Everything You Need to Know About Electronics Vending Machine Sourcing in 2025

Introduction: Navigating the Global Market for electronics vending machine

In an increasingly digital world, sourcing the right electronics vending machine can be a daunting task for international B2B buyers, particularly in emerging markets like Africa, South America, the Middle East, and Europe. As businesses strive to enhance accessibility to tech products and streamline operations, the demand for sophisticated vending solutions has surged. This comprehensive guide addresses the complexities of navigating the global market for electronics vending machines, including various types, applications, supplier vetting processes, and cost considerations.

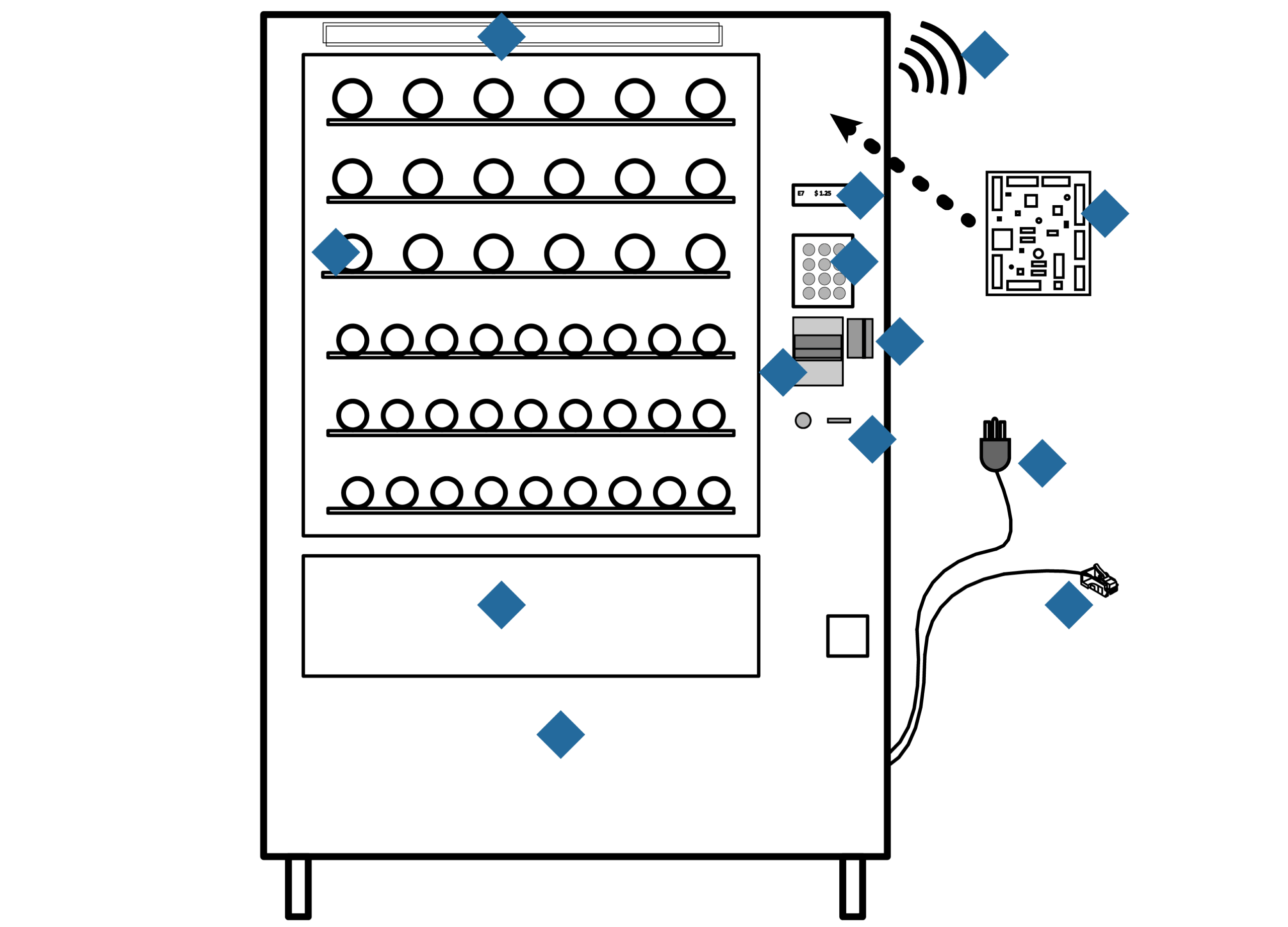

Understanding the unique challenges faced by organizations in different regions is crucial. For instance, while some markets prioritize the availability of high-tech accessories, others may focus on robust supply systems for essential electronics. This guide empowers decision-makers by providing actionable insights into selecting the right vending machine tailored to specific operational needs. Furthermore, it delves into innovative technologies such as iQ systems for real-time inventory management and user-friendly interfaces that can significantly enhance the user experience.

By equipping B2B buyers with the knowledge necessary to make informed purchasing decisions, this guide serves as an invaluable resource for those looking to invest in electronics vending machines. Whether you’re in Vietnam seeking to expand your retail revenue streams or in Brazil looking to manage IT assets more effectively, this guide will help you navigate the complexities of the global market with confidence.

Understanding electronics vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Electronics Vending Machine | Dispenses small electronics and accessories via gravity feed. | Offices, schools, and public spaces. | Pros: Low initial cost, easy to maintain. Cons: Limited to non-fragile items, less sophisticated. |

| Smart Electronics Vending Machine | Equipped with advanced technology for real-time inventory management and user interaction. | Retail environments, tech hubs, and corporate offices. | Pros: Enhanced user experience, customizable access. Cons: Higher upfront investment, requires tech support. |

| Configurable Supply Dispenser | Features adjustable trays for various product sizes, including fragile items. | Hospitals, labs, and specialized retail. | Pros: Versatile product offerings, guaranteed delivery. Cons: Larger footprint, complex setup. |

| Mobile Electronics Vending Machine | Compact and portable units designed for temporary or outdoor settings. | Events, festivals, and construction sites. | Pros: Flexible placement, caters to on-the-go consumers. Cons: Limited capacity, potentially higher per-item cost. |

| Specialized Vending Solutions | Custom machines designed for niche markets (e.g., medical supplies, high-value items). | Pharmacies, medical facilities, and high-security areas. | Pros: Tailored solutions for specific needs, enhances security. Cons: Often expensive, may require custom service agreements. |

What Are Traditional Electronics Vending Machines?

