Everything You Need to Know About Edm Machine Parts Sourcing in 2025

Introduction: Navigating the Global Market for edm machine parts

In today’s global marketplace, sourcing high-quality EDM machine parts can present significant challenges for B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. The complexity of navigating various suppliers, understanding the nuances of different parts, and ensuring compatibility with existing machinery is a critical concern. This comprehensive guide is designed to address these challenges head-on, providing in-depth insights into the various types of EDM machine parts, their specific applications, and the critical process of supplier vetting.

From electrodes and nozzles to power feed contacts and wear parts, this guide covers an extensive range of EDM components essential for optimizing manufacturing processes. Buyers will learn how to assess supplier reliability, evaluate cost structures, and understand the implications of different material choices on performance and durability. With actionable tips and expert analysis, this resource empowers international buyers to make informed purchasing decisions that align with their operational needs and budget constraints.

Whether you are based in bustling markets like Nigeria or established industries in Germany, the knowledge contained within this guide will enhance your procurement strategy, streamline your sourcing process, and ultimately drive the success of your operations in the competitive landscape of EDM technology.

Understanding edm machine parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Power Feed Contacts | Made from materials like tungsten carbide; ensures efficient power transfer. | Wire EDM machines | Pros: High durability, excellent conductivity. Cons: Can be costly; specific to machine models. |

| Electrodes | Available in various shapes and sizes; crucial for the erosion process. | Precision machining | Pros: Versatile for different applications. Cons: Requires regular replacement; performance varies with material. |

| Nozzles | Directs coolant and flushing fluids; different sizes for specific needs. | Cooling and flushing in EDM processes | Pros: Enhances machining efficiency; easy to replace. Cons: Incorrect sizing can affect performance. |

| Tension Rollers | Ensures consistent tension in wire; critical for wire stability. | Wire feed systems in EDM | Pros: Improves wire longevity and performance. Cons: Maintenance required; can wear out over time. |

| Guides | Essential for guiding the wire; available in various materials. | Wire EDM operations | Pros: Increases accuracy; reduces wire breakage. Cons: Different models require careful selection. |

What Are Power Feed Contacts and Why Are They Important for EDM Machines?

Power feed contacts are critical components in wire EDM machines, designed to ensure efficient electrical power transfer during the machining process. Typically made from high-quality materials like tungsten carbide, these contacts guarantee durability and high conductivity, which are essential for optimal machine performance. When purchasing, buyers should consider compatibility with specific machine models, as well as the cost-effectiveness of using premium materials versus alternatives.

How Do Electrodes Impact the Erosion Process in EDM?

Electrodes are pivotal in the EDM process, as they are responsible for creating the electrical discharge that erodes the workpiece. They come in various shapes and sizes, allowing for customization based on the specific machining needs. Buyers should focus on the material of the electrodes, as different materials can yield varying performance levels. Regular replacement is necessary to maintain machining precision, making the cost of consumables an important consideration for B2B purchasing.

Why Are Nozzles Critical for EDM Efficiency?

Nozzles play a vital role in directing the coolant and flushing fluids during the EDM process. They come in different sizes and configurations to suit specific machine requirements. The right nozzle can significantly enhance machining efficiency and reduce the risk of overheating. B2B buyers should ensure they select the correct size and type for their machines to avoid performance issues, as an improperly sized nozzle can lead to inefficient cooling and increased wear on components.

What Role Do Tension Rollers Play in EDM Operations?

Tension rollers are essential for maintaining consistent wire tension during the EDM process, which is critical for ensuring wire stability and preventing breakage. These components help improve the longevity and performance of the wire, making them a crucial investment for businesses relying on precision machining. Buyers should consider the maintenance needs and potential wear of tension rollers, as well as their compatibility with existing systems to ensure optimal performance.

How Do Guides Enhance Wire EDM Performance?

Guides are instrumental in ensuring that the wire moves accurately and smoothly during the EDM process. They come in various materials and designs, tailored to specific machine types and operational needs. By reducing the risk of wire breakage and enhancing machining accuracy, guides can significantly impact overall productivity. B2B buyers must carefully evaluate the compatibility of guides with their machines, as selecting the right model is essential for achieving optimal machining results.

