Everything You Need to Know About Element Panel Clip Square Sourcing in 2025

Introduction: Navigating the Global Market for element panel clip square

In today’s competitive global market, sourcing the right element panel clip square can be a daunting task for B2B buyers. The challenge often lies in navigating a myriad of options while ensuring quality, compatibility, and cost-effectiveness. This guide is designed to streamline the procurement process by providing essential insights into the various types of element panel clips available, their applications across different industries, and the critical factors to consider when selecting suppliers.

With a focus on international markets, particularly for buyers from Africa, South America, the Middle East, and Europe (including key players like Germany and Vietnam), this comprehensive resource addresses common pain points in sourcing. It covers everything from identifying reliable suppliers and understanding pricing structures to evaluating product specifications and compliance with regional standards.

By equipping you with actionable insights and expert recommendations, this guide empowers informed purchasing decisions. Whether you’re looking to secure a consistent supply of clips for automotive applications or construction projects, understanding the nuances of the global market for element panel clip squares will enhance your sourcing strategy and ultimately contribute to your business’s success. Dive in to discover how to make the most of your procurement efforts in this specialized area.

Understanding element panel clip square Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OEM Square Base Clip | Square base, often white or black, specific part numbers | Automotive assembly and repairs | Pros: High quality, guaranteed fit. Cons: Typically higher cost. |

| Aftermarket Square Clip | Variable quality, often sold in bulk packs | Automotive repair shops, DIY enthusiasts | Pros: Cost-effective, bulk purchasing options. Cons: Potential compatibility issues. |

| Plastic Retainer Clip | Made from durable plastic, diverse sizes | Automotive parts replacement | Pros: Lightweight, corrosion-resistant. Cons: May not withstand extreme conditions. |

| Heavy-Duty Square Clip | Reinforced design for high-stress applications | Commercial vehicle maintenance | Pros: Enhanced durability, long-lasting. Cons: Higher price point. |

| Specialty Clips (e.g., Weatherproof) | Designed for specific environments, often rubberized | Automotive and industrial applications | Pros: Excellent sealing properties, specialized use. Cons: Limited versatility. |

What Are the Key Characteristics of OEM Square Base Clips?

OEM Square Base Clips are designed for specific vehicle models, ensuring a precise fit. These clips usually feature a square base and come in various colors, such as white or black. They are primarily used in automotive assembly and repairs, making them essential for maintaining vehicle integrity. For B2B buyers, sourcing OEM clips guarantees compatibility and quality, albeit at a higher price point compared to aftermarket options. Businesses focused on high-quality repairs often prioritize these clips despite the cost.

How Do Aftermarket Square Clips Compare to OEM Options?

Aftermarket Square Clips are widely available and often sold in bulk, making them an attractive choice for automotive repair shops and DIY enthusiasts. These clips may vary in quality and compatibility, which presents a risk for businesses that rely on precise fitment. While they offer significant cost savings, B2B buyers should thoroughly vet suppliers to ensure the clips meet their quality standards. The flexibility in purchasing options can be advantageous for businesses looking to manage inventory costs.

What Are the Advantages of Using Plastic Retainer Clips?

Plastic Retainer Clips are lightweight and resistant to corrosion, making them suitable for various automotive applications. Their diverse sizes allow for use in multiple settings, from interior fittings to exterior paneling. For B2B buyers, the key consideration is the environment in which these clips will be used; while they are generally durable, extreme conditions may affect their performance. Businesses should weigh the benefits of cost-effectiveness against the potential need for replacements in harsher environments.

When Should Heavy-Duty Square Clips Be Considered?

Heavy-Duty Square Clips are engineered for high-stress applications, such as in commercial vehicles or heavy machinery. Their reinforced design offers enhanced durability, making them ideal for situations where traditional clips may fail. While these clips come at a premium price, B2B buyers in industries requiring robust components often find the investment worthwhile. The longevity and reliability of heavy-duty clips can minimize downtime and reduce long-term costs associated with replacements.

What Makes Specialty Clips Unique for Specific Applications?

Specialty Clips, including weatherproof options, are tailored for specific environments, often featuring rubberized or sealed designs. These clips provide excellent sealing properties, making them ideal for automotive and industrial applications where moisture and debris could compromise performance. For businesses focused on niche markets, investing in specialty clips can enhance product reliability. However, their limited versatility means that buyers should carefully assess whether these clips are necessary for their specific applications before purchasing.

Key Industrial Applications of element panel clip square

| Industry/Sector | Specific Application of element panel clip square | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Fastening body panels and trim components | Ensures structural integrity and enhances vehicle aesthetics | OEM specifications, material durability, and compatibility |

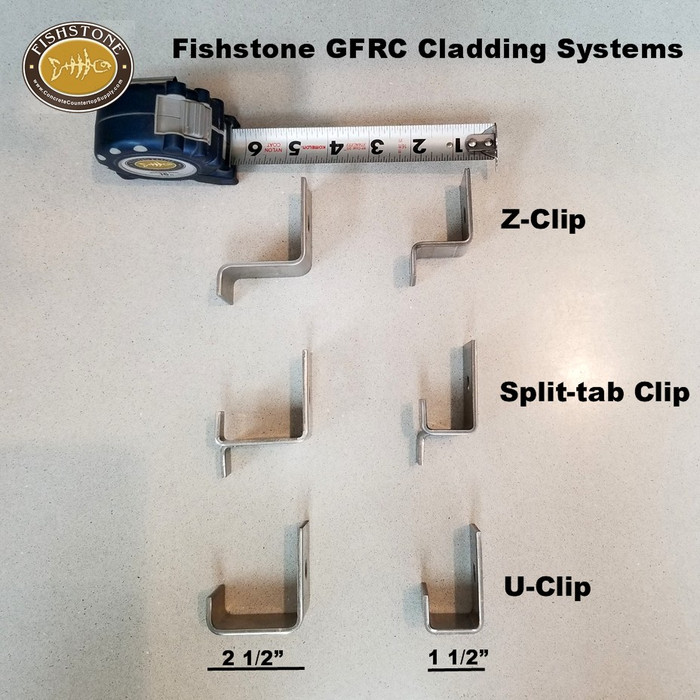

| Construction | Securing cladding and façade elements | Provides stability and weather resistance for buildings | Material specifications, load-bearing capacity, and weather resistance |