Traditional electronics vending machines are designed to dispense smaller electronic items and accessories, such as chargers, headphones, and USB drives. They typically operate using a gravity-fed mechanism, making them straightforward in design and function. These machines are best suited for environments like offices and schools where users can quickly access essential tech items without the need for extensive features. B2B buyers should consider the initial cost and ease of maintenance, but keep in mind that these machines are limited to non-fragile items.

How Do Smart Electronics Vending Machines Enhance User Experience?

Smart electronics vending machines leverage advanced technology to provide real-time inventory management and an engaging user interface, often featuring touchscreens. They are ideal for retail environments and corporate offices, where the need for quick access to tech items is paramount. These machines allow for customizable access methods, such as RFID or biometrics, enhancing security and user experience. Although they require a higher initial investment, the long-term benefits, such as improved customer satisfaction and operational efficiency, make them a compelling choice for B2B buyers.

What Are the Benefits of Configurable Supply Dispensers?

Configurable supply dispensers are versatile machines equipped with adjustable trays, allowing them to dispense a variety of products, including fragile items. They are particularly useful in settings like hospitals and laboratories, where specialized supplies may be needed. B2B buyers should consider these machines for their guaranteed delivery systems and ability to accommodate various product sizes. However, they typically require a larger footprint and a more complex setup, which could be a drawback for some organizations.

Where Are Mobile Electronics Vending Machines Most Effective?

Mobile electronics vending machines are compact units designed for flexibility and portability, making them suitable for events, festivals, and construction sites. They cater to on-the-go consumers who need quick access to tech products. While their flexible placement is a significant advantage, B2B buyers should be aware of their limited capacity and potentially higher per-item costs compared to stationary models.

What Are Specialized Vending Solutions and Their Applications?

Specialized vending solutions are custom-built machines tailored for niche markets, such as medical supplies or high-value electronics. These machines often include enhanced security features, making them suitable for pharmacies and medical facilities. B2B buyers should consider the tailored solutions these machines provide, which can significantly improve operational efficiency and security. However, they often come with a higher price tag and may require custom service agreements, which could be a barrier for some businesses.

Key Industrial Applications of electronics vending machine

| Industry/Sector | Specific Application of electronics vending machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Information Technology | IT asset management in corporate offices | Streamlined access to tech supplies, reducing downtime for employees | Reliability of machine technology and maintenance support |

| Retail | In-store electronics sales for consumer goods | Expands product offerings without requiring additional staff | Customization options for branding and user experience |

| Healthcare | Dispensing medical devices and supplies in hospitals | 24/7 access to critical supplies, improving patient care efficiency | Compliance with health regulations and product safety standards |

| Education | Providing laptops and educational tools in universities | Enhances learning opportunities and access to technology | Capacity to handle various device sizes and types |

| Manufacturing | Distributing tools and electronic components on factory floors | Minimizes delays in production by ensuring immediate access to tools | Durability and robustness of the vending machine for industrial use |

How Are Electronics Vending Machines Used in IT Asset Management?

In corporate offices, electronics vending machines serve as a pivotal solution for IT asset management. They allow employees to access essential tech items such as chargers, headphones, and peripherals without needing to wait for IT personnel. This on-demand availability minimizes downtime and enhances productivity. B2B buyers should consider the reliability and maintenance support of these machines, as consistent functionality is crucial in a fast-paced corporate environment.

What Role Do Electronics Vending Machines Play in Retail?

In the retail sector, electronics vending machines enable businesses to sell tech gadgets and accessories directly to consumers. This application allows retailers to expand their product offerings without the need for additional staff, optimizing labor costs. Customization options for branding and user experience are vital for attracting customers and enhancing sales. International buyers should focus on the adaptability of these machines to different retail environments and consumer preferences.

How Can Electronics Vending Machines Improve Healthcare Supply Access?

In healthcare settings, electronics vending machines are invaluable for dispensing medical devices and supplies, providing 24/7 access to critical items like glucose monitors and first-aid kits. This capability significantly improves patient care by ensuring that healthcare professionals have immediate access to the tools they need. Buyers in this sector must ensure that the machines comply with health regulations and product safety standards to mitigate risks associated with medical supply distribution.

What Benefits Do Electronics Vending Machines Offer in Education?

In educational institutions, electronics vending machines can distribute laptops, tablets, and other learning tools, thereby enhancing students’ access to technology. This solution not only supports learning but also ensures that students can borrow devices as needed, promoting a more inclusive educational environment. Buyers should consider the machine’s capacity to handle various device sizes and types, ensuring that it meets the diverse needs of students.

How Do Electronics Vending Machines Enhance Manufacturing Operations?

In manufacturing, electronics vending machines are utilized to distribute tools and electronic components directly on the factory floor. This application reduces delays in production by providing immediate access to necessary items, thereby increasing operational efficiency. For B2B buyers, the durability and robustness of the vending machine are essential considerations, as they must withstand the demands of a high-paced industrial environment.

3 Common User Pain Points for ‘electronics vending machine’ & Their Solutions

Scenario 1: Inconsistent Product Availability Leads to Frustration

The Problem: One of the most common pain points for B2B buyers of electronics vending machines is inconsistent product availability. Companies rely on these machines to provide quick access to essential electronic supplies, such as chargers, USB drives, or even small laptops. However, when items run out or are not restocked promptly, it can lead to employee frustration, reduced productivity, and a lack of trust in the system. This is particularly critical in environments like manufacturing plants or tech companies, where downtime due to a lack of supplies can be costly.

The Solution: To address this challenge, businesses should invest in vending machines equipped with advanced inventory management systems like iQ Technology. This technology provides real-time analytics and reporting tools that allow managers to monitor stock levels remotely. By setting up automated alerts for low stock, companies can ensure timely restocking of essential items. Additionally, partnering with reliable suppliers who can provide regular replenishment services will further mitigate the risk of stockouts. Ensuring that the vending machines are configured to handle a variety of items—taking advantage of customizable trays—can also enhance the range of products available, ensuring that employees have access to the items they need when they need them.