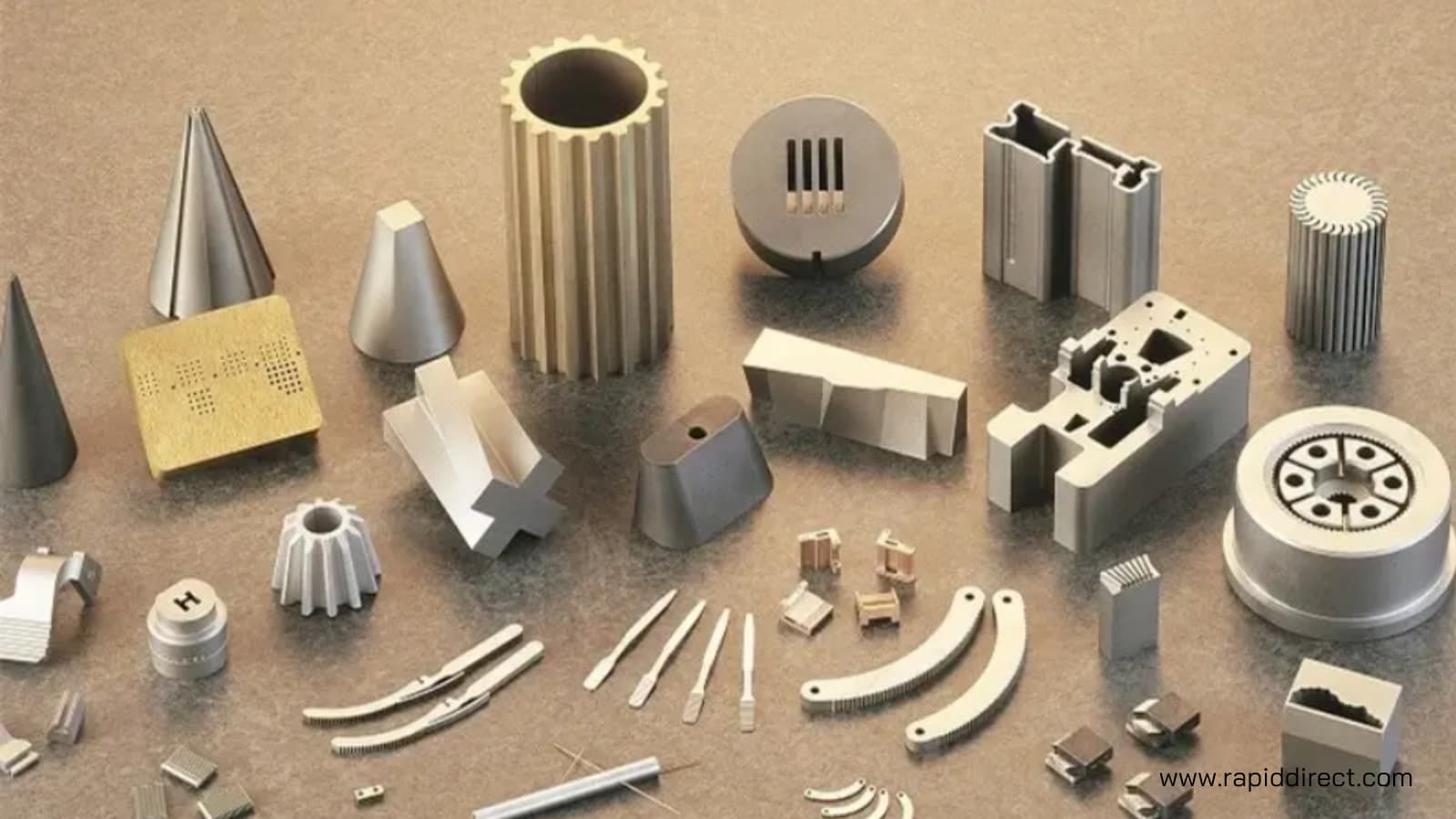

Key Industrial Applications of edm machine parts

| Industry/Sector | Specific Application of edm machine parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision component manufacturing for aircraft parts | Enhances safety and reliability in critical systems | Need for strict compliance with international standards |

| Automotive | Tooling and die production for automotive components | Increases production efficiency and reduces waste | Availability of OEM parts and compatibility with existing machinery |

| Medical Devices | Fabrication of intricate surgical instruments | Ensures high precision and sterility | Quality certifications and material specifications |

| Electronics | Production of microelectronic components | Supports high-volume production with minimal defects | Sourcing from suppliers with advanced technology capabilities |

| Oil & Gas | Manufacturing of specialized equipment for drilling | Improves operational efficiency in harsh environments | Robustness of parts to withstand extreme conditions |

How Are EDM Machine Parts Used in Aerospace Applications?

In the aerospace industry, EDM machine parts are crucial for the production of precision components such as turbine blades, landing gear, and other critical aircraft parts. These components require extremely tight tolerances to ensure safety and performance. The use of EDM technology allows manufacturers to create intricate shapes and features that are often impossible to achieve with traditional machining methods. For international buyers, especially from regions like Africa or Europe, sourcing EDM parts necessitates a focus on suppliers that adhere to stringent aerospace standards and certifications, ensuring reliability and quality.

What Role Do EDM Parts Play in Automotive Manufacturing?

EDM machine parts are integral to the automotive sector, particularly in the tooling and die production processes. These parts help in creating molds for complex automotive components, enabling high production rates while maintaining precision. The ability to produce intricate designs minimizes material waste and reduces overall production costs. Buyers from South America and the Middle East should prioritize sourcing from manufacturers who can provide OEM-compliant parts and have a proven track record of efficiency in production timelines.

How Are EDM Parts Essential in Medical Device Manufacturing?

In the medical devices sector, EDM machine parts are used to manufacture intricate surgical instruments and implants. These components must meet high standards of precision and sterility, as they are critical to patient safety. EDM technology allows for the production of complex geometries that enhance the functionality of medical devices. B2B buyers in this field must ensure that suppliers can meet specific regulatory requirements and provide documentation for material traceability and quality assurance.

In What Ways Are EDM Parts Used in Electronics Production?

The electronics industry relies heavily on EDM machine parts for the production of microelectronic components, which require exceptional precision and minimal defects. EDM technology facilitates the creation of fine features and shapes essential for modern electronics, such as circuit boards and connectors. Buyers from Europe and Africa should seek suppliers with advanced capabilities in EDM technology, ensuring they can handle high-volume production demands while maintaining quality control.

Why Are EDM Parts Important in Oil & Gas Equipment Manufacturing?

In the oil and gas sector, EDM machine parts are vital for the fabrication of specialized equipment used in drilling and extraction processes. These components must withstand extreme conditions, including high pressures and corrosive environments. EDM technology allows for the creation of durable parts that enhance operational efficiency. For international buyers, particularly in regions like the Middle East, sourcing robust EDM parts requires careful consideration of suppliers’ capabilities to meet the harsh operational demands of the industry.

3 Common User Pain Points for ‘edm machine parts’ & Their Solutions

Scenario 1: Inconsistent Quality of EDM Machine Parts

The Problem: A manufacturing company based in Germany frequently faces issues with the quality of EDM machine parts sourced from various suppliers. With inconsistent performance of components like power feed contacts and flush nozzles, the company experiences increased downtime and reduced production efficiency. The buyer is frustrated, as poor-quality parts lead to defects in the final product, affecting customer satisfaction and the company’s reputation in a competitive market.

The Solution: To mitigate quality issues, B2B buyers should establish robust supplier evaluation criteria. This includes checking for ISO certifications and customer reviews, as well as requesting samples for testing before committing to larger orders. Additionally, implementing a quality assurance protocol that includes regular inspections and feedback loops can help maintain high standards. Forming long-term partnerships with trusted suppliers who specialize in EDM machine parts can ensure consistency in quality and lead to better service, as these suppliers are more likely to understand the specific needs of the buyer’s manufacturing processes.

Scenario 2: Difficulty in Sourcing Specialized EDM Components

The Problem: A machining facility in Nigeria struggles to find specialized EDM components tailored to their unique machinery, particularly for older models. The buyer often spends excessive time searching through catalogs or online stores, only to find that many suppliers lack the specific parts needed, resulting in project delays and increased operational costs.

