the types of fake chains you need (e.g., Miami Cuban links, Franco chains, etc.), including dimensions, materials, and styles. This clarity helps potential suppliers provide accurate quotes and ensures that the products align with your market demands.

- Consider material quality: Look for options such as tarnish-resistant or hypoallergenic materials.

- Specify customization needs: If you require branding or unique designs, outline these expectations early.

Step 2: Conduct Market Research

Before reaching out to suppliers, conduct thorough market research to identify trends and pricing benchmarks. This knowledge allows you to make informed decisions and negotiate effectively.

- Analyze competitor offerings: Understanding what similar businesses offer can provide insights into market standards.

- Evaluate pricing trends: This helps to ensure that you don’t overpay and can identify competitive pricing.

Step 3: Evaluate Potential Suppliers

It’s crucial to vet suppliers thoroughly before making any commitments. Request company profiles, case studies, and references from other buyers in similar industries.

Illustrative image related to fake chains

- Review supplier certifications: Look for certifications that validate the quality and ethical sourcing of materials.

- Check customer reviews: Feedback from previous clients can provide insights into reliability and product quality.

Step 4: Request Samples

Before placing a bulk order, always request samples of the chains you are considering. This step allows you to assess the quality firsthand.

- Inspect craftsmanship: Look for any imperfections or inconsistencies in the product.

- Test durability: Evaluate how the material holds up under everyday use.

Step 5: Negotiate Terms and Conditions

Once you have identified a suitable supplier and reviewed samples, negotiate the terms of the contract. This includes pricing, delivery schedules, and payment terms.

- Clarify shipping costs: Understand all potential costs associated with shipping, customs, and duties.

- Establish return policies: Ensure you have clear guidelines for returns in case the products do not meet your specifications.

Step 6: Monitor Production and Quality Control

After placing an order, maintain communication with the supplier to monitor production and quality control measures. This proactive approach helps identify any issues early in the process.

- Set milestones: Agree on specific checkpoints to review progress.

- Request updates: Regular updates can provide peace of mind and keep the project on track.

Step 7: Plan for Logistics and Distribution

Finally, strategize your logistics and distribution plans to ensure timely delivery to your market. This includes understanding local customs regulations and delivery timelines.

Illustrative image related to fake chains

- Coordinate with local partners: If necessary, partner with local distributors to streamline the process.

- Prepare for potential delays: Anticipate possible delays and have contingency plans in place.

By following this checklist, you can effectively source fake chains that meet your business needs while minimizing risks and maximizing quality.

Comprehensive Cost and Pricing Analysis for fake chains Sourcing

What Are the Key Cost Components in Sourcing Fake Chains?

When sourcing fake chains, understanding the cost structure is critical for effective budgeting and price negotiation. The primary cost components include:

-

Materials: The choice of materials significantly affects the overall cost. Chains can be made from various metals, including stainless steel, gold-plated brass, or even plastic. Higher-quality materials typically yield a longer lifespan and better aesthetic appeal but come at a higher price.

-

Labor: Labor costs vary depending on the manufacturing location and the complexity of the chain design. Regions with lower labor costs may provide more competitive pricing, but this can sometimes compromise quality.

-

Manufacturing Overhead: This includes factory utilities, equipment maintenance, and administrative costs. Efficient manufacturing processes can help reduce overhead, thereby lowering the price for buyers.

-

Tooling: Initial tooling costs for custom designs can be significant. If a buyer requires unique shapes or sizes, these costs need to be factored into the total price.

-

Quality Control (QC): Investing in rigorous quality control processes ensures that the final product meets standards. However, this can increase the overall cost. Buyers should evaluate whether the added expense aligns with their quality requirements.

-

Logistics: Transportation and handling costs can vary widely based on the origin of the chains and the shipping methods used. Factors like distance, shipping mode, and customs duties must be considered.

-

Margin: Suppliers will typically add a margin to cover their costs and generate profit. Understanding the supplier’s margin can help buyers negotiate better prices.

How Do Price Influencers Impact the Cost of Fake Chains?

Several factors influence the pricing of fake chains, particularly for international B2B buyers:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often provide better pricing for larger orders. Understanding the MOQ can help buyers plan their purchases effectively and secure discounts.