Scenario 2: Difficulty in Access Control Complicates Usage

The Problem: Another significant pain point arises from difficulties in access control, especially in organizations that have strict security protocols. Traditional vending machines often rely on cash transactions, which can be impractical in a corporate environment. Furthermore, without robust access control mechanisms, unauthorized personnel may misuse the machines, leading to inventory losses and safety concerns.

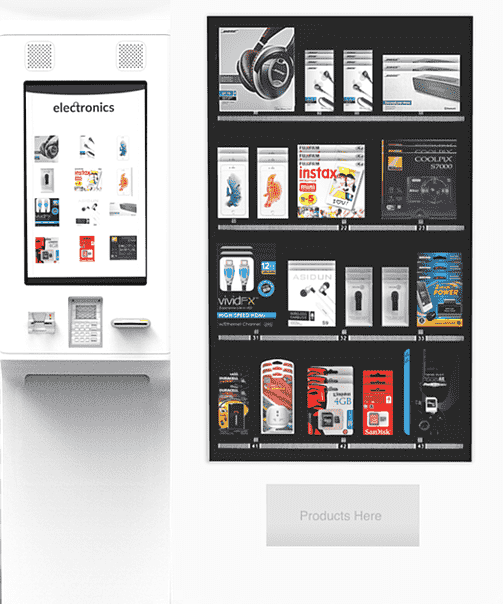

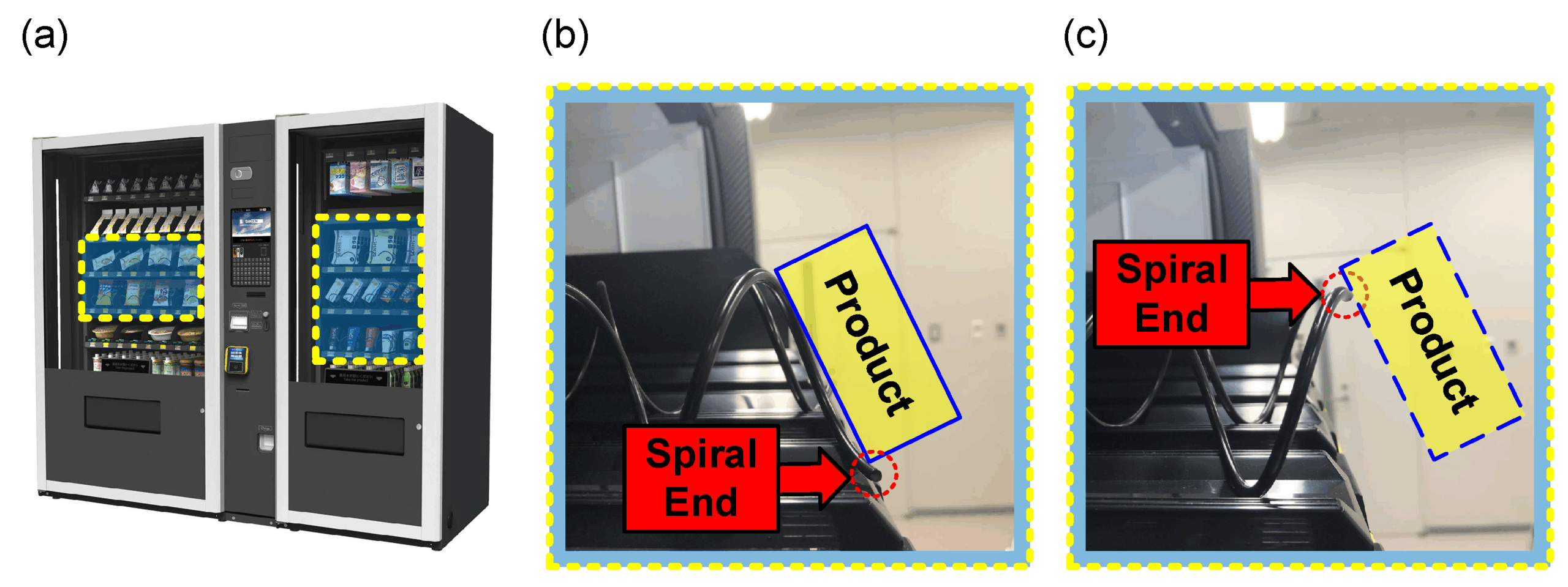

Illustrative image related to electronics vending machine

The Solution: To overcome this issue, businesses should opt for electronics vending machines that offer multiple access methods tailored to their security requirements. Machines equipped with RFID badges, biometric scanners, or PIN access can help restrict usage to authorized employees only. It’s crucial to integrate the vending machine system with existing employee access control systems, ensuring seamless operation. Customizing user interfaces to display relevant information based on access credentials can also enhance the user experience while maintaining security. For organizations in regions where cash transactions are still common, offering credit card payment options can provide flexibility without compromising security.

Scenario 3: Lack of User Engagement and Education

The Problem: Many businesses find that their electronics vending machines are underutilized due to a lack of user engagement and education. Employees may not fully understand how to use the machines, the products available, or the benefits of using them, leading to missed opportunities for efficiency and convenience. This issue can be particularly prevalent in organizations with diverse workforces or in regions where technology adoption rates vary.

The Solution: To boost user engagement, companies should implement a comprehensive training and onboarding program for employees. This could include interactive demonstrations, easy-to-understand user manuals, and visual aids that highlight the benefits of using the vending machines. Additionally, upgrading the user interface to a vibrant touch screen display can make the experience more engaging and intuitive. Companies can also consider gamifying the experience by offering incentives or rewards for using the vending machines frequently, which can foster a culture of convenience and accessibility. Regular feedback sessions with employees can help identify any ongoing issues or areas for improvement, ensuring the vending machines remain a valuable resource for the organization.

Strategic Material Selection Guide for electronics vending machine

What Are the Best Materials for Electronics Vending Machines?

When selecting materials for electronics vending machines, various factors must be considered to ensure optimal performance, durability, and compliance with international standards. Below are analyses of four common materials used in the construction of these machines, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Steel Perform as a Material for Electronics Vending Machines?