| Appliance Manufacturing | Mounting panels and covers in household appliances | Facilitates easy assembly and maintenance | Size, material compatibility, and thermal resistance |

| Aerospace Engineering | Attaching interior panels and components | Reduces weight while maintaining safety and structural integrity | Aerospace standards, weight considerations, and corrosion resistance |

| Electronics and IT | Securing casings and covers for electronic devices | Protects internal components while allowing easy access | Size precision, electromagnetic interference (EMI) shielding, and thermal management |

How is the element panel clip square utilized in automotive manufacturing?

In the automotive industry, the element panel clip square is crucial for fastening body panels and trim components. These clips ensure that various parts of a vehicle, such as fenders and rocker panels, remain securely attached, which is vital for both safety and aesthetics. For international buyers, especially in regions like Africa and South America, sourcing high-quality clips that meet OEM specifications is essential to avoid issues related to vehicle integrity and compliance with local automotive regulations.

What role does the element panel clip square play in construction projects?

In construction, the element panel clip square is used to secure cladding and façade elements, contributing to the overall stability and weather resistance of buildings. This application is particularly relevant in regions with extreme weather conditions, where robust fastening solutions are necessary. Buyers should consider the material specifications and load-bearing capacity of these clips to ensure they meet the demands of the specific construction project.

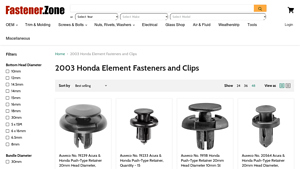

Illustrative image related to element panel clip square

How does the element panel clip square enhance appliance manufacturing?

In the appliance manufacturing sector, the element panel clip square is employed to mount panels and covers in household appliances such as refrigerators and washing machines. These clips facilitate easy assembly and maintenance, making them a preferred choice for manufacturers aiming to streamline production processes. Buyers should focus on size and material compatibility to ensure that the clips can withstand the operational conditions of various appliances.

Why is the element panel clip square important in aerospace engineering?

The aerospace industry utilizes the element panel clip square for attaching interior panels and components, where weight reduction is critical without compromising safety. These clips must adhere to stringent aerospace standards, emphasizing the importance of sourcing high-quality materials that offer corrosion resistance and durability. International buyers in aerospace must prioritize suppliers who can provide reliable certifications and compliance with industry regulations.

What benefits does the element panel clip square provide in electronics and IT?

In the electronics and IT sectors, the element panel clip square secures casings and covers for devices, protecting internal components while allowing for easy access during maintenance. The precision of these clips is vital, especially for products requiring electromagnetic interference (EMI) shielding. Buyers should consider sourcing clips that meet specific size requirements and thermal management capabilities to ensure optimal performance in their electronic devices.

3 Common User Pain Points for ‘element panel clip square’ & Their Solutions

Scenario 1: Difficulty in Identifying the Correct Clip Part Number

The Problem: B2B buyers often face challenges in identifying the exact part number for the element panel clip square required for their vehicles. This issue is compounded by inconsistent information across various sources, making it difficult to confirm compatibility. Misidentifying clips can lead to costly errors, delays in repair processes, and increased frustration among fleet managers or automotive parts suppliers who rely on precision.

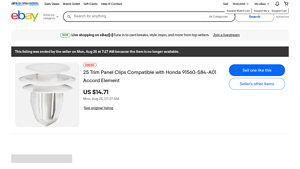

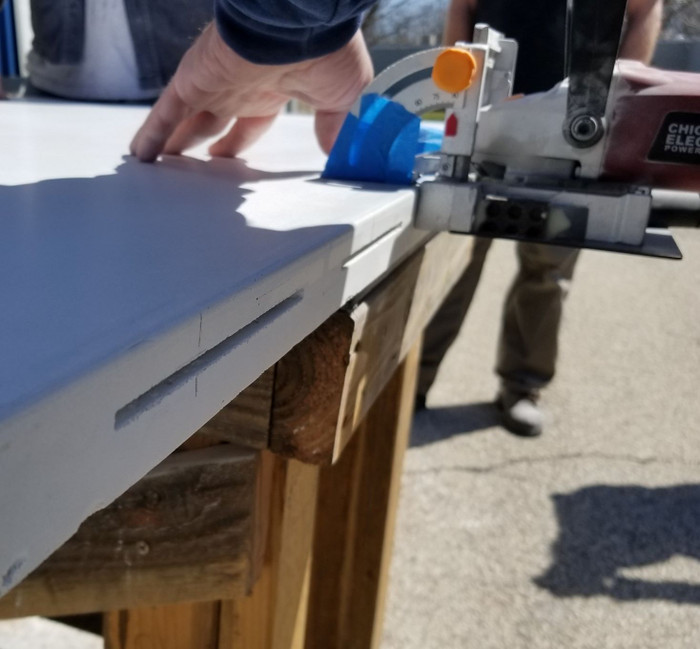

Illustrative image related to element panel clip square

The Solution: To effectively source the correct clip, buyers should leverage multiple resources. Start by consulting OEM parts diagrams specific to the vehicle model in question. Websites like Honda Parts Now and other OEM suppliers typically provide detailed diagrams and part numbers that can clarify which clip is needed. Additionally, engaging with online automotive communities or forums can yield insights from other users who faced similar challenges. Taking the time to cross-reference information from different platforms can significantly reduce the risk of errors. If feasible, buyers should also consider maintaining a sample of existing clips to facilitate in-person consultations at local automotive parts stores, ensuring a perfect match.