-

Specifications and Customization: Custom designs or specific specifications can increase costs. Buyers should clearly communicate their requirements to avoid unexpected charges.

-

Materials and Quality Certifications: Higher-grade materials or products with certifications (e.g., lead-free, hypoallergenic) usually cost more. Buyers should evaluate the necessity of these features based on their target market.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven quality and service levels, while lesser-known suppliers might offer lower prices but come with risks.

-

Incoterms: Understanding international commercial terms is essential for pricing negotiations. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) affect the final cost and responsibilities of both parties.

What Are the Best Buyer Tips for Cost-Efficiency in Fake Chain Sourcing?

International buyers, especially from Africa, South America, the Middle East, and Europe, should consider the following tips to enhance cost-efficiency:

-

Negotiation: Always negotiate prices, especially when placing larger orders. Establishing a good rapport with suppliers can lead to better deals and additional perks, such as free shipping.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but the total cost of ownership, which includes shipping, customs duties, and potential warranty costs. This comprehensive approach helps in making informed decisions.

-

Pricing Nuances: Be aware that cultural differences can influence pricing strategies. In some regions, haggling is expected, while in others, prices may be more fixed. Understanding these nuances can facilitate smoother negotiations.

-

Market Research: Conduct thorough market research to identify competitive pricing and supplier capabilities. This knowledge empowers buyers to make strategic choices.

-

Supplier Diversification: Relying on multiple suppliers can mitigate risks associated with supply chain disruptions and enhance negotiating power.

Disclaimer for Indicative Prices

Please note that prices for fake chains can vary significantly based on the aforementioned factors, and the figures provided in this analysis are indicative. It is advisable to request detailed quotes from suppliers to obtain accurate pricing tailored to specific needs.

Alternatives Analysis: Comparing fake chains With Other Solutions

Exploring Alternatives to Fake Chains in the Jewelry Market

When considering the procurement of jewelry items, particularly chains, businesses often evaluate various options to ensure they meet their specific needs. In this context, “fake chains”—often made from lower-cost materials and designed to mimic more expensive jewelry—can be compared to alternative solutions such as authentic gold or silver chains and advanced synthetic materials. Each option presents unique advantages and challenges that can influence purchasing decisions.

Comparison Table

| Comparison Aspect | Fake Chains | Authentic Gold/Silver Chains | Advanced Synthetic Chains |

|---|---|---|---|

| Performance | Low durability, prone to tarnishing | High durability, long-lasting | Moderate durability, some resistance to wear |

| Cost | Low-cost (typically $30-$100) | Higher cost (typically $200+) | Mid-range (typically $100-$200) |

| Ease of Implementation | Easy to source and distribute | Requires reputable suppliers and certification | Moderate sourcing complexity, requires tech knowledge |

| Maintenance | Minimal upkeep, may require replacement | Regular cleaning needed, durable | Low maintenance but may require special care |

| Best Use Case | Casual wear, promotional items | Luxury markets, formal events | Fashion-forward markets, innovative designs |

Detailed Breakdown of Alternatives

Authentic Gold/Silver Chains

Authentic chains made from gold or silver are a traditional choice for buyers looking for quality and longevity. They offer high durability and a timeless aesthetic, making them suitable for luxury markets and formal occasions. However, the costs can be significantly higher, often starting at $200 and going up depending on the weight and craftsmanship. Authentic chains require regular maintenance to keep them looking their best, including cleaning to prevent tarnishing and scratches. For B2B buyers targeting high-end clientele, these chains represent an investment in quality and reputation.

Advanced Synthetic Chains

Advanced synthetic chains, crafted from innovative materials like polymer composites or high-quality plated metals, provide a modern alternative that balances style and cost. Priced typically between $100 and $200, these chains can mimic the appearance of gold or silver without the hefty price tag. They are becoming increasingly popular in fashion-forward markets and can cater to a younger demographic looking for trendy yet affordable options. While they offer moderate durability and require less maintenance than authentic metals, buyers should be aware that they may not last as long as their genuine counterparts.