Key Properties: Steel is known for its high tensile strength and durability. It can withstand high temperatures and pressures, making it suitable for environments where machines may be exposed to varying conditions.

Illustrative image related to electronics vending machine

Pros & Cons: The primary advantage of steel is its robustness, which translates to a longer lifespan and lower maintenance costs. However, it is prone to corrosion if not properly treated, which can be a significant drawback in humid or coastal regions. Additionally, the manufacturing process can be complex, leading to higher initial costs.

Impact on Application: Steel is compatible with various media, including electronic components and consumables. Its structural integrity supports the weight of heavy items, making it ideal for machines that dispense larger electronics.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the steel used complies with local corrosion resistance standards, such as ASTM A123 for galvanized steel. Understanding local environmental conditions is crucial for selecting the right type of steel.

What Role Does Aluminum Play in Electronics Vending Machines?

Key Properties: Aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity. It can be anodized for additional protection, enhancing its durability.

Pros & Cons: The lightweight nature of aluminum makes it easier to transport and install, reducing shipping costs. However, it is less durable than steel and may not withstand heavy impacts as well. The cost of aluminum can also be higher than that of steel, depending on market conditions.

Impact on Application: Aluminum’s corrosion resistance makes it suitable for machines placed in humid environments. Its thermal properties help in managing the heat generated by electronic components.

Considerations for International Buyers: Compliance with international standards such as JIS H 8601 for aluminum alloys is essential. Buyers should also consider the availability of aluminum in their region, as supply chain issues can affect project timelines.

Why is Plastic a Viable Option for Electronics Vending Machines?

Key Properties: Plastics are lightweight, versatile, and resistant to corrosion and chemicals. They can be molded into various shapes, allowing for design flexibility.

Pros & Cons: The primary advantage of plastic is its cost-effectiveness and ease of manufacturing. However, plastics may not offer the same level of durability as metals, particularly in high-impact scenarios. They can also be sensitive to temperature extremes, which may limit their application in certain environments.

Impact on Application: Plastic is suitable for less demanding applications, such as vending machines for smaller electronic accessories. Its resistance to corrosion makes it ideal for environments where moisture is present.

Considerations for International Buyers: Buyers should ensure that the plastics used comply with safety standards such as ASTM D638 for tensile properties. Understanding local regulations regarding plastic materials is also critical, especially in regions with strict environmental laws.

How Does Glass Factor into the Design of Electronics Vending Machines?

Key Properties: Glass is transparent, allowing for product visibility, and can be tempered for increased strength. It is also resistant to many chemicals.

Pros & Cons: The aesthetic appeal of glass enhances the user experience by allowing customers to see the products inside. However, glass is fragile and can shatter under impact, posing a risk in high-traffic areas. Additionally, the cost of tempered glass can be high compared to other materials.

Impact on Application: Glass is often used in the front panels of vending machines to display products clearly. Its chemical resistance makes it suitable for environments where cleaning agents are frequently used.

Considerations for International Buyers: Compliance with safety standards like DIN 1249 for glass products is essential. Buyers should also consider local regulations regarding the use of glass in public spaces, especially in regions where safety is a concern.

Summary Table of Material Selection for Electronics Vending Machines

| Material | Typical Use Case for Electronics Vending Machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components and frames | High durability and strength | Prone to corrosion if untreated | Medium |

| Aluminum | Lightweight enclosures and panels | Lightweight and corrosion-resistant | Less durable than steel | High |

| Plastic | Housing for smaller electronic accessories | Cost-effective and versatile | Less durable, sensitive to temperature | Low |

| Glass | Front panels for visibility | Aesthetic appeal and visibility | Fragile and can shatter easily | Medium |

This strategic material selection guide provides essential insights for international B2B buyers, helping them make informed decisions based on performance, cost, and compliance with local standards.

Illustrative image related to electronics vending machine

In-depth Look: Manufacturing Processes and Quality Assurance for electronics vending machine

What Are the Key Stages in the Manufacturing Process of Electronics Vending Machines?

The manufacturing of electronics vending machines involves several critical stages that ensure the final product is reliable, efficient, and capable of meeting the demands of modern users. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with sourcing high-quality materials that meet industry standards. Common materials include steel for the frame, tempered glass for doors, and high-grade plastics for components. Suppliers often conduct pre-qualification assessments to ensure that materials meet specifications. This phase may also involve the use of advanced materials like UV-resistant coatings to enhance durability.

-

Forming: This stage involves shaping the prepared materials into the required components. Techniques such as laser cutting and CNC machining are frequently employed to achieve precise dimensions. For instance, metal frames are typically laser cut to ensure accuracy, while plastic components may be molded using injection techniques. This precision is crucial, as any deviation can affect the machine’s functionality and aesthetic appeal.

-

Assembly: Once components are formed, the assembly process begins. This includes integrating mechanical parts, electrical wiring, and software systems. Advanced robotics and automation technologies are often utilized to streamline this process, ensuring consistent quality and reducing labor costs. Each unit is typically assembled on a production line, where workers or machines install components like the user interface, payment systems, and inventory management technology.

-

Finishing: The final stage involves applying protective coatings, conducting cosmetic enhancements, and ensuring that all components are securely fitted. This might include powder coating for the frame to improve aesthetics and resistance to corrosion. Additionally, quality checks are performed at this stage to ensure that the machine meets both visual and functional standards.

How Is Quality Assurance Implemented in Electronics Vending Machines?

Quality assurance (QA) is a critical component of the manufacturing process for electronics vending machines, ensuring that every unit meets international and industry-specific standards. Various standards such as ISO 9001 and CE certification play a significant role in this process.

-

International and Industry-Specific Standards: Compliance with ISO 9001 ensures that manufacturers follow a quality management system that promotes continuous improvement and customer satisfaction. CE marking indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area. Additionally, industry-specific standards like API (Application Programming Interface) for software integration are essential for electronic functionalities.

-

Quality Control Checkpoints: Quality control (QC) is integrated at multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival to ensure they meet specified standards before production begins.

– In-Process Quality Control (IPQC): During assembly, ongoing inspections are conducted to verify that each component is correctly installed and functioning. This may include testing electronic connections and software functionality.