The Solution: To address sourcing challenges, buyers should leverage specialized EDM parts distributors who maintain a comprehensive inventory of components for both new and older machines. Creating a detailed parts list with OEM specifications can streamline the search process. Additionally, engaging with industry forums or trade shows can connect buyers with niche suppliers who might offer hard-to-find components. Utilizing digital platforms that allow for reverse searches (where buyers can input their needs and receive matches) can significantly reduce time spent in sourcing and ensure that the right parts are obtained quickly.

Illustrative image related to edm machine parts

Scenario 3: High Costs Associated with EDM Parts Procurement

The Problem: A manufacturing business in South America finds itself facing soaring costs when procuring EDM machine parts. The buyer is concerned about the impact of these expenses on overall profitability, especially in a market where price competition is fierce. The financial burden is compounded by the need for frequent orders due to a lack of bulk purchasing options.

The Solution: To combat high procurement costs, B2B buyers should explore bulk purchasing agreements with suppliers. By negotiating contracts that allow for volume discounts, businesses can significantly reduce their per-unit costs. Moreover, implementing a just-in-time (JIT) inventory system can minimize stockholding costs while ensuring that necessary parts are available when needed. Establishing relationships with multiple suppliers can also create competitive pricing and offer alternative options in case one supplier raises their prices. Finally, analyzing the total cost of ownership (TCO) of parts—including maintenance and replacement frequency—can provide insights into making more cost-effective decisions in the long run.

Strategic Material Selection Guide for edm machine parts

What Are the Key Materials Used in EDM Machine Parts?

When selecting materials for EDM (Electrical Discharge Machining) machine parts, understanding the properties, advantages, and limitations of common materials is crucial for optimizing performance and ensuring compliance with international standards. Below are analyses of four prevalent materials used in EDM machine parts, tailored for B2B buyers, particularly from Africa, South America, the Middle East, and Europe.

How Does Tungsten Carbide Perform in EDM Applications?

Tungsten carbide is a favored material for EDM parts due to its exceptional hardness and wear resistance. It can withstand high temperatures and pressures, making it suitable for high-performance applications. Tungsten carbide also exhibits excellent corrosion resistance, which is critical in environments where coolant fluids may be aggressive.

Pros: The durability of tungsten carbide translates to longer tool life and reduced downtime for replacements. However, the manufacturing process can be complex and costly, which may affect overall pricing.

Cons: While it offers superior performance, the initial investment is higher than other materials. Additionally, its brittleness can be a concern during machining, as it may fracture under extreme conditions.

Impact on Application: Tungsten carbide is ideal for applications requiring precision and longevity, particularly in high-speed machining environments.

What Role Does Copper Play in EDM Parts?

Copper is another commonly used material in EDM machine parts, particularly for electrodes. It has excellent electrical conductivity, which enhances the efficiency of the machining process. Copper also has good thermal conductivity, allowing for effective heat dissipation during operations.

Pros: The cost of copper is relatively low compared to tungsten carbide, making it an economical choice for many applications. Its machinability is also superior, allowing for easier fabrication.

Cons: However, copper is less durable than tungsten carbide and can wear out more quickly, especially under high-stress conditions. It is also susceptible to corrosion, which can limit its use in certain environments.

Impact on Application: Copper is best suited for applications where electrical conductivity is paramount, such as in the manufacturing of intricate geometries and fine details.

Why Is Steel a Common Choice for EDM Parts?

Steel, particularly tool steel, is widely used in EDM parts due to its balance of strength, toughness, and affordability. It can be treated to enhance its hardness and wear resistance, making it versatile for various applications.

Illustrative image related to edm machine parts

Pros: Steel’s relative cost-effectiveness and availability make it a popular choice. Additionally, it can be heat-treated to improve its properties, providing flexibility in design.

Cons: The main drawback is that steel may not offer the same level of wear resistance as tungsten carbide or copper. It can also be prone to corrosion if not properly treated.

Impact on Application: Steel is suitable for general-purpose applications and is often used in components that do not require extreme precision or durability.

How Does Graphite Compare in EDM Applications?

Graphite is increasingly being used in EDM applications, particularly for electrodes. It has excellent machinability and thermal conductivity, which can enhance the machining process.

Pros: The lightweight nature of graphite makes it easier to handle and reduces wear on machinery. It is also less expensive than tungsten carbide and has a lower density, which can be advantageous in certain applications.

Cons: Graphite is more fragile and can break easily under stress, which may limit its use in high-impact scenarios. Additionally, it can produce dust during machining, necessitating proper dust management.

Impact on Application: Graphite is particularly effective in applications where intricate designs are required, and where the benefits of lightweight materials can be fully utilized.

Summary Table of Material Selection for EDM Machine Parts

| Material | Typical Use Case for edm machine parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Tungsten Carbide | High-performance machining tools | Exceptional hardness and durability | High cost and brittleness | High |

| Copper | Electrodes for EDM machines | Excellent electrical conductivity | Lower durability and corrosion | Medium |

| Steel | General-purpose EDM components | Cost-effective and versatile | Less wear resistance | Low |

| Graphite | Electrodes for intricate designs | Lightweight and easy to machine | Fragile and dust production | Medium |

This guide provides a comprehensive overview of material selection for EDM machine parts, facilitating informed decision-making for international B2B buyers. Understanding the properties and implications of each material will help optimize performance and ensure compliance with relevant standards.