Illustrative image related to fake chains

Conclusion: Making the Right Choice for Your B2B Needs

In choosing between fake chains and their alternatives, B2B buyers should consider their target market, budget constraints, and desired brand image. If the aim is to appeal to a luxury clientele, authentic gold or silver chains are likely the best option despite the higher costs. Conversely, for brands targeting a younger, trend-conscious demographic, advanced synthetic chains may provide a compelling balance of style and affordability. Ultimately, the right solution will depend on the specific goals and positioning of the business within the competitive jewelry landscape.

Essential Technical Properties and Trade Terminology for fake chains

What Are the Key Technical Properties of Fake Chains?

When sourcing fake chains for your business, understanding their technical properties is essential. These specifications not only influence the quality and durability of the chains but also affect their marketability and cost-effectiveness.

1. Material Grade

The material grade is crucial for determining the quality and durability of fake chains. Common materials include stainless steel, brass, and various types of plated metals (such as gold or silver plating). Higher-grade materials typically offer better resistance to tarnishing and wear, making them ideal for long-term use. In B2B transactions, specifying material grade ensures that the product meets the required quality standards, which can enhance customer satisfaction and reduce returns.

2. Chain Thickness

Chain thickness, often measured in millimeters, impacts both the aesthetic appeal and the strength of the chain. Thicker chains can provide a more substantial look and feel, which is often preferred in fashion jewelry. For B2B buyers, understanding the thickness helps in aligning product offerings with market trends and consumer preferences, ultimately aiding in inventory management.

3. Length Variability

Chains are typically available in various lengths, from short chokers to long necklaces. Offering a range of lengths allows businesses to cater to diverse customer needs and preferences. When negotiating with suppliers, specifying length variability can help optimize product lines and meet market demand effectively.

4. Tarnish Resistance

Tarnish resistance is a critical property for chains, especially those made from plated metals. This feature enhances the longevity of the product and maintains its aesthetic appeal over time. In B2B dealings, emphasizing tarnish resistance can be a selling point, particularly in markets where jewelry care is a concern.

5. Weight

The weight of the chain can affect both its perceived quality and shipping costs. Heavier chains may be viewed as more luxurious, while lighter options may appeal to consumers seeking comfort. For buyers, understanding weight specifications is vital for accurate product descriptions and can influence pricing strategies.

Illustrative image related to fake chains

What Are Common Trade Terms Used in the Fake Chains Industry?

Navigating the business of fake chains involves familiarizing yourself with industry-specific jargon that can impact negotiations and transactions.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are then marketed by another company under its brand name. In the fake chains market, partnering with an OEM can facilitate customized designs and lower production costs, allowing businesses to offer unique products.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell in a single order. This term is critical for B2B buyers to understand, as it directly impacts inventory levels and cash flow. Buyers must negotiate MOQs that align with their sales forecasts to optimize their supply chain.

Illustrative image related to fake chains

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers solicit price quotes from suppliers for specific products or services. In the context of fake chains, issuing an RFQ can help businesses compare pricing, quality, and terms from multiple suppliers, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for B2B buyers engaged in cross-border trade of fake chains, as they clarify shipping responsibilities, risk transfer, and cost allocation.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. In the fake chains industry, lead time can vary based on the supplier and production processes. Awareness of lead time is essential for B2B buyers to manage inventory effectively and meet customer demand.

By grasping these essential technical properties and trade terms, B2B buyers can make more informed decisions, streamline their purchasing processes, and improve their competitive edge in the fake chains market.

Navigating Market Dynamics and Sourcing Trends in the fake chains Sector

What are the Current Market Dynamics and Key Trends in the Fake Chains Sector?

The global fake chains market is experiencing significant growth, driven by a blend of fashion trends, cultural influences, and increased accessibility through e-commerce platforms. Notably, urban fashion and hip-hop culture have popularized various chain styles, such as Miami Cuban links and tennis chains, making them highly sought after among younger demographics. This trend is particularly pronounced in regions like Africa and South America, where local cultures embrace bold, eye-catching accessories.

Illustrative image related to fake chains

Emerging B2B technology trends are reshaping sourcing practices. Innovations in supply chain management, such as blockchain for transparency and inventory management systems, allow businesses to optimize their procurement processes. International B2B buyers, especially from regions like the Middle East and Europe, are increasingly prioritizing suppliers who can demonstrate agility and reliability in their logistics capabilities. The rise of social media marketing also plays a crucial role, enabling brands to reach wider audiences and engage directly with consumers, thereby impacting purchasing decisions.