– Final Quality Control (FQC): Before shipping, each vending machine undergoes a thorough inspection. This includes functional testing, aesthetic evaluations, and performance assessments to confirm that it meets all specifications. -

Common Testing Methods: Various testing methods are employed to verify the quality and functionality of the machines. These include:

– Functional Testing: Ensures that all features, including payment systems, product dispensing mechanisms, and user interfaces, operate correctly.

– Environmental Testing: Machines may be subjected to conditions simulating extreme temperatures or humidity to assess durability.

– Safety Testing: This involves checking electrical systems and components for compliance with safety standards to prevent hazards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial for ensuring that the products meet their operational needs.

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control practices. This includes reviewing their quality management system, production capabilities, and adherence to standards.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand the QC measures in place. These reports should outline testing results, defect rates, and corrective actions taken for any issues identified.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing quality. These organizations can conduct pre-shipment inspections to verify that products meet the agreed-upon specifications and standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers face unique challenges when it comes to quality control and compliance. Understanding these nuances is critical for ensuring successful procurement.

-

Cultural and Regulatory Differences: Different regions may have varying standards and regulations governing product safety and quality. Buyers should familiarize themselves with local regulations in their target markets, such as the European Union’s stringent CE marking requirements or specific compliance standards in emerging markets.

-

Communication Barriers: Language differences can complicate quality assurance processes. Buyers should establish clear communication channels with suppliers to ensure that expectations regarding quality standards and testing procedures are well understood.

-

Logistical Considerations: Transportation and shipping can impact product quality. Buyers should work with suppliers to ensure that proper packaging and handling procedures are in place to prevent damage during transit.

By taking these steps, B2B buyers can effectively navigate the complexities of quality assurance in the electronics vending machine industry, ensuring that they source reliable and high-quality products that meet their operational needs.

Illustrative image related to electronics vending machine

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electronics vending machine’

The procurement of electronics vending machines is a strategic investment that can enhance efficiency and accessibility in various business environments. This guide provides a practical checklist to assist B2B buyers in navigating the selection process for these advanced vending solutions.

Step 1: Define Your Technical Specifications

Understanding your specific needs is crucial when sourcing electronics vending machines. Define the types of products you intend to offer, such as accessories, small devices, or medical supplies. Consider the machine’s capacity, size, and the technology required for secure transactions and inventory management.

- Product Range: Identify the range of electronic items you want to dispense.

- Capacity Needs: Estimate the volume of items to determine the appropriate machine size.

Step 2: Research Market Trends and Innovations

Stay informed about the latest trends in vending technology to ensure you choose a machine that meets future demands. Features like contactless payment options, real-time inventory tracking, and energy efficiency are increasingly important.

Illustrative image related to electronics vending machine

- Smart Technology: Look for machines equipped with advanced analytics and management software.

- User Experience Enhancements: Consider machines with touch screens or customizable interfaces for better customer interaction.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure reliability and quality. Request company profiles, product catalogs, and references from other businesses that have purchased similar machines. This step helps you gauge their experience and industry reputation.

- Supplier Experience: Look for suppliers with a proven track record in electronics vending.

- Customer Feedback: Seek testimonials or case studies from similar industries to assess satisfaction levels.

Step 4: Verify Compliance and Certifications

Ensure that the vending machines comply with local regulations and international standards. Certifications can provide assurance of safety, quality, and performance, which is especially important in healthcare or educational settings.

- Regulatory Compliance: Check if the machines meet local health and safety requirements.

- Quality Certifications: Look for ISO or similar certifications that indicate adherence to high manufacturing standards.

Step 5: Assess Customization Options

Customization can enhance the functionality and branding of your vending machines. Evaluate how easily the machines can be tailored to your specific requirements, including branding, access methods, and product configurations.

Illustrative image related to electronics vending machine

- Branding Opportunities: Ensure the supplier offers custom graphics or wraps to promote your brand.

- Access Methods: Consider machines that support various access technologies like RFID, biometrics, or credit cards to enhance user convenience.

Step 6: Request Detailed Proposals and Cost Analysis

Once you have shortlisted potential suppliers, request detailed proposals that outline costs, warranties, and service agreements. A comprehensive cost analysis will help you make informed budget decisions and assess long-term value.

- Total Cost of Ownership: Evaluate not just the purchase price but also maintenance, installation, and operational costs.

- Warranty and Support: Understand the terms of warranties and after-sales support to minimize future risks.

Step 7: Plan for Installation and Maintenance

A successful implementation involves planning for installation and ongoing maintenance. Discuss timelines with your supplier and ensure you have a clear understanding of their support services.

- Installation Services: Check if the supplier offers installation assistance or training for your staff.

- Maintenance Plans: Inquire about regular maintenance services to ensure optimal machine performance.

Following this checklist will guide you in making a well-informed decision when sourcing electronics vending machines, ultimately enhancing your operational efficiency and service delivery.

Comprehensive Cost and Pricing Analysis for electronics vending machine Sourcing

What Are the Key Cost Components in Sourcing Electronics Vending Machines?

When sourcing electronics vending machines, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Illustrative image related to electronics vending machine

-

Materials: The materials used in manufacturing vending machines, such as metals for the chassis, plastics for components, and electronic parts for the vending mechanism, significantly influence the overall cost. High-quality materials may increase initial investment but can enhance durability and reduce long-term maintenance costs.

-

Labor: Labor costs encompass both direct labor involved in assembly and indirect costs associated with factory operations. Regions with lower labor costs can provide more competitive pricing, but this may also reflect on the quality of workmanship.

-

Manufacturing Overhead: This includes the indirect costs related to production facilities, utilities, and administrative expenses. Efficient manufacturing processes can help minimize these costs, allowing suppliers to offer better pricing.

-

Tooling: Custom tooling may be necessary for specific machine designs or features. This upfront investment can be significant, particularly for customized machines, but it is essential for achieving the desired specifications.

-

Quality Control (QC): Robust QC processes ensure that machines meet industry standards and function reliably. While this adds to the cost, it is an essential investment to prevent costly failures and maintain customer satisfaction.

-

Logistics: Shipping and handling costs can vary widely based on distance, volume, and the chosen shipping method. Incoterms, which define the responsibilities of buyers and sellers in international shipping, play a critical role in determining who bears these costs.