Scenario 2: High Costs of OEM Clips vs. Affordable Alternatives

The Problem: Many B2B buyers are dismayed by the high prices associated with OEM element panel clips, often costing upwards of $7 per clip. For businesses managing large fleets or requiring bulk purchases, these costs can quickly escalate, impacting overall budget and profit margins. Additionally, the lack of affordable aftermarket options may leave buyers feeling trapped between quality concerns and budget constraints.

The Solution: Buyers should explore reputable aftermarket suppliers that specialize in automotive fasteners. Conduct thorough research to identify suppliers with positive reviews regarding their product quality and customer service. Websites like eBay or Amazon frequently offer bulk purchasing options that can lower per-unit costs significantly. Buyers can also look for specialty shops that focus on automotive clips and fasteners, as they often carry high-quality alternatives at lower prices. It’s advisable to request samples before making large orders to ensure compatibility and quality. This approach allows businesses to maintain budgetary control while ensuring they have reliable supplies of necessary components.

Scenario 3: Quality Assurance of Aftermarket Clips

The Problem: When sourcing element panel clips from aftermarket suppliers, buyers frequently worry about the quality and durability of the products. Low-quality clips can result in premature failures, leading to increased maintenance costs and operational downtime. This concern is particularly pronounced in industries like automotive repair and fleet management, where reliability is paramount.

The Solution: To mitigate quality concerns, buyers should prioritize suppliers who offer warranties or guarantees on their products. This ensures that if a clip fails prematurely, the supplier will replace it without additional costs. Additionally, buyers can look for brands that have established reputations in the market for producing durable automotive parts. Reading user reviews and seeking recommendations from industry peers can provide valuable insights into the reliability of different aftermarket options. It’s also beneficial to conduct periodic quality checks on the clips received to ensure they meet necessary specifications. By establishing relationships with trusted suppliers and implementing quality control measures, businesses can confidently source aftermarket clips without compromising on performance.

Strategic Material Selection Guide for element panel clip square

What Are the Key Materials for Element Panel Clip Squares?

When selecting materials for element panel clip squares, it’s crucial to consider properties such as durability, temperature resistance, and corrosion resistance. Below, we analyze four common materials used in the manufacturing of these clips, focusing on their advantages and disadvantages, as well as their implications for international B2B buyers.

1. Polypropylene (PP)

Key Properties:

Polypropylene is a thermoplastic polymer known for its excellent chemical resistance and low moisture absorption. It can withstand temperatures up to 100°C (212°F) and offers good impact resistance.

Pros & Cons:

The main advantage of polypropylene is its lightweight nature and cost-effectiveness, making it a popular choice for automotive applications. However, it has lower tensile strength compared to other materials, which may affect its performance under high-stress conditions.

Impact on Application:

Polypropylene is suitable for applications that require moderate strength and resistance to various chemicals, including automotive fluids. However, it may not perform well in high-temperature environments.

Considerations for International Buyers:

B2B buyers from regions like Africa and South America should ensure compliance with local regulations regarding plastic materials. Polypropylene is widely accepted and can be sourced from numerous suppliers, but buyers should verify the material’s compliance with ASTM or JIS standards.

2. Nylon (PA)

Key Properties:

Nylon is a synthetic polymer known for its high strength, excellent abrasion resistance, and ability to withstand temperatures up to 120°C (248°F). It also has good chemical resistance, although it can absorb moisture.

Pros & Cons:

Nylon’s durability and strength make it ideal for high-stress applications. However, its moisture absorption can lead to dimensional changes, which may affect the fit of the clips over time. Additionally, it can be more expensive than polypropylene.

Impact on Application:

Nylon is suitable for applications requiring high strength and durability, such as in automotive assemblies exposed to mechanical stress. Its moisture sensitivity must be considered, especially in humid environments.

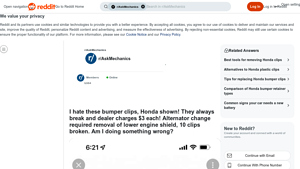

Illustrative image related to element panel clip square

Considerations for International Buyers:

Buyers in Europe, particularly Germany, should be aware of the stringent material standards and certifications required for automotive parts. Ensuring that nylon clips meet these standards will be essential for compliance and performance.

3. Polycarbonate (PC)

Key Properties:

Polycarbonate is a high-performance thermoplastic known for its exceptional impact resistance and transparency. It can withstand temperatures up to 135°C (275°F) and offers good dimensional stability.

Pros & Cons:

The primary advantage of polycarbonate is its superior impact resistance, making it suitable for applications where safety is a concern. However, it is generally more expensive than other materials and can be prone to scratching.

Impact on Application:

Polycarbonate is ideal for applications requiring high transparency and impact resistance, such as in safety features in automotive design. Its higher cost may limit its use in mass production.

Considerations for International Buyers:

For buyers in the Middle East, understanding the local market’s acceptance of polycarbonate is essential, as it may not be as commonly used as other materials. Compliance with international standards like ISO or ASTM is also crucial.

4. Steel

Key Properties:

Steel is a strong and durable metal known for its high tensile strength and resistance to deformation. It can withstand high temperatures and is often treated for corrosion resistance.

Pros & Cons:

The key advantage of steel is its unmatched strength and durability, making it suitable for heavy-duty applications. However, it is heavier than plastic alternatives and can be prone to rust if not properly coated.

Impact on Application:

Steel is ideal for applications requiring high load-bearing capacity and durability, such as in structural automotive components. The weight factor may affect fuel efficiency in vehicles.