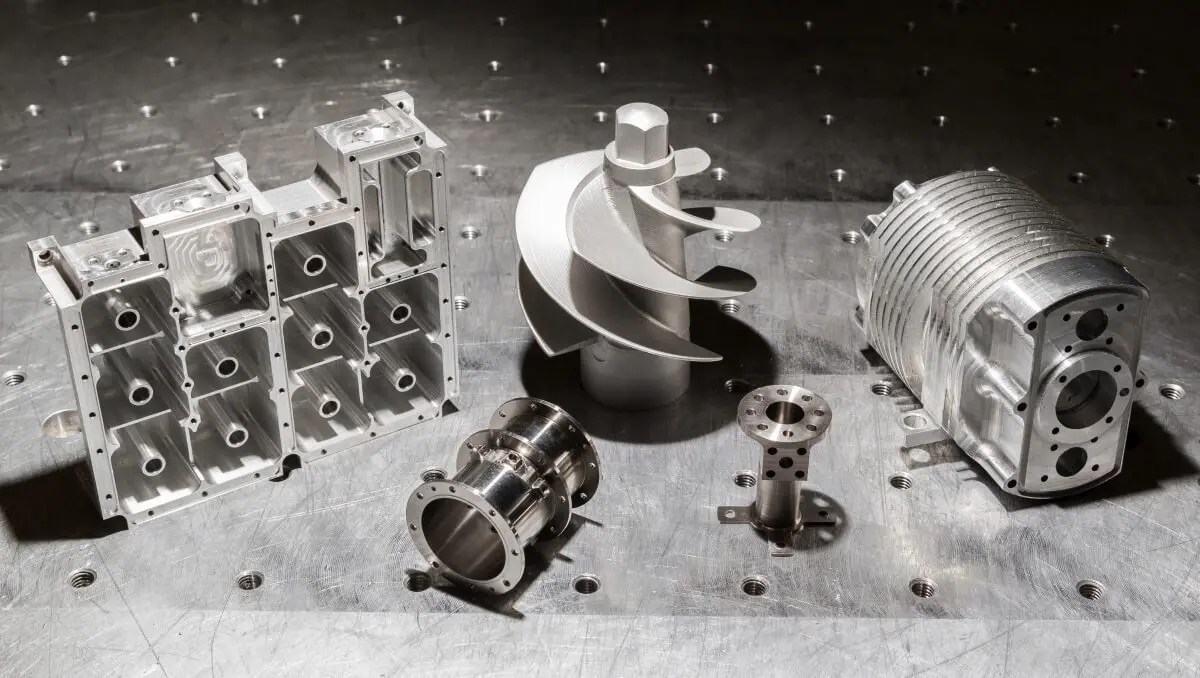

In-depth Look: Manufacturing Processes and Quality Assurance for edm machine parts

What Are the Main Stages in the Manufacturing Process of EDM Machine Parts?

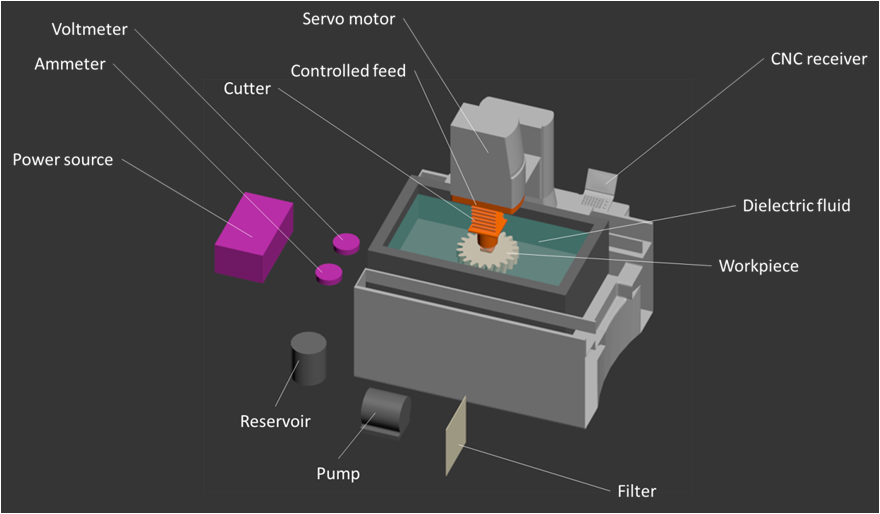

The manufacturing process of EDM (Electrical Discharge Machining) machine parts involves several critical stages, each designed to ensure precision and quality. These stages typically include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in the manufacturing process is material preparation, which involves selecting the appropriate metal or alloy based on the required properties of the EDM part. Common materials include tungsten, copper, and various grades of steel. After selection, these materials undergo processes such as cutting, grinding, and polishing to achieve the necessary dimensions and surface finishes. Advanced technologies like CNC (Computer Numerical Control) machining may also be employed to enhance precision during this stage.

How Is Forming Conducted for EDM Parts?

Forming is the next critical stage where the prepared materials are shaped into the desired configurations. Techniques such as wire EDM and sinker EDM are commonly used. In wire EDM, a thin wire acts as an electrode to cut through the workpiece, while sinker EDM uses a shaped electrode to create complex geometries. This stage is crucial for ensuring the accuracy of the dimensions and the intricate details of the parts being manufactured.

What Does the Assembly Stage Involve?

After forming, the assembly stage comes into play, where various components are joined to create the final product. This may involve welding, soldering, or using adhesives, depending on the design specifications. During assembly, it is vital to maintain strict tolerances to ensure that the assembled parts function correctly together. In some cases, assembly might also include integrating electronic components, particularly in more complex EDM machines.

Which Finishing Techniques Are Commonly Used?

The finishing stage enhances the surface quality and prepares the EDM parts for their operational environment. Common techniques include anodizing, plating, and polishing. These finishing processes not only improve the aesthetic appeal but also enhance corrosion resistance and wear properties. Final inspections are often performed during this stage to confirm that the parts meet the required specifications.

Illustrative image related to edm machine parts

How Does Quality Assurance Ensure High Standards in EDM Machine Parts?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that EDM machine parts meet international standards and customer expectations.

What International Standards Are Relevant for Quality Assurance?

For B2B buyers, understanding international quality standards is crucial. ISO 9001 is a widely recognized standard that outlines the criteria for a quality management system. Compliance with ISO 9001 ensures that manufacturers have processes in place to consistently provide products that meet customer and regulatory requirements. Additionally, industry-specific standards such as CE (Conformité Européenne) for safety and API (American Petroleum Institute) for oil and gas applications may apply, depending on the end-use of the EDM parts.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This is the first line of defense, where raw materials are inspected upon arrival. Ensuring that materials meet specified standards can prevent defects in later stages.

- In-Process Quality Control (IPQC): During the forming and assembly stages, periodic inspections are conducted to monitor the processes and detect any deviations from quality standards.

- Final Quality Control (FQC): At the end of the manufacturing process, final inspections are performed to ensure that the finished products meet all specifications before they are shipped.