-

Margin: Suppliers typically add a profit margin to the total cost of production, which can vary based on market demand and competition. Understanding this margin can help in negotiations.

How Do Price Influencers Affect Electronics Vending Machine Costs?

Several factors can influence pricing, particularly for international buyers:

-

Volume/MOQ: Ordering in larger quantities often leads to lower per-unit costs. Establishing a minimum order quantity (MOQ) can be beneficial for negotiating better pricing.

-

Specifications and Customization: Custom features, such as advanced user interfaces or specific dispensing mechanisms, can significantly affect pricing. Standard models typically come at a lower price point compared to customized options.

-

Materials and Quality Certifications: Machines built with premium materials and certified for quality (ISO, CE, etc.) may command higher prices but can also offer better performance and longevity.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may have higher prices but offer superior service, warranties, and support.

-

Incoterms: The choice of Incoterms impacts the total cost of ownership. Understanding whether costs for shipping, insurance, and duties are included in the quoted price can affect budget planning.

What Negotiation Strategies Should B2B Buyers Use?

For B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, effective negotiation can significantly impact costs:

-

Research and Benchmarking: Gather data on market prices and competitor offerings to leverage during negotiations. Understanding the typical costs in your region can provide a strong basis for discussions.

-

Long-Term Partnerships: Consider establishing long-term relationships with suppliers. This can lead to better pricing and service due to the ongoing nature of the partnership.

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the initial purchase price. Consider ongoing costs such as maintenance, energy consumption, and potential downtime when assessing value.

-

Flexibility in Specifications: If possible, remain open to alternative specifications that may lower costs. Standardized solutions often offer better pricing compared to highly customized machines.

-

Timing and Market Conditions: Be aware of market conditions and timing when negotiating. Prices may fluctuate based on demand, seasonality, and economic factors, allowing for strategic purchasing decisions.

Disclaimer on Indicative Prices

Pricing for electronics vending machines can vary widely based on the factors outlined above. Buyers should seek multiple quotes and conduct thorough due diligence to ensure they are receiving competitive offers. Always clarify what is included in the pricing and any potential additional costs that may arise during the procurement process.

Alternatives Analysis: Comparing electronics vending machine With Other Solutions

Understanding Alternatives to Electronics Vending Machines

As the demand for efficient distribution of electronic products rises, businesses are exploring various solutions to meet their needs. While electronics vending machines offer a high-tech way to dispense devices and accessories, other alternatives also provide unique advantages. This section compares electronics vending machines with two viable alternatives: retail kiosks and direct sales through online platforms. Each solution has its merits and potential drawbacks, making it crucial for B2B buyers to evaluate their specific requirements.

Comparison Table

| Comparison Aspect | Electronics Vending Machine | Retail Kiosk | Direct Online Sales |

|---|---|---|---|

| Performance | 24/7 access, high tech, real-time inventory tracking | Limited hours, manual restocking needed | Flexible hours, depends on shipping efficiency |

| Cost | Higher initial investment, ongoing maintenance costs | Moderate initial investment, moderate upkeep | Low overhead, variable shipping costs |

| Ease of Implementation | Requires space and infrastructure setup | Easier to set up in high-traffic areas | Minimal setup, relies on existing web platforms |

| Maintenance | Regular maintenance needed for tech components | Requires manual inventory management | Minimal, unless managing returns and customer service |

| Best Use Case | High-traffic locations needing quick access to tech | Retail environments with diverse product needs | Businesses with established online presence |

What Are the Pros and Cons of Retail Kiosks Compared to Electronics Vending Machines?

Retail kiosks serve as a popular alternative for businesses looking to sell electronic products. They allow for a tactile shopping experience where customers can interact with products before purchasing. Kiosks can be strategically placed in high-traffic areas, increasing visibility. However, they require manual inventory management and restocking, which can lead to downtime. Additionally, their operational hours are often limited, affecting potential sales.

How Do Direct Online Sales Compare to Electronics Vending Machines?

Direct online sales represent a cost-effective solution for distributing electronics without the need for physical infrastructure. This method allows businesses to reach a global audience, particularly beneficial for companies operating in regions like Africa and South America. However, online sales rely heavily on shipping logistics, which can delay product delivery. Furthermore, without a physical presence, customer engagement may suffer, and product returns can become cumbersome.

Making the Right Choice: How Should B2B Buyers Select the Best Solution?

When evaluating the best solution for distributing electronics, B2B buyers should consider their specific operational needs, budget constraints, and target audience. Electronics vending machines may be ideal for businesses prioritizing 24/7 access and real-time inventory management in environments with high foot traffic. In contrast, retail kiosks may suit those who value customer interaction and tactile experiences. Direct online sales are best for organizations looking to minimize overhead and reach a wider market. Ultimately, the decision should align with the company’s strategic objectives and operational capabilities.

Essential Technical Properties and Trade Terminology for electronics vending machine

What Are the Key Technical Properties of Electronics Vending Machines?

Electronics vending machines represent a sophisticated intersection of technology and convenience, providing essential features tailored for both users and businesses. Understanding their technical specifications can significantly impact procurement decisions.

1. Material Grade

Electronics vending machines are typically constructed from high-grade steel or aluminum. These materials offer durability and resistance to wear and tear, which is crucial for machines exposed to frequent use. For B2B buyers, selecting machines made from robust materials ensures longevity, reducing the need for replacements and maintenance costs.

2. Electrical Requirements

Vending machines require specific electrical configurations, usually rated at 115 VAC/60Hz or 230 VAC/50Hz. Understanding these requirements is vital for ensuring compatibility with local power supplies, particularly in diverse international markets. Buyers must verify these specifications to avoid operational disruptions and ensure compliance with local electrical standards.

3. Capacity and Configuration

Most modern vending machines can accommodate up to 300 items, with configurable trays that can dispense various product sizes and shapes. This flexibility allows businesses to tailor their offerings based on customer needs and inventory. A higher capacity can support a wider range of products, catering to diverse consumer demands, thus enhancing revenue potential.

Illustrative image related to electronics vending machine

4. User Interface

The interface of a vending machine, which can range from a simple keypad to a 7-inch touchscreen, significantly influences user experience. A more engaging interface can facilitate smoother transactions and enhance customer satisfaction. For B2B buyers, investing in advanced user interfaces may improve operational efficiency and reduce transaction times.