Moreover, buyers are gravitating towards customizable options that cater to local tastes and preferences. This trend is evident in the rising demand for unique pieces that reflect cultural heritage or personal style. As buyers navigate this dynamic market, understanding these trends can help them make informed sourcing decisions and capitalize on emerging opportunities.

How is Sustainability and Ethical Sourcing Shaping the Fake Chains Sector?

Sustainability and ethical sourcing are becoming paramount in the fake chains sector, influenced by growing consumer awareness regarding environmental issues. The production of fake chains, particularly those made from non-precious metals or synthetic materials, poses significant environmental challenges, including pollution and resource depletion. B2B buyers are increasingly aware of these impacts and are seeking suppliers who prioritize sustainable practices.

To align with these values, businesses are adopting ‘green’ certifications and sourcing materials that minimize environmental footprints. This includes using recycled metals and ethically sourced synthetic materials. Suppliers who can demonstrate compliance with sustainability standards not only enhance their marketability but also build trust with conscientious buyers.

In addition, transparency in supply chains is essential. Buyers should prioritize partnerships with suppliers who provide clear information about their sourcing practices and the environmental impact of their products. This shift towards ethical sourcing not only addresses ecological concerns but also aligns with the growing demand for corporate social responsibility in international markets.

What is the Brief Evolution and History of Fake Chains in the Market?

The evolution of fake chains can be traced back to the early 1980s, when hip-hop culture began to influence fashion trends. Initially, these accessories were crafted from inexpensive metals to mimic the appearance of high-value gold chains. Over time, advancements in manufacturing techniques allowed for the creation of more intricate and visually appealing designs, including iced-out options that featured cubic zirconia and other synthetic stones.

As the popularity of fake chains surged, they became symbols of status and style, particularly in urban environments. Today, they are embraced globally, with various styles catering to diverse cultural tastes and fashion preferences. This evolution reflects the ongoing demand for affordable yet stylish jewelry that allows consumers to express their individuality without compromising their budgets.

In conclusion, the fake chains sector presents a wealth of opportunities for international B2B buyers. By understanding market dynamics, prioritizing sustainability, and appreciating the historical context of these accessories, businesses can make strategic sourcing decisions that resonate with contemporary consumer values.

Frequently Asked Questions (FAQs) for B2B Buyers of fake chains

-

How do I solve quality concerns when sourcing fake chains?

To mitigate quality concerns, it’s essential to conduct thorough supplier vetting. Look for suppliers with a proven track record in the industry, verified certifications, and positive customer reviews. Request product samples before placing large orders to assess the quality firsthand. Additionally, consider visiting the manufacturer’s facility if feasible, or utilize third-party inspection services to ensure that the products meet your specifications and standards. -

What is the best way to identify reputable suppliers for fake chains?

To find reputable suppliers, leverage online B2B marketplaces and trade shows that specialize in jewelry and accessories. Verify suppliers by checking their business licenses, certifications, and references from other clients. Engage in direct communication to gauge their responsiveness and willingness to address your concerns. Platforms such as Alibaba, Global Sources, and TradeIndia often feature supplier ratings and reviews that can guide your selection. -

What customization options are available for fake chains?

Many manufacturers offer customization options such as material selection (e.g., gold plating, stainless steel), chain styles (e.g., Miami Cuban, Franco, Tennis), and sizes. You can also request personalized designs, engravings, or brand logos to enhance your product’s appeal. Discuss your specific needs with potential suppliers to see how they can accommodate your requirements, including minimum order quantities for custom items. -

What are the typical minimum order quantities (MOQs) for fake chains?

Minimum order quantities can vary significantly among suppliers, often ranging from 50 to 500 units depending on the product type and customization level. When negotiating with suppliers, inquire about their MOQs and whether they can accommodate smaller orders, especially if you are testing the market. Some suppliers may offer flexibility for first-time buyers or bulk orders, so it’s worth discussing your needs. -

What payment terms should I expect when buying fake chains internationally?