Considerations for International Buyers:

B2B buyers in regions with high humidity, such as parts of South America, should consider the corrosion resistance of steel clips. Compliance with local and international standards for metal components is also essential.

Summary Table of Material Selection

| Material | Typical Use Case for element panel clip square | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | General automotive applications | Lightweight and cost-effective | Lower tensile strength | Low |

| Nylon | High-stress automotive assemblies | High strength and durability | Moisture absorption affects dimensions | Medium |

| Polycarbonate | Safety features and high-impact areas | Exceptional impact resistance | Higher cost and prone to scratching | High |

| Steel | Heavy-duty structural components | Unmatched strength and durability | Heavier and prone to corrosion | Medium |

This guide provides a comprehensive overview of material options for element panel clip squares, enabling international B2B buyers to make informed decisions based on performance requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for element panel clip square

What Are the Main Stages in the Manufacturing Process of Element Panel Clip Squares?

The manufacturing of element panel clip squares involves several critical stages that ensure high-quality production. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The primary materials used for manufacturing panel clip squares are usually high-grade plastics, such as nylon or polypropylene, which provide durability and resistance to environmental factors. In this stage, raw materials are sourced from certified suppliers who meet international standards. Quality checks are performed to ensure that the materials meet the required specifications before they proceed to the next phase.

-

Forming: The forming process typically involves injection molding, where heated plastic is injected into molds to create the desired shape of the panel clip. This method is favored for its efficiency and ability to produce consistent shapes at scale. Advanced techniques such as multi-cavity molds may be used to enhance production speed without compromising quality.

-

Assembly: After forming, the clips may undergo an assembly process, especially if they include multiple components or features. Automated assembly lines are often utilized to increase efficiency and reduce labor costs. Each clip is assembled under controlled conditions to maintain quality consistency.

-

Finishing: The finishing stage includes processes such as trimming, surface treatment, and packaging. Trimming removes any excess material from the injection molding process, ensuring a clean final product. Surface treatments may be applied to enhance aesthetics or provide additional protection against wear and tear. Finally, the clips are packaged in bulk or as per customer specifications for shipping.

What International Standards Are Relevant for Quality Assurance in Panel Clip Manufacturing?

Quality assurance in the manufacturing of element panel clip squares is crucial, especially for B2B buyers operating across different regions. Several international standards guide this process:

-

ISO 9001: This is one of the most widely recognized quality management standards. Companies adhering to ISO 9001 demonstrate a commitment to quality, customer satisfaction, and continuous improvement. Compliance with this standard involves regular audits and documentation of processes to ensure that they meet quality benchmarks.

-

CE Marking: For manufacturers targeting the European market, CE marking is essential. It indicates that the product meets the health, safety, and environmental protection standards set by the European Union. This certification is crucial for gaining access to the EU market.

-

API Standards: For clips used in automotive applications, adherence to American Petroleum Institute (API) standards may be relevant. These standards ensure that products are suitable for their intended use in automotive applications, particularly regarding performance and safety.

How Are Quality Control Checkpoints Structured in Panel Clip Manufacturing?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that each clip meets the required specifications. The typical checkpoints include:

-

Incoming Quality Control (IQC): This is the first line of defense against defects. IQC involves inspecting raw materials upon arrival to verify their compliance with specifications. Only materials that pass this inspection are allowed into the production line.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC monitors various parameters such as temperature, pressure, and timing during the injection molding phase. Operators conduct random sampling and testing to ensure that the process remains within acceptable limits.

-

Final Quality Control (FQC): Once the clips are completed, FQC involves thorough testing of finished products. This may include dimensional checks, functional tests, and visual inspections to identify any defects before packaging.

What Common Testing Methods Are Used to Ensure Quality in Panel Clips?

To ensure that element panel clips meet industry standards, several testing methods are commonly employed:

-

Dimensional Testing: This involves measuring the physical dimensions of the clips to ensure they meet specified tolerances. Tools such as calipers and micrometers are often used for precise measurements.

-

Material Testing: Tests such as tensile strength and impact resistance are performed to evaluate the durability of the materials used in the clips. This is crucial for ensuring that the clips can withstand operational stresses.

-

Environmental Testing: Clips may be subjected to tests that simulate real-world conditions, including exposure to UV light, moisture, and extreme temperatures. These tests help assess the longevity and reliability of the clips in various environments.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control practices is essential for ensuring product reliability. Here are several strategies:

-

Supplier Audits: Conducting on-site audits of potential suppliers allows buyers to assess their manufacturing processes, quality control measures, and compliance with international standards firsthand. This can also help in building a strong relationship with suppliers.

-

Quality Reports: Requesting quality assurance reports can provide insights into a supplier’s QC processes. These reports often detail the results of various tests and inspections, highlighting the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of the manufacturing and quality control processes. These organizations conduct thorough evaluations and provide detailed reports that can help in making informed purchasing decisions.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

When dealing with suppliers from different regions, B2B buyers must navigate various quality control and certification nuances:

-

Regional Standards: Different regions may have specific regulations and standards that must be adhered to. For instance, while ISO certifications are globally recognized, compliance with regional standards such as ANSI in North America or EN standards in Europe may also be required.

-

Cultural Differences: Understanding cultural approaches to quality management is crucial. For example, manufacturers in Germany may place a strong emphasis on precision engineering, while suppliers in Asia might focus on cost efficiency. Aligning expectations is vital for successful partnerships.

-

Documentation and Traceability: Ensuring that suppliers provide comprehensive documentation regarding their QC processes and product traceability is essential. This not only aids in compliance but also enhances transparency in the supply chain, which is particularly important for international transactions.