5. Guaranteed Delivery System

This feature ensures that every product dispensed is tracked, and if an item fails to deliver, the user receives a refund. This reliability is crucial for maintaining customer trust and satisfaction, which is particularly important in competitive markets. Businesses can leverage this feature to enhance service quality, ultimately driving higher sales and customer loyalty.

6. Advanced Technology Integration

The incorporation of smart technologies, such as iQ Technology for inventory management and analytics, allows businesses to optimize operations. Real-time data insights can help in effective stock management and demand forecasting, enabling businesses to reduce waste and improve profitability.

What Are Common Trade Terms in the Electronics Vending Machine Industry?

Navigating the electronics vending machine market requires familiarity with specific trade terminology that can influence purchasing decisions and operational strategies.

Illustrative image related to electronics vending machine

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for B2B buyers when sourcing components or entire machines, as it can affect pricing, warranty, and support.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product a supplier is willing to sell. Knowing the MOQ is essential for businesses planning to stock vending machines, as it can impact initial investment and inventory management strategies.

3. RFQ (Request for Quotation)

An RFQ is a document used to invite suppliers to bid on specific products or services. For buyers, issuing an RFQ can streamline the procurement process, ensuring they receive competitive pricing and terms from multiple vendors.

4. Incoterms

International Commercial Terms (Incoterms) define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is crucial for B2B buyers to understand shipping costs, risks, and delivery responsibilities when importing vending machines from abroad.

5. Lead Time

This term refers to the amount of time from placing an order until it is fulfilled. Understanding lead times is critical for B2B buyers, as it impacts inventory levels and operational planning.

6. Asset Management

In the context of electronics vending machines, asset management involves tracking and managing the physical and digital assets associated with the machines. Effective asset management can optimize inventory levels and enhance operational efficiency, making it a vital consideration for businesses.

By grasping these essential technical properties and trade terminologies, B2B buyers can make informed decisions when investing in electronics vending machines, ultimately improving their operational efficiency and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the electronics vending machine Sector

What Are the Key Trends in the Global Electronics Vending Machine Market?

The electronics vending machine market is experiencing significant growth driven by several global factors. One of the primary drivers is the increasing demand for convenient access to electronic devices and accessories. As businesses seek to enhance employee productivity and customer satisfaction, the need for 24/7 access to tech supplies has surged. This trend is particularly prominent in regions like Africa, South America, the Middle East, and Europe, where rapid urbanization and technological adoption are reshaping consumer behavior.

Emerging technologies such as smart vending solutions are revolutionizing this sector. These machines incorporate advanced features like real-time inventory management, user-friendly interfaces, and secure payment options, making them attractive to international B2B buyers. Additionally, the rise of e-commerce and digital transactions is pushing businesses to adopt automated solutions that streamline operations and reduce overhead costs.

Moreover, customization has become a critical trend, allowing businesses to tailor machines to specific needs, whether for branding or product selection. This flexibility is essential for markets with diverse consumer preferences, such as Brazil and Vietnam, where localized solutions can enhance user engagement and drive sales.

How Does Sustainability Impact Sourcing in the Electronics Vending Machine Sector?

Sustainability is increasingly becoming a focal point for B2B buyers in the electronics vending machine sector. The environmental impact of electronics manufacturing and disposal necessitates a shift towards more responsible sourcing practices. Companies are now prioritizing ethical supply chains that not only minimize their carbon footprint but also ensure fair labor practices. This commitment to sustainability is not just a regulatory requirement; it is also a competitive advantage in today’s eco-conscious marketplace.

B2B buyers are encouraged to seek vendors that offer ‘green’ certifications and utilize environmentally friendly materials in their machines. For instance, opting for machines made from recycled materials or those equipped with energy-efficient technologies can significantly reduce operational costs while appealing to environmentally aware consumers. Furthermore, the integration of features like UVend Technology, which enhances hygiene and safety, aligns with the growing demand for health-conscious solutions in public spaces.

By adopting sustainable practices, companies can also improve their brand image and foster customer loyalty. As consumers become more discerning about their purchases, businesses that demonstrate a commitment to sustainability are likely to see enhanced customer engagement and retention.

What Is the Evolution of Electronics Vending Machines?

The evolution of electronics vending machines reflects broader technological advancements and changing consumer needs. Initially, vending machines primarily dispensed snacks and beverages, but with the rise of digital technology, these machines have transformed into sophisticated retail solutions. The introduction of smart vending technology marked a turning point, enabling the sale of not just small electronic devices but also IT peripherals and accessories.

Illustrative image related to electronics vending machine

As businesses recognized the potential of these machines for asset management and customer engagement, the market expanded. Today, electronics vending machines are equipped with features like real-time analytics, customizable interfaces, and secure payment systems, making them invaluable assets for companies looking to optimize their operations and enhance customer service. This evolution underscores the importance of adapting to market dynamics and consumer preferences in a rapidly changing technological landscape.

By understanding these trends and embracing sustainability, international B2B buyers can strategically navigate the electronics vending machine sector, ensuring they meet both operational goals and customer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of electronics vending machine

-

1. How do I choose the right electronics vending machine for my business needs?

When selecting an electronics vending machine, consider factors such as product variety, capacity, and customization options. Evaluate the types of items you plan to dispense—like tech accessories or larger devices—and ensure the machine can accommodate them. Look for features like smart technology for inventory management, user interface options, and secure payment methods. Additionally, assess the machine’s footprint to ensure it fits your space requirements and aligns with your branding strategy. -

2. What are the payment options available for electronics vending machines?

Electronics vending machines typically support multiple payment options to enhance user convenience. Common methods include credit and debit card readers, mobile payment systems, and access control through RFID or biometric systems. It’s important to choose a machine that integrates seamlessly with your existing payment infrastructure and offers secure transactions to protect both your business and your customers. -

3. What customization options should I consider for my electronics vending machine?

Customization is key for branding and user engagement. Many suppliers offer options such as custom graphic wraps, touch screen interfaces, and tailored user experiences. Consider how you can incorporate your company’s branding elements, such as logos and color schemes, to create a cohesive look. Additionally, assess whether you need specific configurations for the types of products you plan to sell, ensuring that the machine meets your operational needs. -