What Common Testing Methods Are Used in Quality Control?

To verify the quality of EDM machine parts, various testing methods are employed, including:

- Dimensional Inspection: Using tools like calipers and micrometers to ensure that parts meet specified dimensions.

- Surface Roughness Testing: This assesses the surface finish of the parts, which is critical for performance in EDM applications.

- Material Testing: Techniques such as hardness testing and tensile testing are used to evaluate the mechanical properties of the materials used.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to ensure reliability and performance.

What Audits and Reports Should Buyers Request?

Buyers should request regular quality audits and reports from potential suppliers. These documents provide insights into the supplier’s adherence to quality standards and their internal QC processes. Audits can help identify any weaknesses in the supplier’s operations and assure buyers of the supplier’s commitment to quality.

How Do Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can further validate a supplier’s quality assurance processes. These independent inspectors can conduct thorough evaluations and provide unbiased reports on the quality of the products and the manufacturing processes. This step is particularly beneficial for buyers dealing with unfamiliar suppliers or new partnerships.

What Are the QC and Certification Nuances for International B2B Buyers?

B2B buyers from different regions may encounter unique challenges regarding quality control and certification. For instance, compliance with local regulations in Africa or South America may differ significantly from European standards. Buyers should be aware of these nuances and ensure that suppliers can provide certifications that meet both local and international standards.

By taking a proactive approach to understanding the manufacturing processes and quality assurance practices in the EDM machine parts industry, B2B buyers can make informed decisions, ensuring that they procure high-quality components that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘edm machine parts’

In the competitive landscape of B2B procurement, especially for specialized components like EDM machine parts, having a structured approach can significantly enhance the efficiency and effectiveness of your sourcing process. This guide provides a practical checklist to ensure that your procurement strategy is thorough and aligns with your operational needs.

Step 1: Define Your Technical Specifications

Understanding the exact specifications of the EDM machine parts you require is crucial. This includes identifying the type, size, material, and compatibility with your existing machinery. A clear definition helps in avoiding costly mistakes and ensures that the parts perform optimally within your production environment.

- Consider OEM vs. Aftermarket: Decide whether you need original equipment manufacturer (OEM) parts for guaranteed compatibility or aftermarket options that may offer cost savings.

- Documentation: Ensure all technical specifications are documented clearly to facilitate communication with suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in EDM machine parts. Look for companies with a strong reputation in your industry and positive reviews from other buyers.

Illustrative image related to edm machine parts

- Supplier Directories: Utilize online directories and industry-specific platforms to find reputable suppliers.

- Local vs. International: Consider the pros and cons of sourcing locally versus internationally, especially in terms of shipping costs and lead times.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to vet them comprehensively. Request company profiles, case studies, and references from buyers in a similar industry or region.

- Certifications and Compliance: Verify that suppliers adhere to industry standards and possess relevant certifications.

- Visit Facilities (if possible): If feasible, a visit to the supplier’s facilities can provide valuable insights into their operations and quality control measures.

Step 4: Request Samples and Quotes

Once you have shortlisted potential suppliers, request samples of the EDM parts and detailed quotes. This allows you to assess the quality of their products and compare pricing effectively.

- Quality Assessment: Use the samples to evaluate material quality and craftsmanship against your specifications.

- Transparent Pricing: Ensure quotes include all potential costs, such as shipping, taxes, and duties, to avoid surprises later.

Step 5: Negotiate Terms and Conditions

Engage in negotiations with selected suppliers to finalize terms and conditions that meet your business needs. This includes pricing, payment terms, delivery schedules, and warranties.

- Long-Term Partnerships: Consider discussing the potential for long-term agreements or bulk purchasing discounts.

- Flexibility and Support: Assess the supplier’s willingness to provide support in case of issues with the parts.

Step 6: Confirm Logistics and Delivery

Before finalizing your order, ensure that logistics and delivery methods are clearly defined. Reliable delivery is critical to maintaining your production schedule.

- Shipping Options: Discuss various shipping options and their associated costs.

- Lead Times: Confirm lead times and any potential delays that could impact your operations.

Step 7: Establish a Feedback Loop

Once you begin receiving parts, establish a feedback mechanism with your supplier. This will help in addressing any issues promptly and maintaining a strong relationship.

- Performance Metrics: Monitor the performance of the EDM parts in your operations to assess quality and reliability.

- Supplier Communication: Maintain open lines of communication for ongoing support and potential future orders.

By following these steps, B2B buyers can streamline their sourcing process for EDM machine parts, ensuring a more effective procurement strategy that meets both technical and operational needs.

Comprehensive Cost and Pricing Analysis for edm machine parts Sourcing

What Are the Key Cost Components in EDM Machine Parts Sourcing?

When sourcing EDM machine parts, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly affects pricing. High-quality materials like tungsten carbide or specialized alloys, often used in power feed contacts and nozzles, can increase costs. Buyers should assess the material specifications to ensure they meet operational requirements without overspending.

-

Labor: Labor costs vary based on the region and the complexity of manufacturing processes. Skilled labor is essential for precision machining, which is critical in EDM applications. Buyers should consider the labor rates in the supplier’s location when evaluating overall costs.

-

Manufacturing Overhead: This encompasses costs related to facilities, utilities, and equipment maintenance. Efficient manufacturing processes can lead to lower overhead costs, which can be passed on to buyers.

-

Tooling: Custom tooling may be required for specific parts, which can add to the initial costs. However, investing in high-quality tooling can enhance production efficiency and part quality in the long run.

-

Quality Control (QC): Implementing stringent QC measures ensures that parts meet quality standards, but this also incurs additional costs. Buyers should inquire about the QC processes in place to gauge the potential for defects and rework.

-

Logistics: Shipping and handling costs can vary widely based on the distance, shipping method, and weight of the parts. Understanding these logistics costs is vital, especially for international buyers.

-

Margin: Suppliers typically include a profit margin in their pricing, influenced by their operational costs and market demand. Buyers should be aware of industry standards for margins to identify competitive pricing.

How Do Price Influencers Affect EDM Machine Parts Costs?

Several factors can influence the pricing of EDM machine parts:

-

Volume/MOQ: Bulk orders often lead to lower per-unit prices. Understanding the minimum order quantities (MOQ) can help buyers negotiate better deals and reduce costs.