In conclusion, the manufacturing processes and quality assurance practices for element panel clip squares are integral to delivering reliable products to B2B buyers. By understanding these processes and actively engaging in quality verification, buyers can ensure that they receive products that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘element panel clip square’

Introduction

This guide aims to assist B2B buyers in the international market with a structured approach to sourcing ‘element panel clip square.’ This type of clip is essential in various automotive applications, particularly for securing panels and components. By following this checklist, buyers can ensure they procure high-quality products that meet their specific needs while navigating the complexities of global sourcing.

Step 1: Define Your Technical Specifications

Understanding the precise requirements for the element panel clip square is crucial. Specifications may include dimensions, material type (e.g., plastic or metal), and color. Clearly defined specifications help avoid mismatches and ensure the clips fit the intended applications.

- Consider design variations: Different vehicle models may require specific clip designs.

- Determine load-bearing requirements: Ensure the clips can withstand the necessary pressure without failure.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers specializing in automotive fasteners. Look for companies with a solid reputation and experience in providing similar products.

- Utilize online platforms: Websites like Alibaba, ThomasNet, or industry-specific directories can yield valuable leads.

- Check for local suppliers: Especially important for buyers in regions like Africa and South America where logistics can be a concern.

Step 3: Evaluate Supplier Certifications

Before proceeding with any supplier, verify their certifications and compliance with international standards. Certifications such as ISO 9001 indicate a commitment to quality management.

- Request documentation: Ask for copies of relevant certifications and quality assurance processes.

- Review customer feedback: Look for reviews or testimonials from other B2B clients to gauge reliability.

Step 4: Request Samples for Testing

Once you’ve shortlisted potential suppliers, request samples of the element panel clip square. Testing samples helps ensure they meet your quality and performance standards before placing a bulk order.

- Conduct quality checks: Evaluate the samples for durability, fit, and finish.

- Test under operational conditions: If possible, simulate the actual usage conditions to assess performance.

Step 5: Negotiate Pricing and Terms

Engage in negotiations to secure favorable pricing and terms. Understand market rates to ensure you are getting a fair deal without compromising on quality.

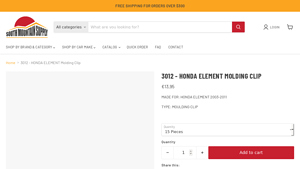

Illustrative image related to element panel clip square

- Discuss bulk order discounts: Many suppliers offer better rates for larger quantities.

- Clarify payment terms: Ensure that the payment terms align with your cash flow requirements.

Step 6: Finalize Logistics and Delivery Schedule

Once you agree on terms, finalize the logistics for shipping and delivery. Clear communication regarding timelines and responsibilities is vital for smooth operations.

- Confirm shipping methods: Choose reliable shipping options that align with your delivery timelines.

- Track shipments: Ensure you have a tracking mechanism in place to monitor the shipment’s progress.

Step 7: Establish a Long-Term Relationship

After successful procurement, consider establishing a long-term relationship with the supplier. This can lead to better pricing, priority service, and improved product offerings in the future.

- Maintain regular communication: Keep in touch for updates on new products or changes in the market.

- Evaluate performance regularly: Periodically assess the supplier’s performance to ensure they continue to meet your needs.

By following this comprehensive checklist, B2B buyers can streamline their sourcing process for element panel clip squares, ensuring they secure quality products that meet their operational requirements effectively.

Comprehensive Cost and Pricing Analysis for element panel clip square Sourcing

What Are the Key Cost Components for Sourcing Element Panel Clip Squares?

When evaluating the cost structure for sourcing element panel clip squares, several key components should be considered. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s profit margin.

Materials: The type of plastic used can significantly influence the cost. High-grade materials that offer better durability and weather resistance will typically come at a premium. Conversely, lower-quality materials may reduce upfront costs but lead to increased failure rates and replacements.

Labor: Labor costs will vary based on the geographical location of the manufacturing facility. Countries with lower labor costs, such as certain regions in Asia, may offer more competitive pricing but could sacrifice quality.

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and administrative expenses. Manufacturers with efficient processes may be able to offer lower prices without compromising quality.

Tooling: The initial investment in molds and tools is a significant upfront cost, particularly for custom designs. The amortization of these costs over larger production runs can lead to more competitive pricing.

Quality Control (QC): Implementing robust QC processes adds to the cost but is essential for ensuring product reliability. Certifications for quality standards can also influence the price.

Logistics: Shipping costs can vary significantly based on the supplier’s location and chosen shipping methods. Understanding Incoterms is crucial as they define the responsibilities of buyers and sellers regarding shipping costs and risk.

Margin: Finally, the supplier’s profit margin will affect the final price. Negotiating terms and understanding the supplier’s cost structure can help in achieving a more favorable deal.

How Do Price Influencers Affect the Sourcing of Element Panel Clip Squares?

Several factors can influence the pricing of element panel clip squares. Volume and Minimum Order Quantity (MOQ) are significant. Suppliers often provide better pricing for bulk orders, so understanding your consumption needs can lead to cost efficiencies.

Specifications and Customization: Custom designs and specifications will typically incur higher costs. If standard clips meet your requirements, opting for these can result in significant savings.

Quality and Certifications: Higher-quality clips often come with certifications that may be required in specific markets. While these may increase upfront costs, they can reduce long-term expenses associated with failures and replacements.

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established suppliers with proven track records may charge a premium, but their quality assurance can justify the investment.

Incoterms: Understanding shipping terms can lead to better pricing strategies. For instance, choosing “FOB” (Free on Board) terms can allow buyers to control shipping costs, while “CIF” (Cost, Insurance, and Freight) might offer convenience at a higher price.

What Are the Best Buyer Tips for Sourcing Element Panel Clip Squares?

To ensure a successful sourcing experience, international B2B buyers should consider several key strategies. Negotiation is paramount. Engage suppliers in discussions about pricing, especially for larger orders, and be transparent about your budget constraints.