4. What is the minimum order quantity (MOQ) when sourcing electronics vending machines?

Minimum order quantities can vary significantly by manufacturer and the complexity of the machines. Some suppliers may require you to order several units to benefit from bulk pricing, while others might offer single-unit purchases. Always clarify the MOQ with potential suppliers during the initial discussions to ensure it aligns with your budget and operational requirements. -

5. How do I ensure quality assurance when purchasing electronics vending machines?

To ensure quality assurance, conduct thorough research on potential suppliers. Request product samples and detailed specifications to evaluate durability and functionality. Look for certifications or compliance with international standards, especially if you are importing machines. Additionally, inquire about warranty terms and after-sales support to address any potential issues post-purchase. -

6. What logistics considerations should I keep in mind when importing electronics vending machines?

Logistics is crucial when importing vending machines. Consider factors like shipping methods, customs regulations, and potential tariffs. Work with a logistics provider experienced in international trade to navigate these complexities. Ensure that you have clear agreements on delivery timelines and shipping costs, and verify that the machines are packaged securely to prevent damage during transit. -

7. How can I manage inventory effectively with electronics vending machines?

Utilizing smart technology integrated into modern vending machines can greatly enhance inventory management. Look for machines that offer real-time analytics and reporting tools, allowing you to track product usage and stock levels efficiently. Regularly monitor the data to identify popular items and trends, enabling you to optimize your inventory and reduce waste. -

8. What are the benefits of using electronics vending machines for my business?

Electronics vending machines provide several benefits, including 24/7 access to products, enhanced customer convenience, and reduced labor costs. They can help streamline IT asset management by offering a secure and efficient method for distributing technology. Additionally, these machines can serve as an innovative revenue stream, especially in high-traffic areas, while also improving brand visibility and customer engagement.

Top 7 Electronics Vending Machine Manufacturers & Suppliers List

1. Silkron – Smart Vending Machine

Domain: silkron.com

Registered: 2004 (21 years)

Introduction: Smart Vending Machine offers convenience and low-cost options for consumers. It features interactive components such as touch-screens and gesture-based interaction, supports all modes of cashless payments, and displays nutritional facts. The machine can process fresh juices and smoothies, sell higher-value products like electronics, and provide services like utility bill payments and mobile top-up…

2. Laurel Metal Products – 399 Electronic Vending Machine

Domain: dultmeier.com

Registered: 1996 (29 years)

Introduction: {“manufacturer”:”Laurel Metal Products”,”model”:”399″,”type”:”Electronic Vending Machine, Single Column”,”features”:{“LED_readout”:”with counter”,”adjustable_price_setting”:”from $.25 to $99.00″,”security_bar”:”standard”,”coin_box”:”standard”,”drop_shelf_design”:”24 \””,”dimensions”:”42\” H x 12-1/4\” W x 6-1/4\” D”,”maximum_vended_product_size”:”1-1/4\” H x 8\” L x 4-1/4\” D”},”note”:”Credit Card…

3. LaCie – Rugged 2TB Drive

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Vending machines for electronics have been explored for their success, with insights suggesting that specific types of machines may be required. One user noted challenges with profit margins when sourcing products, mentioning a LaCie rugged 2TB drive priced at $96 but retailing for $99.99, indicating potential markup issues. Another user mentioned a brother-in-law who owns smart vending machines f…

4. Ellenby Technologies – Vending Electronics Solutions

Domain: ellenbytech.com

Registered: 2000 (25 years)

Introduction: Ellenby Technologies offers a range of vending electronics including:

– LED Lighting: High-efficiency vending machine LED light tubes with programmable dimming (Patent #8,905,579).

– Motor Drives: Control and monitor vending motors for over current and home position.

– Product Drop Sensing: Light curtain electronics for monitoring the vending drop chute.

– Compressor Control: Controllers and sens…

5. Candy Machines – Electronic Bulk Vending Solutions

Domain: candymachines.com

Registered: 1998 (27 years)

Introduction: This company, Candy Machines – Electronic Bulk Vending Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. ecoATM – Sell Your Device for Cash

Domain: ecoatm.com

Registered: 2009 (16 years)

Introduction: ecoATM allows users to sell cell phones and tablets for cash through over 6,500 kiosks located in retail locations such as Walmart and Kroger across the U.S. Users can get an instant price estimate on the website or app, prepare their device by removing personal information, and then sell it at a kiosk. The kiosks are regularly cleaned and equipped with security features for a safe selling experie…

7. VMFS – CEVM-ELEC Electronics Vending Machine

Domain: vmfsusa.com

Registered: 2024 (1 years)

Introduction: Electronics Vending Machine

– Price Range: $7,950.00 – $8,150.00

– Monthly Profit: $900 (approx. 20% ROI)

– Model: CEVM-ELEC

– Capacity: Up to 600 products with 7 standard trays (supports up to 8)

– Features:

– Elevator Delivery System for fragile items

– Tool-free tray reconfiguration for easy inventory management

– Commercial-grade components ensuring 99% uptime

– Advanced theft protect…

Strategic Sourcing Conclusion and Outlook for electronics vending machine

In the rapidly evolving landscape of electronics vending machines, strategic sourcing emerges as a pivotal element for businesses aiming to enhance operational efficiency and customer satisfaction. By leveraging advanced technologies such as iQ Technology and UVend systems, companies can optimize inventory management, ensure product safety, and provide a seamless user experience. This not only facilitates 24/7 access to essential electronic devices but also aligns with the growing demand for contactless and automated solutions in various markets.

As international B2B buyers from regions like Africa, South America, the Middle East, and Europe evaluate their options, it is crucial to consider the scalability and customization capabilities of these machines. The ability to configure vending machines to dispense a wide variety of products—ranging from tech accessories to essential supplies—can significantly enhance revenue streams and streamline asset management.

Looking ahead, the integration of smart vending solutions will continue to redefine how businesses interact with their customers. This is an opportune moment for buyers to invest in these transformative technologies, which not only meet current demands but also position their enterprises for future growth. Embrace the potential of electronics vending machines to elevate your business strategy and enhance service delivery today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to electronics vending machine

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.