-

Specifications and Customization: Customized parts or those with specific tolerances may come at a premium. Buyers should balance the need for customization with budget constraints.

-

Material Selection: The choice of materials can significantly impact price. High-performance materials may offer durability and efficiency but at a higher cost. Buyers should evaluate the trade-off between material quality and pricing.

-

Quality Certifications: Parts that meet specific industry certifications (e.g., ISO standards) may have higher prices due to the assurance of quality. Buyers should weigh the importance of certifications against cost.

-

Supplier Factors: The supplier’s reputation, reliability, and location can influence pricing. Established suppliers may command higher prices due to their proven track record.

-

Incoterms: Understanding shipping terms (Incoterms) is vital for international buyers, as they define the responsibilities of buyers and sellers in the shipping process. This can affect total costs, including shipping and customs duties.

What Buyer Tips Can Enhance Cost-Efficiency in EDM Parts Sourcing?

To optimize sourcing costs, buyers should consider the following strategies:

-

Negotiation: Always negotiate pricing and terms with suppliers. Building a rapport can lead to better deals, especially for repeat orders.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, downtime, and replacement. Lower upfront costs may lead to higher TCO if quality is compromised.

-

Pricing Nuances for International Buyers: Be aware of potential additional costs such as tariffs, taxes, and currency exchange rates when sourcing from international suppliers. These factors can significantly impact the final price.

-

Supplier Evaluation: Conduct thorough research on suppliers, including their financial stability and production capabilities. A reliable supplier can provide consistent quality and timely deliveries, which may save costs in the long run.

-

Market Trends: Stay informed about market trends and shifts in demand. Understanding the market can help buyers time their purchases to take advantage of lower prices.

In conclusion, a comprehensive understanding of the cost structure and pricing influences in EDM machine parts sourcing can empower buyers to make strategic purchasing decisions that optimize value and minimize costs.

Illustrative image related to edm machine parts

Alternatives Analysis: Comparing edm machine parts With Other Solutions

When evaluating EDM machine parts, it’s essential to consider viable alternatives that can fulfill similar functions within manufacturing processes. These alternatives may offer different benefits or drawbacks based on specific operational needs and cost considerations. In this section, we will compare EDM machine parts with two notable alternatives: CNC Machining and Laser Cutting.

Comparison Table

| Comparison Aspect | EDM Machine Parts | CNC Machining | Laser Cutting |

|---|---|---|---|

| Performance | High precision and detail | Excellent for complex shapes | Fast cutting speed |

| Cost | Moderate initial investment | Higher operational costs | Variable costs based on material |

| Ease of Implementation | Requires specialized setup | Requires skilled operators | User-friendly, less training needed |

| Maintenance | Regular wear part replacements | Moderate maintenance needed | Low maintenance requirements |

| Best Use Case | Intricate metal parts | Large batch production | Thin materials and quick prototypes |

What Are the Pros and Cons of CNC Machining Compared to EDM Machine Parts?

CNC machining is a versatile manufacturing process that uses computer-controlled machines to create parts. The primary advantage of CNC machining lies in its ability to produce complex shapes with high accuracy, making it suitable for a range of materials including metals and plastics. However, the operational costs can be higher due to the necessity of skilled labor and the setup time involved. While it may require more maintenance than EDM machine parts, CNC machines are typically capable of handling larger volumes of production.

How Does Laser Cutting Compare to EDM Machine Parts in Terms of Functionality?

Laser cutting is another alternative that excels in speed and efficiency, particularly for thin materials. Its primary benefit is the ability to execute intricate designs quickly, making it ideal for rapid prototyping and small batch production. However, while laser cutting offers lower maintenance requirements, it is generally less effective for thicker materials compared to EDM processes. Additionally, the cost can fluctuate based on the type of material being cut, potentially impacting budget considerations for B2B buyers.

How Can B2B Buyers Choose the Right Solution for Their Needs?

In choosing the right solution, B2B buyers should assess their specific operational requirements, including the types of materials they work with and the precision needed for their applications. For manufacturers focused on intricate metal parts, EDM machine parts may offer the best performance. Conversely, those looking to produce larger volumes of complex shapes may find CNC machining more beneficial. For businesses that prioritize speed and flexibility with thinner materials, laser cutting could be the ideal choice. Ultimately, a thorough analysis of each alternative’s advantages and constraints will empower buyers to make informed decisions tailored to their unique production needs.

Essential Technical Properties and Trade Terminology for edm machine parts

What Are the Key Technical Properties of EDM Machine Parts?

Understanding the critical specifications of EDM (Electrical Discharge Machining) machine parts is essential for B2B buyers, especially those looking to optimize their machining processes. Here are several key technical properties to consider:

-

Material Grade

– The material grade of EDM parts, such as tungsten carbide or copper, significantly influences their performance and durability. Tungsten carbide, for example, offers high wear resistance, making it ideal for components like power feed contacts. Selecting the right material ensures that parts can withstand operational stresses, reducing downtime and replacement costs. -

Tolerance

– Tolerance refers to the permissible limit of variation in a part’s dimensions. In EDM machining, tight tolerances (often in the range of ±0.001 mm) are critical for achieving precise cuts and finishes. Understanding the required tolerances helps buyers ensure that parts will fit correctly and function as intended, which is particularly important in high-precision industries like aerospace and medical device manufacturing. -

Surface Finish

– The surface finish of EDM components affects not only the aesthetic quality but also the performance and longevity of the parts. Common finishes include Ra values (roughness average) ranging from 0.2 to 1.6 micrometers. A smoother finish can improve the part’s resistance to wear and friction, which is vital for components subjected to continuous motion. -

Electrical Conductivity

– The electrical conductivity of materials used in EDM parts impacts the efficiency of the machining process. High conductivity materials, such as copper, are often preferred for electrodes, as they facilitate better energy transfer, resulting in quicker machining times and improved surface quality. -

Weight and Dimensions

– The weight and dimensions of EDM parts are crucial for ensuring compatibility with specific machines and applications. Buyers need to assess the machine’s capacity and the part’s weight to avoid operational issues. This consideration is particularly important for large-scale operations where multiple components are used. -

Packing Quantity

– Understanding packing quantity is essential for inventory management. It refers to the number of units contained in a single package. Optimizing order quantities can lead to cost savings and reduce the frequency of reorders, making it vital for efficient supply chain management.