Cost-Efficiency: Perform a Total Cost of Ownership (TCO) analysis. This includes not just the purchase price but also shipping, handling, and potential costs associated with product failures. A lower initial price may not always equate to a better deal if higher failure rates lead to increased replacement costs.

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of currency fluctuations and regional tariffs that can affect pricing. Consider using local suppliers where possible to mitigate these risks.

Quality Assurance: Always request samples before placing large orders. Testing these samples can help avoid potential issues down the line.

In conclusion, understanding the comprehensive cost structure and pricing influencers of element panel clip squares can empower B2B buyers to make informed sourcing decisions. By leveraging negotiation strategies and being aware of the nuances in international trade, buyers can secure better pricing while ensuring product quality.

Alternatives Analysis: Comparing element panel clip square With Other Solutions

When evaluating the ‘element panel clip square,’ it is essential for international B2B buyers to consider various alternatives that may offer similar functionalities. This analysis will compare the element panel clip square against two viable alternatives: aftermarket plastic clips and metal fasteners. Each option presents its own strengths and weaknesses, making it crucial for buyers to understand the differences before making a purchasing decision.

| Comparison Aspect | Element Panel Clip Square | Aftermarket Plastic Clips | Metal Fasteners |

|---|---|---|---|

| Performance | Good for automotive use; designed for specific models | Varies; may not match OEM specifications | Excellent; durable and reliable |

| Cost | Moderate ($3.18 each) | Low ($0.50 – $2.00 each) | High ($1.50 – $5.00 each) |

| Ease of Implementation | Straightforward; fits specific applications | Can be tricky due to size variations | Requires tools and expertise |

| Maintenance | Low; typically lasts the lifespan of the vehicle | Varies; may need replacement sooner | Low; very durable with minimal wear |

| Best Use Case | OEM replacements in automotive applications | General use in various applications | Heavy-duty applications requiring strength |

What Are the Pros and Cons of Aftermarket Plastic Clips?

Aftermarket plastic clips are often more affordable than OEM options, typically costing between $0.50 and $2.00 each. These clips can be a cost-effective solution for businesses looking to reduce expenses. However, they may not always meet the same quality standards as the original equipment manufacturer (OEM) clips. Performance can vary significantly based on the manufacturer, which may lead to issues such as poor fitment or reduced durability over time. For companies seeking to maintain strict quality control, this variability could pose challenges.

How Do Metal Fasteners Compare as an Alternative?

Metal fasteners provide an alternative that excels in performance and durability, making them suitable for heavy-duty applications. Priced between $1.50 and $5.00 each, they are typically more expensive than both the element panel clip square and aftermarket plastic clips. While their implementation requires more tools and expertise, metal fasteners are advantageous for situations where strength and longevity are critical. Maintenance is low, as these fasteners can withstand harsh conditions without frequent replacement. However, their rigidity may not be ideal for all applications, especially where flexibility is required.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate fastening solution ultimately depends on the specific requirements of your project. For B2B buyers in Africa, South America, the Middle East, and Europe, factors such as cost, application, and the expected lifespan of the fasteners should guide your decision. If you need a reliable and durable solution for automotive applications, the element panel clip square may be your best bet. However, if cost is a primary concern, exploring aftermarket plastic clips could provide an affordable alternative, provided you can manage the potential quality risks. For heavy-duty applications that demand strength, metal fasteners offer unparalleled reliability despite their higher price point. By thoroughly assessing these alternatives, you can make an informed choice that aligns with your business’s operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for element panel clip square

What Are the Key Technical Properties of Element Panel Clip Square?

When sourcing element panel clip squares, understanding their technical properties is crucial for ensuring compatibility and performance in various applications. Here are some essential specifications to consider:

-

Material Composition

The most common materials used for element panel clips are plastics such as polypropylene (PP) and polyamide (PA). These materials provide durability and resistance to environmental factors such as moisture and UV light, which is especially important in automotive applications. Choosing the right material can significantly affect the clip’s longevity and performance. -

Load Capacity

Load capacity refers to the maximum weight or force that the clip can support without failure. This property is critical in applications where the clips are subjected to dynamic loads, such as in automotive or industrial settings. Understanding load capacity ensures that the selected clips can withstand operational stresses without breaking or deforming. -

Tolerance Levels

Tolerance defines the acceptable range of dimensions for the clip. This is essential for ensuring that the clips fit perfectly within their intended assembly, preventing issues such as rattling or loosening. High precision in tolerances is particularly important in sectors like automotive manufacturing, where safety and functionality are paramount. -

Temperature Resistance

Temperature resistance indicates the range of temperatures the clip can withstand without losing its structural integrity. This property is vital for applications that involve exposure to heat or cold, such as under-hood automotive components. Knowing the temperature resistance helps buyers select the right clips for environments with extreme temperature fluctuations. -

Surface Finish

The surface finish of a clip can affect its aesthetic appearance and its friction properties. A smooth finish may reduce wear and tear during assembly and disassembly, while a textured finish can enhance grip. Understanding the implications of surface finish can help buyers choose clips that meet both functional and aesthetic requirements.

What Are the Common Trade Terms Used in Sourcing Element Panel Clip Squares?