Payment terms can vary by supplier and region. Common options include advance payment, letter of credit, or payment upon delivery. For international transactions, consider using secure payment methods such as PayPal or escrow services to protect your investment. It’s advisable to negotiate terms that are favorable to both parties, ensuring clarity on payment schedules, currency, and any applicable taxes or tariffs. -

How can I ensure compliance with international shipping regulations for fake chains?

To ensure compliance with international shipping regulations, familiarize yourself with the import laws of the destination country, including any restrictions on materials used in fake chains. Work with suppliers who understand the necessary documentation, such as commercial invoices and certificates of origin. Additionally, consider collaborating with logistics companies that specialize in international trade to navigate customs procedures effectively. -

What quality assurance measures should I implement when sourcing fake chains?

Implementing quality assurance measures involves establishing clear specifications for the products you are sourcing. Require suppliers to provide documentation on quality control processes, and consider setting up periodic inspections during production. It’s also beneficial to draft a quality assurance agreement that outlines acceptable quality levels and procedures for handling defective items to protect your interests. -

What logistics options are available for shipping fake chains internationally?

When shipping fake chains internationally, various logistics options are available, including air freight for faster delivery and sea freight for cost-effective bulk shipments. Evaluate the trade-offs between speed and cost based on your business needs. Collaborate with freight forwarders who can provide expertise in customs clearance and shipping logistics, ensuring timely and compliant delivery to your destination.

Top 5 Fake Chains Manufacturers & Suppliers List

1. Etsy – Unique Handmade Chains

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Unique Handmade Chains, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. JAXXON – Men’s Gold Chains Collection

Domain: jaxxon.com

Registered: 2008 (17 years)

Introduction: Men’s Gold Chains collection at JAXXON includes various styles such as Cuban, Rope, Franco, Figaro, Tennis, Round Box, and Mariner chains. Key products include: 14k Gold Cuban Link Chains (8mm, 5mm, 10mm, 3mm), 14k Gold Rope Chains (2.5mm, 4mm), 14k Gold Franco Chains (2.5mm, 3mm), 14k Gold Round Box Chains (2mm, 4mm), 14k Gold Iced Out Cuban Link Chains (5mm, 8mm, 10mm), and 14k Gold Tennis Chain…

3. Pinterest – 15 Fake Chains That Look Real

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: 15 Fake Chains That Look Real in 2020 – A Fashion Blog | Gold chains for men, Chains for men, Gold chain jewelry

4. GLD – Gold Jewelry & Accessories

Domain: gld.com

Registered: 1995 (30 years)

Introduction: The GLD Shop offers a variety of gold jewelry for men and women, including Cuban chains, custom chains, and other accessories. Key promotions include: 50% OFF with 2+ items using code HEAT50, 50% OFF sitewide with code FALL50, and a Buy One, Get One FREE offer with code BOGO. The shop features markdowns up to 60% off on various items such as chains, pendants, bracelets, earrings, watches, and ring…

5. eBay – Fake Gold Chains

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Fake Gold Chain listings on eBay include various styles and sizes such as Miami Cuban Link chains, chunky gold chains, and dollar sign chains. Prices range from approximately ILS 33.06 to ILS 106.15, with many items offering free international shipping. Products are typically brand new or pre-owned, and they cater to costume accessories and hip hop fashion. Notable features include sizes like 24″ …

Strategic Sourcing Conclusion and Outlook for fake chains

In the evolving landscape of fake chains, strategic sourcing emerges as a pivotal component for international B2B buyers. By prioritizing quality, authenticity, and supplier reliability, businesses can ensure they deliver products that resonate with their target markets in Africa, South America, the Middle East, and Europe. Establishing partnerships with reputable manufacturers not only enhances product offerings but also builds a strong brand reputation that can lead to increased customer loyalty and sales.

Furthermore, understanding regional preferences and trends in jewelry design can significantly influence purchasing decisions. For instance, the popularity of styles like Miami Cuban links and Tennis chains varies across different cultures, and aligning sourcing strategies with these insights can lead to more effective market penetration.

Looking ahead, the demand for unique, stylish, and customizable fake chains is expected to grow. B2B buyers should seize this opportunity by engaging with innovative suppliers who are capable of meeting diverse customer needs. By taking action today, businesses can position themselves as leaders in this competitive market, ready to meet the evolving demands of consumers globally.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to fake chains

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.