What Are Common Trade Terms in the EDM Industry?

Familiarity with industry jargon can enhance communication and streamline transactions. Here are some common terms used in the EDM parts market:

-

OEM (Original Equipment Manufacturer)

– OEM refers to a company that manufactures products that are sold under another company’s brand. In the context of EDM parts, OEM numbers signify specific parts made for particular machine models, ensuring compatibility and performance. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ helps buyers manage their budgets and inventory levels while ensuring they meet production demands without overstocking. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing information for specific parts or services. It is an essential part of the procurement process, allowing buyers to compare prices and terms from multiple suppliers. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping arrangements. Familiarity with these terms is crucial for international transactions, as they dictate who bears costs and risks during transportation. -

Lead Time

– Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is essential for effective planning and inventory management, allowing businesses to align their production schedules with supply availability. -

Aftermarket Parts

– Aftermarket parts are components not made by the OEM but are designed to fit and function similarly. They often offer cost-effective alternatives for buyers, making them an attractive option for maintenance and repairs.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the right EDM machine parts for their specific needs while optimizing procurement processes.

Navigating Market Dynamics and Sourcing Trends in the edm machine parts Sector

What Are the Current Market Dynamics and Key Trends in the EDM Machine Parts Sector?

The EDM (Electrical Discharge Machining) machine parts sector is experiencing notable growth driven by increased automation and precision manufacturing demands across various industries, including aerospace, automotive, and electronics. The global market is projected to expand as manufacturers seek to enhance operational efficiency and reduce production costs. Key trends influencing this landscape include the rise of Industry 4.0 technologies, such as IoT and AI, which facilitate real-time monitoring and predictive maintenance, thereby minimizing downtime and maximizing productivity.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly focusing on sourcing quality EDM parts that adhere to stringent standards. In particular, buyers from countries like Nigeria and Germany are prioritizing suppliers that offer not just competitive pricing but also advanced technology integrations. The demand for customized EDM solutions is also on the rise, as manufacturers seek parts tailored to specific applications, enhancing their competitive edge in the global market.

Emerging sourcing trends include the adoption of digital platforms for procurement, which streamline the buying process and improve supply chain transparency. Additionally, the emphasis on local sourcing is gaining traction, driven by the need to reduce lead times and transportation costs while fostering regional economic growth. As global supply chains face disruptions, companies are increasingly diversifying their supplier networks to mitigate risks and ensure continuity.

How Is Sustainability Influencing Sourcing Decisions in the EDM Machine Parts Sector?

Sustainability has become a critical consideration for B2B buyers in the EDM machine parts sector, as environmental impacts and ethical sourcing practices gain prominence. Manufacturers are under pressure to adopt sustainable practices, not only to comply with regulations but also to meet the growing expectations of environmentally conscious consumers. This shift is prompting companies to seek suppliers who prioritize eco-friendly materials and processes.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing the sourcing and production methods of their suppliers, emphasizing the need for transparency and accountability. This trend is particularly relevant for regions like Europe, where regulations around sustainability are becoming more stringent. Companies that can demonstrate compliance with environmental standards and ethical labor practices are likely to gain a competitive advantage.

In terms of materials, the use of ‘green’ certifications, such as ISO 14001 or LEED, is becoming essential. Suppliers that can provide documentation proving the sustainability of their processes and materials are more likely to attract discerning buyers. Additionally, the incorporation of recycled materials in the production of EDM parts is gaining traction, reducing waste and promoting a circular economy. These efforts not only enhance brand reputation but also contribute to long-term cost savings through improved resource efficiency.

Illustrative image related to edm machine parts

How Has the EDM Machine Parts Sector Evolved Over Time?

The EDM machine parts sector has undergone significant evolution since its inception in the mid-20th century. Initially, EDM technology was primarily utilized for creating complex shapes in hard metals, catering mainly to the aerospace and automotive industries. Over the years, advancements in technology have expanded the applicability of EDM, leading to its widespread adoption across various sectors, including medical devices and electronics.

The transition from traditional EDM methods to more advanced forms, such as wire EDM and sinker EDM, has enhanced precision and efficiency, allowing manufacturers to meet the increasingly demanding specifications of modern engineering. Additionally, the integration of computer numerical control (CNC) technology has revolutionized the sector, enabling automated processes that reduce human error and improve production timelines.

As the industry continues to adapt to changing market demands and technological advancements, B2B buyers can expect ongoing innovations in EDM machine parts, leading to improved performance, sustainability, and cost-effectiveness in manufacturing processes.

Frequently Asked Questions (FAQs) for B2B Buyers of edm machine parts

-

How do I solve compatibility issues with EDM machine parts?

To address compatibility issues, start by identifying the specific model and OEM numbers of your EDM machine. Cross-reference these with the part specifications from suppliers. It’s advisable to consult with the manufacturer or a knowledgeable distributor who can provide insights on equivalent parts if originals are unavailable. Additionally, consider requesting samples before placing larger orders to ensure fit and functionality. -

What is the best type of electrode for my EDM machine?

The best electrode type depends on your specific machining requirements and the materials being processed. For general use, copper or graphite electrodes are common, with copper providing better conductivity and graphite offering superior wear resistance. Consult your machine’s manual or a supplier for recommendations tailored to your application, as certain materials may require specialized electrodes for optimal performance. -

How can I verify the quality of EDM machine parts from suppliers?

To ensure quality, request certifications such as ISO 9001 from potential suppliers. Reviews and testimonials from previous customers can also provide insights into their reliability. Additionally, consider asking for product samples and conducting a thorough inspection for material integrity and precision. Establishing a direct line of communication with the supplier for ongoing quality assurance is also beneficial. -

What are the common payment terms for international B2B transactions in EDM parts?

Payment terms can vary widely among suppliers, but common practices include advance payment, letters of credit, or payment upon delivery. Always clarify payment terms upfront to avoid misunderstandings. For first-time transactions, consider escrow services or partial payments to mitigate risks. Understanding the currency and any potential exchange rate implications is also crucial in international dealings. -

What is the minimum order quantity (MOQ) for EDM machine parts?