Familiarity with industry terminology is vital for effective communication and negotiation in B2B transactions. Here are some commonly used terms related to element panel clips:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the manufacturer of the original product. In the context of element panel clips, OEM clips are designed to meet the specific standards set by the vehicle manufacturer, ensuring a perfect fit and reliable performance. B2B buyers often seek OEM parts for quality assurance. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory and cash flow effectively. Suppliers often set MOQs to ensure that production and shipping costs are covered. -

RFQ (Request for Quotation)

An RFQ is a formal document that buyers send to suppliers to request pricing and terms for a specific quantity of products. This process is crucial for comparing offers from multiple suppliers and negotiating favorable terms, ensuring that buyers make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. They clarify aspects such as shipping costs, insurance, and delivery points. Familiarity with Incoterms helps buyers avoid misunderstandings and ensures smooth logistics. -

Lead Time

Lead time refers to the period from placing an order to receiving the goods. Understanding lead times is essential for planning inventory and production schedules. Buyers should consider lead time when sourcing element panel clips to avoid delays in their operations. -

Compatibility

Compatibility refers to the ability of a part to fit and function correctly with other components. In the context of element panel clips, ensuring compatibility with existing systems is crucial for successful assembly and operation. Buyers should verify compatibility specifications to avoid costly rework or replacements.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing element panel clip squares, ultimately leading to better procurement strategies and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the element panel clip square Sector

What Are the Current Market Dynamics and Key Trends in the Element Panel Clip Square Sector?

The element panel clip square market is experiencing significant growth driven by the increasing demand for automotive parts and the expansion of the automotive sector globally. Emerging markets in Africa and South America are witnessing a surge in vehicle ownership, leading to heightened demand for reliable and cost-effective fasteners. In Europe, particularly in Germany and Vietnam, the focus on efficient supply chains and advanced manufacturing technologies is reshaping sourcing trends.

B2B buyers are increasingly adopting digital procurement platforms to streamline sourcing processes, reduce costs, and enhance transparency. This trend is particularly prevalent in industries that require high-volume procurement, such as automotive manufacturing. Additionally, the rise of e-commerce has enabled international buyers to access a wider range of suppliers, facilitating competitive pricing and diverse product options. Buyers are also prioritizing suppliers that offer OEM parts alongside aftermarket alternatives, ensuring quality and compatibility with existing vehicle models.

Moreover, innovations in materials technology are influencing product development in the element panel clip sector. For instance, the integration of advanced polymers and composites is enhancing durability and performance, catering to the evolving demands of automotive applications. As a result, international buyers are encouraged to stay informed about these advancements to make informed sourcing decisions.

Illustrative image related to element panel clip square

How Can Sustainability and Ethical Sourcing Impact the Element Panel Clip Square Market?

Sustainability is becoming an essential consideration for B2B buyers in the element panel clip square sector. The environmental impact of manufacturing processes, from material extraction to product disposal, is under scrutiny. Buyers are increasingly seeking suppliers who prioritize eco-friendly practices and sustainable materials, such as recycled plastics and biopolymers.

The importance of ethical supply chains cannot be overstated. Buyers are encouraged to evaluate the sourcing practices of their suppliers to ensure compliance with ethical standards, including fair labor practices and responsible sourcing of raw materials. Certifications such as ISO 14001 for environmental management and the Global Recycled Standard (GRS) are becoming critical benchmarks for assessing supplier sustainability.

Incorporating sustainability into procurement strategies not only meets regulatory requirements but also enhances brand reputation among environmentally conscious consumers. As the global emphasis on sustainability intensifies, B2B buyers in the element panel clip sector must adapt their sourcing strategies to align with these values, ensuring long-term viability and competitiveness in the market.

What Is the Brief Evolution of the Element Panel Clip Square Sector?

The evolution of the element panel clip square sector can be traced back to the early days of automotive manufacturing when fasteners were primarily made from metal. Over the decades, advancements in materials science led to the development of plastic and composite materials, offering benefits such as weight reduction and corrosion resistance.

The introduction of standardized fasteners allowed for greater compatibility across different vehicle models, simplifying the sourcing process for manufacturers. Additionally, the rise of aftermarket suppliers has expanded options for buyers, providing alternatives to OEM parts at competitive prices.

In recent years, the focus has shifted towards innovation and sustainability, with manufacturers investing in research and development to create high-performance, environmentally friendly fasteners. This evolution reflects the changing demands of the automotive industry, where efficiency, quality, and sustainability are paramount. As the market continues to mature, B2B buyers must stay abreast of these trends to leverage opportunities and mitigate risks in their sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of element panel clip square

-

How do I solve issues with low-quality element panel clips?

To address low-quality element panel clips, begin by researching reputable suppliers known for their quality assurance processes. Request samples before placing bulk orders to assess durability and fit. Additionally, consider suppliers that offer a warranty or return policy, as this can protect your investment. Engaging with suppliers who have positive reviews and certifications can further ensure you receive high-quality products. Lastly, establishing a quality control process upon receipt of the clips can help identify any issues early in the supply chain. -

What is the best way to find reliable suppliers for element panel clips?

Finding reliable suppliers requires a multi-faceted approach. Start by utilizing trade platforms such as Alibaba, Global Sources, or industry-specific directories. Attend trade shows and exhibitions to meet manufacturers in person and evaluate their offerings. Leverage online reviews and testimonials to gauge supplier credibility. It’s also beneficial to seek recommendations from industry peers. Once you shortlist potential suppliers, conduct due diligence, including verifying their certifications and production capabilities to ensure they meet your quality standards. -

What customization options are available for element panel clips?

Many manufacturers offer customization options for element panel clips, including variations in size, color, material, and design features. When requesting customization, provide detailed specifications, such as dimensions and mechanical properties. Discuss your specific application requirements to ensure the clips meet performance expectations. Be aware that customized products may have longer lead times and potentially higher minimum order quantities (MOQs). It’s advisable to clarify these details upfront and request prototypes to evaluate before committing to larger orders. -

What are typical minimum order quantities (MOQs) for element panel clips?

Minimum order quantities (MOQs) for element panel clips can vary significantly depending on the supplier and the complexity of the clips. Generally, MOQs may range from a few hundred to several thousand units. For custom designs, MOQs tend to be higher due to the setup costs involved in production. It’s essential to communicate your volume needs early in discussions with suppliers and explore options for lower MOQs if necessary. Some suppliers may offer flexibility or tiered pricing based on order size. -

What payment terms should I expect when sourcing element panel clips internationally?