The MOQ often depends on the type of part and the supplier’s policies. Generally, standard components may have lower MOQs, while specialized or custom parts could require higher quantities. It’s advisable to negotiate with suppliers to find a mutually agreeable MOQ, especially if you’re testing new parts or entering a new market. -

How do I manage logistics for sourcing EDM machine parts internationally?

Effective logistics management involves selecting a reliable shipping partner with experience in handling industrial components. Determine the most cost-effective shipping method, whether air freight for speed or sea freight for bulk orders. Familiarize yourself with customs regulations and documentation requirements in both the exporting and importing countries to avoid delays and additional costs. -

What should I consider when customizing EDM machine parts?

When customizing parts, provide clear specifications, including dimensions, materials, and performance requirements. Collaborate closely with your supplier during the design process to ensure feasibility and compatibility. Be prepared for potential lead times and costs associated with custom tooling or manufacturing, and ask for prototypes or samples to validate the design before full-scale production. -

How can I find reliable suppliers for EDM machine parts in my region?

Start by researching online directories and trade platforms that specialize in industrial components. Attend industry trade shows or expos to meet suppliers face-to-face and assess their offerings. Networking with other businesses in your region can also lead to referrals. Always perform due diligence by checking reviews, certifications, and financial stability before entering into contracts.

Top 7 Edm Machine Parts Manufacturers & Suppliers List

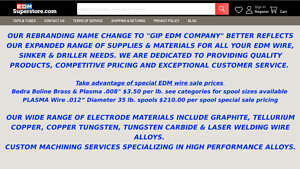

1. EDM Superstore – Key Product

Domain: edmsuperstore.com

Registered: 2020 (5 years)

Introduction: Key product details include: 1. Categories of EDM wear parts: AGIE, CHARMILLES, FANUC, MAKINO, MITSUBISHI, SODICK. 2. Types of EDM wires: Brass EDM wires, Coated EDM wires, Molybdenum specialty wire. 3. EDM filters for various machines: ACCUTEX, AGIE, BROTHER, CHARMILLES, CHMER, EBBCO, ELOX, FANUC, HITACHI, JAPAX, MAKINO, MITSUBISHI, SODICK, YCM. 4. EDM driller supplies: Ceramic pipe guides, bulle…

2. Alternative Machine Tool – EDM Supplies & Components

Domain: alternativemachinetool.com

Introduction: EDM supplies for sale: Consumables, accessories & machine components. Popular items include: 3.4 X 400MM BRASS, 3.5 X 400MM BRASS, O-RING Rubber Grommet for EDM Hole Driller, 3.6 X 400MM BRASS FLANGE BEARING, 6-PIN WIRE ALIGNMENT CABLE, CARBIDE for MITSUBISHI, RECTIFIER RING DBJ1900. Product categories include: EDM Wire (Nex-Gen – Hard Brass, Nex-Gen – Soft Brass, Nex-Gen – Gamma, Bedra – Better B…

3. Novotec EDM – Wear Parts for EDM Applications

Domain: us.novotec-edm.com

Registered: 1998 (27 years)

Introduction: Novotec EDM offers a comprehensive range of wear parts designed for electrical discharge machining (EDM) applications. These parts include electrodes, filters, and other essential components that enhance the efficiency and performance of EDM processes. The wear parts are manufactured to high standards, ensuring durability and precision in machining operations. Novotec’s products are compatible wit…

4. BMEDM – EDM Consumable Parts & Machines

Domain: bmedm.com

Registered: 2011 (14 years)

Introduction: EDM Consumable Parts, EDM Wires, EDM Spare Parts, EDM Fluid, EDM Coolant, EDM Tube, EDM Electrode, Wire Cut EDM Stepper Control, Wire Cut EDM High Performance Economical Type, Servo Control Wire Cut EDM High Performance Economical Type, Customized Machines, Drill EDM, Die Sinker EDM, CNC Sinker EDM, ZNC Sinker EDM, CNC Milling and Engraving, CNC Machining Center, Spare Parts, BM Series Working Sol…

5. EDMStore – OEM Quality EDM Parts

Domain: edmstore.com

Introduction: EDMStore.com offers OEM quality EDM parts at competitive prices. Key product categories include EDM Wire, Wear Parts, EDM Oils, Cleaners & Greases, DI Water, EDM Resin, Copper Electrodes, Driller Guides & Seals, and Brass Electrodes. Featured products include Dynamic Filters for Ebbco Hurricane Filter Systems (8″ x 30″, 5 Micron) priced at $192.00, Copper Multi Channel EDM Tubes (300mm) ranging fr…

6. IQS Directory – EDM Machining Essentials

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: EDM Machining is a manufacturing process that uses electrical discharges to remove material from a workpiece. Key components include: 1. **DC Power Generator**: Supplies consistent electrical energy for spark erosion. Types include Resistance-capacitance type (RC type), Rotary impulse type, Electronic pulse generator, and Hybrid EDM generator. 2. **Workpiece**: Typically made of hard materials lik…

7. HiTech Machinery – Precision Alignment & Consumables

Domain: hitechmachinery.com

Registered: 2000 (25 years)

Introduction: This company, HiTech Machinery – Precision Alignment & Consumables, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for edm machine parts

How Can Strategic Sourcing Benefit Your EDM Machine Parts Procurement?

In the fast-evolving landscape of EDM machine parts, strategic sourcing emerges as a crucial strategy for international buyers. By focusing on quality, compatibility, and supplier reliability, companies can reduce operational downtime and improve production efficiency. As the demand for precision engineering grows, understanding the nuances of sourcing parts—such as electrode pins, power feed contacts, and nozzles—becomes essential.

Moreover, leveraging global supplier networks allows buyers from regions like Africa, South America, the Middle East, and Europe to access advanced technologies and competitive pricing. Engaging with reputable suppliers not only ensures high-quality components but also fosters strong partnerships that can adapt to future industry trends.

Looking ahead, the EDM market is poised for growth, driven by technological advancements and increased manufacturing needs. International buyers are encouraged to take proactive steps in their sourcing strategies—prioritizing long-term relationships with suppliers who can provide innovative solutions. Embrace this opportunity to elevate your operations and secure a competitive edge in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.