Payment terms for international sourcing of element panel clips can vary widely. Common practices include a deposit upfront (usually 30-50%) with the balance due before shipment or upon delivery. Some suppliers may accept letters of credit or escrow services for larger orders, providing added security. Discuss payment options during the negotiation phase to align on terms that suit both parties. Be mindful of currency exchange rates and transaction fees, which can impact the overall cost of your order. -

How can I ensure quality assurance for element panel clips?

To ensure quality assurance, establish a clear set of quality standards and specifications before placing an order. Collaborate with suppliers to develop a quality assurance plan that includes inspection protocols at various stages of production. Consider hiring third-party inspection services to verify product quality before shipment. Additionally, maintain open communication with your supplier throughout the manufacturing process to address any concerns proactively. Documenting all quality requirements in the purchase agreement can also help hold suppliers accountable. -

What logistics considerations should I keep in mind when importing element panel clips?

Logistics plays a critical role in the importation of element panel clips. Consider the shipping method (air or sea) based on your budget and time constraints. Ensure you understand customs regulations and import duties in your country to avoid unexpected costs. Partnering with a reliable freight forwarder can streamline the shipping process and help navigate complex logistics. It’s also essential to plan for potential delays in shipping and customs clearance, especially during peak seasons or due to geopolitical factors. -

What are the best practices for maintaining a long-term relationship with suppliers?

Maintaining a long-term relationship with suppliers involves consistent communication, transparency, and mutual respect. Regularly provide feedback on product quality and service to help suppliers improve. Establish clear expectations regarding delivery timelines, pricing, and quality standards to minimize misunderstandings. Additionally, consider engaging in joint problem-solving to address any challenges that arise. Building rapport through regular check-ins or site visits can strengthen the partnership and foster collaboration on future projects or product developments.

Top 6 Element Panel Clip Square Manufacturers & Suppliers List

1. Honda – Hinge Cover Clip 91504-SCV-A00

Domain: elementownersclub.com

Registered: 2002 (23 years)

Introduction: Honda OEM name: Hinge Cover Clip 91504-SCV-A00; Aftermarket availability: Yes; Dealer price: $7 each; Alternative part number: Rocker Molding Clip 91513-SM4-000; Confirmed part number for white square clip: 91505-SCV-A00; Price for part 91505-SCV-A00: $3.18 each.

2. Auveco – Acura & Honda Push-Type Retainers

Domain: fastener.zone

Introduction: [{‘name’: ‘Auveco No. 19239 Acura & Honda Push-Type Retainer’, ‘quantity’: 25, ‘description’: ‘Front Fender, Interior Trim, Washer Tank & Bumper Support Push-Type Retainer’, ‘color’: ‘Black’, ‘head_diameter’: ’20mm’}, {‘name’: ‘Auveco No. 19233 Acura & Honda Push-Type Retainer’, ‘quantity’: 15, ‘description’: ‘Front Bumper Push-Type Retainer’, ‘color’: ‘Black’, ‘head_diameter’: ’20mm’, ‘hole_size’…

3. Au-ve-co – 25 Trim Panel Clips Compatible with Honda

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “25 Trim Panel Clips Compatible with Honda 91560-S84-A01 Accord Element”, “Price”: “$14.71”, “Condition”: “New”, “Brand”: “Au-ve-co”, “MPN”: “2947719”, “UPC”: “821641544223”, “Quantity Available”: “More than 10 available”, “Shipping”: “Free Standard Shipping”, “Location”: “Clawson, Michigan, United States”, “Delivery Estimate”: “Between Mon, Sep 29 and Fri, Oct 10”, “Returns”: “30…

4. Honda – Bumper Clips

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Honda bumper clips, prone to breaking, dealer charges $3 each, required for removal of lower engine shield, 10 clips broken during alternator change.

5. South Mountain Supply – 3012 HONDA ELEMENT Molding Clip

Domain: southmountainsupply.com

Registered: 2009 (16 years)

Introduction: {“product_name”: “3012 – HONDA ELEMENT Molding Clip”, “brand”: “South Mountain Supply”, “made_for”: “HONDA ELEMENT 2003-2011”, “type”: “MOULDING CLIP”, “variants”: [{“quantity”: 15, “price”: 16.17}, {“quantity”: 30, “price”: 32.34}, {“quantity”: 60, “price”: 64.68}, {“quantity”: 90, “price”: 97.02}]}

6. Facebook – Fender Clips for Honda Element

Strategic Sourcing Conclusion and Outlook for element panel clip square

The strategic sourcing of element panel clips, particularly the square type, is pivotal for businesses involved in automotive repair and manufacturing. Understanding the nuances of OEM versus aftermarket options can lead to significant cost savings and enhanced supply chain efficiency. Buyers should prioritize sourcing high-quality clips that meet industry standards to ensure durability and compatibility, thereby reducing the likelihood of future replacements. Engaging with reliable suppliers who can provide both OEM parts and vetted aftermarket alternatives is essential.

As you navigate the sourcing landscape, consider leveraging digital platforms and local distributors to access a wider range of products and pricing options. Establishing strong relationships with suppliers across regions—especially in Africa, South America, the Middle East, and Europe—can yield better terms and foster innovative solutions tailored to your specific needs.

Looking ahead, the demand for reliable automotive components like element panel clips will continue to grow, driven by evolving vehicle designs and maintenance needs. Take proactive steps today to optimize your sourcing strategies, ensuring your business remains competitive in a dynamic market. By investing in strategic sourcing practices, you position your company for success in meeting the demands of the global automotive industry.

Illustrative image related to element panel clip square

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.